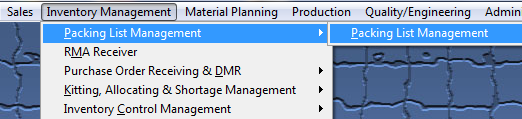

| 1. Inventory Management |

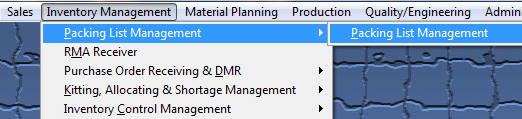

| 1.1. Packing List Management |

| 1.1.1. Prerequisites for Packing List Mgmt | ||||||

Prerequisites for Entering a New Packing List:

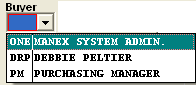

After activation, "Packing Slip" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

The packing normally refers to a Sales Order, which includes the part numbers and description of the material being shipped. Also, the Sales Order must have been approved for shipment by placing a check in the Order Acknowledgment box. There is also provision for a stand-alone packing list (manual invoice). The Number System Setup must be defined for either automatic or manual packing list numbers. If the order involves serial numbers, such numbers must have been set up in Work Order Serial Number Control.

|

| 1.1.2. Introduction for Packing List Mgmt |

The Packing List Module is used to record the details of shipments to customers. The Packing List is created when the user has completed assembly, or pulled parts for an order and the order is scheduled to ship. There is also provision for a stand-alone (manual invoice) packing list. Note: In order to initiate the packing list, the Sales Order MUST have the Order Acknowledgment box checked, indicating that it is OK to ship the product to the customer. For further Detail See Article #1150. |

| 1.1.3. Fields & Definitions for Packing List Mgmt |

| 1.1.3.1. Packing List Tab | ||||||||||||||||||||||||||||||||||

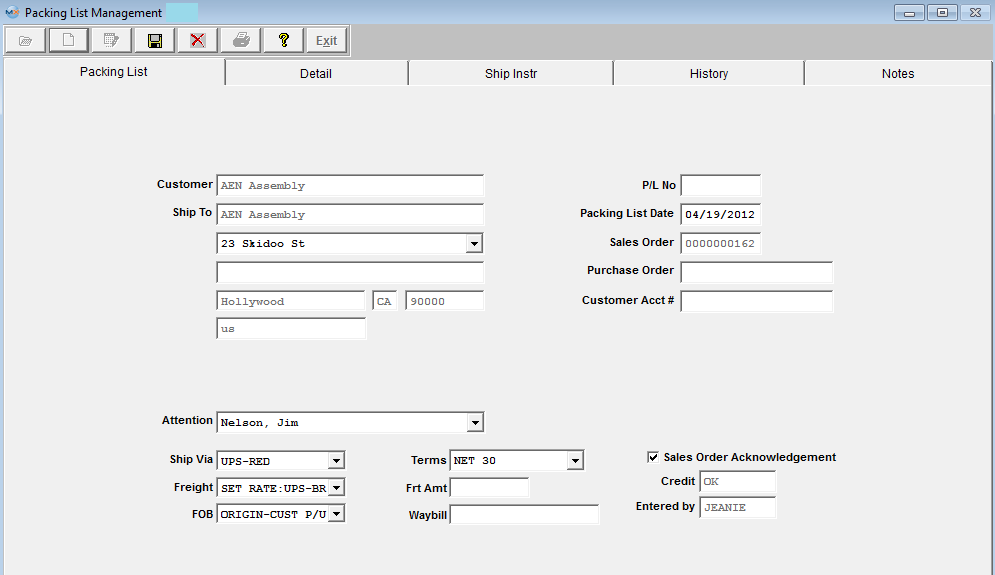

Packing List tab field definitions

|

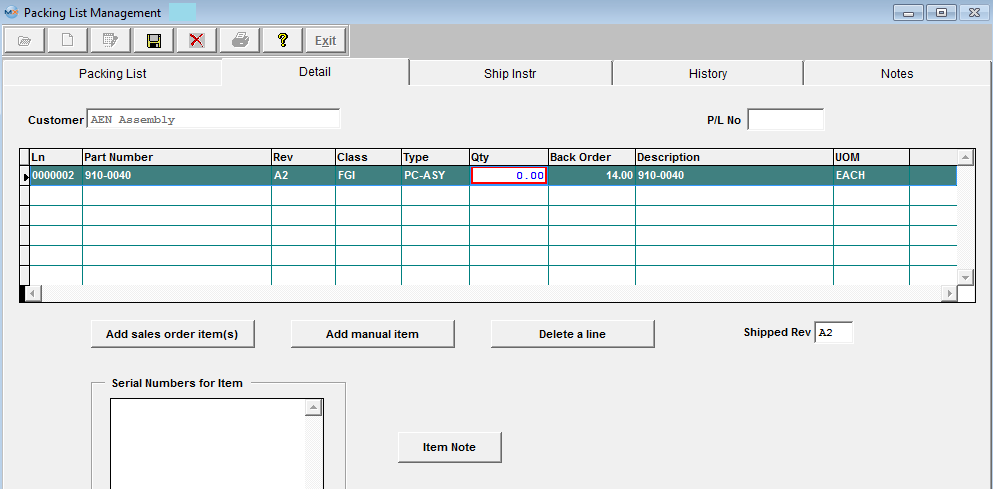

| 1.1.3.2. Detail Tab | ||||||||||||||||||||||||||||||||||||

Detail tab field definitions

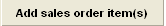

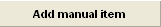

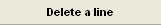

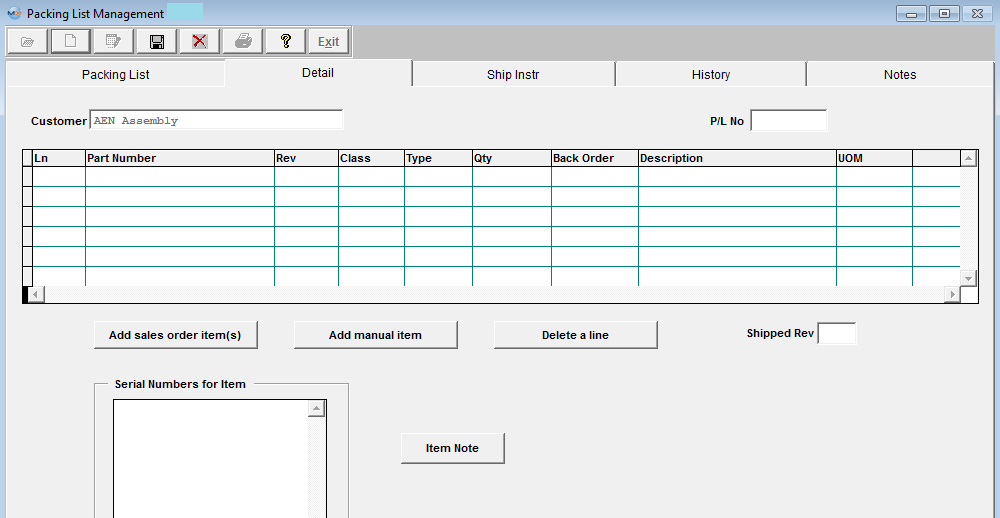

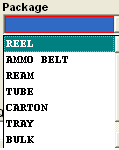

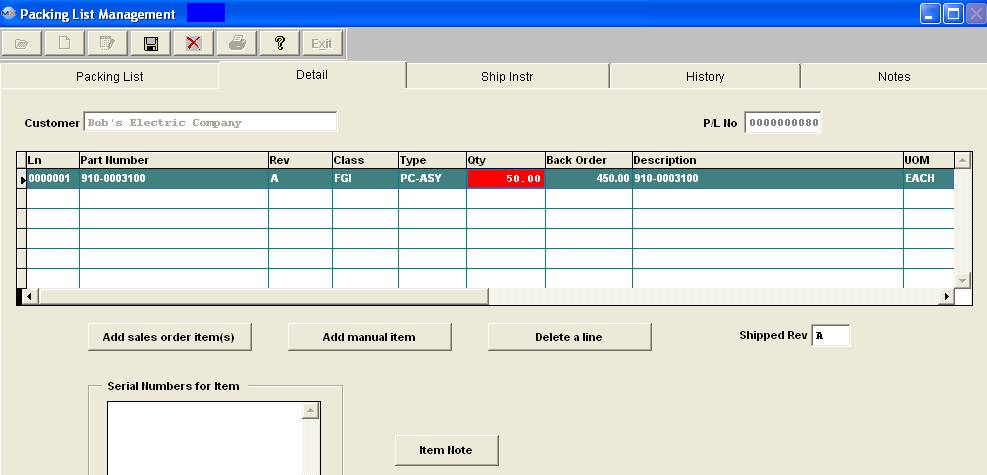

The name of the Customer. The number assigned to the packing list. The Sales Order Line item number. The number the user has assigned to the product. The revision number applicable to the Part Number. The classification to which the Part Number belongs. The number of units shipped with this Packing List. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. The number of units still not shipped. The description of the product. The unit of measure for the product. If the Packing List is revised, the revision number will appear in this field. Buttons

If there is a Sales Order associated with the shipment, depressing this button will display the Sales Order line items for the user to select for this shipment. Depressing this button will allow the user to add a manual item to the Packing List. Highlighting a line item and depressing this button will delete the line. This button is depressed to enter Sets of Serial numbers to ship For the line item highlighted, this field is for any applicable notes.

|

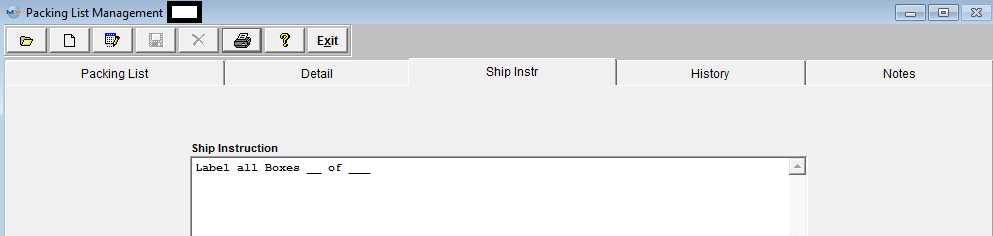

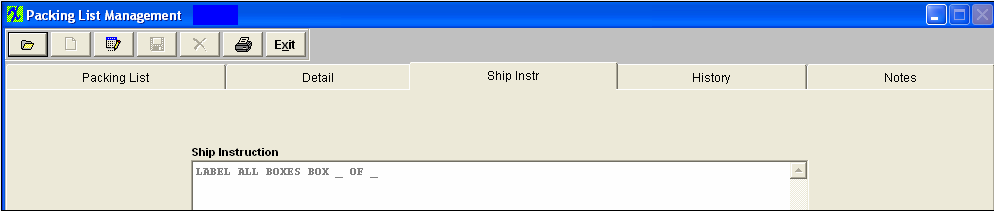

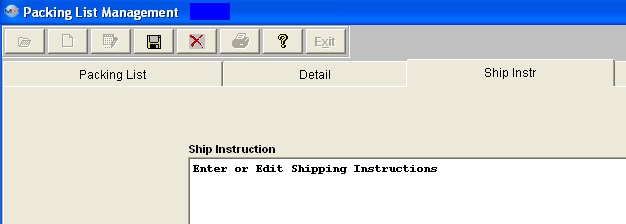

| 1.1.3.3. Ship Instruction Tab |

Shipping Instructions Tab Detail This tab is used for special instructions regarding the shipment. This note will be displayed on all Packing Lists created for the same Sales Order.

|

| 1.1.3.4. History Tab | ||||

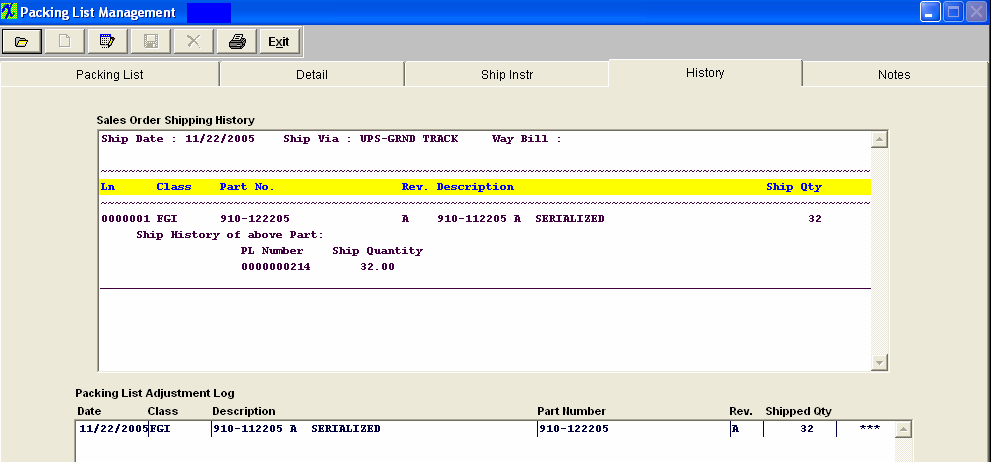

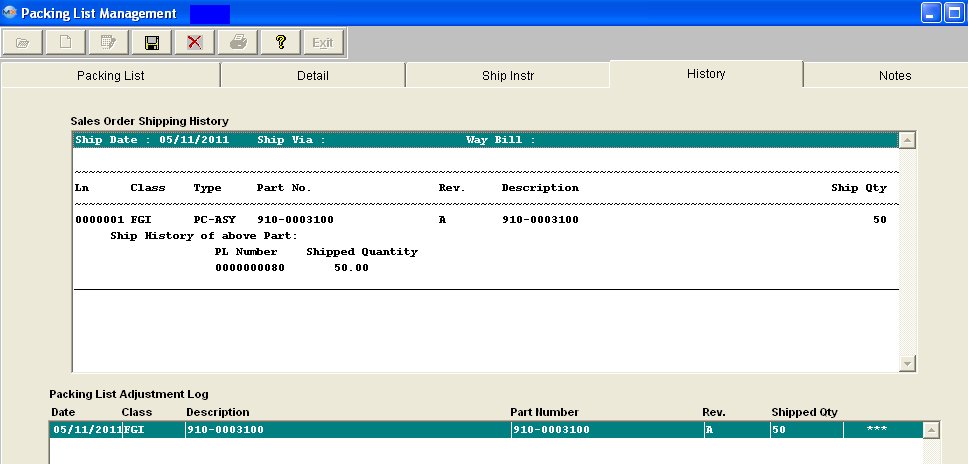

History tab field definitions

This section displays the Ship Date, Ship Via, Way Bill number, Line Number, Class, Part No. Rev., Description and Ship Quantity for this packing list.It also displays the Ship History of the Part by displaying the Packing List number and the Ship Quantity. This section displays any packing list adjustments for this packing list and details the Date, Class, Description, Part Number, Rev., and Shipped Qty. |

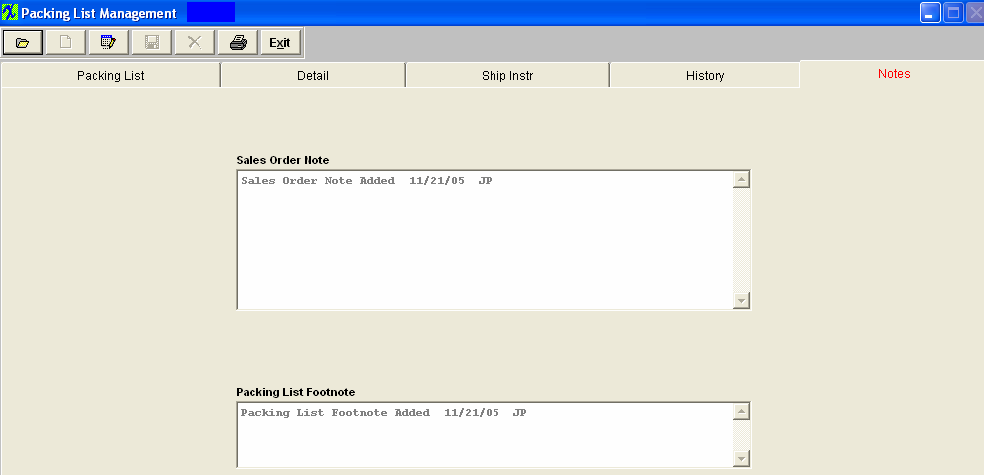

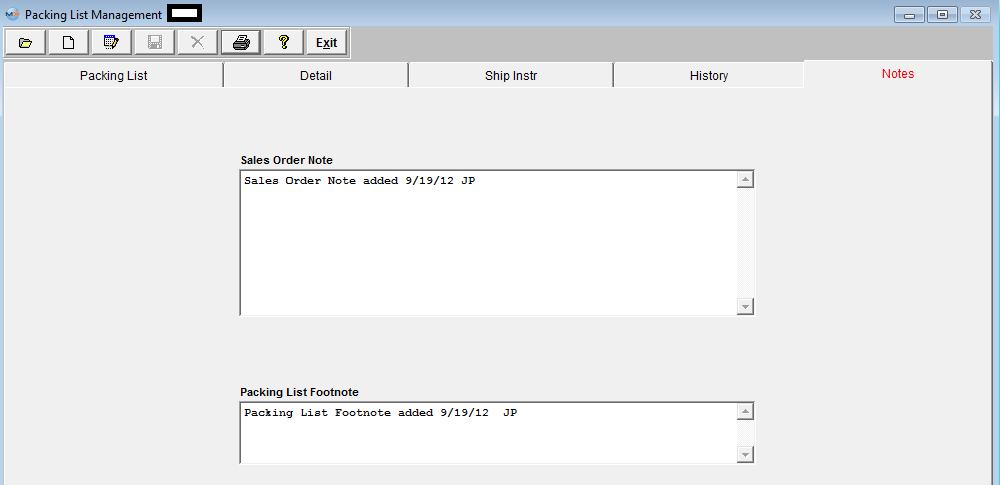

| 1.1.3.5. Notes Tab | ||||

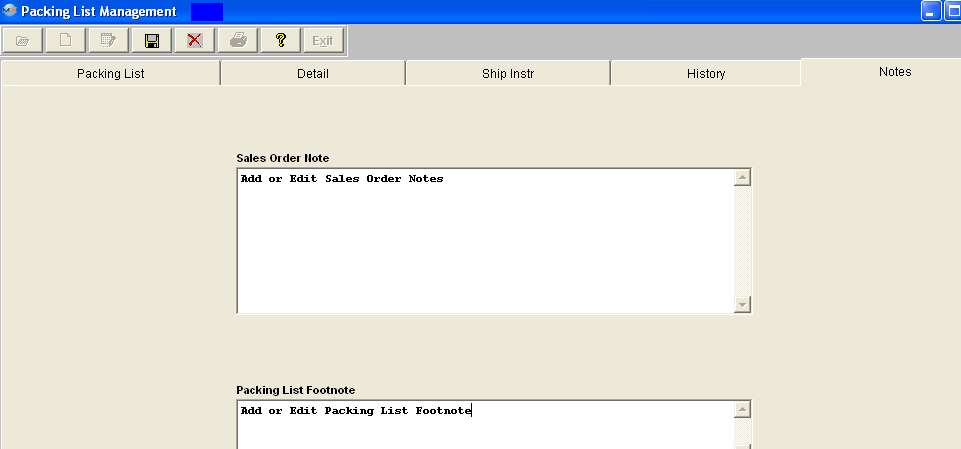

Notes tab field definitions

This section will display any note pertaining to the Sales Order. This note will be displayed on all Packing Lists created for the same Sales Order. This section is for any packing list footnotes which will appear when the Packing List is printed. |

| 1.1.4. How To ..... for Packing List Mgmt |

| 1.1.4.1. Find an Existing Packing List | ||||||||

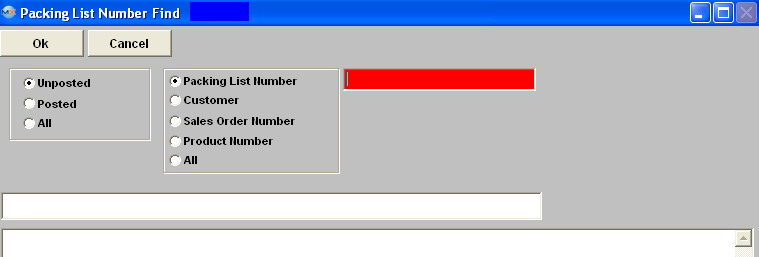

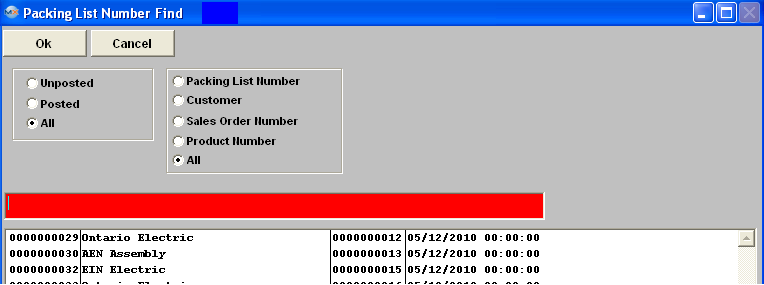

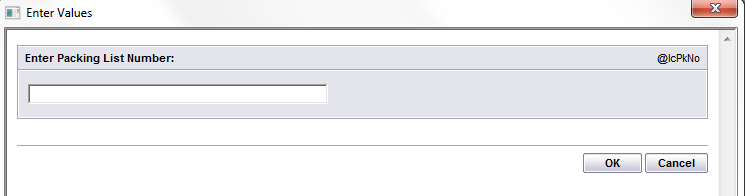

The following screen will be displayed.

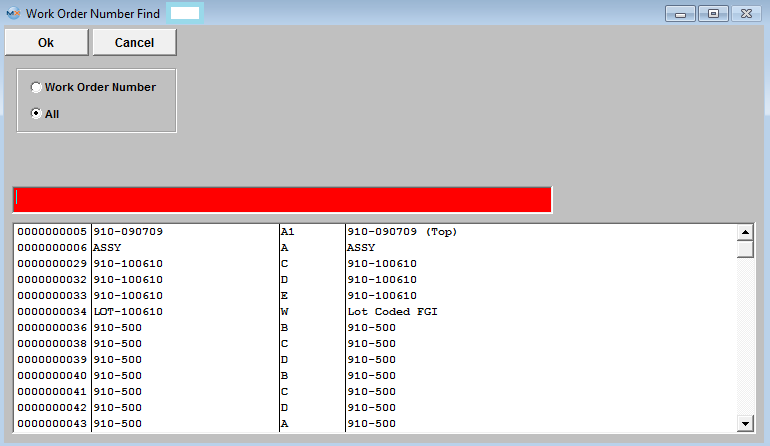

Depress the Find action button. The following selection screen will be displayed.

If user selects ANY of the Filters and Find by All - a screen will appear listing all the Packing List filtered by the selection, in numberical order, along with the Customer name. Once you have made your choice, the information will be displayed as follows

|

| 1.1.4.2. Add a New Packing List | ||||||||||||||||

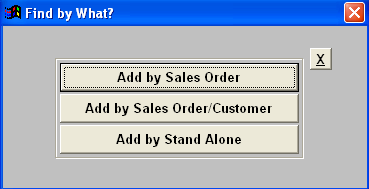

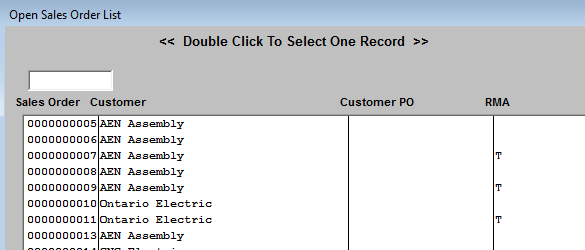

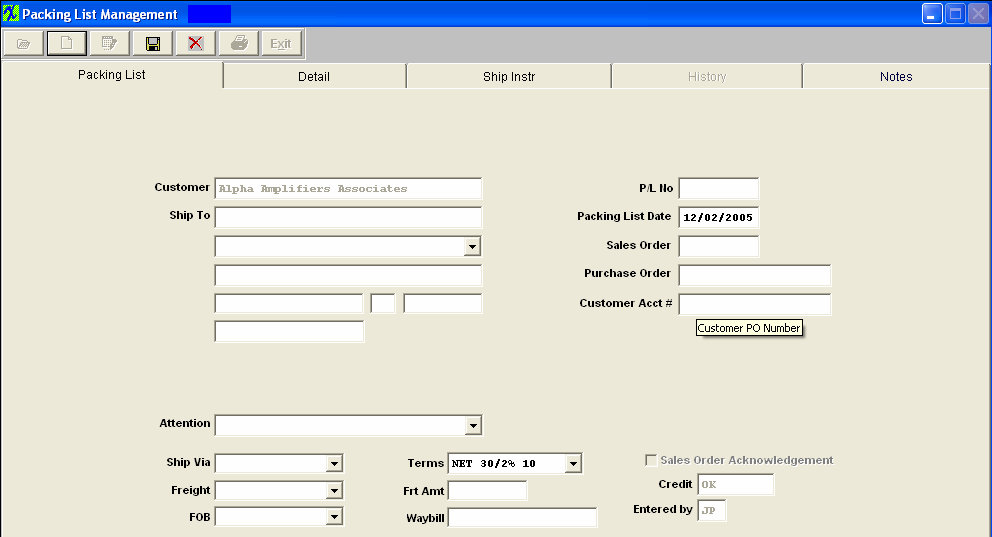

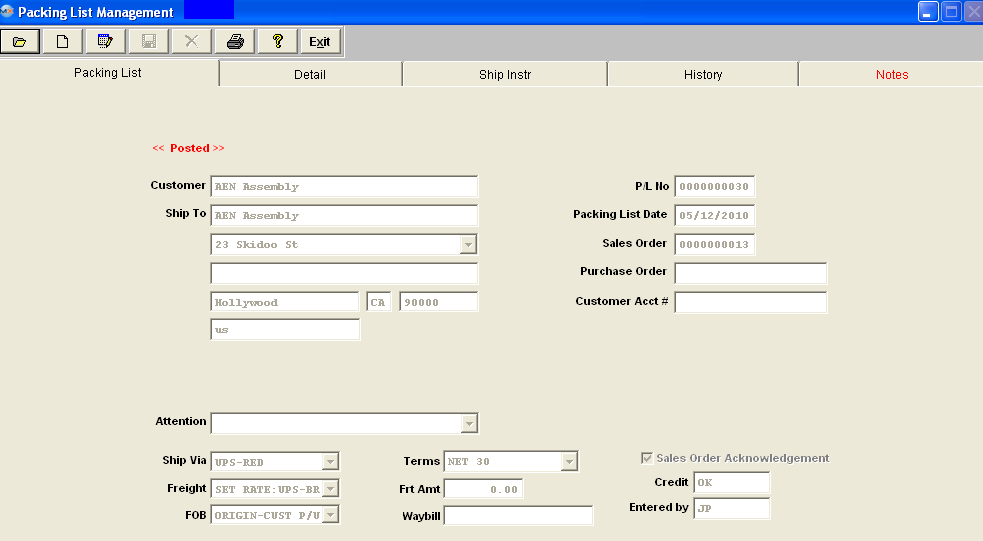

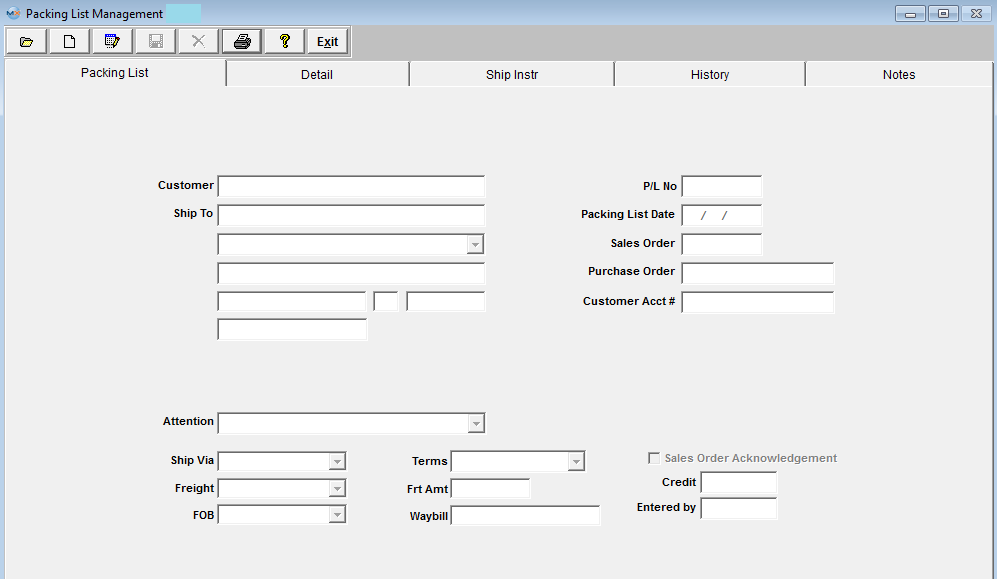

The following screen will be displayed. Pressing the Add Button displays the following sequences:

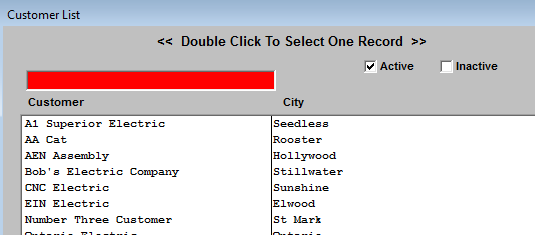

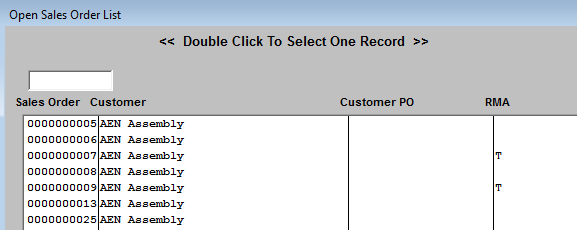

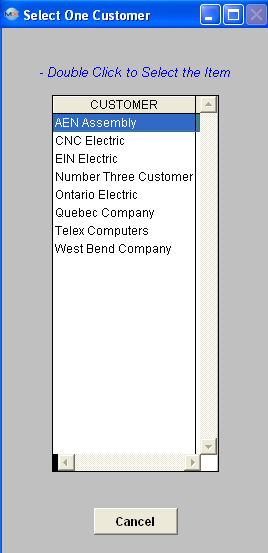

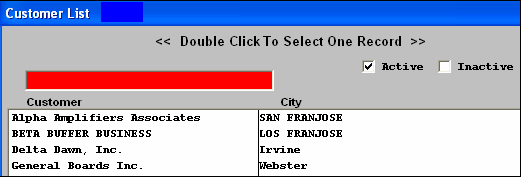

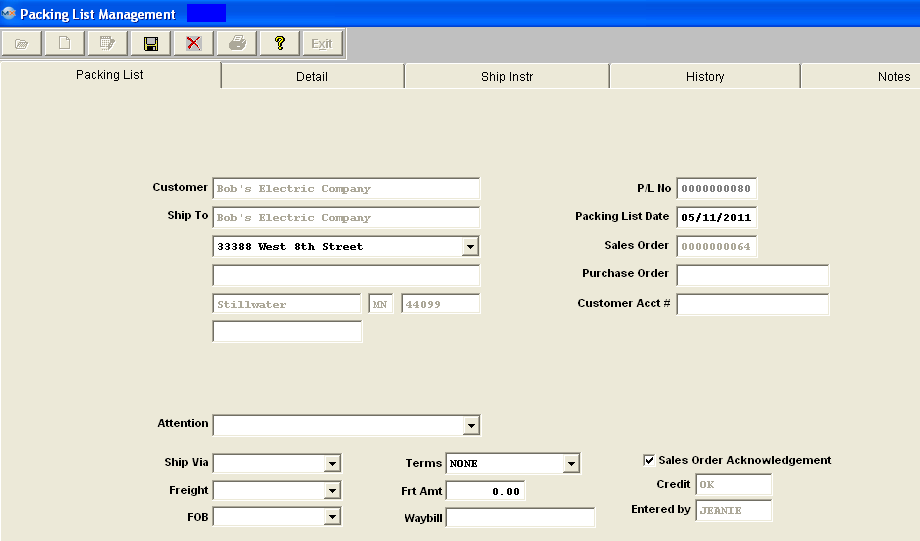

If the user elects to add by Sales Order, a screen appears listing Open Sales Orders in numerical order, along with the Customer Name, Customer PO, and if applicable a "T" under the RMA coulmn. The user selects the Sales Order number by either entering it into the box, or scrolling down the list and clicking on the selected order. If the user elects to add by Sales Order/Customer, a screen appears listing Customers. Select Active or Inactive Customers by checking the appropriate box. The user selects the customer by either entering it into the red box, or scrolling down the list and clicking on the selected Customer. Then a list of all of the selected Customer Sales orders are shown in numerical order, along with the Customer Name, Customer PO, and a "T" for an RMA (If applicable). The user selects the Sales Order by either entering it into the box, or scrolling down the list and clicking on the selected order. If the user elects to add by Stand Alone, a screen appears listing all Customers. The user selects the customer by scrolling down the list and clicking on the selected Customer. See procedures below to Add a Stand Alone Packing List (Manual Invoice). Once the Sales Order selection has been made, the Packing List screen is popluated with the appropriate data based on the default shipping destination established for the customer selected:

If Manual is selected for Packing List numbers in Number System Setup user will need to enter P/L No. If the customer has multiple ship-to addresses established, then pressing on the down-arrow button to the right of the field will display alternate shipping destinations. Selecting an alternate shipping destination will cause the default values shown on the screen to change and match those of the selected destination. Move cursor to the Frt Amt (Freight Amount) field. The user may then enter the amount of the freight charges for the shipment. (These may also be entered during the invoicing, if the freight amounts are not yet known). The user may also enter the Waybill number. This is the tracking number used by the freight carrier to identify and track (and bill) the shipment. The Ship Via, Freight and FOB fields are populated with the default information from the customer ship-to files, but the user may select alternate actions by pressing on the down-arrow on the right side of the field. (The choices shown at this point must have been established in the System Setup/Sales)

After completing the Packing List information screen, the user clicks on the Detail Tab

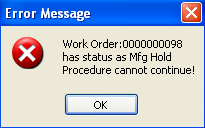

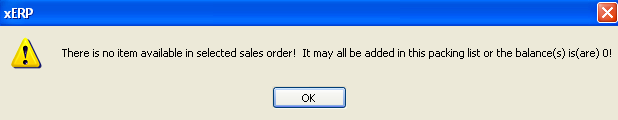

In this screen, the user defines the material to be shipped. The user may choose from one of the directive buttons to proceed: If the user has selected the Add Sales Order Item(s) option, and user receives the following message, it may be due to the status of the line item on the SO. If the line item Status on the Sales order is Admin Hold or Mfgr Hold you will receive this message when creating the PL.

