| 1. Inventory Control Management (ICM) |

| 1.1. Prerequisties for ICM Mgmt |

After activation, "Inventory Control" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

Before entering products and parts in the Item Master, the following product, part and system classifications and item parameters must be setup in ManEx using the System Setup Material Module. Note: that although data entry is possible with only the Prerequisites below, using the Data Entry Defaults explained in the next section is strongly advised to save time and maintain consistency.

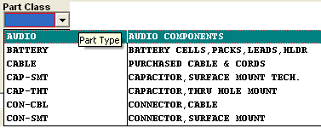

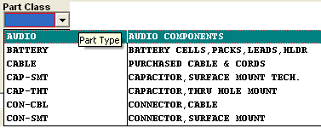

| Product and Part Class |

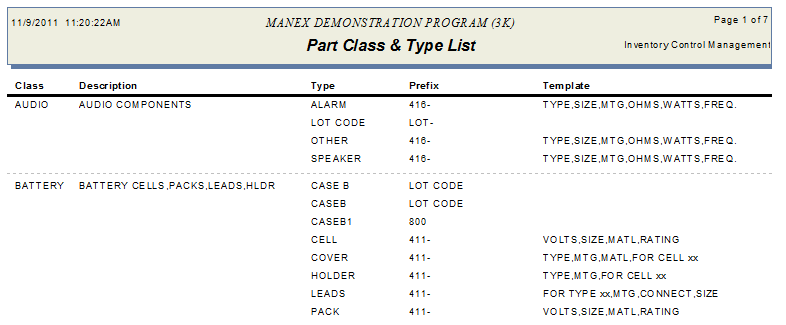

All items must be assigned a Class code (Finished Goods, Subassembly, Resistor, Capacitor, Raw PCB, etc.) in order for ManEx to number, connect, sort and organize the items. Class codes are User-defined but chosen carefully.

|

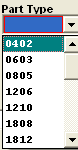

| Product and Part Type |

Each Class is further grouped into Types (Surface Mount, Thru-Hole, Precision, Programmed, etc.) to standardize description fields and allow use of default values. This speeds up data entry and eliminates redundant data and duplicate records.

|

| Units of Measure |

Several standard Units of Measure (U/M) are already setup in ManEx.Additional purchase or stocking U/M’s must be added in System Setup. Also, if the Purchase and Stocking U/M are different (eg. Wire purchased in FT, issued in IN.), a Conversion Formula must be entered in System Setup Unit of Measure & Conversion.

|

| Numbering System |

The User must select Automatic or Manually Numbering in System Setup Number System Module. For Auto-numbering, the Beginning Number must be entered. A customer-selected prefix can be entered in System Setup Number System to be added to each Manual or Auto-Numbered part no.

|

| Warehouse Assignments |

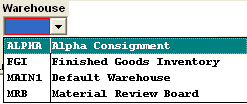

A System Setup (Warehouse Setup) to assign names and General Ledger Numbers (for ManEx Accounting) to the hard-coded MAIN1, WIP, WO-WIP and MRB Warehouses is required. Additional FGI and/or In-Store Warehouses can be added if assignment as stocking locations during Item Master data entry is desired.

|

Optional Data Entry Default fields are not required for Item Master entries, but are highly recommended to ensure consistency and save time during data entry.They are shown below.

Data Entry Defaults

|

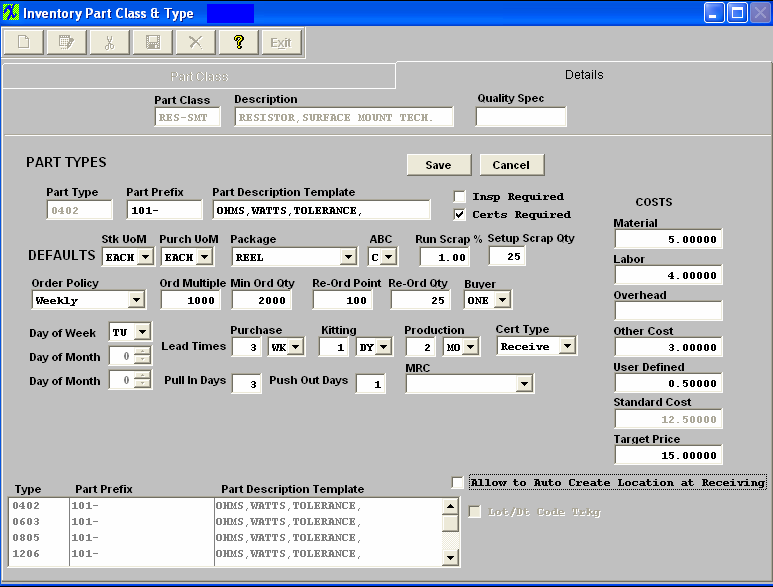

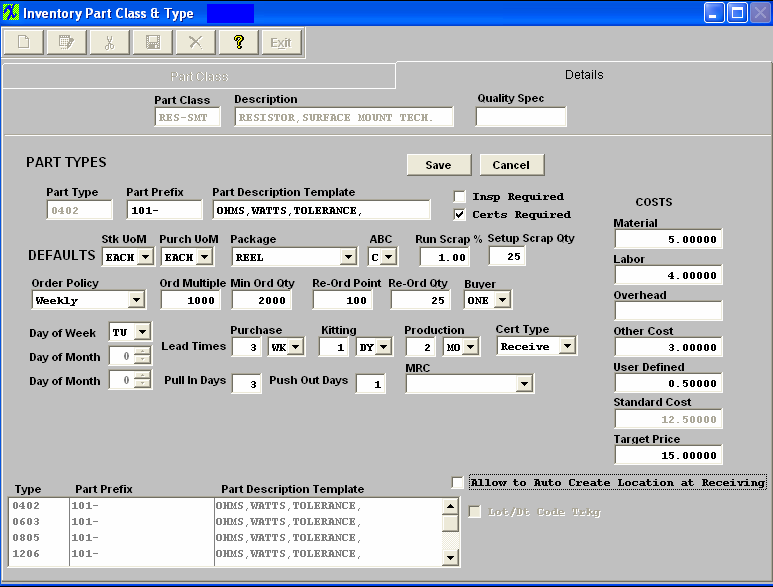

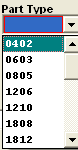

Item Master Data Entry Defaults are selections that remain the same for most of the items for a particular Class and Type. These Defaults are entered in System Setup Inventory Part Class and will be automatically filled in by ManEx once the Item Class and Type have been selected during data entry of a new Item. Defaults can be over-ridden during data entry.

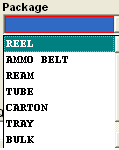

For instance, if the User wished to make the Default entry for Item Package to be REEL for all Items with the Class RES-SMT and the Type 0402, the User should select REEL in the Package field of the System Setup when entering Type “0402" as shown in the example.

|

|

The same procedure would be used to set up Defaults for all of the fields for each Item Master Class and Type as shown. The information entered in each of the Default fields will be automatically entered in the corresponding field during data entry of a new Item after selecting the Class and Type. Defaults should be setup to apply in most cases. If the default in a particular field is not appropriate for a new Item being entered, the User may make another choice on a one-time basis or if the default has changed. Use System Setup Inventory Part Class to change the default. If too many over-rides are necessary for a particular Type, it may be too general. Consider splitting it into two Types, each with its own set of Defaults. Changed defaults only affect future data entry, not items already entered. Each existing item must be reassigned to a new Type before the old Type can be deleted from setup.

|

| 1.2. Introduction for ICM Mgmt | Information entered and maintained in the Inventory Control Management Module is used in nearly ALL of the ManEx Modules. Product, assembly and part information that is necessary to plan, purchase, receive, inspect, stock, issue, kit and cost all items can be found and should be maintained in this location. In particular this information includes:

- Item Master Part and Product Descriptions, Classifications and Revisions

- Purchasing Parameters, Buyer Assignments, Lead Times and Units of Measure

- Inspection, Certification and Specification Data and Notes

- Warehouse Assignments, Inventory and Stocking Locations and Quantities on Hand

- Material Requirements Planning Variables, Re-order Policy and Re-stocking Method

- Internal and Customer Approved Vendor List with Manufacturer Part Numbers

- Our system operates on a "Standard Cost Basis" (for further information see Article #3386 ) and Purchase Price Weighted Averages for Parts and Assemblies

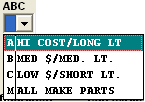

- ABC Classification for Cycle Counts, Buyer Assignment and Inventory Stratification

- Supplier Name and Supplier Part Number

- Manufacturing Specifications with either a .bmp or a .pdf file

|

| 1.3. Fields & Definitions for ICM Mgmt |

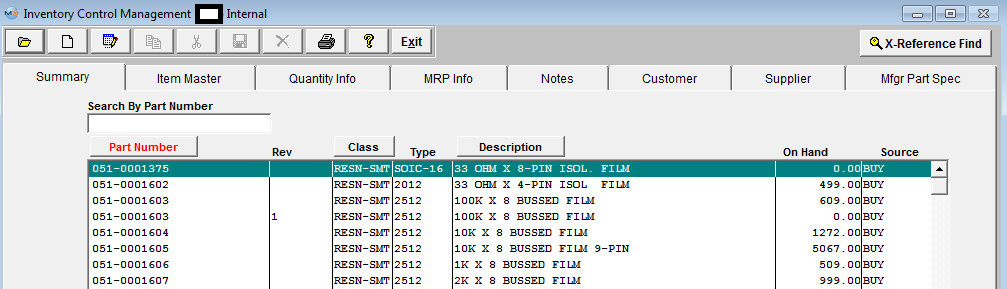

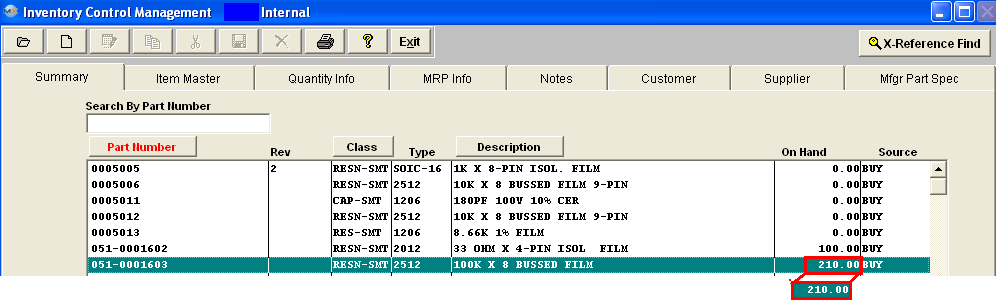

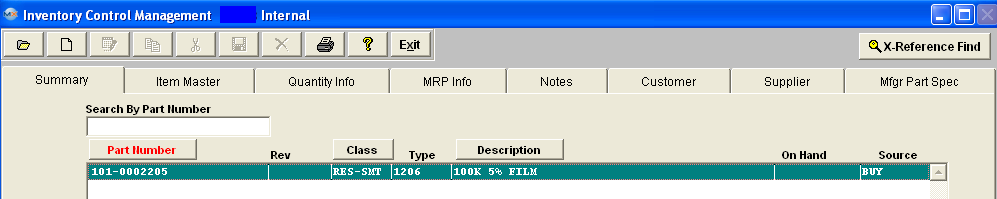

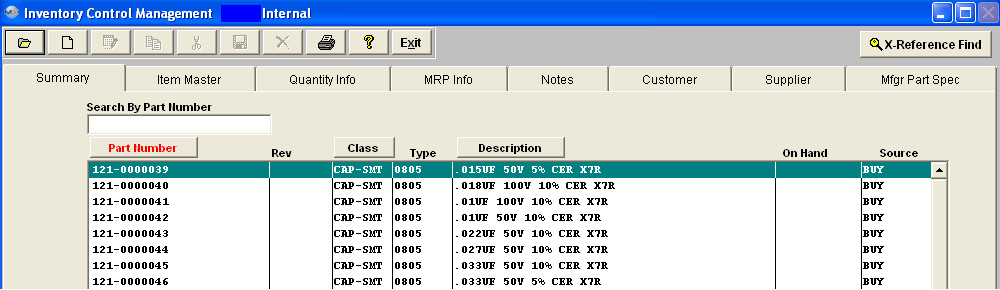

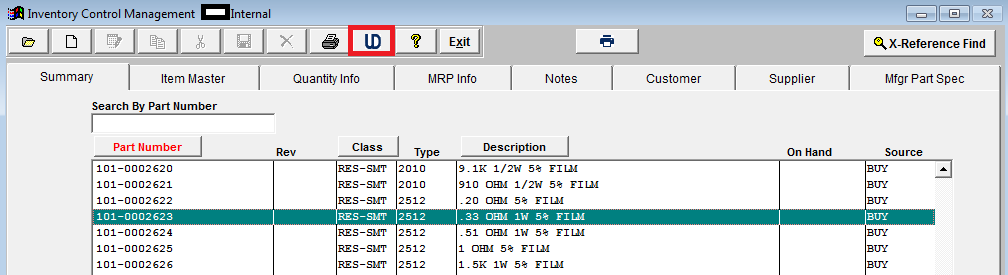

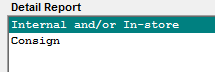

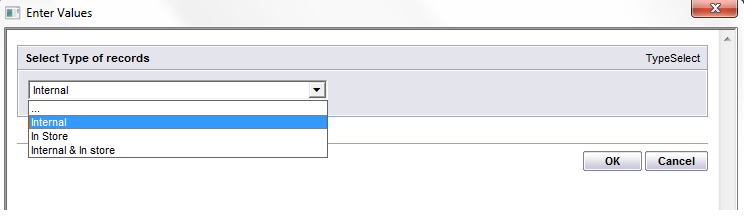

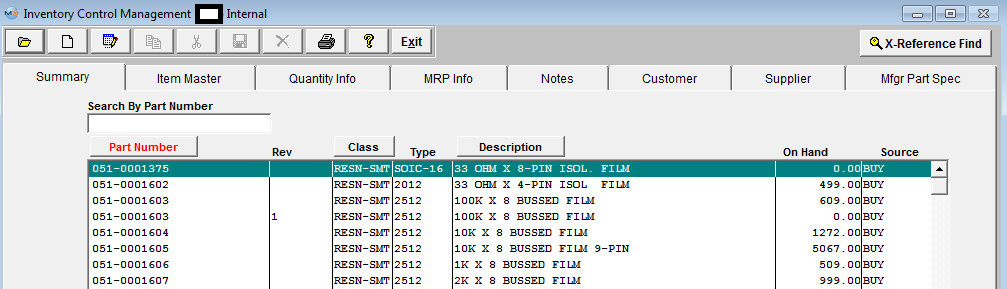

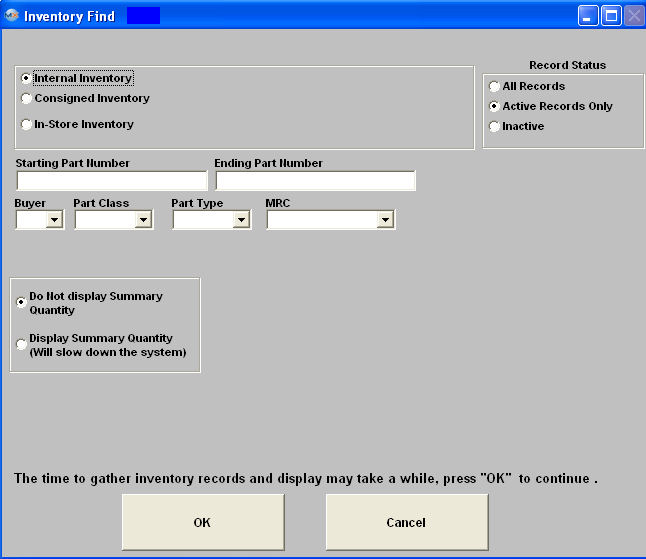

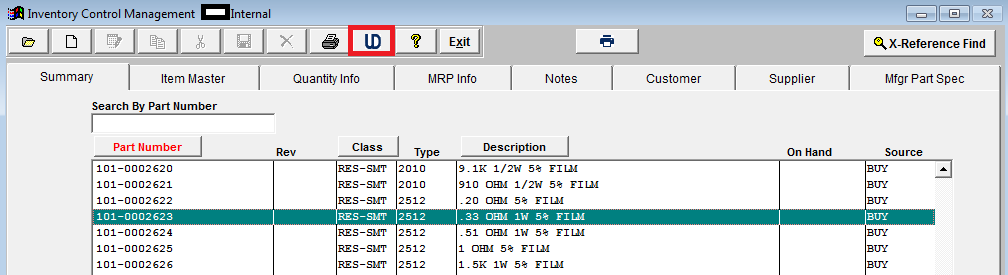

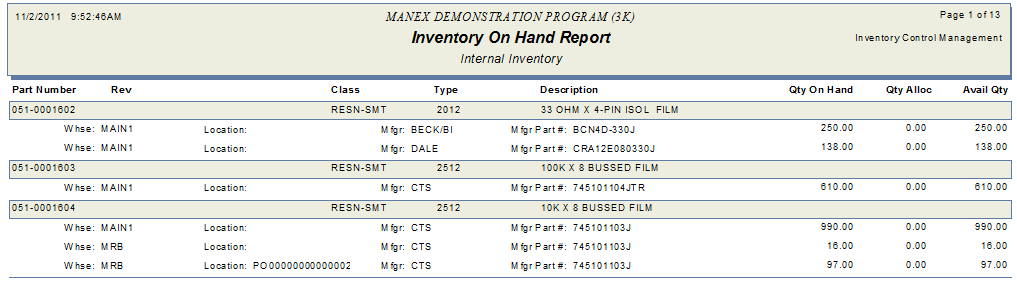

| 1.3.1. Summary Tab | The Summary Tab (screen) displays the results of an Inventory Find operation and is the starting point for further sorts, searches and selections based on Part Number, Part Class or a word or string of characters in the Description field. To view detailed information on a particular item, highlight the item and click on the appropriate Tab. An example Summary screen for all Internal Inventory is shown below.

Note: To display changes made in other windows or by other Users while this window is open, you must repeat the Inventory Find and refresh the screen data.

If a particular item does not appear on the Summary Screen, it may have been excluded by an Inventory Find that was too specific. Click on the Find a record and broaden the search criteria to display more records. Clicking OK with “Internal Inventory” and both “All Records” boxes checked will display ALL Internal items. Display all Consigned or In-Store records for a selected Customer or Supplier the same way.

Sorting, Searching and Selecting in the Inventory Summary Screen

- To sort the contents of the Summary screen by Part Number, Part Class or Description, click the button at the top of the column.

- It will turn red and the list will automatically sort in ascending alphanumeric sequence per the selection.

- To search for an item by Part Class, click Class and enter the first few characters of the Part Class in the Search by Part Class field.

- The list will scroll down to the first incidence of each character in the sequence entered. If a character is not found in the position typed, the list will scroll to the bottom.

- To Search for an item by Description starting with the 1st character on the left, click Description and begin entering the first characters in the field. The list will scroll down to the first incidence of each character in the sequence entered. If a character is not found in the position typed, the list will scroll to the bottom.

- To Search for an item by a word or character string anywhere in the Description, click on Description, click on the Left button next to the Search by Description window (changes to “Random”).

- Enter the search word or characters in the window. Hit return and the first match in the list will be highlighted. Click on the window and hit return to highlight the next match in the summary list. After the last match or if a match is not found, the last item in the summary list will be highlighted.

- To visually search the summary list, use the scroll bar or arrows to the right of the list. The Source (Buy, Make, Consigned or In-Store) and total On Hand quantity is displayed in the last two columns.

For further Details on any item in the summary list, highlight the item by a search or mouse click and select the appropriate Tab to display the desired detail information.

To display changes made in other windows or by other Users while this window is open, you must repeat the Inventory Find and refresh the screen data.

|

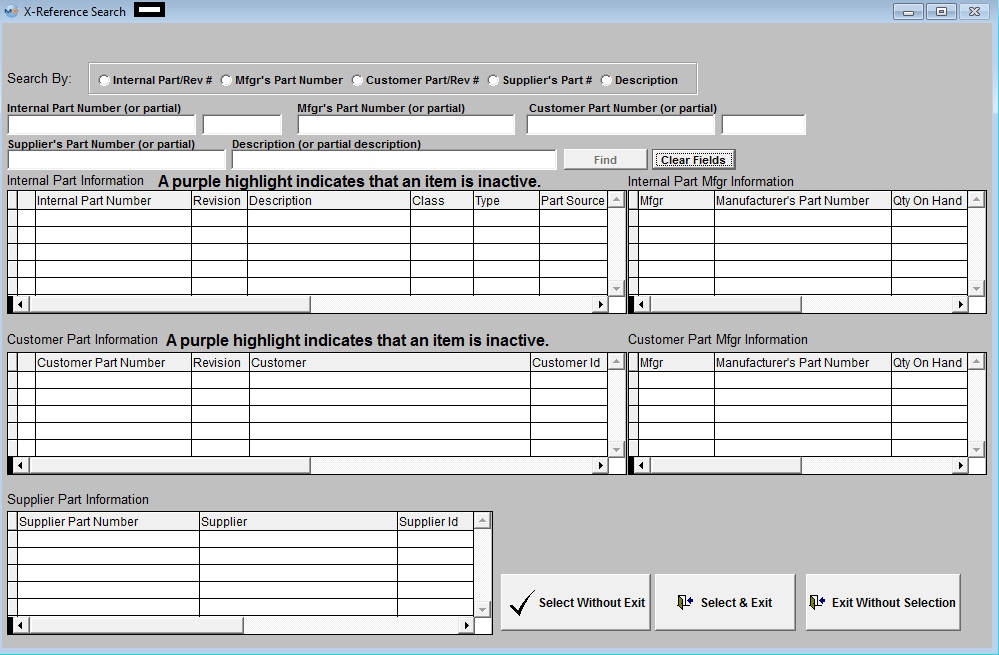

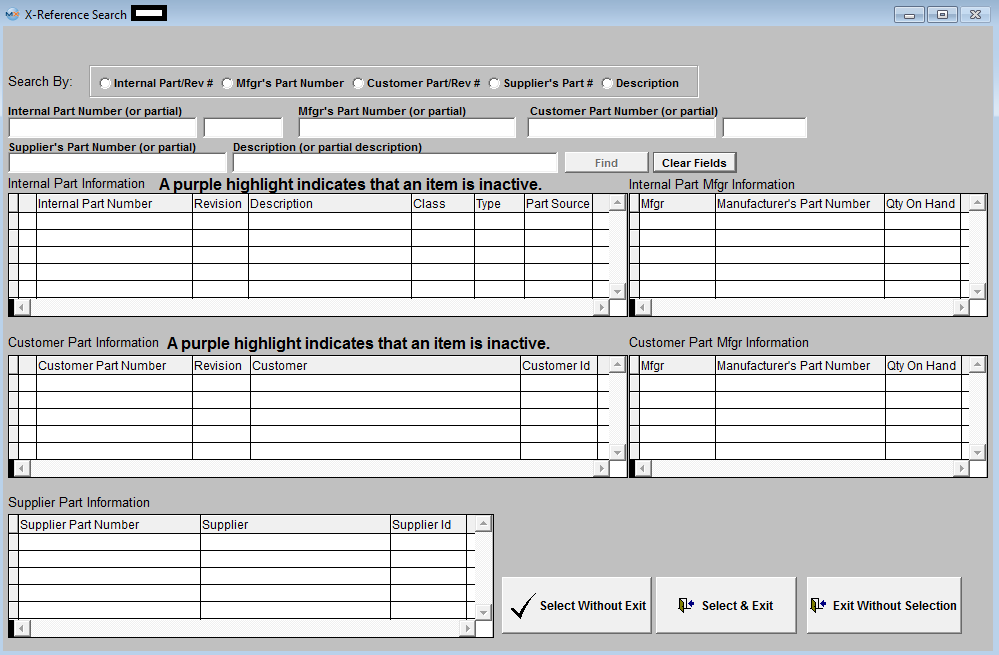

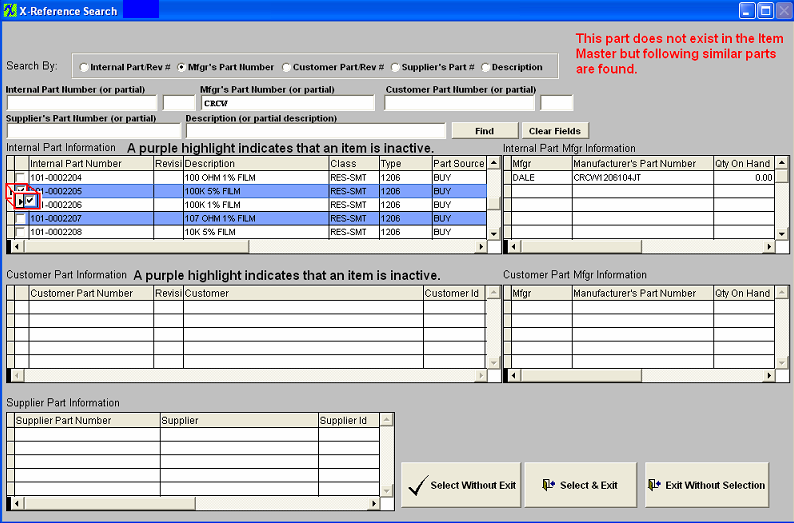

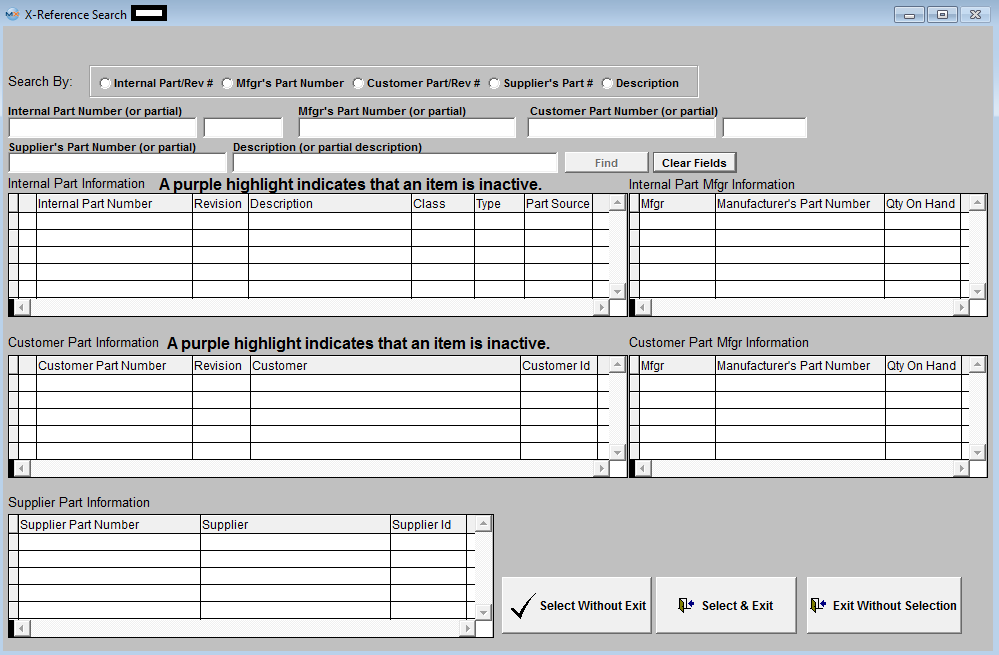

This button will take the user to a screen, where they can make a selection by what ever criteria needed by choosing (internal part number, mfgr part number, customer part number, supplier part number, or description) to search. |

