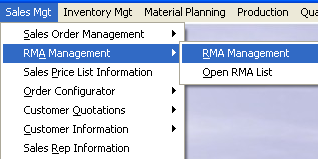

| Add a Standard RMA | ||||||||||||||||||||||||||||||||||||||||||||

|

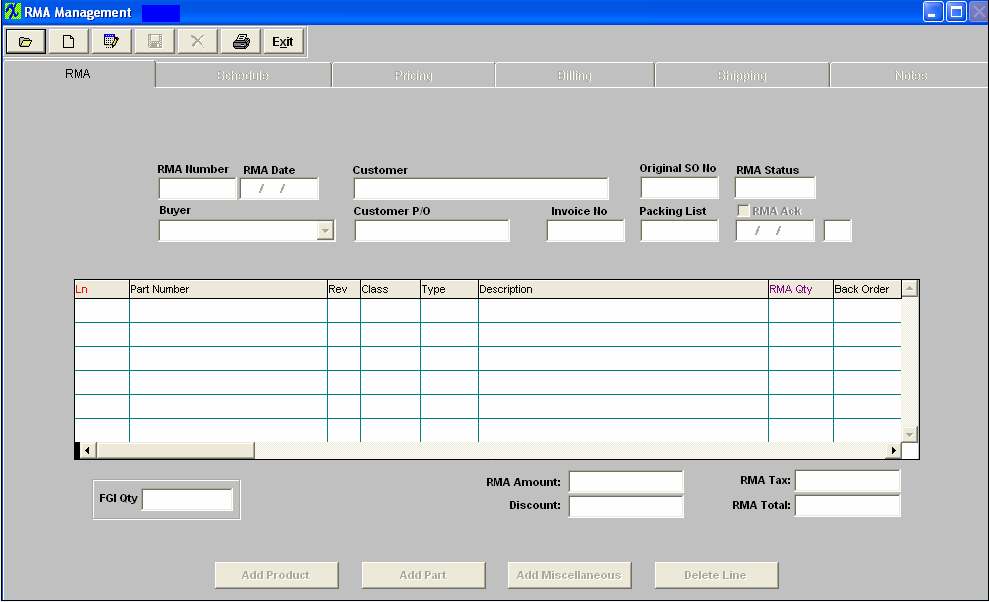

The following screen will appear:

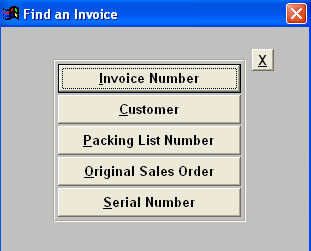

Find Invoice Number by Invoice Number

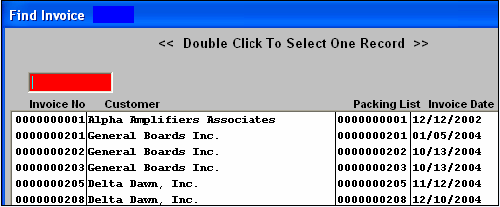

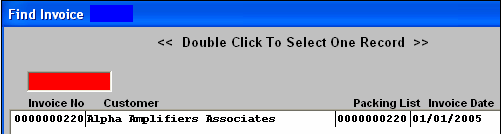

To find an Invoice by Invoice Number, depress the Invoice Number selection. A list of invoices will appear. Type the invoice number into the red box or highlight your selection and double click. Find Invoice Number by Customer

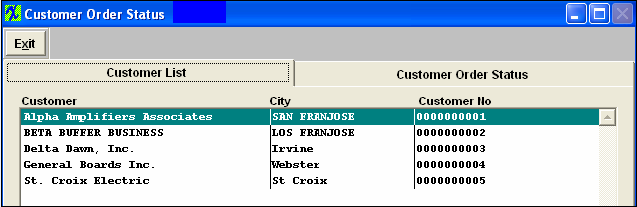

To find the Invoice Number by the Customer name, depress the Customer button. The following screen will appear: Type the Customer name into the red box or highlight your selection and double click. A list of all of the invoices for that customer will appear: Type the Invoice Number into the red box or highlight your selection and double click. Find Invoice Number by Packing List Number

To find the Invoice Number by Packing List Number, depress the Packing List button. A selection of Packing Lists will appear: Type the Packing List number into the red box or highlight your selection and double click. Find Invoice Number by Original Sales Order

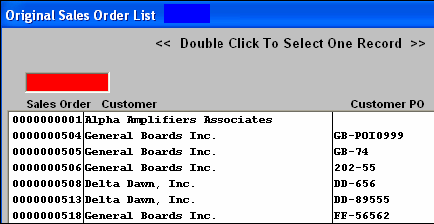

To find the Invoice Number by the Original Sales Order, depress the Original Sales Order button.The following screen will appear: Type the original Sales Order into the red box or highlight your selection and double click. A list of invoices pertaining to the selected Sales Order will appear: Type the invoice number into the red box or highlight your selection and double click. Find Invoice Number by Serial Number

