| 1. Fields & Definitions - EBD |

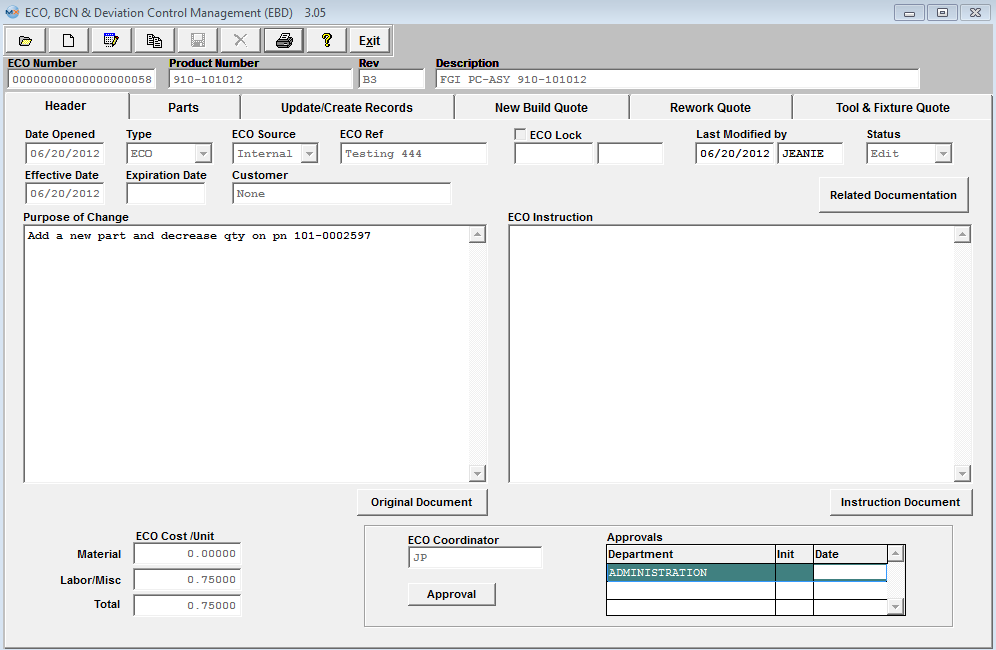

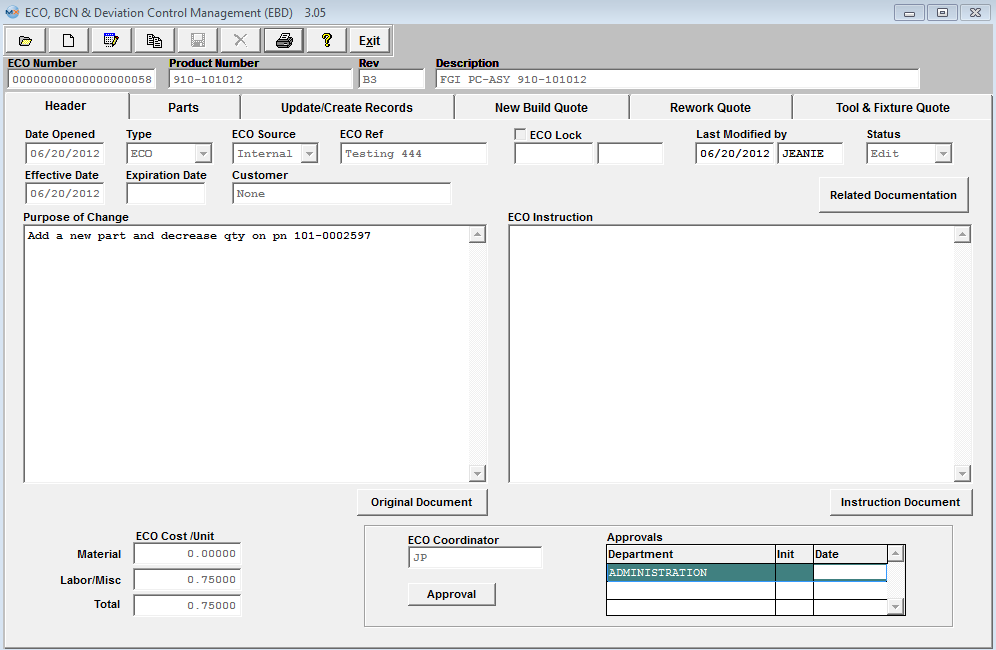

| 1.1. Header Tab |

Header Tab Field Definitions

| ECO Number |

The number assigned to the ECO, BCN, or Deviation.

