| 1. System Setup |

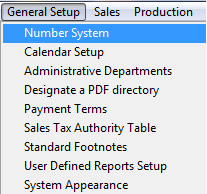

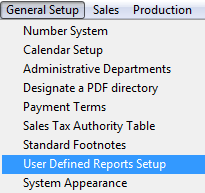

| 1.1. General Setup |

| 1.1.1. General Setup Introduction |

| This section covers the setups to be used in various modules. Please take time to consider how to use these tables to take the maximum advantage of the ManEx features. Each section entered will affect the way that operations are performed.

The ManEx program is designed to minimize the user’s keystrokes when entering data. By careful consideration of strategies for system control, the user may arrive at the point where ManEx can automatically assign numbers to a variety of functions.

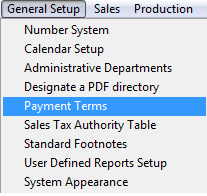

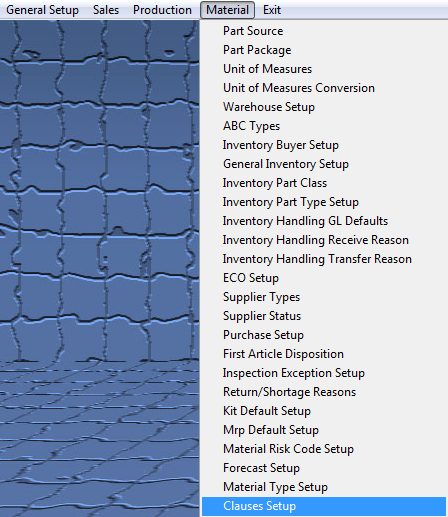

The General Setup section covers the following modules: Number Systems, Admin/Production Calendar, Administrative Departments, Designate a PDF Directory, Payment Terms, Sales Tax Authority Table, Standard Footnotes, User Defined Reports Setup, and System appearance.

User MUST have full rights to the "System Setup" in System Security to setup these modules. Users with “Supervisor Rights” will automatically have access. |

| 1.1.2. Number System |

| 1.1.2.1. Prerequisties for Number System |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-a" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security. Users with “Supervisor Rights” will automatically have access. |

| 1.1.2.2. Introduction for Number System |

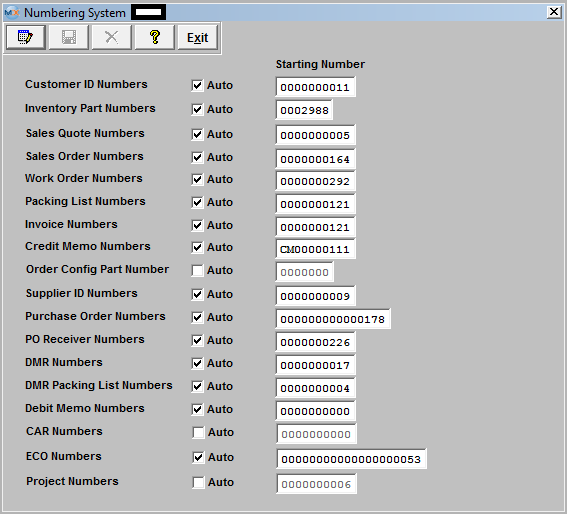

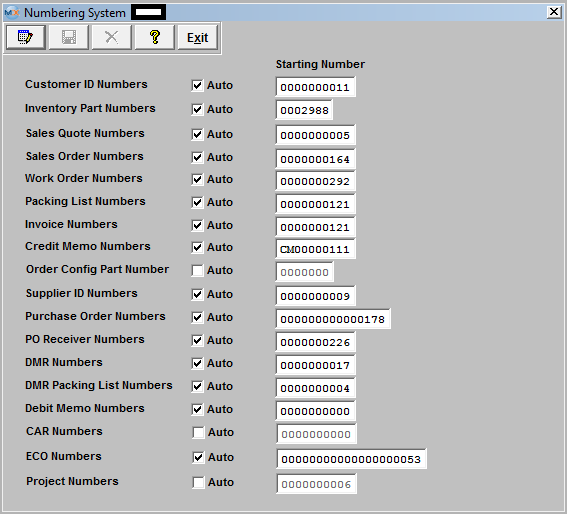

The Number System setup determines whether your company will use automatic or manual numbering method for the items listed.

If "Auto" numbering is selected, the user will need to enter the starting number in the space provided on the right side of the form (starting number.) If no starting number is entered, the system will automatically start assigning numbers with number one. ManEx will automatically assign the next available sequential number (with no revision) when adding a new record in a selected module, user may at this time enter a revision if applicable. Once the "Next" number is selected, the counter moves to the succeeding number, if the abandon changes button is depress that number will be considered as used and will be skipped even though the record was never saved.

