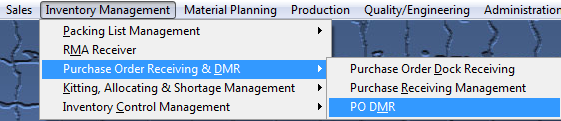

| 1. PO DMR |

| 1.1. Prerequistes for PO DMR | ||||||

Prerequisites for PO Inspection/Acceptance Received with Rejected Quantities:

After activation, "Purchase Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

There must have been a rejection in the Purchase & Receiving Management module. Prerequisites for Rejects from Inventory:

A MRB (materials review board) Warehouse must be set up in Warehouse Setup. Within Inventory Handling the discrepant quantity must have been transferred to MRB (materials review board) warehouse.

|

| 1.2. Introduction for PO DMR |

Discrepant Material Return is used to return material which is different than what was ordered, received late, over shipment, damaged, etc. There are two ways to return discrepant materials. 1. The discrepancy is discovered in PO Inspection/Acceptance Receiving and rejected there. 2. The discrepancy is discovered after the Inventory has been placed into stock. This module allows for review by the Materials Review Board. Then, if not acceptable, the material may be returned to the supplier. Once the DMR (discrepant material return) is created, information regarding the return is forwarded into Accounting where a Debit Memo and the accompanying accounting journal entry is created. Once the Discrepant Material is added, the user may print out a DMR (discrepant material return) Packing List.

In Defect Code Entry we allow users to move product into FGI, when a part is transferred to FGI, the program will compare the total cost of components with the "material cost" of the assembly, then create the configuration variance. In addition to that, the system will create additional 4 records for "Labor", "Overhead", "Other Costs" and "User Defined" costs.