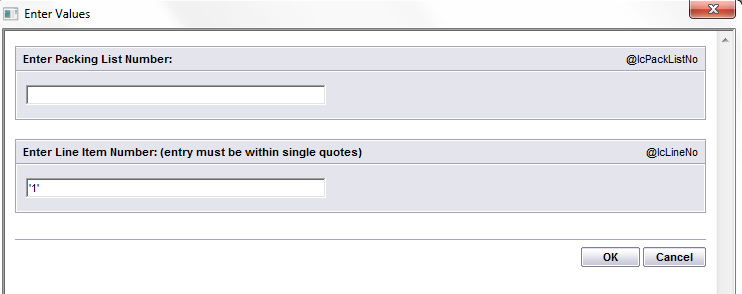

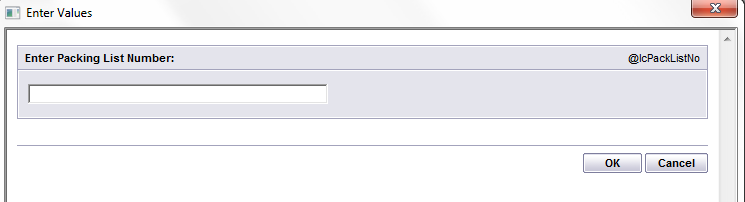

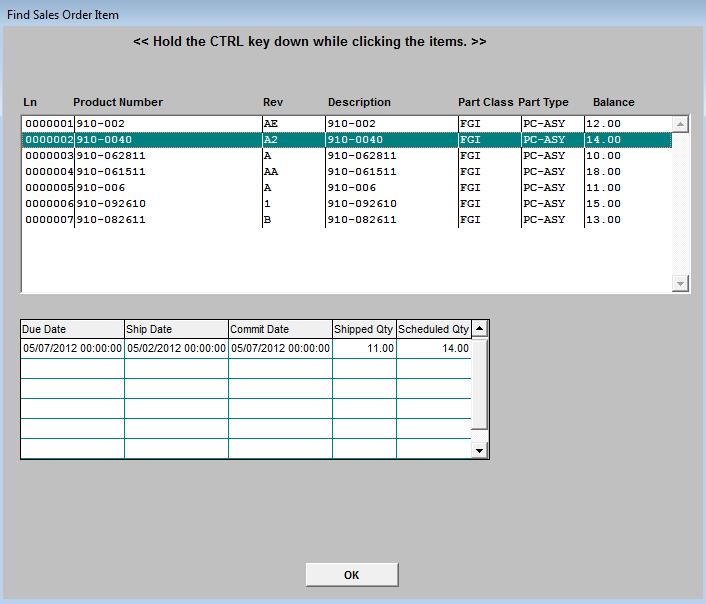

If the user has selected the Add Sales Order Item(s) option, the following screen will appear: Note: Each item defined on the Sales Order will be displayed on this list for user to select from. The user can highlight and add one item at a time, or highlight and add more than one at a time. If the sales order has many lines and only a few are NOT being shipped, the user can add them all, and delete the lines that do not apply.  Highlight the appropriate Sales Order line item. Depress the OK button and the sales order line item(s) will populate the detail screen.

The user then completes the quantity column with the amount of product shipped for this packing list.

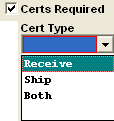

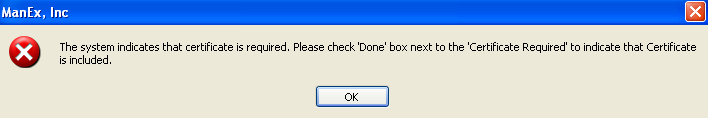

The following message will appear if the part requires a certificate and the "Done" box has NOT be checked. The packing list will NOT be allowed to be saved until checking off the certificate required "Done" box.

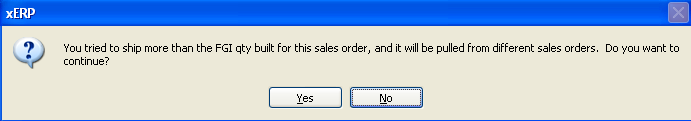

The following message will appear if the user is attempting to ship product out of FGI that was not originally transfered into FGI from a Work order that was associated to that Sales order. This is just a warning that you will be releaving stock that was transfered into FGI from a Work order that was associated to a different Sales order, and is asking the user if they are sure that is what they want to do? It does not hurt anything to answer yes, the only thing that might happen later down the road is the product that you had transfered into FGI from a different sales order has already been shipped against this Sales order or packing list.

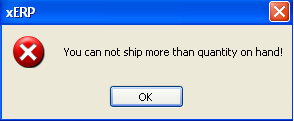

Depress the Yes button. If the user attempts to ship a product with no or not enough available inventory, ManEx advises the user and prompts to cancel the transaction.

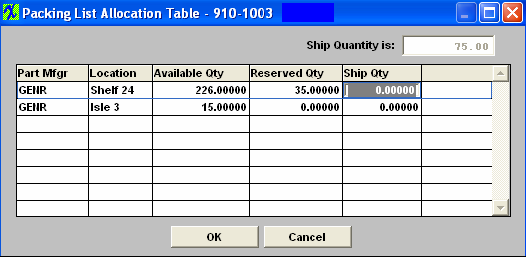

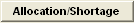

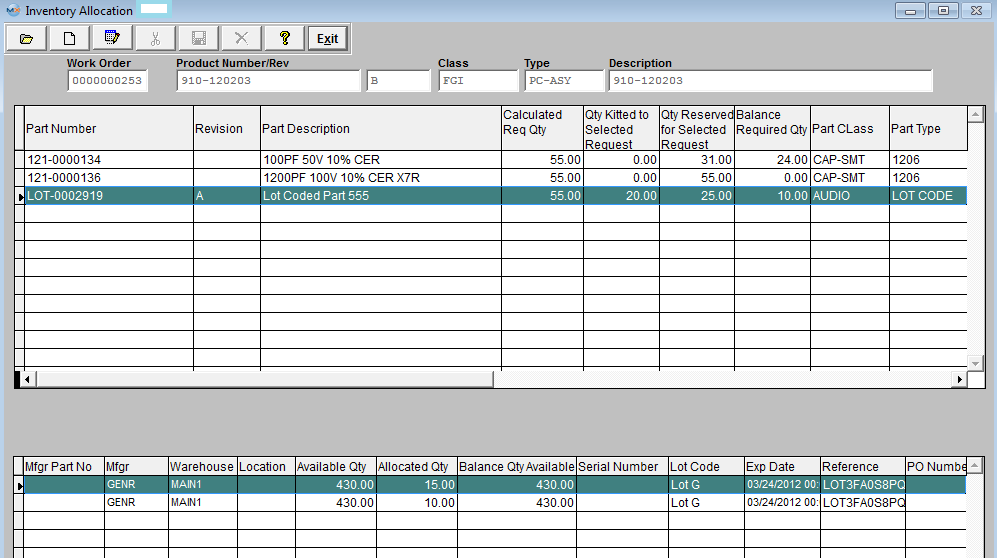

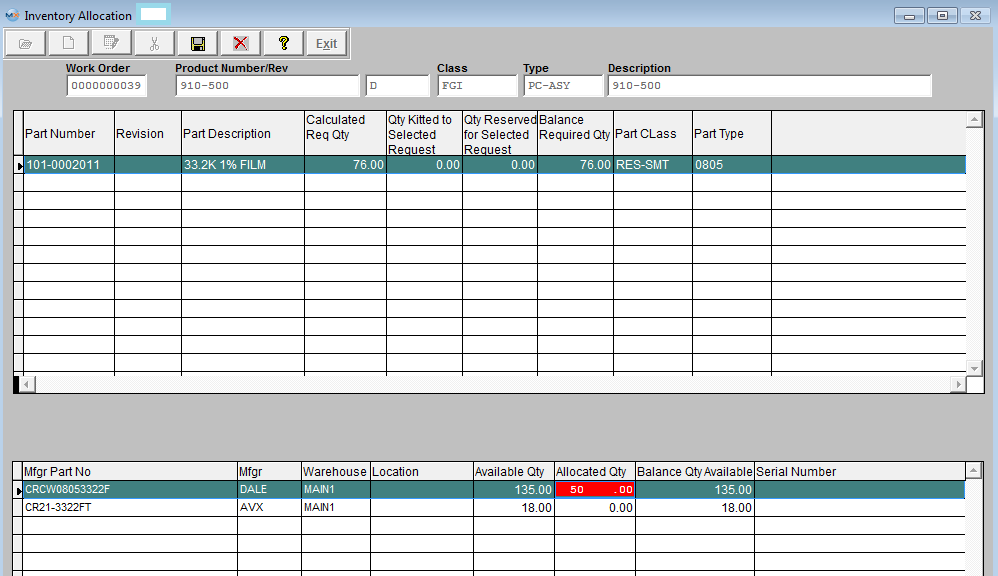

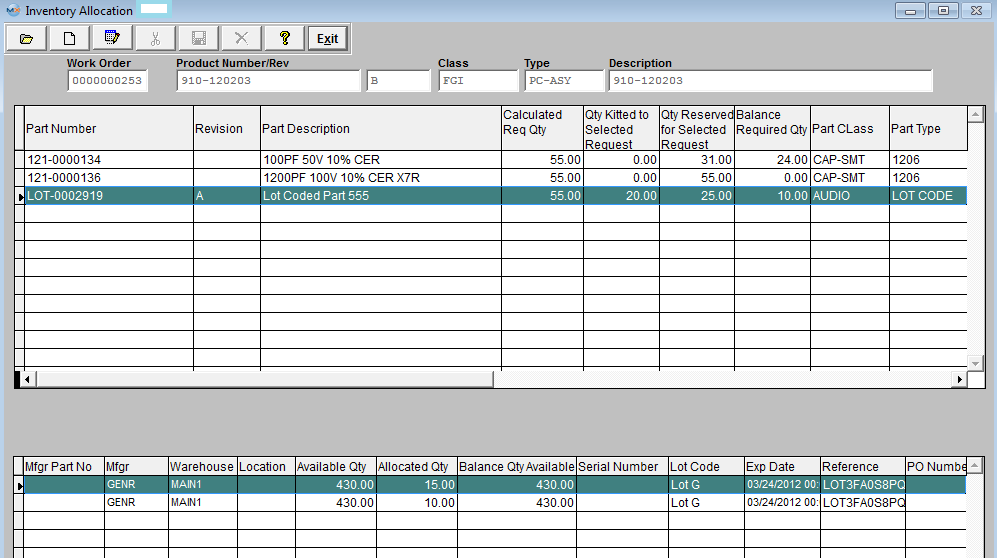

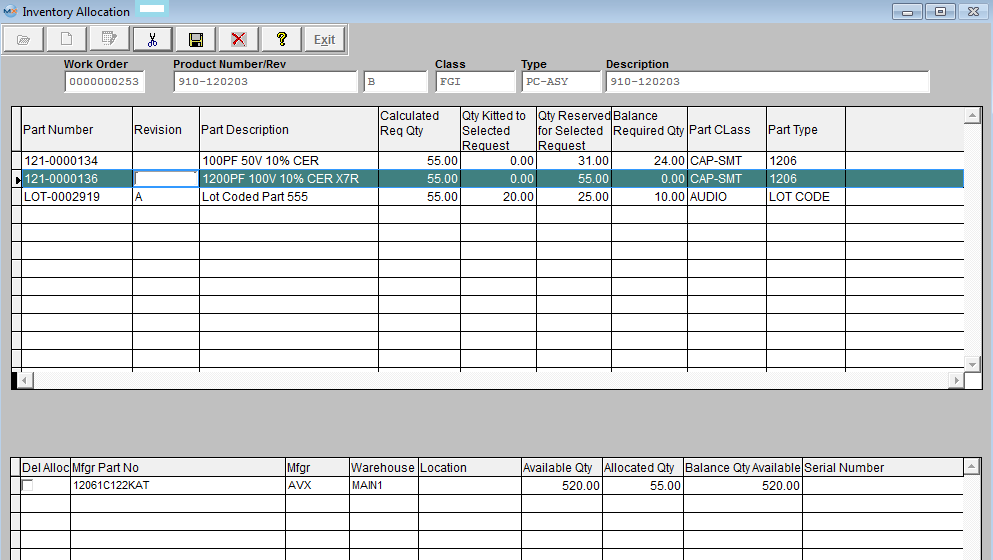

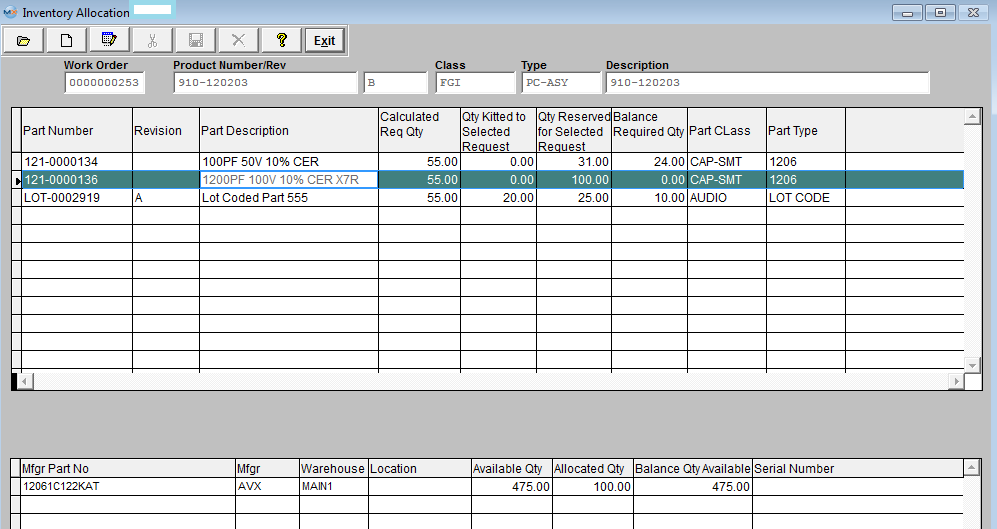

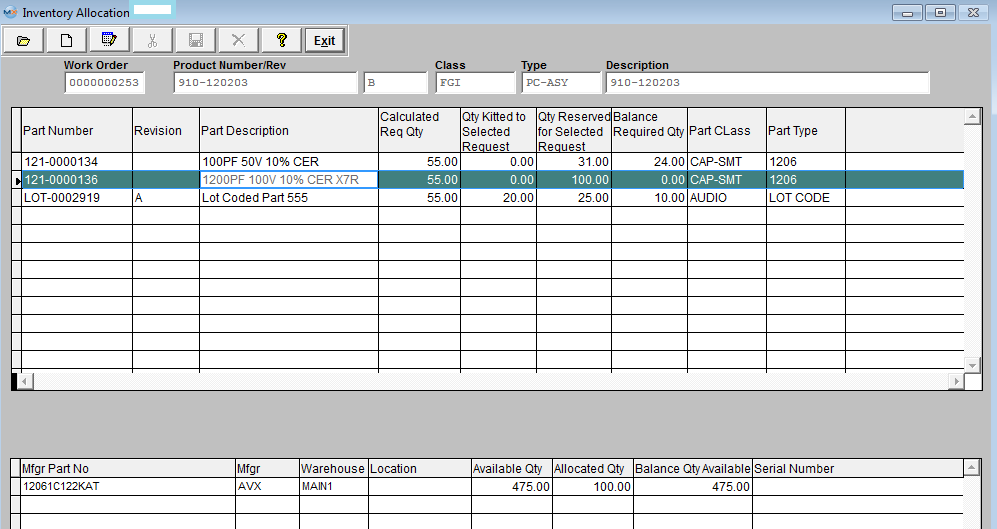

TIP Users may modify the appearance of the columns on the spread sheet by click and holding on the column header description, and slide the description to the right or left, then releasing the mouse button. The width of the columns may also be modified by click and holding on the right edge of the column header and sliding the border right or left. As the user completes a quantity shipped, ManEx produces an inventory allocation table displaying the available and reserved inventory on hand for the product being shipped if there is more than one location. If the Sales Order allocated product for this order, the quantity will be shown in the Reserved Qty column.

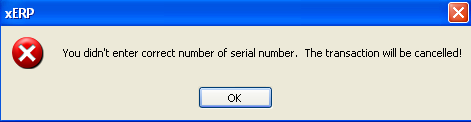

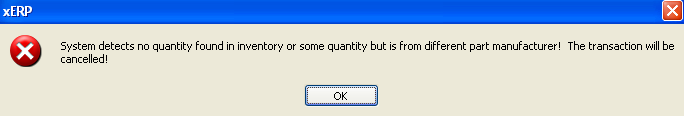

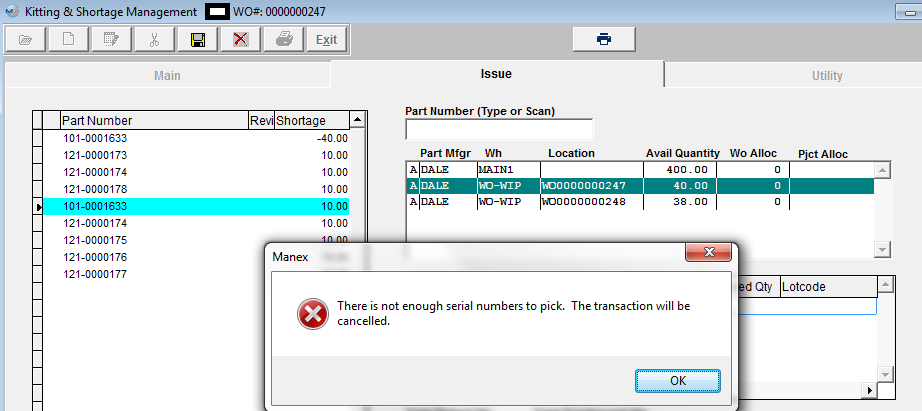

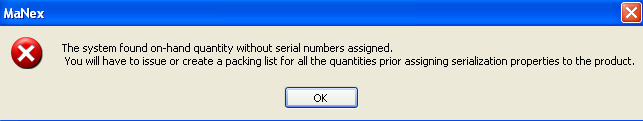

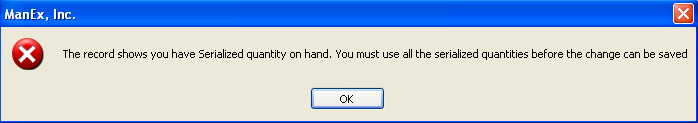

Enter Ship Qty. If the product and the work order were identified as requiring serial numbers and there are no products available in inventory with the appropriate serial numbers, the following message will display:

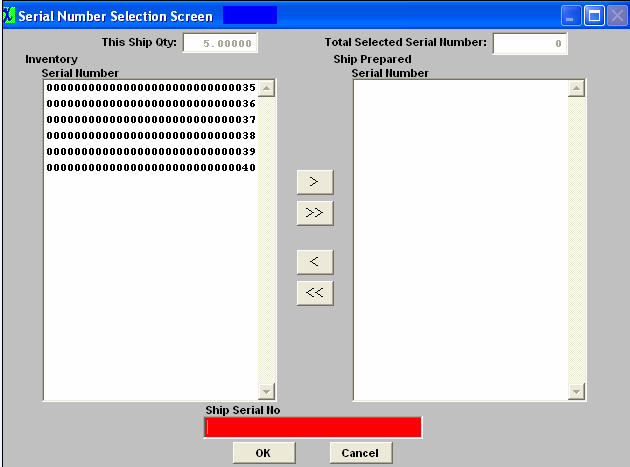

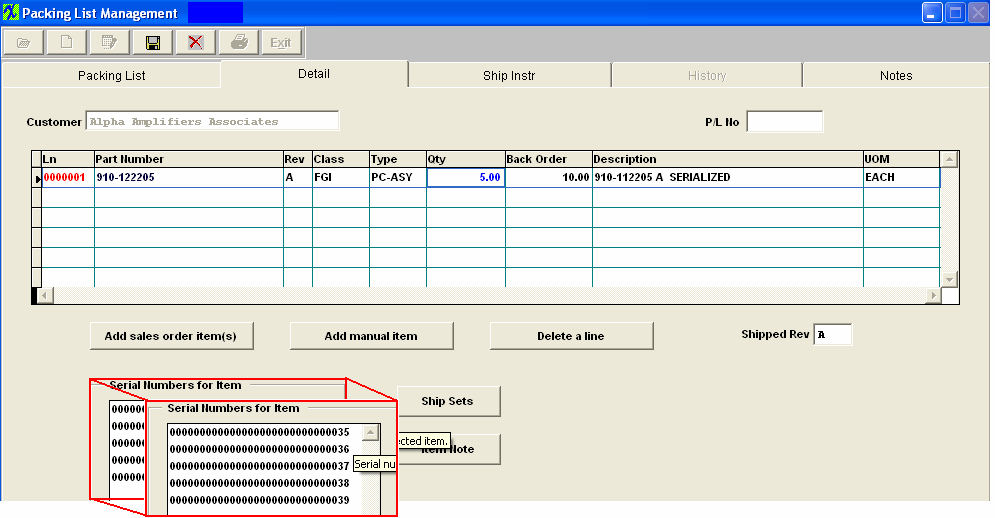

Depress the OK button. The transaction will be cancelled. If the product and the work order were identified as requiring serial numbers and there is product available in inventory the following screen will display:

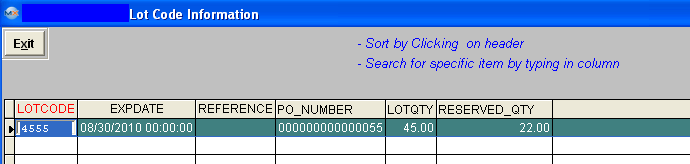

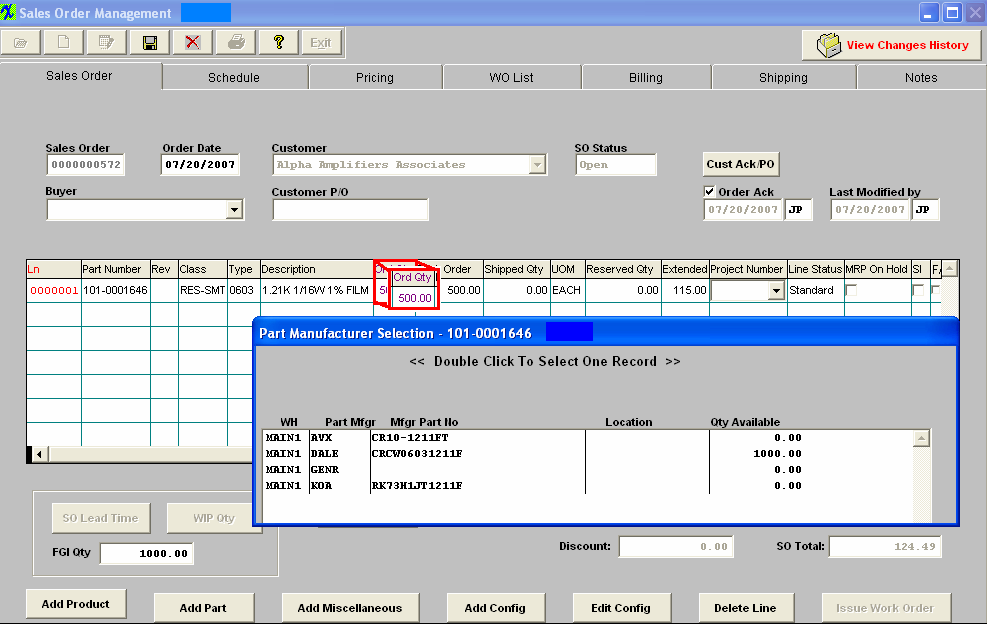

If user receives the following message when trying to ship out parts:

The user may return to the SO, depress the Edit button and double click on the Order Qty field. The available MFGRs will be listed and the users can make the needed changes.

Return to the Packing List module and the record can then be processed.

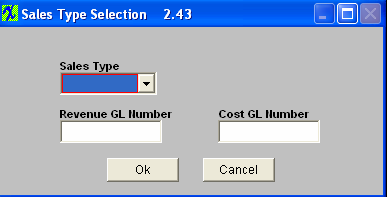

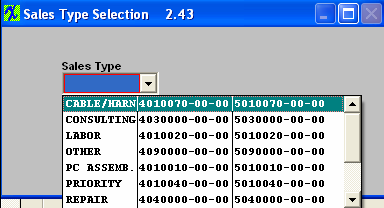

Depress the down arrow for Sales Type and the following list will appear:

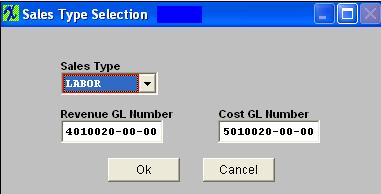

Highlight and click on the Sales Type of Interest and the following screen will appear:

The Revenue GL number and the Cost GL number will update. Note: When creating Stand Alone Invoices users should not select the same GL account number that is entered in the Actsetup for the Account Receivables. IF you do, then the resulting transaction will debit and credit both the sane GL account number. Depress the OK button. The user will be prompted for Quantity, Back Order amount, Description and Units of Measure. The user may enter notes of any length for a line item by highlighting the appropriate line item and then selecting the Item Note. If the user wishes to establish shipping instructions, then pressing on the screen tab Ship Inst will bring up the following screen. These notes will appear on all Packing Lists created for the same Sales Order.

Tabbing on the History tab will bring up the following:

This will give you the Shipping History of the Part highlighted in the Detail screen. In addition to special notes to the shipping department, tabbing to the Notes screen, there are two additional areas for notes: the Sales Order Notes, and the Packing List Footnotes. The Sales Order Notes will be maintained in the ManEx system for review by other users and will be displayed on all the Packing Lists created for the same Sales Order, and the Packing List Footnotes will be added to the packing list when printed.

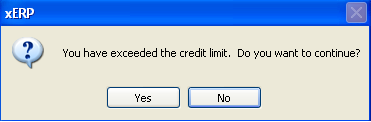

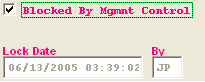

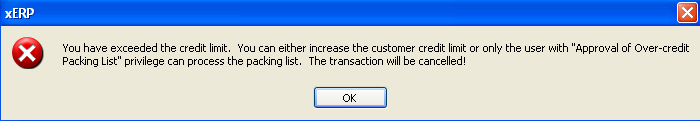

When the user has completed all of the information needed for the packing list, the information must be saved. Note: The Packing List MUST be printed for the shipping information to advance to Invoice Administration. If the user has set the system setup to Manual Invoice numbering, then ManEx will prompt for the invoice number to be used for the packing list. If automatic numbering is used in the setup, then ManEx will supply the invoice number, and close the screen. Hold for Credit Limit If the user has elected "Enforce Credit Limit at Shipment" feature in AAccounting Setup/Accounts Receivable Defaults, the following message will appear if a non-supervisor attempts to ship:

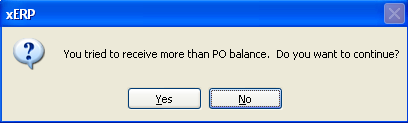

The program gets the total Accounts Receivable (AR Aging) + Not Posted Invoice (invoice not printed out of the Admin/Invoice module) + Open SO Amounts. Compares it to the Credit Limit setup in the Customer Information module. This is based on having the "Include Open Orders for Credit Approvals for Shipping" option checked, (within the Print PL/Invoice setup module) (if you do not want to include open Sales Orders you would want to uncheck this option) and the "Enforce Credit Limit at Shipment" option checked, (within the Sales-A/R setup module)(uncheck this option if you do not want to Enforce the Credit Limit at Shipment). Make sure that these options are marked properly to get the results you are expecting.Depress the OK button, and enter a supervisor password or a password for a user with rights within the Security module, that has the ability to approve the credit limit exceed message. The following warning will appear:

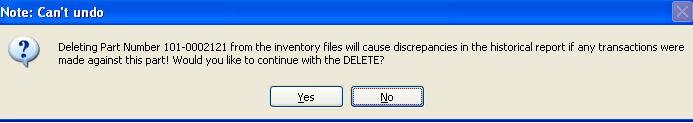

To continue, select "Yes" to abandon select "No". Add a Stand Alone Packing List Add by Stand Alone procedure is the ONLY way that a manual invoice can be created.

If the user elects to add by Stand Alone, a screen appears listing Customers. The user selects the customer by either entering it into the red box, or scrolling down the list and clicking on the selected Customer. Decide between Active or Inactive customer by checking the appropriate box. Type in the Customer name or highlight the customer and double click to select. Once the customer is selected, you will be prompted for your password. The following screen will appear:

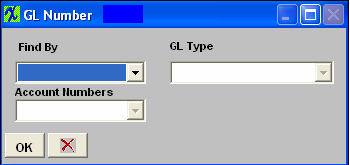

Go to the Detail Tab, and select Add manual item, the user will be prompted for the Credit G/L Number:

Depress the down arrow, s elect to Find By either Account Type or Account Numbers.If you select by Account Type, the GL Type box will be enabled. Depress the down arrow next to the GL Type box and a list of accounts will appear. Select the desired GL Type. Once the GL Type is selected the Account number box will be enabled. Depress the down arrow next to the Account Numbers box, and only the G/L accounts within that range will appear. Select the desired GL account number. If you select by Account Numbers, the Account Numbers box will be enabled. Depress the down arrow next to the Account Numbers box, and the list of ALL of the G/L Account numbers will appear. Select the desired G/L account number. The user will be prompted for Quantity, Back Order amount, Description and Units of Measure. Finish the process as detailed above. Note: The user may edit a Packing List up until the time it is released to Invoice. Once the Packing List has been "Released to Invoice" no edits are allowed.

|

| 1.1.4.3. Edit an Existing Packing List | ||||

The following screen will be displayed:  Find a Packing List. (Note: The Packing List will be editable if the Invoice has NOT been Released to A/R, once the Invoice has been Released to A/R the Packing List is no longer available). Depress the Edit Action button. All fields available for editing will be enabled for modification. Packing List tab - The Ship to address, Attention, Ship Via, Freight, FOB, Terms, Freight Amount, Way Bill number and the Packing List date may be edited.

Detail tab - The user may change the qty, delete the line item, add a manual item or add an Item Note.

Ship Instructions - The user may add/edit shipping instructions. These shipping instructions will be displayed on all the Packing Lists created for the same Sales Order.

History tab - This screen is not editable

Notes tab - The user may add/edit Sales Order notes and/or Packing List Footnotes. The Sales Order notes will be displayed on all the Packing Lists created for the same Sales order.

At the conclusion of the modification process, the user may either press the Save button to save the changes or press the Cancel button to cancel changes. The user may then re-print the Packing List.

|

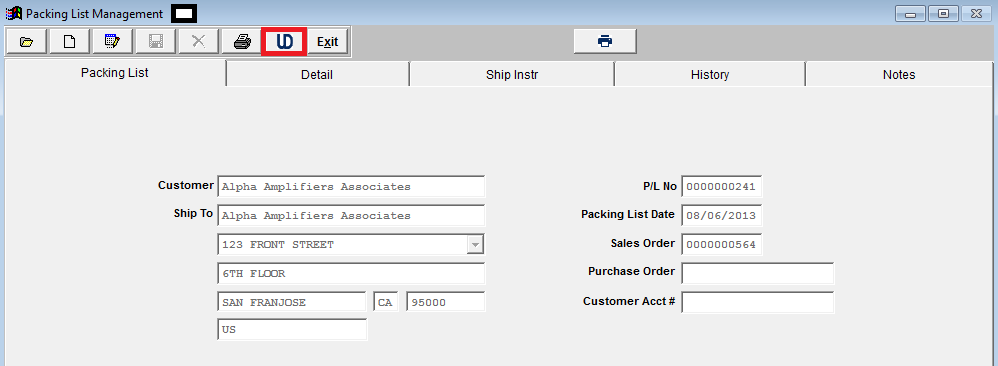

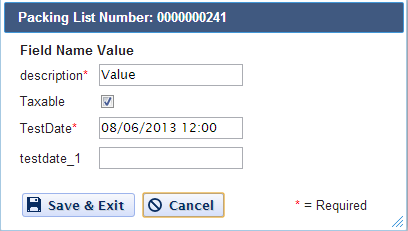

| 1.1.4.4. Link User Defined Fields to a Packing List |

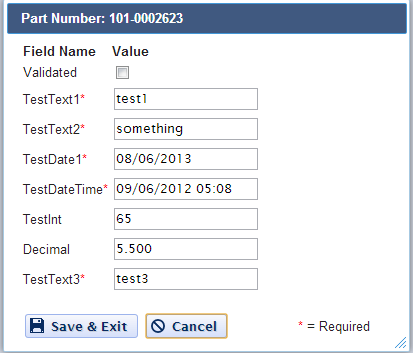

| The User Defined fields MUST be setup within Web ManEx. For further detail see Article #5454.

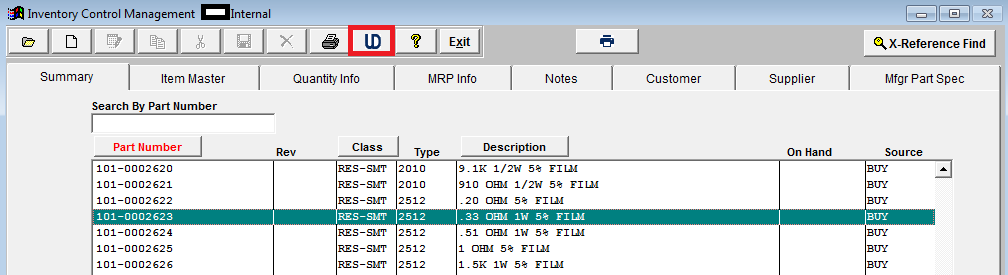

To link a UDF to a Packing List select a record in the ManEx Desktop, and select the UD action button (as displayed below).

The UDF for that section will then be displayed, and user can make changes (if applicable), Save & Exit or Cancel.

|

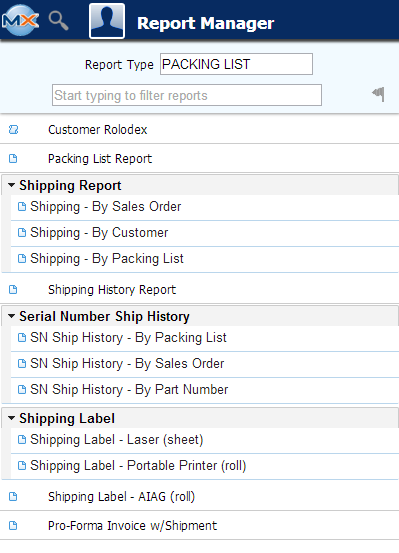

| 1.1.5. Reports - Packing List Mgmt | ||||||||||||||||||||||

|

To obtain the Packing List Reports within the Web, select the WEB Print button from the ManEx action buttons at the top of the screen. For further detail on How the Reports work within the Web refer to Article #5477.

Note: In order to access the Reports within the Web the Company Root URL must be setup within the System Appearance module and user must be linked to web within the System Security Module.