If "Manual" mode is selected, the user will need to maintain a manual numbering sequence log and manually enter the number when adding a new record in a selected module. It is not necessary to fill in the starting number field when using manual mode. In the manual mode, the user may combine alpha and numeric characters up to the length of the field.

If the user wishes to begin with manual assignment of tracking numbers, it is recommended that they begin with an alpha character imbedded in the numbers. When the user decides to change to automatic number assignment, there will be no possibility of duplicate numbers, because all of the auto-numbering systems use numbers only. It may be appropriate for the user to enter the last number used in a manual system as the starting number for auto-numbering in the ManEx setup. |

| 1.1.2.3. Fields & Definitions for Number System |

The following numbering systems are established in this setup:

If the user wishes to start the number sequence for a number type at a number other than the one shown, the user types in the new starting number. The user must NOT enter a number below a number already existing. If "Auto" numbering is selected, the user will need to enter the starting number in the space provided on the right side of the form (starting number.) If no starting number is entered, the system will automatically start assigning numbers with number one. ManEx will automatically assign the next available sequential number (with no revision) when adding a new record in a selected module, user may at this time enter a revision if applicable. Once the "Next" number is selected, the counter moves to the succeeding number, if the abandon changes button is depress that number will be considered as used and will be skipped even though the record was never saved. If the Auto mode is unchecked the system will require user to manually assign the numbers. "Manual" mode is where the user will need to maintain a manual numbering sequence log and manually enter the number when adding a new record in a selected module. It is not necessary to fill in the starting number field when using manual mode. In the manual mode, the user may combine alpha and numeric characters up to the length of the field.

If the user wishes to begin with manual assignment of tracking numbers, it is recommended that they begin with an alpha character imbedded in the numbers. When the user decides to change to automatic number assignment, there will be no possibility of duplicate numbers, because all of the auto-numbering systems use numbers only. It may be appropriate for the user to enter the last number used in a manual system as the starting number for auto-numbering in the ManEx setup. Customer ID NumbersAs the user adds customers to the database, it is useful to have a customer code assigned to each customer. In many systems, the user is required to remember the customer code in order to process information concerning the customer. In such a system, mnemonic code is usually assigned so the user can remember the customer code. In ManEx, the customer code may be used to find a customer, but every screen requiring a customer identification code will display at least the customer’s full name to choose from, and often the code also. The ManEx user does not need to customize the customer codes, but can let ManEx automatically apply a new number for each new customer. Inventory Part Number As discussed in the Materials Setup section, ManEx provides users with the ability to automatically assign part numbers to new items being added to the inventory item master. Utilization of this numbering system relieves the user of the chore of having to maintain a separate logbook of assigned numbers. The user has the option of assigning a prefix to the number based on part type information established in the materials setup section. In most instances, the user may easily find an inventory item without having to remember the number, because ManEx provides several ways to locate a part – by customer, by class and type, by description, by where used, etc. Sales Quote Numbers If the user is in the quotation module, the creation of a new quotation will require a control number before saving the quotation. The user may have ManEx assign these numbers, releasing the user from having to maintain a separate log, or the user may assign numbers at the time of the quote generation. Sales Order Numbers When a sales order is created, there must be a control number assigned before the order is saved. The user may have ManEx assign these numbers, releasing the user from having to maintain a separate log, or the user may assign numbers each time a new sales order is entered. Work Order Number When a work order is created, there must be a control number assigned before the order is saved. The user may have ManEx assign these numbers, releasing the user from having to maintain a separate log, or the user may assign numbers each time a new work order is entered. Also, if the user elects to have ManEx automatically create work orders from sales orders, the numbering system for work orders MUST be automatic. Packing List Numbers When the shipping department is ready to make a shipment, they must create a packing list to go with the shipment, and to record in ManEx the details of the shipment. These too, must have a control number assigned at the time the packing list is created. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Invoice Numbers Invoices are created after the shipment has been completed and delivered to a carrier or customer. When the user assigned to printing invoices is ready to do so, the invoices must have a control number assigned to them. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Credit Memo Numbers Credit memos are created in accounting or via an RMA Receiver, and also require control numbers. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Order Configuration Part Number Order configuration is set up in the ManEx Sales section’s Order Configuration module. The numbering selection for Order Configuration can be either automatic or manual.If automatic, the user is spared from maintaining a manual log. Supplier ID Numbers As the user adds suppliers to the database, it is useful to have a supplier code assigned to each supplier. In many systems, the user is required to remember the supplier or vendor code in order to process information concerning the vendor. In such a system, mnemonic code is usually assigned so the user can remember the vendor code. In ManEx, the supplier code may be used to find a vendor, but every screen requiring a supplier identification code will display at least the supplier’s full name to choose from, and often the code also. So the ManEx user does not need to customize the supplier codes, but can let ManEx automatically apply a new number for each new supplier. Purchase Order Numbers Tracking numbers are vital to purchase orders, as they are the legal binding of the user to the supplier for the delivery and payment of goods. These numbers may be assigned manually, as many users do. However, the reasons for assigning them manually is usually associated with the ability to group purchasing actions by buyer or commodity. In ManEx, the user may use a wide variety of selections to view procurement information. The user may view the orders by buyer code, by class code, by part types, by require actions, and more. Because of the ease of extracting data about the purchase orders, it is recommended that the user utilize the auto-numbering system to track order numbers. The auto-numbering obviates the need for separate log books for each buyer, and trying to find the book when the buyer is not available. PO Receiver Number Each time a shipment is received against a purchase order, it is assigned a tracking number to identify the specific receipt against the order, and to reconcile the accounts payable. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Discrepant Material Return Numbers Discrepant Material Return Numbers track shipments when items previously purchased are returned to the supplier. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Discrepant Material Return Packing List Numbers When the shipping department is ready to make a shipment, they must create a packing list to go with the shipment, and to record in ManEx the details of the shipment. These too, must have a control number assigned at the time the packing list is created. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log.

