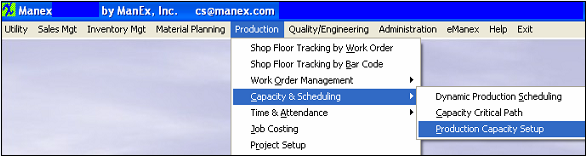

| 1. Capacity & Scheduling (OPTIONAL Module) |

| 1.1. Production Capacity Setup |

| 1.1.1. Prerequisites for Production Capacity Setup |

The following setup is required before the user will be able to use the Production Capacity Schedule.

After activation, "Production Capacity Setup" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

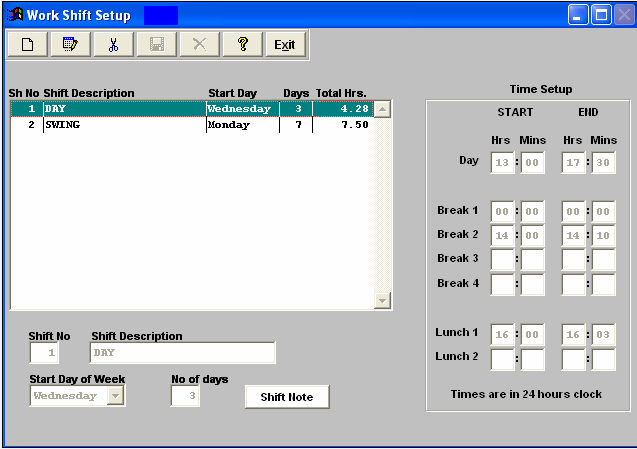

Work Shifts must be setup in the Work Shift setup module. The more work hours you have the higher your capacity.

In System Setup for Shop Floor Tracking Defaults the system assigns the Average Hrs/Work Day as 24 hours.

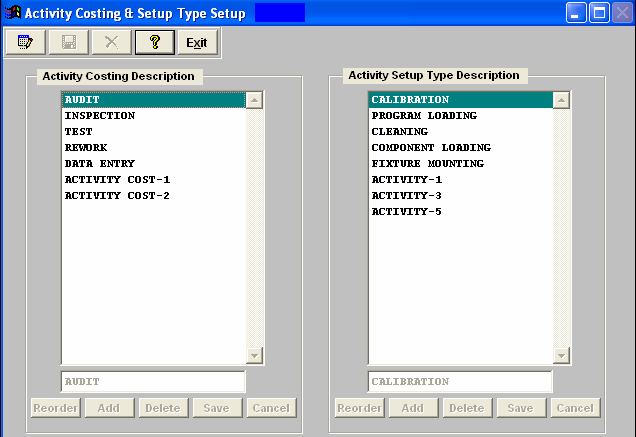

The Activity Costing Description and Activity Setup Type Description must be setup in the Activity Costing & Setup Type Setup module.