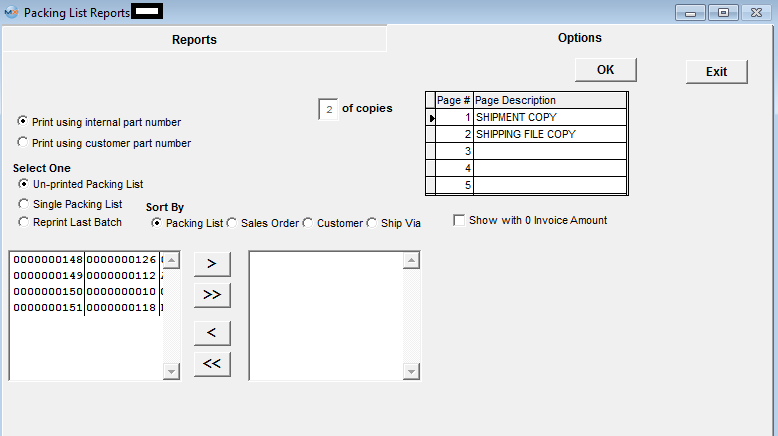

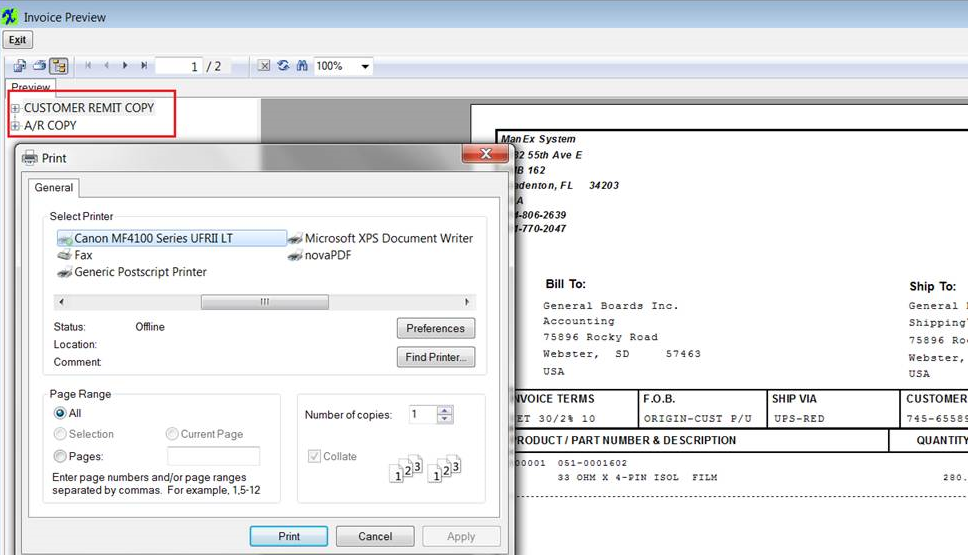

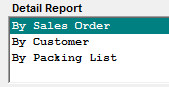

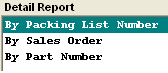

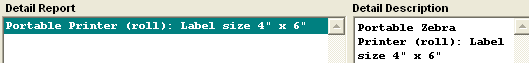

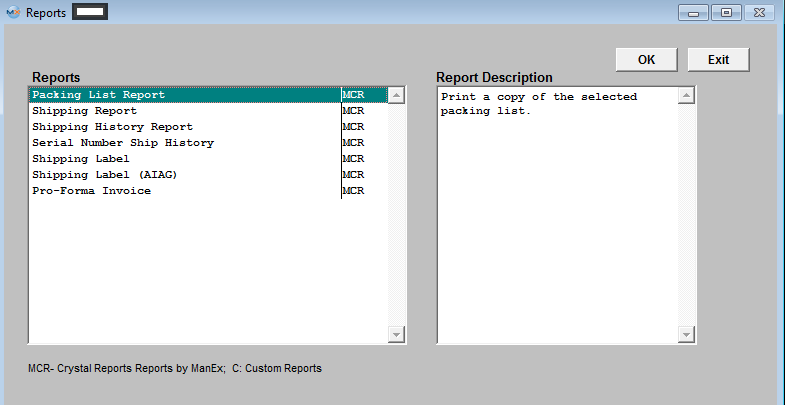

Select the Report Type: PACKING LIST - A List of Reports will be displayed that are available on the Web for PACKING LIST  To obtain the Packing List reports, select the Print button from the ManEx action buttons at the top of the screen. The following reports screen will display a list of reports that are available on the ManEx Desktop:

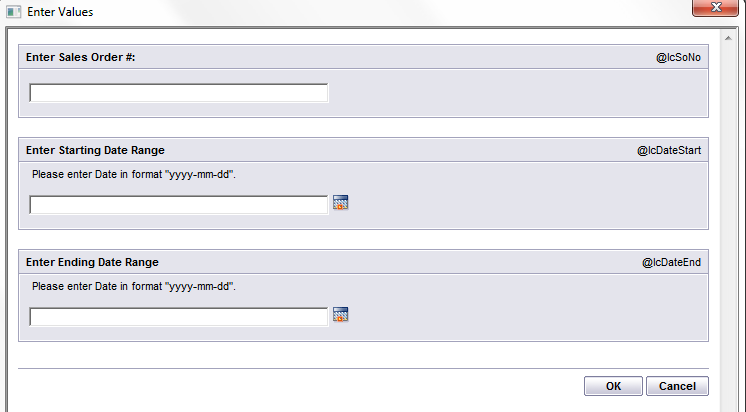

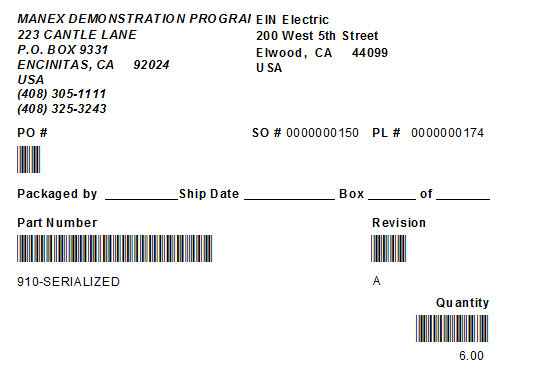

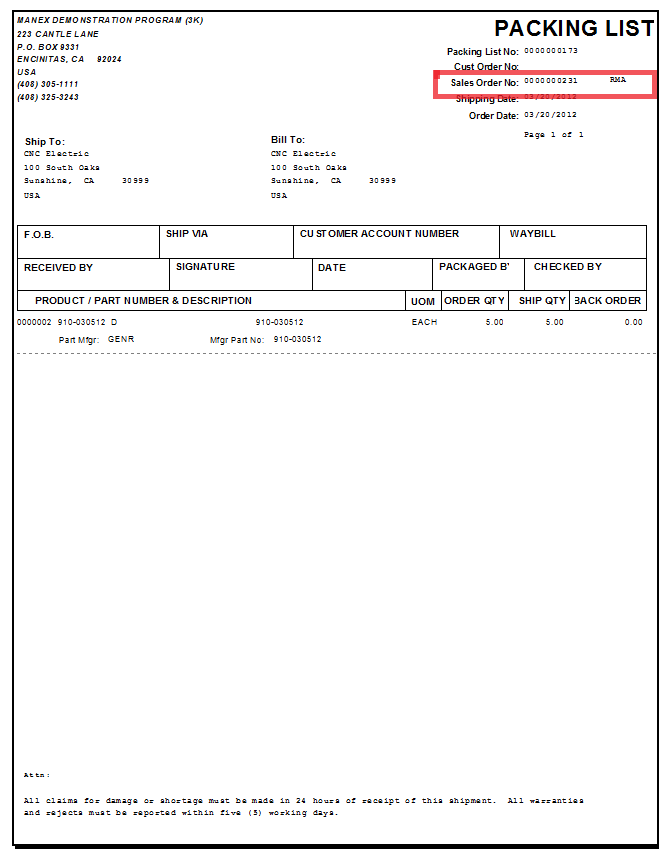

Highlight the desired report and then depress the OK button PACKING LIST REPORT

The following is printed

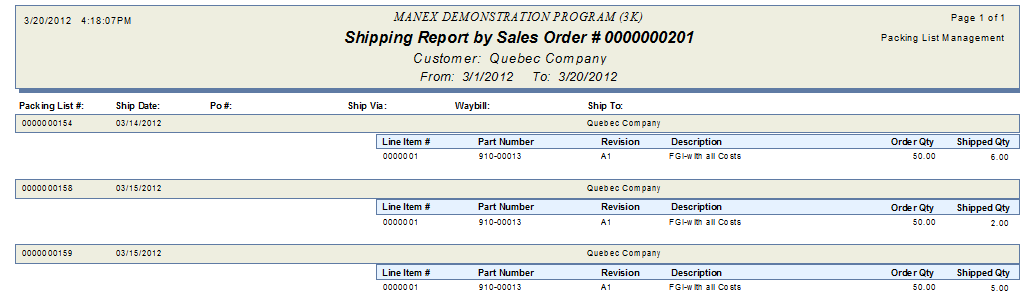

SHIPPING REPORT

The following is printed:

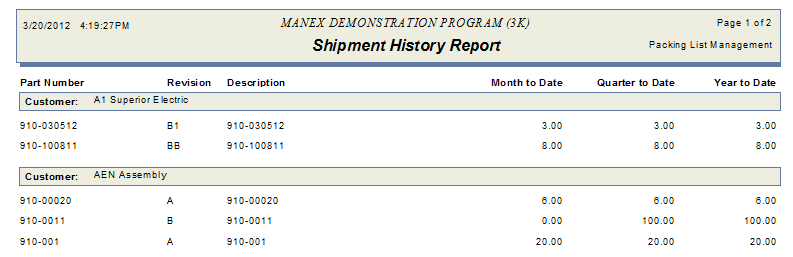

SHIPPING HISTORY REPORT Depress the OK button and the following will print:

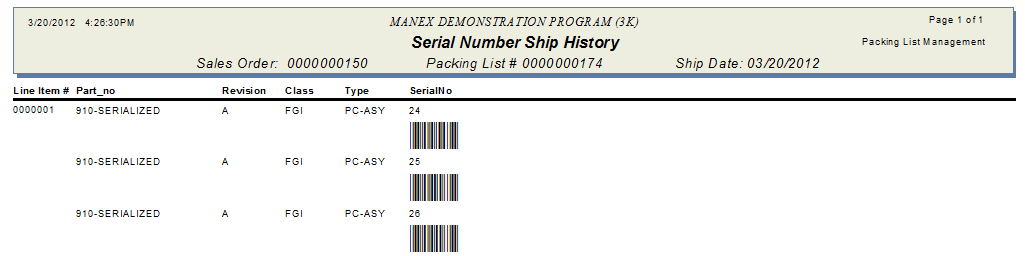

SERIAL NUMBER SHIP HISTORY

The following will print:

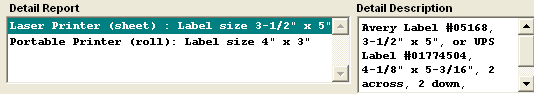

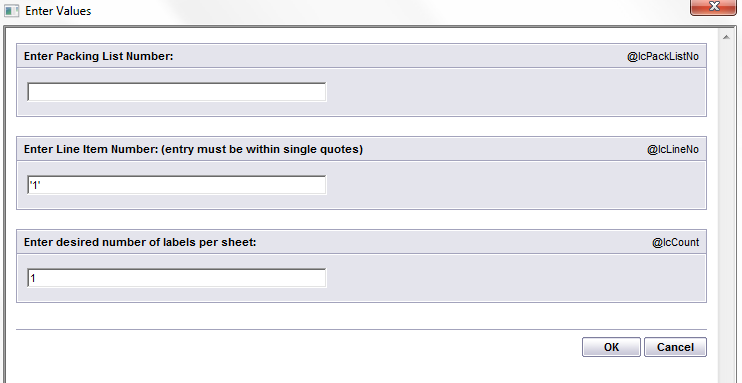

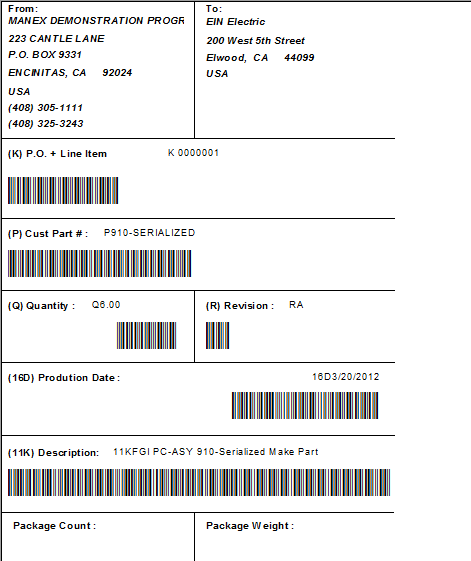

SHIPPING LABEL

The following is printed:

SHIPPING LABEL (AIAG)

The following is printed:

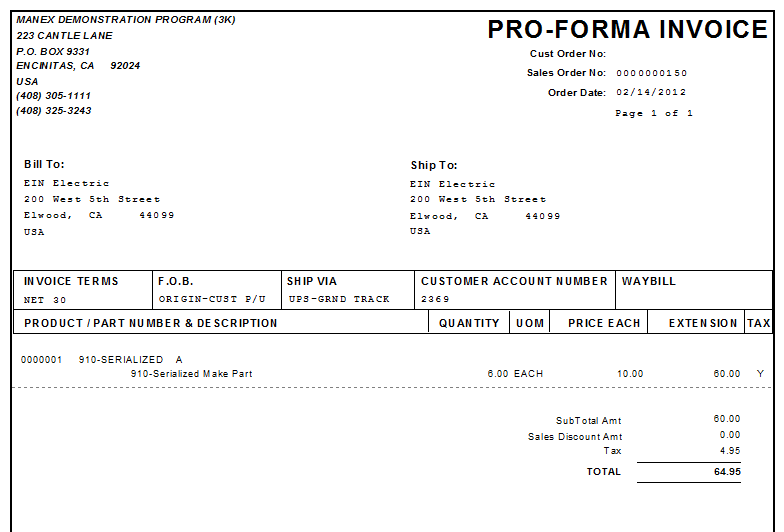

ProForma Invoice

The following will print:

|

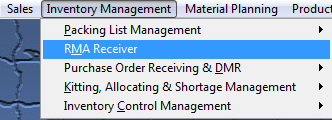

| 1.2. Return Material Authorization (RMA) Receiver |

| 1.2.1. Prerequisites for RMA Receiver | ||

After activation, "RMA Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.2.2. Introduction for RMA Receiver |

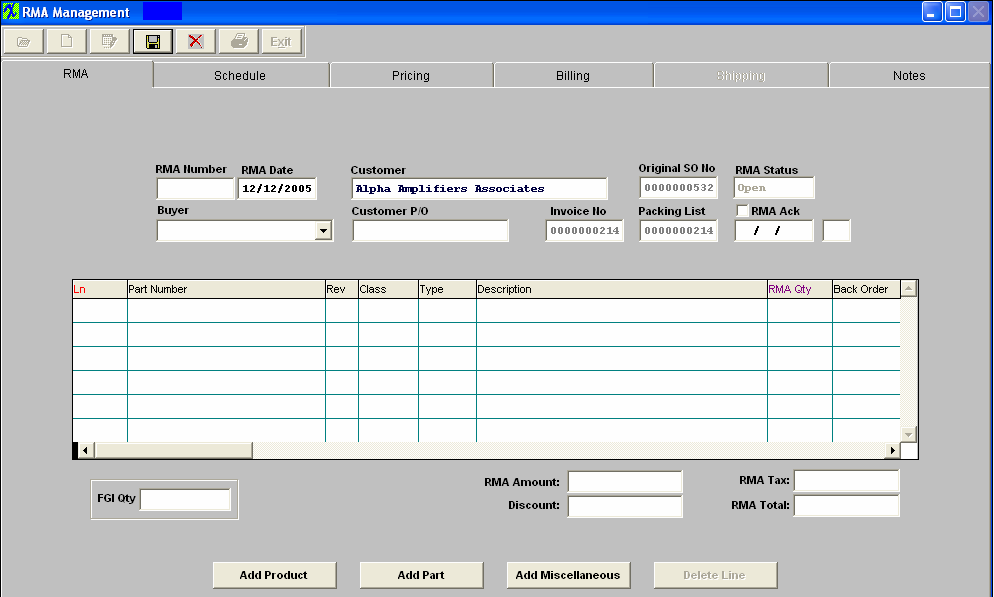

The Return Material Authorization module notifies receiving to expect a return from a customer. Once the material is received back from the Customer, this module is used to record the receipt, create the Re-Work Work Order, adds the product into the work order, and the applicable Credit Memo. Once the RMA is received, a Credit Memo automatically forwards to the Accounting Accounts Receivable Credit Memo module, if a dollar amount was entered for the return. When the re-work/replacement is ready to re-ship, a Packing List and Invoice can be created. Note: When an RMA is created, both the pending receipt of the items from the customer and the subsequent shipment of replacement product to the customer are entered. Reference is made to the original Sales Order and Invoice only to allow the Credit Memo (when created) to have a place to apply the credit. Utilizing this approach, the user is free to set different schedules for receiving and/or shipping the material without affecting the original Sales Order. It also allows the user to place different prices or costs on the line items. For example, it may be that full credit is issued on the RMA receipt, but extra charges apply on the reshipment because of non-warranty issues. Or the user may wish to have a “no-credit, no-charge” RMA policy where items are received and reshipped with no General Ledger affects. Or, the receipts may be at no credit, but the return shipment includes only the rework charges. Because of the variety of possibilities, trying to incorporate any of these actions into the original Sales order would make it really difficult to maintain data about the costs associated with the order. This also permits the user to develop reports for on-time shipments, and shipping/scheduling quality.

To review how an RMA impacts MRP see Article #2507.

NOTE: If you do not follow this procedure to bring material back into your plant, your rework work orders do not have the value of the original product placed in WIP, and therefore when completing your rework work orders, there will be a huge variance created because there were no items placed in WIP (except for a few replacement parts), yet the product is moved from WIP to FGI at standard cost. When you use the RMA module these accounts balance out, with the variance being only those items added to the work order.

|

| 1.2.3. Fields and Definitions for RMA Receiver |

| 1.2.3.1. RMA Receiver Tab | ||||||||||||||||||||||||||||||

RMA Receiver Tab Field Definitions

|

Customer

|

This is the name of the Customer who returned the material.

|

RMA Receiving Number

|

This is the unique number assigned to the RMA Receiver.

|

Ship From

|

This is the Customer’s address from which the material was returned.

|

RMA Receiving Date

|

This is the date the user’s Receiving Department received the returned material.

|

RMA Order Number

|

This is the RMA Order Number assigned in the RMA Management module.See above.

|

Purchase Order

|

The was the customer’s original purchase order number for the original Sales Order.

|

Attention

|

This is the contact name at the Customer.

|

Ship Via

|

This is the original carrier for the original Sales Order.

|

Freight Amount

|

This is the freight originally charged the customer on the original Sales Order.

|

RMA Order Acknowledgement

|

This box is checked in the RMA Management module, as explained above.

|

Freight

|

This is the freight arrangement per the original Sales Order.

|

Waybill

|

This is the Waybill number pertaining to the original Sales Order.

|

Credit

|

This is the Customer’s Credit Status with the user.

|

FOB

|

This is the original FOB terms pertaining to the original Sales Order.

|

Entered By

|

These are the user’s initials authorizing the material return in the RMA Management module. |

| 1.2.3.2. Detail Tab | ||||||||||||||||||||||||||||||||||

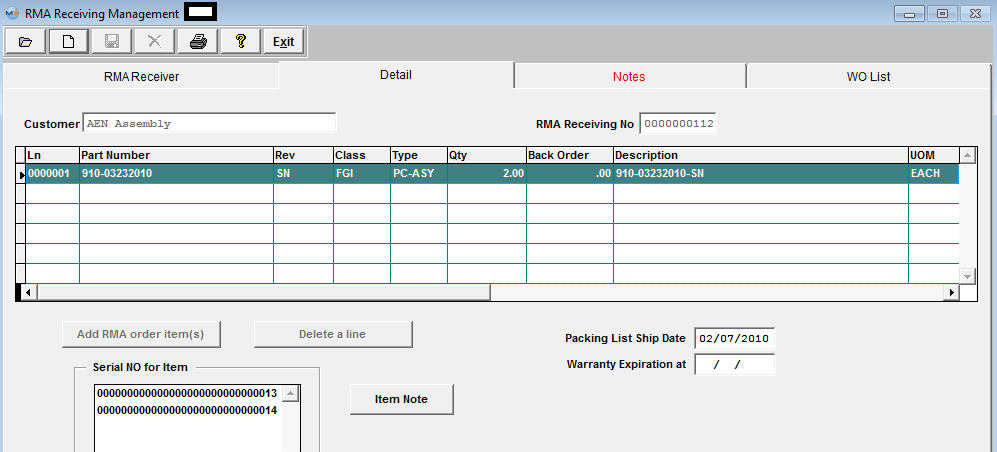

RMA Receiver Detail Tab Field Definitions

|

|

Customer |

This is the name of the Customer who returned the material |

|

RMA Receiving Number |

This is the unique number assigned to the RMA Receiver. |

|

Ln |

The line number of the Return Material Authorization or the line member of the order to be re-worked/replaced and returned to the customer. |

|

Part Number |

The user’s internal number for the part or assembly. |

|

Rev |

The revision number pertaining to the Part Number. |

|

Class |

The user’s classification covering the Part Number. |

|

Type |

The type within the classification covering the Part Number. |

|

Qty |

It’s the amount of the original order which the customer is returning. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. |

|

Back Order |

The amount of product still expected to be returned by the customer. |

|

Description |

The user’s description covering the Part Number. |

|

UOM |

The unit of measure pertaining to the product. |

|

|

This button allows the user to add items from the RMA Management module. |

|

|

This button allows the user to delete the highlighted line. |

|

Packing List Ship Date |

The date the Original Packing list was created. |

|

Warranty Expiration |

The date the warranty originally extended to the customer expires. |

|

Serial Number Entry |

The serial numbers pertaining to the items returned. |

|

|

The note pertaining to the Part Number as entered in the Inventory Master. |

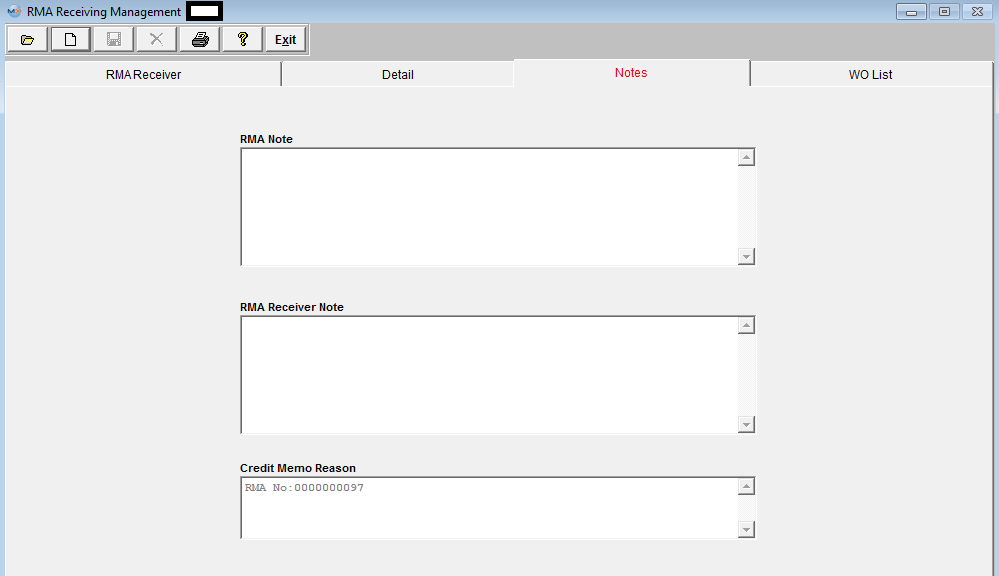

| 1.2.3.3. Notes Tab | ||||||

RMA Receiver Notes Tab Field Definitions

|

RMA Note

|

This is the internal note used by the user regarding the Return Material Authorization as entered in the RMA Management module. RMA Receiver Note |

|

This is a note that will be displayed on the RMA Packing List.

|

Credit Memo Reason

|

This is the note created when the Credit Memo was created. |

| 1.2.3.4. WO List Tab | ||||||||||||||||||||||||

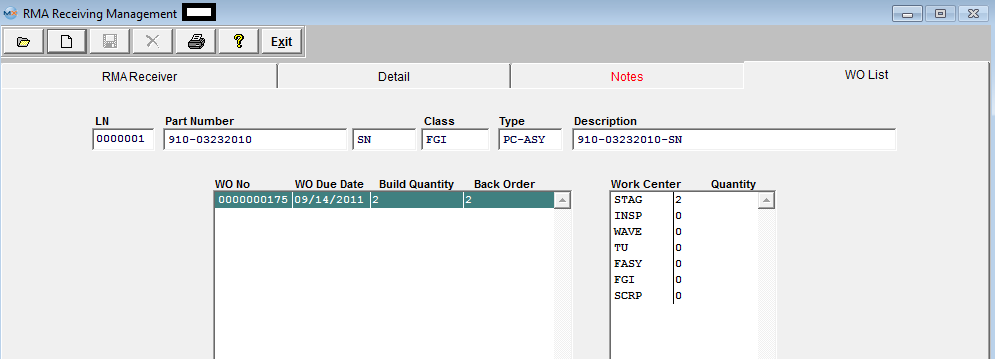

RMA Receiver Work Order List TabIf the RMA Management module called for a re-work or replacement in addition to authorization of the return of material, the system will have created a Work Order. Information regarding any such Work Order will appear in this tab. RMA Receivng Work Order List Tab Field Definitions

|

| 1.2.3.5. Overview Regarding Return Material Authorization Accounting |

No Journal Entry is created in the RMA module, however the system was collecting the JE components from that module as follows: Assume that the original sale was for 10 units @ $100.00 each, with a standard cost of $80.00 each and freight charged the customer of $15.00. At the time the user selects the original Invoice number in the Return Material Authorization module, the system “remembers” the original accounting entry that was created at the time the original Invoice was printed, which was: Debit Accounts Receivable – Trade $1,015.00 Debit Cost of Goods Sold $800.00 Credit Sales $1,000.00 Credit Finished Goods Inventory $800.00 Credit Freight Income $15.00

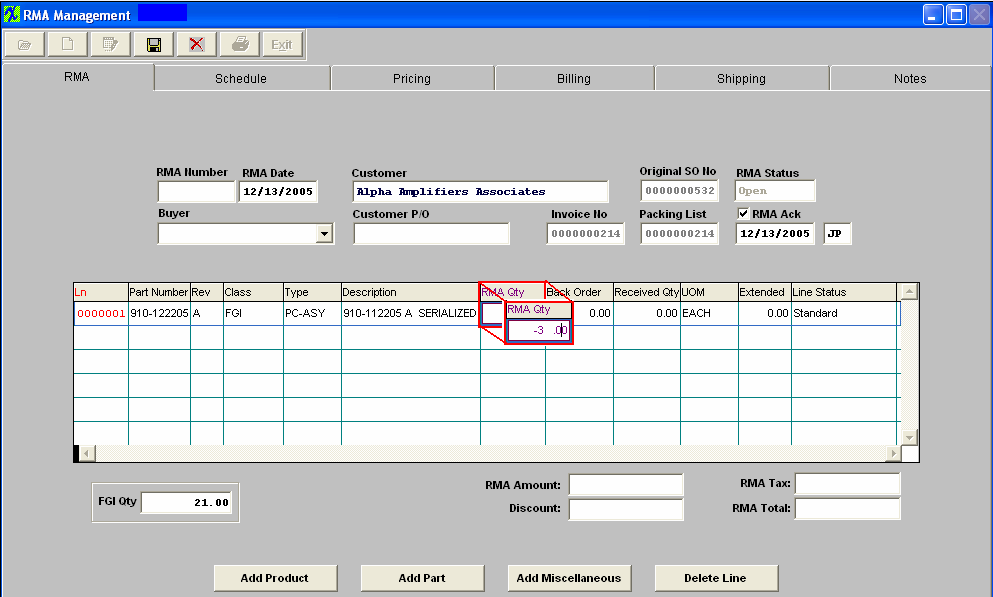

When the user enters the “return quantity” (the one entered as a negative quantity), the system will remember that the original cost of sales was $80.00 per unit.

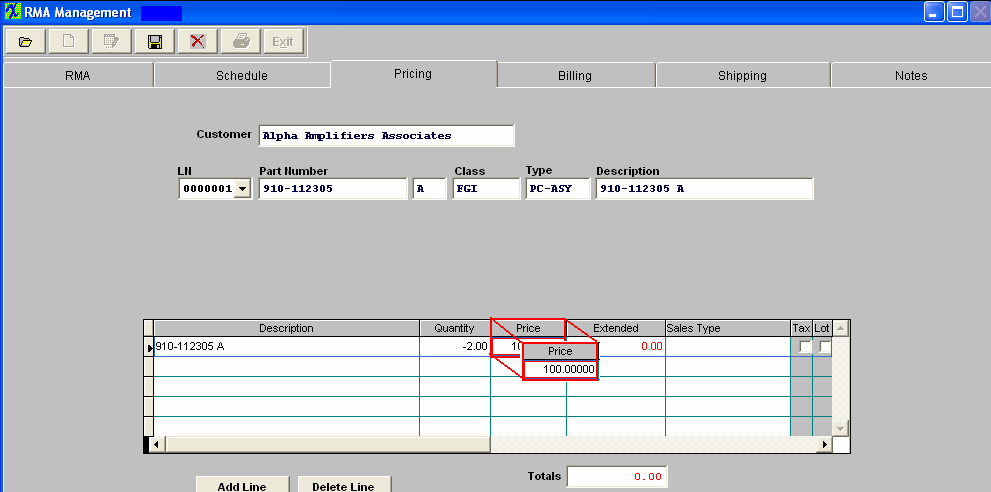

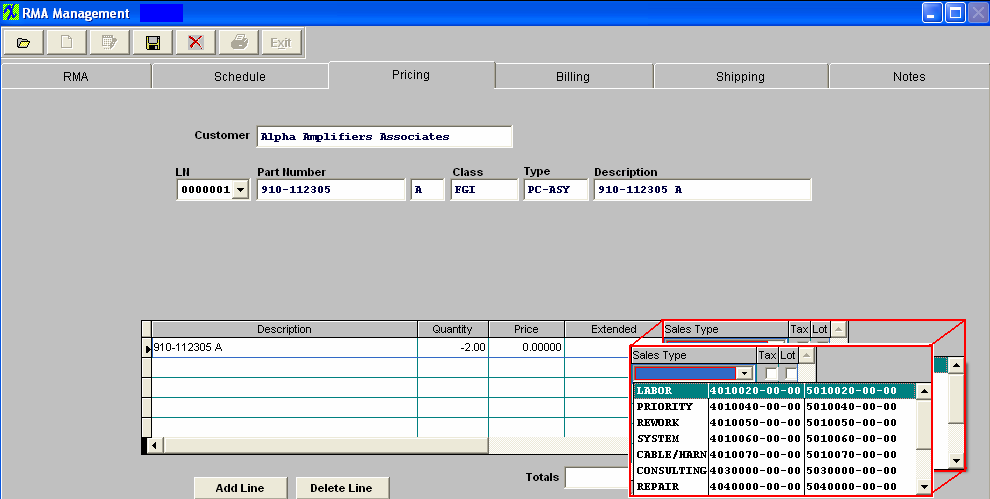

The user then enters the pricing on the item to be returned on the Pricing page of the RMA module.