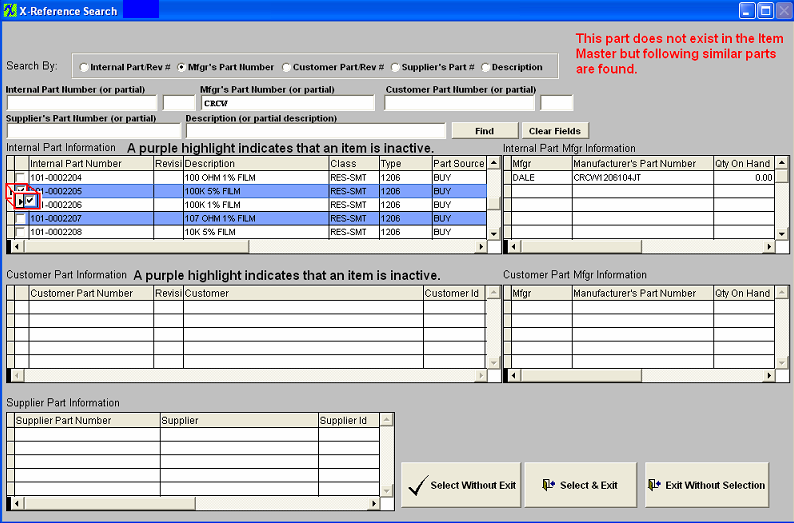

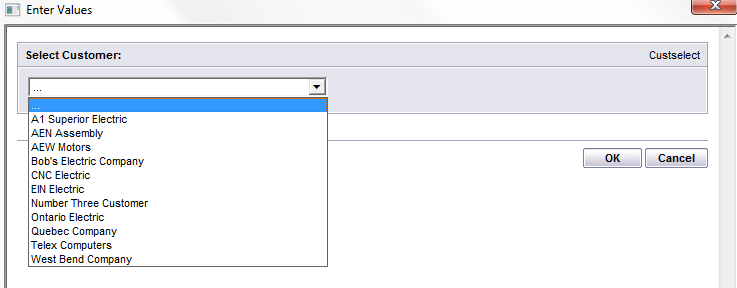

The following screen will appear:

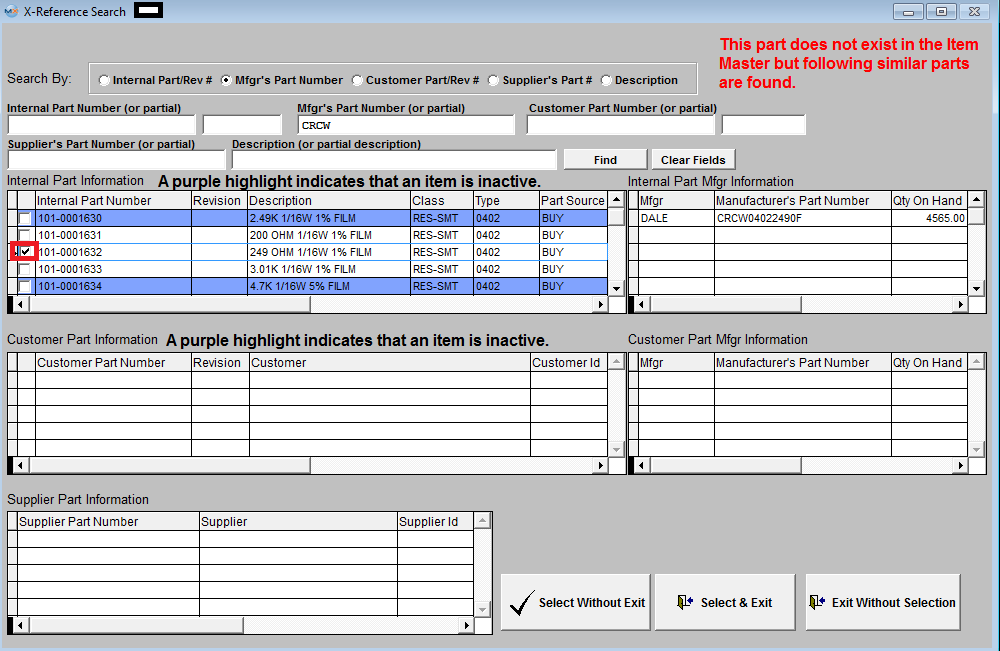

The user can enter partial string and search is not case sensitive. After system finds parts in response to the search (inactive parts will be highlighted in Purple), the user can make a selection by checking on one of the check boxes located at the left. If system was unable to find the exact match, a message will appear up in the right hand corner (in red) to let the user know that the part did not exist in the item master but the following are similar parts found.

The user can choose to "Select Without Exit"; "Select & Exit"; or "Exit Without Selection".

|

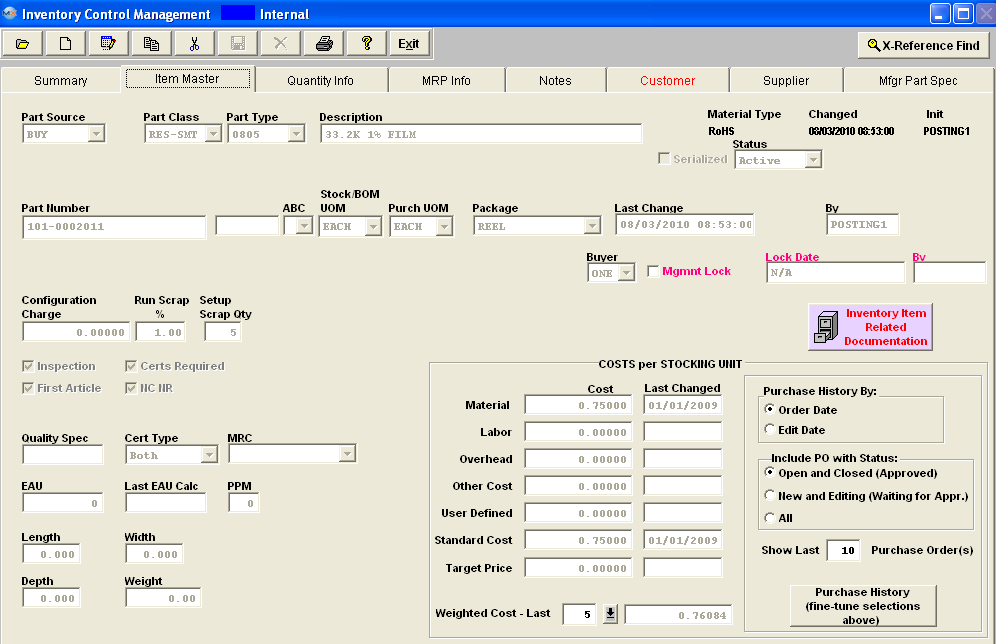

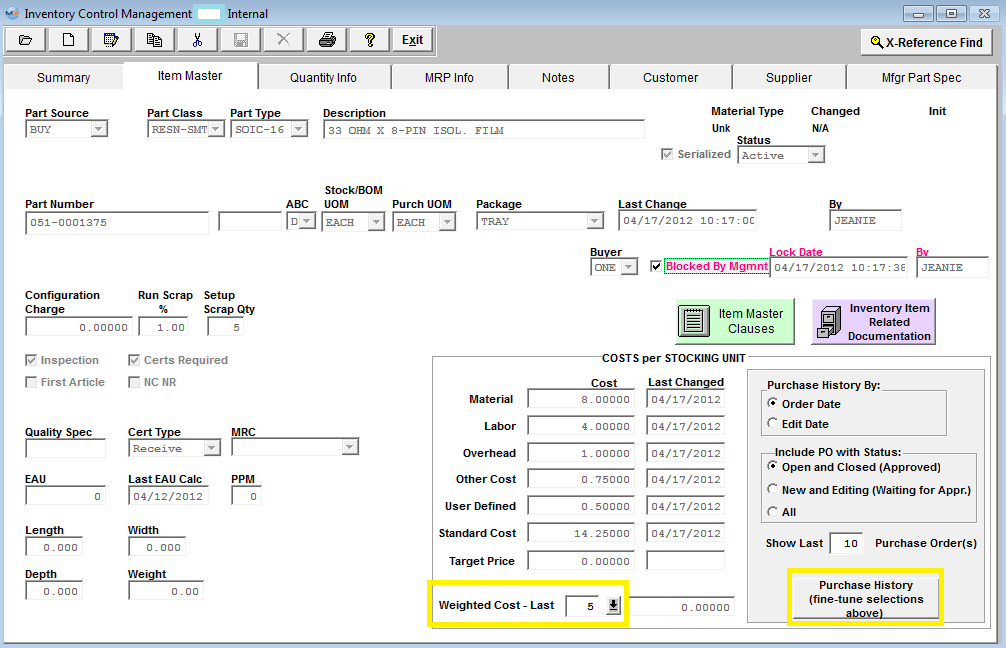

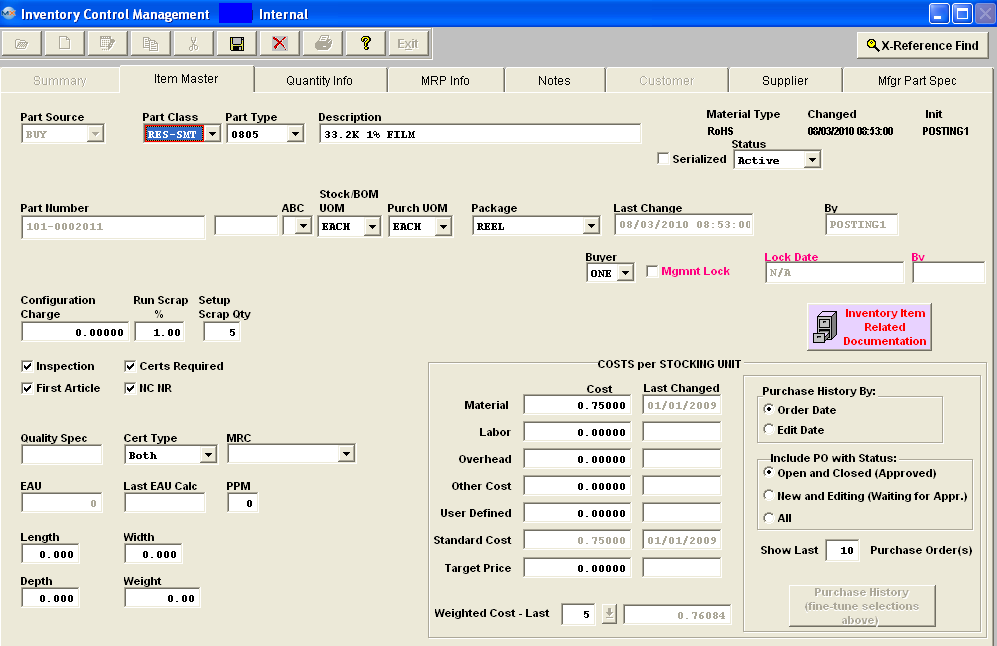

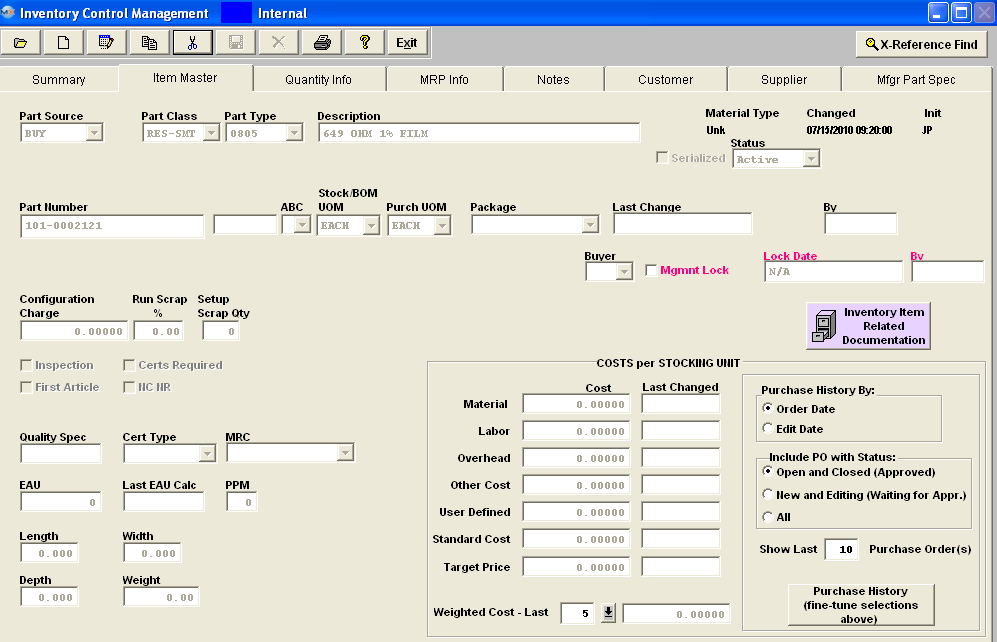

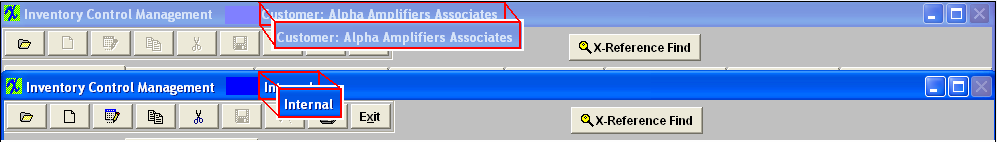

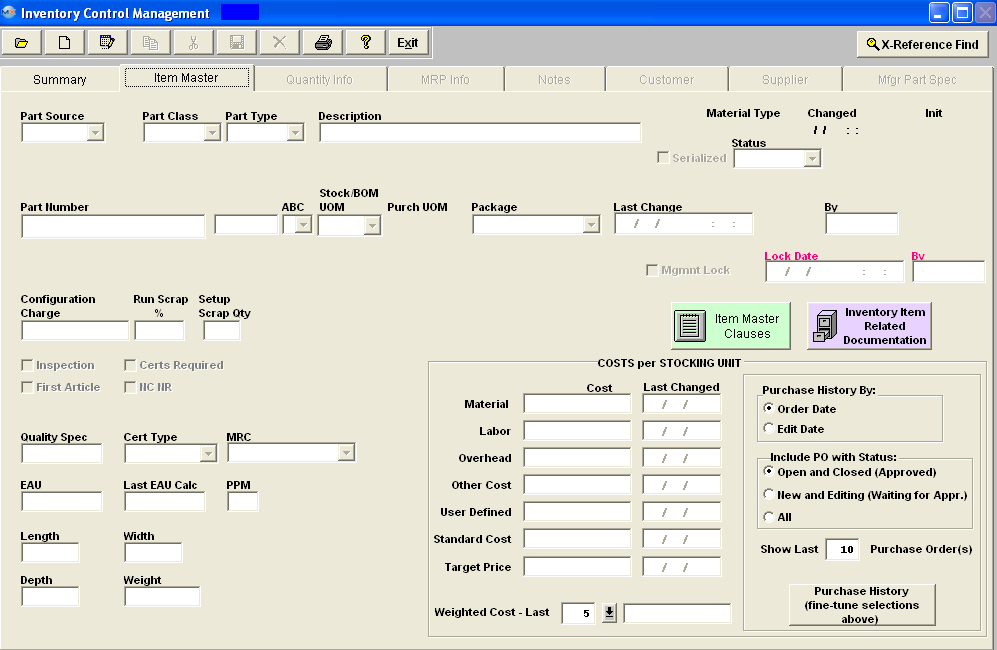

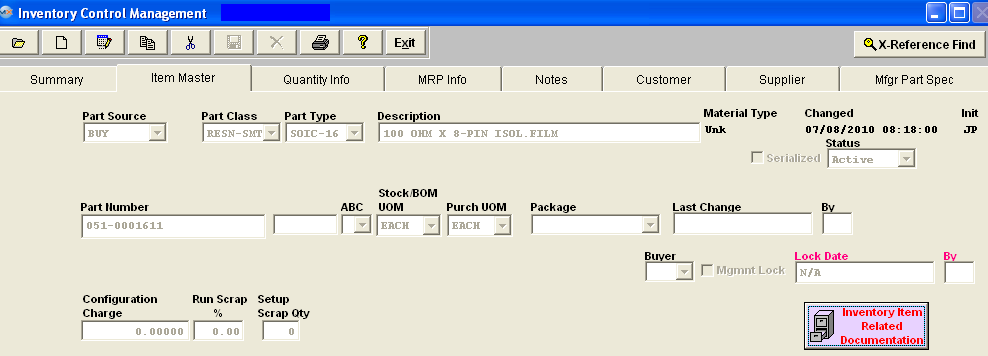

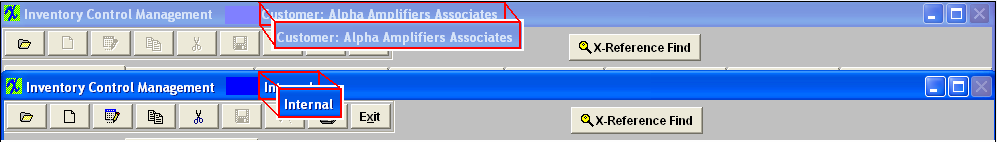

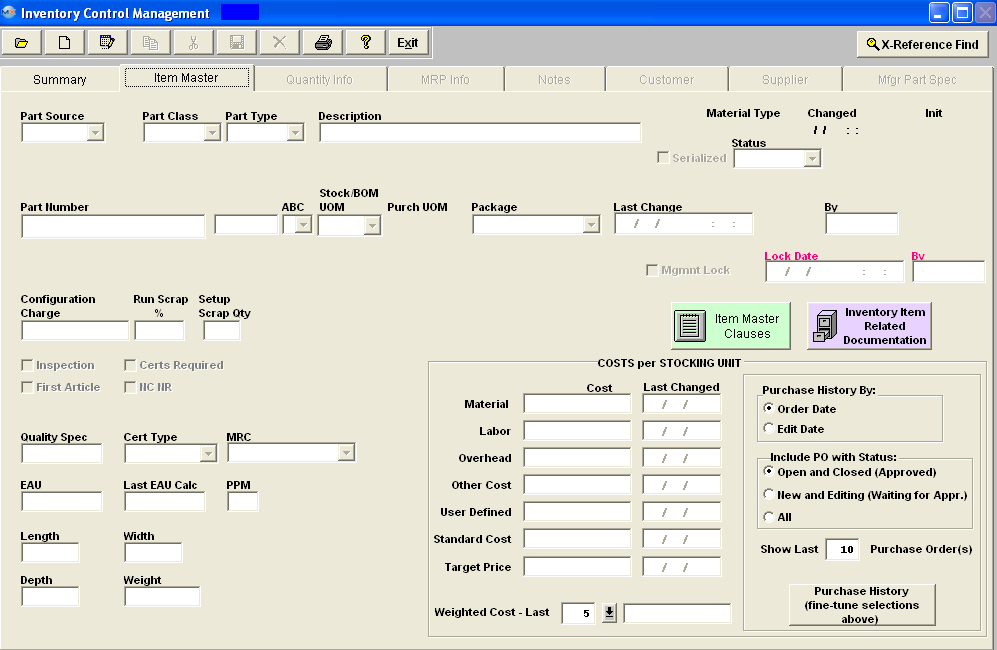

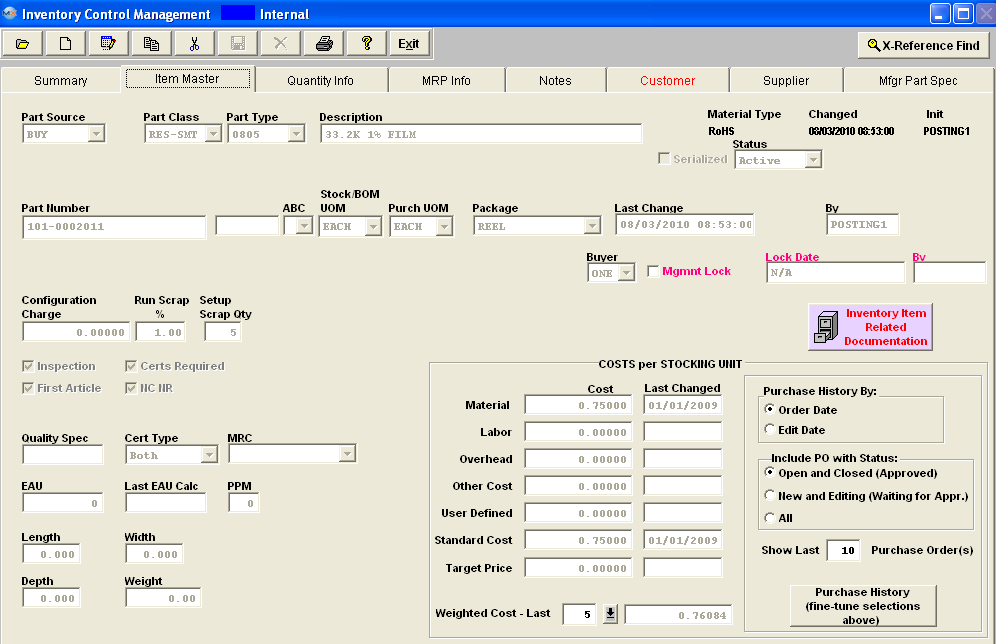

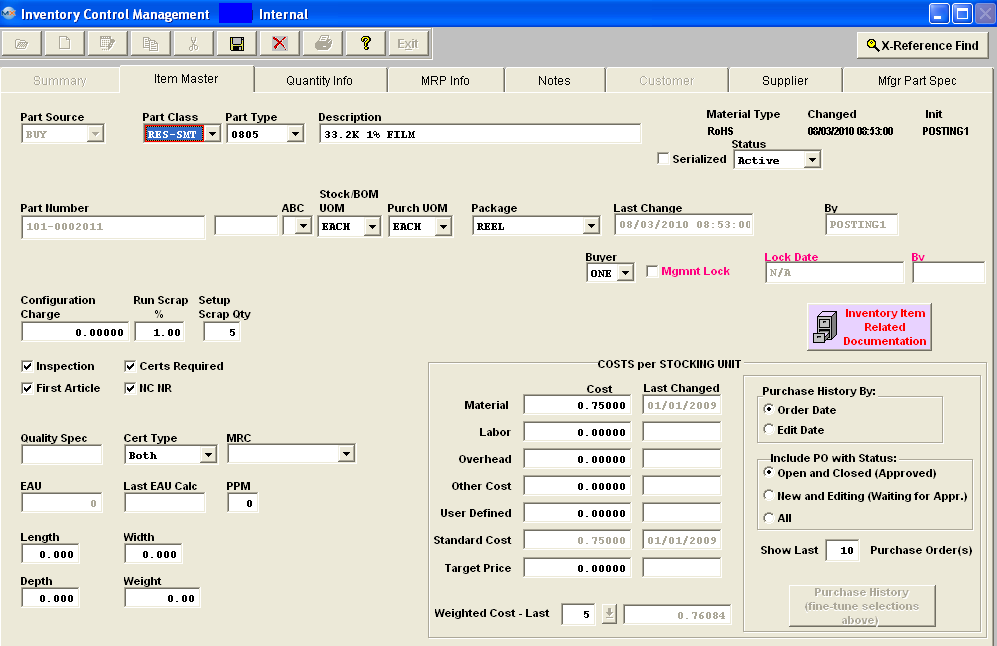

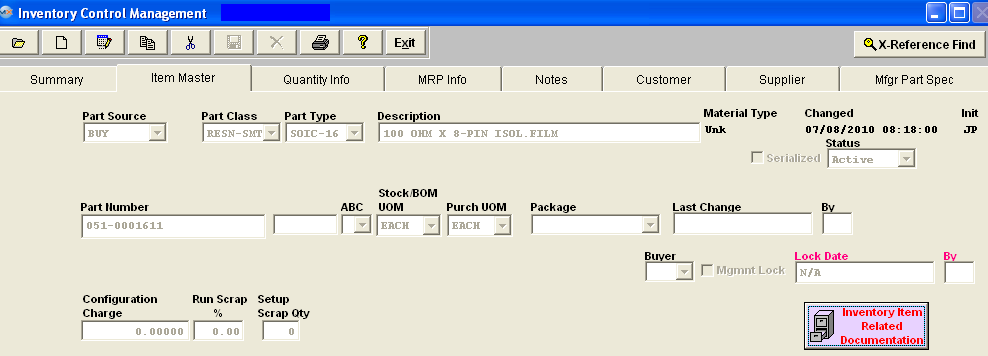

| 1.3.2. Item Master Tab | The following fields may be viewed in the Item Master screen. This screen is the starting point when the Add a New Inventory Record Action button is clicked or an existing record is highlighted within the summary screen. Clicking the Edit action button allows editing of existing Fields that are not grayed out. The ICM module will display "Internal" in the screen Header/Title bar, if internal inventory is open, and display the Customer name in the Screen Header/Title Bar if you have consigned inventory open. This will allow users that have multiple inventory screens open at the same time to seen at first glance which screen contains what type of inventory data.

|

See Article #4766 for further detail on how to Use the X-Reference Find |

Item Master Tab Field Definitions

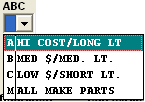

| Part Source |

This field is hard coded in the system. Select BUY for purchased parts and assemblies, MAKE for an item made in-house (assemblies and sub-assemblies) and PHANTOM which is a list of parts that is common to several subassemblies.

