| 1. Fields & Definitions for Inventory Cycle Count |

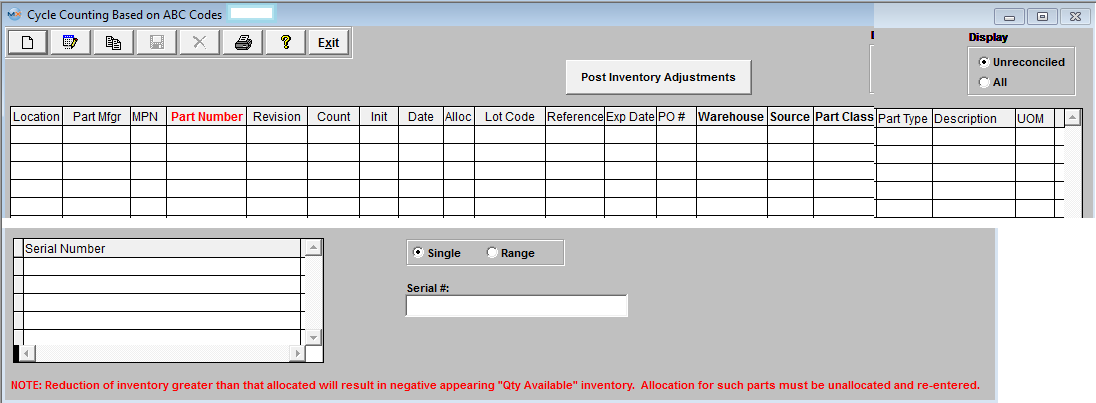

| 1.1. Main Screen | ||||||||||||||||||||||||||||||||||||||||||||

Main Screen field definitions

The warehouse location for the part to be counted. The Manufacturer for the part to be counted. If the source is a buy, the number that the manufacturer has assigned to the part. The Internal Part Number for the item to be counted. Depressing the Part Number button will sort the grid by part number. The Part Number Revision for the item. An item may exist under multiple revisions. The initials of the individual who performed the cycle count. The date that the inventory was counted. The date will default to the current date, but may be over-written. If an inventory part number has allocated inventory, the line will show in red and the Allocated box will have a check mark.This field is a reference field which indicates to the user that there is allocated inventory against this item and the system will not allow you to adjust the qty below the allocated amount. If the part type has been designated as requiring lot tracking, then the lot tracking reference number appears. The source of the part number, Make or Buy. Depressing the Source button will sort the grid by source. The part type within the classification of the part number. The description of the part number. The unit of measure of the part number.

|

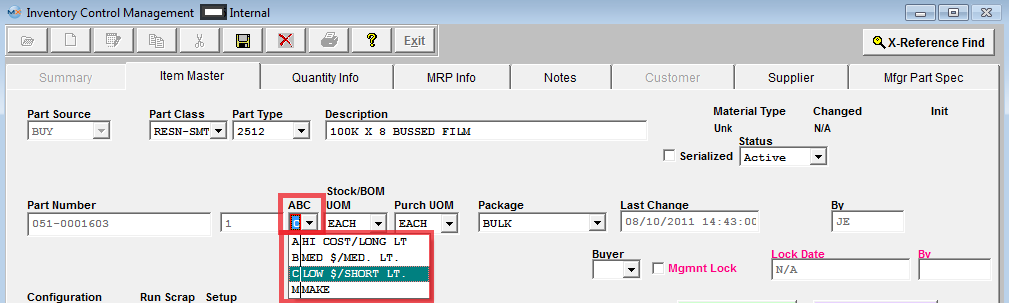

| 1.2. ABC Types |

ABC codes are used as an aid to manage inventory tracking. Traditionally, ABC codes are established to divide the inventory by value, and to guide in the cycle counting of inventory. First the value of all inventory in stores is added up and listed by part in order of the highest extended value first. Then, the top percentage value (e.g. 80 % of the parts value) would be classified as “A” items, and will probably consist of about 10-15% of the inventory part numbers. The next 15% of the value items would be classified as “B” items, and will be in the neighborhood of 20-40% of the part numbers. The last 5% of the value will be classified as “C” items, and represent at least 50% of the part numbers. The user then sets up an inventory counting program called “Cycle Counting”, which assists in counting all inventory over a period of time. The “A” items might be counted completely within each month. Therefore, a list of all of the “A” items (the highest dollar value) is generated, and randomly divided into 20 days, and each day 1/20th of the list counted and checked. The “B” items might be checked every quarter, and the “C” items checked once a year. This is one way to verify the accuracy of stockroom transactions, and to take measures necessary to keep the counts accurate. In ManEx, the ABC codes have a slightly different meaning. In addition to identifying the most or least expensive part numbers, a Dock to Stock period may be included in each ABC code. Dock to Stock is the number of days a part is expected to take to be delivered to the stock room after the part is received on the user’s dock. This duration may include the amount of time it takes to organize the shipment, count the parts, log the receipt into the inventory system, perform incoming inspection, and physically move the parts to stores. Intuitively, the higher dollar parts may have longer dock to stock times because of increased inspection. And the lesser valued parts may not require inspection. Also, for each ABC code, ManEx provides a cycle count tolerance, which, if exceeded, will result in reporting unfavorable inventory control results during cycle counting. These tolerances may be expressed in an absolute dollar value, or a percentage of the inventory being counted. For further information on the cycle count tolerances and what the purpose of setting them up in ManEx is see the attachment <<Cycle Count Tolerance.docx>> And, the ABC code identifies a part source for inventory parts. Because ManEx allows up to 36 ABC codes, it also provides for identifying if a part is a make or buy part. The ABC codes need to be specifically setup for Make parts. If Make parts are to be included in the cycle count. If an ABC code is setup for a buy part and that ABC code is assigned to a Make part the make part will NOT be included in the cycle count and vica vera. Note: If an internal part number does NOT have an ABC code assigned, that part will NEVER be selected for cycle counting. Therefore, all internal parts which the user wished to be cycle counted, MUST have a code in the ABC field in the Inventory Control Item Master.

|