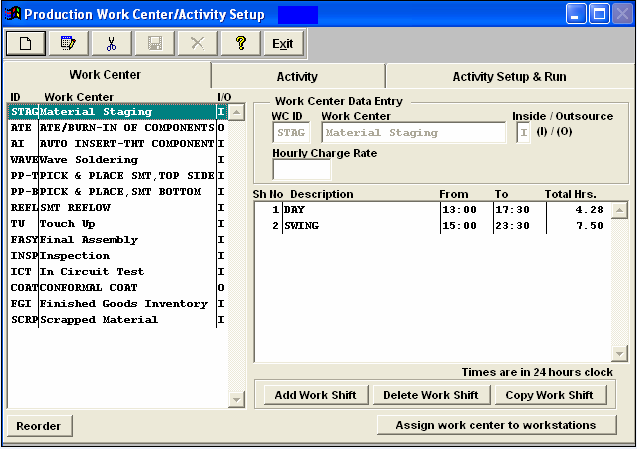

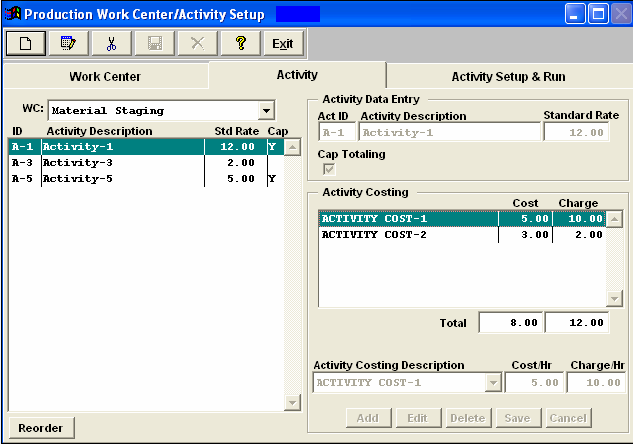

Shifts and activities must be entered to each application Work Center in the Production Work Centers & Activities module.

Within the Activity screen, the user checks the Cap Totaling box and enters the applicable Activity Costing information.

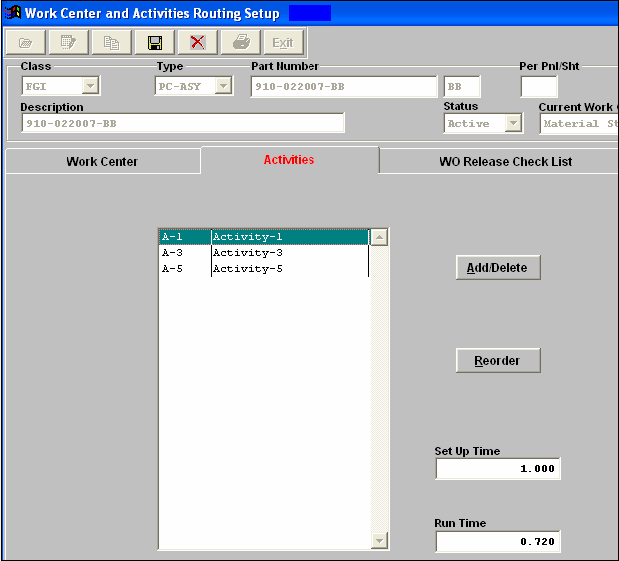

The Work Center Activity Setup and Run Times must be entered in the Work Order Traveler Setup module for any applicable product.

Check the status of the Work Order of interest – it can not be on Administrative Hold (for example), to complete the scheduling.

|

| 1.1.2. Introduction for Production Capacity Setup |

Capacity is at units/hour/operator-machine. Capacity then depends on the number of resources available, and that includes the number of shifts available. The program determines the duration of the job based on the resources, shifts, and active time during shifts (breaks and meals are excluded). The capacity planning module will stack up the requirements for multiple jobs on the same day and either require the user to add resources, or extend the completion time. Once the extensive setup requirements are met, the user may add a resource assignment. There are two views available in the Production Capacity Setup module. The Capacity Summary screen and the Activity Capacity View screen.From there, the user can enter the Dynamic Production Scheduling module and re-schedule Work Orders. There is also the opportunity to graphically view the Capacity Critical Path. |

