| 1. Inventory Buyer Setup |

| 1.1. Prerequisites for Inventory Buyer Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 4-f before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2. Introduction for Inventory Buyer Setup |

| This is the section to enter all the inventory buyers responsible for procuring materials. This is a requirement when adding to or editing the item master record. This information is used when setting up Part Class and Type in system setup. |

| 1.3. Fields and Definitions for the Inventory Buyer Setup |

For inventory parts, it is often useful to assign code to parts of the person responsible for buying the parts. This makes it easy for receiving to resolve any issues with incoming material, and it makes it easy to divide up the workloads in purchasing. Also, several reports are available which can be sorted by the buyer code. One valuable report is the order actions necessary to be taken as a result of running MRP. The buyers may have a list of only those parts affecting their own workload, and not be burdened with looking at all of the rest of the actions. Also, shortages may be better resolved with the inclusion of a buyer code for the part number. ManEx provides the ability to assign a three-character buyer code to each part. ManEx also provides for the eventuality that the buyer codes will change from time to time, and provides a buyer reassignment utility to change all parts for a specific buyer to another buyer. |

| 1.4. How To ..... for Inventory Buyer Setup |

| 1.4.1. Setup the Inventory Buyer Setup Module | ||||

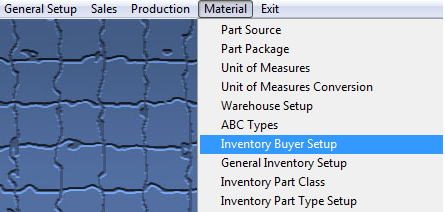

|

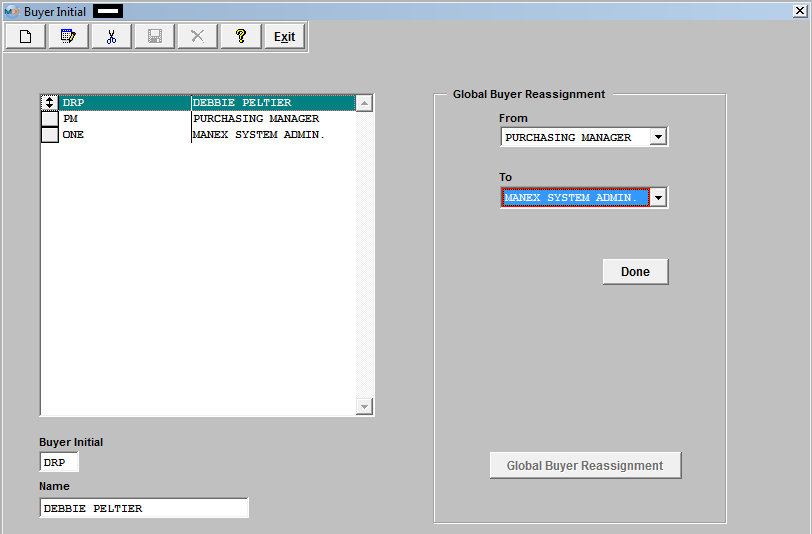

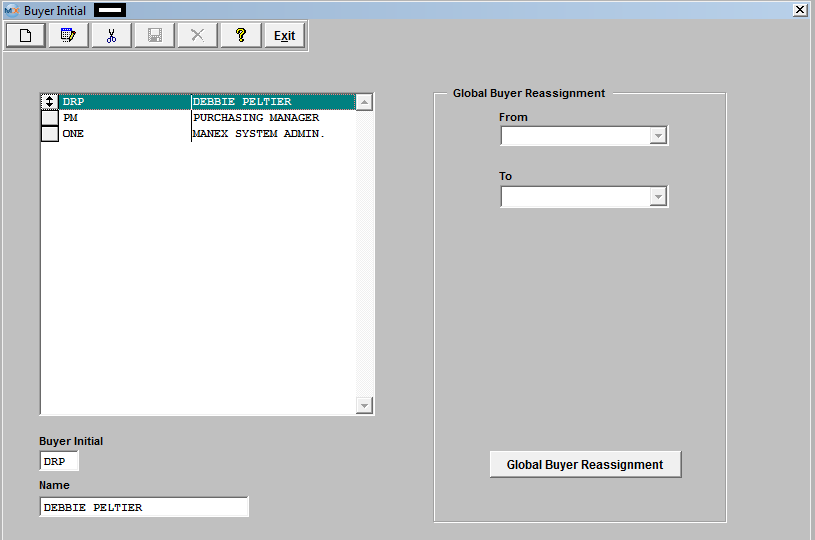

The following screen will be displayed:

To add and Inventory Buyer, depress the Add button. Type in the Initial, type in the Buyer Name. Depress the Save or Abandon changes button. These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In all Part Type Setup, Inventory Item Master and Material Requirements Planning functions.

«Mark as Completed in RoadMap in Sect B Item 4-f» |

| 1.4.2. Global Buyer Re-assignment |

Global Buyer Reassignment is a utility program that allows users to replace current inventory buyers of all items linked to a buyer to another buyer. This is helpful when a buyer goes on vacation or leaves the company. To reassign, depress the Global Buyer Reassignment button.

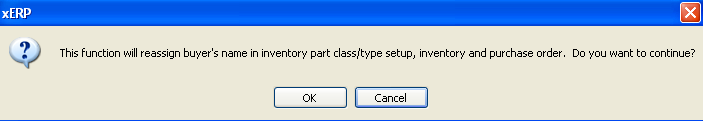

Depress the OK button to continue.

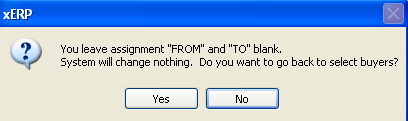

Depress the down arrow next to the From field. A list of existing buyers will appear. Select the buyer to be changed. Depress the down arrow next to the To field. Select the To buyer. Depress the Done button. All of the records (inventory part class/type setup, inventory, and purchase order) associated with the From buyer will update to the To buyer. If the the "Done" button is depress with the From and To fields blank, user will receive the following message:

User MUST depress the "DONE" button for the changes to be made to the records.

|