| Setup the ABC Types | ||||

|

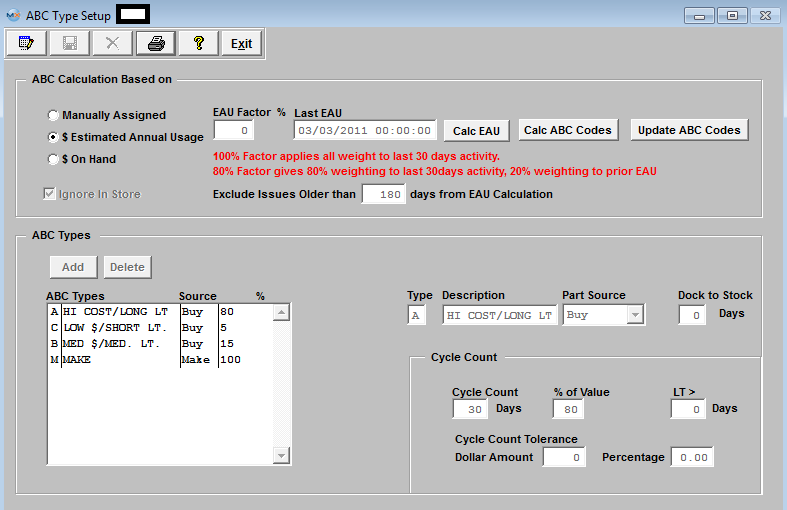

The following screen will be displayed:

The "ABC calculation based on:" affects the meaning of the % of Value field. If Manual has been selected then it does not apply. If $ Estimated Annual Usage (EAU) has been selected, then it is EAU x STD cost and % of that value (top 80%, 15-80%, etc) If $ On-Hand has been selected, then it is On-Hand x STD cost and % of that value (top 80%, 15-80%, etc).

ABC Codes will be calculated using the information in the % value and LT> fields. These fields are used to determine which parts should have their ABC codes automatically adjusted. After the ABC codes are updated, those parts will be included with the appropriate group for cycle counting.

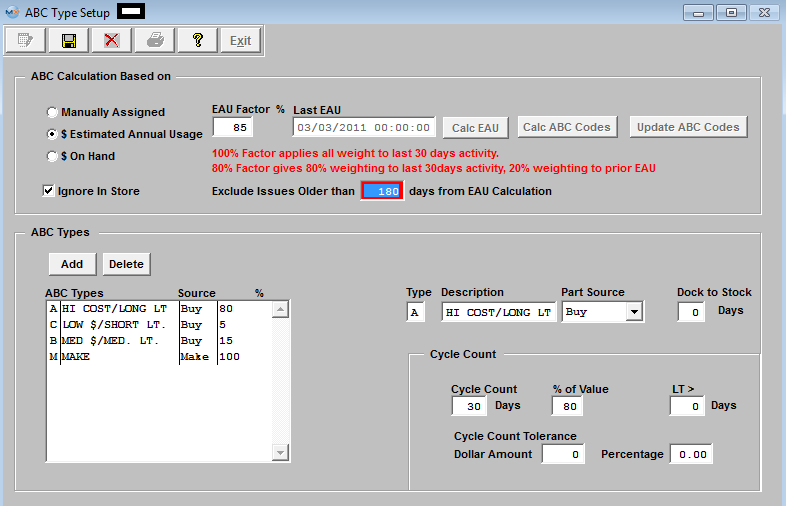

Check the "Ignore In-Store" box only if you do NOT want the In-Store warehouses to be included in the Cycle Counts, regardless of which Calculation Based on is selected. Depress the Edit button. Select the "ABC Calculation based on" by clicking on the appropriate radio. If the user selects $ Estimated Annual Usage, the following screen will appear. Type in the EAU factor. then depress the "Calc EAU" button will update the EAU field within the ICM screen. This button will only be available if the screen is in "EDIT" . Depressing this button will update the EAU field within the ICM screen. The term EAU, (ESTIMATED Annual USAGE) may be considered as consumption, depletion, loss, used up, etc. So the EAU calculations MUST include the In-store issues to be accurate. If a user is issuing a part out of in-store to a Sales Order to be shipped the parts still count as an issue, or usage and was consumed, so it is necessary to include them when considering plans for future usage. If a user were to deliver ALL material directly to work orders from in-house, and these transactions were not included, there would be no calculated EAU. This is why we do NOT allow in-store issues to be ignored. The only time in-store issues will NOT be calculated in the EAU is if they are being returned to the vendor through Inventory Handling.  Depress the Save button.  User can then depress any of the Calculation buttons.