|

| 1.3. Fields & Definitions for PO DMR |

| 1.3.1. Return Items Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

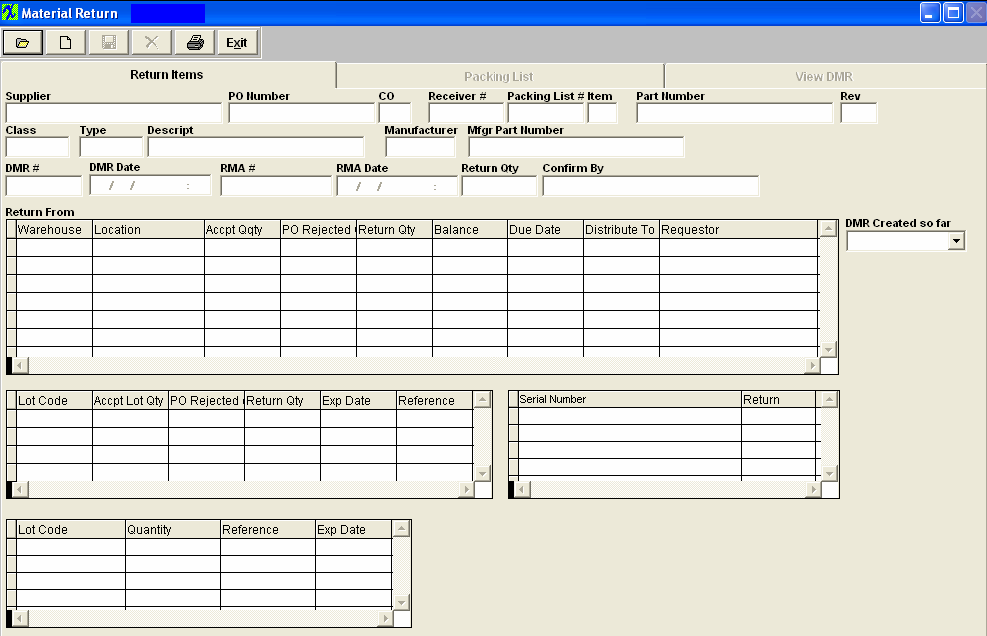

Fields & Definitions

Return Items tab field definitions

|

| 1.3.2. Packing List Tab | ||||||||||||||||||||

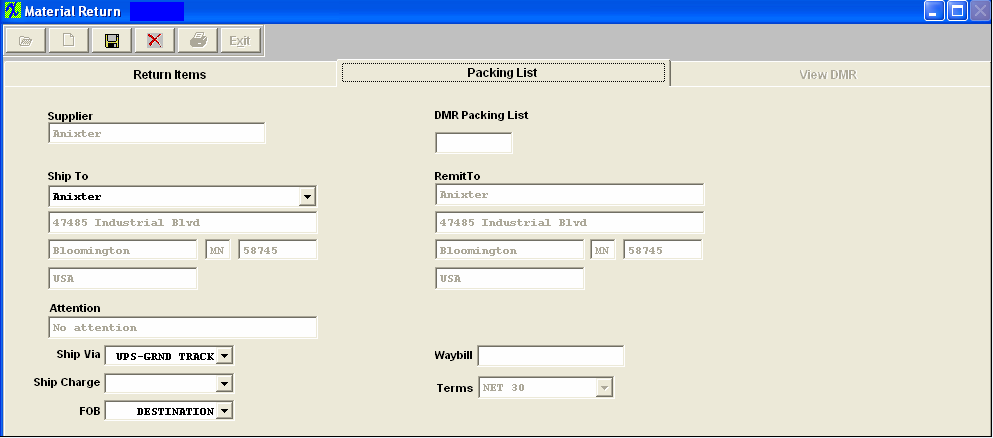

Field & Definitions

|

| 1.3.3. View DMR Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| 1.4. How To ..... for PO DMR |

| 1.4.1. Adding a DMR from Inventory | ||||

This procedure is used after accounting has Reconciled the Purchase Order. If accounting has NOT yet reconciled the purchase order, see Rejecting Items if Accounting hasn't Processed the Invoice. Note that the discrepant material must be transfer into the MRB (materials review board) warehouse via Inventory Handling before you can proceed.