A good example of where a Phantom can be used is a video card with different memory options. On all the variations of the memory card, there are a lot of parts which are common, including the circuit board. If we assume the only thing unique to each assembly is the amount or type of memory component and a couple of resistors, then the parts common to all the assemblies can be listed as a PHANTOM assembly. The PHANTOM part number is then listed as a component under each of the top-level assemblies. The BOM of the Phantom is exploded in the kitting module as if they were part of the BOM (hence the word Phantom) and pulled with the top level assembly. It becomes easy to maintain these BOMs since one change in the Phantom will ripple through all the video card variations.

|

| Phantom/Make |

If the Part Source is a MAKE and this box is checked, the system will treat the part as a Phantom when the sub-assembly components are called up during the Kitting process BUT as a Make part for a stand alone assembly when the part is NOT a sub-assembly.

You can assign the status of "Make/Phantom" to a sub assembly. In this condition, it will cause the components to be added to a kit for the top assembly as if it was a Phantom BOM. On the other hand, you can also create work orders and demands for the sub assembly itself. The difference between this Make/Phantom and a straight Phantom is that you cannot build the straight Phantom.

Phantoms - We suggest that the user utilizes this feature, especially if the subgroup of parts are going to be used in more than one top assembly. If the subgroup has a modification to its BOM, the user does not have to go to each top level and change all of them. By simply changing the BOM in the Phantom assembly (or Make/Phantom), the kitting for all top assemblies including this sub assembly will be changed to the new configuration. If you did not use the Phantom, and copied the parts into numerous top assemblies, you will have to make a change to every one of them if the subgroup of parts was modified. NOTE: When creating a phantom part user will NOT be required to enter any physical parameters for it, because it is just a pointer to a group of parts that are used together on the BOM. In kitting we explode the group as an individual item so this is also another reason why user is NOT required to enter any physical parameters when creating a phantom part. |

| Make/Buy |

Make/Buy is setup to allow users to have a part in the system that they wished to BUY but also keep documentation within the system (BOM). If the Part Source is a MAKE and this box is checked, the assembly MUST be purchased from an outside source. If a Part is marked as Make/Buy within Inventory the MRP will only give PO Actions and that product will not be available for selection within the Work Order Management module, (due to MRP calculating incorrect demand and showing incorrect message with safety stock). If the part souce on a product is originally setup as a MAKE the user WILL be allowed to edit the record and change the part souce to Make/Buy. For further details see Article #3289 .

|

| Part Class |

This is a general part, product or item classification that must be selected from the drop-down box. If an appropriate choice is not available when entering a new item, you may add a new part class in Inventory Part Class, (examples of Part Classes are BATTERY, DIODE, FUSE, FILTER, IC-SMT, CAP-SMT, RES-TH, etc.)

|

| Part Type |

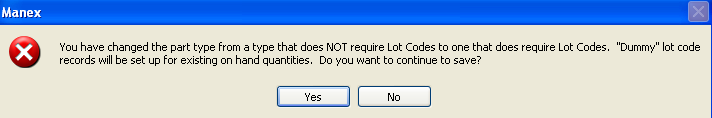

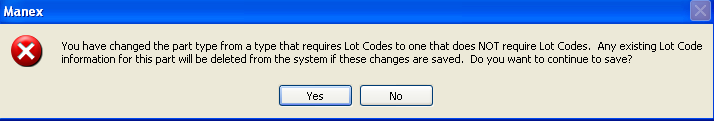

Type is a sub-classification of Part Class. If an appropriate choice is not available when entering a new item, you may add a new part type in Inventory Part Class (examples of Part Types for the Class IC-SMT would be 0603-5%, 0805-10%, 0805-5%, 1206-5%, 1210-5%, Lot-Coded, etc.)

If the Part Type selected is Lot-Coded, the user will be required to enter a lot number, date code, expiration date (optional) and internal lot number information whenever performing a transaction for the part. If the user wishes to maintain inventory to this level, then they MUST enter information each time a part is moved. This will allow complete traceability by date and lot code for products assembled. The user will be able to determine all work orders or sales orders in which a certain date code was used. Users should use caution when changing the lot code tracking status. When lot code tracking status is change the entire history of the lot code is removed from system.

NOTE: A user does have the option of leaving the Part Type blank, however if this option is selected the prefix for the part number will be omitted. There is no reason to enforce part type if a user doesn’t want to have that kind of detailed classification. If the user decides to leave the Part Type blank they will receive a message and at this point they have the option to continue or go back and pick a Part Type

Manex uses the Part Class and Type as an extension to the description of the part. Therefore Class and type will be displayed throughout the system on screen and in reports as an extension of the description.

|

| Description |

There are 45 characters available to put descriptive data about the item being entered that is not already in Part Class and Part Type. For instance, in the previous figure the Part Class and Type already show that it is a RESN-SMT 2512 so this information need not be repeated in the Description. We suggest when entering the description, that you be consistent with your capitalization and punctuation. Some of the screens and reports can be sorted by description so the more consistent you are the easier it will be to use the system in the future.

|

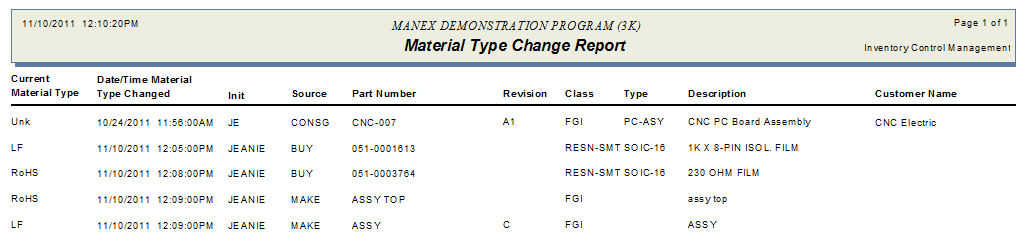

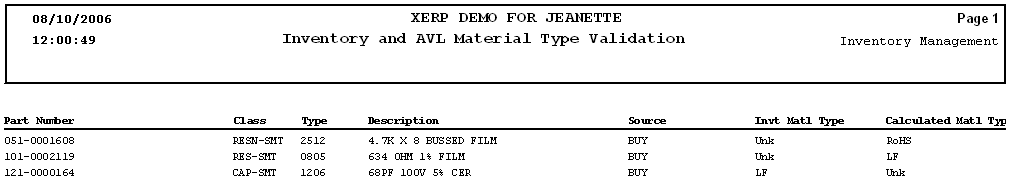

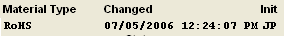

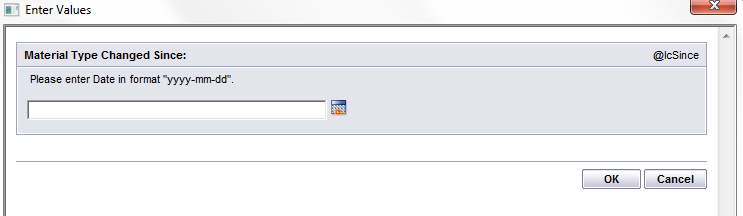

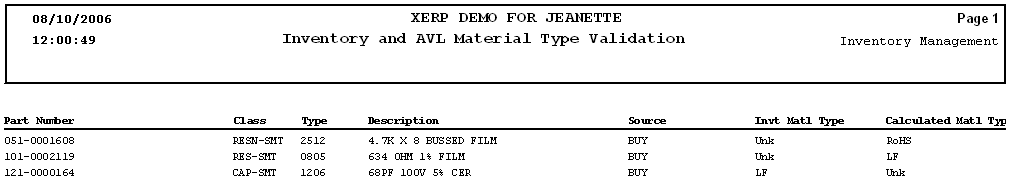

| Material Type |

This field is an Item fields which is repeat at the top of all Tabs to display the selected Item.

If the Inventory Material Type is set to "Auto" (within the Material Type Setup), everytime the user modifies the AVL material type, the program will update the Inventory Material Type automatically.

>> If any of the AVL material type for the item is 'Unk' - the item level type will be 'Unk'

>> If any the material type is the same for all of the AVL's of the same item, the material type for the item will be the same as material type of the AVL's without a suffix. For example: if AVL types is anyof the 'LF-P/N', 'LF-Date', 'LF-Mark', the material type for the item will be 'LF'. If AVL's material type is 'ROHS-P/N', 'ROHS-Date', 'ROHS-Mark', the item's material type will be 'ROHS'

>> If any of the material type of the AVL's for the same item are different and none of them is 'Unk' then the type of the item will be 'LF'

Any changes to the AVL material type that drives the item material type to a lower level will display a warning.

If the control is set to "Manual", then the user will be able to modify the Inventory Material Type from the Material Type pulldown. Keep in mind that the program will NOT validate if the material type in Inventory and AVL levels are in sync.

The AVL Material Type is carried forward for the consign part when the consign part is first added to the system or when new AVL was added to the internal part and the user elects to add this AVL to the existing consign parts. If the user later changes the Material Type on the internal part, the change is NOT carried over to the consigned part.

|

| Changed |

This field will display the date of the last change to the material type. |

| Initials |

This field will display the User ID of the user that made the last change to the material type. |

| Serialize |

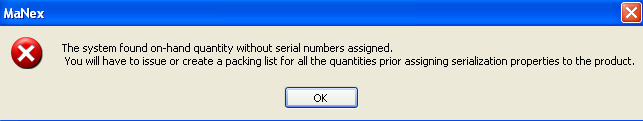

This box will be available only if the option to use Serial Number Tracking in Shop Floor Tracking Defaults is set up.

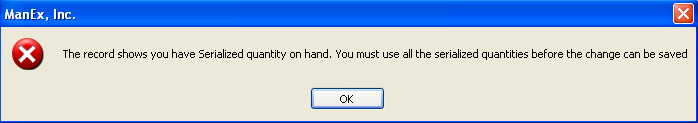

The system allows this box to be check for a MAKE or BUY part. If this box is checked for a BUY part, all components are being tracked by a serial number that was assigned to the part at time of receipt. If this box is checked for a MAKE part, the FG assemblies will be tracked by the serial number through complete process. Note: Once a serial number for a MAKE part is created, we don't allow user to turn off the serialized checkbox anymore, even if there is no qty on hand and all accounting records are cleared. This is so no history of Shop Floor tracking, shipping, RMA’s, etc. . . . for the Make Parts are lost.

If a user changes a non-serialized part to a Serialize part the system will check. * If the part has allocated qty, (user has to un-allocate parts before the system will allow user to check the "Serialize" box). *If the part has any OPEN kit (kit in process), (user has to de-kit or close kit before system will allow user to check the "Serialize" box) *If the parts is a BUY part and has un-reconciled PO (user has to reconcile all receipts before system will allow user to check the "Serialize" box).

After all these criterias are passed, if the part has quantity on hand, the user has to enter the serial numbers to match the quantity on hand.

Note: Users have to have special access in order to modify this checkbox, this access is assigned through Security/User Rights.

|

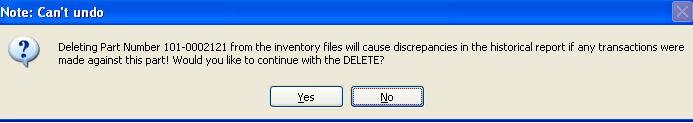

| Status |

All items must be Active in order to buy, receive, issue, invoice or ship. Use Inactive Status to remove items from use that have already had transactions against the Part Number. Use Delete button to delete Items with no transactions. Changing status from Active to Inactive (for a Make Inventory part) will NOT change BOM status. User will have to change BOM status seperately. Changing from Inactive to Active status can be used to release items from Engineering. Note: If WIP (Work-in-Process) exists for a part the system will not allow the part status to be changed. This will prevent any possiblity's of qty on hand being returned to an inactive part if the users would happen to dekit. |

| Part Number |

Item/Part number is a unique identifier for every Item Master record entered in the database. Part numbers can be setup to be manual numbered, or auto assigned to all items except MAKE assemblies, or all items including MAKE assemblies (within the Number System setup module). The standard part number is a 3-digit dash seven digit format where the three-digit prefix is used to define the part class, part type setup in the Inventory Part Class setup module to work with auto or manual numbered parts and assemblies. A manually assigned part number can be 25 characters. Alphanumeric part numbers are permitted. The revision field is 4 characters, also alphanumeric. ManEx uses separate assembly and revision fields making it easier to group all revisions of the same assembly and verify that the correct version is selected for production

|

| ABC |

|

| Stock/BOM UOM |

This is the Unit Of Measure (Foot, Inch, Each, Gallon, Quart, etc.) that is used to specify how much of the Item displayed or being entered is issued from Stock or is used in a Bill of Material for an assembly. ManEx tracks stocking units of measure within inventory, kitting, MRP, etc.

|

| Purchase UOM |

This is the Unit Of Measure (Foot, Inch, Each, Gallon, Quart, etc.) that is used to specify how the Item displayed or being entered is purchased from a supplier.

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter the 24 inches into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

Once the items have been accepted into inventory it is then converted over to Stock UOM and from that point forward everything within the system is using the Stock UOM.

ManEx DOES NOT recommend changing either of the UOM's if the part has a qty on hand. See Article #3414 for further detail.

|

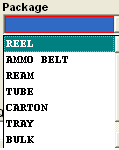

| Package |

This field defines how the components are to be packaged (ie. Reel, Tray, 6-Pak, Ream, Individually, etc.) when it is delivered. This defaults to what is setup in the Inventory Part Class setup. User can edit this field to fit the component package as it is purchased for your organization. This will default to the PO Screen. The buyer has the right to override the package definition in the item master or on the PO screen. (ie. Reel, Tray, 6-Pak, Ream, Individually, etc.)

|

| Last Changed |

This captures the date,and time from the password of the individual making the changes to this screen and/or changes to the fields displayed on this screen from outside modules. Anytime an edit/save occurs this field is updated. Note: This field will NOT be adjusted from outside modules that change the costs, such as the Purchase Order module or the Cost Adjustment module those Last Changed dates will be displayed in the Last Changed fileds displayed next to the costs. |

| By |

This captures the User ID from the password of the individual making the changes to this screen and/or changes to the fields displayed on this screen from outside modules. Anytime an edit/save occurs this field is updated. Note: This field will NOT be adjusted from outside modules that change the costs, such as the Purchase Order module or the Cost Adjustment module

|

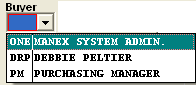

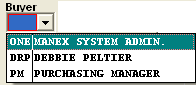

| Buyer |

This field is automatically filled in from the information entered in the Inventory Part Class setup module. This field is used in the MRP lookup as a sort field to allow a buyer to find the parts they are exclusively responsible to purchase. If a buyer leaves or is replaced, there is a global replacement of one buyer to another located in the System Utilities.exe/Change Parameters for the Part/Class .

|

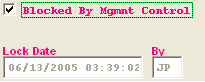

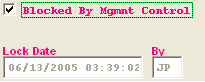

| Mgmnt Lock/Blocked by Mgmnt |

Users MUST have special access in order to modify this checkbox, this access is assigned through Security/User Rights.

If locked caption will change to "Blocked by Mgmnt" and ALL users will have access to the screen, but only those with complete access to inventory can make changes to the item master. Other users will NOT be able to edit the record until the Approved users remove the lock. Fields changed when adding a PO, such as purchase lead time and min/mult orders are back written to the item master. The item master notes are only back written to the item master if the user has edit rights to inventory. The internal and consigned parts have seperate controls.

Note: If locked the caption will be displayed as "Blocked to Mgmnt", if unlocked the caption will be displayed as "Mgmnt Lock".

|

| Lock Date |

This displays the date and time the Approved user implemented the Mgmt lock. |

| By |

This is the users ID that implemented the Mgmt lock.

|

| Configuration Charge |

This is NOT a part of the standard cost total.It is a specific cost used with the MANEX Order Configurator module and represents any additional cost over and above the standard cost total.

|

| Run Scrap % |

This amount is added to the exact quantity used on an assembly to provide an overage to cover losses during running due to predictable machine and human losses.

|

| Setup Scrap Qty |

Setup losses may be added to the BOM requirement and Run Scrap for an item.For instance, an auto-insertion machine may use extra parts for alignment checks.

|

|

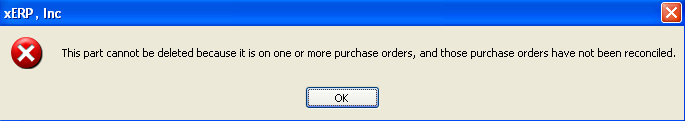

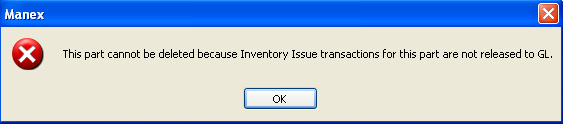

Depressing this button will bring up a screen listing Clause (s) from the Clause Setup module. User may select the desired clause (s) they would like added at the Inventory Part level. When this part is added to a PO any Clause(s) assigned will be defaulted into the PO Item Clauses. This button will be displayed in RED when clauses have been added. By design this button is ONLY editable in the view mode (See Article #3432 for further detail). If user trys to use this button in the add or edit mode the system will display one of the following warnings.

.

|

|

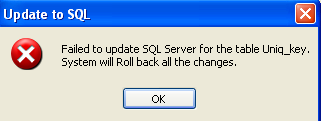

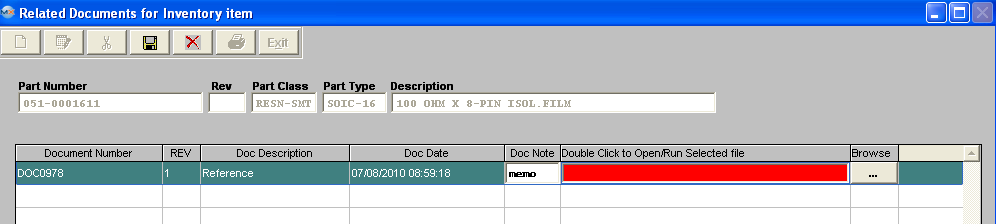

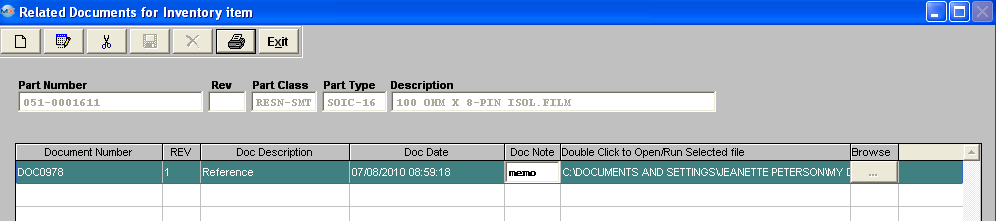

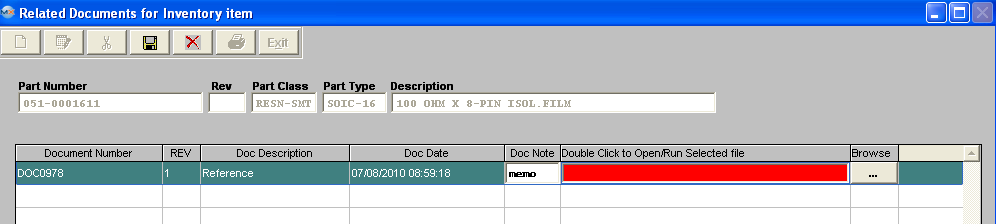

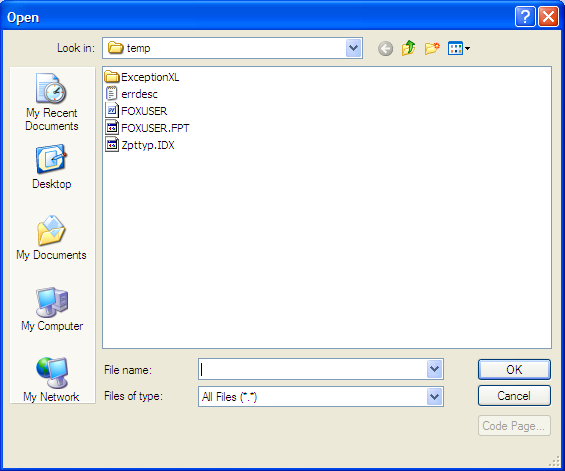

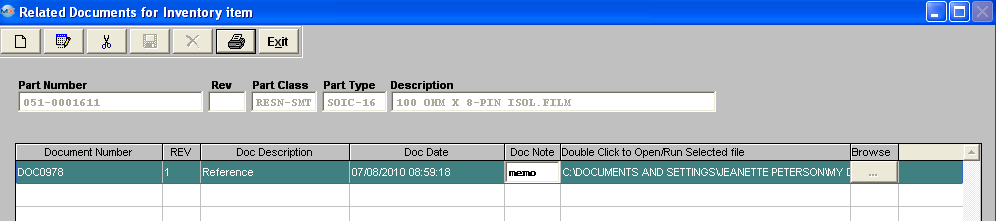

Depressing this button will give the users the ability to scan any related documents directly into the ManEx system and attached the document directly to the item in the ICM Module.For further detail see Article #2396. If this button is displayed in Red there is Related documents attached. |

| Inspection / Quality Spec |

Checking the box will cause the item to require inspection to whatever Quality Spec. shows in the Quality Spec box. The Quality Spec appearing in the box is entered in System Setup Inventory Part Class Setup. Any Part Type in a particular Part Class can have Inspection Required turned on or off.

|

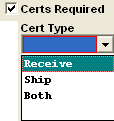

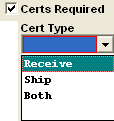

| Certs Required/ Cert Type |

Checking this box will allow selection of Cert Type. Cert Type choices are Receive, Ship or Both. A typical Cert would be UL or CSA Certification on wire. Check the box and then depress the down arrow for the types to display. Select the desired type: Receive - Requires user to check the "Certificate Required" box has been Done at Receiving. Ship - Requires user to check the "Certificate Required" box on Packing List/SHipping. Both - Requires user to check the "Certificate Required" box at both Receiving and Packing List/Shipping.

|

| First Article |

Checking this box will alert the users that the item requires a first article check at receiving inspection |

| NC NR |

Checking this box, means that this part cannot be cancelled or returned. NOTE: This field is for reference only.

|

| Taxable |

Checking this box, will then default the Make Part as taxable when added to new Sales Order and/or Buy parts will default as taxable when added to a purchase order. |

| MRC |

The Material Risk Codes listed in the pull down are entered in the System Setup Material Risk Code Setup. This is to inform the users which items are Low Risk or High Risk (can not be cancelled or returned).

|

| EAU |

The quantity displayed in this box is the estimated Annual quantity. This is calculated from information entered into the ABC Types screen. |

| Last EAU Calculated |

The date shown in this box is the date the EAU was last calculated in the ABC Types screen. |

| PPM (Parts per million) |

This is a data entry field and is not involved in any calculations or used anywhere within the system at this point.It is planned to be used in the future to calculate the component level of PPM and then update the assembly PPM within the routing module.

|

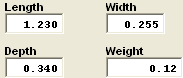

| Length |

Specific length allowed for part.

|

| Width |

Specific width allowed for part.

|

| Depth |

Specific depth allowed for part |

| Weight |

Specific weight allowed for part.

|

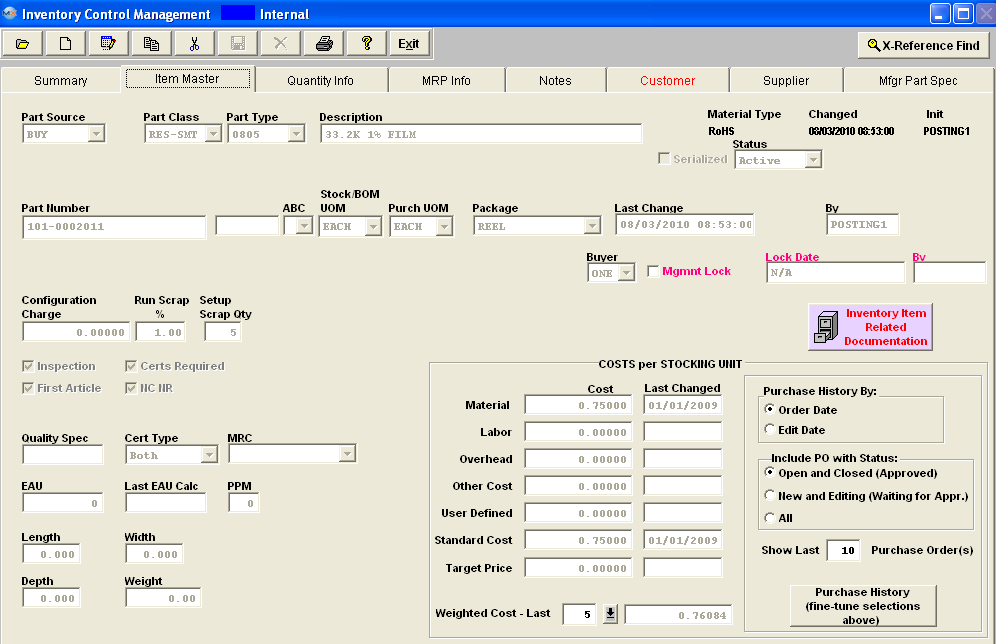

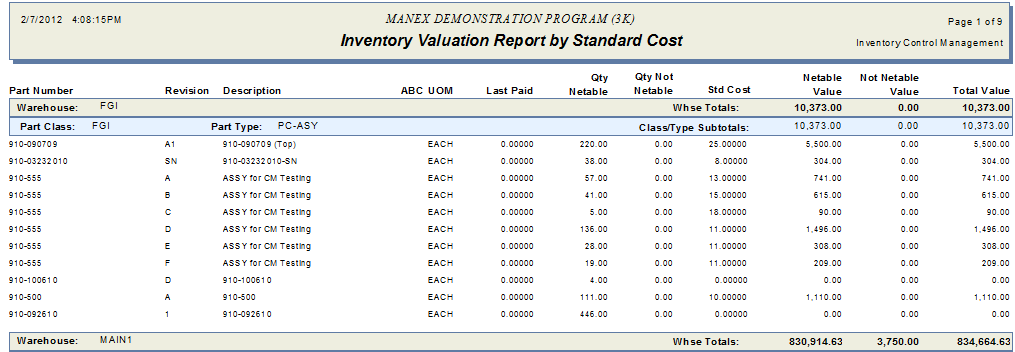

| Material Cost |

For BUY Parts: This is the purchase price of the BUY part. For MAKE Parts: The sum of the STANDARD COSTS of BUY parts in the assembly. Whether or not setup scrap is included is a system setup option. |

| Labor Cost |

For BUY Parts: If the user wishes to include any preparation labor costs associated with a BUY part, like crimping, tinning testing. etc., those costs may be included here. For MAKE Parts: The user may include the labor associated with building the assembly the Value of Labor will then be rolled into the Std Cost for the Make Part |

| Overhead Cost |

For BUY Parts: Any additional costs associated with the labor, such as heating, lighting, etc., that the user may wish to include in the cost of the inventory value. For MAKE Parts: Any additional costs associated with the labor, such as vacations, sick leave, meeting times, etc., that the user may wish to include in the inventory value.

|

| Other Cost |

For BUY or MAKE Parts: This is up to the user to decide if there are any other costs that should be absorbed in the inventory value. |

| User Defined |

For BUY or MAKE Parts: This is a field where a user may define the field name and include any optional costs.

