| 1. Inventory Part | ||||||||||||||||||||||||||||||

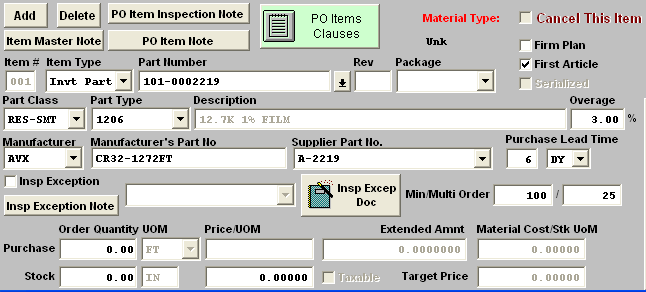

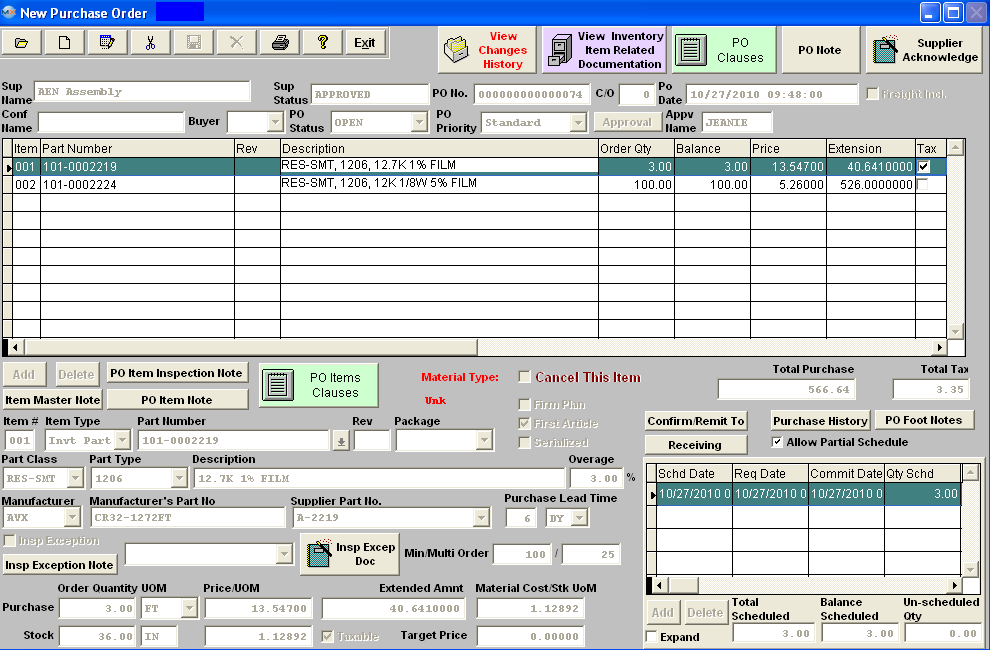

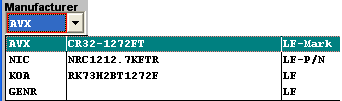

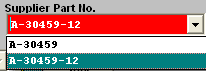

Selecting Inventory Parts as the item type, the user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. Once a part number from Inventory has been entered, ManEx completes the boxes associated with the item master.