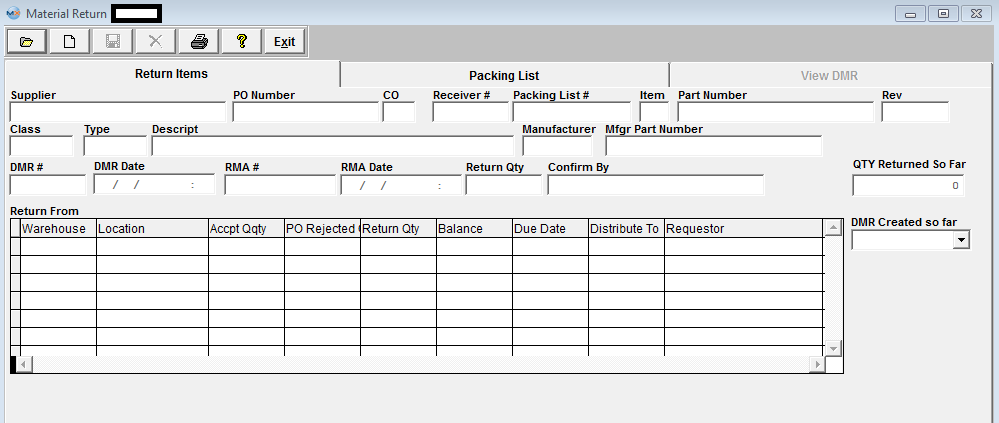

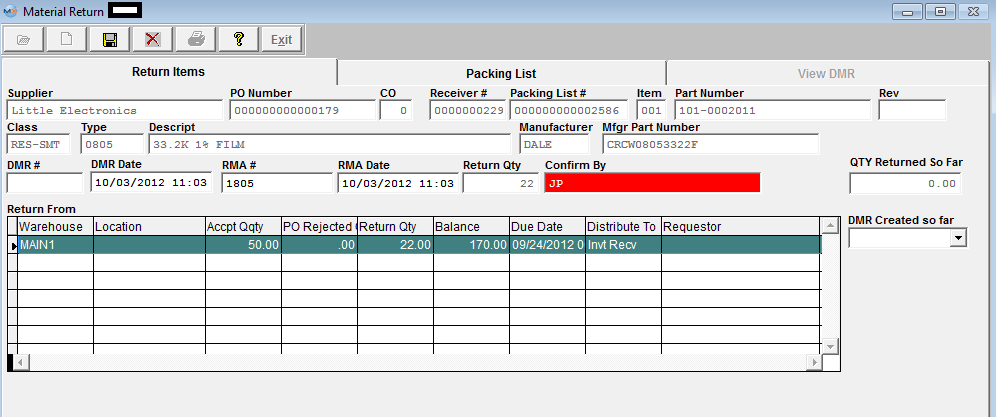

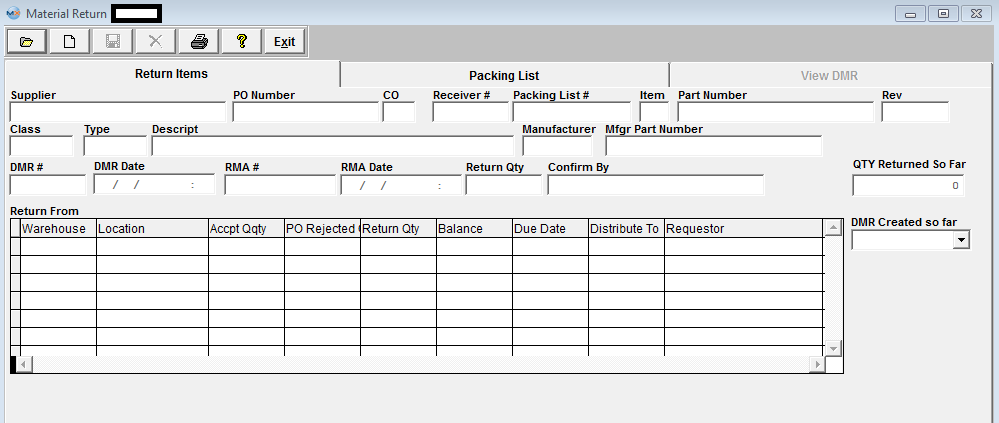

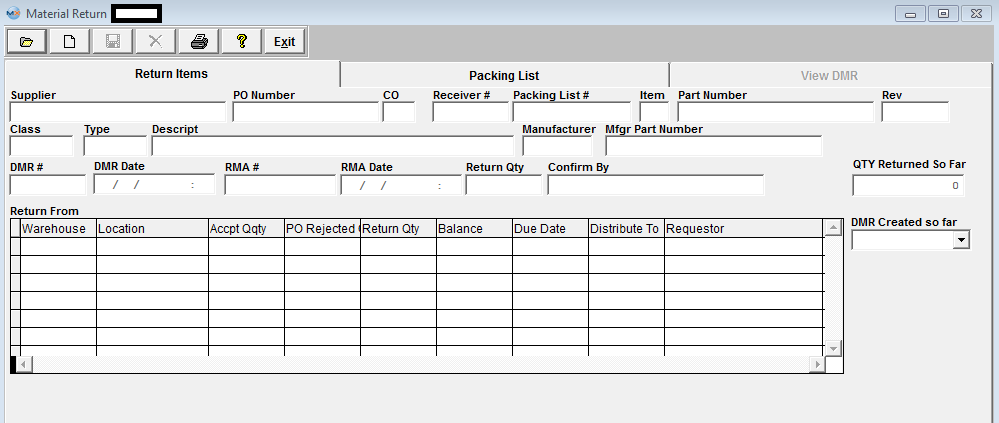

The following screen will be displayed:

Depress the Add button and user will be prompt for a password.

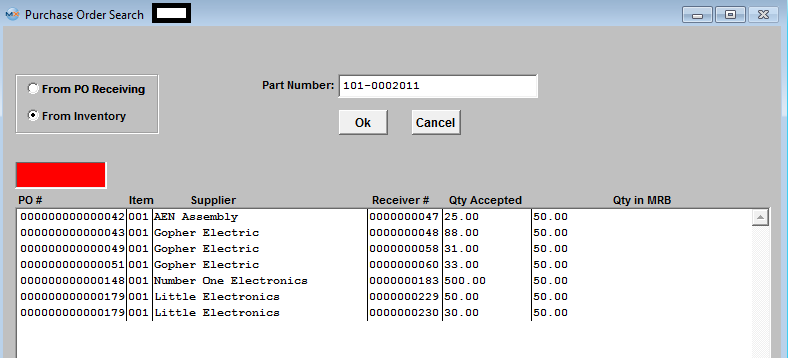

The following screen will be displayed:  Select the "From Inventory" radio and the following screen will be displayed.