|

| Product Number |

The unique internal number assigned to the product |

| Rev |

The revision number or character assigned to the product.

|

| Description |

The description of the product. |

| Date Opened |

The date the ECO/BCN/Deviation was started.

|

| Type |

The type of change, either ECO (Engineering Change Order), BCN (BOM Change Notice), or Deviation. ECO is for permanent changes to the Inventory Item Master and the Bill of Materials when there is a revision or part number change. BCN is for permanent changes to the BOM. Deviation is for a one time change to a work order(s).

|

| ECO Source |

This is the source of the ECO, Customer or Internal.This allows the users to know if this ECO was created internally or upon Customer request. At this time this field is for reference only, but will be used for reporting later on.

|

| ECO Ref |

An internally assigned reference number.

|

| ECO Lock |

If this box is checked, all users can access the screen, but will not be able to edit the record until Aprroved users remove the lock. When locked the users initials and date will default in.

Note: Users MUST have special rights within the Security module to modify this field.

|

| Last Modified |

The users initials and date will default in when modified. |

| Status |

The status of the Engineering Change Order, either Approved, Edit, Pending or Cancelled.

|

| Effective Date |

The date that this ECO become effective. (This Date MUST be prior to the Work Order date to be applied).

|

| Expiration Date |

The date that the Deviation will expire. (This field is only enabled for a deviation and MUST be popluated for the Deviation to be available within the SFT module ) |

| Customer |

The name of the Customer which is linked with the Bill Of Materials.

|

|

This button will allow users the ability to load more documents pertaining to the ECO (cutomer ECO,drawings, instructions,etc). Loaded files will not be carried fwd to the PDM module upon ECO approval. |

| Purpose of Change |

The intent of the change.

|

| ECO Instruction |

The description of the change.

|

|

This Button will allow the users to view any hard copy ECO drawing or Documentation loaded. When files have been loaded this button will appear with Red Text. |

|

This Button will allow the users to view any hard copy ECO drawing or Documentation loaded. When files have been loaded this button will appear with Red Text.

|

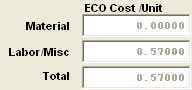

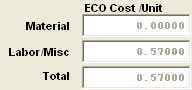

| ECO Cost per Unit |

Material is the Material Cost Change Total forwarding from the Parts tab.

Labor is the Labor Cost Change Total forwarding from the New Build Labor Cost tab.

Total is the sum of the changes in Materials and Labor, above.(Note that the signs can be either positive or negative depending upon the changes made.)

Note: Users MUST have special rights within the Security module to view the pricing information. |

|

| ECO Coordinator |

The name of the engineer entering the Engineering Change Order. |

| Approvals |

The name of the department, initials of the approver and the date of approval. Note: The approving department is setup in the ECO Setup module and the approver must be assigned to the department within the Security module. .

