| 1. MRP Default Setup |

| 1.1. Prerequisites for MRP Default Setup |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 4-r" before continuing the setup. User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. Suggestion: We suggest that if the MRP takes a larger amount of time to run you may want to schedule it to run during non-working hours. If you run it during working hours and it takes a large amount of time, you might experience results that you are not expecting. Because, transactions could have been made in the system after the MRP was started and some data captured in the first part of the run may affect the transaction during the MRP run. The MRP time stamp does not get updated until the very end of the MRP run.

|

| 1.2. Introduction for MRP Default Setup |

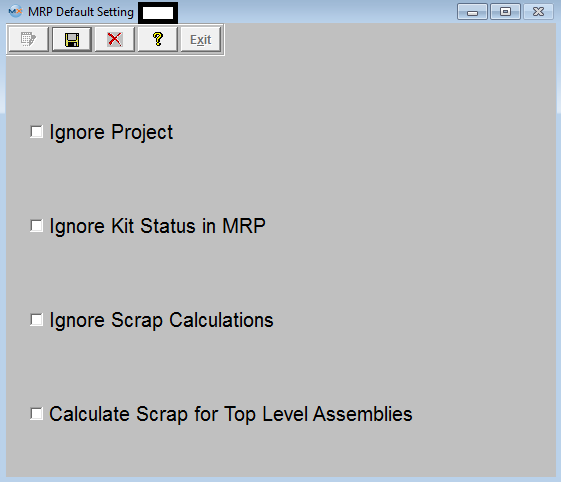

This screen is used to setup what the user wants to see when using MRP. |

| 1.3. Fields & Definitions for MRP Default Setup | ||||||||

|

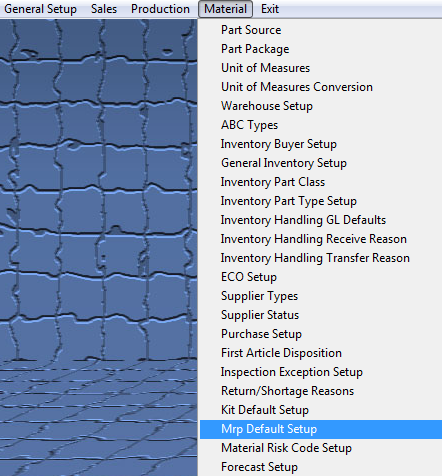

| 1.4. How To ..... for MRP Default Setup |

| 1.4.1. Setup the MRP Default Setup Module | ||||

The following screen will be displayed:

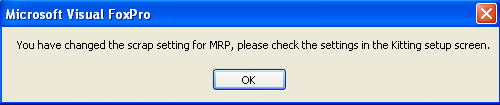

When editing the MRP Scrap Setting the following warning will appear:

|