Note: for Labor Cost, Overhead Cost, Other Cost and User Defined . . . BUY Parts: Transactions will hit the GL for this value upon reconciling the Receipt for AP MAKE Parts: The user may include these extra Costs with building the assembly the Value of extra cost fields will then be rolled into the Std Cost for the Make Part, but there will be no break outs of these as far as GL Transactions are concerned (all Transactions will be for the Std Cost Value). |

| Standard Cost |

The STANDARD COST of an item is a calculated value determined by the sum of individual costs. These individual costs may be in any combination of the Material, Labor, Overhead, Other and User Defined costs. Each of the individual costs should have their own account number in the Inventory Setup , and those accounts will accrue the costs when material is added to inventory. User MUST have optional rights within the Security module to "Allow Updating Inventory Std Cost and Standard Cost Rollups".

If ManEx Accounting is neither installed nor active, then there is no value other than reference in including values in these fields.

Important Notice: It is very important to have standard costs (as determined above) in place for any part entering inventory. ManEx allows users to enter a standard material cost at the time of purchase, if one is not already entered. Without accurate cost data, the inventory value could be next to useless, and major variances would show in Purchase Price, Configuration and Manufacturing Variances. If the material cost if the assembly does not equal the computed sum of the standard costs of the components based on the system setup, a configuration variance will be accrued. Please note Standard cost is based on Stock UOM.

|

| Target Price |

This field is currently only a data entry field and will be reflected in the Purchase Order module for "BUY" or "MAKE/BUY" parts. This field is not editable for "MAKE" or "PHANTOM" parts. NOTE: To assign prices to products ("MAKE" parts), ManEx suggests using the Sales Price List Information module. This module allows users to enter prices by product and by customer so different customers can have different prices. This price will default into the sales order, but is still editable within the Sales Order module. |

|

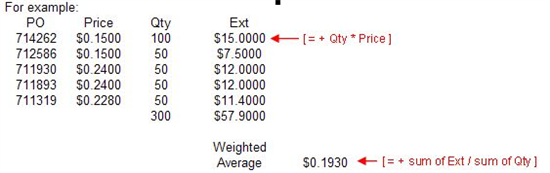

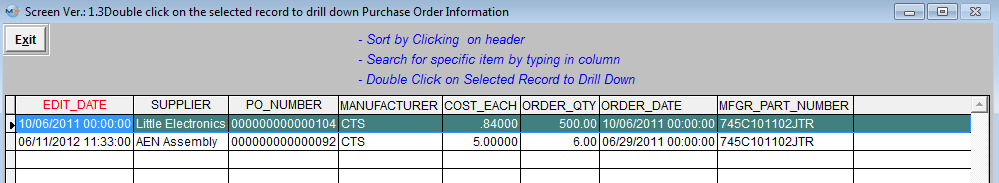

If the Part Source is a BUY, the weighted cost is calculated by dividing the extended total cost(s) by the total qty(s) from the total number of non-cancelled PO line items setup in the General Inventory Setup module or the total number of non-cancelled PO line items entered in theWeighted Cost - Last ( ) field). The Purchase Orders used are with a status of Open or Closed only, and goes by Order Date or Edit Date. You can choose what option it uses on the Inventory screen. You can also select the default use (Order Date or Edit Date) under General Inventory Setup .

Order Date: Order date on Purchase Order

Edit Date: Also known as latest version date (example if the original PO date is 1/3/06, but it was revised/edited on 12/5/06 it will use the 12/5/06 date), no matter what was edited on the PO. (if a user accidently selected the wrong PO to edit and had depressed the edit button, they could depress the abandon changes button to avoid the PO version date from being updated).

NOTE: The User has the option of changing the number of (Weighted Cost - Last ( )) purchase orders within the Inventory screen. Changing this number within the Inventory screen will change the Weighted Cost and also change the number of Purchase Orders displayed in the view screen. User cannot filter out non-received parts. Depress the (down arrow) to display the view screen. This screen allows user to Sort, Search and Drill Down to Selected Records.

|

| Last Changed |

This captures the date of the last change to the cost within this module and/or the outside modules such as the Purchase Order module and/or the Cost Adjustment module. |

| Purchase History By: |

This field allows the users to select which date "Order Date" or "Edit Date" on the PO to use when displaying the PO's in the Purchase History. The default is setup within the General Inventory Setup module.

NOTE: User has the option of changing the selection within this screen for a one time view and will reset back to the default once user exits the ICM module.

|

| Include PO with Status: |

This field allows the user to select the status of the Purchase Orders they would like to have displayed in the Purchase History. "Open and Closed (Approved)" or "New and Editing (Waiting for Appr.)" or "All". The default is setup within the General Inventory Setup module. PO;s with a status of Cancelled will only display when "All" is selected.

NOTE: User has the option of changing the selection within this screen for a one time view and will reset back to the default once user exits the ICM module.

|

| Show Last __ Purchase Order(s) |

This field allows the users to setup the number of Purchase Orders they would like displayed in the Purchase History. The default is setup within the General Inventory Setup module.

NOTE: User has the option of changing the selection within this screen for a one time view and will reset back to the default once user exits the ICM module.

|

|

Once all the selections have been made, depress the "Purchase History" button and the following view screen will be displayed. This screen allows user to Sort, Search and Drill Down to Selected Records.

|

|

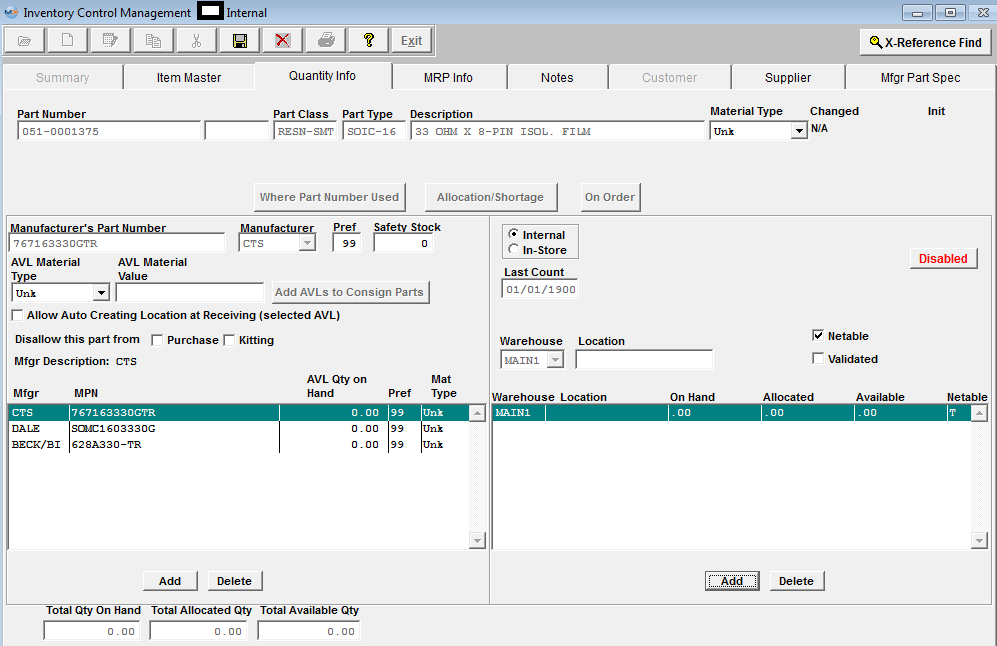

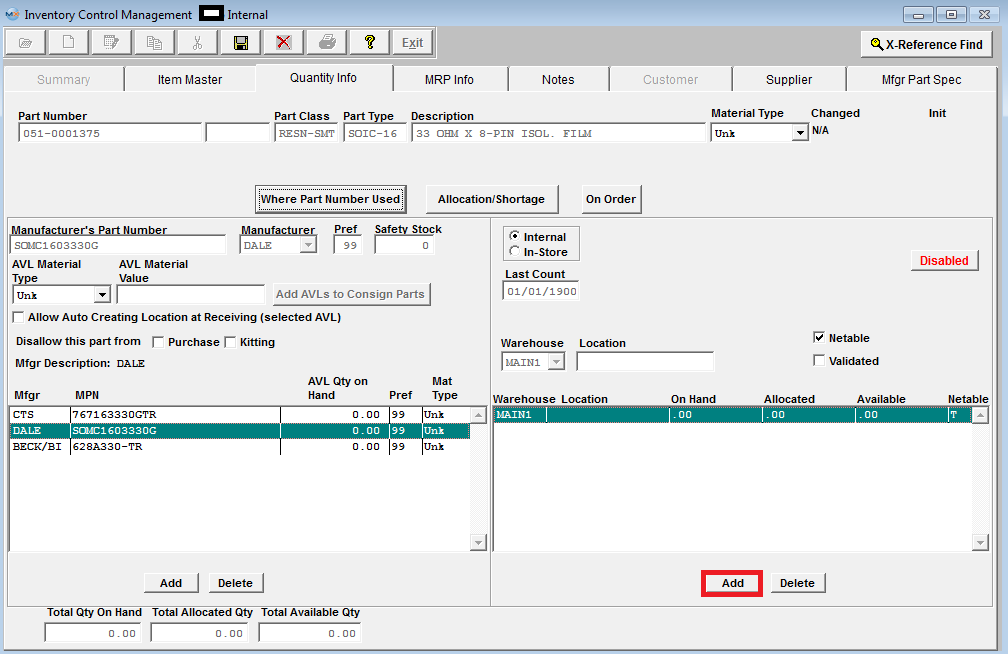

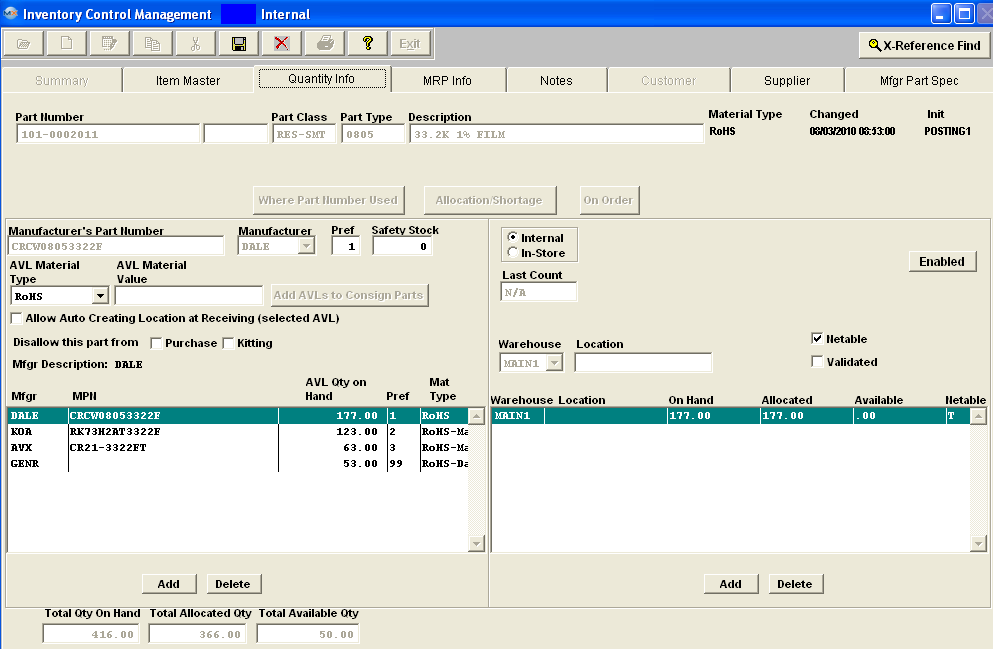

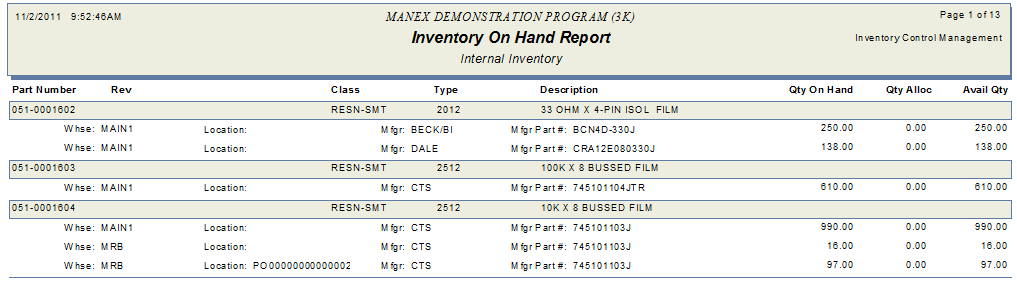

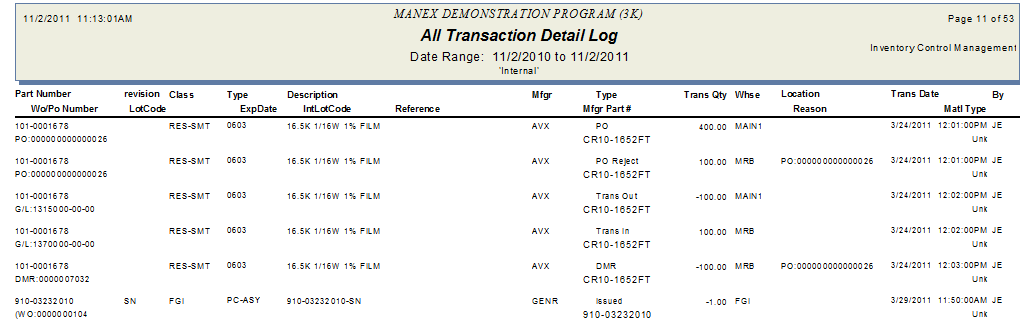

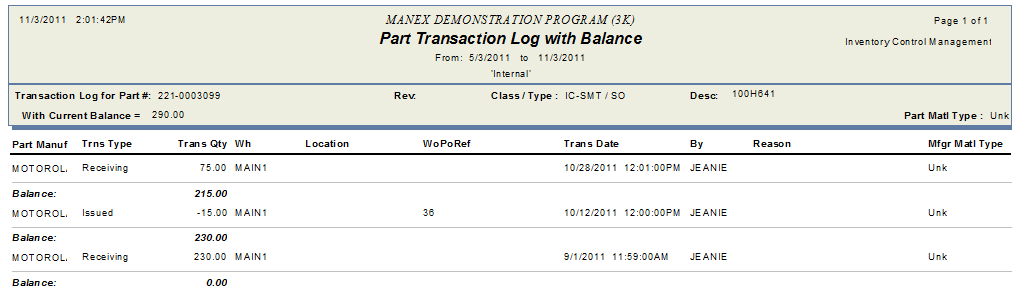

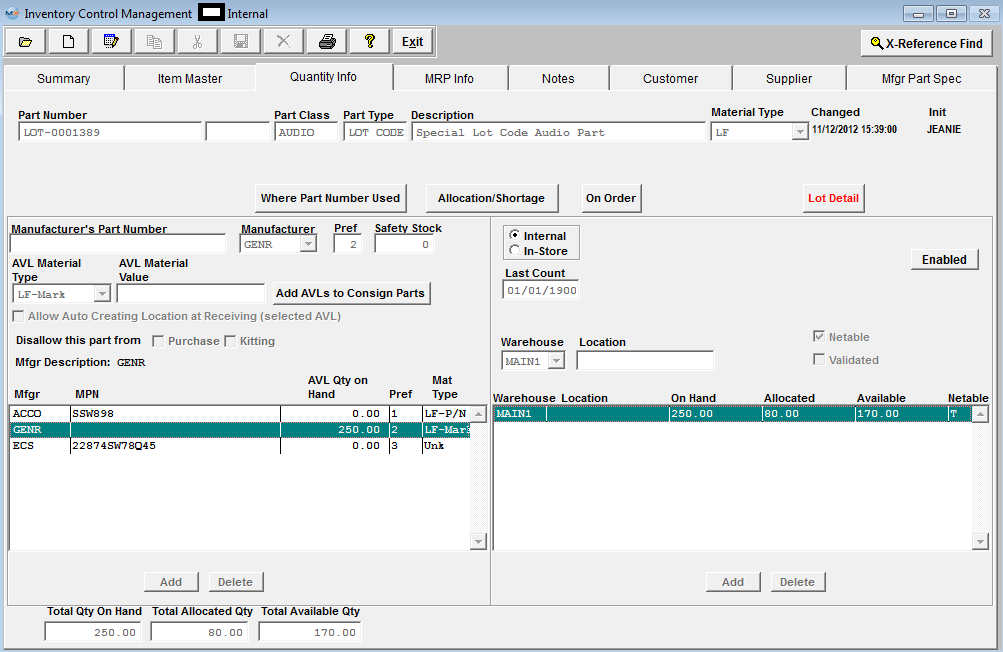

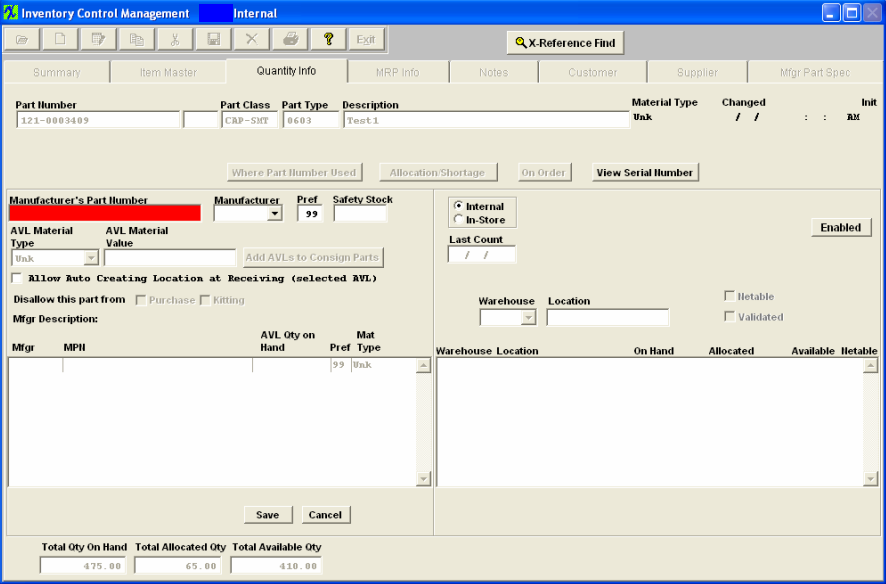

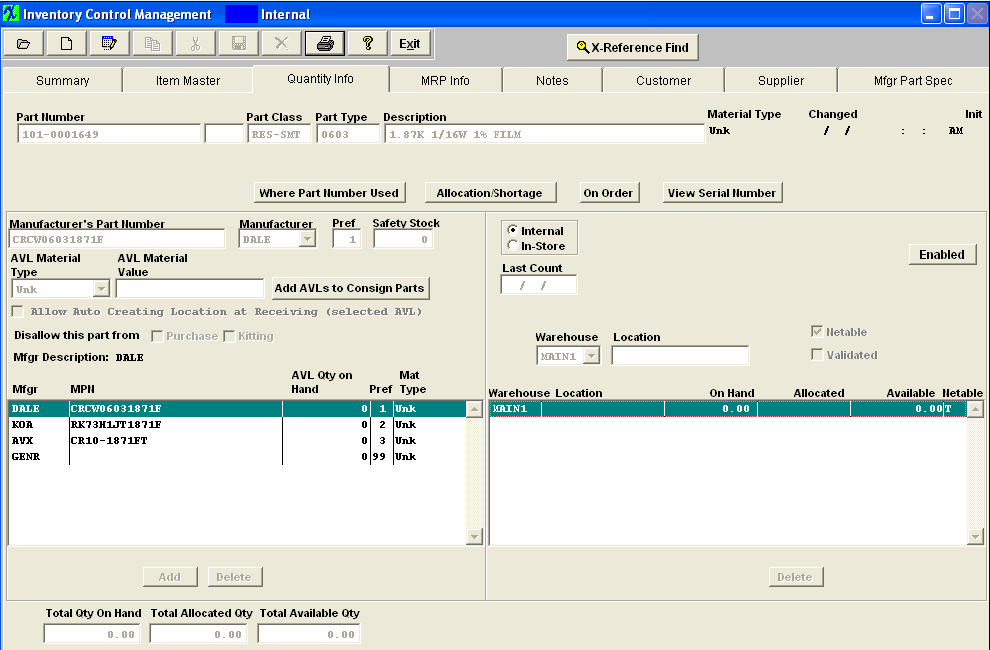

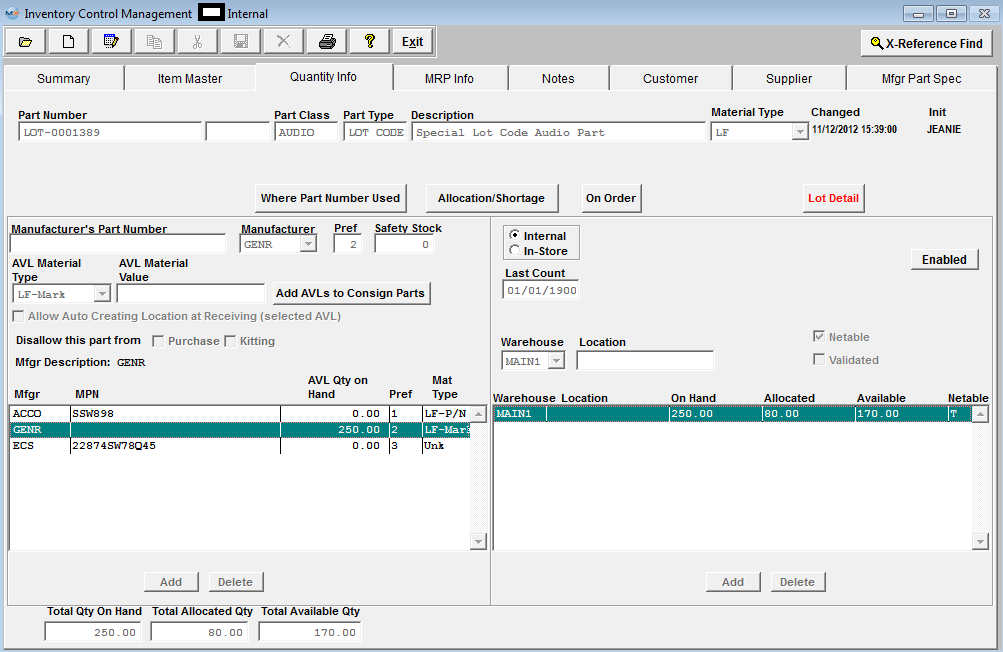

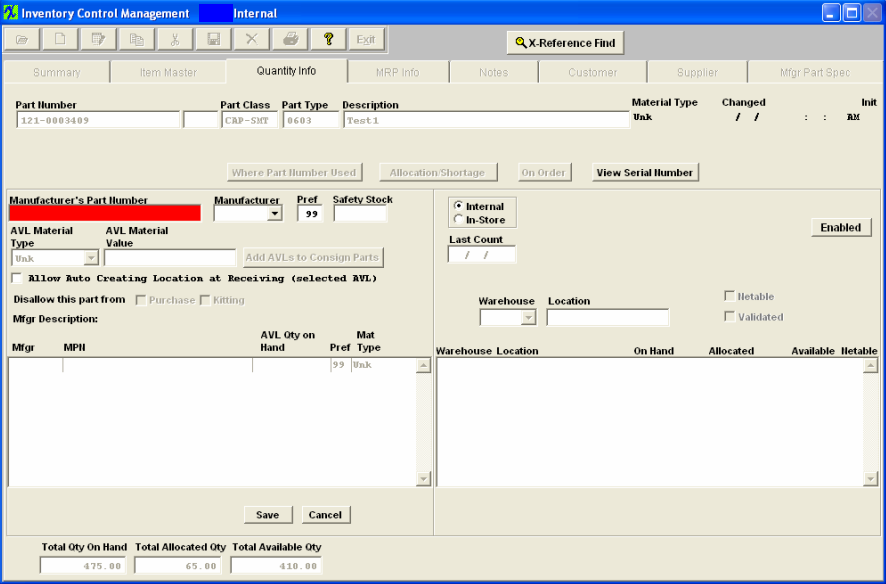

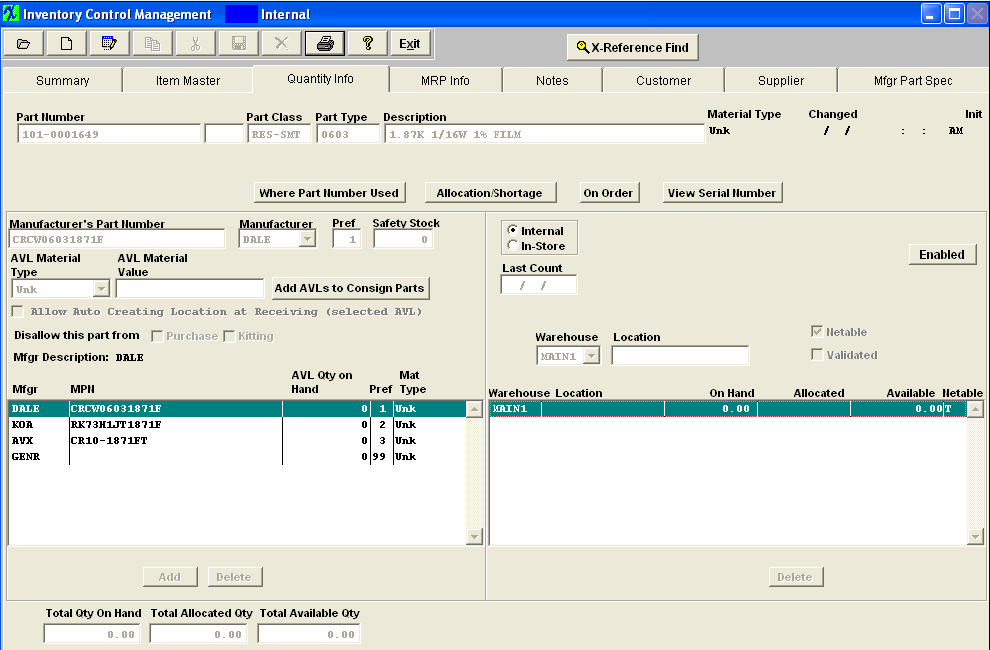

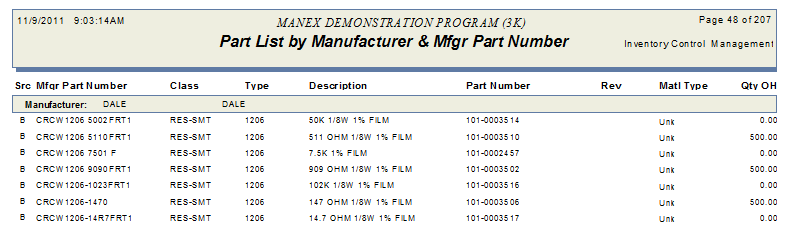

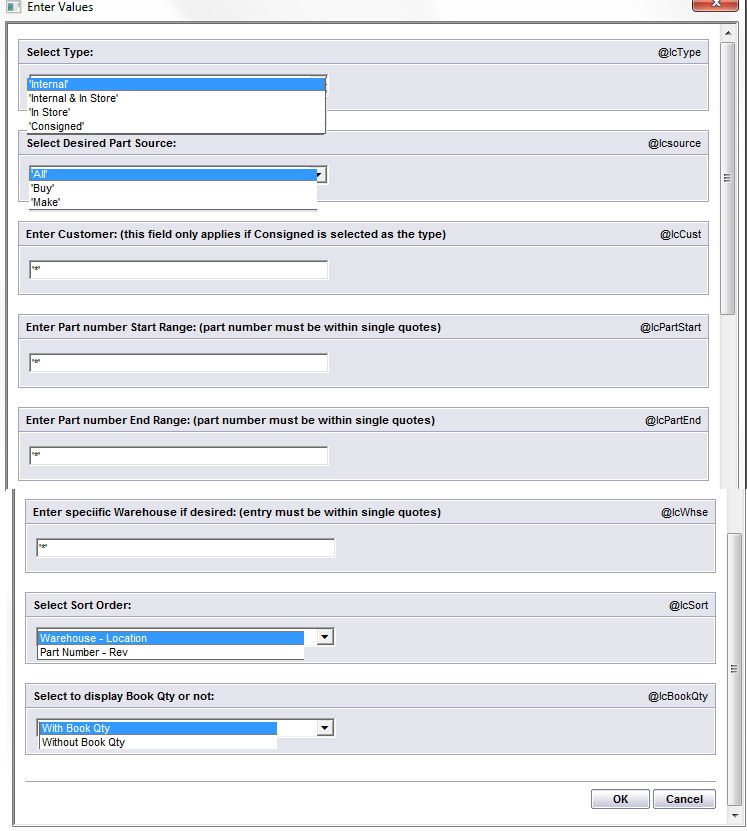

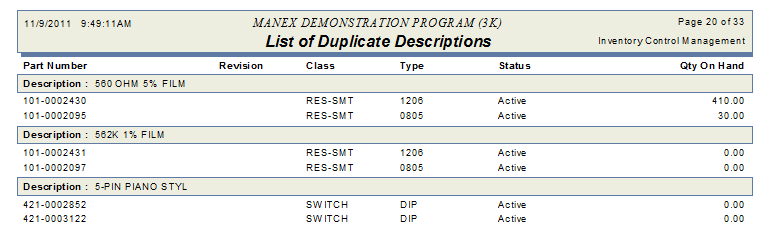

| 1.3.3. Quantity Info Tab | This screen is used to enter, edit and display Warehouse, Location, Manufacturer, and Safety Stock information for an inventory item. Also, after an item has been entered, complete inventory stock, allocation and usage information by Manufacturer is displayed or available at the click of a button. All current inventory information about any selected part can be displayed here.