|

|

This button is used for the approval process for each department indicated |

|

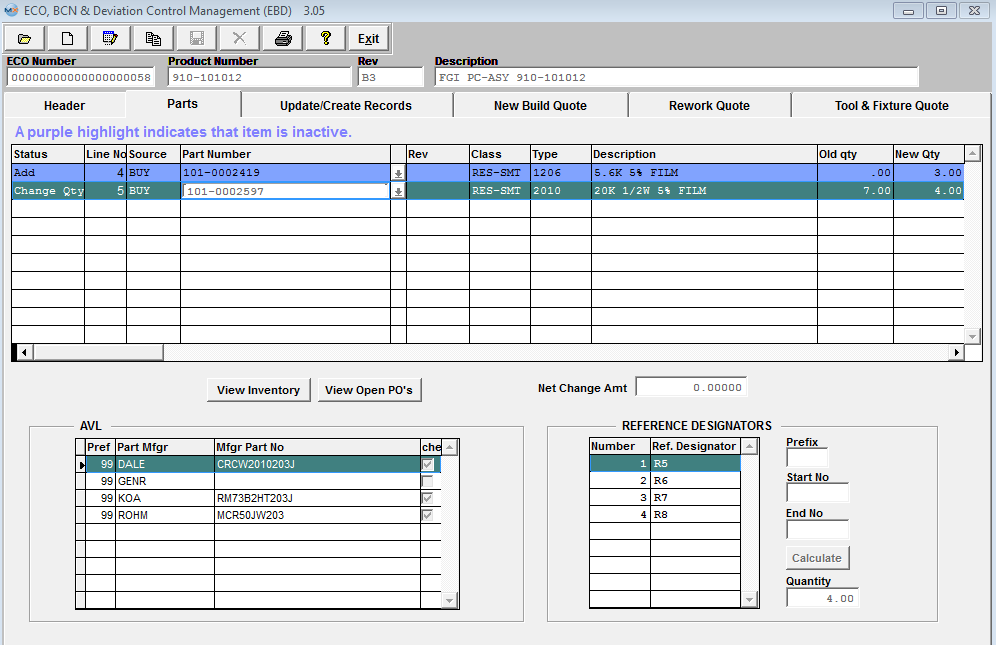

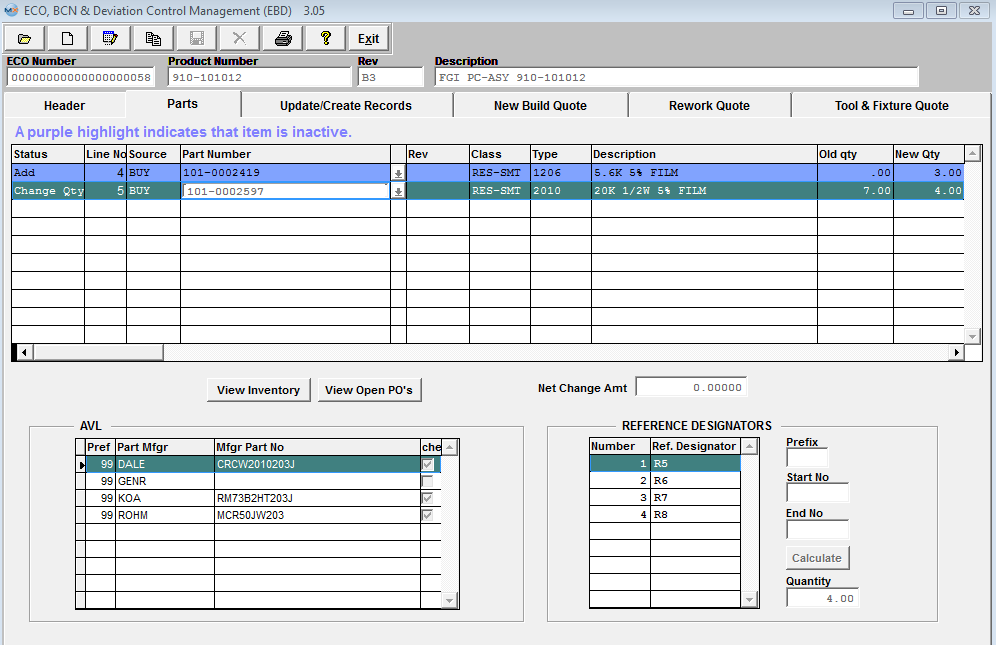

| 1.2. Parts Tab | |

Parts Tab Field Definitions - The Parts tab displays any additional changes or deletions of Bill of Material Components. If the part added has a status of "Inactive" within the Inventory Control Management, it will be highlighted in purple as an indicator to the user that this item is inactive at this time. If the user chooses to leave the inactive part on the ECO, that part number record status will automatically be changed to Active upon the "Update Records" button being depressed, so user will not have inactive parts listed on the BOM. The user will receive a warning that an XLS file has been created for reivew.

| Status |

The status of the component, either Add, Delete, Change. |

| Line No |

The Bill of Materials line number.

|

| Source |

The source of the component, either Buy, Make, Phantom or Consign.

|

| Part Number |

The internal number assigned to the component |

| Rev |

The revision character pertaining to the component part number |

| Class |

The classification of the component.

|

| Type |

The type within the classification of the component |

| Description |

The description of the component part number |

| Old Qty |

The quantityof thecomponent currently called for in the Bill of Materials.

|

| New Qty |

The new quantity ofthe component which will be called for. |

| Std Amt |

The standard cost per the Inventory Control Item Master multiplied by the net change in the number of components used.

|

| Customer Part No |

If there is a customer part number associated with the user’s part number, it will appear here.

|

| Rev |

The revision character associated with the Customer Part number.

|

| Work Center |

The work station where is component is 1st used in the assembly production process.

|

| U/K |

Valid entries for this field are “Y” – Yes used in Kit, “N” – Not used in Kit, “F” – Free Stock.The system will default the value to be “Y.”