| 1.1.3. Fields and Definitions for Production Capacity Setup |

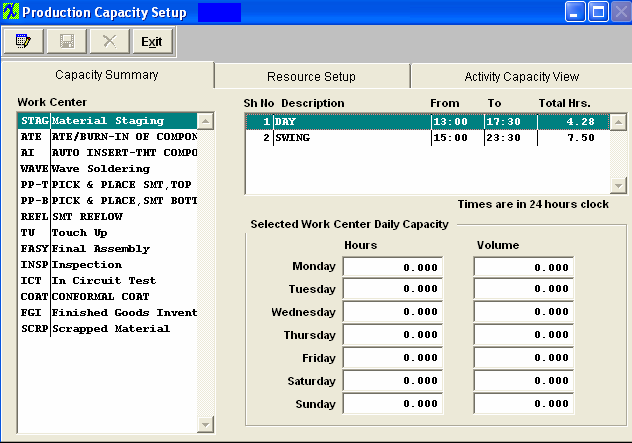

| 1.1.3.1. Capacity Summary Screen | ||||||||||||||||

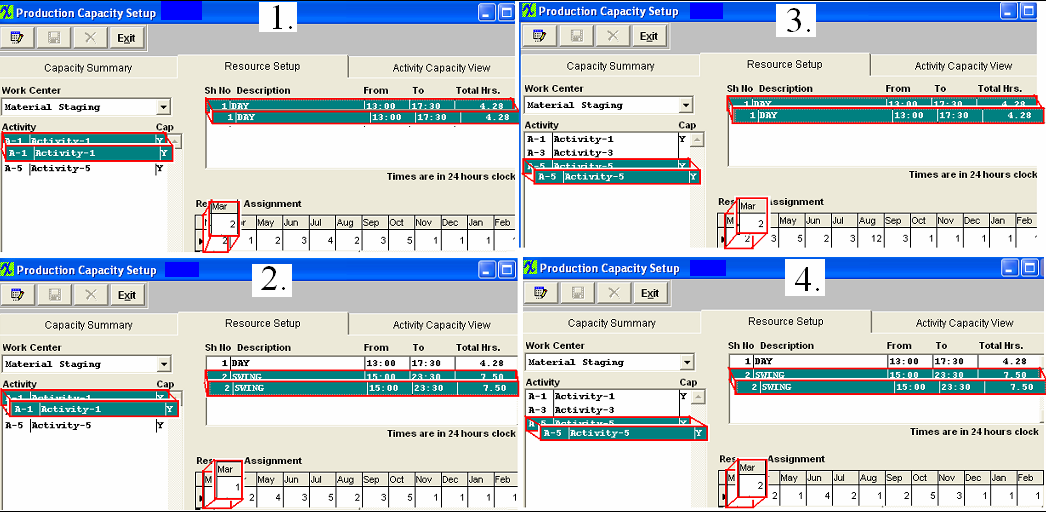

Selected Work Center Daily Capacity

|

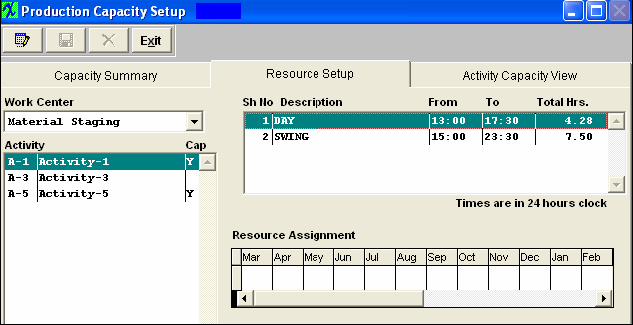

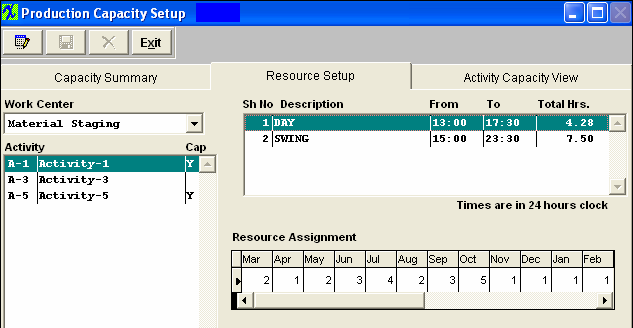

| 1.1.3.2. Resource Setup Screen | ||||||||||||||||||

|

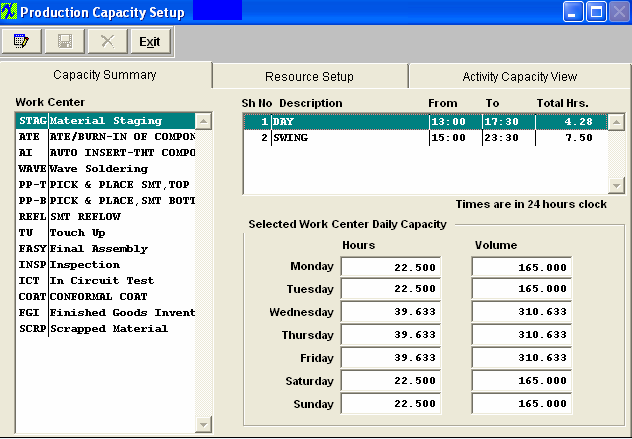

| 1.1.3.3. Activity Capacity View Screen | ||||||||||||||||||||

Selected Activity Daily Capacity

|

| 1.1.4. How To ....... for Production Capacity Setup |

| 1.1.4.1. Production Capacity Setup | ||

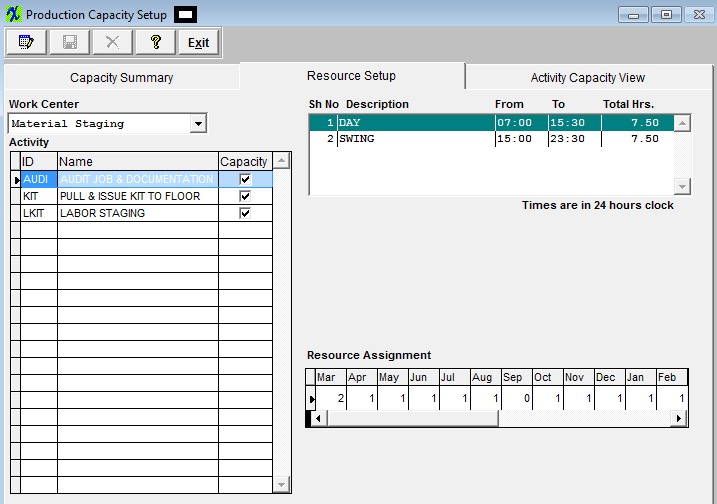

The following screen will appear. Each Work Center can have different shifts associated with it, but it must have at least one

To setup the Resources and Capacity pertaining to a