The pricing entered can be any amount up to the amount of the original pricing of $100.00 per unit. And so the journal entry component for the debit to the sales account is 2X $100.00 = $200.00, in this example. The user selects the sales and cost of goods general ledger accounts to be used per the Sales Type column:

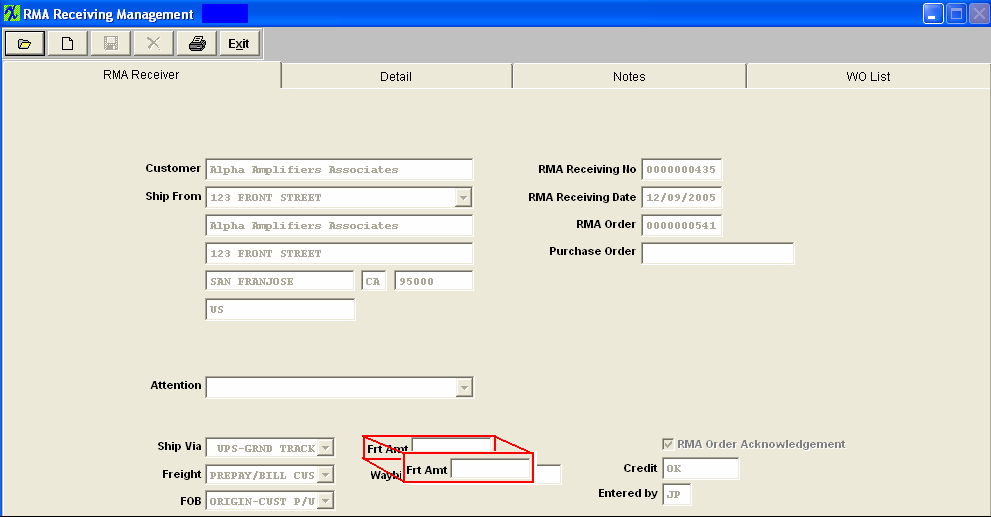

And so, the sales account number selected will be debited for $200.00 once the journal entry is created, upon the actual receipt of the returned item.And the related Cost of Goods sold account will be credited for the $160.00. If the return is to be reworked and then returned back to the customer, the user creates a second line item on the RMA using a positive quantity which is in actuality creating the RMA Sales Order and an eventual invoice upon shipment. The journal entry and the applicable Credit Memo for the returnis created in this Return Material Authorization Receiving module.On this screen, the user indicates the amount of freight to be credited, such as a pro rata 2/10 of $15.00, or $3.00, for example:

After the user types in the quantity received on the Detail page and depresses the Save button, several things happen all at once: The Journal Entry is created as follows and forwards to the Release to General Ledger module: Debit Sales $200.00 Debit WIP $160.00 Debit Freight $3.00 Credit Accounts Receivable $203.00 Credit COGS $160.00

Once the Rework Work order is released, the user may opt to go into kitting and add line shortages which will be included in the Material Variance once the Kit is closed.Please refer to the Kitting and Shortage Management manual. From this point forward, the accounting is the same as for a regular order. |

| 1.2.4. How To .... for RMA Receiver |

| 1.2.4.1. Find a Return Material Authorization Receiver | ||||||||

|

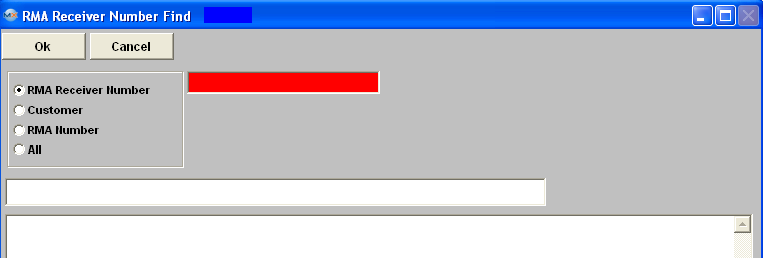

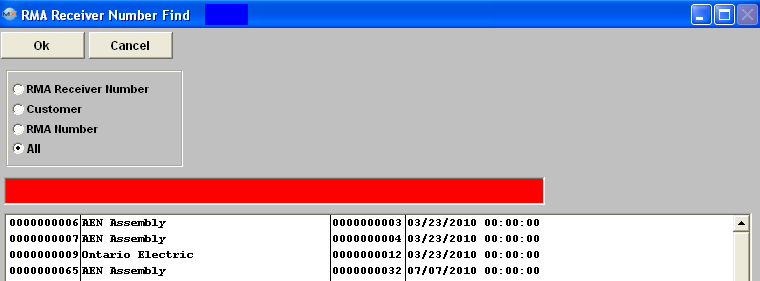

The following screen will be displayed:

Once the Find operation has been completed, the found RMA Receiver will populate the screen.

|

| 1.2.4.2. Add an Return Material Authorization Receiver | ||||

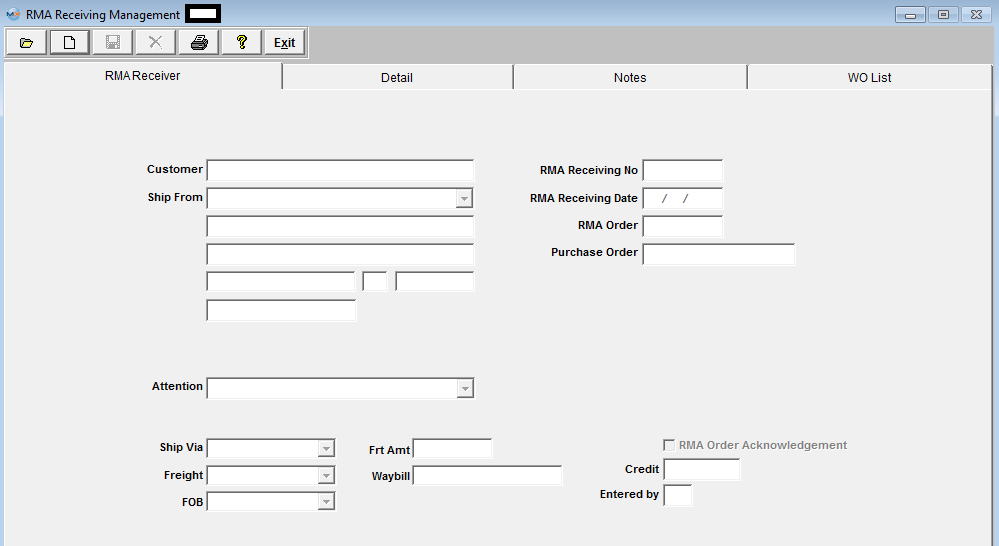

The following screen will be displayed:

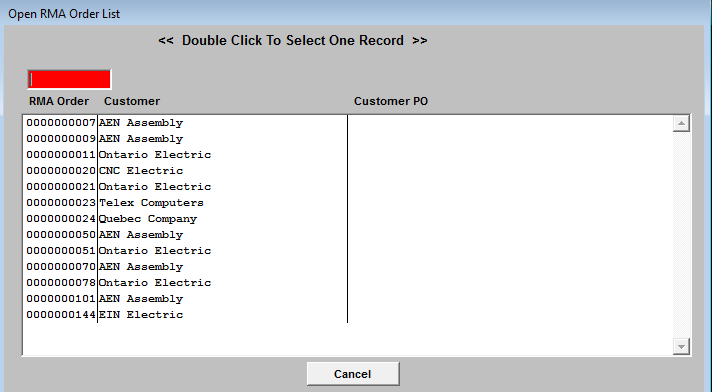

To add a new RMA Receiver, depress the Add record action button. The following selection list will be displayed:

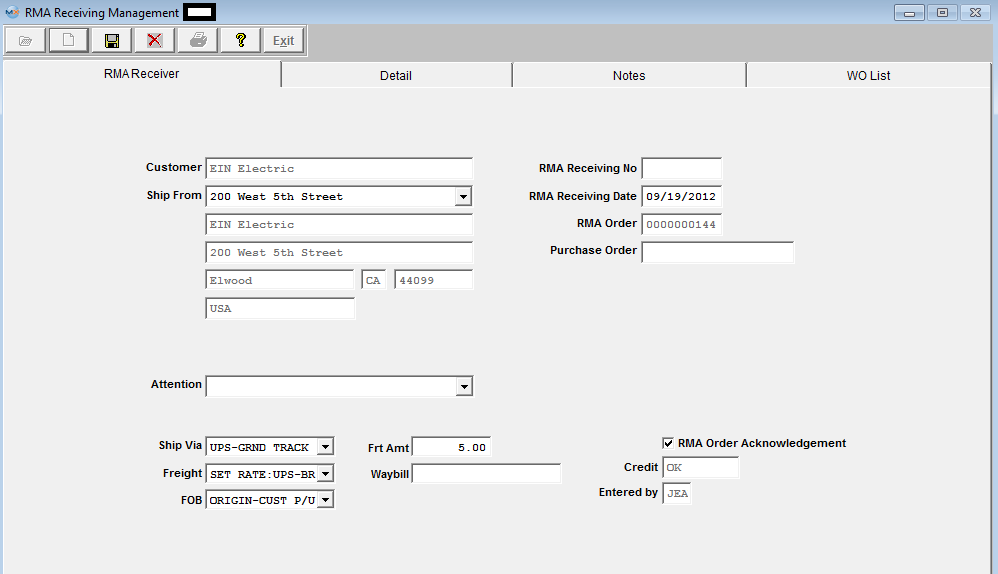

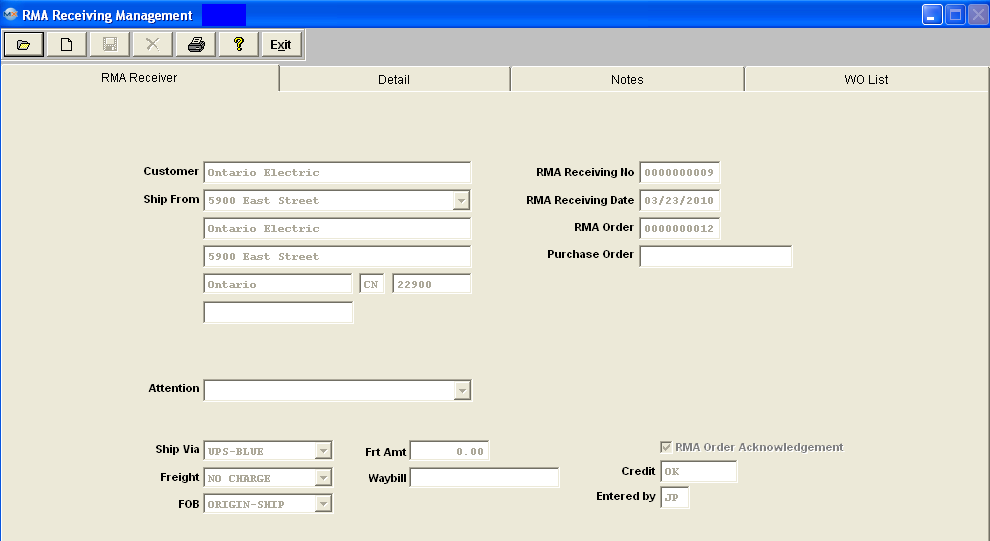

Enter the RMA Order Number into the red box or highlight your choice and double click. Information from the RMA Management module will be displayed once you enter your password, as shown below:

RMA Receiving Tab Depress the down arrow to select the appropriate ship from address. Edit the RMA Receiving Date, if desired. Depress the down arrow to select the appropriate customer contact, Ship Via, Freight, or FOB. Enter the amount of freight, if desired. Enter the number of the Waybill, if desired. All other fields will be defaulted in.

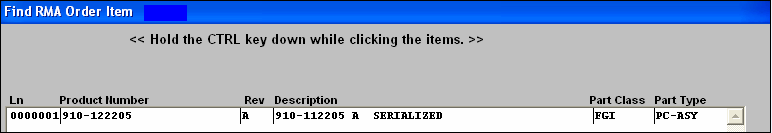

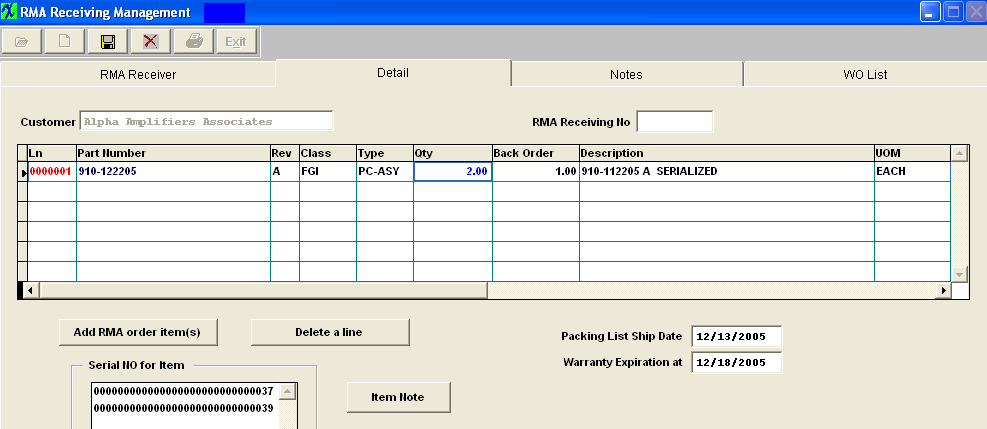

Depress the RMA Receiver Detail Tab. The following screen will be displayed: Depress the Add RMA order item(s) button. A list of products, etc. pertaining to the RMA selected will appear:

Highlight the selection and then depress the OK button. The cursor will go to the Quantity field. Enter the quantity being received.

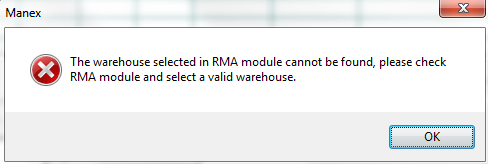

If the warehouse selected in RMA module is not found (deleted or in cycle count/physical inventory), the user will receive the following message and will not be able to continue until this issue has been resolved.

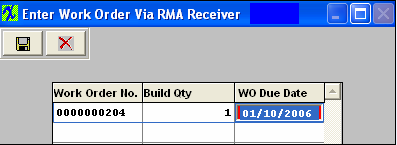

The following Work Order screen will appear:

NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status. Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled. Also, users will NOT be allowed to edit or change the Bld qty because when product is brought into the system with an RMA Receiver it is then automatically issued as itself to the kit at that time.

You may change the Work Order due date. NOTE: The Work Order due dates from the RMA Receiver are generated automatically based on the date the RMA was created. This date may need to be reviewed and adjusted to match the RMA scheduled ship date. MRP will not instruct you to reschedule a rework firm work order, so it is important to make sure all dates match. Depress the Save record action button.

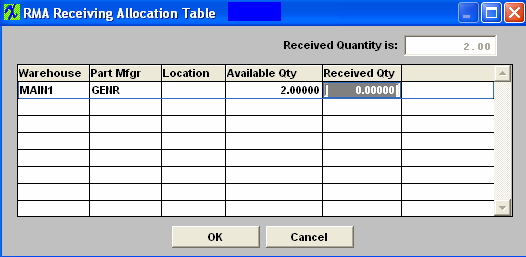

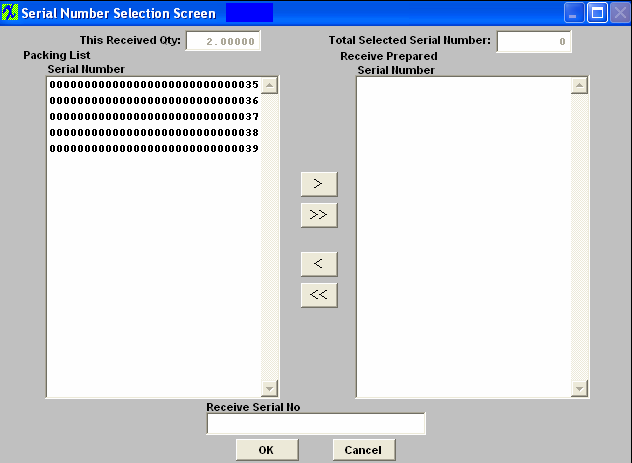

If the returned material contained serial numbers, the following screen will appear displaying the available qty:

Enter the Received Qty and depress the OK button, and the following screen will appear:

Enter the Serial Number to be received into the Receiver Serial No box. Or, select the Serial Number(s) being returned by highlighting and depressing the > button. For multiple serial numbers, hold the CTRL key down while highlighting. If you want to include all Serial Numbers, depress the >> button. Depress the OK button. The Serial Number Entry box will update. Rework Work Order Serial Numbers When a Rework Work order is established for a serialized product, the user may select existing serial numbers that are in inventory (finished goods) that are to be reworked. Rework Work Orders will not accept new serial numbers. When a serial number is placed in the Rework Work Order, the serial number must exist in finished goods, and the number of serial numbers transferred to the Work Order must equal the quantity of assemblies for the Work Order. The part number for the serial number that is moved into the Rework Work Order does not need to be the same part number and revision as the Work Order. Thus, if a user wants to upgrade part number 123 rev A to part number 123 rev B, they can transfer the parts to the Work Order and identify the serial number transferred. Parts may also be changed to a new part number: Example:part number 123 rev A can be placed in a Rework Work Order for part number 234 rev C. The only condition is that the quantity and number of serial numbers must match. You may enter an item Note, if desired. The completed screen will look like this:

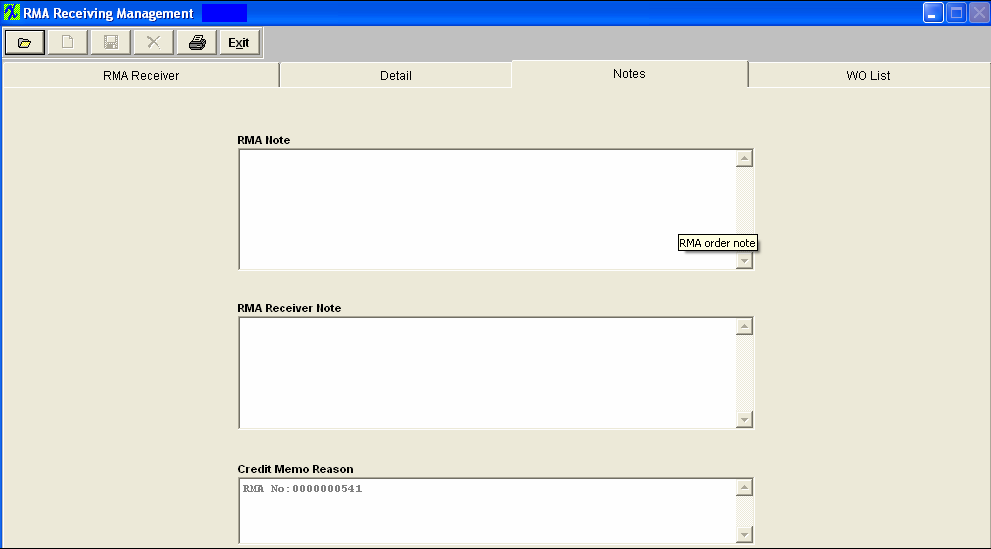

Depressing the Note tab will bring up the following screen:

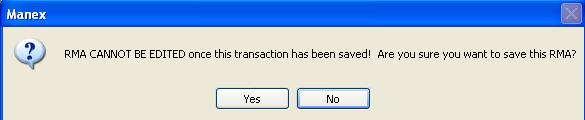

The credit memo reason will display as referencing the RMA number. You may add to the Credit Memo Reason, if you wish. You may add an RMA note or an RMA Receiver Note, if desired. When RMA is complete. Depress the Save record action button to save changes, or depress the Abandon changes button. If you depress the Save record action button, the following message will appear:

To continue the save, depress the Yes button. Selecting the WO list tab will bring up the following:

You may not change anything on this screen. Note: The user can not kit a Rework Work Order. The user may only pull the shortage. Please refer to the Kitting, Allocating & Shortage Management article. Note: If the RMA line number for the negative (returning) item is placed on administrative hold, then receiving will not be able to receive in the parts until it is cleared. Credit Memo The Credit Memo is not created until the returned material is actually RECEIVED in the RMA Receiving module. There is no financial involvement UNTIL the parts are received back. Regarding the matter of advising accounting that a Credit Memo has been created, the system will send an e-mail to the appointed recipient when the RMA is received if a trigger is setup to do so.

|

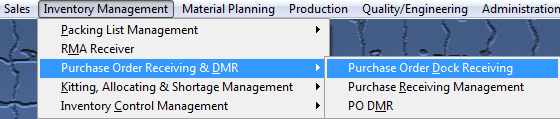

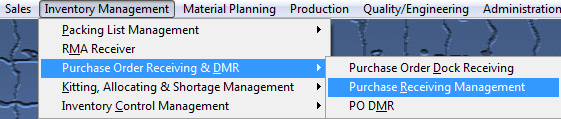

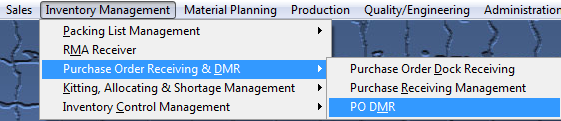

| 1.3. Purchase Order Receiving & DMR |

| 1.3.1. Purchase Order Dock Receiving |

| 1.3.1.1. Prerequisties for PO Dock Receiver | ||

Prerequisites Required for Entering a New RECEIVER

After activation, "Purchase Order & Dock Receiving" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

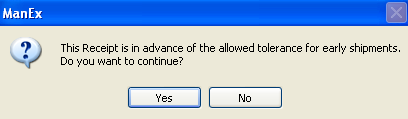

There must be an open purchase order for the receipt and the PO status MUST be "Approved". If the PO is in "Edit" mode the PO Dock will not find receipt.

|

| 1.3.1.2. Introduction - PO Dock Receiver |

In Purchasing Setup it gives the user the option to use PO Dock Receiving. If this box is checked, the purchases are received at the dock requiring the user to complete a PO Dock Receiving record, listing the supplier’s packing list number and the quantities per that packing list. An inspection report is printed. The purchases are inspected and counted. (If this box is left unchecked the user can skip the PO Dock Receiving step and go directly to the PO Receiving and Inspection record.)

|

| 1.3.1.3. Fields & Definitions for PO Dock Receiving | ||||||||||||||||||||||||||||||||||

Fields & Definitions

|

| 1.3.1.4. How To ..... for PO Dock Receiver |

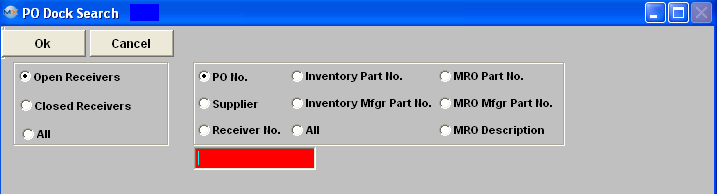

| 1.3.1.4.1. Find Dock Receiver | ||||||||

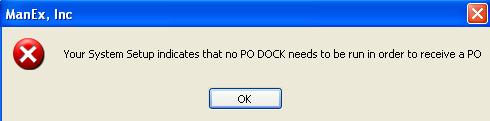

IF DOCK RECEIVING is DISABLED in Purchase Setup user will receive the following message:

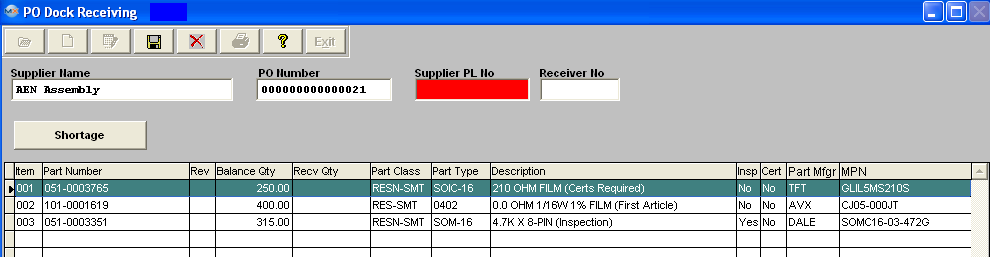

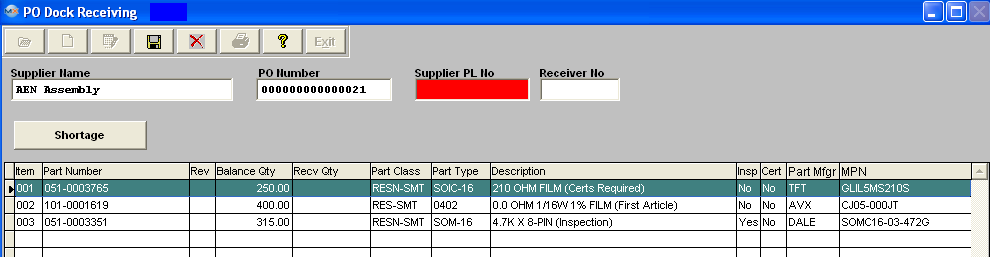

IF DOCK RECEIVING is ENABLED in Purchase Setup the following screen will be displayed:

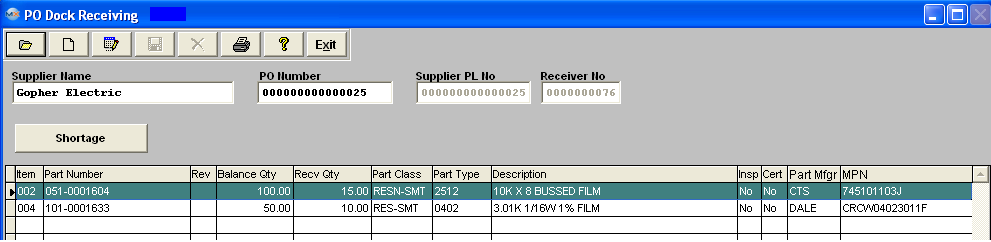

Once you have made your choice, the information will be displayed as follows:

|

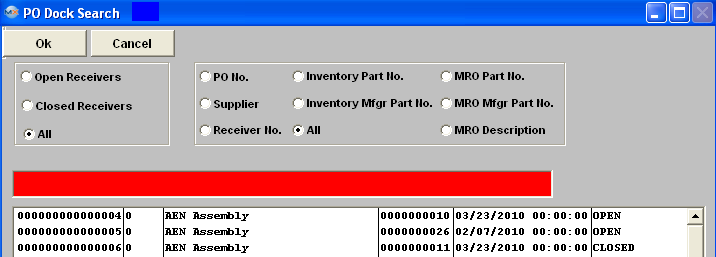

| 1.3.1.4.2. Add a Dock Receiver | ||||||||||||||

IF DOCK RECEIVING is DISABLED in Purchase Setup user will receive the following message:

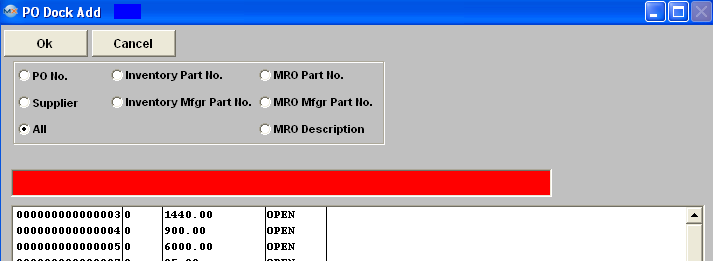

IF DOCK RECEIVING is ENABLED in Purchase Setup the following screen will be displayed:

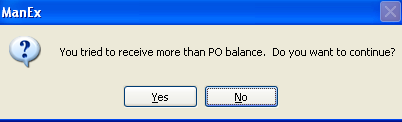

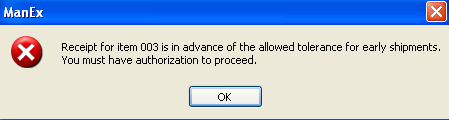

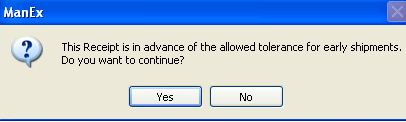

The purchase order selected will populate the Dock Receiving screen, as displayed:  Enter the Supplier’s Packing List Number into the red box. Fill in the Received Qty column. (The qty entered in this field will have to either be accepted or rejected when completing the PO Receiver, user will not be allowed to create a PO receiver for only a Partial of this qty).  Depress the Save changes action button.

If the "Shortage" button is RED that reminds the user that there are shortages for this part. Depress the "Shortage" button and a screen will be displayed listing the shortage's for this specific part.

The Complete PO Dock Receiving Screen will look like this:

|

| 1.3.1.4.3. Editing a Dock Receiver | ||||||||

The Following screen will be displayed:

The user may edit the Dock Receiving record as long as a related PO Receiving has NOT been done.

|

| 1.3.1.5. Reports - PO Dock Receiving | ||||

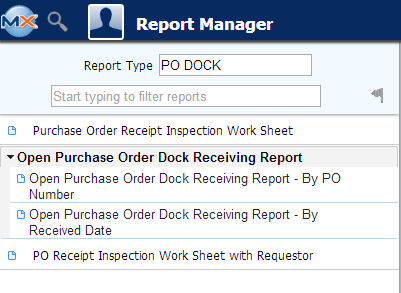

To obtain the AP

Aging Reports within the Web, select the WEB Print button from the ManEx action buttons at the top

of the screen. For further detail on How the Reports work within the Web refer

to Article #5477.

Select the Report Type: PO DOCK - A List of Reports will be displayed that are available on the Web for PO DOCK

To obtain the PO Dock Receiving reports, select the Print button from the ManEx action buttons at the top of the screen.

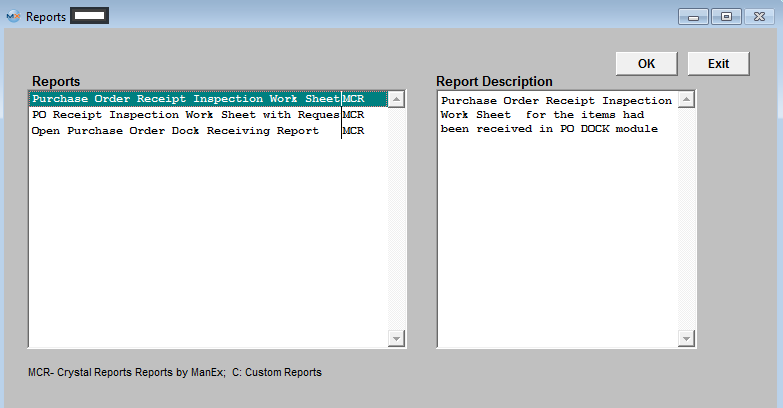

The following reports screen will display a list of reports that are available on the ManEx Desktop:

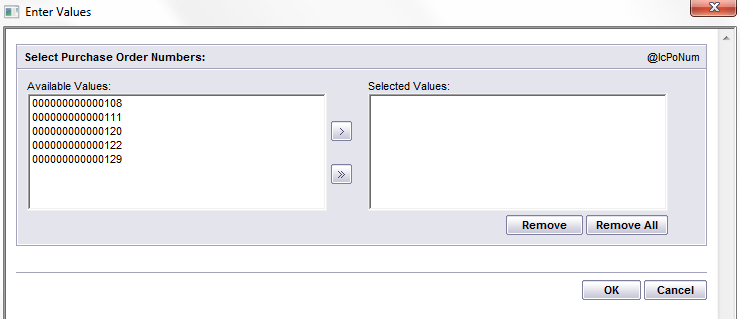

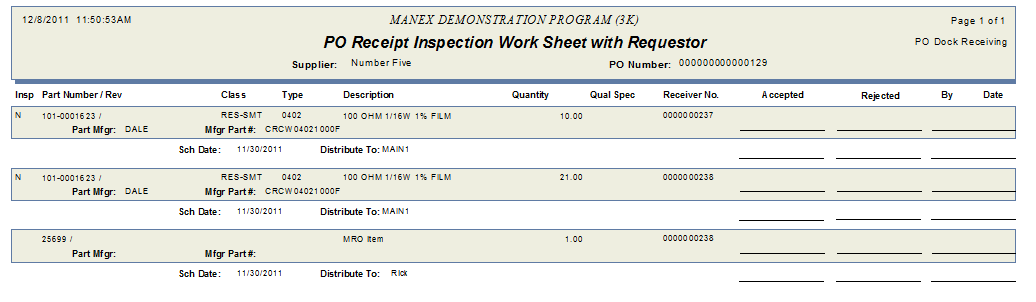

Highlight the desired report and then depress the OK button. If you select the Purchase Order Receipt Inspection Work Sheet report, or Purchase Order Receipt Inspection Work Sheet with Requester report highlight that report. Depress the OK button. This screen appears:

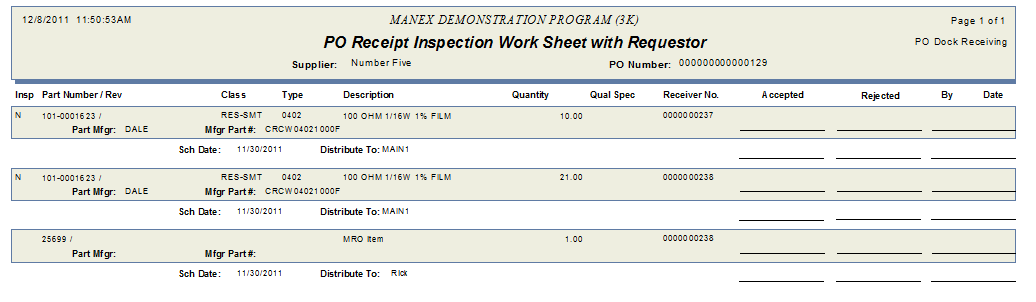

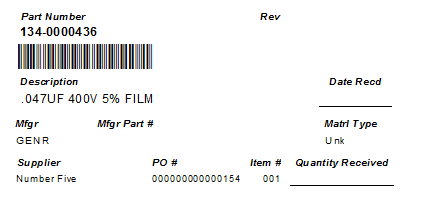

The following is printed:

The following is printed:

|

| 1.3.1.6. FAQs for PO Dock Receiver |

| Facts & Questions for the PO Receiving & DMR Module |

| 1.3.2. Purchase & Receiving Management |

| 1.3.2.1. Prerequisties for Purchase & Receiving Mgmt | ||||

After activation, "Purchase Order & Dock Receiving" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.3.2.2. Introduction for Purchase & Receiving Mgmt |

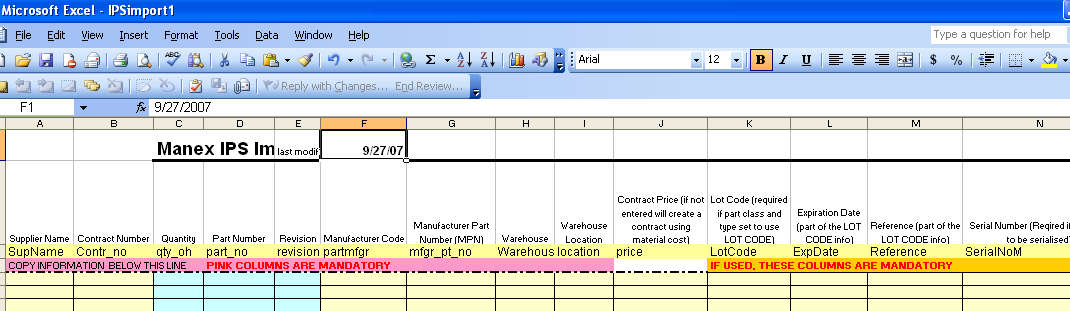

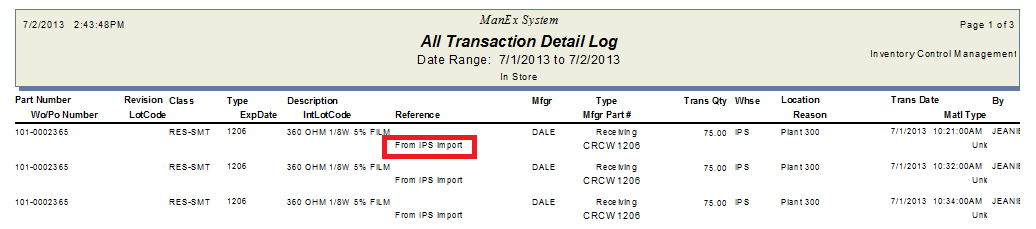

Receiving is the next step after creating and submitting a Purchase Order. In System setup/Purchase Setup it gives the user the option to use PO Dock Receiving. If this box is checked, the purchases are received at the dock requiring the user to complete a PO Dock Receiving record, listing the supplier’s packing list number and the quantities per that packing list. An inspection report is printed. The purchases are inspected and counted. (If this box is left unchecked the user can skip the PO Dock Receiving step and go directly to the Purchase Order Receiving & Inspection record. The user then is required to complete a PO Receiving & Inspection record. This module has a provision for rejected purchases. For rejected materials, ManEx provides for a PO DMR (Discrepant Materials Receipt) module. The Discrepant Material Receiver is used to receive material which does not meet the specifications for the purchased part or purchase order. This module allows for review by the Materials Review Board. Then, if not acceptable, the material may be returned to the supplier. The user may reject in the Purchase & Receiving Management module OR may return an item From Inventory. If an item is returned From Inventory, and the Once the data entry is completed, the purchase receivers are forwarded to the Accounting module for PO Receipt Reconciliation. (The attached Print Screens below <<PO_Recv_Resulting_Trans.docx>> displays the resulting transactions that affect the Un-reconciled Receipt accounts after accepting items into stock through PO Receiving).