|

| Scrap Item |

This field is for reference only, it will not affect any other modules. |

| Net Change Amount |

The sum of the Standard Amount column.

|

|

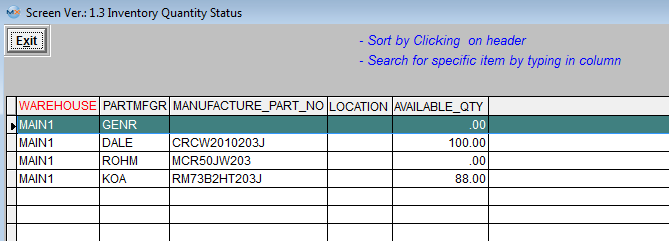

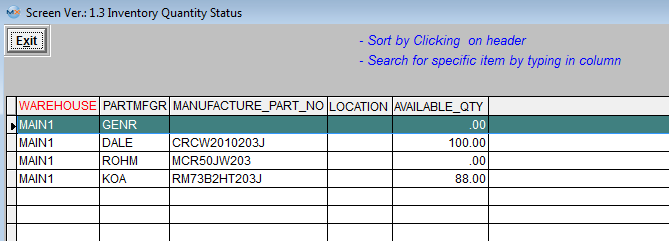

The following screen will be displayed, showing the currently available inventory information for the line item highlighted. This screen allows you to Sort and Search for specific items by typing in column.

|

|

The following screen will be displayed, showing current Open PO for the line item highlighted: |

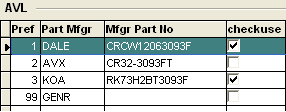

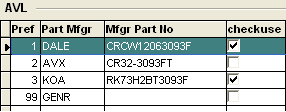

| AVL Information |

For the highlighted line item |

|

| Pref |

This is a number indicating the preference for use |

| Part Mfgr |

Displays the Part mfgr. name |

| Mfgr Part No |

Displays the Part mfgr. part number |

| Checkuse |

This box will be checked if this Mfg. and Mfg. Part number may be used |

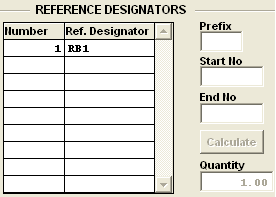

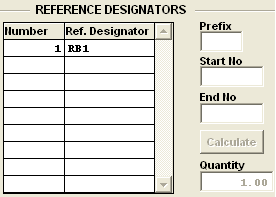

| Reference Designator |

For the highlighted line item |

|

| Number |

The number assigned to the reference designator.

|

| Ref. Designator |

The alpha numeric characters assigned to the Reference Designator number.

|

| Prefix |

The character assigned to all of the reference designator numbers.

|

| Start No |

The first Reference Designator number.

|

| End No |

The last Reference Designator number.

|

| Calculate (button) |

The button used to calculate the Reference Designator.

|

| Quantity |

The new quantity for which Reference Designators have been assigned.