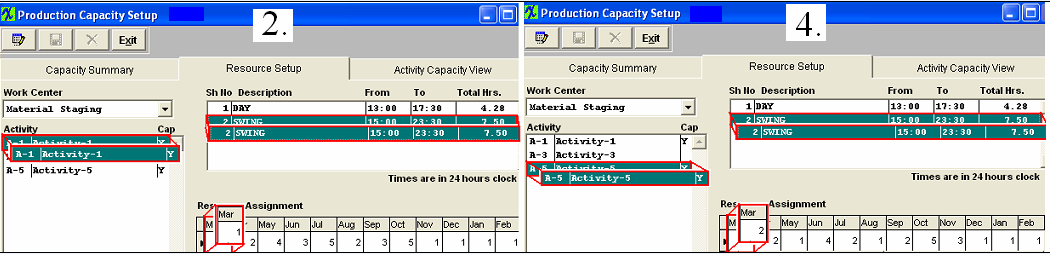

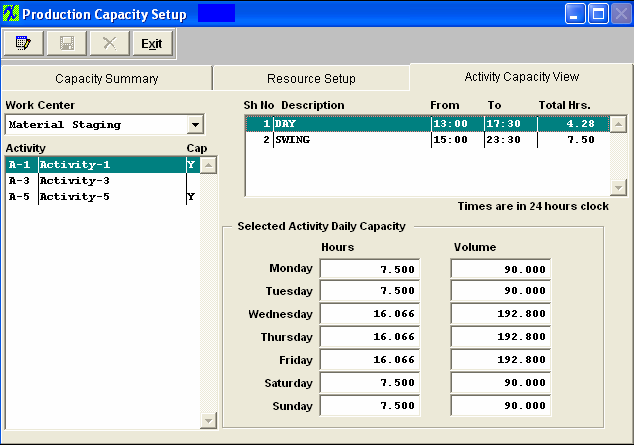

Each time a user enters the Capacity Setup module, the program checks the current date, and updates the month in the "Resource Assigment" grid to show the 12 months from current month. For Example: If the last time a user entered the module was March, so the 12 months are March/2008 to February/2009 (as displayed below). If user re-enters this module in June, the program will change the 12 months to June/2008 to May/2009 and also assign "1" to the 3 new new added months (March, April, and May/2009).

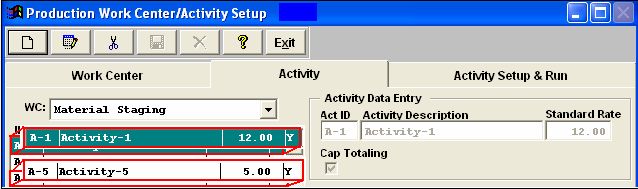

Notice there are three activities listed, but only 2 of them (“Activity-1” and “Activity-5”) will be calculated in the capacity because the “Cap” box has been checked in the Production Work Centers & Activities module.