Enter in the Part Number and depress the OK button. The following screen will appear (If there is more than one Purchase Order involved it will list them all)

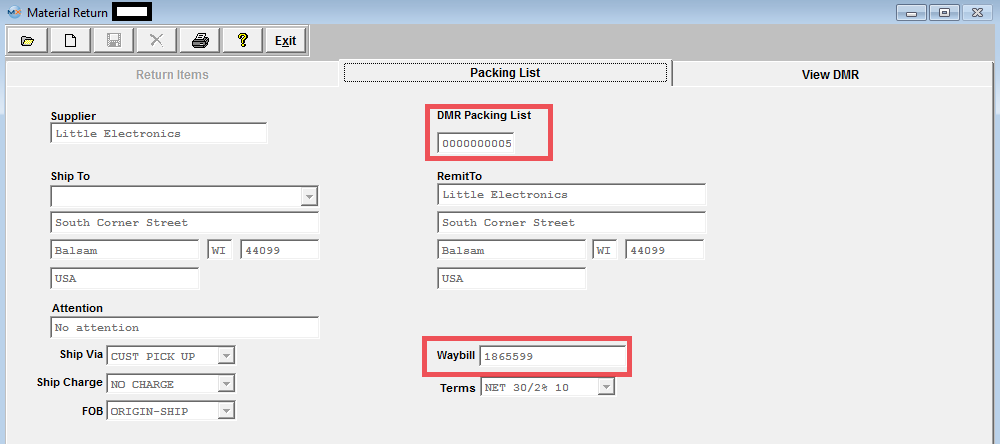

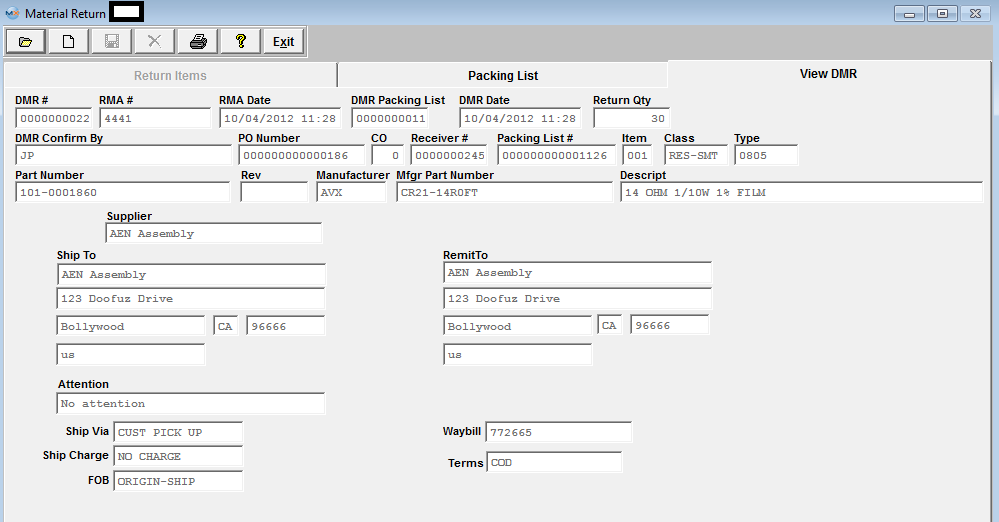

Highlight the Purchase Order of Choice, Depress the OK button. Information regarding that part number for the Purchase Order selected will display:  Depress the Packing List tab, and enter in a DMR Packing List number (if set to manual) for the return, and a Waybill number if applicable.

Once the DMR (discrepant material return) has been added and saved, a Debit Memo will be created, if an AP invoice exists (in order for a AP Invoice to exist you have to have reconciled the PO and transferred it to AP). If Debit memo numbering is manual, the user will be prompted for the number. Additionally, the corresponding entry will be created and the balance in the Accounts Payable Aging will adjust as soon as the Debit Memo is printed. If a PO DMR is created for parts "From Inventory" and the PO has NOT been reconciled and Transferred to AP the qty rejected will be put back on the PO.