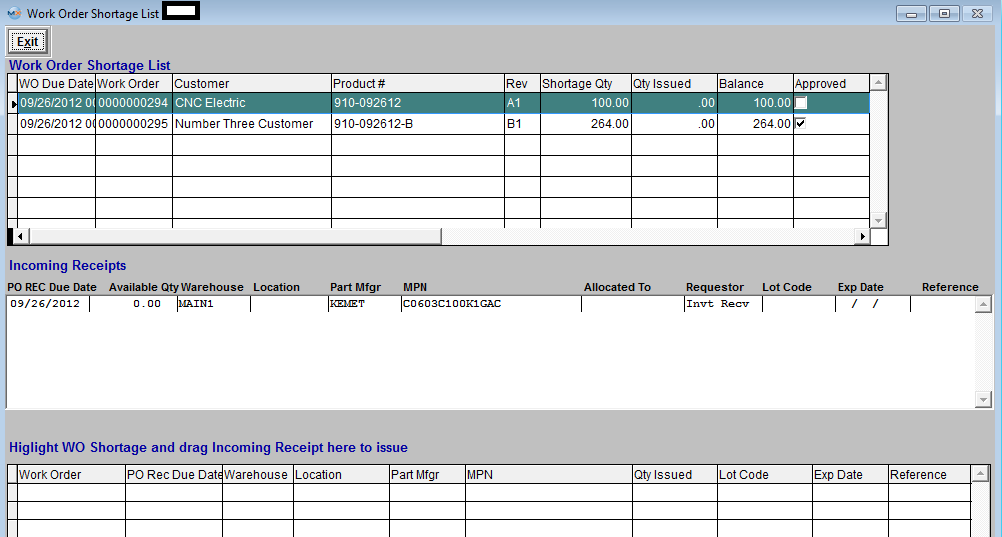

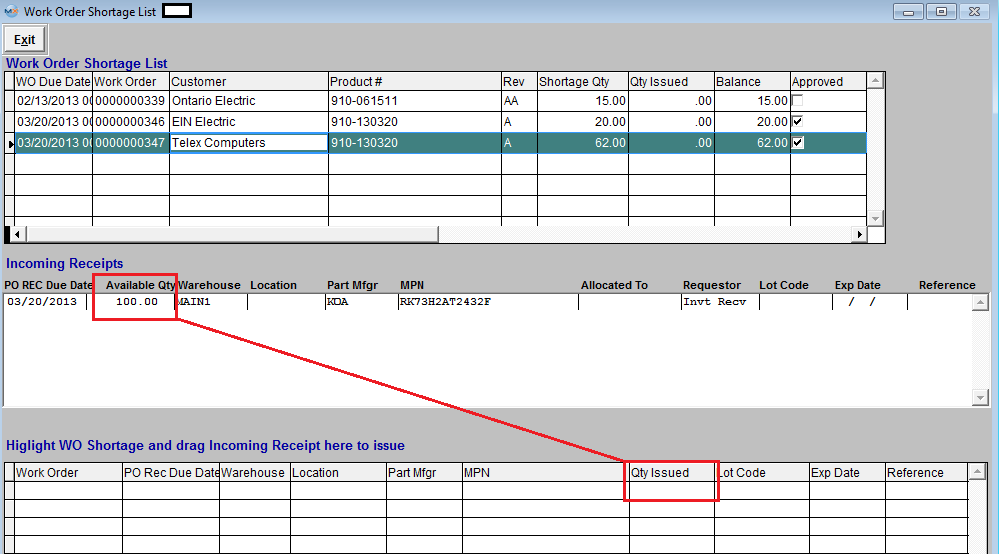

Within the PO Receiving module there is a "Shortage List and Issue" button. This will allow users to issue parts from receiving directly to the Kit Shortages. This screen will display all shortages for that part and AVL. There is an Approved Check box for reference to the Work Order Shortage List. This will be checked if the AVL that you are receiving is an approved AVL for that shortage. This will give the users the needed information on screen to make the decision to use or not use a non-approved AVL to fulfill a shortage. |

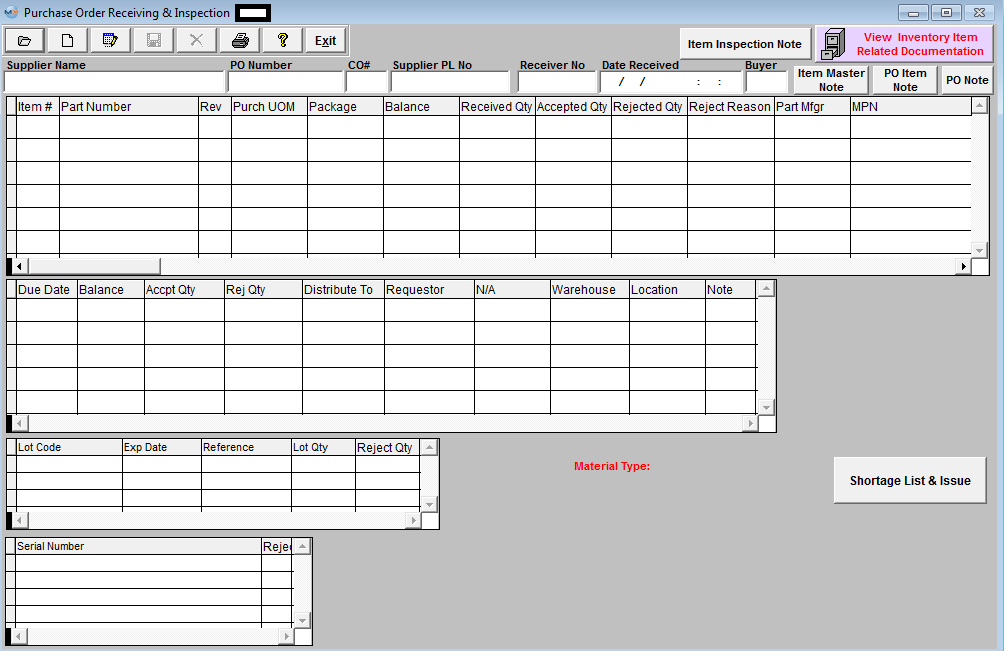

| 1.3.2.3. Fields & Definitions for Purchase & Receiving Mgmt | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For the Highlighted Line Item:

Directive Buttons:

The system shows all the shortages for the part that is received, if:

It is up to the user to decide which receipt has to be applied to which shortage. Work Order Shortage List field definitions:

Incoming Receipts field definitions:

Highlight WO Shortage and drag Incoming Receipt here to issue field defintions:

|

| 1.3.2.4. How To ..... for Purchase & Receiving Mgmt |

| 1.3.2.4.1. Find a Purchase Order in Receiving Inspection | ||||||||

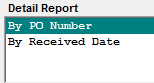

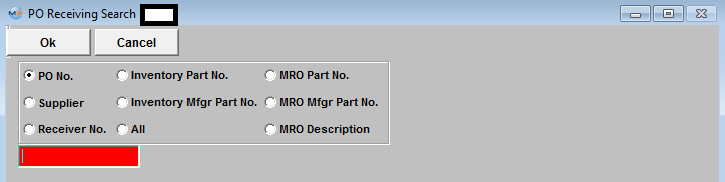

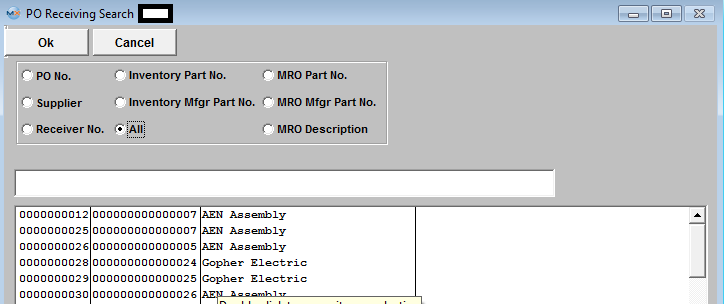

The following screen will be displayed:

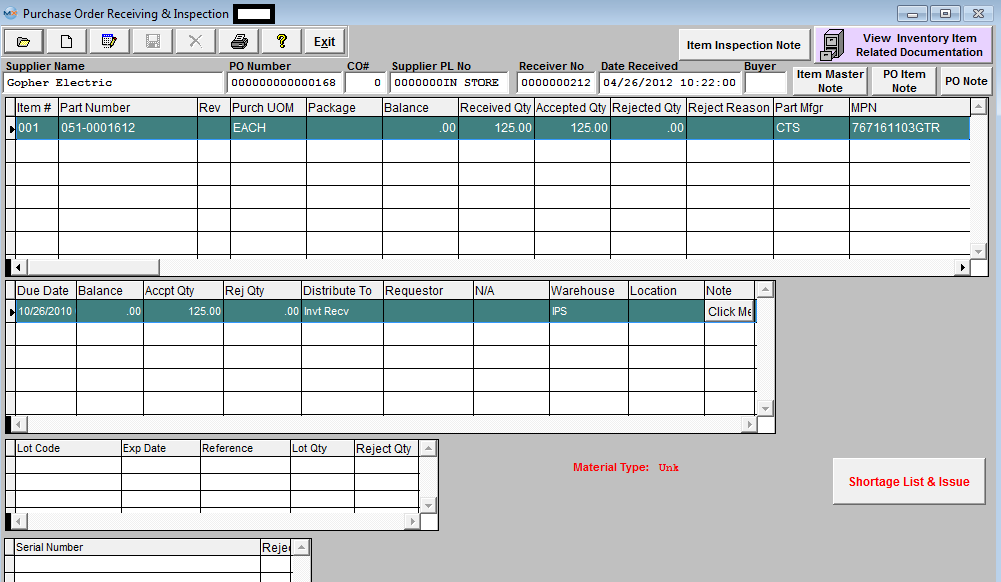

3. The found information will populate the screen, as follows:

|

| 1.3.2.4.2. Add a PO Receiving Inspection Record | ||||||||

The following screen will be displayed:  If system is setup for Dock Receiving a PO Dock receiver MUST be created before the PO will be available.

|

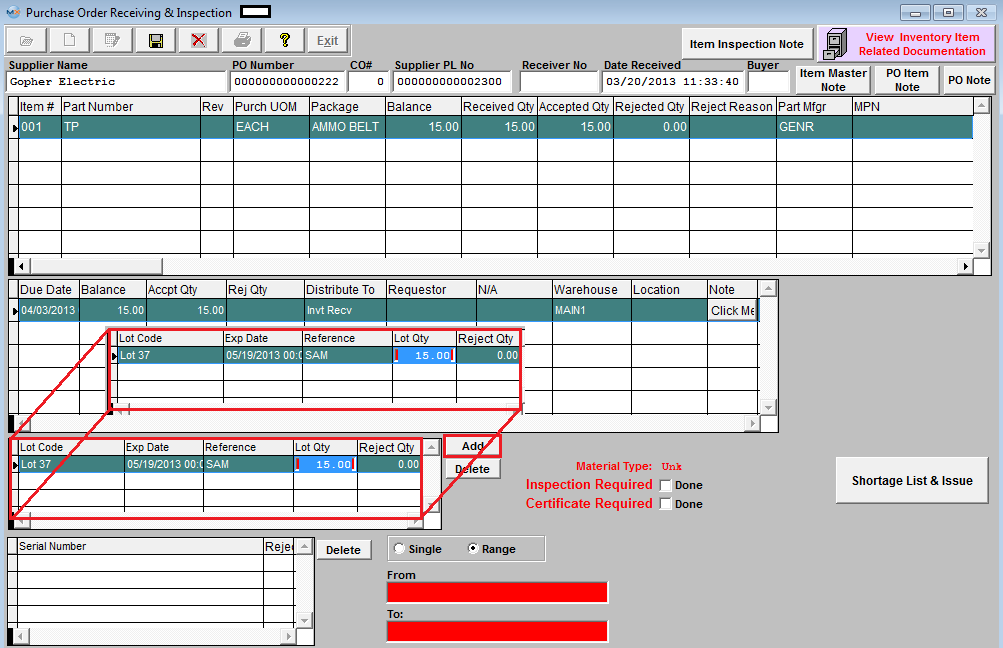

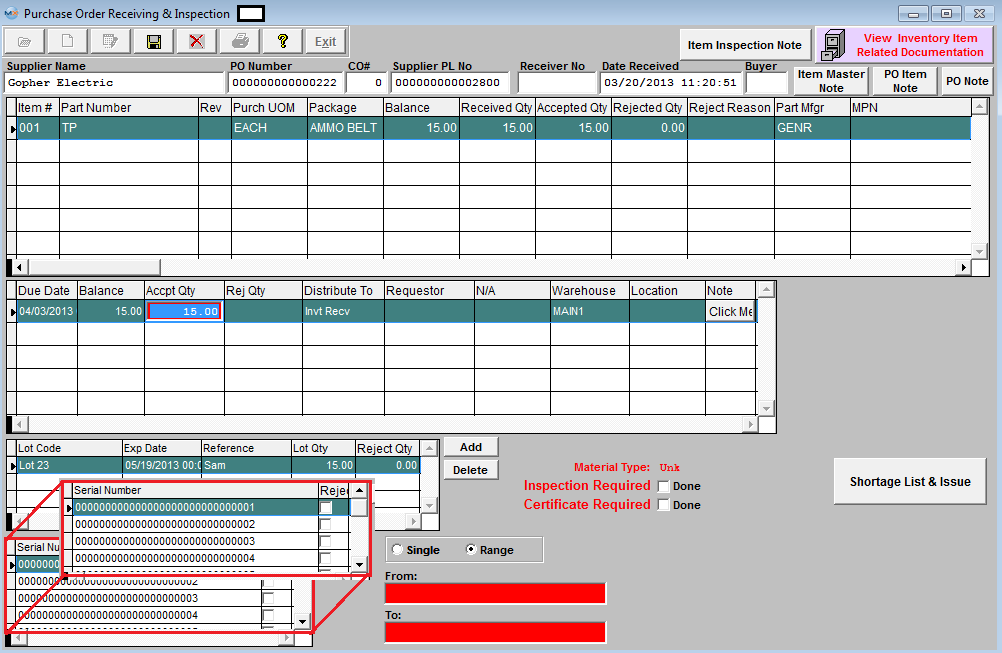

| 1.3.2.4.2.1. Entering Serial Number and/or Lot Information |

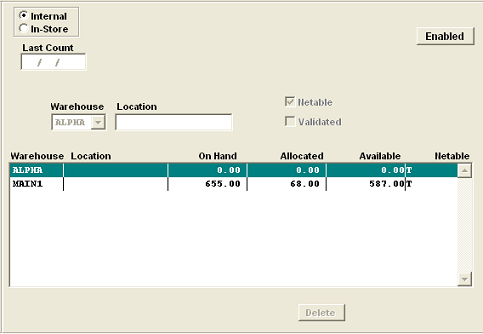

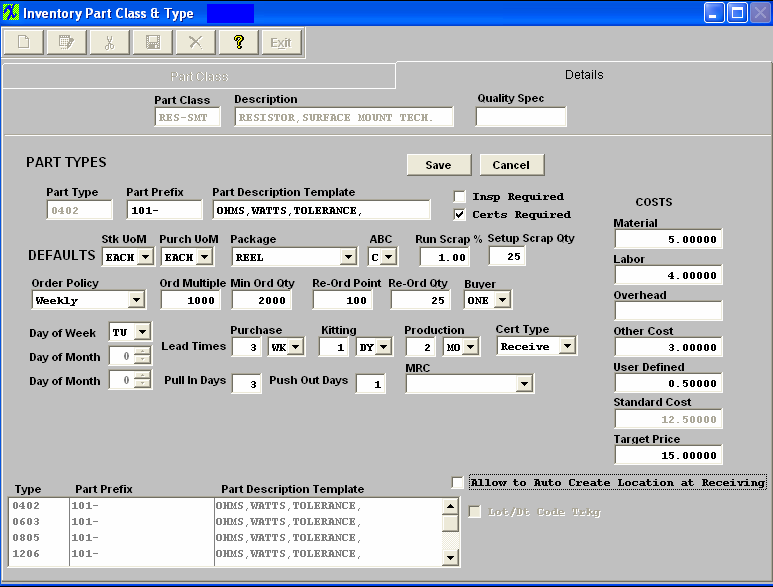

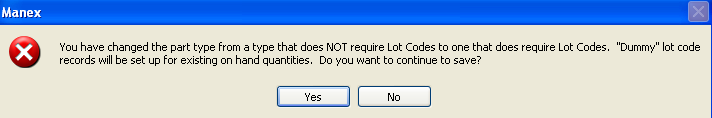

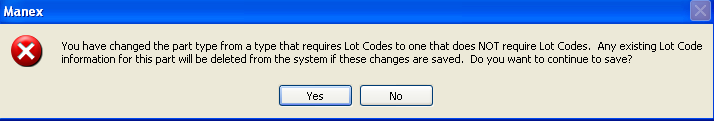

Introduction The users can receive components that require Lot Code Only, Serial Number Only, or both Serial Number and Lot Code, following the instructions listed below. A part that requires a Lot Coded is setup in the Inventory Part Type set-up module. A part that requires Serial numbers is set-up in Inventory Control Module.

|

| 1.3.2.4.2.2. Issue Directly to Work Order Shortages |

Highlight the line item of interest on the PO Receiving and Inspection screen. Depress the Work Order Shortage List and Issue button. Highlight the work order shortage at top of screen. Drag Available Qty located in the middle of your screen under Incoming Receipt. Drop it in the quantity issued at the bottom of your screen as displayed below. System will allow users to pick to each of the individual shortages within the same Work Order and/or different Work Orders.

The Approved box will be checked if the AVL that you are receiving is an approved AVL for that shortage. This will give the users the needed information on screen to make the decision to use or not use a non-approved AVL to fulfill a shortage.

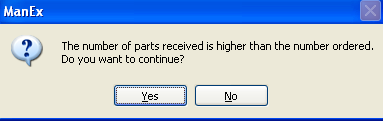

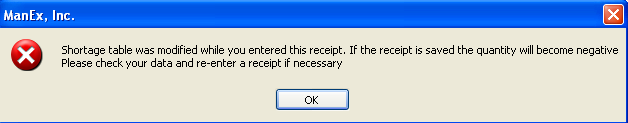

System will not allow user to issue quantities greater than the shortage quantity. See Article #2479 for further detail. The following messge will be displayed if user issues a quantity greater than the shortage quantity.  NOTE: If a user has the Work Order Checklist feature active and tries to use the PO Receiving shortage and issues feature within the PO Receiving, it will not recognize the shortages until the kit has been flagged as "Kit Complete". It is designed this way because the user will not know if the parts are short until the kit is completed. You may have parts in the inventory and have not pulled them to the kit yet. If you allow seeing the shortage (which may not be a shortage because parts are not pulled yet) from the PO receiving, the receiver may be trained to automatically issue to the shortages first, but it may not be a shortage because parts have not been pulled from inventory, so how would they know if it is a real shortage or just not pulled from inventory yet. |

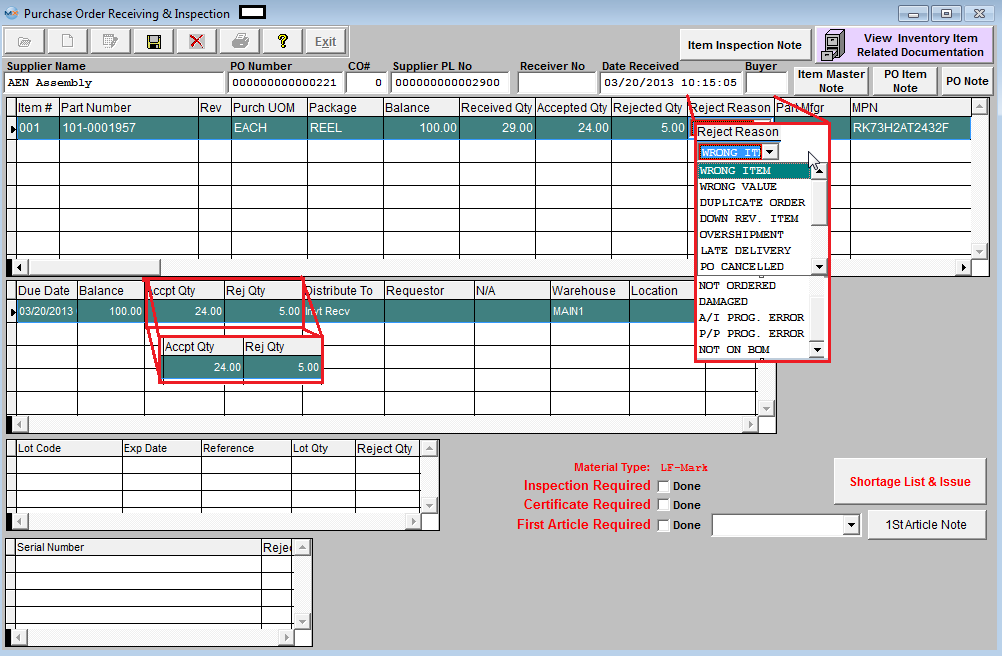

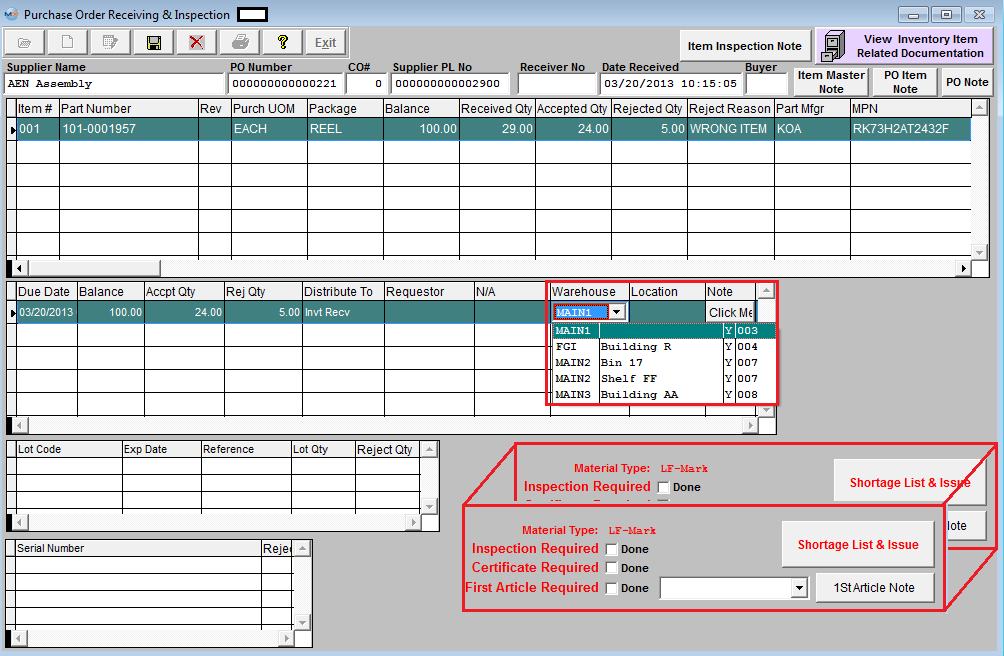

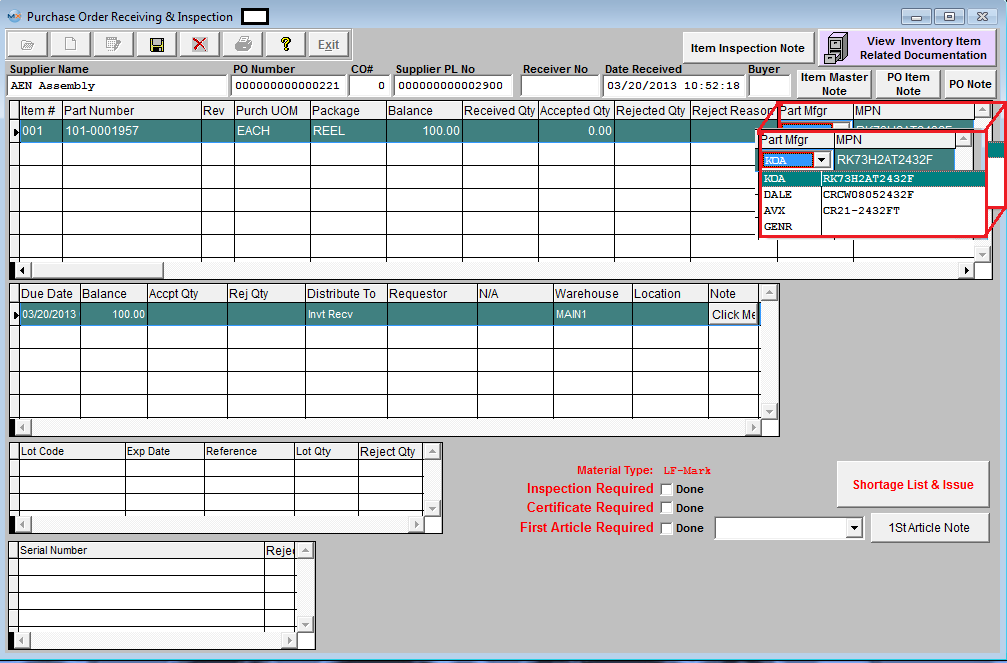

| 1.3.2.4.3. Rejecting Quantity in PO Receiving & Inspection |

|

| 1.3.2.4.3.1. Rejecting Items if Accounting has Processed the Invoice |

|

| 1.3.2.4.3.2. Rejecting Items if Accounting hasn't Processed the Invoice |

Introduction After the user has accepted all of the items on a Closed Purchase Order and then subsequently it’s discovered that the material received is discrepant, do the following if Accounting hasn’t already processed the Supplier’s Invoice for payment:

|

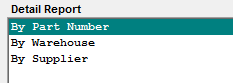

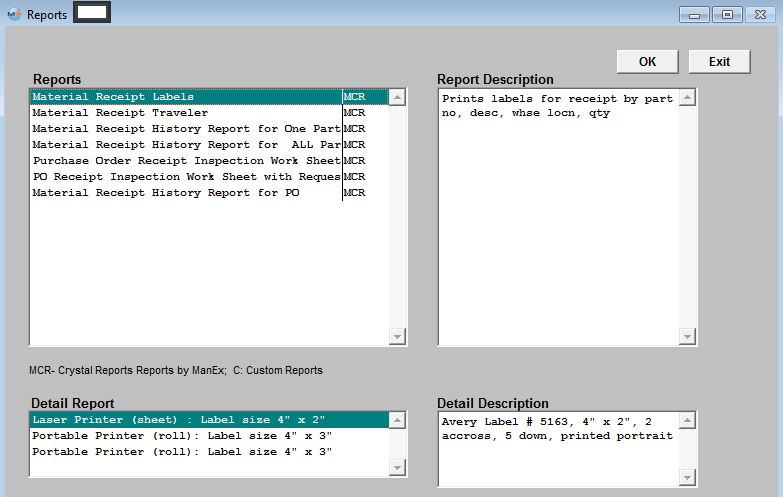

| 1.3.2.5. Reports - Purchase & Receiving Mgmt | ||||||||||||||||

To obtain the AP

Aging Reports within the Web, select the WEB Print button from the ManEx action buttons at the top

of the screen. For further detail on How the Reports work within the Web refer

to Article #5477.

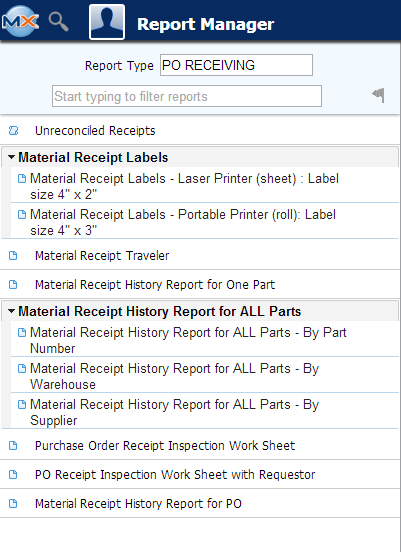

Select the Report Type: PO RECEIVING - A List of Reports will be displayed that are available on the Web

for PO RECEIVING

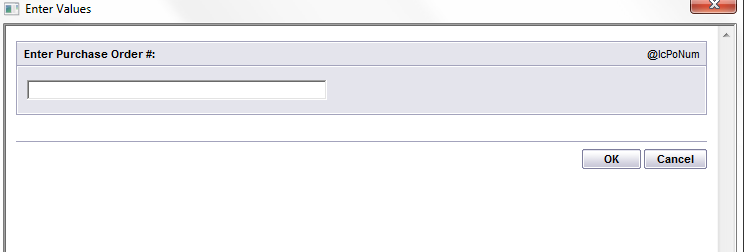

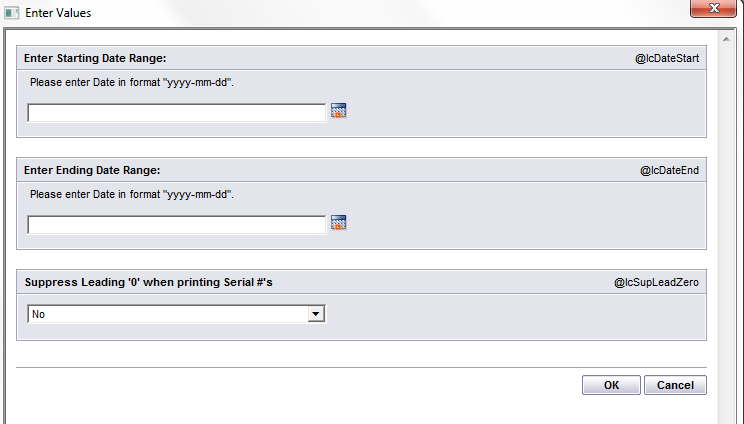

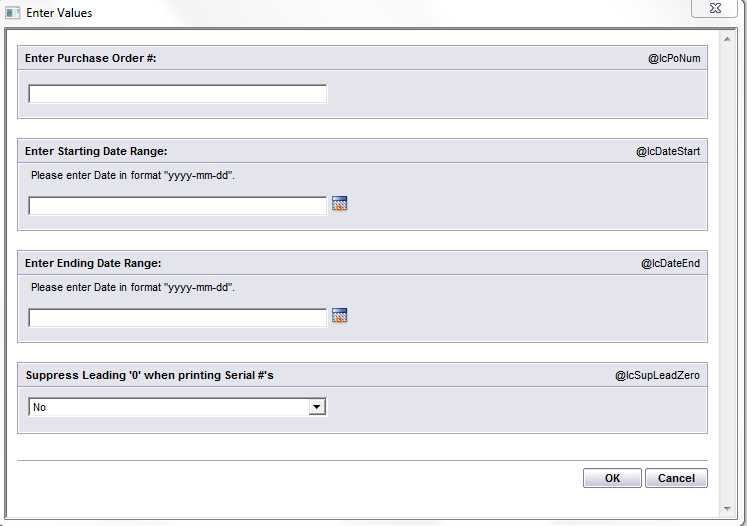

To obtain the PO Receiving reports, select the Print button from the ManEx action buttons at the top of the screen. The following reports screen will display a list of reports that are available on the ManEx Desktop:  Highlight the desired report and then depress the OK button.

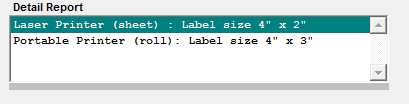

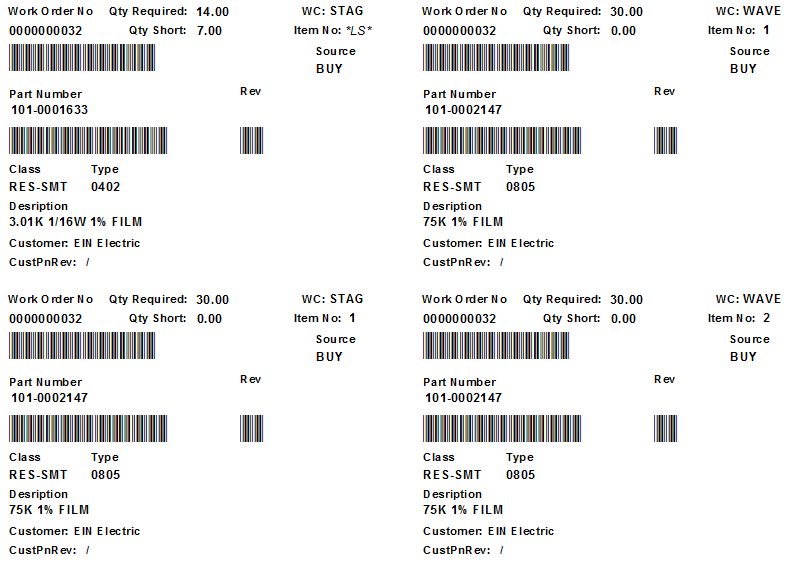

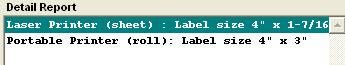

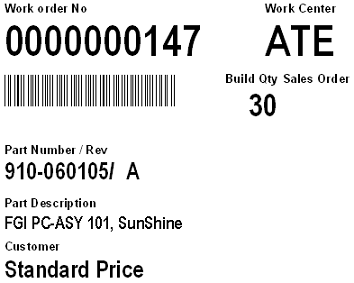

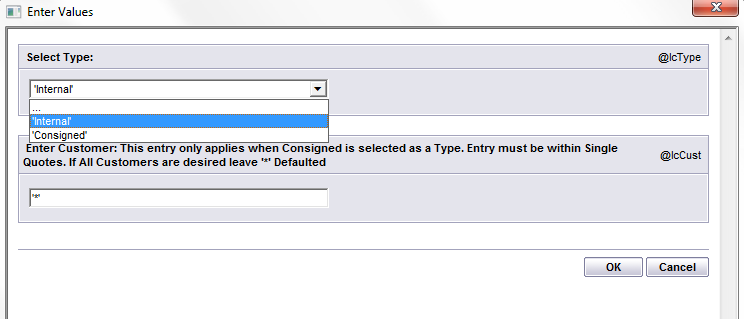

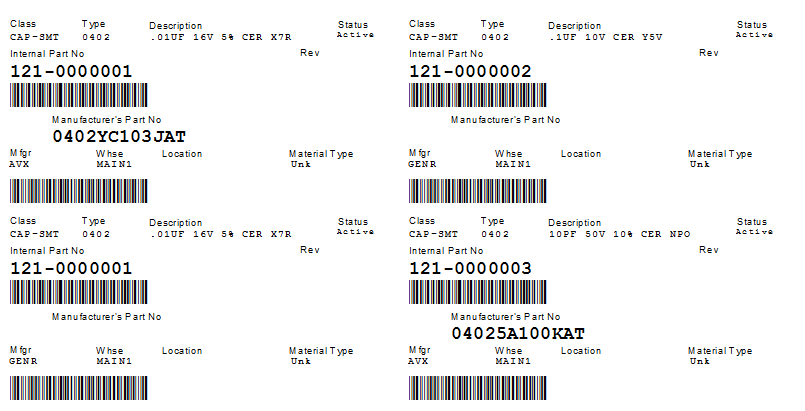

MATERIAL RECEIPT LABELS - Prints labels for receipt by part no, desc, whse locn, qty

The following is printed (This example is Printing to the Laser Printer (Sheet): Label size 4" x 2")

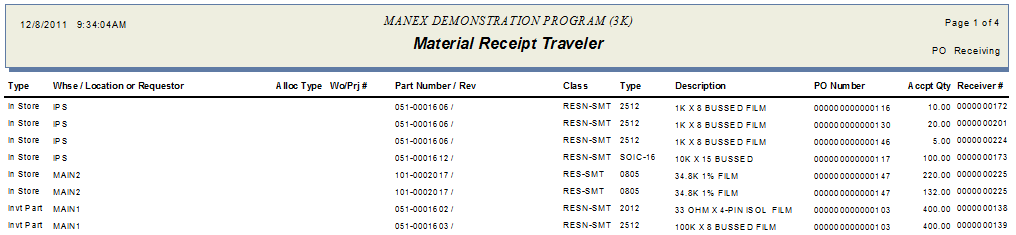

MATERIAL RECEIPT TRAVELER REPORT - This report will display requestor, par no, PO #, accept qty, receiver #

For the Material Receipt Traveler report, highlight that report. MATERIAL RECEIPT HISTORY FOR ONE PART REPORT - This report will display PO#, Supplier, requestor, date, recd qty, rej qty

The following is printed:  MATERIAL RECEIPT HISTORY REPORT FOR ALL PARTS - This report will display PO#, supplier, requestor, date, recd qty, location, mfg pn

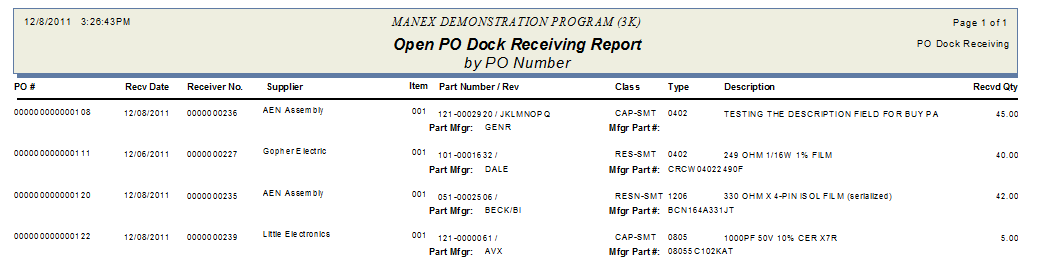

The following is printed:  PURCHASE ORDER RECEIPT INSPECTION WORKSHEET - Purchase Order Receipt Inspection Work Sheet for the items had been received in PO DOCK module

PURCHASE ORDER RECEIPT INSPECTION WORKSHEET with REQUESTER - Purchase Order Receipt Inspection Work Sheet for the items had been received in PO DOCK module with Requester Information

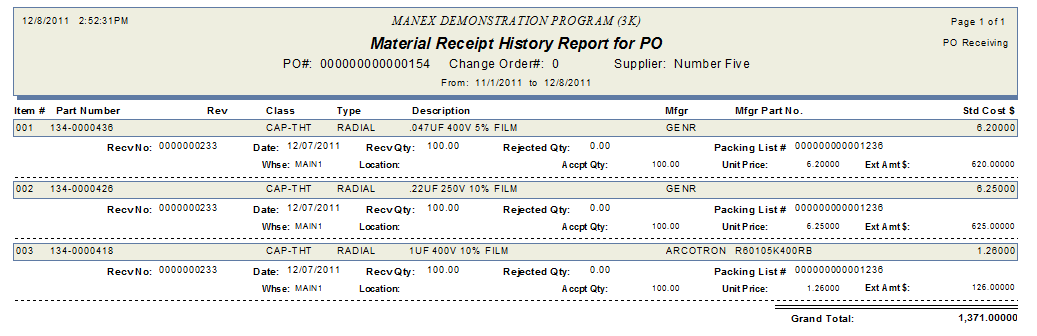

The following is printed:  Material Receipt History Report for PO - This report displays the Item #, type, date, qty rec'd,. price, total $

The following will print:

|

| 1.3.2.6. FAQs - Purchase & Receiving Mgmt |

| Facts and Questions for the PO Receiving & DMR Module |

| 1.3.3. PO DMR |

| 1.3.3.1. Prerequistes for PO DMR | ||||||

Prerequisites for PO Inspection/Acceptance Received with Rejected Quantities:

After activation, "Purchase Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

There must have been a rejection in the Purchase & Receiving Management module. Prerequisites for Rejects from Inventory:

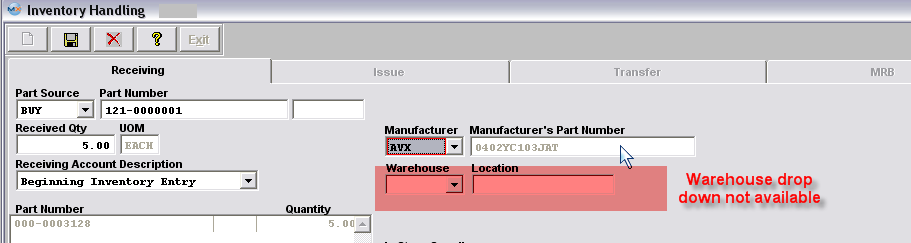

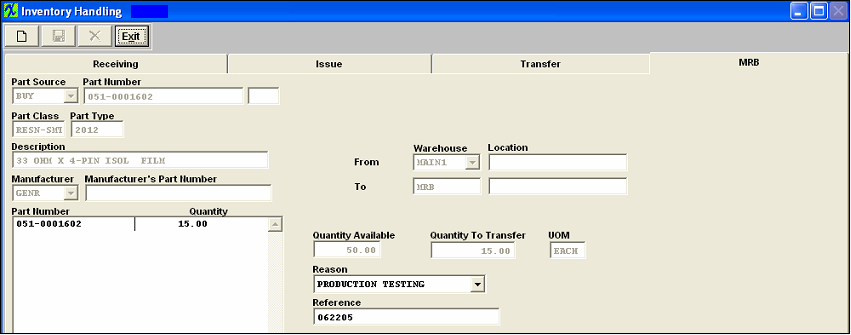

A MRB (materials review board) Warehouse must be set up in Warehouse Setup. Within Inventory Handling the discrepant quantity must have been transferred to MRB (materials review board) warehouse.

|

| 1.3.3.2. Introduction for PO DMR |

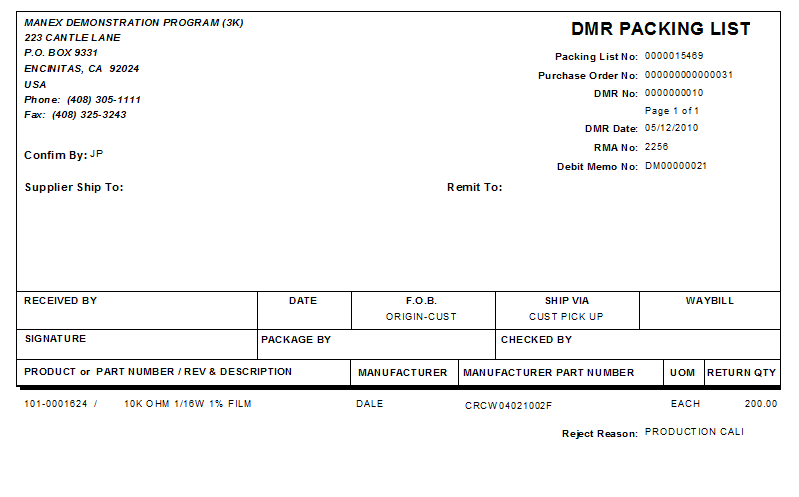

Discrepant Material Return is used to return material which is different than what was ordered, received late, over shipment, damaged, etc. There are two ways to return discrepant materials. 1. The discrepancy is discovered in PO Inspection/Acceptance Receiving and rejected there. 2. The discrepancy is discovered after the Inventory has been placed into stock. This module allows for review by the Materials Review Board. Then, if not acceptable, the material may be returned to the supplier. Once the DMR (discrepant material return) is created, information regarding the return is forwarded into Accounting where a Debit Memo and the accompanying accounting journal entry is created. Once the Discrepant Material is added, the user may print out a DMR (discrepant material return) Packing List.