|

|

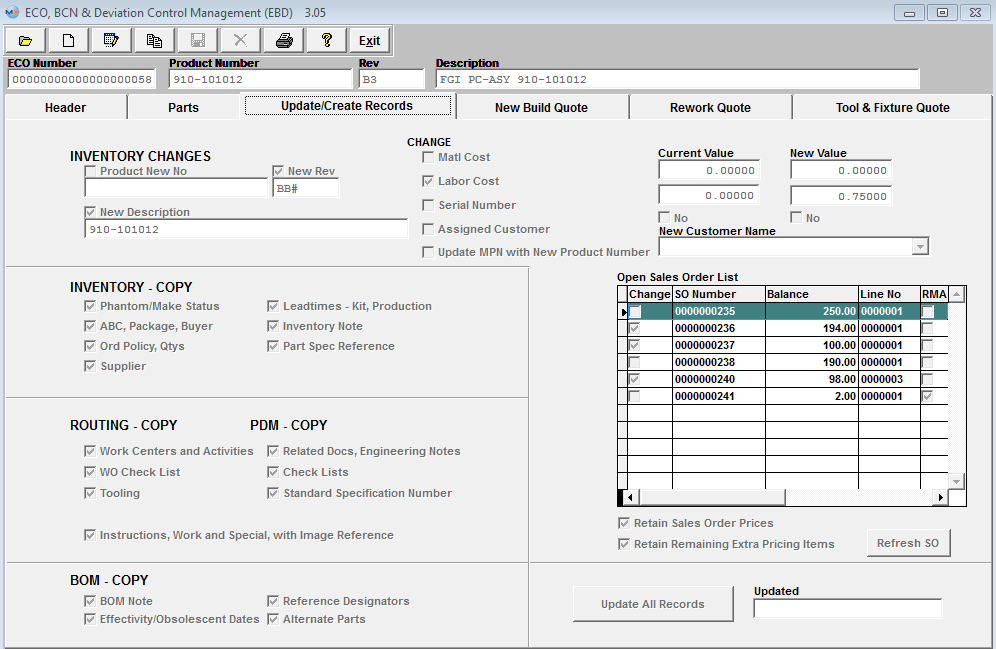

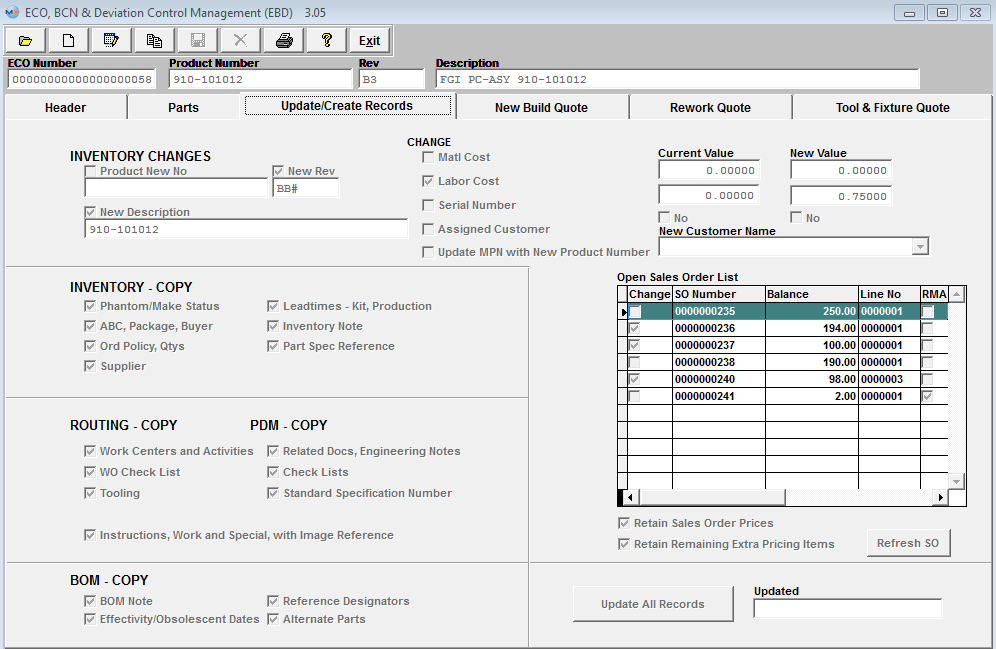

| 1.3. Update/Create Records Tab |

Update/Create Records Tab Field Definitions - This tab displays the revised product number, description, changes in Standard Cost, Labor Cost, whether serial number is required and updates for Engineering Change Orders only. Note: This tab is not available for Deviations or BCN.Inventory Changes section:

| Product New No: |

If the check box is checked, a new product number may be entered here.

|

| New Rev: |

If the check box is checked, the new revision character may be added here.

Note: that either a new Product No or Rev has to be entered in order for the system to allow the user to save the ECO record – this check has been added to prevent any duplicated inventory records within the system. See Article #3062 on why the customer part number or revision is not updated at the same time.

NOTE: When product is changed through ECO module the same material type will be carried fwd for the next/new product at the part level but not at the AVL level.

|

| New Description: |

If the check box is checked, a new description may be entered.

|

Change section:

| Matl Cost |

If this box is checked, the material cost for the product will be updated based on the changes made within the Parts Section and the inventory part standard cost. |

| Labor Cost |

If this box is checked, the new Labor cost for the product will be updated based on information entered within the ECO New Build Labor Cost section. |

| Current Value |

The mat'l or labor cost currently existing for the product within the Inventory Control Module. |

| New Value |

The revised mat'l or labor cost for the product. |

| Serial # Required |

If box is checked, a serial number will be required for the revised product. |

| No/Yes |

If the serial box is checked you have an option to check Yes |

| Assigned Customer |

This will allow the user to Assign a new Customer to the BOM. NOTE: This field is only editable if there are NO open Sales Orders or Work Orders linked to this product. |

| New Customer Name |

If the Assigned Customer box is checked, user may select a customer from the pull down.