Header Information fields

Part Number, Part Class, Part Type, Description and Material Type are Item fields which repeat at the top of all Tabs to display the selected Item.

|

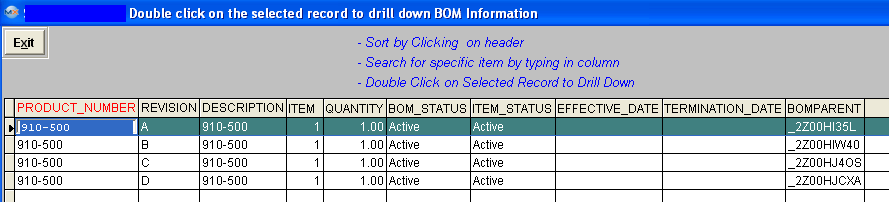

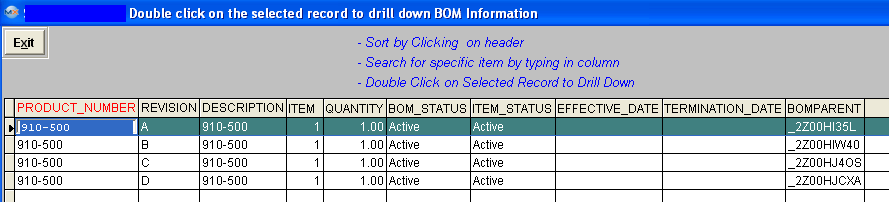

Clicking on this button will display all Active assemblies and sub-assemblies with this item appearing in their BOM. This screen allows user to Sort, Search and Drill Down to Selected Records. |

Where Part Used field Definitions

| Product Number |

Is the number assigned to the assembly for which the internal Part Number is a component |

| Revision |

Is the revision number of the assembly |

| Description |

Is the description of the assembly |

| Item |

Is the item number on the Bom |

| Quantity |

Pertains to the amount of the component used for 1 unit of the completed assembly |

| Bom Status |

Is status of the Bom (Active, Inactive,etc.) |

| Item Status |

Is status of the assembly (Active, Inactive, etc.) |

| Effective Date |

Pertain to any effective dates regarding the assembly |

| Termination Date |

Pertain to any obsolete dates regarding the assembly |

| BOM Parent |

|

|

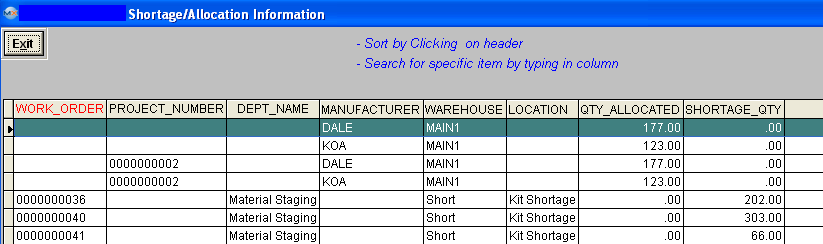

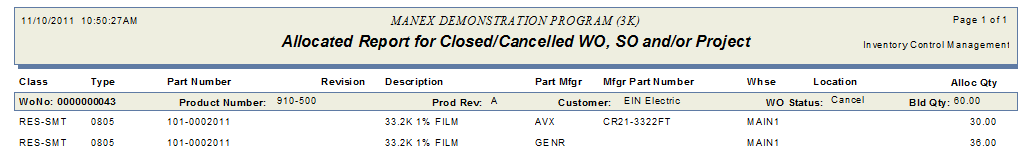

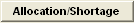

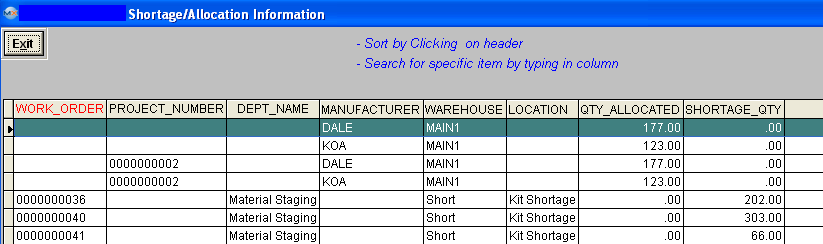

Clicking on this button will display Inventory Allocations and Shortages for this item by Work Order number, as displayed: This screen allows user to Sort, and Search for Selected Records.

|

Part Shortage and Allocation Field definitions

| Work Order |

Is the number assigned to the Work Order for which the component part is short |

| Project Number |

Is the number assigned to a work order for a special project |

| Dept Name |

Is the name of the Work Center where the Part Number is short |

| Manufacturer |

Is the name of the manufacturer of this part. |

| Warehouse |

Is the name of the warehouse where this Part Number is stored |

| Location |

Displays if the shortage is a kit shortage, line item shortage, or an allocation. |

| Qty Allocated |

Displays the quantity allocated to a specific Work Order or Project |

| Shortage Qty |

Shows the number of units short for the Work Order |

The User may sort on Work Order Number, Project No, Work Center, Part Manufacturer or Warehouse by depressing the appropriate button.

|

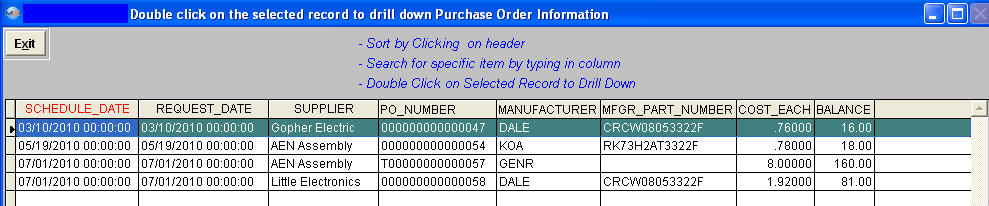

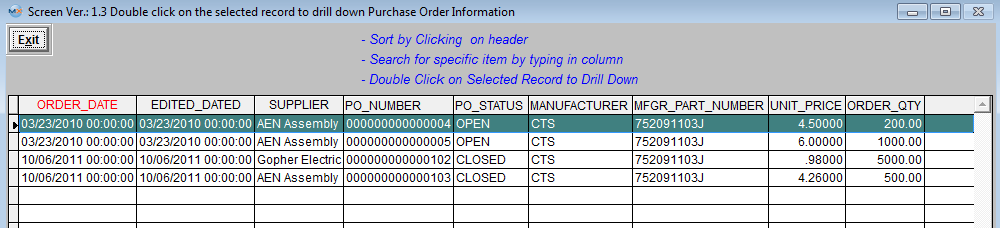

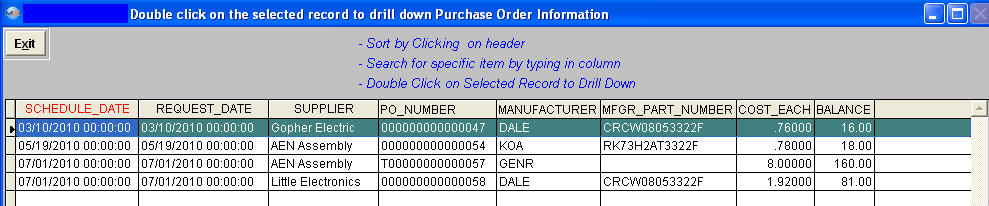

Clicking on this button will display all Open, Approved Purchase Orders for this item, as displayed: (The quantity being displayed is the qty scheduled not the qty on order) This screen allows user to Sort, Search and Drill Down to Selected Records. |

On Order Field definitions

| Schedule Date |

Represents the calendar date of the Purchase Order |

| Request Date |

|

| Supplier |

Is the name of the Supplier to which the Purchase Order was sent |

| PO Number |

Is the internal number assigned to that Purchase Order |

| Manufacturer |

Is the name of the Manufacturer specified in the Purchase Order |

| Mfgr Part Number |

Is the Manufacturer Part Number on order. |

| Cost Each |

Is the amount of money to be paid for one unit in the Purchase Order line item |

| Balance |

Is the amount of unit(s) scheduled on the PO, not the qty on order |

The User may sort on Date, Supplier, PO Number, Manufacturer or Price by depressing on the appropriate button.

|

This field is read only. The button will be displayed in Red when there are serial numbers present. Clicking on this button will display all serial numbers assigned to this item, as display: (only if this item is serialized). This information comes from the PO Receiving module or Inventory Handling (Receiving) module and is not editable. This screen allows user to Sort, and Search for Selected Records. |

Serial Number Field definitions

| Serial Number |

Is the number assigned to that part |

| Manufacturer |

Is the name of the mfg. specified |

| Manufacturers Part Number |

Is the mfg. part number on order |

| Warehouse |

Is the name of the warehouse the parts are being stored in |

| Location |

Displays where the parts can be found |

| Lotcode |

Lot Code number if part is lot coded |

| Exp Date |

Displays the date the parts can no longer be used. This field is for reference only. Manex doesn't act on that date to expire the part. But it is part of the unique combination users can have LOT code A, exp date 01/10/2005 and LOT code A, exp date 01/01/2010 and the system will consider it as a completely different LOT. |

| Reference |

Is a name/number to identify the Lot. |

| PO Number |

Is the internal number assigned when order is placed. |

| Reserved |

|

|

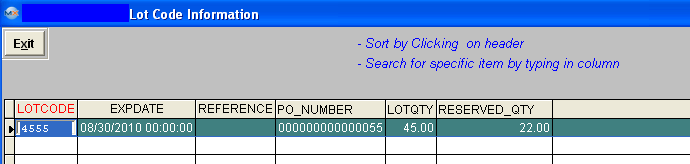

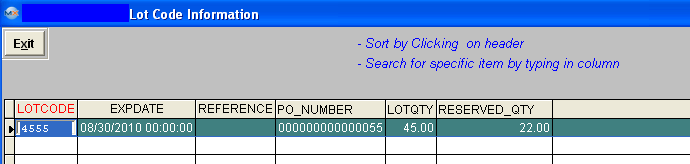

This field is read only and is not editable. The button will be displayed in Red and will be only displayed if the item is Lot Coded. Clicking on this button will display all the Lot Code Detail assigned to this item, as display below. All Lot Codes received by Purchase Order (in the PO Receiving module) will have a PO Number displayed against which they were received. If received using the Inventory Handling (Receiving) module the PO Number will be empty. This screen allows user to Sort, and Search for Selected Records |

Lot Detail Field Definitions

| LotCode |

Is the number of the Lot/Date Code |

| ExpDate |

Displays the date the parts can no longer be used. This field is for reference only. Manex doesn't act on that date to expire the part. But it is part of the unique combination users can have LOT code A, exp date 01/10/2005 and LOT code A, exp date 01/01/2010 and the system will consider it as a completely different LOT.

|

| Reference |

Is a name/number identify the Lot |

| PO Number |

Is the internal number assigned when order is placed |

| Lot Qty |

Displays the qty available in Inventory |

| Reserved Qty |

Displays the quantity allocated to a specific Work Order or Project |

|

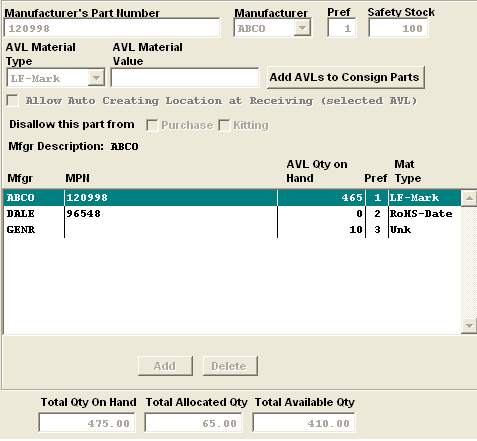

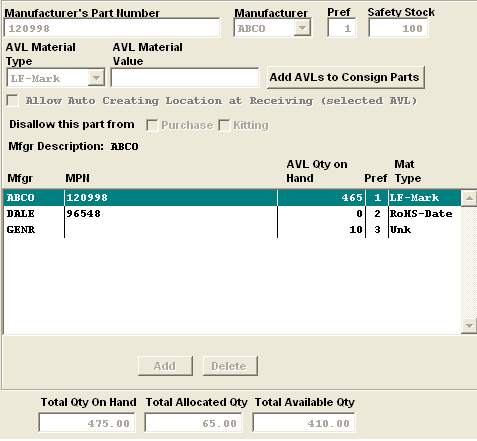

AVL Information

This section will define all the AVL, and Safety Stock information assigned to the inventory part. The user may Add, Delete, or Edit the AVL information here.

When adding new MPN's to the item master, if you do not want the BOM's automatically updated be sure that the "Disable Automatic BOM AVL update" is Enabled. See article #4010 for more information.

Note: When deleting an MPN - keep in mind that the MPN will be deleted from the screen but NOT from the tables. The MPN's that have been deleted are retained in the tables for history tracking purposes.

|

|

AVL Field Definitions

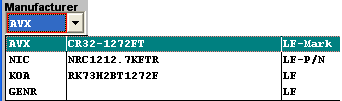

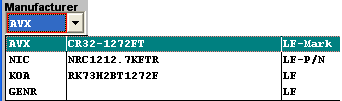

| Manufacturers Part Number |

Displays the Mfg. Part Number for an existing highlighted Mfg. Also, Used to enter Mfg. Part Number during data entry. If no manufacturers Part Number is entered into the Inventory Master during data entry, GENR (Generic) will be automatically entered by the system as the Manufacturer and the Manufacturers Part Number will be left blank. If a Buy item is fabricated by a customer, then the Customers name must be added to the list of Manufacturers and the Customers Part Number entered in the Manufacturers Part Number field.

|

| Manufacturer |

Any Manufacturer entered in Part Manufacturer Setup can be selected in this field. If no specific Manufacturer is required, GENR. (Generic) may be used to show that any Manufacturer is usable. Also displays Manufacturer for an existing inventory record choosen.

|

| Pref |

This is a number indicating the preference for use in Work Order Kitting for each Manufacturer shown. The number 1 indicates 1st ranking, 2 is 2nd ranking, etc. User will only be allowed to enter postive numbers (1 through 99). If no preference code is entered the preference automatically is assigned 99. All items will be at the bottom of the preference list unless the user assigns another number to it. For further detail on how the preference code is used in MRP see Article #3032 . |

| Safety Stock |

Enter in a qty that you want kept on hand for this specific AVL. User may have safety stock for more than one AVL for a given part number. (Safety stock is calculated in MRP at the AVL level NOT the part number level). This qty is in addition to the MRP demands. ManEx will ensure that there is always the safety stock qty on hand regardless of the MRP demands. Please see Article #2331 for more detail. (This field is calculated off of the Stock UOM).

|

| AVL Material Type |

Select from the pull down, Unk, LF-P/N, LF-Date, LF-Mark, RoHS-P/N, RoHS-Date, RoHS-Mark. See Article 2267 for definitions. These choices have been defaulted in. Customers may establish the logic by which the material type for the parts are established by the material types at the AVL level in Material Type Setup.

The AVL Material Type is carried forward for the consign part when the consign part is first added to the system or when new AVL was added to the internal part and the user elects to add this AVL to the existing consign parts. If the user later changes the Material Type on the internal part, the change is NOT carried over to the consigned part.

If the Inventory Material Type is set to "Auto" (within the Material Type Setup), everytime the user modifies the AVL material type, the program will update the Inventory Material Type automatically, if the control is set to "Manual", then the user will be able to modify the Inventory Material Type from the Material Type pulldown. Keep in mind that the program will NOT validate if the material type in Inventory and AVL levels are in sync.

|

| AVL Material Value |

This field is a text modifier for a given material type. For example, if the material type was "LF-Date", the text in the field could be a date code. This value could be different for various AVL with the same Material Code. This field is optional and does not have to be populated. |

|

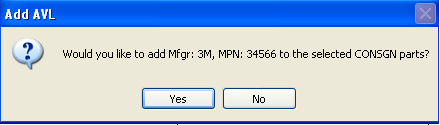

This field is to add the AVL(s) to a consigned part. Note: This button is disabled when in Add or Edit mode.

|

| Allow Auto Creating Location at Receiving (Selected AVL) |

Note: Users have to have special access in order to modify this checkbox, this access is assigned through Security/User Rights.

If the box is checked (for the highlighted AVL) it will allow the user to create a location when entering the Purchase Order or at PO Receiving. Note: The "Allow Auto Creating Location at Receiving" box must be checked also in Warehouse Setup.

If the user has the " Remove location with this warehouse from the Inventory when qty on hand gets to zero Box" box checked within the Warehouse Setup Setup module this box MUST be checked also. |

|

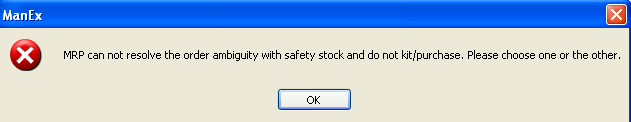

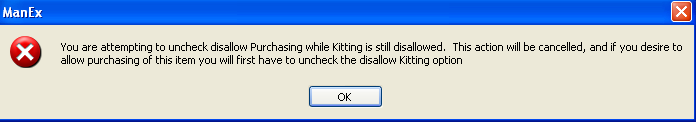

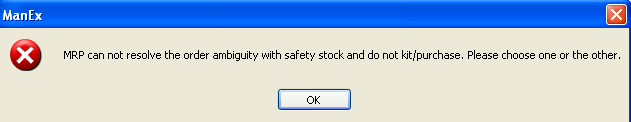

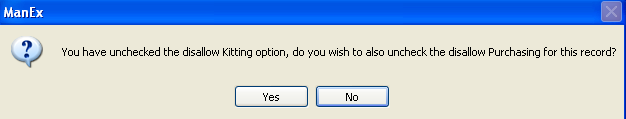

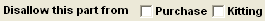

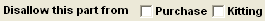

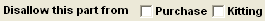

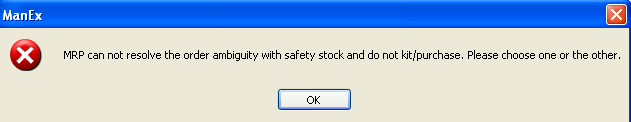

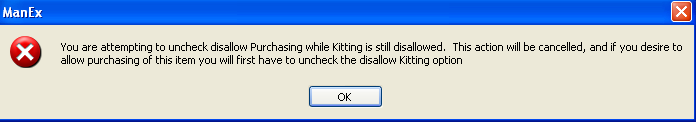

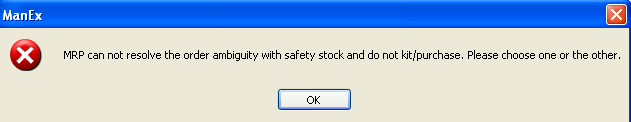

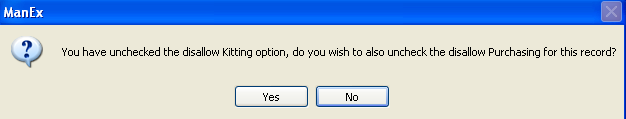

There are situations where the Users customers will allow them to use up non-conforming inventory, but cannot replace the same AVLs. So, at the AVL level, we added two logic fields that would signify that the AVL is NOT to be purchased and/or kitted. In such a circumstance, it is NOT appropriate to delete the parts, but neither can they be purchased for future requirements. Likewise, they may want to avoid kitting so you would check these boxes to "Disallow this part from Purchase and/or Kitting". For special circumstances, the user can override the block from kitting if their customer permits it. For further information on how to use these fields effectively refer to Article #2329. For information on how these fields affect MRP refer to Article #3211 . (See the non-nettable function for the warehouse level described below).

|

| AVL Qty on Hand |

Total qty on hand for each individual mfg. |

| Total Qty on Hand |

Total qty on hand for all mfg.'s combined

|

| Total Allocated Qty |

Total qty allocated to a specific work order or project |

| Total Available Qty |

Total qty available minus the allocated qty

|

| Add |

Allows data entry to add Manufacturer record. Enter Manufacturer part number and a drop down list will appear to choose the Manufacturer. Click on the save button and the information entered will be displayed in the screen.

|

| Delete |

Deletes the highlighted manufacturer part number record. A ????? screen will appear. Click the NO button to restore the deleted record if this button is clicked in error. Deletion of manufacturer part number records is not allowed if a Warehouse quantity other than zero (0) is shown for that record. Before manufacturer records are deleted, please realize that SOME of the history regarding the manufacturer may also be deleted.

|

| Save |

Appears after clicking the Add button. Clicking on this button saves the record |

| Cancel |

Appears after clicking the Add button. Click to abort saving a new record or changes to existing records.

|

|

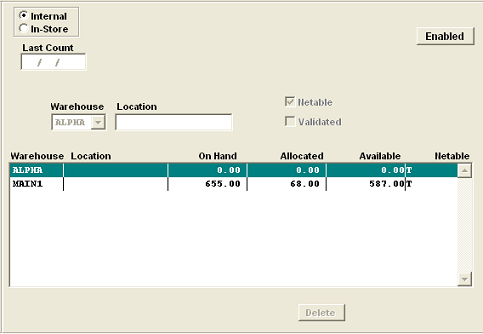

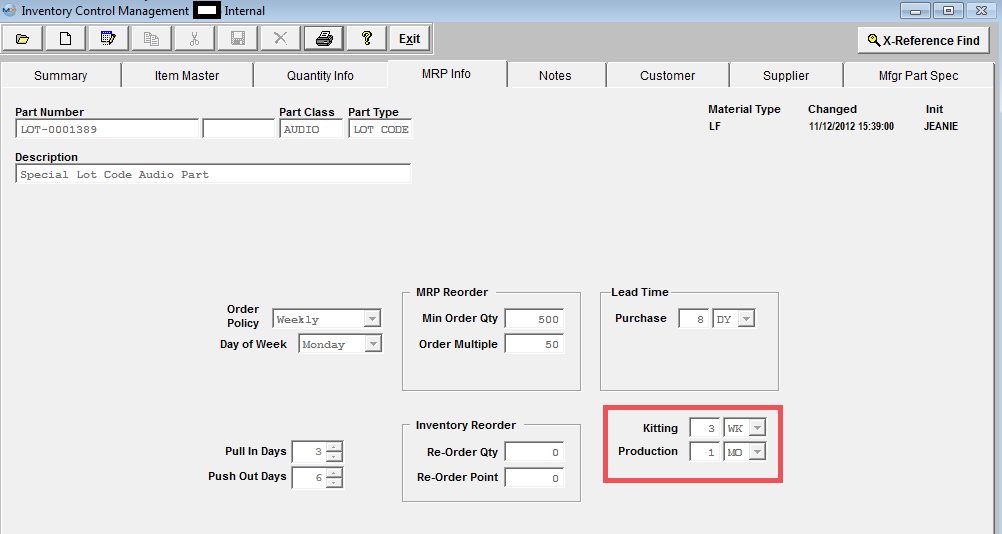

Warehouse Information

This section will define all the Warehouse information assigned to the inventory part. The user may add or edit the Warehouse information here also.