The following message will be displayed and the system will NOT be able to create a DMR from Inventory for a part that has been changed from being a Lot-Coded part to a Non-Lot Coded part or visa-versa after PO Receipt has been created.

User should change lot code tracking status with caution. If a part has lot code history and the lot code tracking is de-activated the entire lot code history is wiped out.

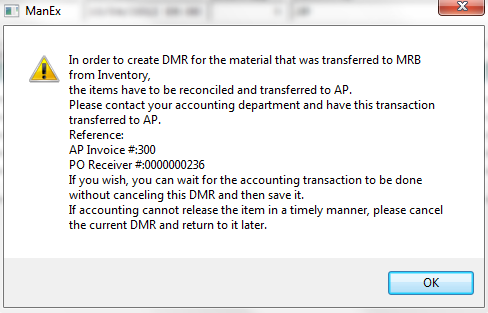

1. If accounting HAS reconciled the PO but HAS NOT transferred the reconciled invoice into AP Aging, the following message will appear:

If the invoice happens to be in a Saved Check batch the following warning will be displayed:

|

| 1.4.2. Add a DMR from a PO Inspection/Acceptance Receiving Rejection | ||||

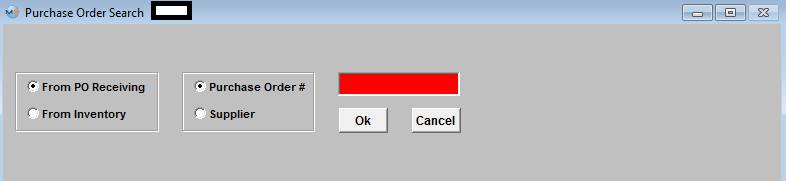

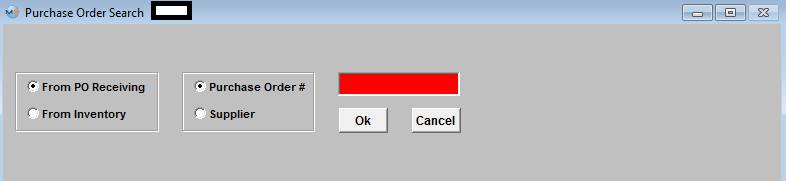

The following screen will be displayed:  Depress the Add button and user will be prompt for a password, enter their password and the following screen will be displayed:

The defaults for this screen are "From PO Receiving" and "Purchase Order #"

If you chose the default (Purchase Order #), you will need to enter in the number of the PO on which the material was rejected. If you chose Supplier, you must then enter in the name of the Supplier.

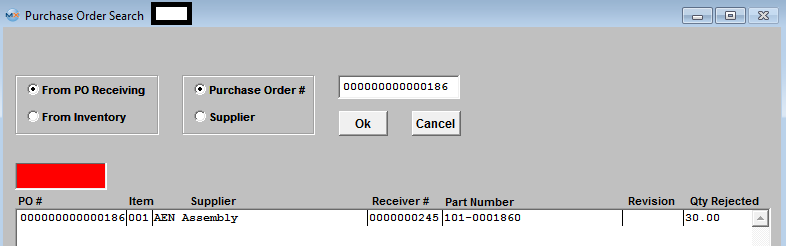

Enter in the number of the PO which the material was rejected and the PO and related information will populate on screen.

Highlight the PO and depress the OK button.