In Defect Code Entry we allow users to move product into FGI, when a part is transferred to FGI, the program will compare the total cost of components with the "material cost" of the assembly, then create the configuration variance. In addition to that, the system will create additional 4 records for "Labor", "Overhead", "Other Costs" and "User Defined" costs.

|

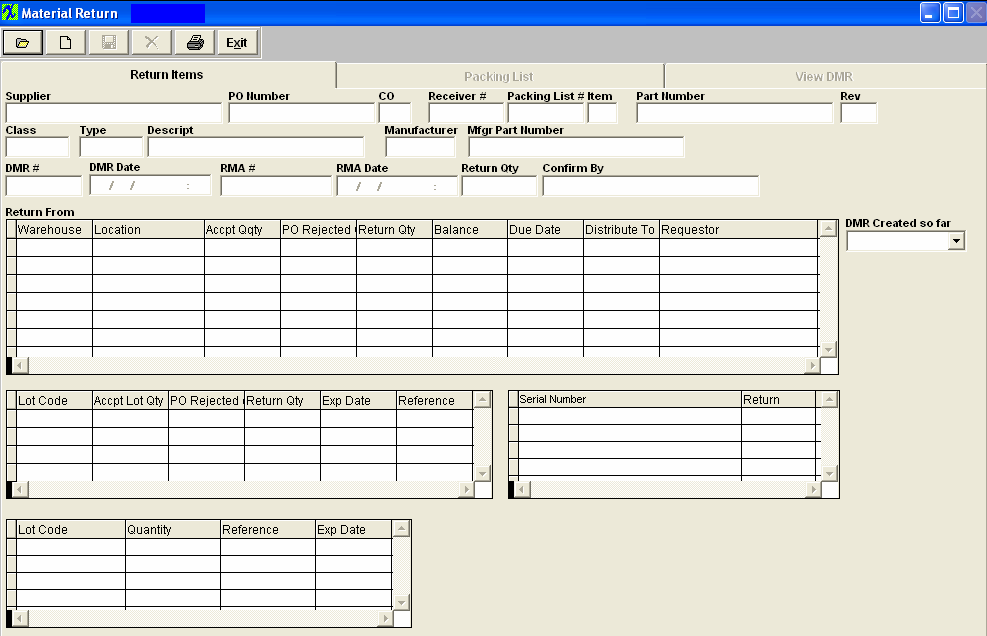

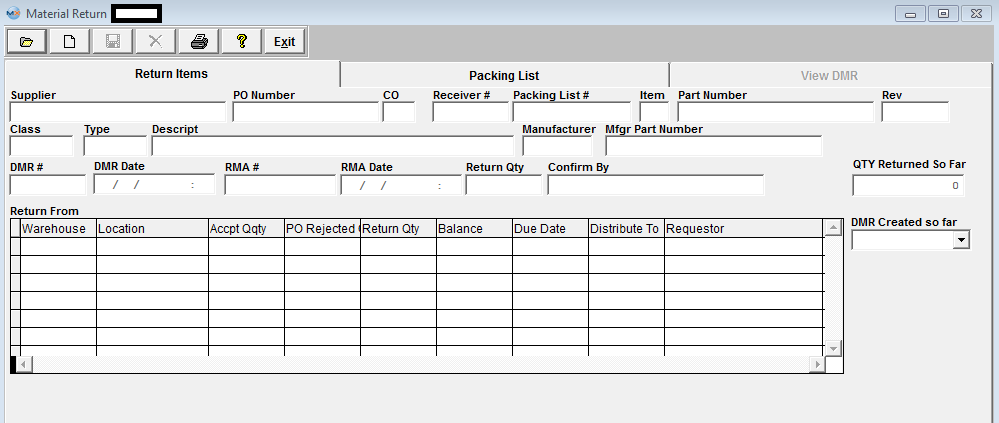

| 1.3.3.3. Fields & Definitions for PO DMR |

| 1.3.3.3.1. Return Items Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fields & Definitions

Return Items tab field definitions

|

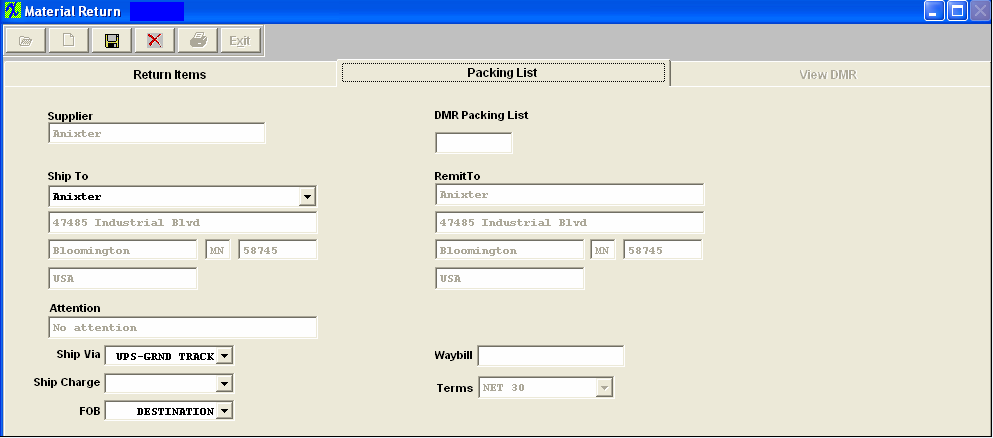

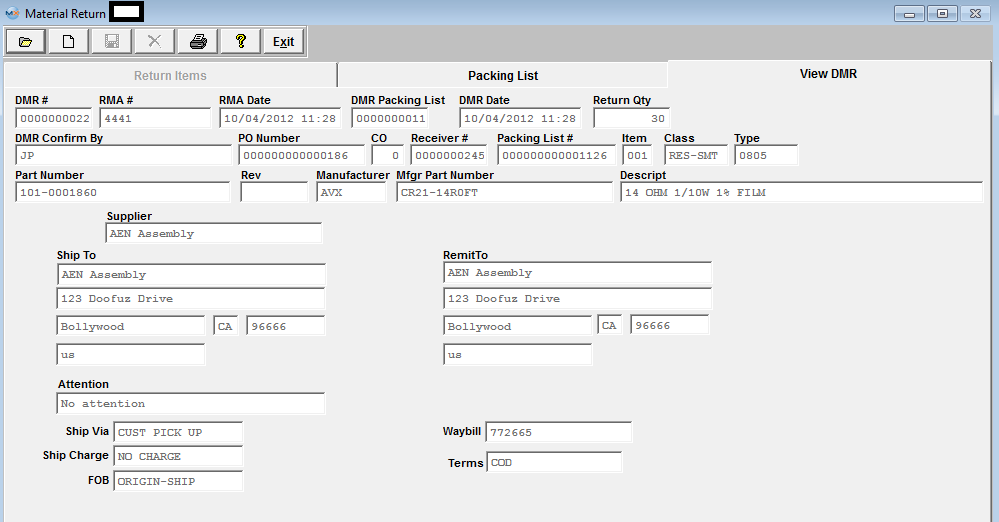

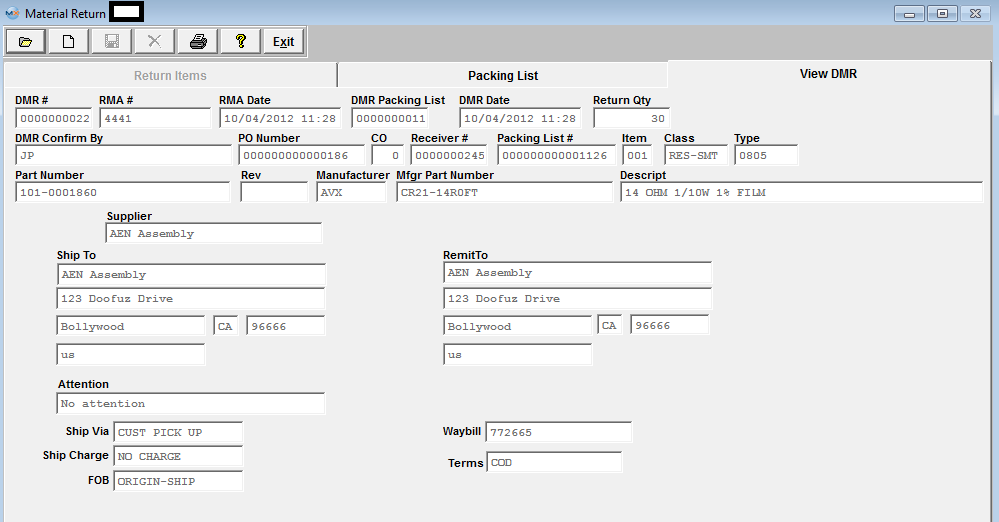

| 1.3.3.3.2. Packing List Tab | ||||||||||||||||||||

Field & Definitions

|

| 1.3.3.3.3. View DMR Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| 1.3.3.4. How To ..... for PO DMR |

| 1.3.3.4.1. Adding a DMR from Inventory | ||||

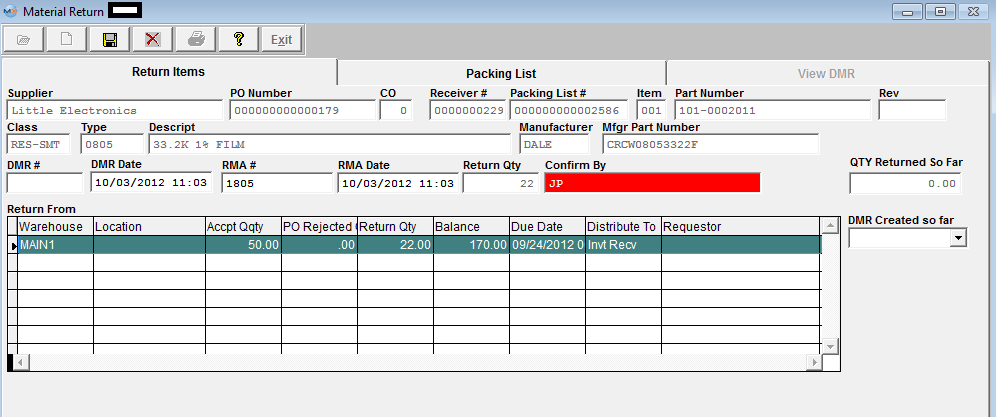

This procedure is used after accounting has Reconciled the Purchase Order. If accounting has NOT yet reconciled the purchase order, see Rejecting Items if Accounting hasn't Processed the Invoice. Note that the discrepant material must be transfer into the MRB (materials review board) warehouse via Inventory Handling before you can proceed.

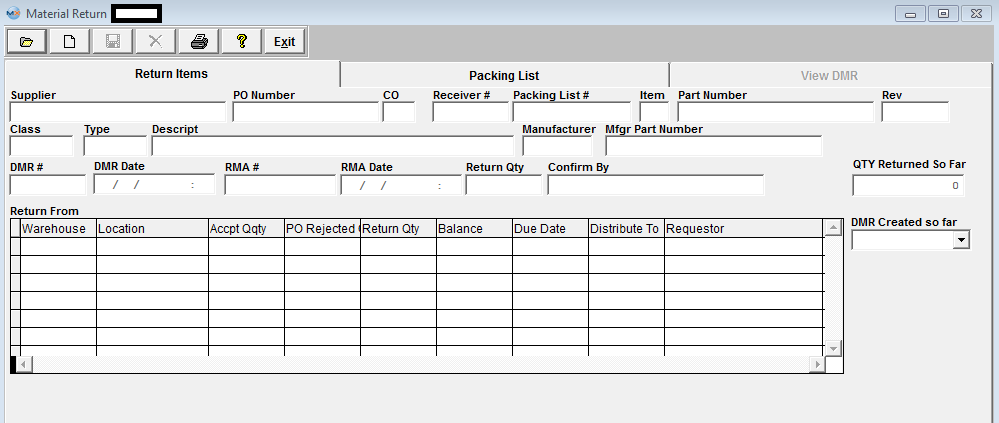

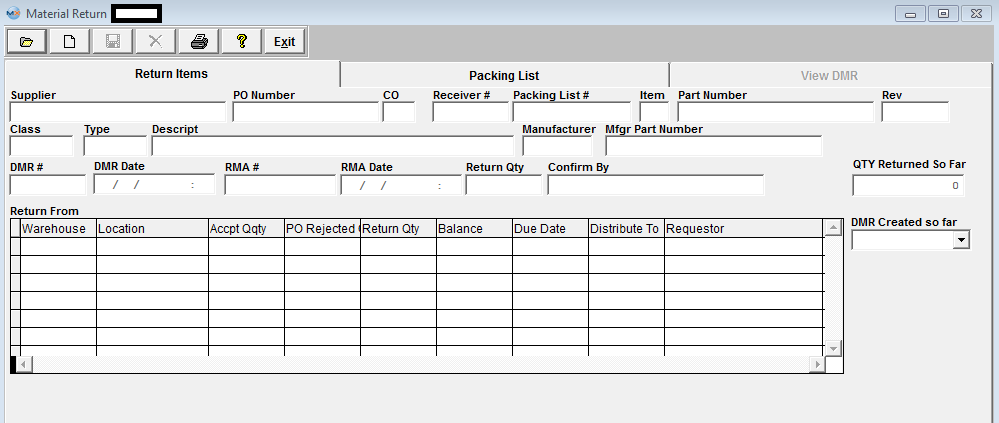

The following screen will be displayed:

Depress the Add button and user will be prompt for a password.

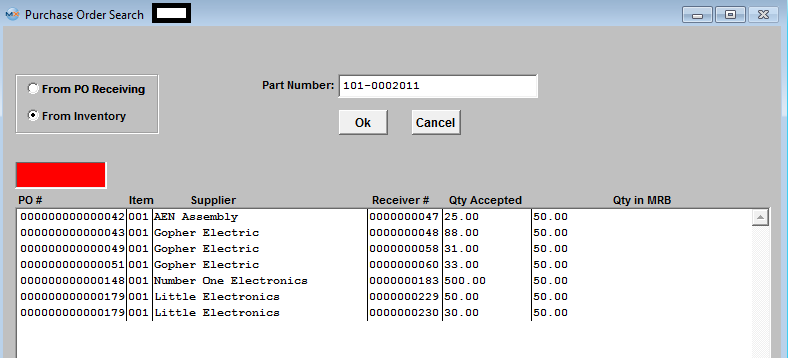

The following screen will be displayed:  Select the "From Inventory" radio and the following screen will be displayed.

Enter in the Part Number and depress the OK button. The following screen will appear (If there is more than one Purchase Order involved it will list them all)

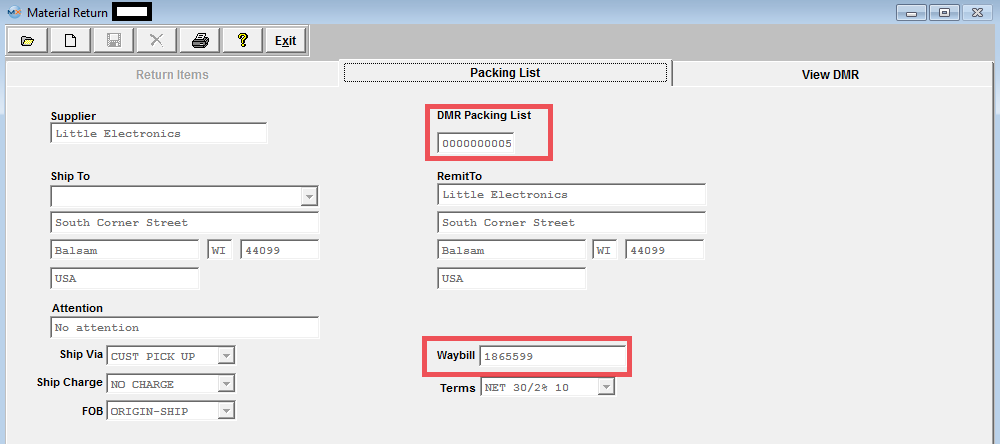

Highlight the Purchase Order of Choice, Depress the OK button. Information regarding that part number for the Purchase Order selected will display:  Depress the Packing List tab, and enter in a DMR Packing List number (if set to manual) for the return, and a Waybill number if applicable.

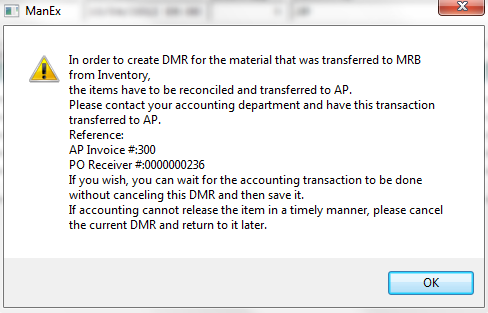

Once the DMR (discrepant material return) has been added and saved, a Debit Memo will be created, if an AP invoice exists (in order for a AP Invoice to exist you have to have reconciled the PO and transferred it to AP). If Debit memo numbering is manual, the user will be prompted for the number. Additionally, the corresponding entry will be created and the balance in the Accounts Payable Aging will adjust as soon as the Debit Memo is printed. If a PO DMR is created for parts "From Inventory" and the PO has NOT been reconciled and Transferred to AP the qty rejected will be put back on the PO.

The following message will be displayed and the system will NOT be able to create a DMR from Inventory for a part that has been changed from being a Lot-Coded part to a Non-Lot Coded part or visa-versa after PO Receipt has been created.

User should change lot code tracking status with caution. If a part has lot code history and the lot code tracking is de-activated the entire lot code history is wiped out.

1. If accounting HAS reconciled the PO but HAS NOT transferred the reconciled invoice into AP Aging, the following message will appear:

If the invoice happens to be in a Saved Check batch the following warning will be displayed:

|

| 1.3.3.4.2. Add a DMR from a PO Inspection/Acceptance Receiving Rejection | ||||

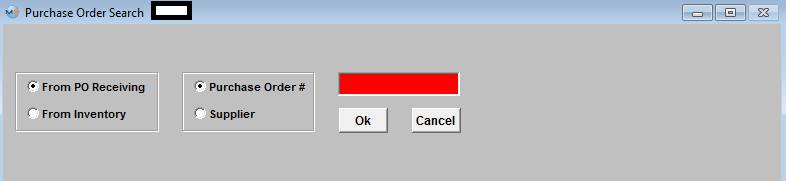

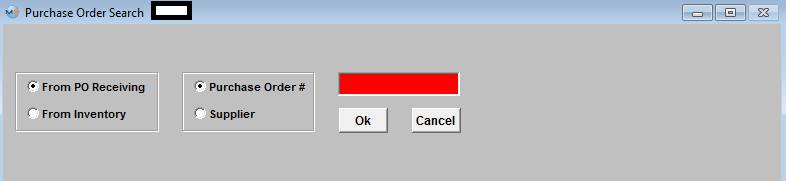

The following screen will be displayed:  Depress the Add button and user will be prompt for a password, enter their password and the following screen will be displayed:

The defaults for this screen are "From PO Receiving" and "Purchase Order #"

If you chose the default (Purchase Order #), you will need to enter in the number of the PO on which the material was rejected. If you chose Supplier, you must then enter in the name of the Supplier.

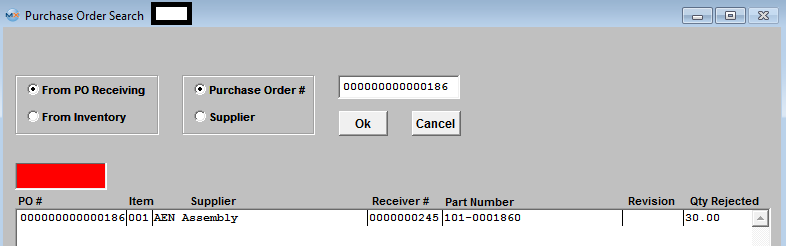

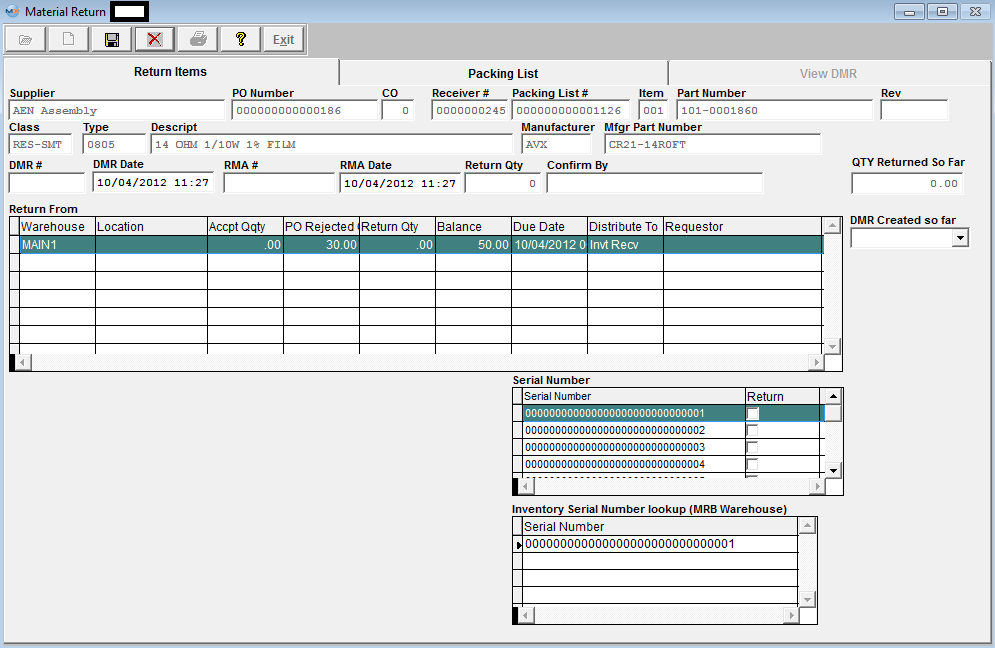

Enter in the number of the PO which the material was rejected and the PO and related information will populate on screen.

Highlight the PO and depress the OK button.

Note: Ther are additional fields displayed on screen if there are Serial Numbers and Lot Codes involved.

Enter in the DMR number (if set-up for manual numbering) you are assigning to this return. Enter in the RMA number as provided by the supplier. Then enter your name in the Confirm By space.

Highlight the line item containing the rejected quantity. (If returning a part that involves a Lot Code, type in the returned quantity in the Lot Code section and it will automatically update the Return From section. Check the serial numbers being returned).

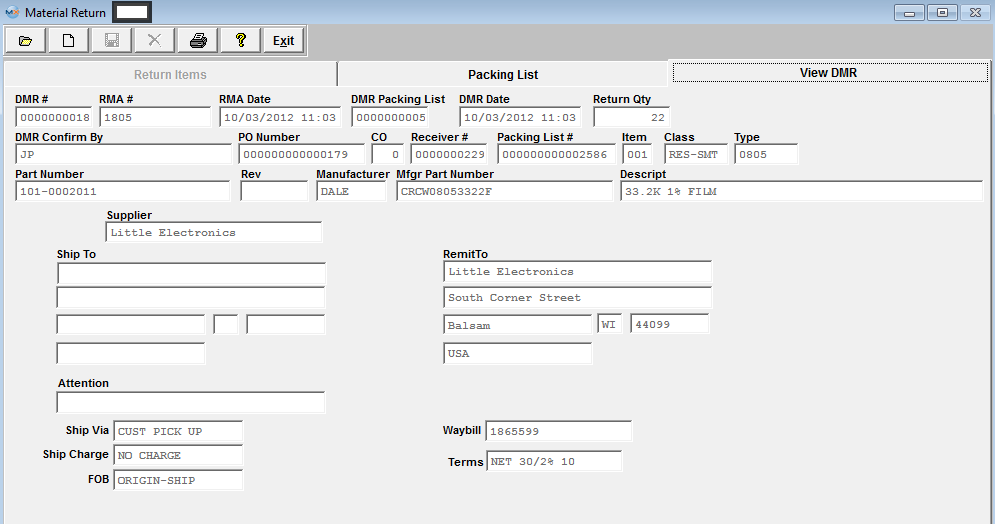

Depress the Packing List Tab, enter in a Packing List number you wish to assign to the return (if set to manually numbering). (Note that this number is NOT tied to regular shipping Packing Lists. This field is only for reference on the DMR’s. Any alpha-numeric code can be used here. DMR packing list numbers cannot be found in the regular shipping module – Packing List Management. It is suggested that the user manually log these codes or type in some kind of significant code, such as the date followed by the PO#). Enter in the Waybill.

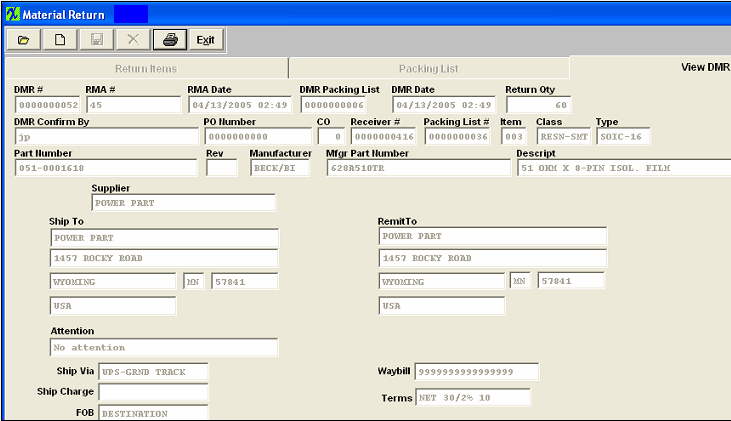

Depress the Save button. The View DMR screen will appear:

|

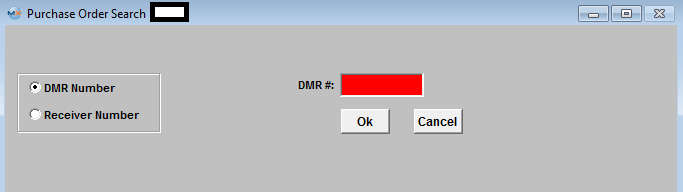

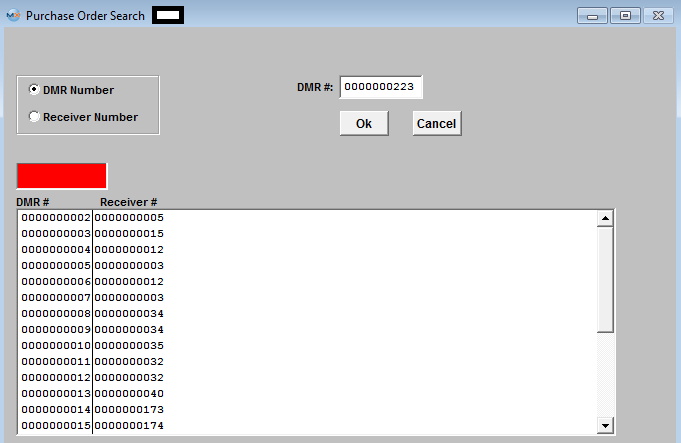

| 1.3.3.4.3. Find an Existing Discrepant Material Record (DMR) | ||||

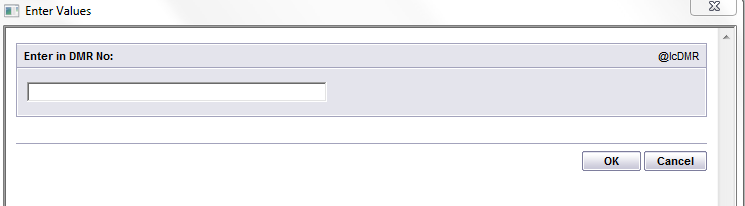

The following screen will be displayed:  Depress the Find icon, the following screen will be displayed. User can select to find an existing DMR by entering the DMR Number or entering the Receiver Number in the Rd box and depressing the OK button:

If the system cannot find any information about the DMR # entered the following message will be displayed giving the user the option to select from a list of existing DMR's:

If User Selects "YES" the following screen will be displayed listing all of the existing DMR's

Enter the DMR# in the Red box or double click on the DMR# and the following information will be displayed:

|

| 1.3.3.5. Reports - PO DMR | ||||

|

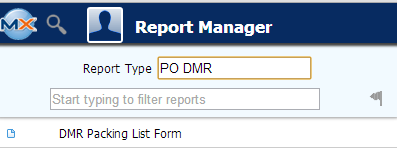

To obtain the DMR (Discrepant Material Return) Packing List Report within the Web, select the WEB Print button from the ManEx action buttons at the top of the screen. For further detail on How the Reports work within the Web refer to Article #5477. Note: In order to access the Reports within the Web the Company Root URL must be setup within the System Appearance module and user must be linked to web within the System Security Module Select the Report Type: PO DMR - A List of Reports will be displayed that are available on the Web for PO DMR

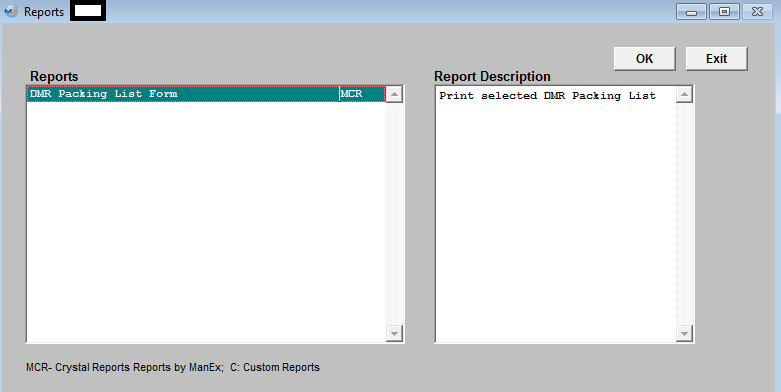

To obtain the DMR Reports within the desktop, select the Print button from the ManEx action buttons at the top of the screen.