|

|

Warehouse Field Definitions

|

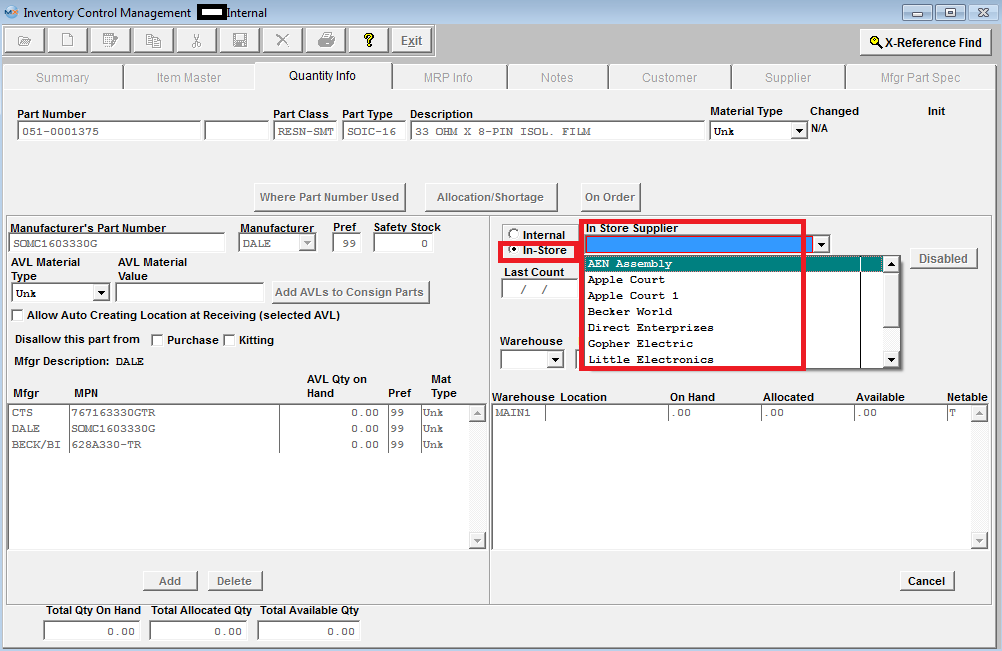

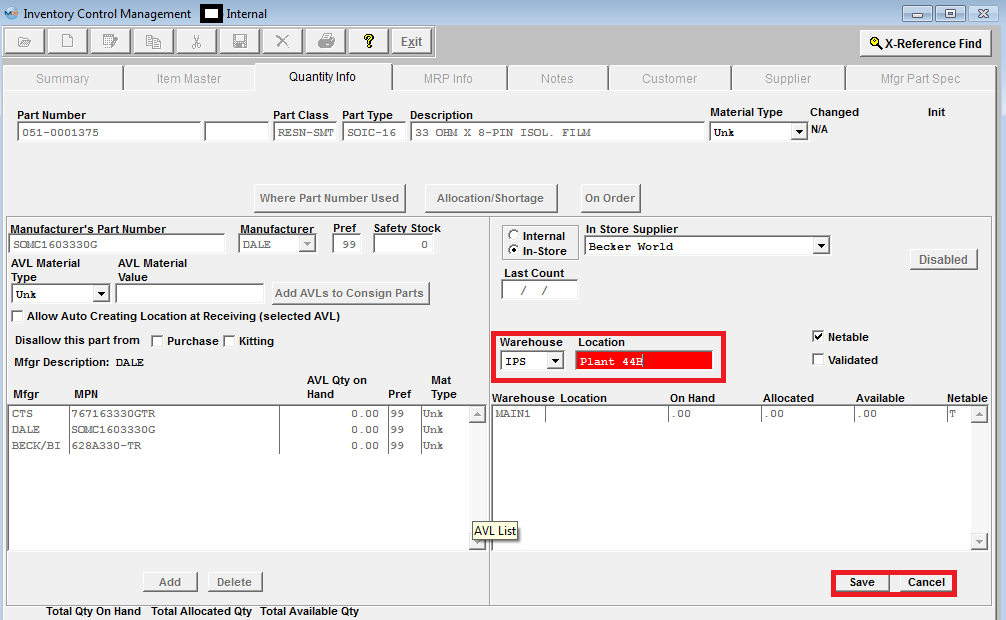

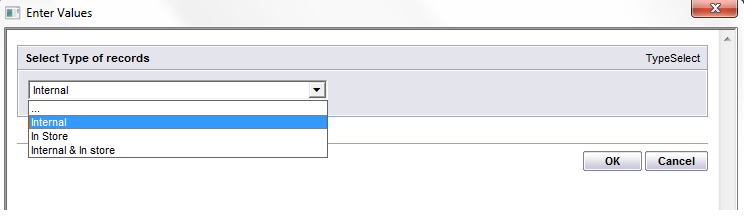

One of these radials must be checked. Internal (User owned) or In-Store (supplier owned). This selection is available only for "BUY" parts. This selection will not be displayed for "MAKE" or "PHANTOM" parts.

|

| Last Count |

Displays the date of the last physical Inventory or Cycle Count for the highlighted item in the Warehouse/Location/Manufacturer display window.

|

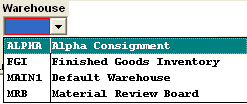

| Warehouse |

Used to display the stocking Warehouse for an existing item or to select a Warehouse during entry of a new Location or Manufacturers Part Number. Only Warehouses entered in Warehouse Setup may be selected in this field.

|

| Location |

Allows entry of any Location code desired. It could be an area assigned for Finished Goods, High Value items, Programmed parts or a Row, Aisle and Shelf Code. Also displays Location for an existing highlighted Warehouse record. This field is flagged "Read Only" for MRB whse (meaning you can not create a location for an MRB whse).

|

| Netable (box) |

If this is checked, any On Hand inventory of the item in the Warehouse location being added or highlighted (if already added) will be used to fill Material Requirements Planning stipulations when processing the MRP. If you want to exclude this part from MRP, uncheck this box. You Cannot have a netable part that is excluded by MRP. The only warehouse that is non-netable is the MRB warehouse. Any parts in that warehouse are deemed questionable until the parts are validated and returned to a normal warehouse. So they will not be considered by MRP.

|

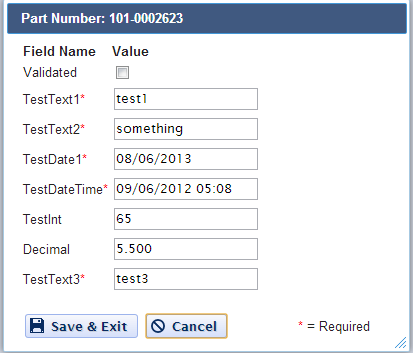

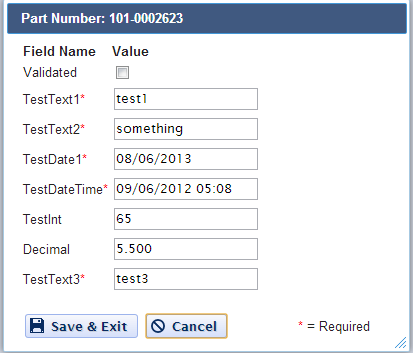

| Validated (box) |

This is for reference only and does not affect any other modules in Manex. This is simply to help users keep track of changes and for the users to check that the part being added has been verified as appropriate.

|

or or  |

If Enabled ManEx will add the new AVL to all existing BOMs and check them as approved. If Disabled ManEx will add the new AVL to all existing BOMs but will NOT mark them as approved. Then they will not drive any demands or be available for pulling to that kit. Then you will have to manually go into each individual BOM and Check mark the ones that you do intend to use that new AVL on. See article #4010 for more information.

|

| On Hand |

Shows the total quantity of the Manufacturer Part Number indicated which is currently in the Warehouse and Location shown.

|

| Allocated |

Quantity of the item that has been allocated to a Work Order in the Inventory Mgt./ Kitting, Allocating and Shortage Management/ Work Order Allocation screen.

|

| Available |

(Calculated field) Equals the quantity On Hand minus the Allocated quantity.

|

| Add |

Allows data entry to add a Warehouse, and Location. A drop down list appears to select a warehouse. Enter in a location if you choose. Click on the save button and the information entered will appear in the screen.

|

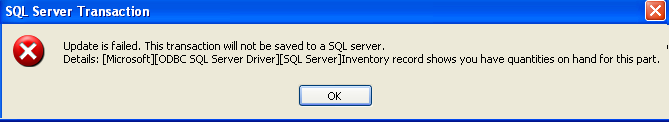

| Delete |

Deletes the highlighted Warehouse record. A reminder screen will appear. Click the NO button to restore the Deleted record if this button is clicked in error. Deletion of Warehouse records is not allowed if a Warehouse quantity other than zero (0) is shown for that record.Before warehouse records are deleted, please realize that SOME of the history regarding the warehouse may also be deleted.

|

| Save |

Appears after depressing the Add button. Depressing this button saves the record.

|

| Cancel |

Appears after depressing the Add button. Depress to abort saving a new record or changes to existing records.

|

|

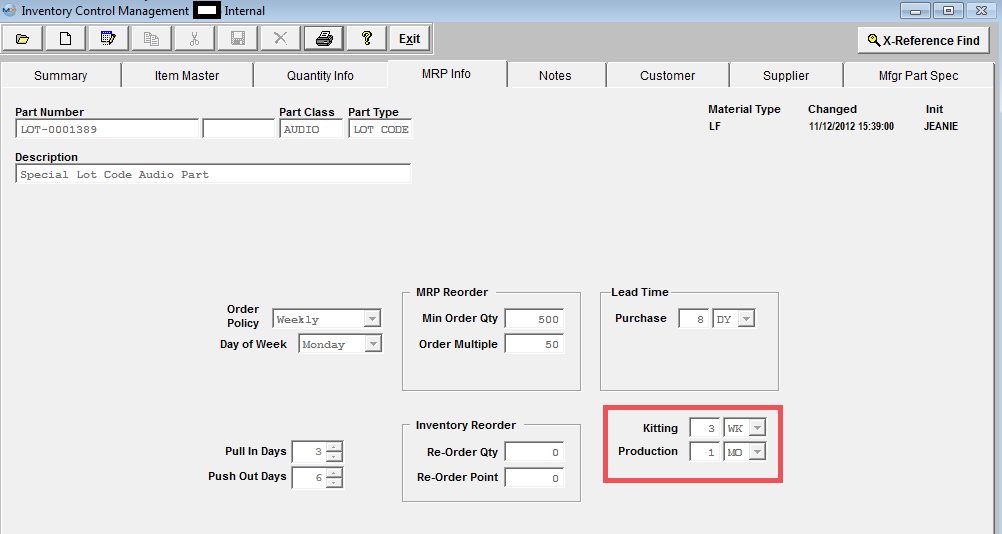

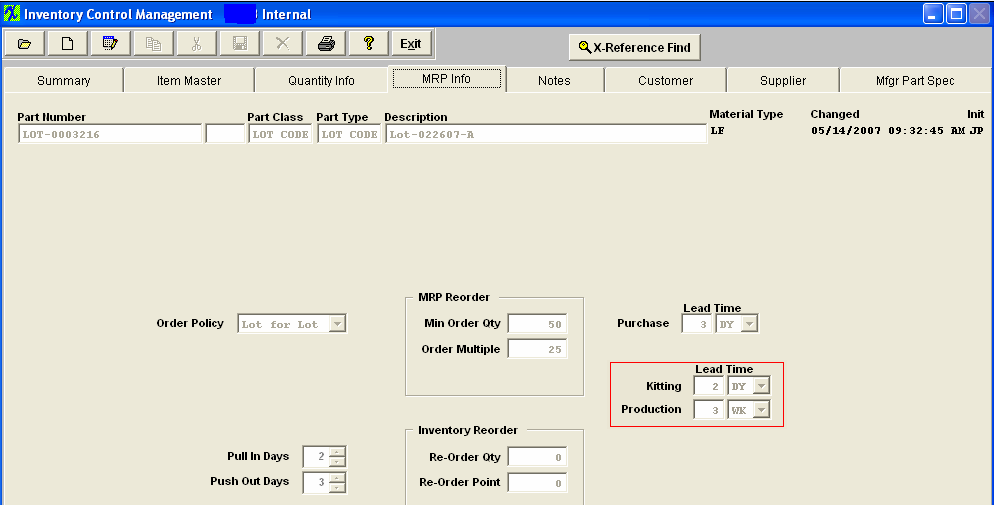

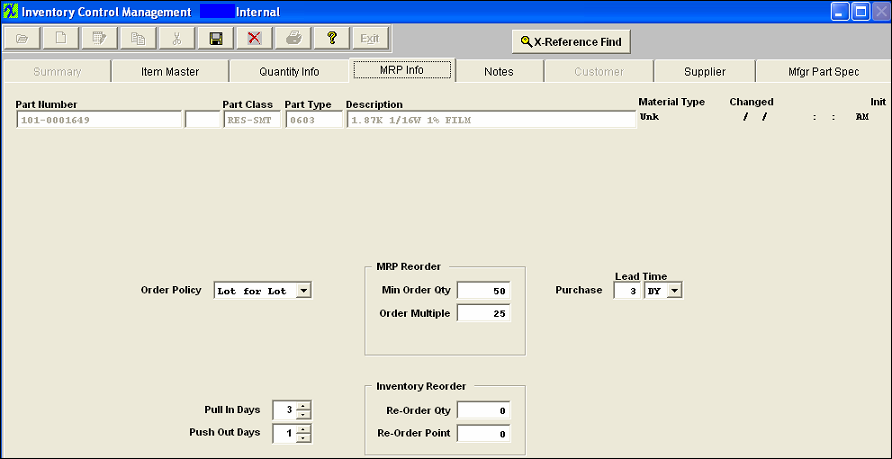

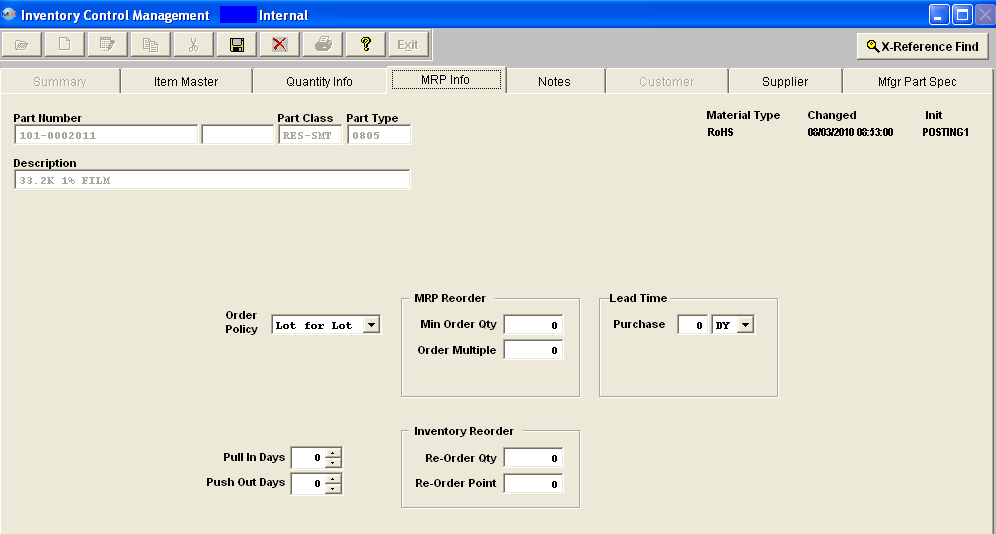

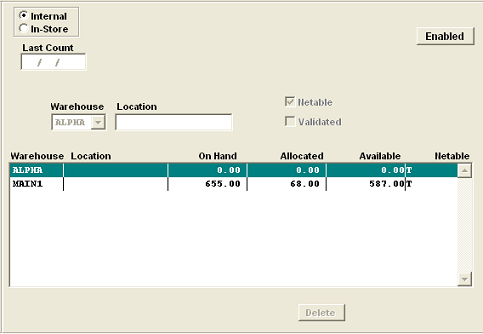

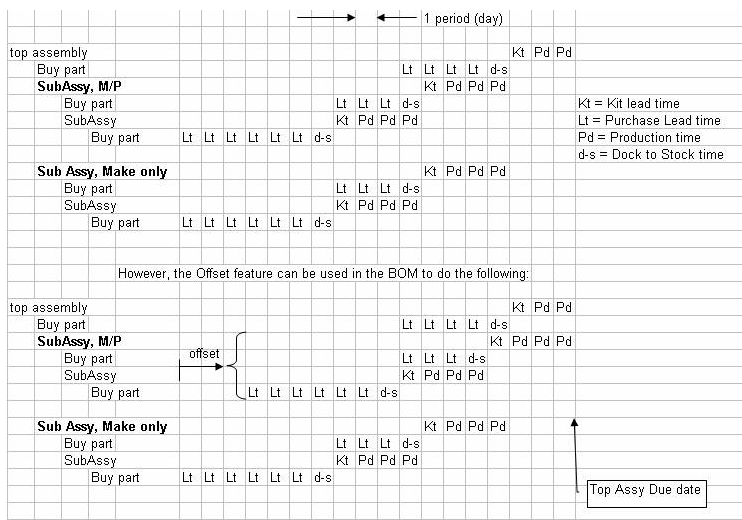

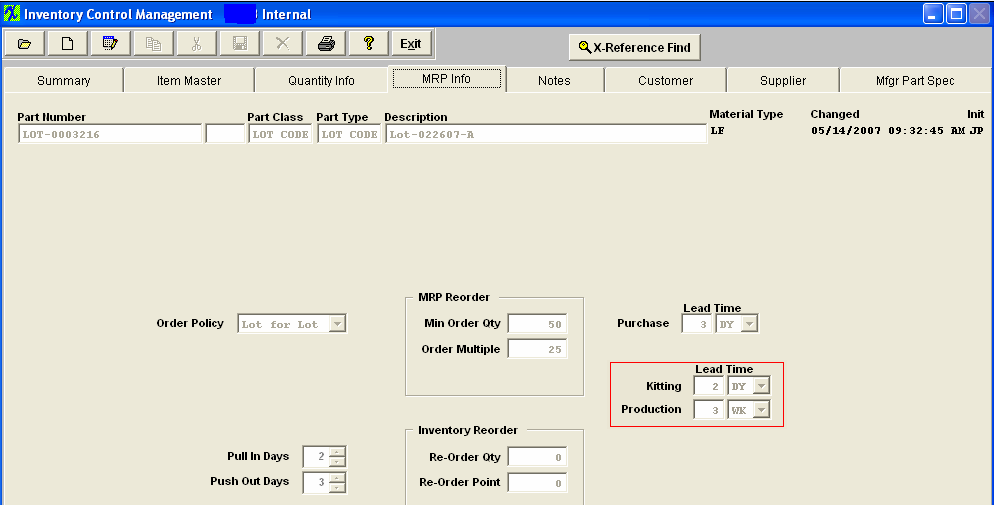

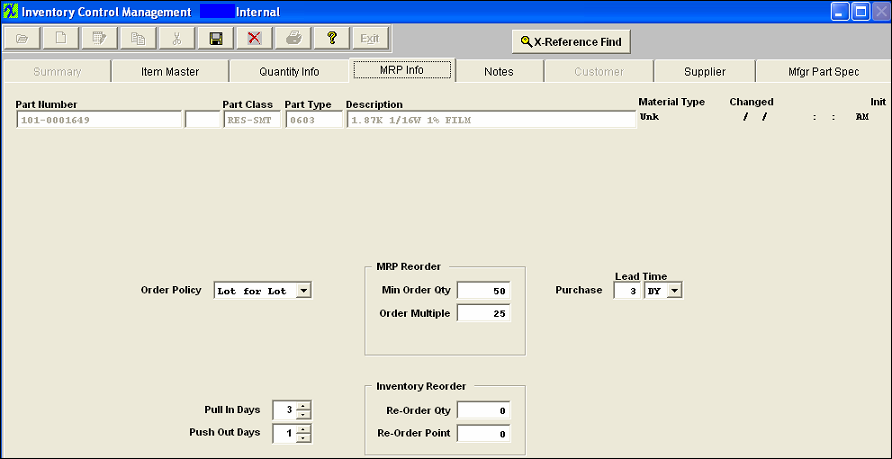

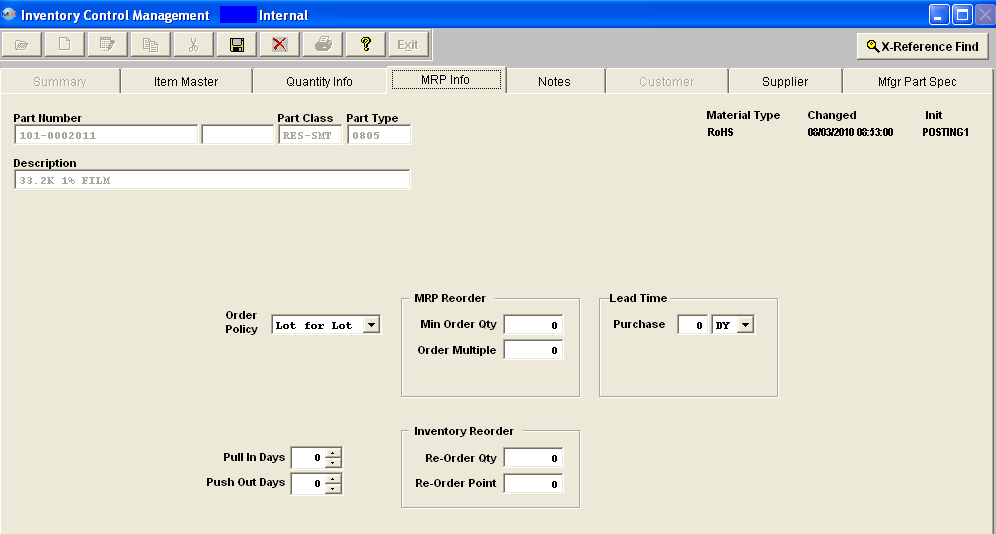

| 1.3.4. MRP Tab (Material Requirements Planning Info Tab) | This Tab displays the screen in which Material Requirements Planning parameters are entered, edited or viewed. Default choices for each of these fields may be selected in System Setup Inventory Part Class Setup.

Header Information fields

Part Number, Part Class, Part Type, Description, and Material type are Item fields which repeat at the top of all Tabs to display the selected Item.

Note: All lead times are calculated with the Production Calendar.

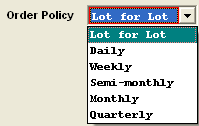

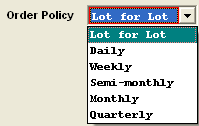

| Order Policy field |

This field is used to select the method used by the Material Requirements Planning module to combine requirements for this item in creating Planned Purchase Orders (PO’s). For instance if the choice is “Lot for Lot”, for a BUY part, the Material Requirements Planning module will plan one PO per requirement or if you select Daily then it will plan one PO for the total requirements on a daily basis. If the choice is "Lot for Lot" for a MAKE part MRP will calculate off of each Sales Order individually . If the choice were “Weekly”, for a BUY part, the Material Requirements Planning module would combine all the requirements each week and plan one PO on the first requirement day for the entire week’s needs, etc. Note: If order policy is left blank "Lot For Lot" will be used upon default for MRP calculations.

|

| Min Order Qty field |

This is smallest number of the item that can be ordered from the supplier in one PO. For instance, Surface Mount components on a reel usually have a minimum order of 1000 items or more. (This field is calculated off of the Stock UOM).

|

| Order Multiple field |

This field defines the even multiples of the Unit of Measure in which an item must be purchased. For example, 16AWG Wire might be only available in even hundreds of feet on a spool in which case the Material Requirements Planning module would plan a PO for the next higher even hundred above the requirement. (This field is calculated off of the Stock UOM). |

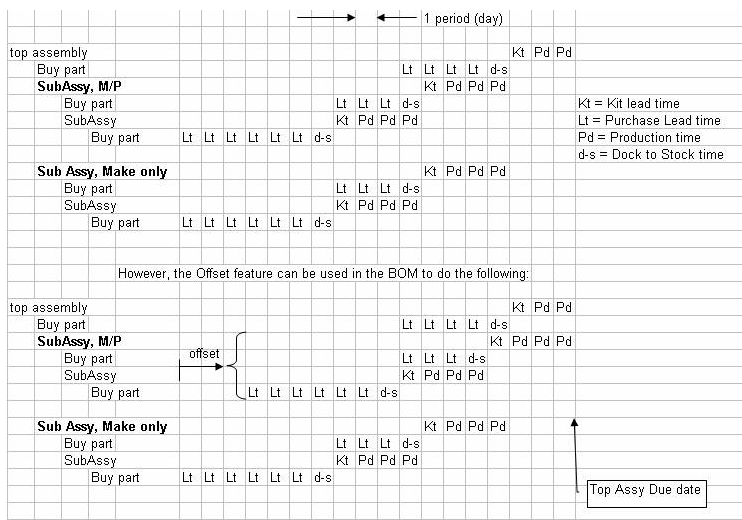

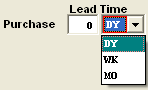

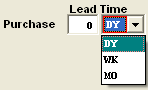

| Purchase Lead Time field |

This field will be displayed for a Buy part or a Make with Make/Buy Flag part. Purchase of all items other than In-Store items requires that the PO be placed a minimum number of days before the actual requirement. This Lead Time requirement is what tells the Material Requirements Planning module how many days before a requirement to plan a PO. Changing the leadtime of a Buy part will NOT change the due date in MRP, only the date to take action. For more detail see diagram shown below. |

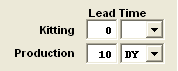

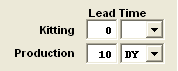

| Kitting Lead Time field |

This field will be displayed for a Regular Make part or a Make with Make/Phantom Flag part. This Lead Time requirement is what tells the Material Requirements Planning module how many days to allow for kitting. Changing the kitting leadtime of a Make or Make/Phantom part will change the due date in MRP. A TRUE phantom does NOT require any lead times and should be left blank. BUT . . . if for some reason you need to add a lead time for a TRUE phantom ManEx does have the capability. For more detail see diagram shown below.

|

| Production Lead Time field |

This field will be displayed for a Regular Make part, a Make with Make/Phantom Flag part or a Straight Phantom part. This Lead Time requirement is what tells the Material Requirements Planning module how many days to allow for production. Changing the production leadtime of a Make or Make/Phantom part will change the due date in MRP. A TRUE phantom does NOT require any lead times and should be left blank. BUT . . . if for some reason you need to add a lead time for a TRUE phantom ManEx does have the capability. For more detail see diagram shown below.