Note: Customer name can be changed on the BOM for the product only if either the Product number or revision and the product has no consigned parts for another customer nor any make/phantom parts that are assigned to another customer, and the product is not a sub-assembly for another product.

|

| Open Sales Order List |

Shows all SOs (with any status except for cancel) and RMAs with this assembly number, Balance and item number. The selected SOs and RMAs will be updated with the new Product number and/or Rev number and/or Description shown upper left corner.

Note: If there have been no items shipped against the sales order selected then the system will just replace the existing product with the new within the Sales Order.

If shipments have been made against the item the old line item will be have the Ord Qty updated to equal the total Shipped and the status changed to Closed.A new line item will have been create for the new Product/Rev for the remaining balance that was left on the original item.

|

| Retain Sales Order Prices |

Check this box only if you want the Unit Price to remain the same. |

| Retain Remaining Extra Pricing Items |

Check this box only of you want the extra pricing to remain the same. Note: If you don't check "Retain Sales Order Prices"checkbox, then for either part itself or extra price item, no price will be updated. The "Retain Remaining Extra Pricing Items" is for adding extra items only, for the "price" column, it's still controlled by "Retain Sales Order Prices" checkbox. |

|

“Refresh SO” button has been provided so the user can refresh the Sales Order list to check for any new SO created in the system since the ECO was first created.

|

|

This button is depressed to update all records within the system based on the selections made. |

The rest of this screen comes up with all of the boxes checked for copying the revisions into the Inventory Master, Production Routing, Product Data Management and Bill of Materials. If the user does not want the assembly copied, the box will be unchecked.