The following reports screen will display a list of reports that are available on the ManEx Desktop: The following screen will be displayed:

The following will print:

|

| 1.3.3.6. FAQs - PO DMR |

| Facts and Questions for the PO Receiving and DMR Module |

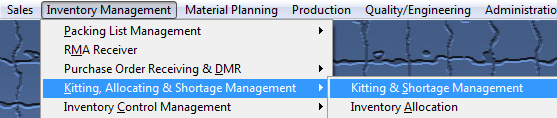

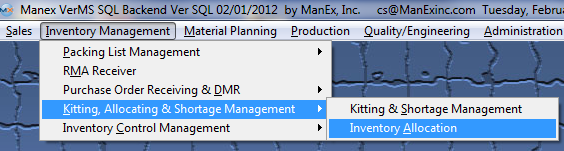

| 1.4. Kitting, Allocating & Shortage Management |

| 1.4.1. Kitting & Shortage Management |

| 1.4.1.1. Prerequisties for Kitting & Shortage | ||||||||||||

Prerequisites Required for Entering a New KITTING & SHORTAGE

After activation, "Kitting & Shortage Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

Optional Prerequisites for Entering a New KITTING & SHORTAGE

|

| 1.4.1.2. Introduction for Kitting & Shortage |

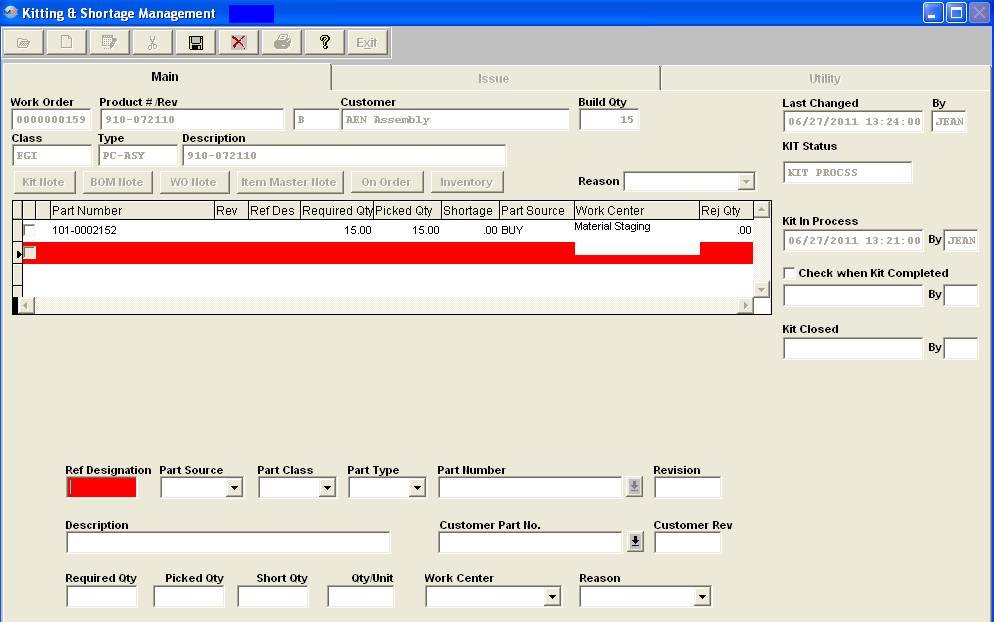

This screen provides a method for gathering data related to a specific Work Order. Users are able to simulate a kit pull to better determine component availability and identify potential delays. They also record unexpected component shortages allowing purchasing to order more and inventory to replace the components as needed.

See Article #3273 on "How ManEx can help you Streamline your Kitting Process".

|

| 1.4.1.3. Fields & Definitions for Kitting & Shortage |

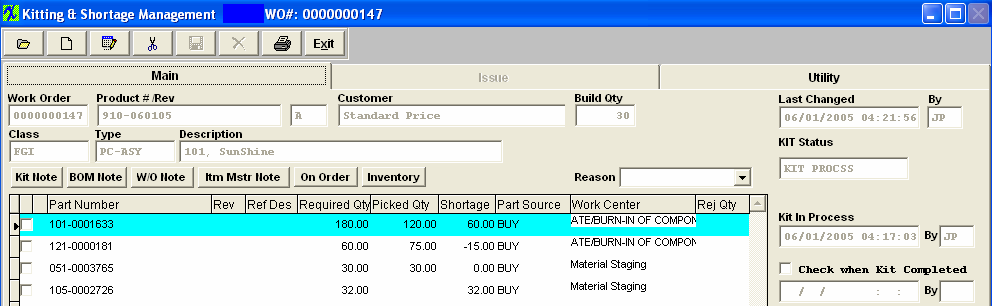

| 1.4.1.3.1. Main Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Screen Field Definitions

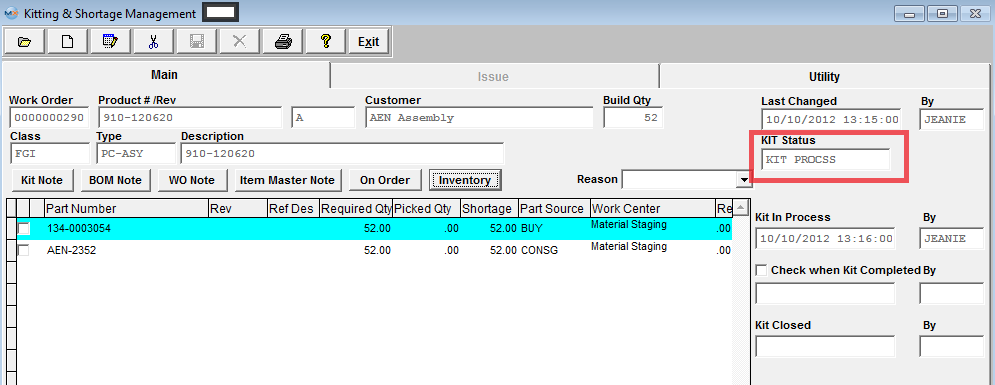

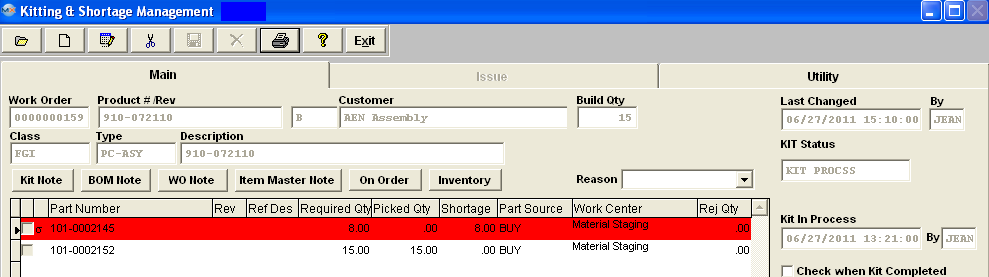

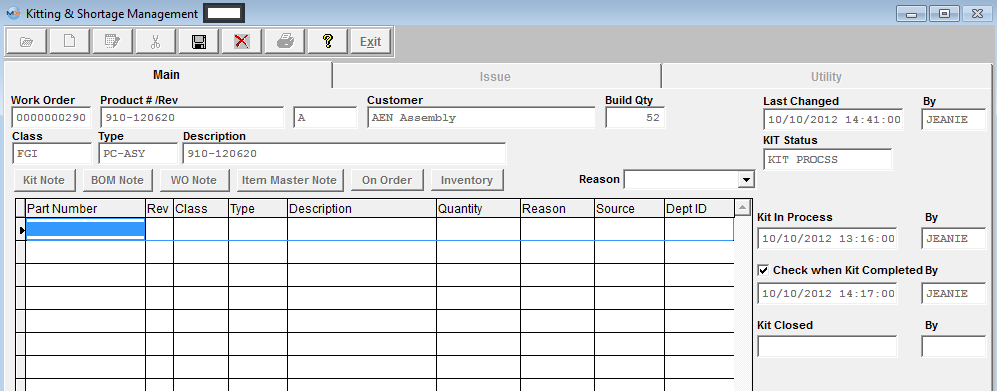

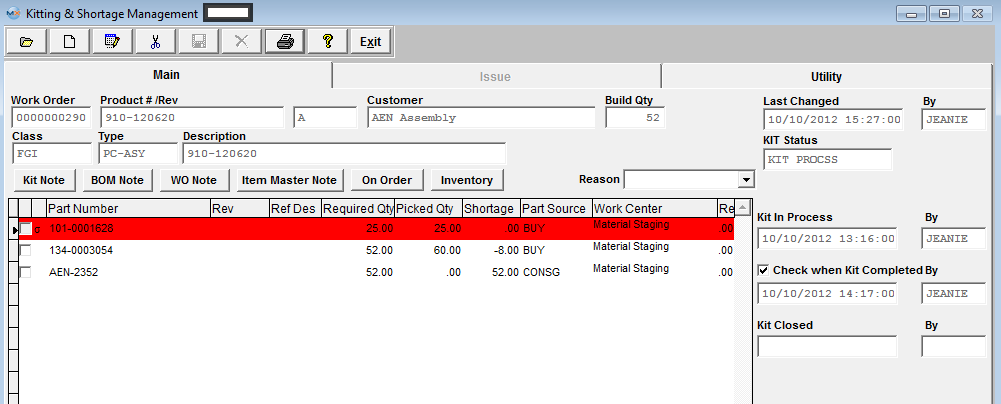

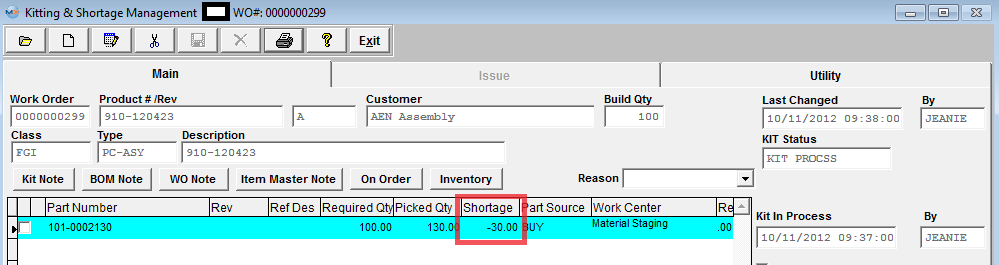

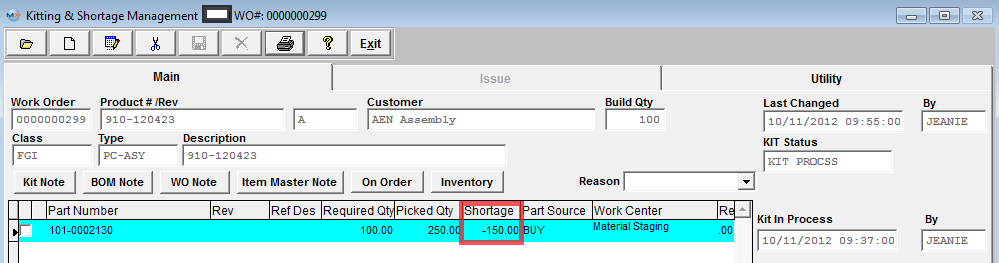

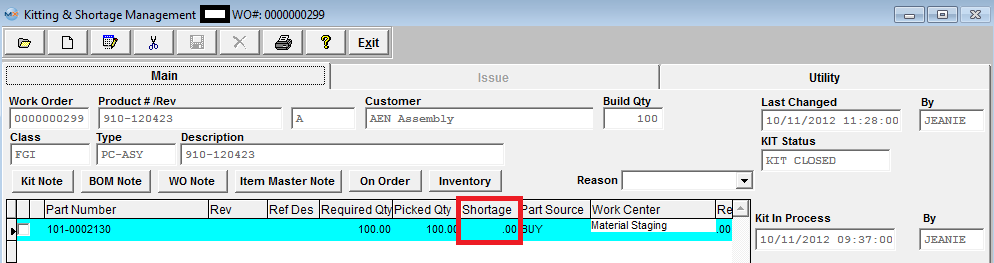

KITSTATUS ( character field) may be empty, or one of the following: Kit Closed, Kit Process, Rework. If the KIT MANAGEMENT screen has been opened, and any material issued to the kit, the condition of this field will be changed from empty to Kit Process. This field is NOT dependant on the KIT field, but by the logic described in Article #2679 , and cannot be changed unless the kit is released. Component Section

DIRECTIVE BUTTONS The following buttons are displayed on the Kitting Main screen

|

| 1.4.1.3.1.1. Kit Status Logic |

Status of Kit: Released is a term that means the work order has moved from the initial input condition, where it is possible to check on details of the work order and to utilize a check list to indicate certain functions (established in the setup) have been completed (e.g., necessary documents have been received, shortages have been resolved, tooling is available, etc.). An unreleased work order cannot be kitted, nor moved on the shop floor. KIT (a logic field) means that the work order has been released for production to work on it. This includes kitting and SFT. It means that in the WO screen, the user has clicked on the “Work Order Released” checkbox. Or, this box is automatically checked when all of the items on a work order check list have been completed. It does not mean that the work order or the kit have been started. Until this box is checked, no kitting nor SFT activities can begin. OPENCLOS ( character field) is the status, or condition of the work order. This condition is required to initiate a work order. These conditions must be one of the following: Archived, Cancel, Closed, Firm Plann, Rework, ReworkFirm, Standard. Every work order must have one of these conditions.

|

| 1.4.1.3.2. Issue Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Issue Screen Fields KIT STATUS SECTION

INVENTORY STATUS SECTION

PICKED STATUS SECTION

The quantity of the highlighted part already picked. Below that is the part number of the completed assembly. The "Next" button should be used with the top "part number (type or scan)" field. When user types (or scans) the part number the user wants to issue, the cursor on the left list will move to the right part number record, then user can issue it. After the user is done, click the "Next" button, the system will save the issued record, and the cursor will move to top "part number" field again for user to enter whatever part number the user wants to issue next. It doesn't mean the "next one" record in sequence. LOT CODE INFORMATION

ADDITIONAL PART INFORMATION

|

| 1.4.1.3.3. Utility Tab | ||

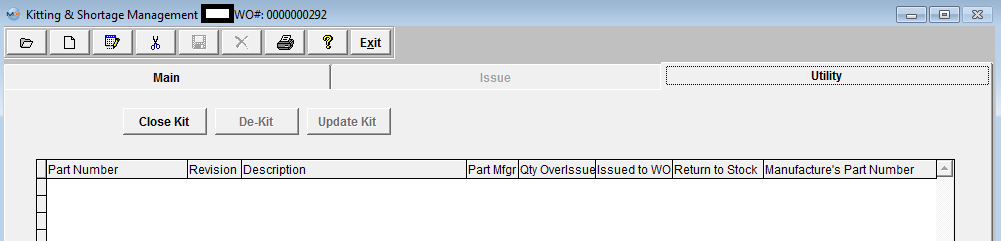

The Utility Tab has four functions:

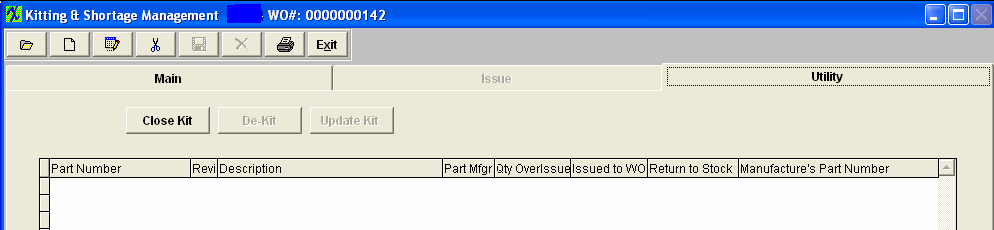

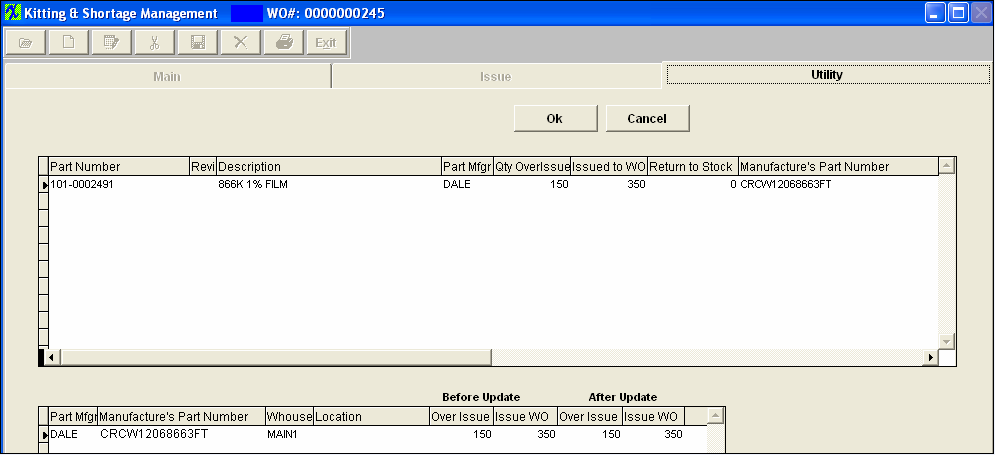

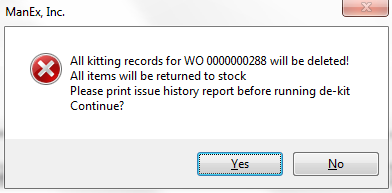

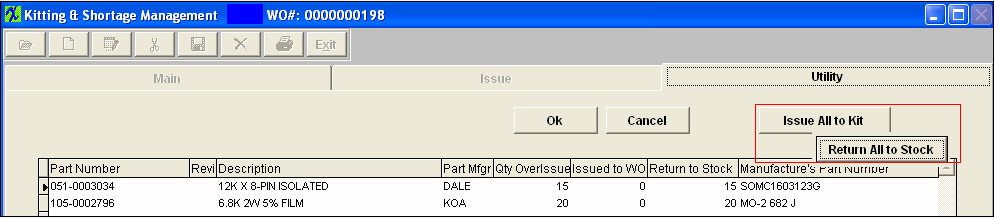

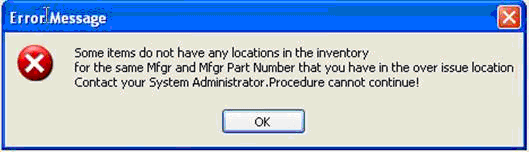

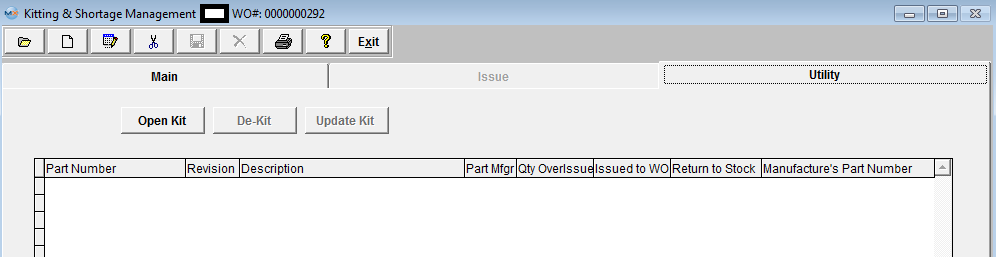

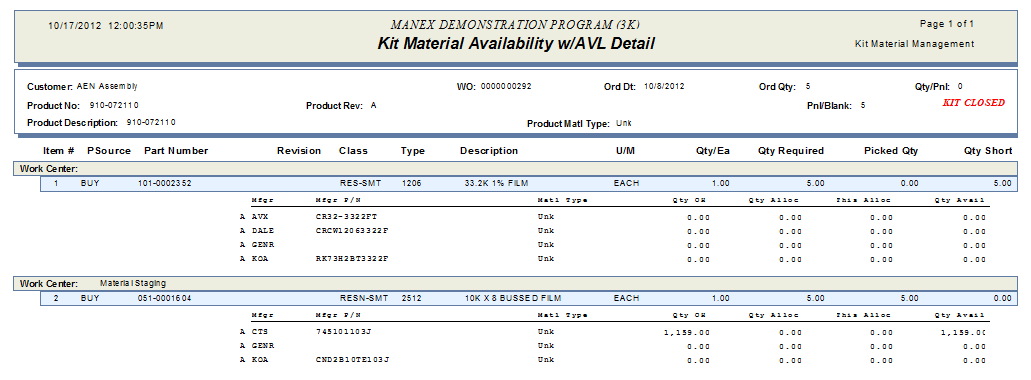

1. Close Kit - This section is used to close the kit from further transactions. Once closed, no further parts may be issued to or from the work order.  Once the Close Kit button has been depress the following screen will appear, this screen will list all over-issues for disposition, it defaults all items to have the over-issue qty returned to stock. If the users wants to return all to stock they just have to click the OK button. If they want to assign all the over-issue to the Work Order (kit) they can do so by depressing the "Issue All to Kit" button.

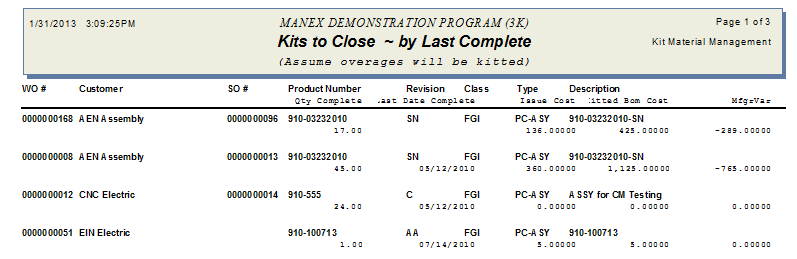

The act of closing the kit sets up the material variance entry for the Accounting module if more parts or less parts than called for by the Bill of Materials were actually used. Note: Only an accounting password can close the kit. The manufacturing variance is based on what should have been kitted according to the BOM for the work order. Under issues, overissues and alternate parts are considered as variances. If a part is allocated to a Work Order or a Project (linked to the work order), when the KIT over-issues to WO-WIP location. Once the WO is closed, and user chooses to return stock, the WO allocation will be cleared, but the Project allocations will be retained and carry back to stock as still allocated to that project. What are the actions that would cause a work order to appear on the “Kits to Close” report? The action that causes a work order to appear on the Kits to Close report is when the Work order is closed. (In the Shop floor tracking module, the units are transferred to the Finished Goods work center). There is no longer a balance due on the order but the work order has not yet had the kit closed. There are two aspects of closing a work order activity – 1, closing the work order; and 2, closing the kit. The work order closes when all of the scheduled parts are either in finished goods or scrap. This happens automatically when the last transfer is made in the shop floor tracking module. The kit closing is a manual function. It is separate, because even though the work order may be closed, somebody may not have completed kitting all the parts to the work order, nor moved all of the over-issue out of the work order. These actions are prompted for when the kit is closed. The user may close the kit without addressing the open issues, but if that happens, each will become a variance within accounting. Unfilled shortages will become a positive variance and overissued parts will become a negative variance. (Important Note: For those instances where the user didn’t issue the parts to the work order initially, but completed the work order in shop floor tracking and then closed the kit, there will be a very large positive variance created because the system will assume that the cost of the components = zero.) Therefore, do not close a kit if it was never pulled. 2. Re-open kit - If the user wishes, he/she may re-open the kit once it has been closed. Note: Only an accounting password can re-open the kit.

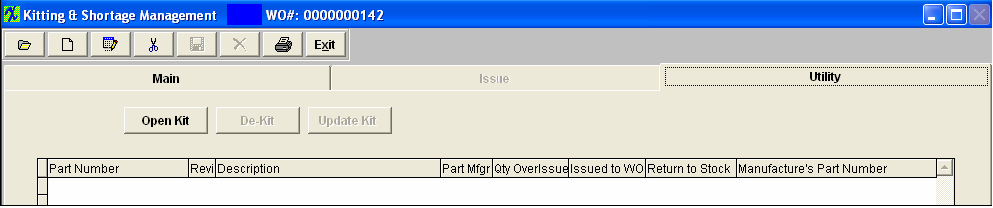

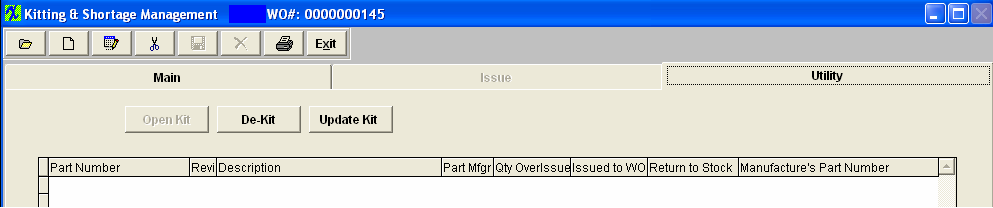

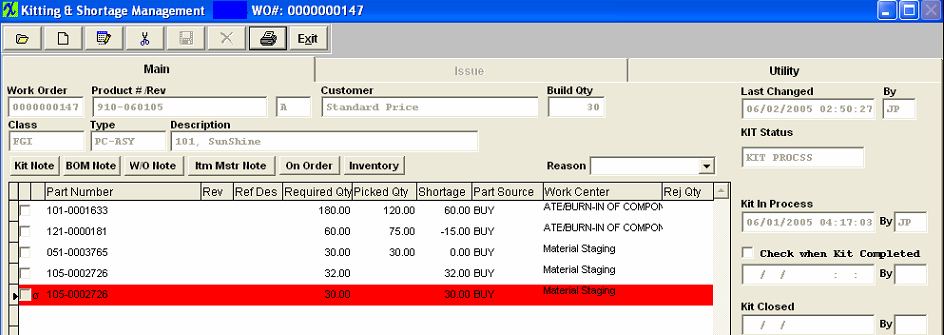

4. Update Kit - The Update Kit button will update the work order with any BOM changes.

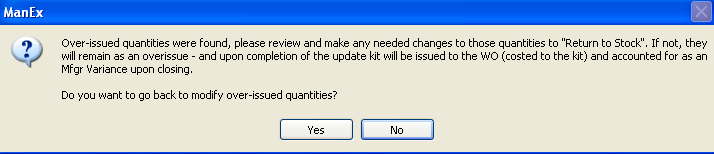

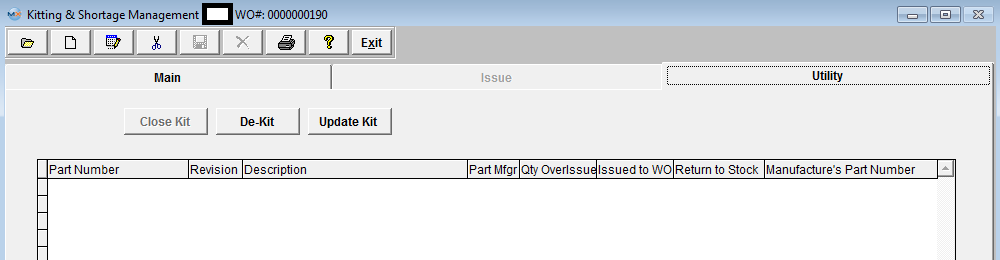

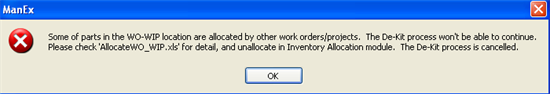

Depress the Update Kit button. Type in your password. You will receive a confirmation message. If the changes to the BOM reflect inventory parts that require dispositioning the following screen will appear:

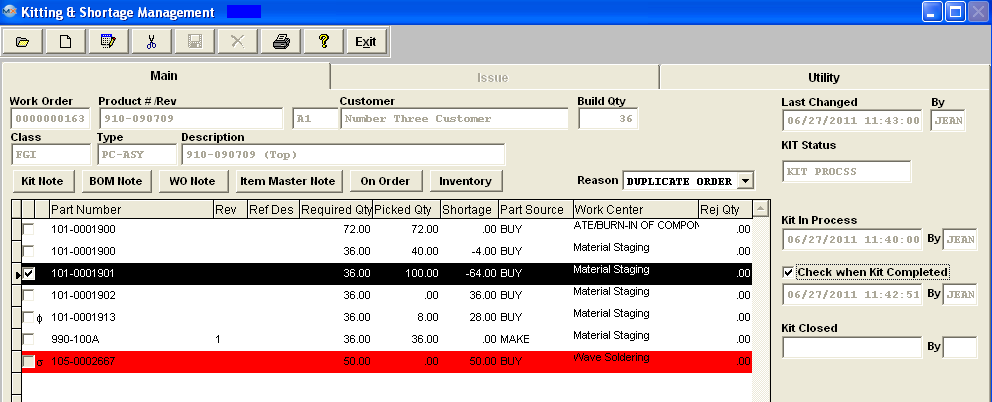

Highlight the item. The system will default in the issued qty into the Issue WO field. If you wish to issue the parts directly to the cost of the Work Order then you can leave the qty in Issue WO. Depressing the OK button will then issue and cost those parts to the kit. If you wish to return those part back to inventory you will change the Issue WO qty to 0 and then you will see the Return to Stock qty adjust. That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory. If there is an Over Issue Quantity found during the update kit, user will receive a message to remind the user that there was an Over-issue qty found, and to make any needed changes to those quantities to "Return to Stock". (If you wish to return those part back to inventory you will change the Over Issue qty to 0 (bottom screen) and then you will see the Return to Stock qty adjust (top screen)). That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory. If not the over-issued qty will remain as an overissue - and upon completion of the update kit the parts will be issued to the WO (costed to the kit) and accounted for as a Mfgr Variance upon closing. If a part is allocated to a Work Order or a Project (linked to the work order), when the KIT over-issues to WO-WIP location. Once the WO is closed, and user chooses to return stock, the WO allocation will be cleared, but the Project allocations will be retained and carry back to stock as still allocated to that project. Depress the OK button and you will receive a confirmation message. For any new parts added to the BOM, they will appear as shortages. You need to make sure to pull them to the kit. If any of the quantities per within the BOM were increased, you’ll have to also pull additional amounts, which will now show as shortages to the Work Order: In the example below, part number 105-0002726 was just added to the BOM and must now be pulled. Additionally, part number 101-0001633 had the quantity per on the BOM increased and now the shortage must be pulled.

|

| 1.4.1.4. How To ..... for Kitting & Shortage |

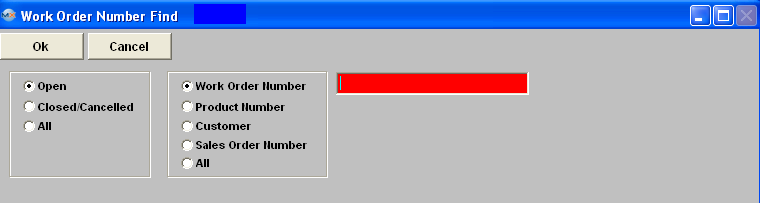

| 1.4.1.4.1. Finding a Work Order Record | ||||||||

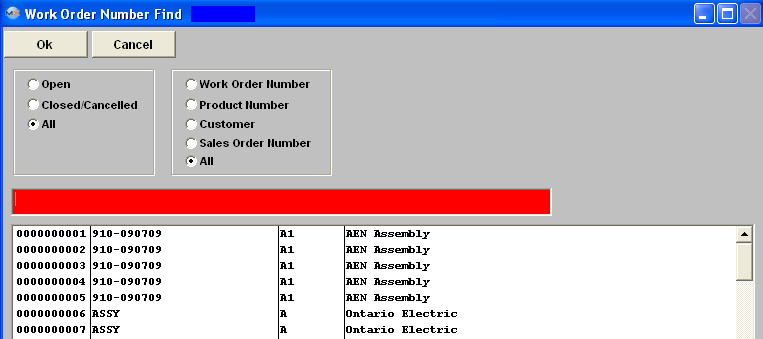

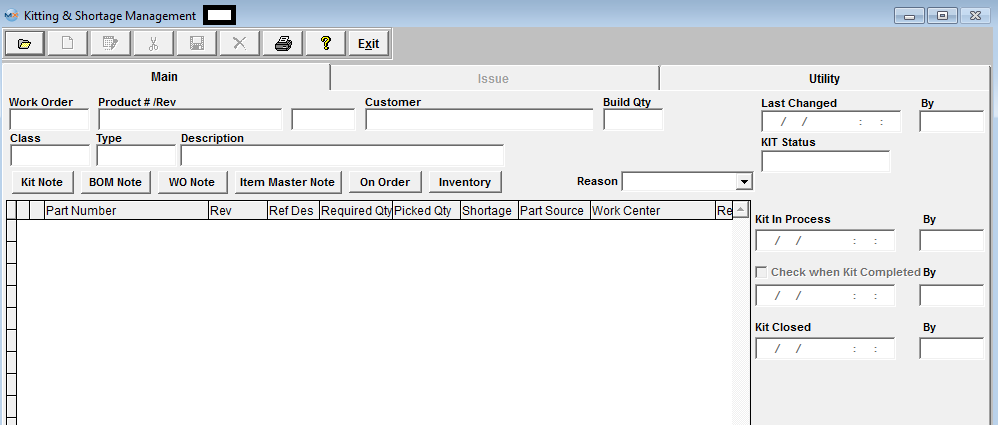

The following screen will be displayed:

|

| 1.4.1.4.2. Issue Parts to Kit | ||||||||||||||||||||||||||||

The following screen will be displayed:

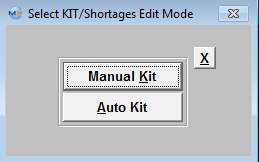

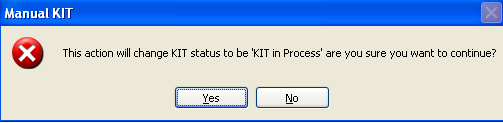

MANUAL KIT

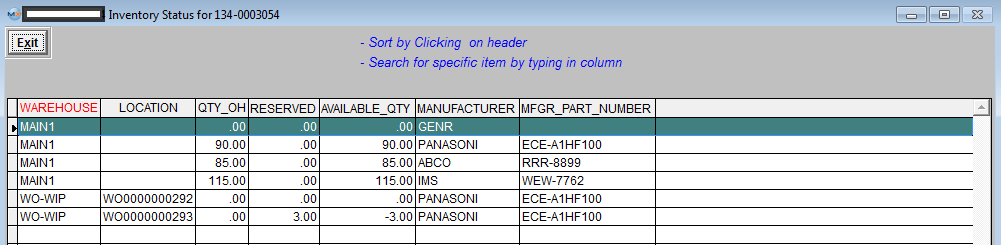

If you would like to see if there is part availability for the highlighted part number before going to the next step depress the "Inventory" button.