NOTE: Once the parts have been pulled to the kit and the kit status is changed to "Kit in Process" MRP is designed to calculate from the Kit Shortage and production lead time NOT from the production offset lead times. Once the parts have been pulled to the kit, the system is assuming that the shortages are needed by the WO due date, rather than the Production offset lead time, so MRP then calculates using the production lead time and due date of the WO as the date the materials must be on hand, MRP no longer takes the production offset lead time into consideration.

|

| Pull In Days field |

When PO due date is more than this number of days too late for a Material Requirements Planning module requirement, a PO Due Date change Action Notice will be generated. It allows the user to have the flexability for SO and WO due dates to be different without MRP actions being generated. For more information on how the Pull-in days work within MRP see Article #2557. Note: These parameters may be thought of as filters for MRP Order Actions when the requirement dates for the parts changes. In the case of the customer pulling forward their required date, it is a greater imperative that the work orders (thus the assembly) be pulled in to match the earlier due date. So the assemblies should probably have a minimum number of days to be sensitive to earlier demands. See attached Document <<pullin-pushout discussion.docx>>.

|

| Push Out Days field |

When PO due date is more than this number of days too early for a Material Requirements Planning module requirement, a PO Due Date change Action Notice will be generated. Example: if there is a PO that is due to be delivered Dec 15, but now it is not needed until Dec 26 and the Push out is 30 days, then there WOULD NOT be a message issued within MRP to reschedule the PO delivery, because it is within 30 days, but if the Push out was 5 days then an action message WOULD BE issue to reschedule the delivery because the new date was outside of the push-out days. It allows the user to have the flexability for SO and WO due dates to be different without MRP actions being generated. For more information on how the Push-out days work within MRP see Article #2557. Note: These parameters may be thought of as filters for MRP Order Actions when the requirement dates for the parts changes. The Push Out value (in days) is the number of days that the required date, base on MRP, may be pushed out (required later than the original date) but will not result in a change order to move the required delivery for the item involved. See attached Document <<pullin-pushout discussion.docx>>.

|

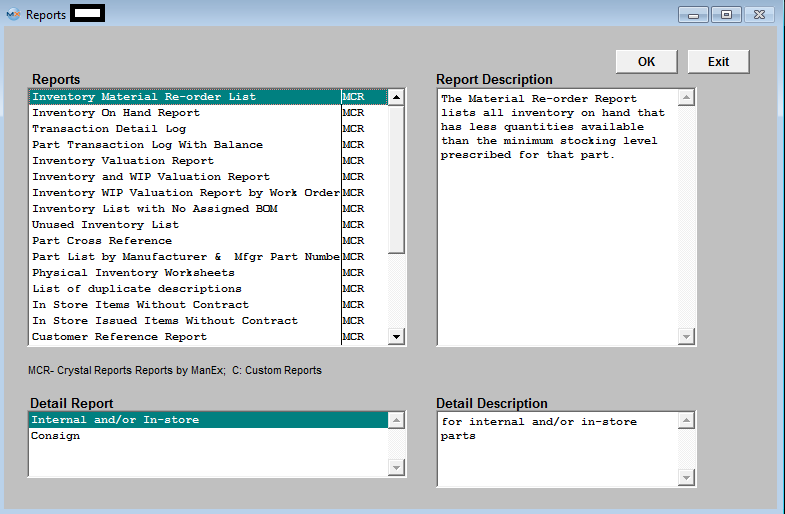

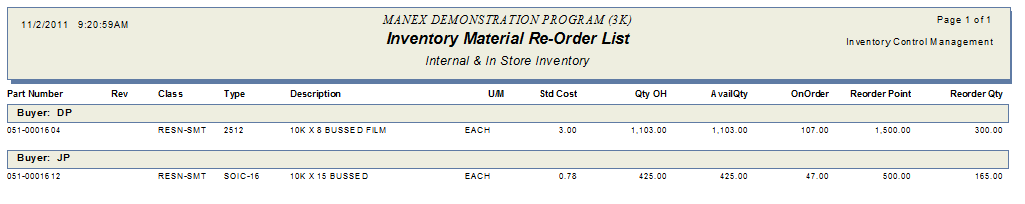

| Re-Order Point field |

To use the Re-Order Point and Re-Order Qty rather than Material Requirements Planning for reordering this item, enter the quantity at or below which the item should be replenished. Print the "Inventory Material Reorder List" report to show items which have dropped below re-order point minimums. NOTE: The Re-Order Point/Qty fields have NO AFFECT on MRP at all. MRP will NOT consider these fields for any calculations (these fields have no connection with MRP). These fields are intended to control stock on overhead items.

|

| Re-Order Quantity field |

To use the Re-Order Point and Re-Order Qty rather than Material Requirements Planning for reordering this item, enter the quantity of the re-order here. Print the "Inventory Material Reorder List" report to show items which have dropped below re-order point minimums. NOTE: The Re-Order Point/Qty fields have NO AFFECT on MRP at all. MRP will NOT consider these fields for any calculations (these fields have no connection with MRP). These fields are intended to control stock on overhead items. |

|

| 1.3.5. Notes Tab | Notes are usable for text information relevant to this item that is of interest to Engineering, Purchasing, Stores or Planning. A typical note is shown below. These item notes are viewable from the Material Requirements Planning, Bill of Material and Purchasing screens.

|

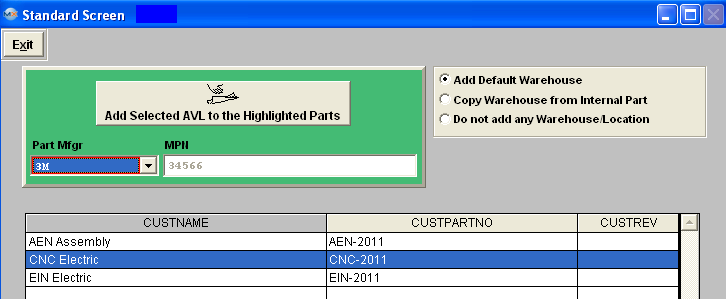

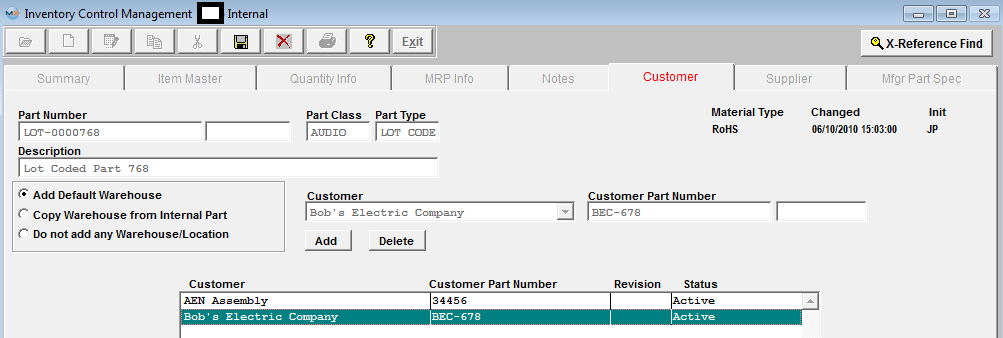

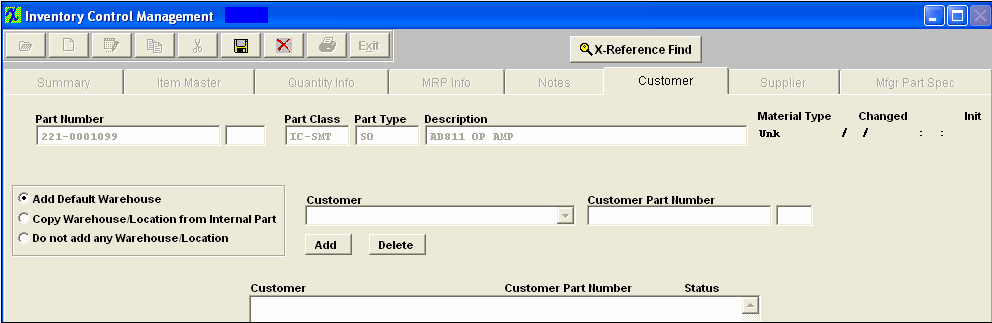

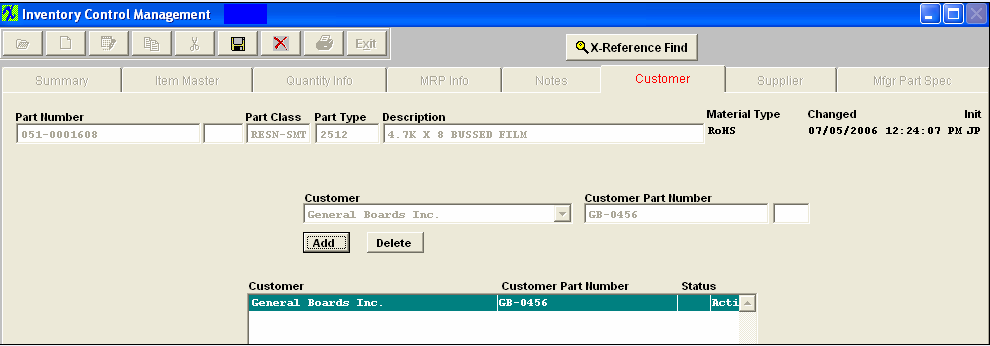

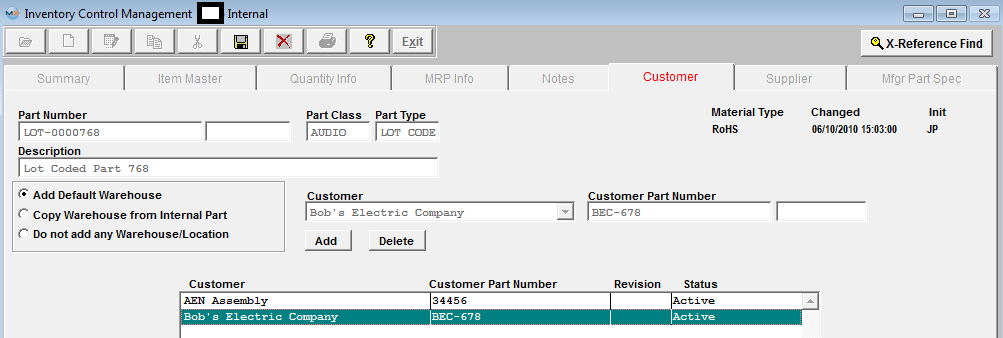

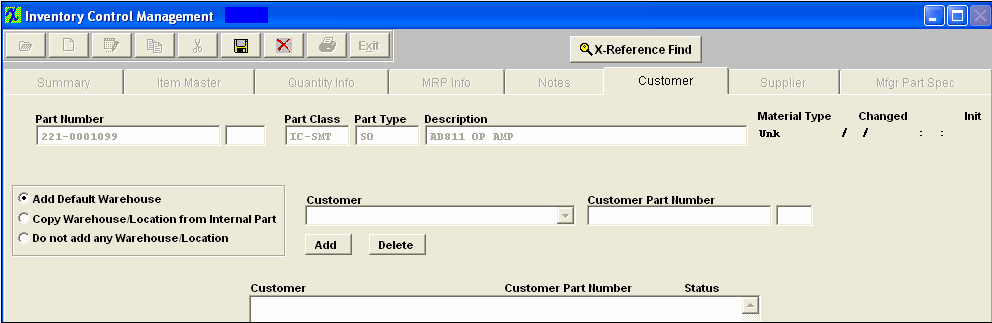

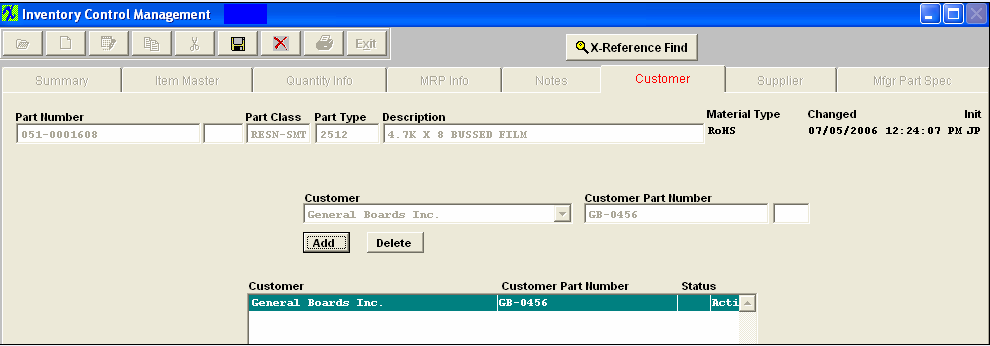

| 1.3.6. Customer Tab | This screen allows users to connect the customer part number and revision with the internal part number and revision. Entry of a Customer Part Number creates a Consigned Inventory Record that does several very important functions:

-

Serves as the place for selection of each Approved Manufacturers (Customer’s Approved Vendor List) from the list of all Manufacturer Part Numbers for that particular generic part

-

Provides a way to cross reference Customer Part Numbers to Internal Part Numbers

-

Allows generation of Bills of Material with Customer Part Numbers

-

Sets up a Consigned Inventory Warehouse(s) to allow receipt, issue and tracking of this Customer part

Header information fields: Displays the Part Number, Class, Type, Description and Material Type selected in the Summary Tab.

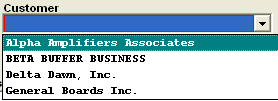

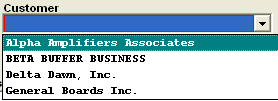

| Customer field |

In View Mode, this screen shows the Customer selected from the Customer window.In Edit Mode, use this field to enter Customer Name |

| Customer Part Number |

For viewing or entry of Customer Part Number for the internal Part Number displayed in the Header.

|

| Display/ select window |

Shows all Customers and Customer Part Numbers for this internal part and their status, (active, in-active, etc).

|

| Add |

Associate a customer and customer part number with the displayed internal part. |

| Delete |

Delete customer/customer part number/revision combination and the link with the displayed internal part.

|

| Save |

Save new Customer Part Number |

| Cancel |

Cancel a Customer Part Number |

| Add Default Warehouse |

Select to add only the default warehouse to customer side when adding a Customer Part Number |

| Copy Warehouse Location from Internal Part |

Select to Copy Warehouse Location(s) from Internal Part to customer side when adding a Customer Part Number |

| Do not add any Warehouse/Location |

Select if user does not want to add any Warehouse/Location(s) from the interanl side to the customer side when adding a Customer Part Number |

ManEx does NOT allow user to link same customer with multiple customer part numbers to the same internal part number. Our structure is based tightly on the internal part number. We link to customer part numbers when needed for showing customer part numbers or for MRP AVL limitations. If we allowed more than one customer part number for the same customer to the same internal part number, we would NOT be able to process MRP AVL selection, nor reports that currently show customer part numbers. For further detail see Article #2489.

ManEx does allow users to link same customer same customer part numbers/revisions to different internal part numbers.

|

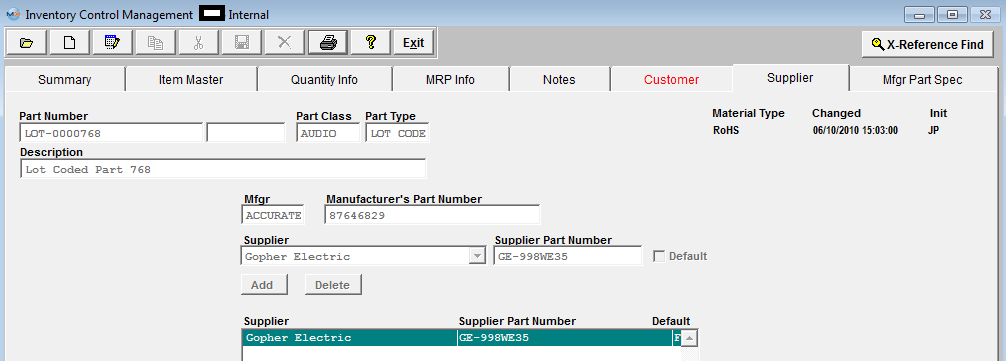

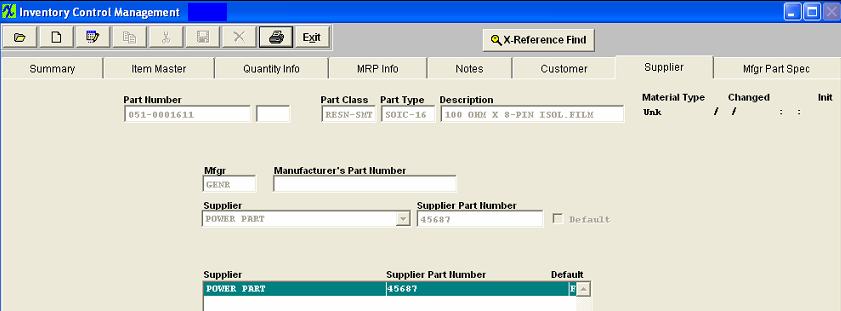

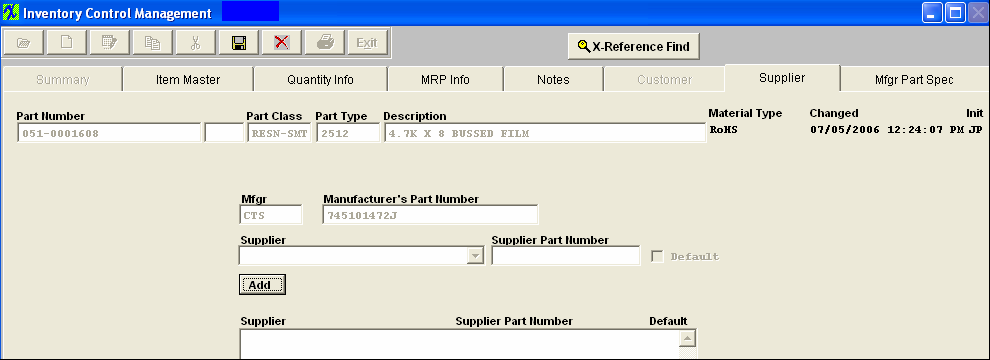

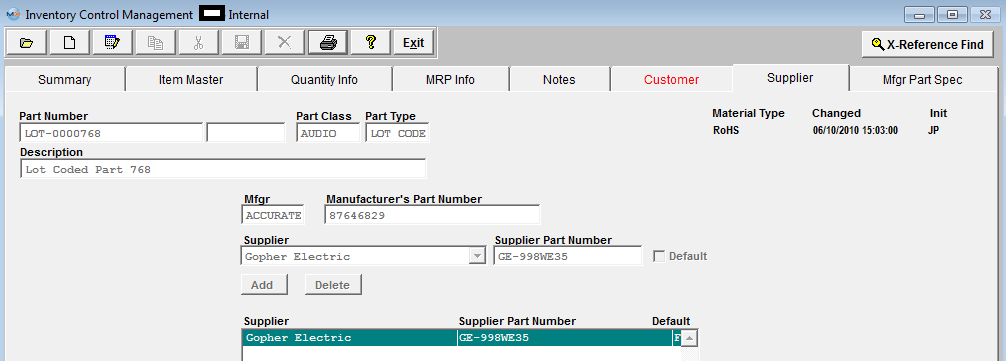

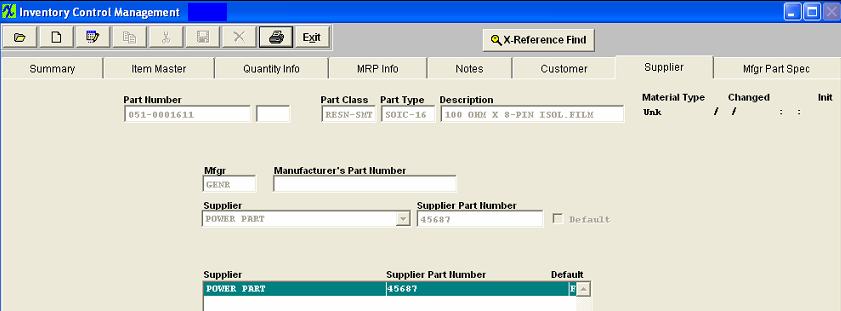

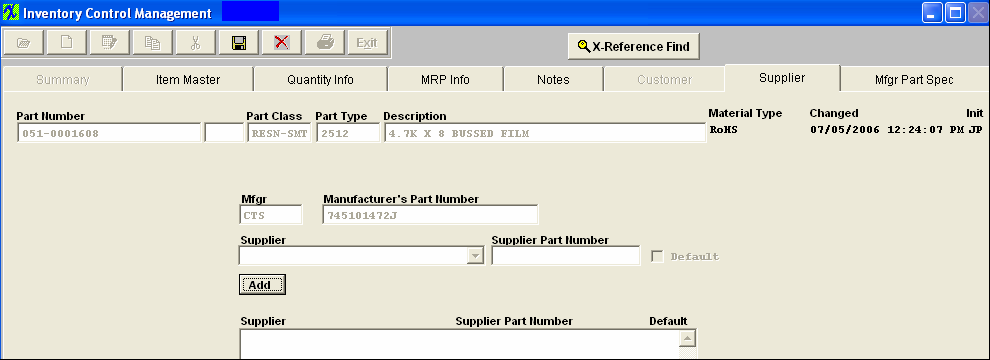

| 1.3.7. Supplier Tab | This screen is for referencing the supplier(s) of this part and the Supplier’s Part Number.

Header information fields: Displays the Part Number, Class, Type, Description, and Material Type selected in the Summary Tab.

| Mfg field |

Displays the mfg. selected in the quantity info. Tab |

| Manufacturer’s Part Number |

Displays the manufactuer’s part number selected in the quantity info. tab.

|

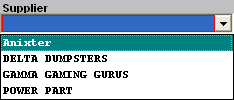

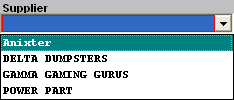

| Supplier field |

In View Mode, this screen shows the Supplier selected from the Supplier window. In Edit Mode, use this field to enter Supplier Name.

|

| Supplier Part Number |

For viewing or entry of Supplier Part Number for the internal Part Number displayed in the Header.

|

| Default |

Check this box if you want this Supplier to be the default when Auto Creating PO within MRP or for reports.

|

| Display Select Window |

Shows all Suppliers and Supplier Part Numbers for this internal part and whether it is chosen as a defalut.

|

| Add |

Add a new supplier and supplier part number |

| Delete |

Delete an existing supplier and supplier part number |

Note: The system allows you to have multiple suppliers per AVL and one default supplier per AVL. But each AVL can have a different default supplier and different suppliers.

|

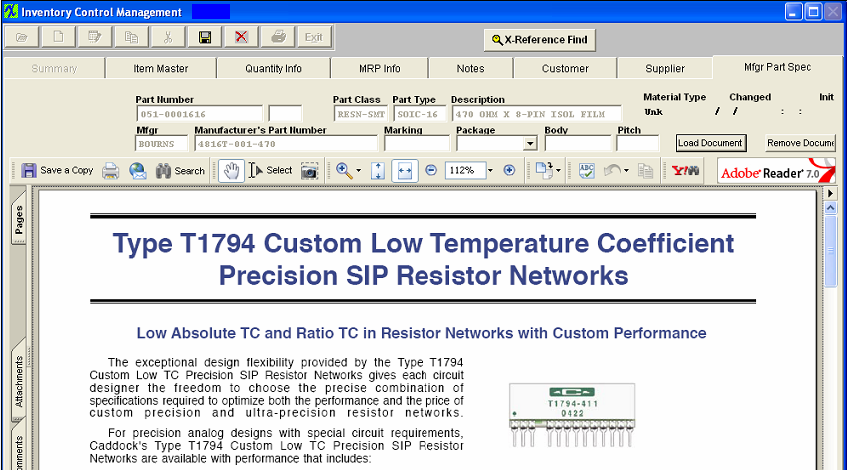

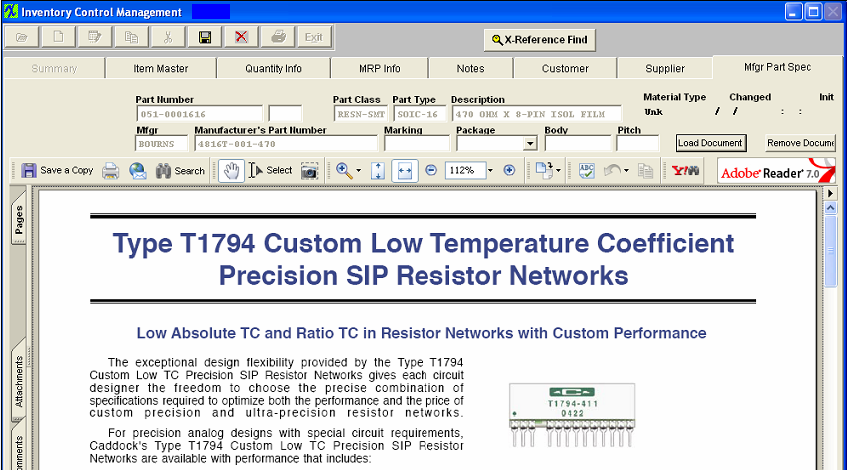

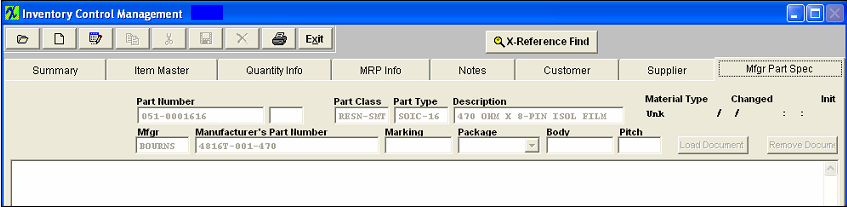

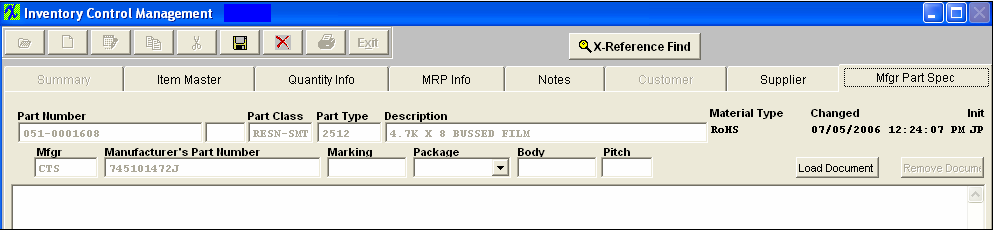

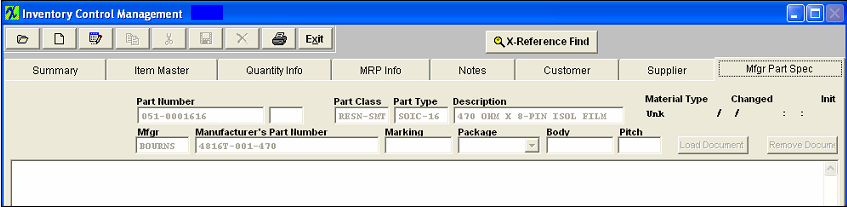

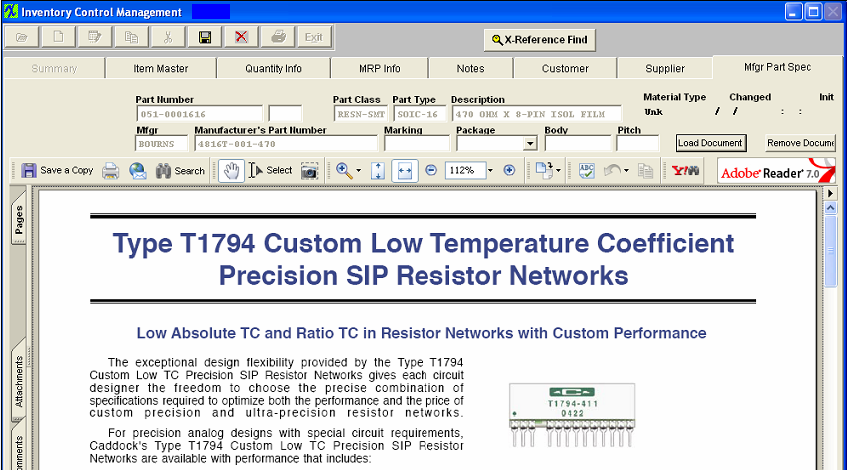

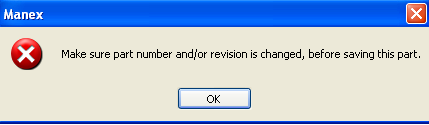

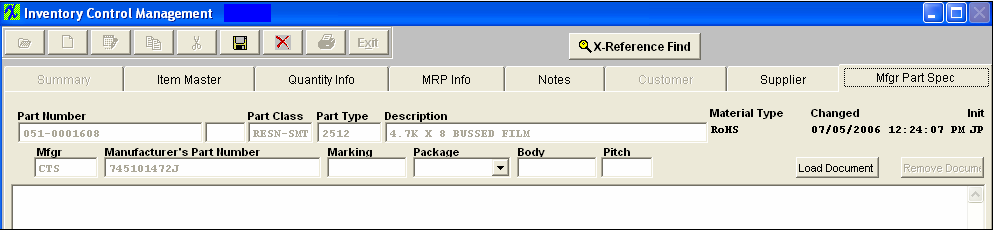

| 1.3.8. Mfg. Part Spec Tab | This screen is used to view or enter a link to a drawing, photograph,image or .pdf file to be used as an on-line reference for engineering, purchasing, quoting or any other item master usage. It can be an assembly drawing, purchased part specification, spec. control drawing, photograph or any other image or .pdf file linkable to Manex. The image or .pdf file is not stored in Manex. The file in which the image or .pdf file is stored is linked to this screen in Manex and can be maintained without access to Manex.