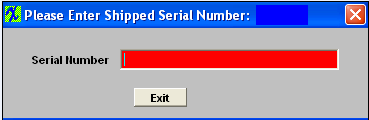

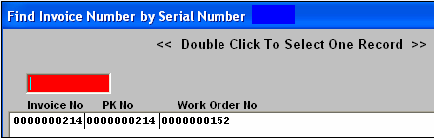

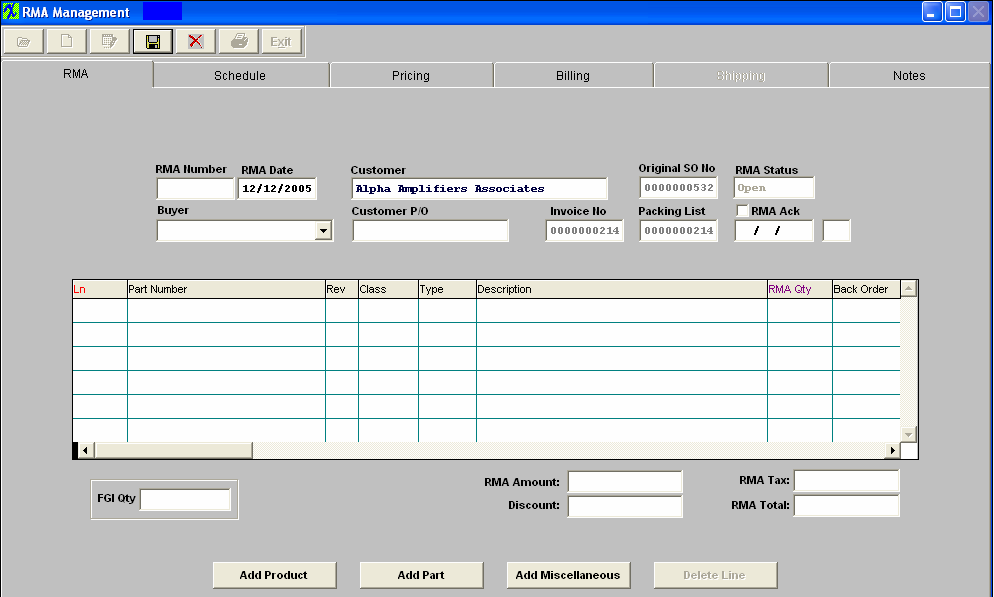

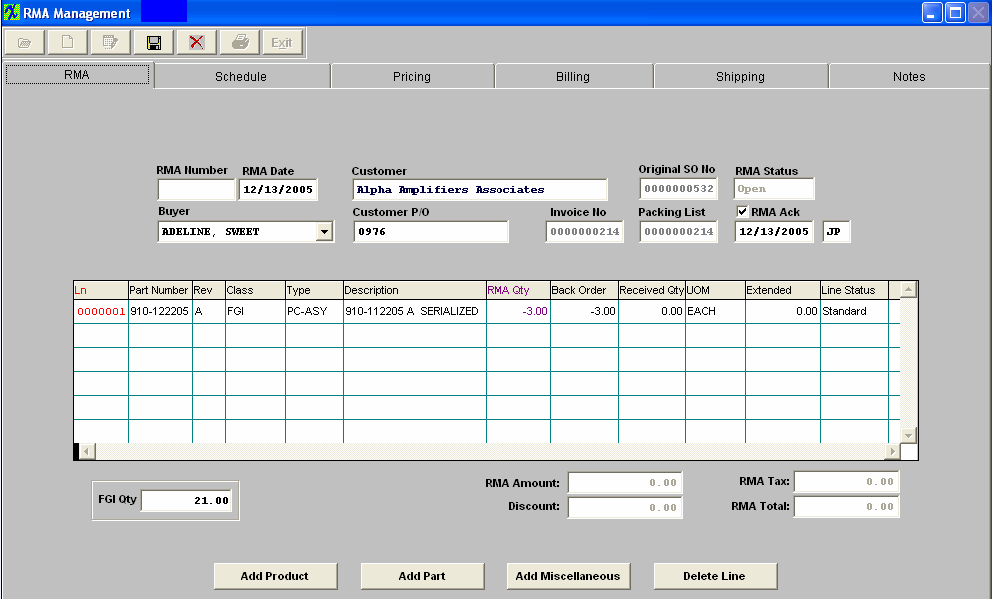

To find the Invoice Number by the Serial Number, depress the Serial Number button.The following screen will appear: Type a serial number into the red box. A list of invoices pertaining to the selected serial number will appear: Type the invoice number into the red box or highlight your selection and double click. Once you’ve made your selection, the original information will populate the screen, as displayed below:

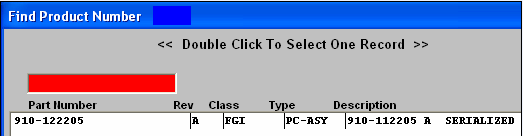

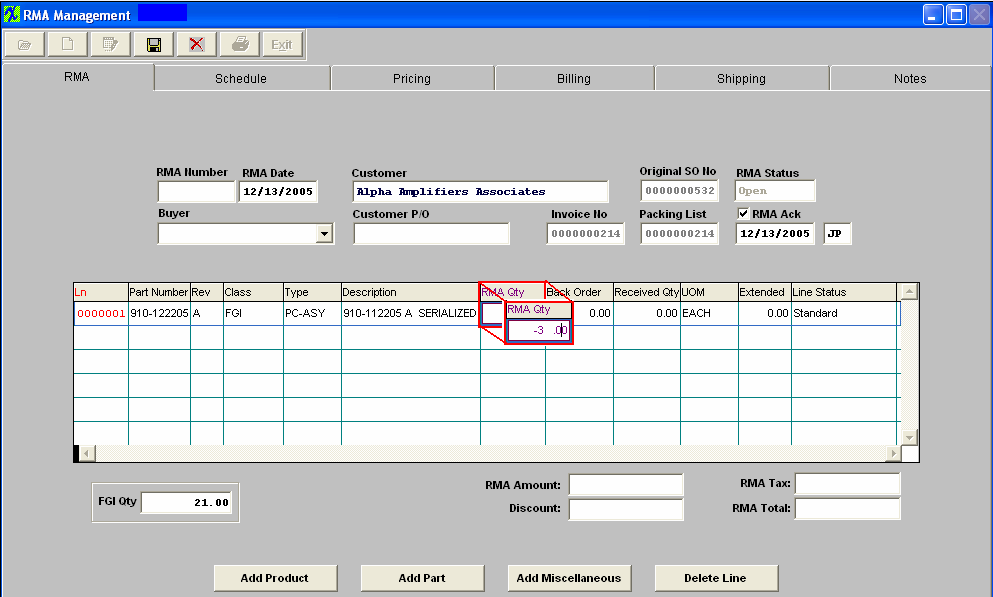

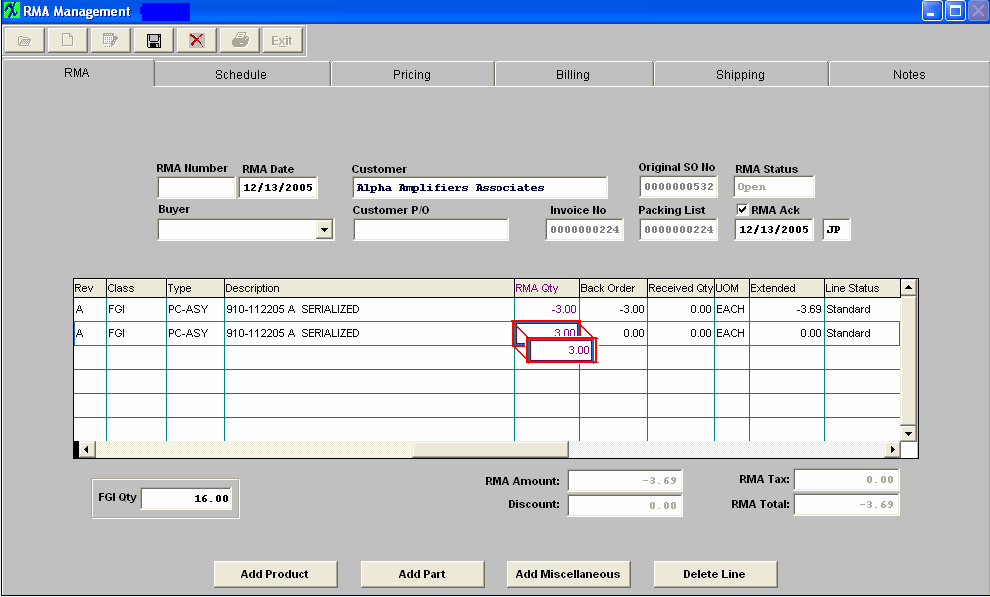

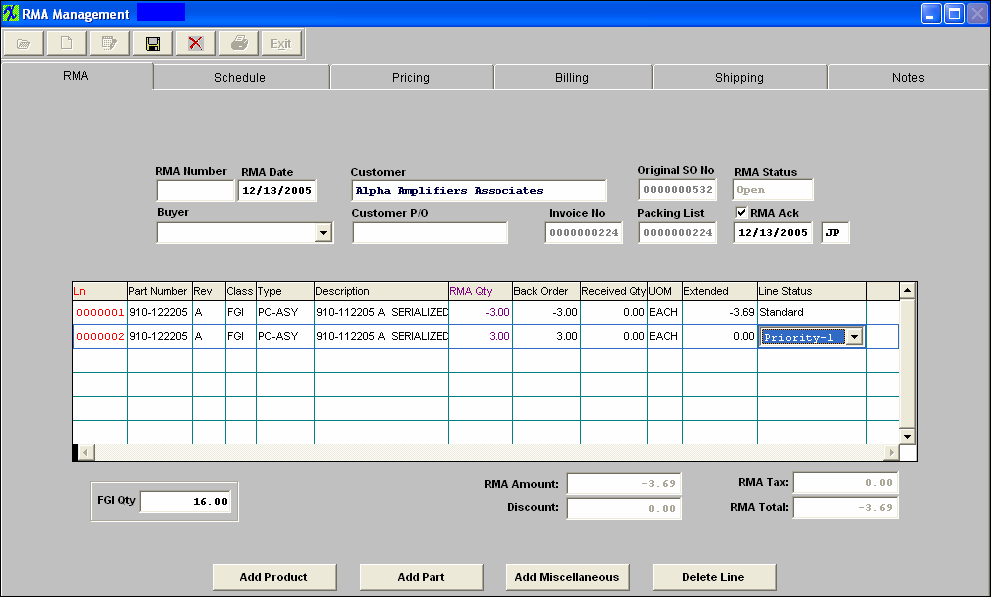

Click on the RMA Ack box, to acknowledge the RMA. The date and your initials will appear. Depress one of the three buttons at the bottom of the screen, Add Product, Add Part, or Add Miscellaneous. Add Product, Add Part, or Add Miscellaneous

Type the RMA quantity in a negative amount into the column. The quantity entered must be equal to or less than the original Sales Order.