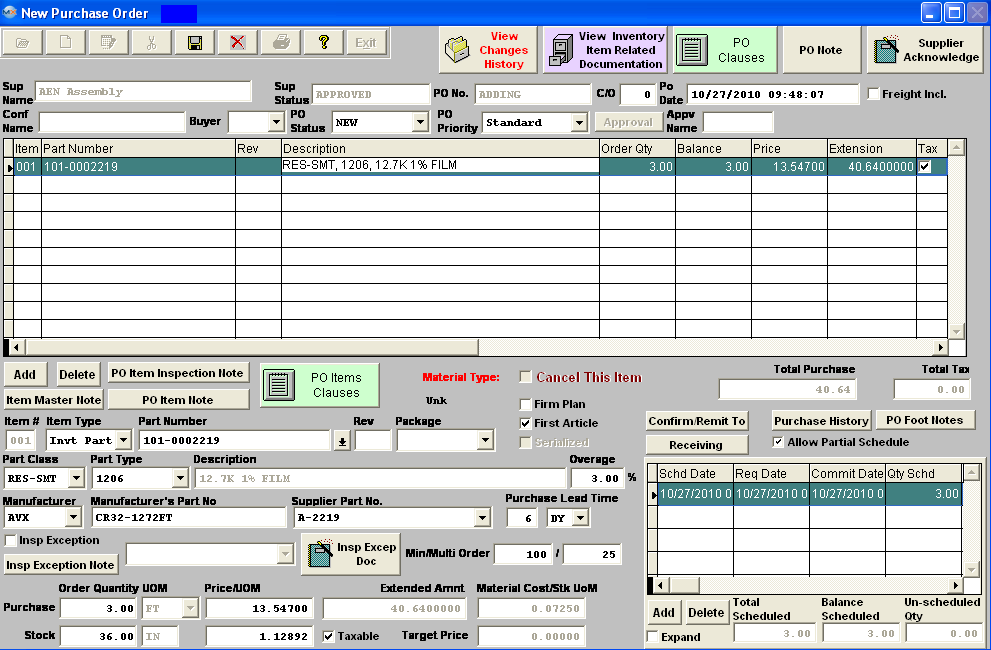

The user may edit or add a percentage amount of extra material that will be allowed to be shipped against the order. By entering a percentage in the OVERAGE field, receiving will be allowed to receive extra parts up to the limit imposed in this field. The user may also edit or add in purchasing lead time and min/mult order quantities through the Purchase Order Management module. Once the record has been saved this information will then be updated within the Inventory Control Management under the MRP Info screen. The user may check the box for Inspection Exception and select from the Inspection Exception Pulldown (which is established in the Inspection Exception Setup module). The user will then also be allowed to enter any Inspection Exception Notes and/or Load Insp Excep doc that pertain to that PO line item. This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system. The user is then prompted for the purchase order quantity of parts to be ordered. The user may enter either the Purchase Quantity or the Stocking Quantity, and ManEx will complete the other field based on the purchase/stocking unit of measure and conversion field.

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter qty of 36 into the stocking qty field and the PO would automatically convert it to 3 feet in the purchasing qty field (as shown in the example below). So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

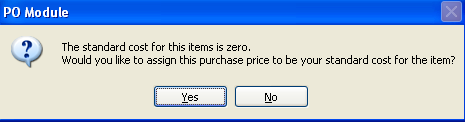

Then the unit price is entered (Price Each). The extended amount is shown, calculated by extending the quantity by price. If the inventory part that you are creating a line item for currently has a standard cost of 0.00 within inventory control the system will prompt the user with the following message, giving the user the option to assign the purchase price to be the standard cost for this item.

This can not be controlled by the Security level due to the fact that it is better practice to have a $$ assigned to the ICM record before the Purchase Order Receipt is accepted into the system. Otherwise you will have stock that is not valued properly, accounting records that will not be correct, etc. . . . So this is why ManEx allows any Purchase Order user to populate the STD cost field for that record with the purchase $ that you are loading. BUT . . Once a Std Cost is associated with the ICM record - the users within Purchase Order Management should no longer be able to change that value through the PO module. The user may then indicate that the items are taxable by clicking on the Taxable check box. The Stock/BOM field will update automatically based upon the conversion table defined in setup. The completed screen should appear as follows: Before saving the order you will need to check the expand box and enter the Schedule detail information.

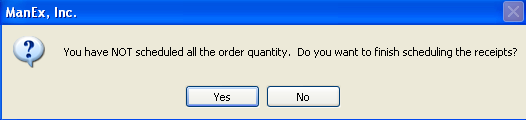

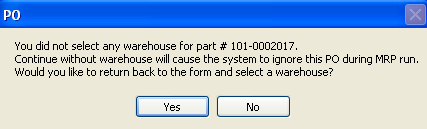

There are situations when the users will either not enter a schedule or enter a partial schedule at time of creating PO. If the scheduled qty does not match the order qty or the "Allow Partial Schedule" box is unchecked, upon depressing the Save button the following message will be displayed. This gives the user the option to stop the save process and return to the item and schedule or continue on and save without scheduling. Some users may not know an exact date for scheduling at the time of the PO creation and just create the PO to get the part on order. Then upon the supplier response add the scheduled dates to the PO at a later time. This is why we do not enforce the scheduling at the time of the PO creation.

If the "Allow Partial Schedule" box is checked upon saving the PO without a schedule or a partial schedule this message will not be displayed.

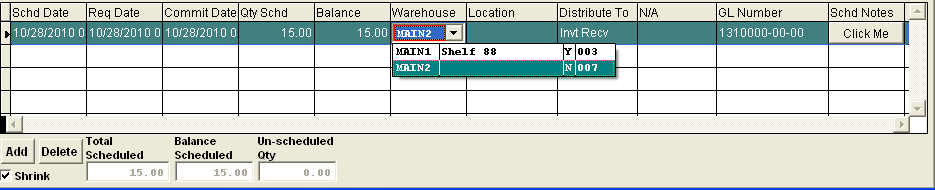

Entering Schedule Detail Information

The item will schedule automatically by adding the lead time to todays date and schedule the entire order amount. (Note: MRP will NOT acknowledge qty's that are NOT scheduled).