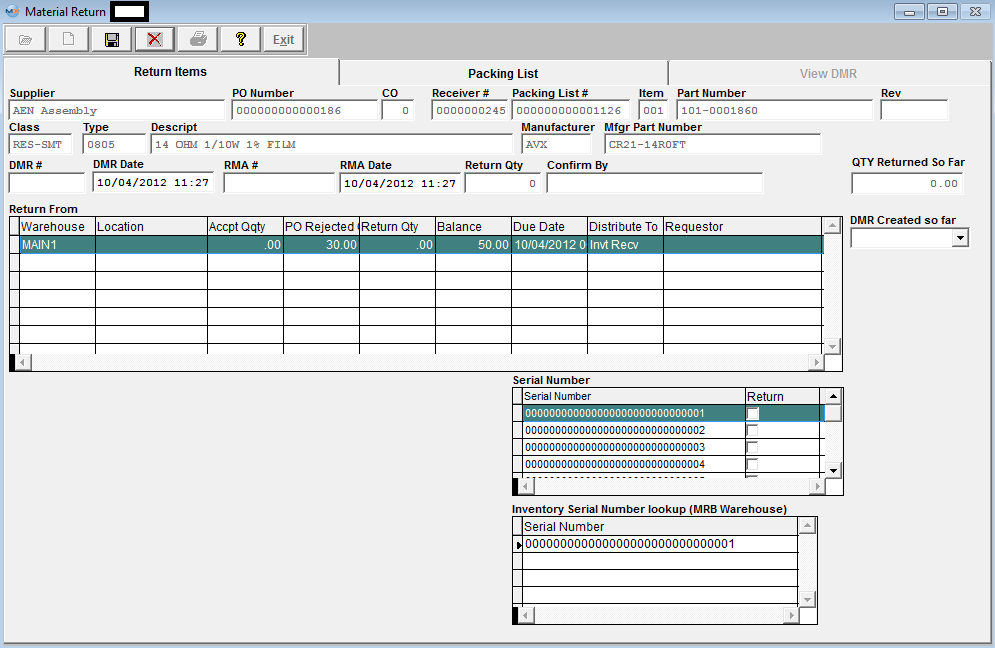

Note: Ther are additional fields displayed on screen if there are Serial Numbers and Lot Codes involved.

Enter in the DMR number (if set-up for manual numbering) you are assigning to this return. Enter in the RMA number as provided by the supplier. Then enter your name in the Confirm By space.

Highlight the line item containing the rejected quantity. (If returning a part that involves a Lot Code, type in the returned quantity in the Lot Code section and it will automatically update the Return From section. Check the serial numbers being returned).