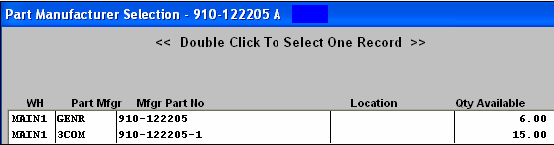

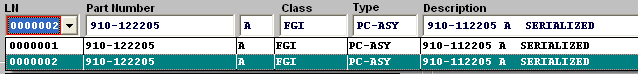

If there are multiple manufacturers or locations for the part in the Inventory Control Quantity Info tab, the following selection list will appear: Highlight the warehouse location and double click. The completed screen will appear as follows:

Schedule Tab Depress the schedule tab.The following screen will appear:  There are two modes available for completing a scheduled delivery for a product: Automatic and Manual. In the Automatic mode, ManEx will take a beginning date and a quantity to be delivered each period (Days, Weeks or Months) and schedule out the delivery using the Delivery Schedule Default Days which are setup in the Delivery Schedule Default Setup module. The following activities are available: Sales Order Line number: Select the line number using the down arrow. Be sure that you’ve selected the line number which pertains to the re-work/replacement.

A Line Item Footnote may be entered for comments on the delivery schedule for reference. Depress the Pricing Tab. The following screen will appear:  There are three options on pricing.

1. The user may enter zero for both the return and the re-work. For further detail on how this affects the GL accounts see Article #3397 .

2. The user may enter full price for both the return and re-work. For further detail on how this affects the GL accounts see Article #3396 .

3. The user may enter zero on the return and a dollar amount for the re-work.

Enter the Price per unit in the Price column. Note that the price entered must be equal to or less than the original Sales Order price. The Extension column will update automatically, and will display as a negative. Any extra line item charges will default in from the original invoice. But, the system will not allow you to add more extra charges to the Retun line item that did not exist on the original invoice. Any additional charges that the users wants to add to the line item being shipped back out (positive line items) as needed for rework, etc... will be allowed.

