| 1. Purchase Setup |

| 1.1. Prerequisites for Purchase Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 4-m" before continuing the setup.

The prerequisites for entering Purchasing Setups are:

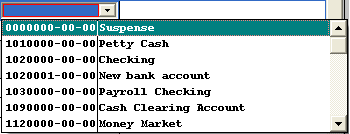

General Ledger Account Numbers set up in the G/L Account Setup module.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2. Introduction for Purchase Setup |

In this section, the approval authority is established for purchase order approval for each user. The company has the option to declare whether one or two approvals are required in order for a purchase order to be approved. If the user chooses to have two approvals, then one of the approval-users must have final approval authority. The company also has the option to declare whether they want approvals Based on the PO Value and approvals when there is date changes or note changes. This section also establishes a default percentage that is allowed over and above the purchase order line item quantity. If material is received that exceeds in quantity the ordered amount by this percentage, then the receiving department cannot receive the material until the order is modified by purchasing. This is a default percentage applied to each order as it is placed, but may be over-ridden at the time the order is created.

|

| 1.3. Fields & Definitions for Purchase Setup |

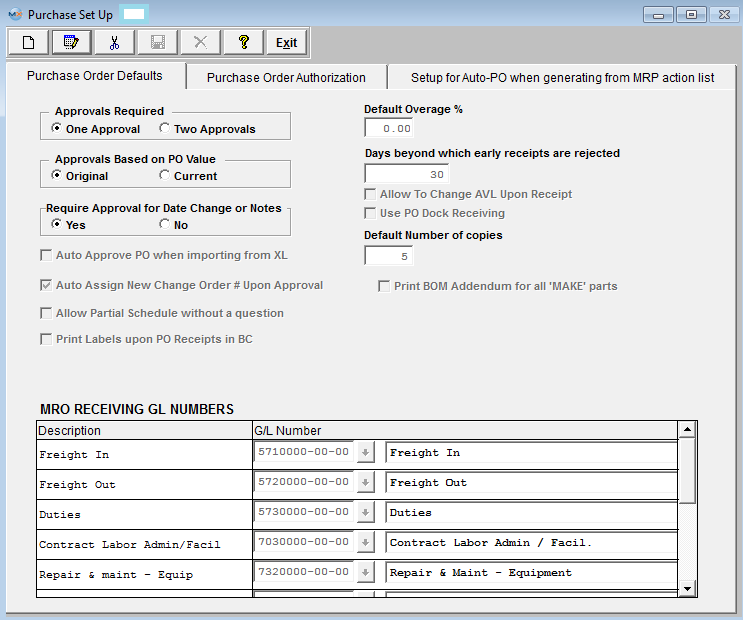

| 1.3.1. Purchase Order Default Tab | ||||||||||||||||||||||||||

|

When a buyer generates a purchase order, it is created as a temporary order until it is approved. These orders will be created with a prefix to distinguish them as temporary until approved. As a temporary order, the document cannot be printed, nor will the order be considered as supply for Material Requirements Planning considerations. When a purchase order undergoes a revision, changing schedules, quantities and/or pricing, the order returns to a temporary status until approved. Note: These changed orders are not changed back to a prefix.

The company has the option to declare whether one or two approvals are required in order for a purchase order to be approved. If the user chooses to have two approvals, then one of the approval-users must have final approval authority.

When a non-inventory item is being purchased, the user must indicate the General Ledger MRO receiving numbers, if Accounting is used.

|

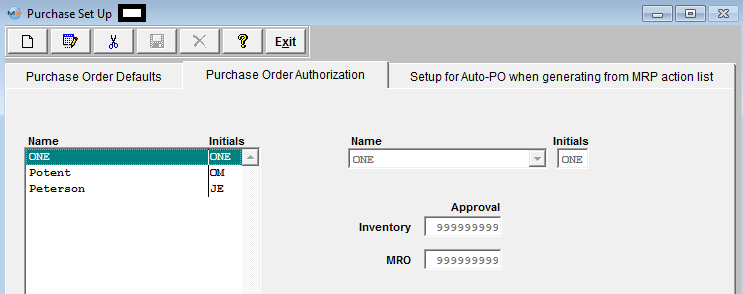

| 1.3.2. Purchase Order Authorization | ||||||||

For each user approval, the user may be authorized to approve one or both: Inventory and/or MRO. And each of these may have different levels of dollar amounts. If the administrator chooses to have one approval for orders, then there must be at least one person with approval for the expected dollar value of purchase orders. If two approvals are chosen, then there must be at least two people with approvals for the expected dollar vaule of purchase orders. The names of the users must have been entered in the Security Setup before entering in the Purchasing Setup, as they become available in the pull down listing for names.