To add/change a Resource Assignment, depress the Edit button and type in your password. Type in the required Resource Assignment. Depress the Save button to save changes or depress the Abandon Changes button to abandon changes.

User may enter a different Resource Assignment number in each month for each activity/shift. Example for March: Activity-1 Day Shift is 2 and Swing Shift is 1; Activity-5 Day Shift is 2 and Swing Shift is 2.

The Activity-1 Standard Rate is 12.00 and the Activity-5 Standard Rate is 5.00 (Setup in the Production Work Centers & Activities module)

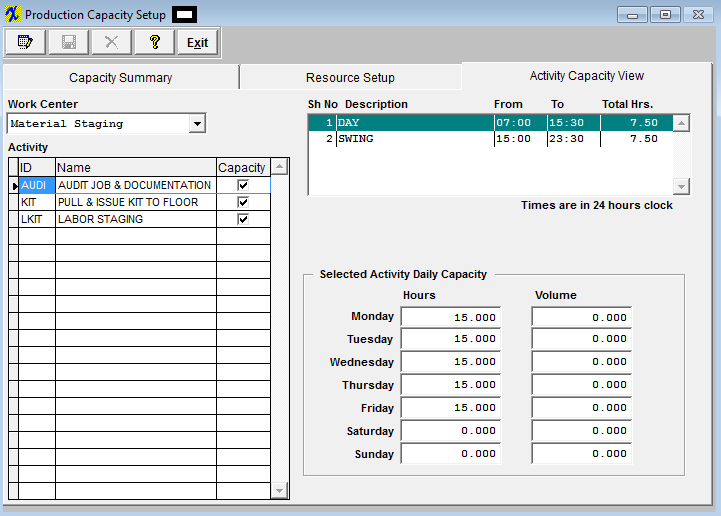

The way the system calculates the hours and volume is: Monday: has only the Swing Shift but is associated with both Activity-1 and Activity-5.

Hours: (7.5*1) + (7.5*2) = 22.50 or (Swing Shift hours x Resource Assignment for Activity-1) (Print Screen 2) plus (Swing Shift hours x Resource Assignment for Activity-5) (Print Screen 4) = 22.50

Volume: (7.5*1*12) + (7.5*2*5) = 165.00 or (Swing Shift hours x Resource Assignment for Activity-1) (Print Screen 2) x Standard Rate for Activity-1 (12.00) = 90.00 plus (Swing Shift hours x Resource Assignment for Activity-5) (Print Screen 4) x Activity-5 Standard Rate (5.00) = 75.00 for a total of 165.00  Tuesday: The same as Monday

Wednesday: has both the Day Shift and the Swing Shift and is associated with both Activity-1 and Activity-5. Hours: (4.28*2 + 7.5*1) + (4.28*2 + 7.5*2) = 39.633 or (Day Shift hours x Resource Assignment for Activity-1) (Print Screen 1) plus (Swing Shift hours x Resource Assignment for Activity-1) (Print Screen 2) = 16.06 plus (Day Shift hours x Resource Assignment for Activity-5) (Print Screen 3) plus (Swing Shift hours x Resource Assignment for Activity-5) (Print Screen 4) = 23.56 for a total of 39.633 Volume: (4.28*2 + 7.5*1)*12 + (4.28*2 + 7.5*2)*5 = 310.633 or (Day Shift hours x Resource Assignment for Activity-1) (Print Screen 1) plus (Swing Shift hours x Resource Assignment for Activity-1) (Print Screen 2) x Activity-1 Standard Rate (12.00) = 192.72 plus (Day Shift hours x Resource Assignment for Activity-5) (Print Screen 3) plus (Swing Shift hours x Resource Assignment for Activity-5 (Print Screen 4) x Activity -5 Standard Rate (5.00) = 117.80 for a total of 310.52

(The screen calculates from minutes, not by hours, so there may be a little bit of a difference.)

Thursday: The same as Wednesday Friday: The same as Wednesday Saturday: The same as Monday Sunday: The same as Monday

To refresh the view in the Capacity Summary tab, highlight the

For each

|

| 1.2. FAQ - Capacity & Scheduling |

Facts and Questions for the Capacity and Scheduling Modules

|