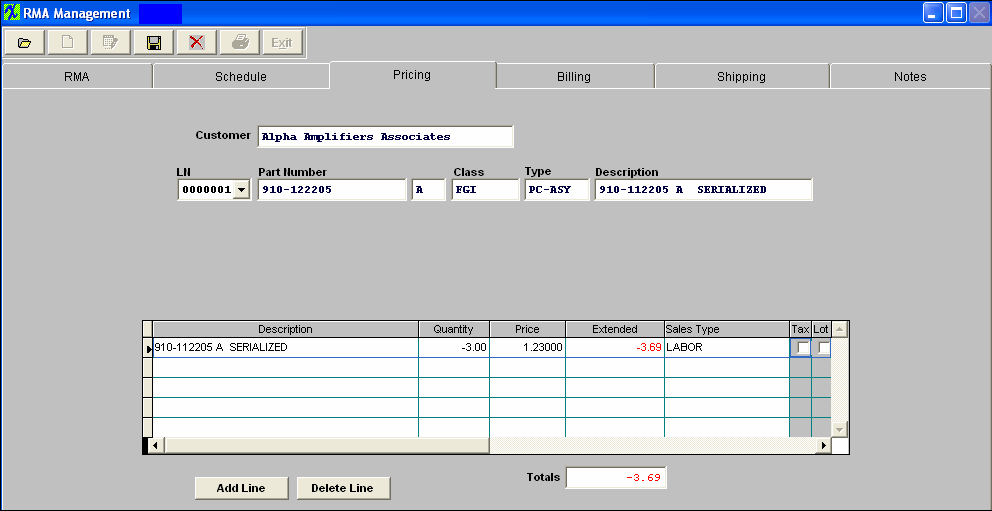

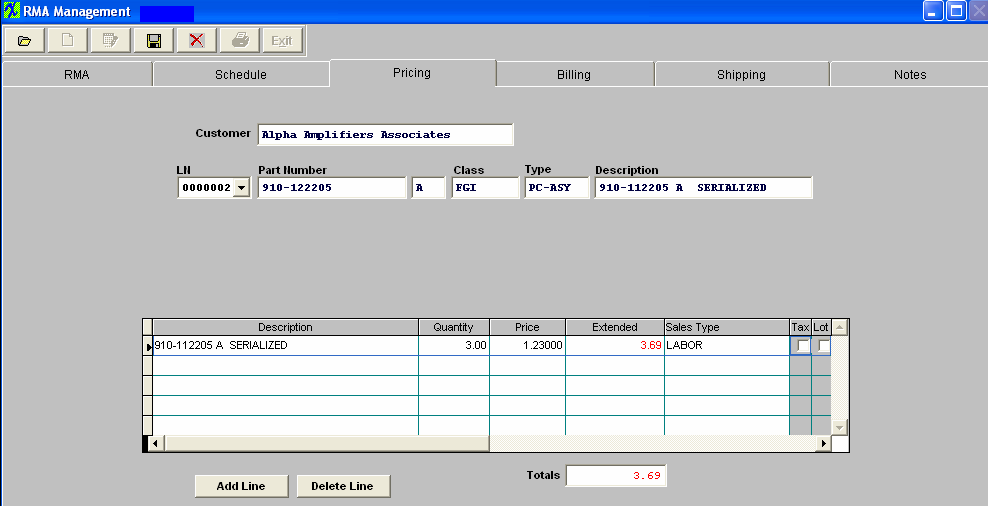

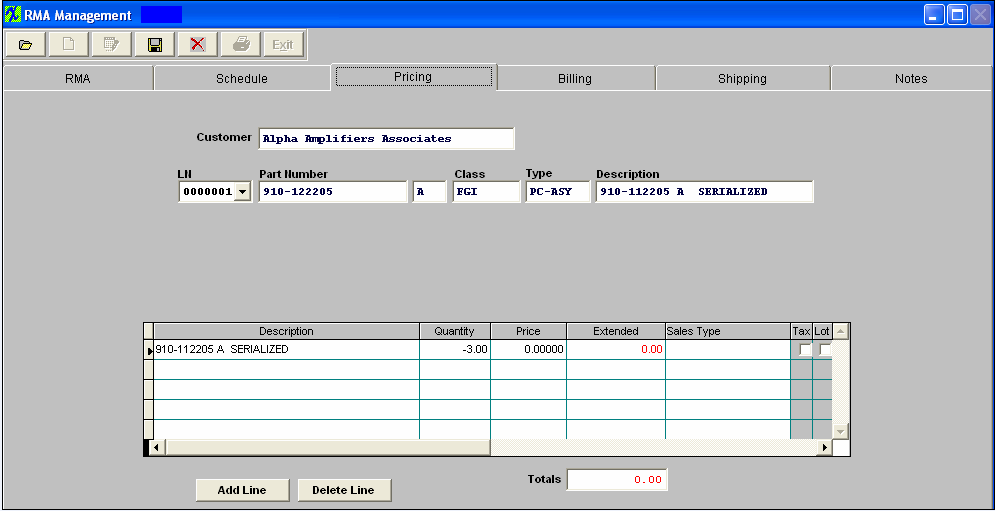

The completed screen will appear as follows:

If you are NOT going to re-work or replace the order, depress the Save button and Exit the module. If you are going to re-work or replace the order, refer to Add a Re-Work/Replacement procedures below: Add a Rework/Replacement RMA Tab While the RMA order is still open, depress the RMA tab. Depress one of the following buttons: Add Product, Add Part or Add Miscellaneous.

If you depress the Add Product button, the following screen will appear: Type in the Part Number or highlight your selection and double click. The Product will populate the screen. If you selected Add Part or Add Miscellaneous, the same type of selection procedure will take place. Note that you can’t add a part or add miscellaneous unless the original order contained such. Type the RMA quantitybeing re-worked or replaced in a positve amount into the column. The quantity entered must be equal to or less than the original Sales Order.

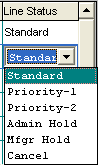

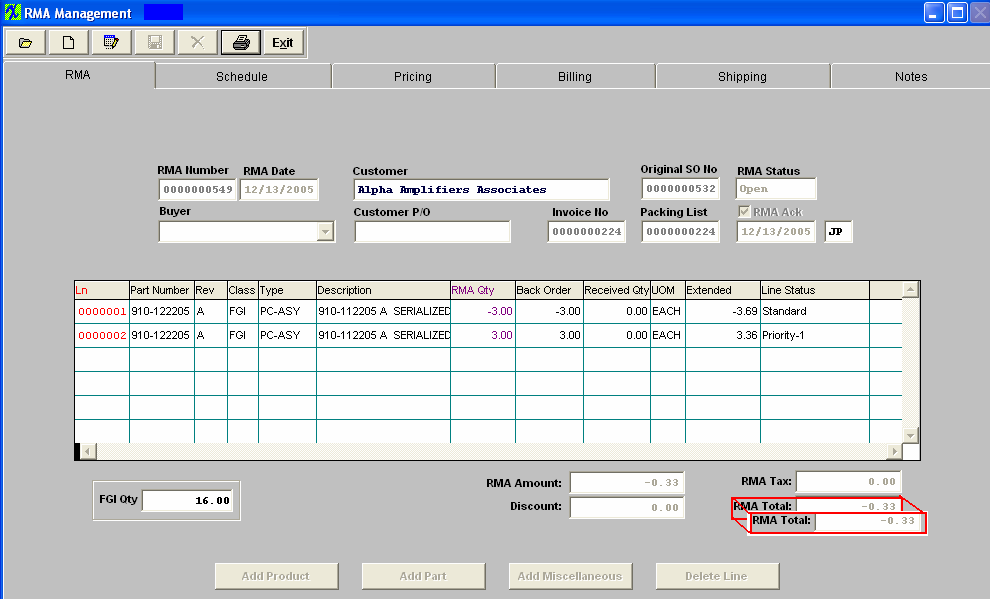

If you want to accelerate the re-work or replacement with a higher priority than standard, go to the Line Status column and depress the Enter key. The following selection will appear: Select the appropriate priority for the re-work/replacement. The completed screen will appear as follows:

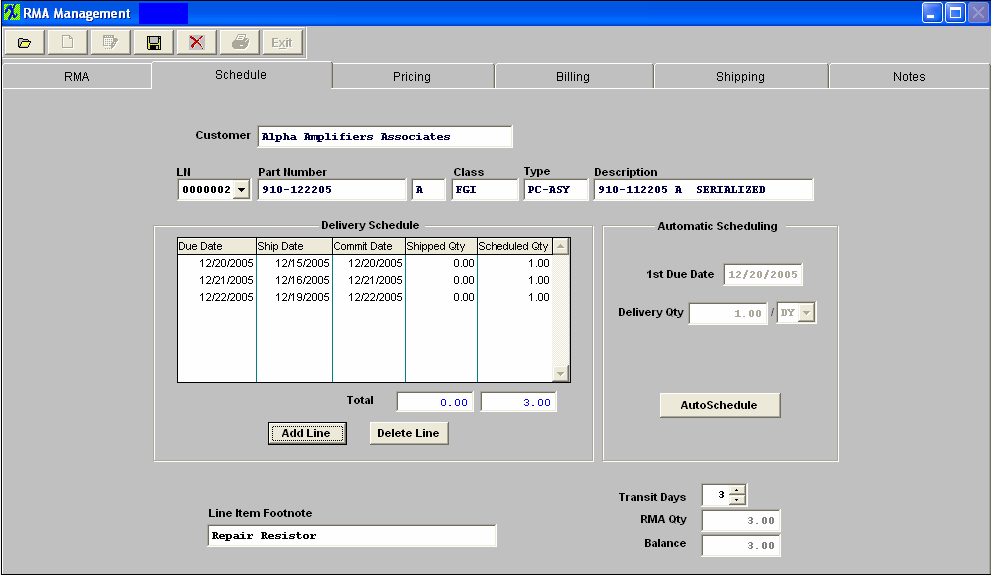

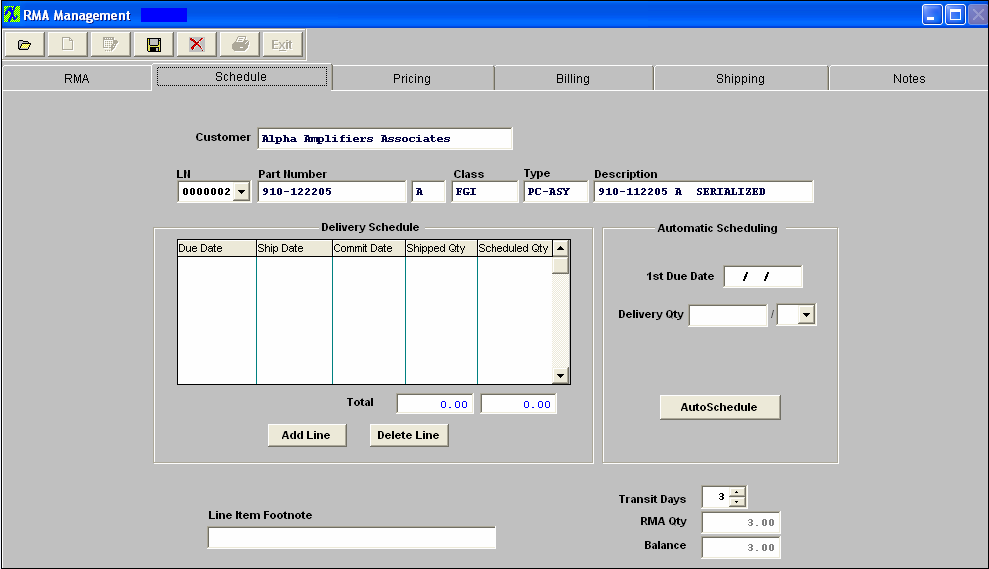

Schedule Tab Depress the schedule tab.The following screen will appear:

There are two modes available for completing a scheduled delivery for a product: Automatic and Manual. In the Automatic mode, ManEx will take a beginning date and a quantity to be delivered each period (Days, Weeks or Months) and schedule out the delivery using the Delivery Schedule Default Days which are setup in the Delivery Schedule Default Setup module.

The following activities are available: Sales Order Line number: Select the line number using the down arrow. Be sure that you’ve selected the line number which pertains to the re-work/replacement.

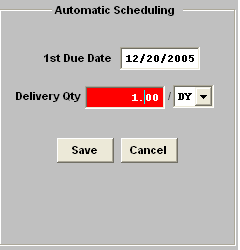

Automatic Scheduling. Pressing this button enables the scheduling box and places the scheduled date in the 1st Due Date box. The user may establish a default number of days from the current date setup in the Delivery Schedule Default Setup module. The user can then use that date, or enter the first (beginning delivery) date the customer expects to receive the order. The Delivery Qty screen allows the user to divide the shipment into multiple deliveries of equal parts. For example, if the order is for a total of 100 pieces, and the customer wishes delivery to be at the rate of 10 units each day, then the delivery quantity should be entered as 10. The next box allows the user to select the delivery intervals. The options are by day (DY), week (WK) or month (MO).