Approval

|

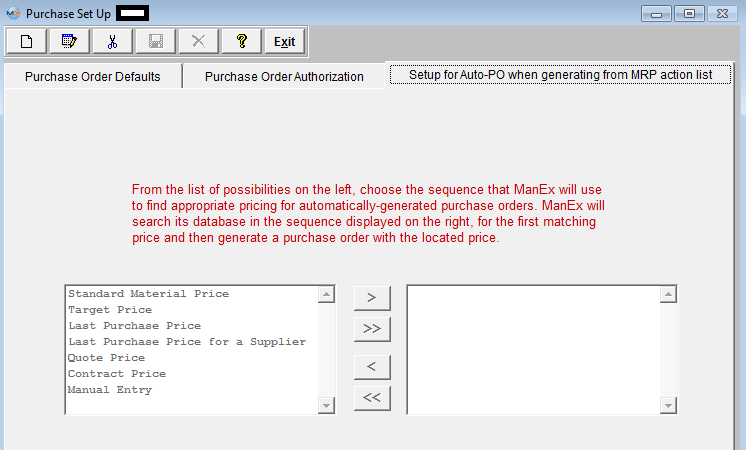

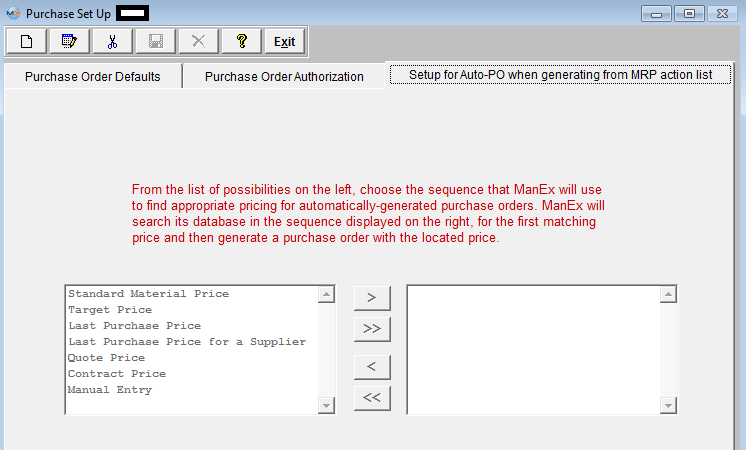

| 1.3.3. Setup for Auto-PO when generating from MRP action List | ||||||||||||||

|

| 1.4. How To ..... for Purchase Setup |

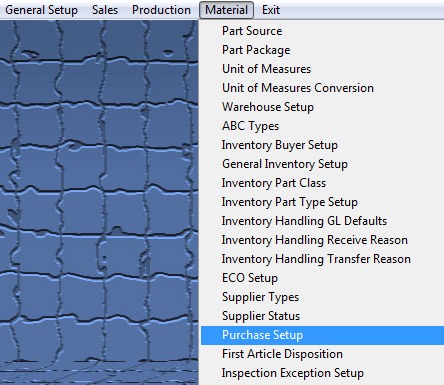

| 1.4.1. Setup the Purchase Setup Module | ||||

|

The following screen will be displayed:

Depress the Edit button. For Approvals Required, click on the desired radial for either One Approval or Two Approvals. Enter Default Overage % if applicable. Click on desired radial for Approvals based on P.O. Value. Click on desired radial if Approvals are required for Date or Note Changes. Enter a Qty of Days beyond which early receipts are rejected if applicable. If you want to Change AVL Upon receipt this box must be checked. If you want to Use PO Dock Receiving this box must be checked. If you want to Auto Apporve PO's when importing from XL this box must be checked. If you want the system to Auto Assign New Change Order #'s upon Approval this box muxt be checked. If user wants to Allow partial schedule without receiving the reminder popup this box must be checked. If you want to Print labels upon PO receipts in the BC (Bar Code Receiving module) this box must be checked. Depress the Add button to add additional MRO (Materials, Repairs and Other) Receiving GL Numbers, enter in the description, then select the appropriate General Ledger account number and description, by clicking on the down arrow next to the field, as follows:

When finished, the user must depress the Save or Abandon changes button. Purchase Order Authorization On this screen, the user establishes the procurement authority levels for individuals.

To add a new user, click on the Add button and select a user from the Name pulldown field. Then enter the dollar amount authorized for either or both (Inventory and/or MRO) Approval and Final OK. If the company chooses only one approval, it must be in the Final column. Each user may have different authority levels for different kinds of purchases. Additionally, the user may have different amounts authorized, depending on whether they are the first approval or the final approval. For example, a buyer may have authority to do a final approval for $1000, but must also approve P.O.s up to $10,000 before the person with final authority will authorize the P.O.

Setup for Auto-PO when generating from MRP action list

In order to create an automatic PO within the MRP action list, the system has to figure out unit cost. Within this screen the user can select multiple methods ordered by their preference, from selecting items on the left and entering them on the right. The system will try to find the price based on the first method in the selected list (on the right) and if the system cannot find any price information it will proceed with the next method (on the right) until price is found. If not found system will assign "Manual Entry" and leave it at zero as a default. The price source can be changed and the price can be overwritten in the screen which creates POs from the MRP action list.

Where Used: Approvals are required on all purchase orders in order to place and receive material. General Ledger Account selection for all MRO purchases.

«Mark as Completed in RoadMap in Section B Item 3-m» |

| 1.5. ManEx Minute for Purchase Set-up |