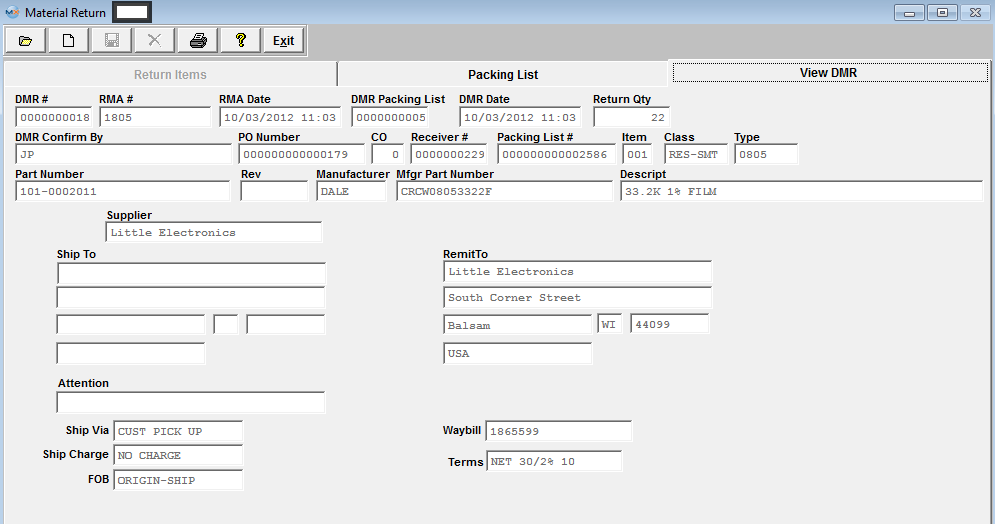

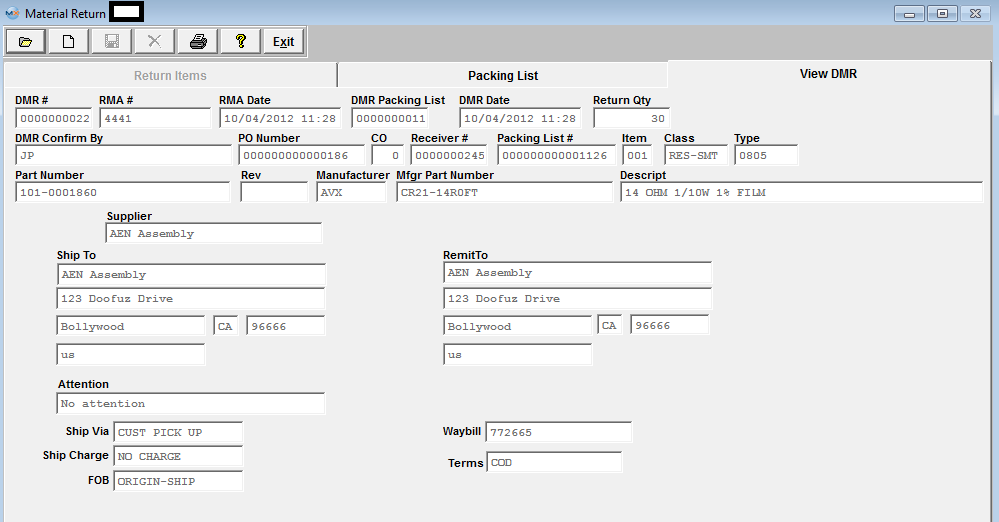

Depress the Packing List Tab, enter in a Packing List number you wish to assign to the return (if set to manually numbering). (Note that this number is NOT tied to regular shipping Packing Lists. This field is only for reference on the DMR’s. Any alpha-numeric code can be used here. DMR packing list numbers cannot be found in the regular shipping module – Packing List Management. It is suggested that the user manually log these codes or type in some kind of significant code, such as the date followed by the PO#). Enter in the Waybill.

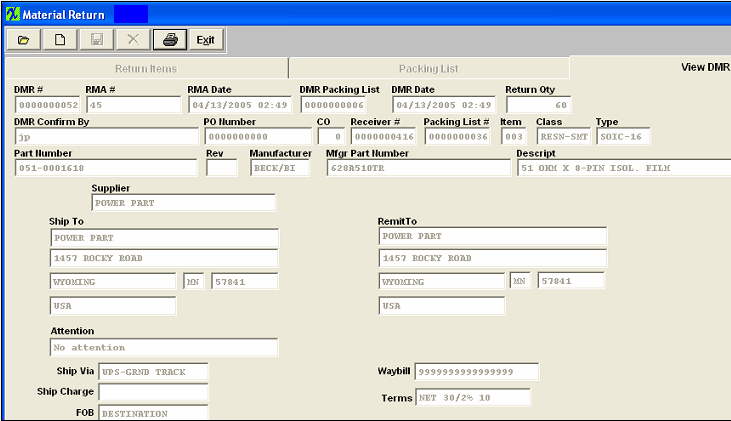

Depress the Save button. The View DMR screen will appear:

|

| 1.4.3. Find an Existing Discrepant Material Record (DMR) | ||||

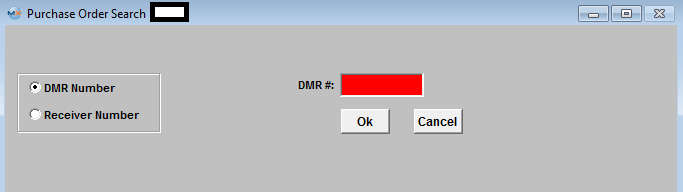

The following screen will be displayed:  Depress the Find icon, the following screen will be displayed. User can select to find an existing DMR by entering the DMR Number or entering the Receiver Number in the Rd box and depressing the OK button:

If the system cannot find any information about the DMR # entered the following message will be displayed giving the user the option to select from a list of existing DMR's:

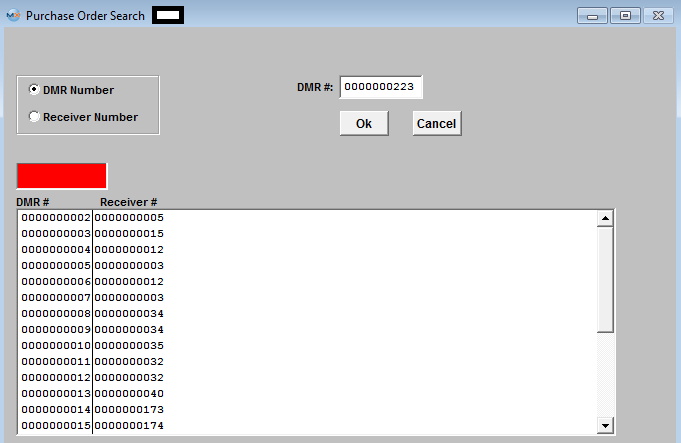

If User Selects "YES" the following screen will be displayed listing all of the existing DMR's