|

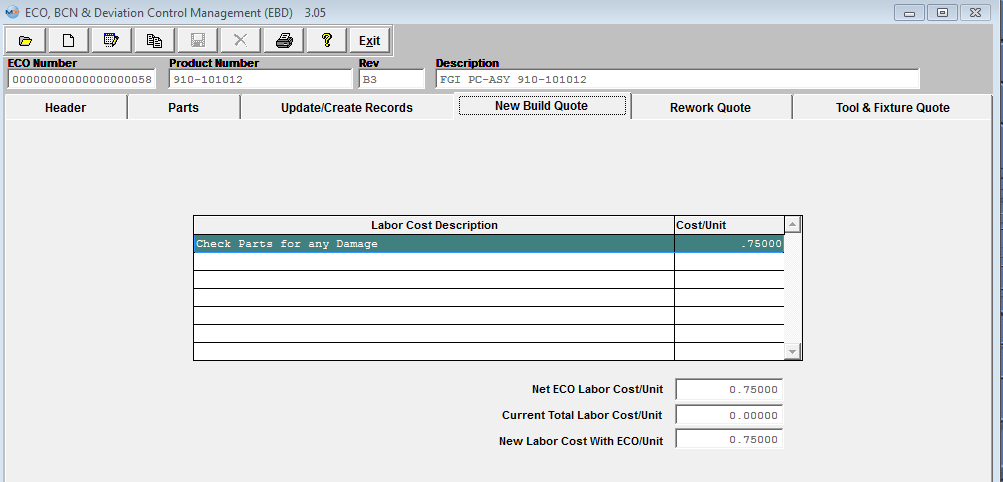

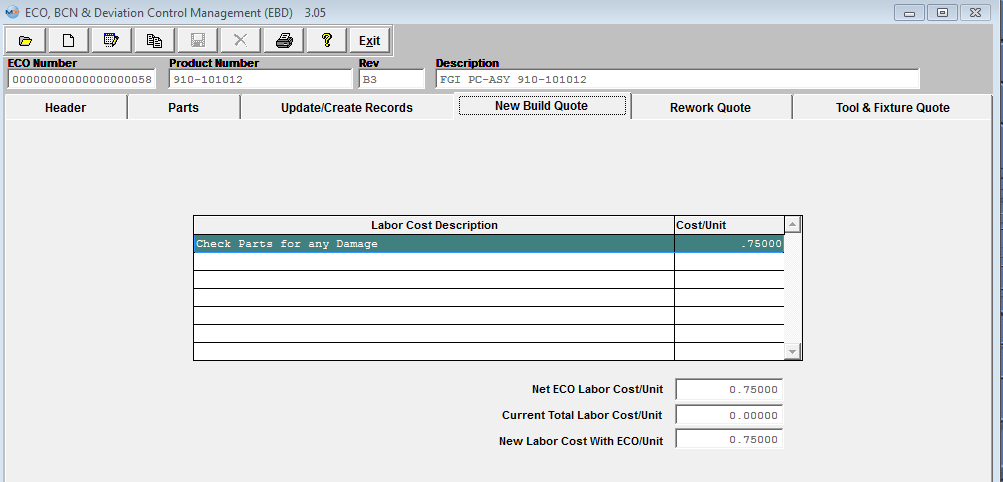

| 1.4. New Build Quote Tab |

New Build Quote Tab Field Defintions - This tab desplays Labor Costs associated with the build of the new product number and revision and calculates the New labor Cost associated with each new unit.

| Labor Cost Description |

Description of the labor. |

| Cost/Unit |

Cost of the Labor |

| Net ECO Labor Cost/Unit |

Sub of the total Labor costs. |

| Current Total Labor Cost/Unit |

This is the total Labor information pulled from the Inventory Control Management module for the Product.

|

| New Labor Cost with ECO/Unit |

This is the sum of the new Net Labor and the Current Labor.

|

|

| 1.5. Rework Quote Tab |

Rework Quote tab Field Definitions - The Rework Quote tab details any Rework Costs due to reworking the existing quantity in Work In Process and/or Finished Goods Inventory.

Open Work Order List (As of ECO Open Date) window: Note: The value of the "as of" is that it can affect the quote pricing and allows customers to better get that information.

| Change |

A check in this column indicates that the Work Order will be revised to the newly changed product number/revision (if applicable).

If Work Order is shaded in WHITE - that means that this Work Order has no qty in FGI so the system will automatically update the Work Order to the New Revision. If a kit is in process for the Work Order selected user MUST depress the "Update Kit" button within the kitting module after the ECO is approved for any part changes to be reflected. NOTE: When the ECO takes place and the WO record is updated SFT losses the transfer history for the old revision and starts over with only xfer history for the new revision from that point on. See Article #3401 for further detail.

If Work Order is shaded in BLUE - this means that this Work Order is partially completed and will be split into two Work Orders: The system will change the original Work Order (original product number and revision) build qty to match the qty completed and close this Work Order. The KIT for that work order will retain only enough material to build the completed quantities. The system will then create a new work order for new product number/revision for the balance quantity. All the extra material issued to the original work order will be de-kitted from original Work Order and issued to the new Work Order.

If Work Order is shaded in PINK - These Work Orders are partially completed and some of the issued components are either serialized or lot code traceability activated. These specific components have to be de-kitted manually prior to proceeding. Or the original Work Order, has to be closed (balance reduced to completed quantities) and extra material de-kitted manually. Then, the new Work Order has to be created for the balance quantities.

|

| Work Order |

Shows all WOs (with any status except for cancel) with this assembly number,. The selected WOs will be updated with the new Product number and/or Rev number and/or Description shown upper left corner.

|

| Balance Qty |

This field indicates the quantity remaining in the specific Work Order. |

| Due Date |

Due date from WO. |

| Status |

Status of WO. |

| New Work Order |

If the Work Order is split into two Work Orders, the number of the New Work created will be listed with in this field. |

| Total of Selected WOs |

The sum of all of the Balance Quantity column, above.

|

|

Refresh WO button has been provided so the user can refresh the Work Order list to check for any new WO's created in the system since the ECO was first created. The value of the "refresh" is they can refresh after it was created if they created it several days before the quote is ready. |

|

Partial WOs button has been provided so the user can view the Work Orders with partial completions that cannot be updated by the ECO process.

|

Rework Cost Description window:

| Rework Cost Description |

This is a description of the rework cost line item.

|

| Cost/Unit |

This is the cost per unit pertaining to the description on the left.

|

| Total Rework Cost/Unit |

The sum of the cost/unit column above.

|

Inventory Locations (As of ECO Open Date) window: Note: The value of the "as of" is that it can affect the quote pricing and allows customers to better get that information.

| Warehouse |

The name of the warehouse where the completed product is stored.

|

| Location |

The name of the location (such as Row 13, Bin 3) within the warehouse above.

|

| Quantity On Hand |

The quantity within that location.

|

|

Refresh Invt Location button has been provided so the user can refresh the Invt Location list to check for any new Locations created in the system since the ECO was first created. The value of the "refresh" is they can refresh after it was created if they created it several days before the quote is ready. |

| Total |

(As of ECO Open Date)The total of Finished Goods Inventory. Note: The value of the "as of" is that it can affect the quote pricing and allows customers to better get that information

|

The window at the bottom right hand side of the tab will display the total costs associated with the rework. Note that these costs DO NOT forward into either the Inventory Control Item Master nor the Accounting records.They are not associated with any new products which will be manufactured after the update to the latest revision, but pertain only to the costs associated with reworking either existing WIP or Finished Goods.

