| 1. Product Prioritization |

| 1.1. Fields and Definitions |

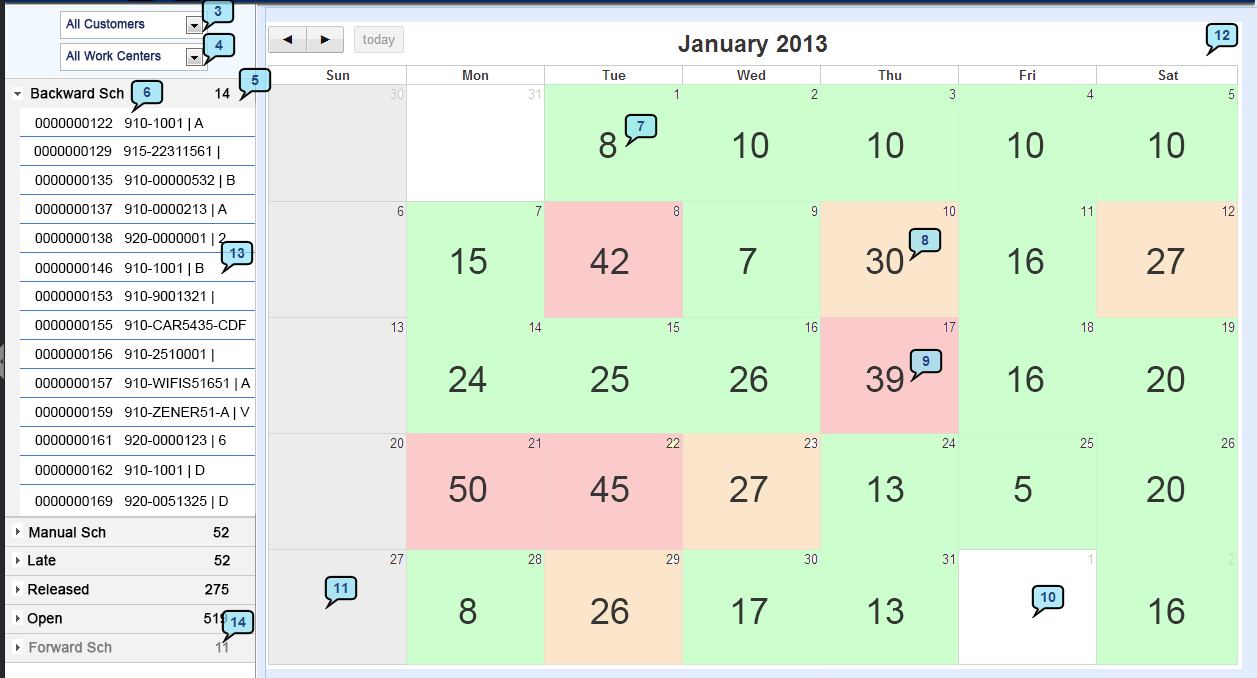

Use Full Calendar for the Calendar Controls.

Month View will display Work Order Count and Capacity Color.

Drag and Drop Scheduling is needed to adjust the start date.

Screen refreshes list of Work Center every 30 seconds (if user does not touch the screen)

Fields and Definitions

3 - Customer Selection - Select All or a specific customer from the pull down and the calendar data will update accordingly.

4 - Work Center Selection - Select All or a specific Work Center from the pull down and the calendar data will update accordingly.

5 - Work Order Accordion - Grouped records of Work Order; Backward Scheduled (auto scheduled) ; Manual Scheduled - user adjusted; Behind - Due Date and Complete Date have not passed, but a WC should have been completed by now, but has not; Late by Due Date - The WO due date has passed and the job is not finished; Late by Sch Date - The scheduled complete date has passed and the job is not finished; Released - Kit released is true; Open - All open WO.

6 - Accordion Details - Group Header displays title and record count; Record displays WO number, part number/Rev.

7 - Day Details - Green color indicates that All WC for that date are under capacity. Count shows total WO in production for that date.

8 - Day Details - Orange color indicates at least one WC is nearing the capacity limit and NO WC is over the capacity.

9 - Day Details - Red color indicates at least one WC is over capacity.

10 - Day Details - White indicates that nothing is scheduled for that date.

11 - Day Details - Grey indicates an non-working date.

12 - Calendar Data

13 - Record Selected Details - Click to expand and see the details and clicks again to revert to calendar view and hide the details.

14 - Category View - If no records belong to the group a 0 will be displayed.

|

| 1.2. How To .... |

| 1.3. Product Prioritization FAQ |

| 1.3.1. How to account for Programming in Scheduling? |

Q: For example: they have Programming or NRE that is associated with the first time they run a product through their system. They want to know from the scheduling point of view how the system will account for the time that it takes for this Programming? A: I don’t believe that we have a method to account for these onetime Programming times. Right now our scheduling so more like prioritizing.

|