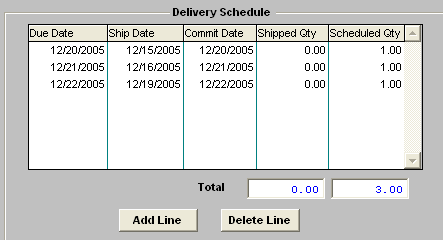

A Line Item Footnote may be entered for comments on the delivery schedule for reference. The completed screen will appear as follows:

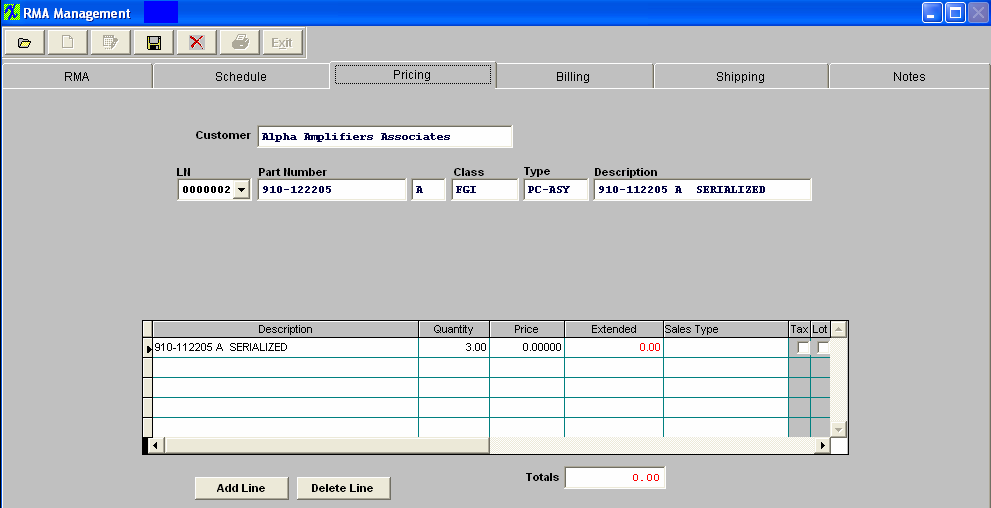

Pricing Tab Depress the Pricing tab. The following screen will display:

Then the unit price for the product can be entered. Note that the unit price for the re-work/replacement must be equal to or less than the original Sales Order price. Once entered, the extended price field is completed. Any additional charges that the users want to add to the line item being shipped back out (postive line items) for rework cost, etc. will be allowed.

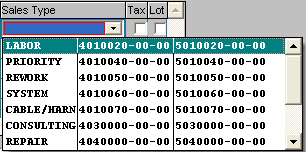

Place the cursor in the Sales Type column and depress the Enter key.The following selection will appear: Select the appropriate sales type. The user may select if the unit is taxable by clicking on the Tax box on the right side of the screen. For Sales Order Items with no Tax, leave the Tax box unchecked. No further action is required. To Manually add Tax (if not set up in Customer Information), enter line item and then in Pricing Screen click on Add Line and enter description of Sales Tax and Tax Amount manually. A Sales Type for the appropriate Tax G/L number should be setup in Accounting so that it can be selected when entering the Sales Tax manually. The full amount of the Tax will be Invoiced upon shipment of the first item so using manual sales tax entries may not be useful for shipments with multiple shipments against the same line item. Checking the Tax box in Sales Order Pricing will not calculate or add US Tax for a line item unless the Shipping Address for the particular Customer selected in the Sales Order Header has been set up. Shipping Address Tax Setup is done in the Tax and Shipping Mode screen in the Customer Information module. Adding a US Sales Tax or a US Shipping Charge Tax in Customer Information requires that those items added be entered in System Setup under Sales Tax Authority Table. If a particular Customer Ship To Address has more than one US Tax (such as a Sales, Use, Excise, etc. tax), then the taxes may be entered in System Setup individually and added individually to the appropriate Customer Ship To addresses. If there is more than one US Tax setup for a Customer Ship To Address, Manex will add up the tax rates and apply the combined percentage to the pre-tax line item total.

User CANNOT manually add Foreign tax to Sales Orders or Invoices. The Foreign tax box must be checked for the Shipping Address for the particular Customer selected in the Sales Order Header. If the Foreign tax box is checked for the Shipping Address for the particular Customer selected in the Sales Order Header. Pricing will be listed as follows on the Sales Order Acknowledgement, Invoice, RMA, and Credit Memo: First the Product Sub-tot AMT, the Sales Discount (if applicable), the Freight AMT (if applicable), a SUB-TOTAL, the GST TAX (Primary tax) (Note: the Primary tax will always be displayed even if it is zero, if a Secondary Tax is present), then a second Sub-Total, PST TAX (secondary tax), and last the TOTAL. If no PST tax (secondary Tax), Sales Discount, or Freight is involved, then no lines would print for these items. See the Foreign Tax Examples.xls attachment to see how the Primary and Secondary taxes are calculated. The Primary tax and Secondary tax is divided into the Sales tax and Shipping tax on the Sales Tax reports. For Example: Primary Tax (GST): 144*10% (sales tax) + 0 (no freight tax is calculated) =$14.40 Secondary Tax (PST): 144*8% (sales tax) + 12*8% (Freight tax) = $12.48 Divided into sales tax and freight tax: Sales Tax: 144*10% (sales tax) + 144*8% (sales tax) = $25.92 Freight Tax 0 (from primary tax) + 12*8% (from secondary tax) = $0.96 If the user has completed the Pricing Screen for the product, then the pricing will be automatically entered. Clicking on the "Add Line" button allows the user to enter additional charges for the product. These charges may carry a different unit price, and may be of any description. As the information is completed, the total cost for the line item is carried to the bottom of the box, to be validated with the customer’s purchase order. If a price is to be assessed as a lot charge rather than as a cost per unit charge, then the user may check (by clicking) the Lot box at the right of the screen. This will take the unit cost as a lot charge for the item without extending the units by the price. This may be used if a flat fee is charged for a number of parts. A Non-inventory line added on this screen will be invoiced on the first shipment made for this sales order. The completed screen will appear as follows:

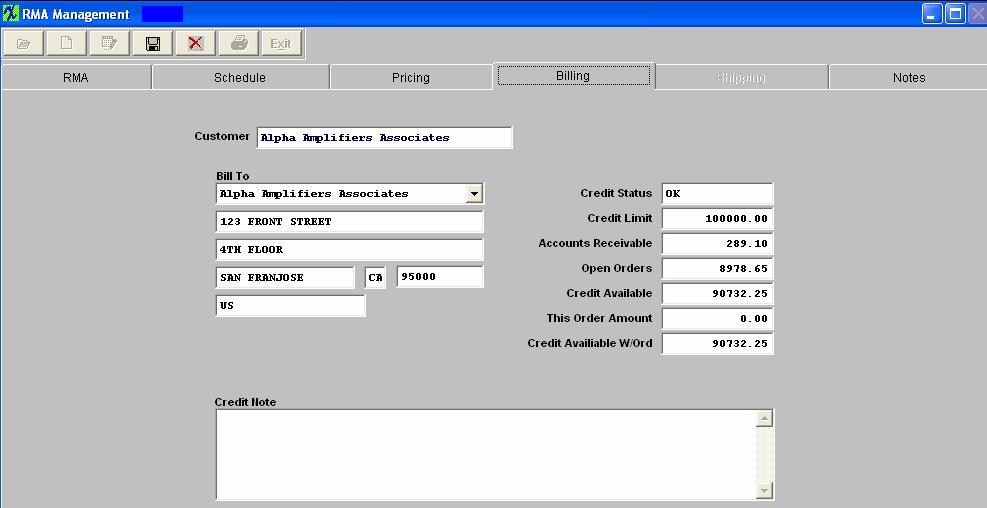

Billing Tab Clicking on the Billing screen tab brings up the following:

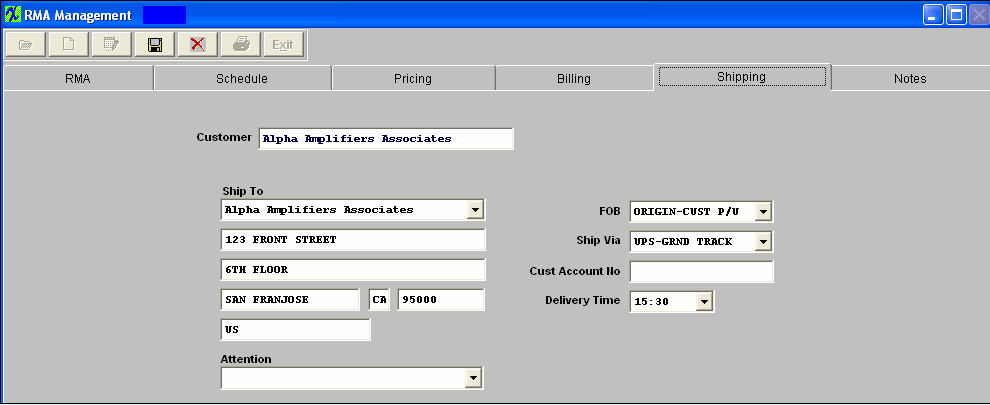

In this screen, a Bill-to address will be completed with the default address established in the Customer setup. The Bill-to address also may be selected from any other addresses entered in the Customer setup.The first prompt is to enter the Bill-to address. The user may accept the default address, or select from any address established in the Customer Module. All address information in the set up will be displayed when the down-arrow is pressed at the right side of the field: After selecting the appropriate bill-to address, the information fields on the screen are populated with the correct data. Shipping Tab Clicking on the Shipping screen tab brings up the following:

As in the Billing screen, the user may select from established ship-to addresses by pressing on the down-arrow at the right of the first field: Once the ship-to address is established, the address fields are populated from the Customer file. In addition to the address, the FOB, Ship Via, Customer Account and Delivery Time are also populated from the Customer File, if they were completed there. If not, or the user wishes to change them, the user may select the appropriate response by clicking on the down-arrow next to the field, and viewing choices set up in the System Setup module. NOTE: The Cust Account No is NOT editable within the RMA module. Notes Tab In the last screen, the NOTES screen, provisions are made to establish RMA Notes, and RMA Acknowledgement notes. These notes are available in their respective sections. The RMA Acknowledgement Footnote will appear on the Acknowledgement printout. Note that when any note is entered on this screen, the screen tab NOTES turns red to indicate there is data in the notes. Depress the Save button. Note that the RMA Total in the RMA tab will update for the net difference between the material to be returned and the material to be re-worked/replaced, as illustrated below:

|