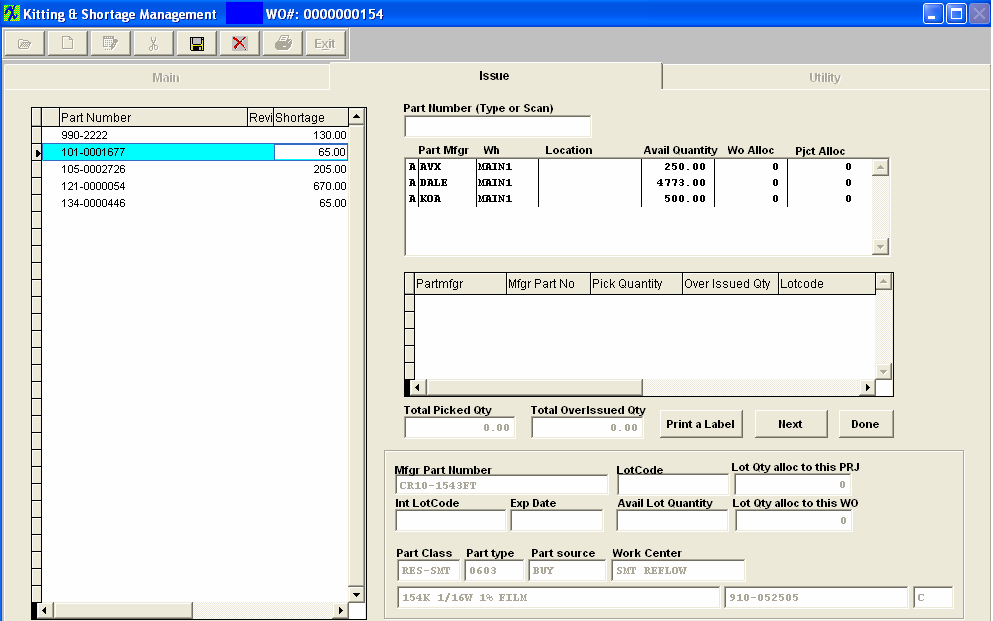

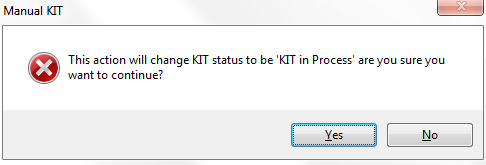

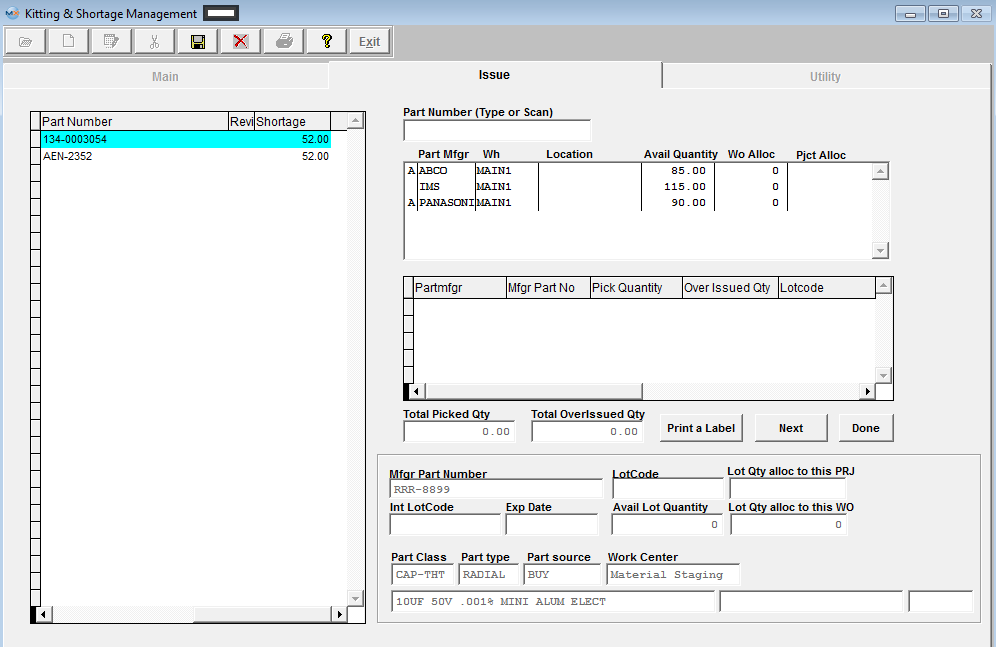

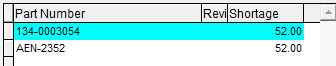

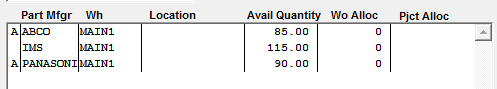

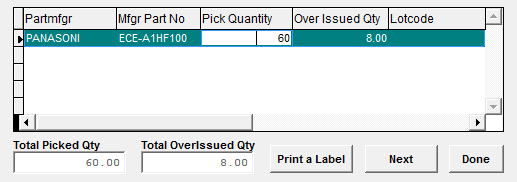

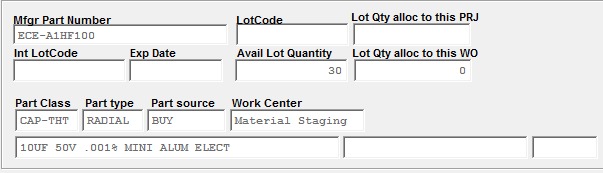

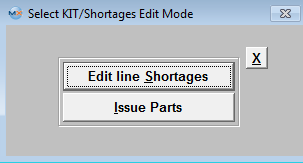

Depress the Edit action button again and the following selection will appear: Depress the Issue Parts button to continue or X to cancel. If you depress the Issue Parts button and enter in a password the Issue Tab screen is displayed: This screen is divided into four operational sections.

The user first selects a part from the kit status section. Place the cursor on a part manufucturer in the inventory status screen and drag it to the Picked Status section in the center of the right side of the screen. To drag, place the cursor on the line indicating an available quantity. Do not remove your finger from the mouse. While you are in the process of dragging, you will see an outline of a hand holding a document. Pull the cursor down to the Pick quantity section. To drop, remove your finger from the mouse. Those manufacturers approved for the bill of material will have the manufacturer preceded with an A. When inventory from the Inventory Status section is dragged to the Picked Status section, the quantity required for the work order is subtracted from the original quantity in inventory. If there is insufficient quantity in inventory, an additional lot may be dragged to the picked status section. If the quantity of parts needed is less than the quantity in inventory, only the quantity needed will be transferred. While still in the Pick Status, the user may modify the quantities being picked. Increasing the quantity that is required for the kit (if there is more available in inventory) will place the extra parts in the overissued qty column. The shortage column will display the over-issues as negative shortages. By reducing the quantity, the remainder of the parts will be returned to inventory. If not returned to Inventory, unused parts in the overissued inventory will continue to be considered as available for use by MRP actions. Other kits may be kitted using these parts. To change the amount Picked, place the cursor on the amount picked. A white box will display. Type the revised amount picked in the white box and depress the Enter key.

REAL TIME KITTING FEATURE When you first enter the ISSUE screen and if you just continue through and Drag & Drop items as described above all of the transactions will be saved to the system upon depressing the Save Record Icon. But as soon as you depress the Next button the system will begin to save the records immediately and the Save and Cancel icons will became inactive. This has been added so our users can begin real-time kitting and since intended for a wireless network connection we need to save individual pulled records instead of the entire kit pull save. Below is a description of how this feature is intended to operate:

This will then bring them back to the Main Kitting screen.

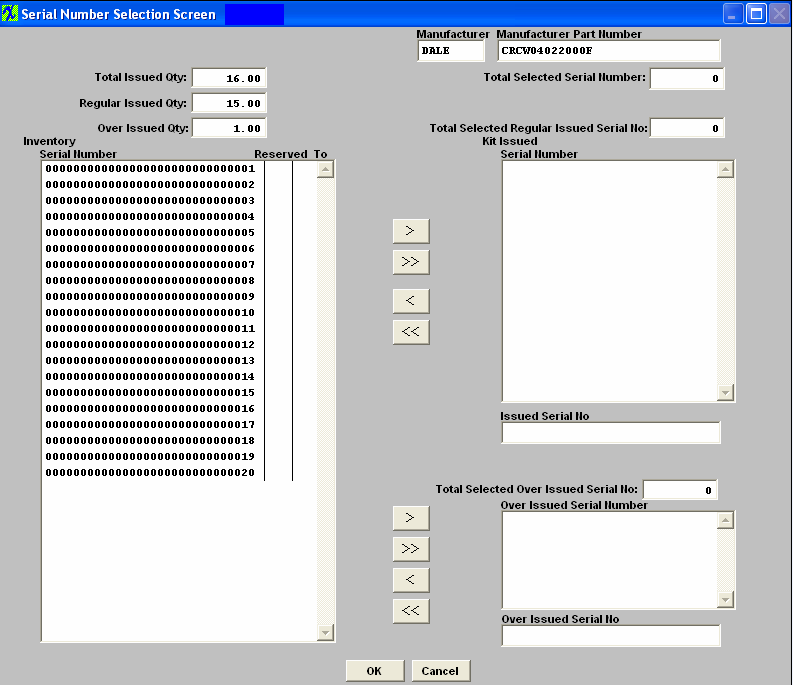

ENTER SERIAL NUMBERS If the Part Number highlighted in the left column, is a serialized part, highlight the Available Quantity. Drag and drop into the Pick Quantity space (as described above). The quantity will appear as 0 in pick quantity. Click on pick quantity and manually fill in quantity. The following screen will appear: All serial numbers for this part number will appear in the left hand column. Highlight the serial numbers you want used for this work order click on the > arrows. They will appear in the right hand column. If you overissued you must highlight the serial numbers for the overissued quantity click on the > arrows and they will appear in the bottom right hand screen. Once the serial numbers that are to be used for this work order appear in the right hand column depress the OK button. Depress the ‘DONE’ Button or ‘Save’ button. The completed Main tab screen appears as below:  NOTE: MRP is designed to calculate from the Kit Shortage and not from the Lead times once the parts have been pulled to the kit and the kit status is changed to "Kit in Process". Once the parts have been pulled to the kit, the systems is assuming that the shortages are needed by the WO due date, rather than the Production lead time, so MRP then calculates using the due date of the WO as the date the materials must be on hand, MRP no longer takes the production lead time into consideration.

This message will be displayed if the user has over-issued to one item, then trying to issue to 2nd item (same part number) from the over-issued SN of first item. The system filters out those SN that are over-issued to the same work order and same part number (might be different kit item) when the program is preparing the SN selection list. In this case user should decrease the over-issued SN from first item, and it will be available for 2nd item.

AUTO KIT

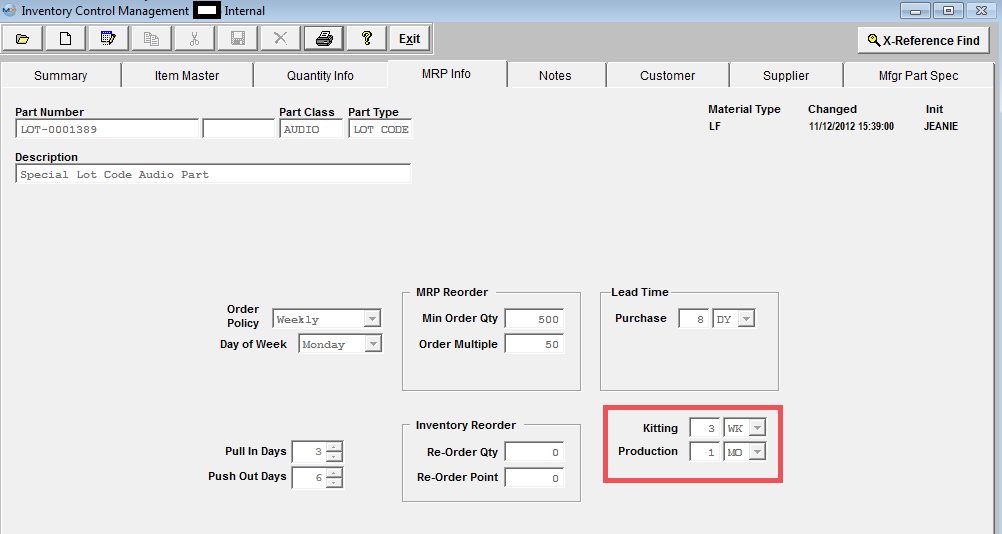

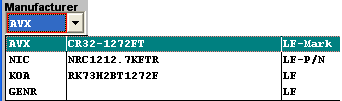

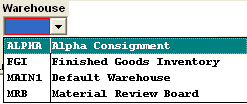

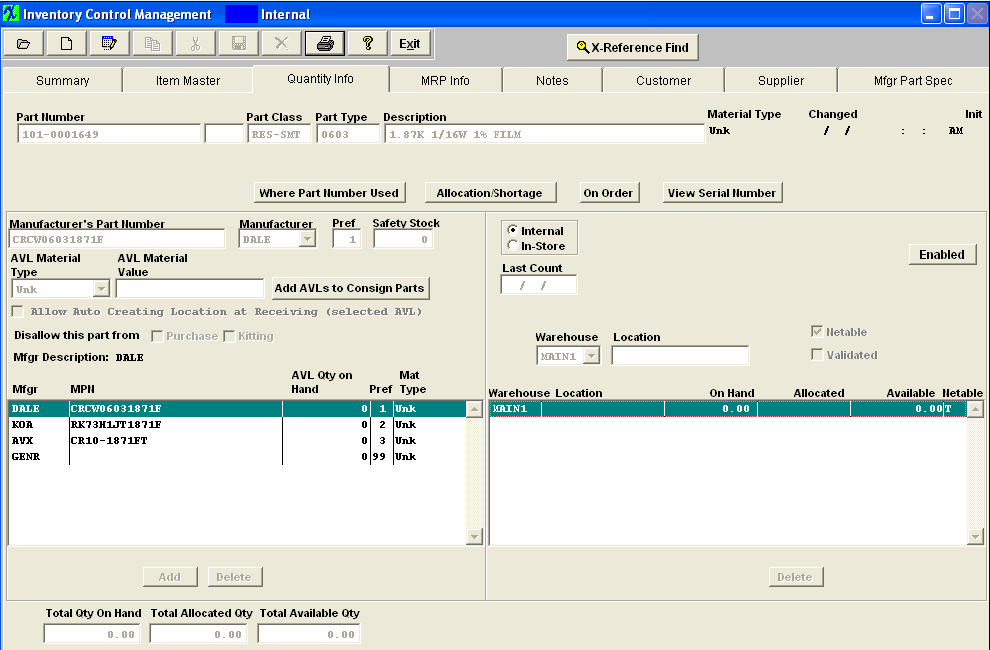

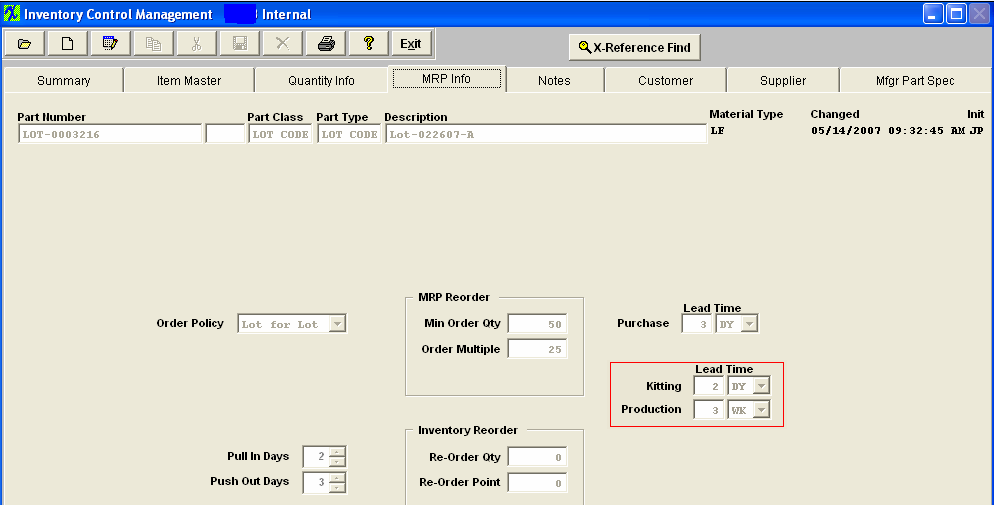

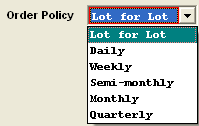

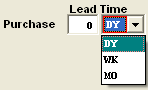

If the Bill of Material does not have any components that are kitted, then no kitting will be done. Kitting Preference Hierarchy When Kitting Manex picks Approved AVL's and in numeric sequence. (1 before 2, 2 before 3, etc.) "99" is the default preference number, if no preferences are entered, then other un-controllable factors affect which is picked first. If the user wants to have a specific warehouse picked first, then they are to enter a preference number such as "1" in the preference field within the Quantity Info screen within Inventory Control Mgmt

If the part is a lot coded part, auto kit considers

the lot code expiration date. The auto

kit sequence should be allocation first then non allocation. If a part has allocation but with a later

expiration date, it still should be picked first than the non-allocation parts

with an earlier expiration date.

COMPLETING KIT

|

| 1.4.1.4.3. Add a Line Item Shortage | ||||||||||||

|

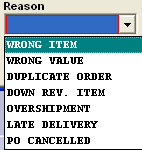

Shortages other than those resulting from an incomplete kit are considered Line Shortages. Line shortages may be a result of poor yield on a part, and additional parts are required, or because one or more additional parts are needed for the work order beyond those described in the bill of materials. Line shortages may be created because of alternate parts, special engineering evaluations, or for any reason that the user decides to enter in the system setup. For Miscellaneous Shortages, (this selection may be used to issue non-inventory items to kit). (See further detail below). If you select Add Line Shortages, you will be prompted for your password and then the following screen will be displayed: (NOTE: If line shortages are added and issued to rework WOs, the kit status will update to “REWORK”). True "Phantoms" cannot be added as a line item shortage to a kit.

NOTE: The Line item shortages are considered as in the WIP account all the way through until the Kit is closed within the Kitting module. Upon Closing the kit within the Kitting module the Line Item Shortages are then costed out and credited out of WIP account and debited in the Mfgr Variance account. So the “Inventory WIP Valuation Report” by Work Order by Standard Cost does not deduct those line item shortages as the product is moved into FGI. See Article #1777 for further detail. The part information for the shortage is entered. The part must be a part defined in the Inventory Control Item Master. Select Part Source, Part Class, Part Type, Part Number from the respective drop down lists. Enter the Short Quantity and the Required Qty will default in then enter the the Quantity per Unit. Select a Work Center from the drop down. Note: Shortages recorded by Ref Designator are case sensitive.

“Ignore Shortage” box: If you want to remove the component from the shortage reports and MRP, check the box at the left of the part number. Note that the box for checking KITTED shortages only works with those items that are kitted based on the BOM for the assembly. Checking the boxes means that the part on the BOM will NOT be considered for MRP purposes, and NOT show up on shortage lists. This is the only way you can get a part on the BOM, off of the shortage list. Line shortages, however, can be edited to make them larger or completed. The user should NOT create a line shortage, then try to check the “ignore shortage” box. A line shortage is either short or not. If it is not short for this particular work order, then check the box to take it off of the shortage list. Add a Miscellaneous Shortage If you select Add a Miscellaneous Shortage you will be prompted for your password, and then the following screen will be displayed:

Enter in the Part Number, Revision and Description. Select Source, Class, Type, Department, Reason from the respective Drop Down lists. Enter in the Quantity and Quantity/Unit. Continue in this fashion until all entries are made. Depress the Save button.

Issue or Edit a Line Item Shortage

Pressing the Edit Button (after finding a work order) displays the following selection choices: If user selects "Edit line Shortages", you will be prompted for your password and then you will have the opportunity to change Quantity, Quantity/Unit or Work Center Selection for an existing line item shortage.

This field is intended for the user to enter in the qty needed for the shortage and the system will make the needed adjustments based off from that qty. For Example: if the user originally added a line item shortage for a qty of 5, and picked a total of 7 to the kit. (Production has no way of knowing how many were pulled to the kit originally, so a week later they come back to the stockroom, and request 4 more). The stockroom will then edit the line item shortage at this time the qty will display a -2.00, stockroom will issue 4 more by entering a qty of 4, the system will make the adjustments based off from that qty, so the Required qty will then become 11. NOTE: You can only reduce the shortage qty if there are no issues against it. If the complete shortage qty has been issued, and user depress the Edit line Shortage button and the qty field is "0" and user enters a qty in the qty field the system will interpret this as an additional qty. To change a qty that has already been issued user would need to un-issue the complete qty and then go back and change the shortage qty. System will not allow user to enter a negative qty.

Depress the Save button when changes are completed. If user selects " Issue Parts" enters their password, they may follow the steps outlined in Article #904.

Add a Line Shortage to a Rework Work Order Overview of a Rework Order When a rework order is created via the RMA Receiver module (Please refer to the Return Material Authorization Management manual), there is no demand created for any parts on the BOM for the product of the work order. But, demand will be created for any line shortages established for the work order. There should be a line shortage created for the assembly being reworked, so the product can be issued to the work order. When the work order has the kit closed, the manufacturing variance is created that is the difference between the standard cost of the parts issued to the work order and the standard cost of the sum of all of the BOM components. If there is no BOM for the product, but if the assembly has a standard cost assigned to it, the following will happen: There will be a favorable variance to the wip (the difference between the standard cost of the product and the standard cost of the sum of the materials on the BOM) Assembly Standard cost – zero BOM cost. The kit close will have an unfavorable variance created for accounting which will be the sum of the standard cost of the components issued to the work order. The kit close will offset the line shortages pulled. To add a line shortage to a rework work order, follow the same procedures as finding the work order, as detailed above. Depress the Add button to add a new line shortage. Type in your password. Then follow the procedures to add and pull a line shortage as detailed above. Upon completion, you will see a message at the top right hand side of the screen that inventory files are being updated. Then the part information in the lower part of the screen will turn blank. Exit the kitting module and then proceed to the shop floor tracking module to complete the rework order. The Delete button is used to remove line shortages BEFORE the parts has been pulled to the kit for that line item. Find the Work Order containing the line shortage, using the find procedures. After selecting the delete button, the user is asked for an authorized password. Then the user selects the item to be deleted. Highlight the line item containing a rho symbol (? ) at the far left of the part number.

If the parts HAVE been pulled to the kit for the line item shortage, user MUST de-kit or return picked qty to stock before the line shortage can be deleted.

The item will still be displayed with a Required Qty of 0.

|

| 1.4.1.4.4. Update Kit | ||

The Update Kit button will update the work order with any BOM changes. Note: This button MUST be depressed after an ECO approval for any part changes to be reflected if the Work Order due date proceeds the effectivity date of the ECO.

Depress the Update Kit button. Type in your password. You will receive a confirmation message. If the changes to the BOM reflect inventory parts that require dispositioning the following screen will appear:

Note: If parts are being displayed for dispositioning even though NO changes to quantities were made it may be due to the fact that the work centers were changed and upon completion of the update kit the parts will be issued to the WO (costed to the kit) and accounted for as a Mfgr Variance.

Highlight the item. The system will default in the issued qty into the Issue WO field (bottom screen). If you wish to issue all the parts directly to the cost of the Work Order then you can leave the qty in Issue WO and Over Issue. Depressing the OK button will then issue and cost all those parts to the kit. If you wish to return those part back to inventory you will change the Issue WO qty to 0 (bottom screen) and then you will see the Return to Stock qty adjust (top screen). That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory.

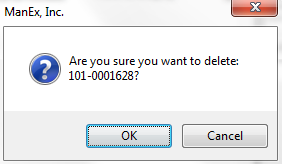

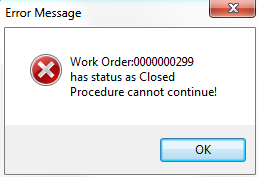

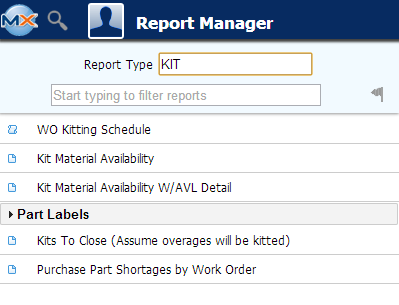

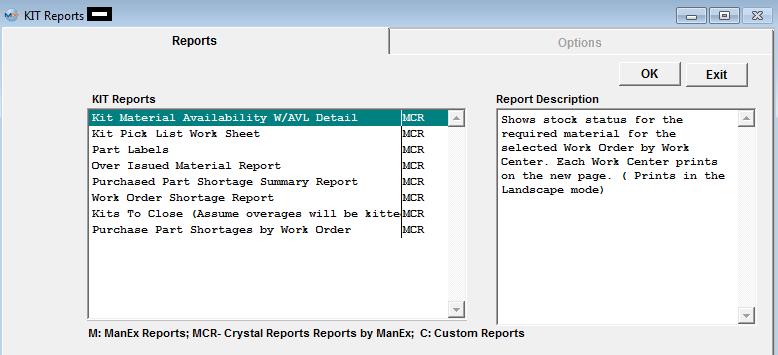

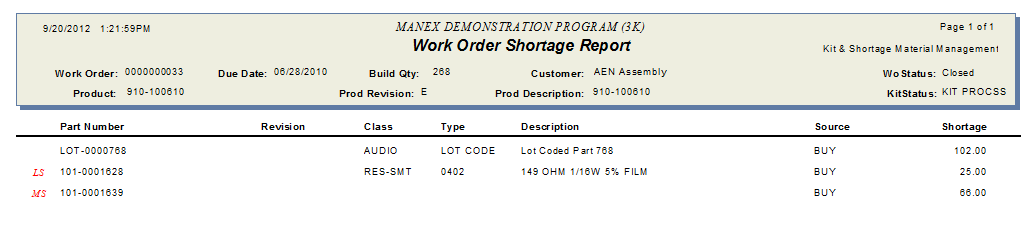

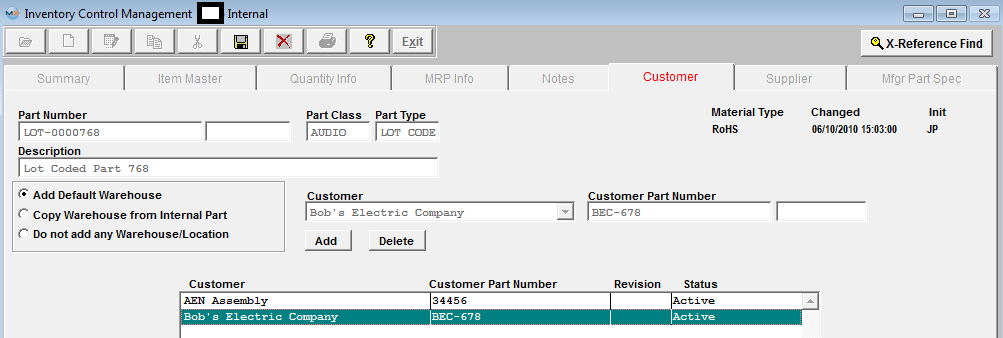

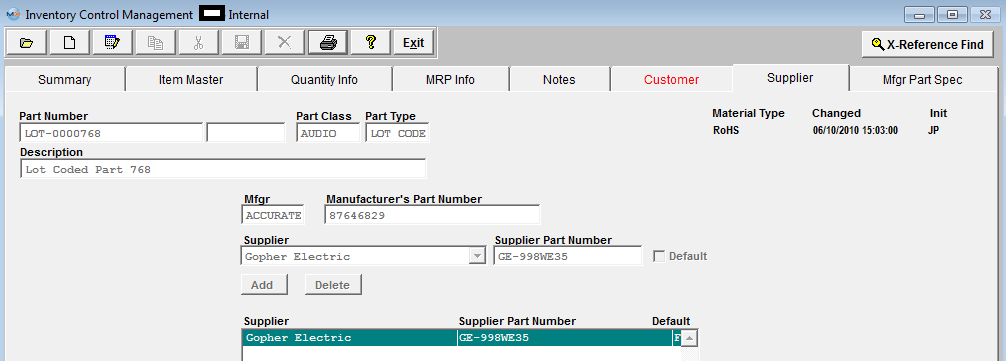

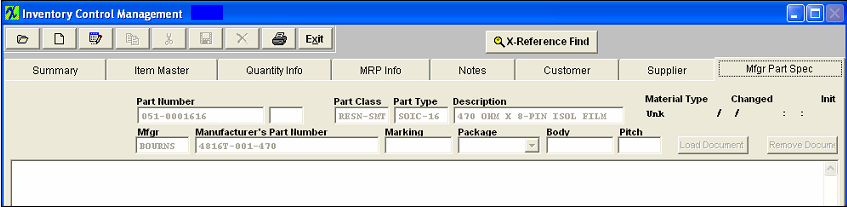

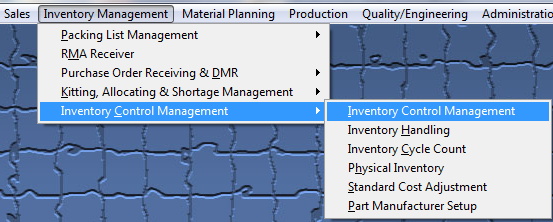

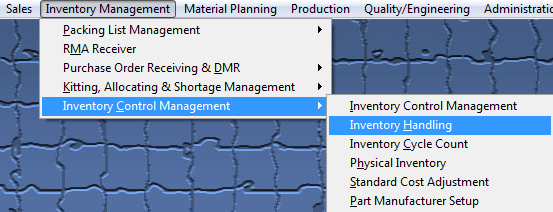

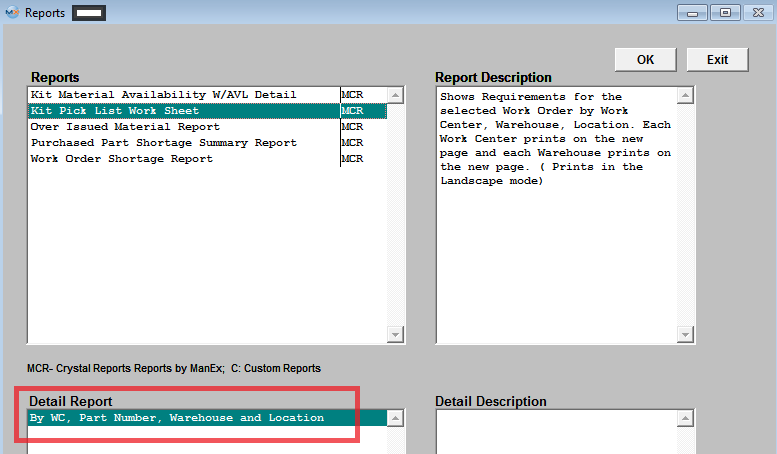

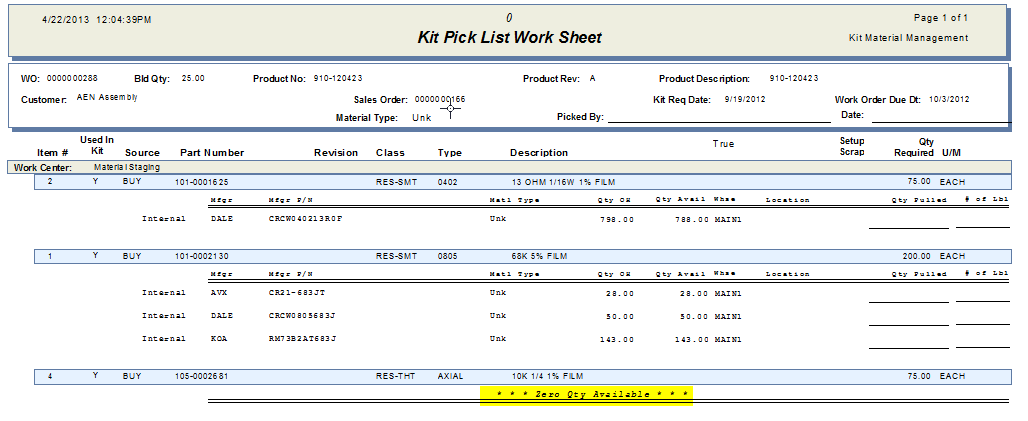

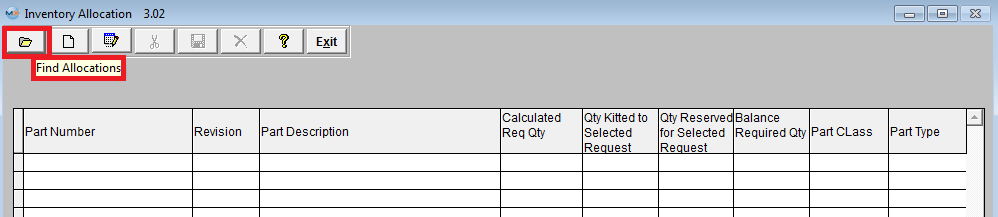

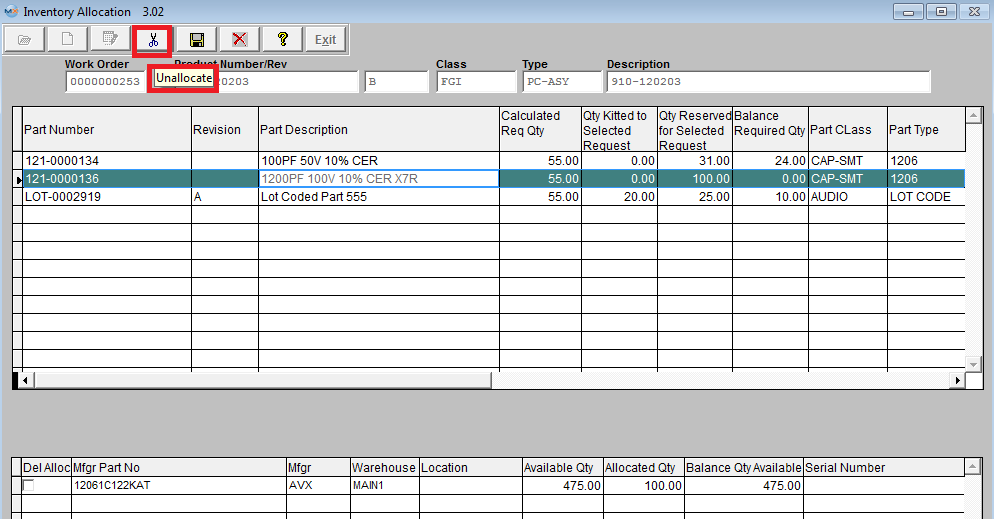

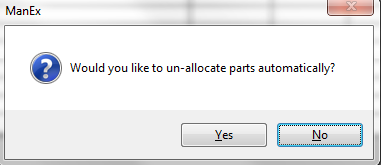

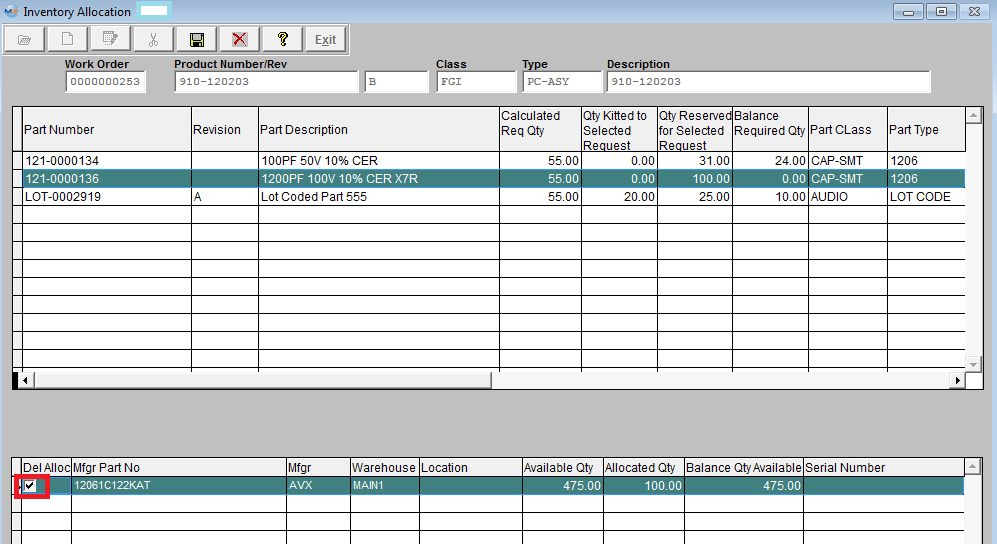

If there is an Over Issue Quantity found during the update kit, user will receive the following message to remind the user that there was an Over-issue qty found, and to make any needed changes to those quantities to "Return to Stock". (If you wish to return those part back to inventory you will change the Over Issue qty to 0 (bottom screen) and then you will see the Return to Stock qty adjust (top screen)). That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory. If not the over-issued qty will remain as an overissue - and upon completion of the update kit the parts will be issued to the WO (costed to the kit) and accounted for as a Mfgr Variance upon closing.