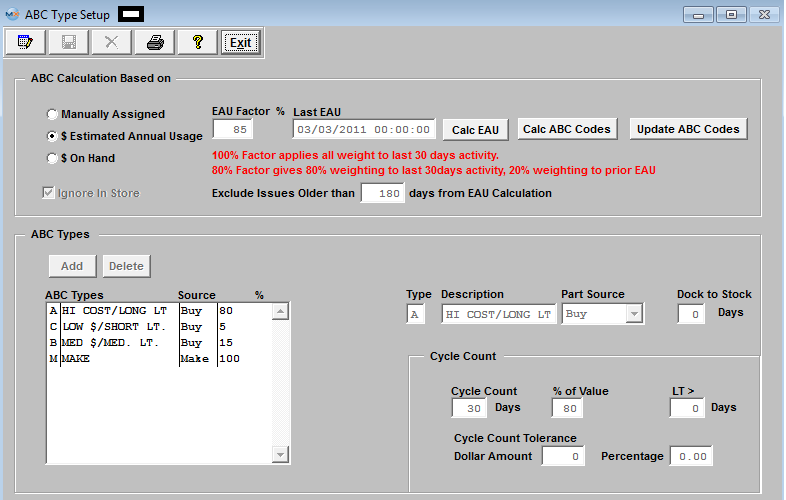

If the "Calc EAU" button will update the EAU field within the ICM screen. The Last EAU date will fill in. If the "Calc ABC Codes" button is depressed, this button will use the information in the % value and LT> fields to determine which parts should have their ABC codes automatically adjusted. After the ABC codes are updated, those parts will be included with the appropriate group for cycle counting. If the "Update ABC Codes" button is depressed this button will use the information in the % value and LT> fields to determine which parts should have their ABC codes automatically adjusted. After the ABC codes are updated, those parts will be included with the appropriate group for cycle counting.

The user then sets up an inventory counting program called “Inventory Cycle Count”, which assists in counting all inventory over a period of time. The “A” items might be counted completely within each month. Therefore, a list of all of the “A” items (the highest dollar value) is generated, and randomly divided into 20 days, and each day 1/20th of the list counted and checked. The “B” items might be checked every quarter, and the “C” items checked once a year. This is a way to verify the accuracy of stockroom transactions, and to take measures necessary to keep the counts accurate. Type the ABC Types into the appropriate boxes.

The ABC code identifies a part source for inventory parts. Because MANEX allows up to 26 ABC codes, it also provides for identifying if a part is a make or buy part. Click on the desired Part Source radial, either Buy or Make. Enter the Dock to Stock days. In MANEX, the ABC codes have a slightly different meaning. In addition to identifying the most or least expensive part numbers, a Dock to Stock period may be included in each ABC code. Dock to Stock is the number of days a part is expected to take to be delivered to the stock room after the part is received on the user’s dock. Also, for each ABC code, MANEX provides a cycle count tolerance, which, if exceeded, will result in reporting unfavorable results during cycle counting. These tolerances may be an absolute dollar value, or a percentage of the inventory being counted. In the Cycle Count section, enter Cycle Count Days (NOTE: This field MUST be populated with a number other than "0". If "0" is entered these parts will NOT be included in the Cycle Count), % of Value, Lead Time Greater than, and Cycle Count Tolerances: Dollar Amount and Percentage. The user must either depress the Save or Abandon changes button. Where Used: In all Part Type Setup, Inventory Item Master, Material Requirements Planning and Cycle Count functions.

«Mark as Completed in RoadMap in Sect. B Item 4-e» |