Enter the DMR# in the Red box or double click on the DMR# and the following information will be displayed:

|

| 1.5. Reports - PO DMR | ||||

|

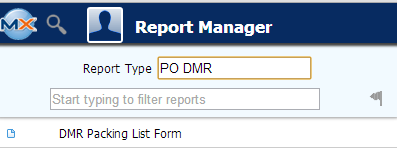

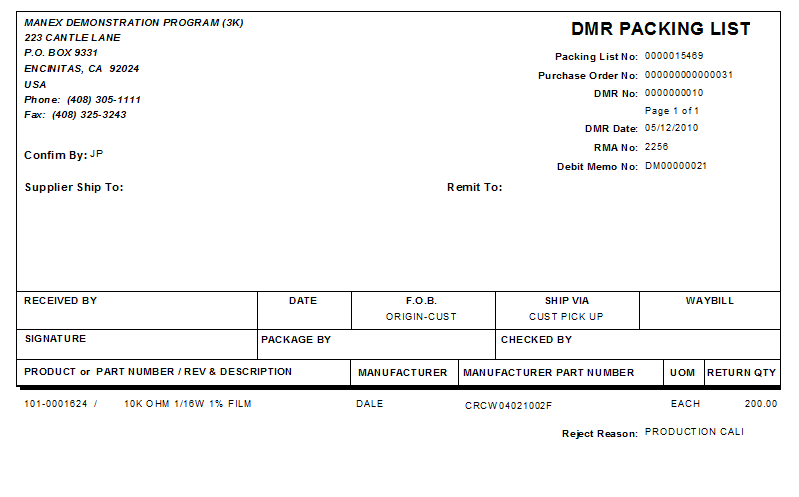

To obtain the DMR (Discrepant Material Return) Packing List Report within the Web, select the WEB Print button from the ManEx action buttons at the top of the screen. For further detail on How the Reports work within the Web refer to Article #5477. Note: In order to access the Reports within the Web the Company Root URL must be setup within the System Appearance module and user must be linked to web within the System Security Module Select the Report Type: PO DMR - A List of Reports will be displayed that are available on the Web for PO DMR

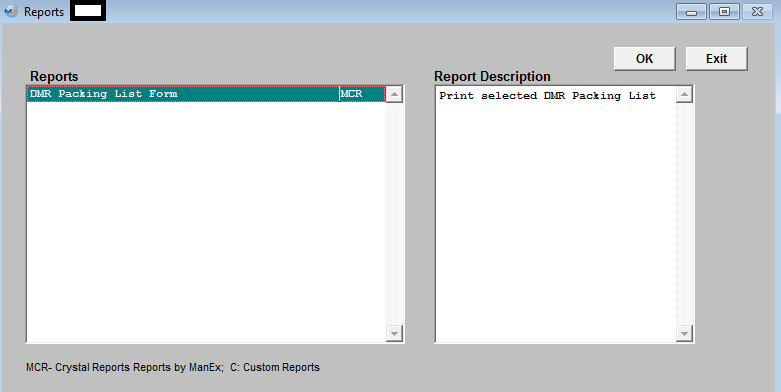

To obtain the DMR Reports within the desktop, select the Print button from the ManEx action buttons at the top of the screen.

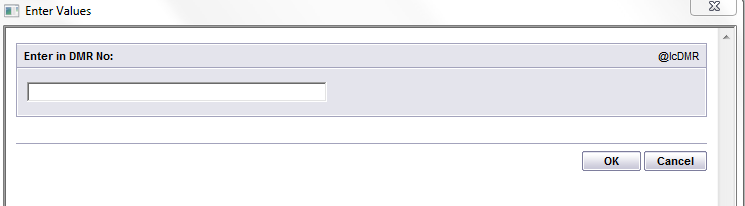

The following reports screen will display a list of reports that are available on the ManEx Desktop: The following screen will be displayed:

The following will print:

|

| 1.6. FAQs - PO DMR |

| Facts and Questions for the PO Receiving and DMR Module |