Header Information: Displays the Part Number, Rev, Class, Type and Description selected in the Summary screen. Displayed on the 2nd line is the manufacturer information selected in the Quantity Info screen. User may enter the Marking, Body and Pitch, and may select the Package configuration from the pull down. The Package Configuration selections are defaulted in from the Package Configuration module. Package configuration setup is provided so that the user may define a machine’s Units Per Hour. This definition can then be accessed in the Production Work Centers & Activities setup/Activities Setup & Run tab.

Load Picture or PDF document (Buttons): Used to link the Image Space below to a file on the local hard drive or any other location on the network connected to the Manex Server. To Load a Picture, while in the add or edit mode, the LOAD PICTURE button becomes active. Pressing this button prompts the User to enter the location of a picture file created for this particular inventory part.

Files (pdf.; word; jpeg;, etc.) should be stored in a permanent directory on the server (all users need network security access). The user will define the directory and file for each product in this module, but the information will be available elsewhere throughout the manufacturing module.

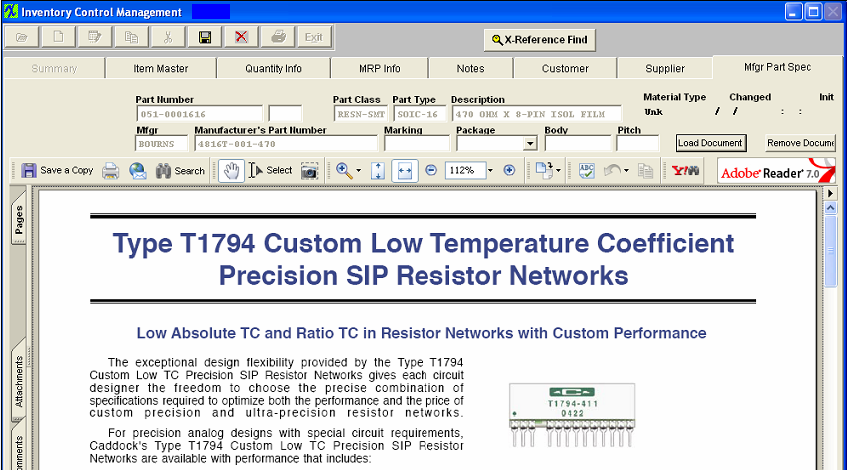

After defining the location for the document, the document is available for viewing, as displayed

Scroll bars: The bars at the bottom and side of the picture allow viewing of the parts of the image that are outside the window’s display. This allows detail viewing of large drawings.As soon as you enter the module, Acrobat will load.The user may load a PDF file to the Mfgr Part Spec tab. This allows users access to whole textbooks from within MANEX.PDF files can be drawings, images, CAD files (as printed to a plotter), and multiple pages of mixed text and graphics.Users may also print these PDF files from MANEX.

PDF and Image files:

PDF and Image files used in the MANEX system should be placed in the server, where all users have access to them. These files are used in the Product Data Management, Inventory, Customer and Supplier Contact programs. We suggest that the users create an additional directory, called "Images" under the MANEX System directory on the server. So then under the Main MANEX system directory, there would be the \apps, \dbfs, \images and \reports subdirectory.

If the user is going to make extensive use of the image capability, they may wish to further provide subdirectories under the Image. These might be called "inventory", "PDM", "photos" etc. These files could, in turn, have further subdirectories. For example, under \manex\images\inventory there might be one for each class of part. Or one for make parts and one for buy parts. Under the PDM group could breakdowns by customer.

Such organization will make it much easier to find files when it is time to update them. MANEX can accommodate file path-names up to 100 characters long.

While viewing a PDF document, the user may scan and zoom throughout the document. Items may be copied from it, and the document can be printed from the MANEX program, as long as there is a default printer assigned to the workstation.

|

| 1.4. How To ..... for ICM Mgmt |

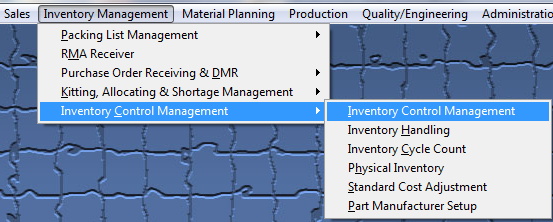

| 1.4.1. Find an Inventory Control Record |

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

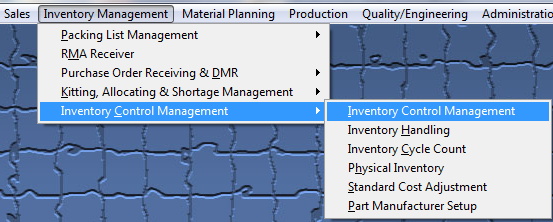

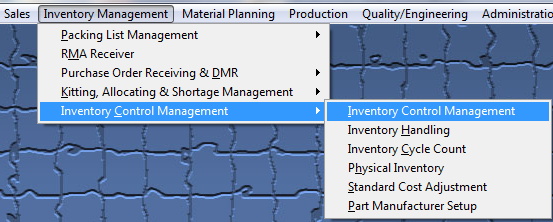

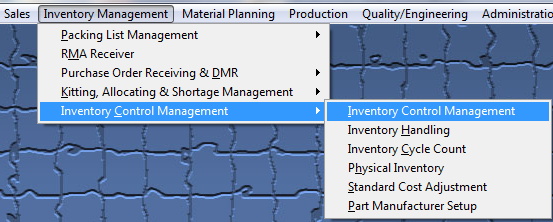

The following screen will be displayed, select Inventory Management/Inventory Control Managment/Inventory Control Management.

|

|

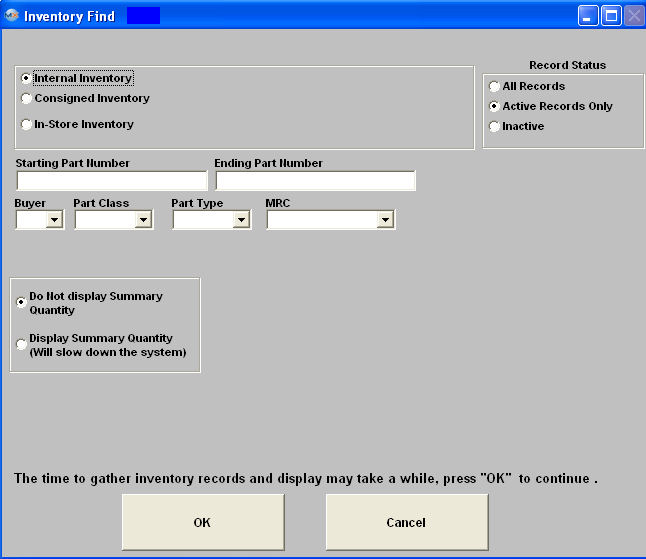

The following screen will be displayed:

Inventory Find Prerequistes

In order to Find items with certain characteristics or parameters using the Inventory Find Screen, the items must have been entered in the Item Master with those characteristics. Listed below are the pre-requisites for doing 3 different kinds of Inventory Finds:

- Internal items must be in the system to be found.Searches for parts between a Starting number and Ending Part Number must include the prefix and any dashes or special characters.

- A part cannot be found in an “In-Store part find” unless it has been set up with an In-Store warehouse and supplier in the Item Master Quantity Info. screen.

- A Consigned record cannot be found for an item until the Customer has been entered and the item has been given a Customer Part No. in the Item Master Customer Reference screen.

When the user does an Inventory Find, in order to speed up the process the user may eliminate the quantity display.

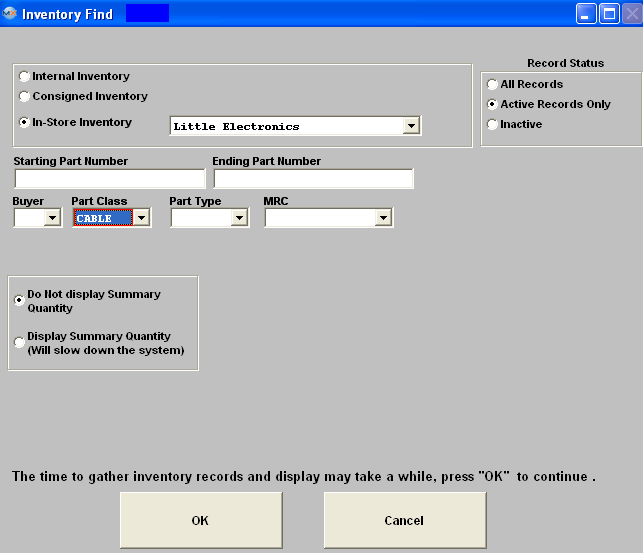

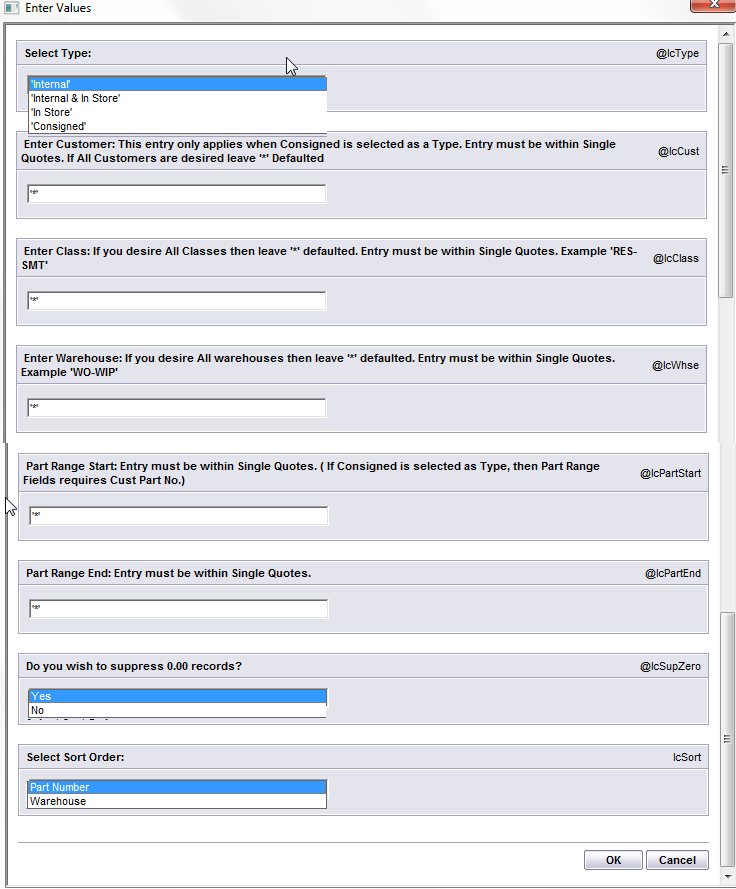

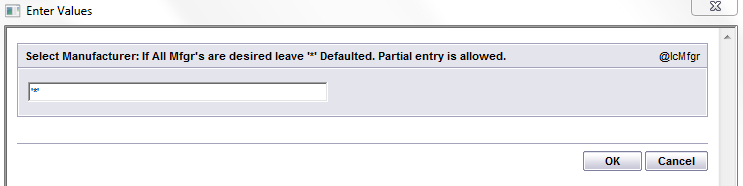

Depress the Find button. The following screen will display:

Note that the default is for the Summary screen to NOT display the quantity.

If the user wants to have the quantity display on the Summary screen, highlight the desired part number and right click your mouse. The quantity will display for the one part number:

If the user wants the entire summary screen to display all of the quantities, then select the Display Summary Quantity radio button.

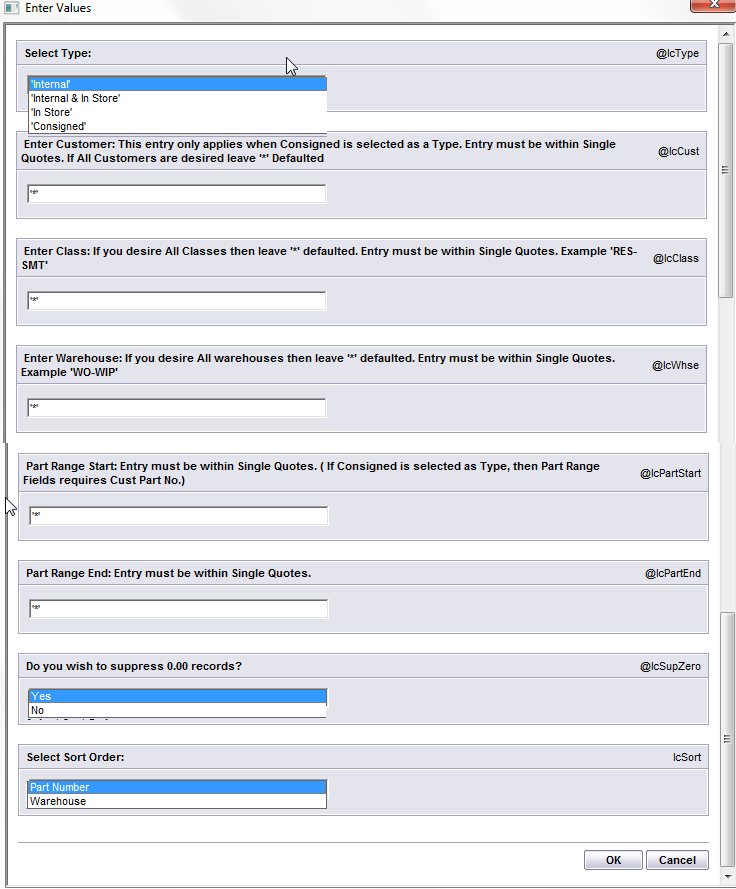

Inventory Find Search Field Definitions

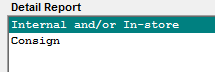

- Internal Inventory – Products, Parts and Assemblies purchased, received, stocked, issued and shipped using standard in-house internal item numbers. These numbers are required and serve as the basis for creation of Consigned and In-Store parts. Just clicking on OK with the default selections shown in the preceding Find Screen will bring up all Active internal inventory parts in the Item Master Summary screen.

- Consigned Inventory – these records are created every time a Customer Part Number is entered in the Item Master Customer Reference screen. These records are used to enter Customer requirements (Approved Vendor List) and preferences (choices within the Approved Vendor List) for Manufacturers for a given Part Number.It is also where Customer-owned item inventory levels and locations can be seen.

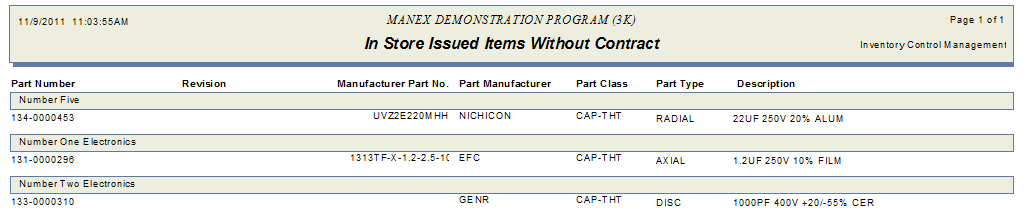

- In-Store Inventory – any internal item can be setup with an In-Store Inventory for a Supplier under contract to supply that item. In-Store items are setup in the Internal Inventory Item Master Quantity Info screen and can be viewed individually in that screen or as a group by supplier in the Summary Screen as the result of an Inventory Find by In-Store Inventory.

- Starting Part Number and an Ending Part Number

- Enter all prefixes, dashes, spaces and alpha characters to show the entire number.

- Enter first and last Part Number of a series for those and all items numbered between.

- Enter a desired single item in the 1st box and hit return to select only that record.

- Assigned Buyer will bring up all items assigned to that particular Inventory Buyer.The Buyer assignment is made in Part Class and Type System Setup Defaults or in the Item Master.

- Part Class and/or Part Type will bring up only those items that match all entries made.Both Part Class and Part Type must be specified to bring up any items.

- Do not display Summary Quantity radio will by-pass the quantity calculation.

- Display Summary Quantity radio will open up another selection "Total On Hand Quantities"

- Total On Hand Quantities will bring up only items with matching inventory quantities.The user may choose from Total Quantity on Hand, Quantity on Hand > 0, or Quantity on Hand = 0.

- Record Status allows selection of All, Active Only or Inactive Only item records.

Tips on Using the Inventory Find Screen

- Selection of at least one parameter will reduce the time to retrieve the information.

- In-Store Inventory searches require that a Contract be entered in order to select a Supplier. (Please refer to Manex / Material Planning / Purchase Setup / Supplier Contract Management and the Supplier Management manual).

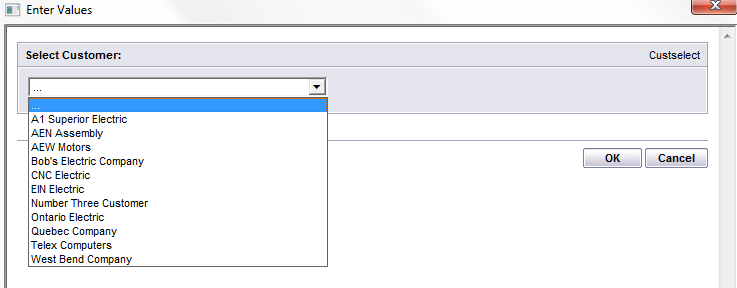

- Consigned Inventory searches show Customer-specific information (such as Approved Vendor List information) as well as Consigned Inventory On-Hand Quantities.

- If no information is selected in a Find operation, try using broader or fewer selection criteria.

Combination Searches

Combinations of search parameters may be made for further filtering of the Inventory Item Master files to see item(s) of interest. For instance, selecting the items on the example screen will find all ACTIVE, In-Store Inventory for "Little Electronics" with the Class “CABLE”.In-Store Inventory Searches are Supplier specific whereas Consigned Inventory searches require entry of a Customer in order to initiate the search.

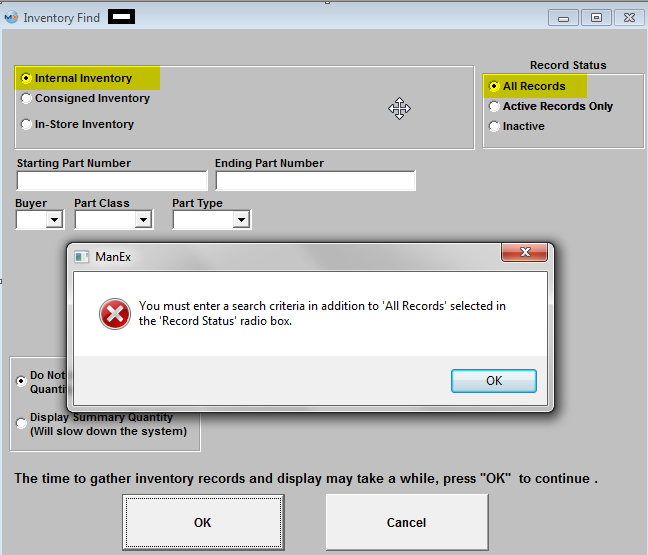

If user selects to find "Internal Inventory" "All Records" they will get the following message "You must enter a search criteria in addition to "All Records" selected in the "Record Status" radio button. This is because the inventory file may be very large so the user is encouraged to narrow down their selection. If they want all they will need

to narrow it down by another criteria, or the system will take way too long to to bring the screen up and put a burden on the network and the SQL server.

Inventory Find Example

The screen shown below is to illustrate Inventory Find results from selecting Internal Inventory, a Part Class of CAP-SMT, a type of 0805, Total On Hand Quantities of Qty on Hand = 0, and Record Status of Active Records Only

The first tab (Summary Tab) is used to display the results of an Inventory Find. The remaining Tabs will then display detail information for any item selected (highlighted) in the Summary screen. If no items have yet been entered in the system or copying an existing part is not needed, it is not necessary to populate the Summary screen by doing an Inventory Find.

If user has the internal inventory screen open as well as the customers inventory screen open, the customer name will be displayed at the top of the page. So when switching between the two screens user will easily be able to determine which screen they are in.

|

| 1.4.2. Find an Inventory Control Record Using the X-Reference Find |

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

The following screen will be displayed, enter Inventory Management

|

|

The following Screen will be displayed:

|

This button will take the user to a screen, where they can make a selection by what ever criteria needed by choosing (internal part number, mfgr part number, customer part number, supplier part number, or description) to search. |

The following screen will be displayed:

The user can enter partial string and search is not case sensitive. After system finds parts in response to the search (inactive parts will be highlighted in Purple), the user can make a selection by checking on one of the check boxes located at the left. If system was unable to find the exact match, a message will appear up in the right hand corner (in red) to let the user know that the part did not exist in the item master but the following are similar parts found.

The user can choose to Select Without Exit; Select & Exit; or Exit Without Selection.

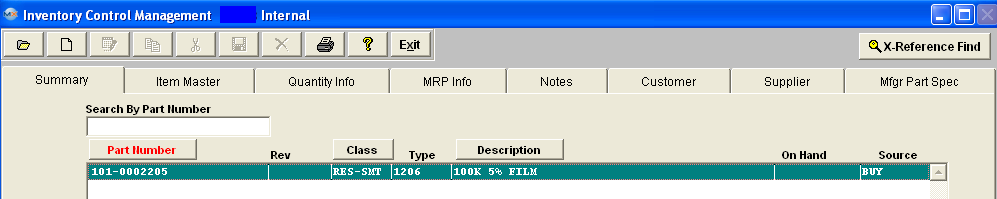

To Select user must check the box to the left of the Part Number. If user Selects a Part Number (Internal or Customer Part Number) then depresses the Select and Exit button, the part will be displayed in the Summary Tab as shown below.

|

| 1.4.3. Add an Inventory Control Record |

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

The following screen will be displayed, select Inventory Management/Inventory Control Management/Inventory Control Management

|

|

The following screen will be displayed:

Following a logical sequence when adding items into the Inventory Master not only eliminates lost time due to continual back-tracking, but ensures that decisions will be made in a sequence which will support the data entry process.The sequence shown below is for adding products, parts, assemblies, subassemblies or Phantoms to the Item Master after completion of System Setup.

-

Search whether item already exists. Use Find an Inventory Control Part to search the existing database along with the archived database, to verify that the items to be added do not already exist.

-

Verify Available Class and Type. Use Find an Inventory Control Part by Class and Type to verify that the item to be added will fit into the existing Class and Types . Refer to System Setup, Inventory Part Class if a new Part Class or Type and the corresponding Data Entry Defaults must be added.

-

Is Customer available? If the items to be entered will have a Customer-Specific Approved Vendor List (Approved Vendor List), then verify that the Customer is in the database using Customer Information. Add the Customer Information if it is not there.

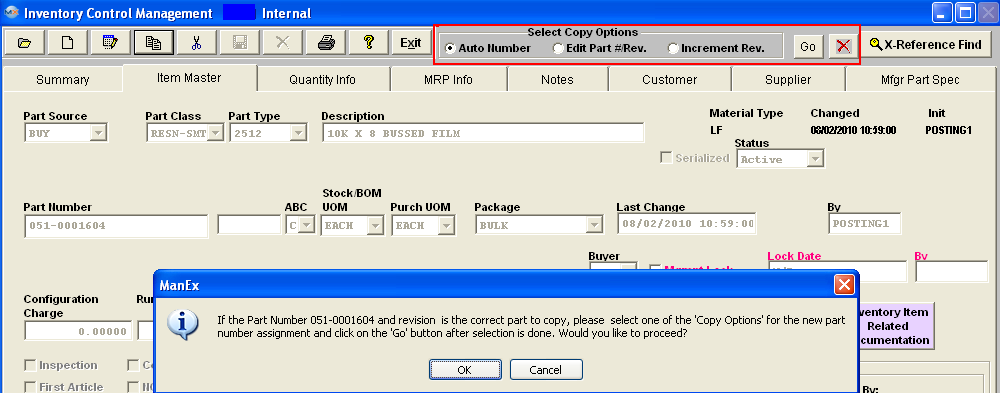

-