At this time the user has the option to change the Schd date/Req date/commit date information and also the Qty Schd.

Note: If user is NOT following MRP suggestions when creating POs they need to keep in mind inspection time when entering a schedule for a PO.

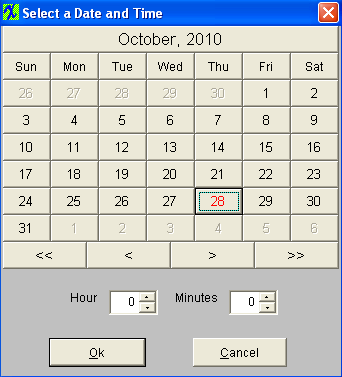

If the user wants to modify the automatic scheduled date, they can either manually adjust the Date information by highlighting the field and typing in the new date, or place the cursor in the Due Date field.Type in a ?. A calendar will appear. Depress the desired delivery date.To advance into the next month, depress the > button. Schedule Field Definitions

Pressing the Save button at the top of the screen saves the order and item(s) entered, and assigns a temporary number to the order. After adding items to the purchase order and saving them, the Purchase Order will display all items added to the order.  User must then Approve the Purchase Order.

The user may use the scroll bars at the right and bottom of the items listed to scroll over additional information. The user may modify the column widths in the current view by placing the cursor on the right border of the column in the column header, and pressing the left mouse button. Moving the border while holding the mouse button then releasing at the new location resizes the columns.

|

| 1.1. Allocate to Special Work Order or Project |

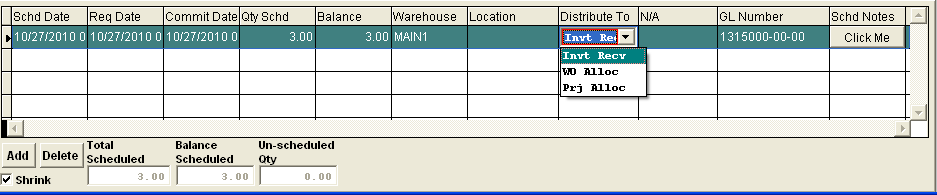

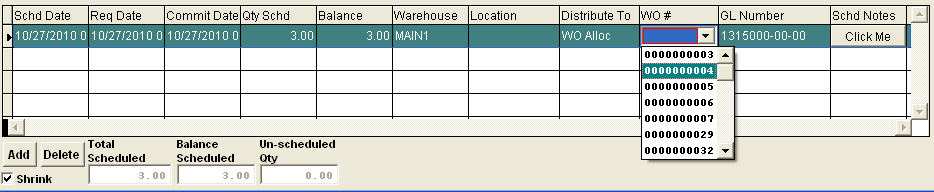

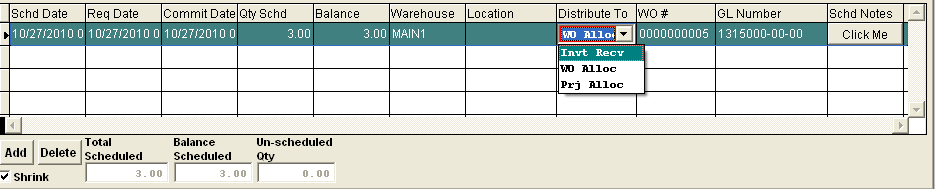

Introduction Inventory Allocation is used to allocate (reserve) quantities of existing items in stock or future Purchase Order deliveries to a Work Order or Project Number. This allocation prevents issuing the quantity reserved to any other use except the Work Order or Project Number specified. Purchase Order Line Item allocations may be removed prior to receipt of the parts by editing the Purchase Order. After receipt of parts allocated by Purchase Order, the allocation may only be removed after the parts are in stock, by using the Inventory Allocation module. ALLOCATION OF PURCHASE ORDER DELIVERIES Allocating a PO Line Item is used to make sure that the item will be reserved for a particular Work Order or Project Number when it is received. PO line item allocation is generally used when allocating to a Work Order or Project Number for which the items are not available in stock. Line Shortages of items NOT on the BOM, which are NOT in stock, are an example of typical PO Line Item Allocations. To allocate Purchase Order Line Item Deliveries to a Work Order or Project Number:

PROCEDURES To Allocate a PO Line Item to a Work Order or Project Number:

To Un-allocate a PO Line Item that has not yet been Dock Received:

To Un-allocate a PO Line Item that has already been Dock Received:

|

button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Enter in the note. Depress the Save button. Exit.

button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Enter in the note. Depress the Save button. Exit.