Totals (As of ECO Open Date): Note: The value of the "as of" is that it can affect the quote pricing and allows customers to better get that information

| Qty in WIP |

This is the quantity in WIP which is available to be reworked.

|

| Qty in FGI |

This is the quantity in FGI which is available to be reworked.

|

Units to Rework:

| Qty in WIP |

This is the quantity in WIP which is available to be reworked.

|

| Qty in FGI |

This is the quantity in FGI which is available to be reworked.

|

Cost to Rework:

| Qty in WIP |

This is the quantity in WIP which is available to be reworked.

|

| Qty in FGI |

This is the quantity in FGI which is available to be reworked.

|

| Total Cost to Rework Selected Quantity |

This is the sum of the two above amounts.

|

|

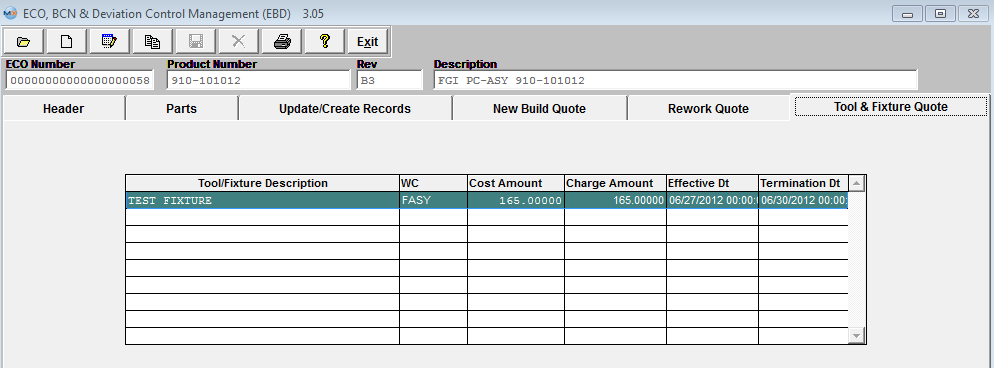

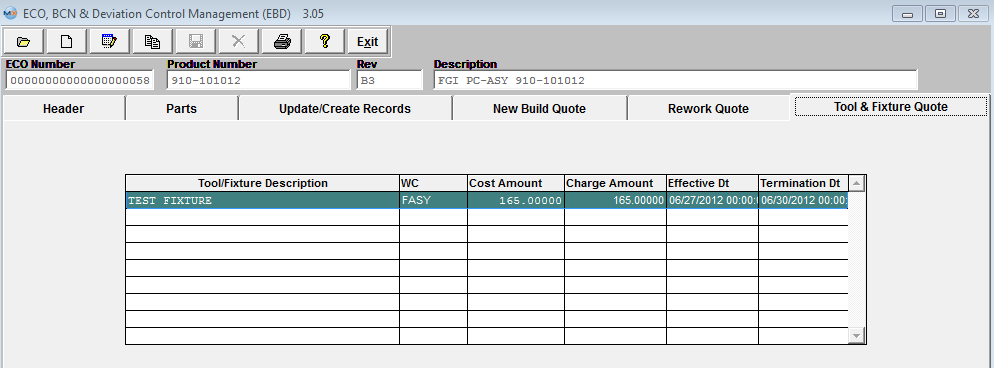

| 1.6. Tool & Fixture Quote |

Tool & Fixture Quote Field Definitions - Once the ECO record has been approved and updated within the system. This Tool/Fixture information will then be carried forward into the PDM and Routing Setup modules.

| Tool/Fixture Description |

This is the description information loaded from the System setup/Tooling Setup for selection.

|

| WC |

This is the Work Center location the tool/fixture is designated to.

|

| Cost Amount |

Original Cost of the Tool/Fixture

|

| Charge Amount |

The amounted that is planned to be charged for the Tool/Fixture

|

| Effective Date |

Date that the Tool/Fixture becomes effective.

|

| Termination Date |

Date that the Tool/Fixture will be terminated.

|

|

|