Debit Memo Numbers Debit memos against a Supplier’s invoice are created in accounting or via a DMR return shipment, and also require control numbers. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Corrective Action Request Numbers If the user is using the CAR module, whenever the user issues a corrective action request, the ManEx program requires the assignment of a tracking number in order to report on the progress and resolution of the findings. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Calibration Numbers Calibration numbers are used to assign control numbers to specific equipment and tooling. If the user is using the Calibration and Maintenance module, these control numbers are provided to identify equipment and tooling that need regular maintenance or calibration. In a manual mode, the user may choose to use asset numbers (if available). Otherwise, ManEx can automatically assign numbers to each piece of equipment or tooling as it is entered into the ManEx database. (The user may wish to use these numbers as asset numbers for their equipment). ECO Numbers If the user has the Engineering Change Order module, whenever the user ADDs and Saves a new ECO, the ManEx program requires the assignment of a tracking and control number. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. Project Numbers If the user has a system which tracks project numbers, when the user sets up a NEW Project, there is a requirement of a new unique number. The user may do this manually, or the user may have ManEx assign these numbers, releasing the user from having to maintain a separate log. |

| 1.1.2.4. How To ..... for Number System |

| 1.1.2.4.1. Setup the Number System | ||||

The following screen will be displayed;

To modify this screen, the user must click on the Edit action button and supply the password. That action will enable the screen, and the user then can select which option to apply. For Auto numbering user MUST check the box by clicking on the radio/box. Unchecking the radio/box will indicate Manual numbering. If the user wishes to start the number sequence for a number type at a number other than the one shown, the user types in the new starting number. The user must NOT enter a number below a number already existing.

If "Auto" numbering is selected, the user will need to enter the starting number in the space provided on the right side of the form (starting number.) If no starting number is entered, the system will automatically start assigning numbers with number one. ManEx will automatically assign the next available sequential number (with no revision) when adding a new record in a selected module, user may at this time enter a revision if applicable. Once the "Next" number is selected, the counter moves to the succeeding number, if the abandon changes button is depress that number will be considered as used and will be skipped even though the record was never saved. If the Auto mode is unchecked the system will require user to manually assign the numbers. "Manual" mode is where the user will need to maintain a manual numbering sequence log and manually enter the number when adding a new record in a selected module. It is NOT necessary to fill in the starting number field when using manual mode. In the manual mode, the user may combine alpha and numeric characters up to the length of the field. If the user wishes to begin with Manual mode of tracking numbers, it is recommended that they begin with an alpha character imbedded in the numbers. When the user decides to change to Auto number mode, there will be NO possibility of duplicate numbers, because all of the auto-numbering systems use numbers only. It may be appropriate for the user to enter the last number used in a Manual system as the starting number for Auto-numbering in the ManEx setup. "Mark as Completed RoadMap Section B Item 1-a"

Where Used: All activities that issue control numbers. |

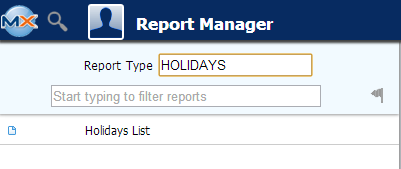

| 1.1.3. Calendar Setup |

| 1.1.3.1. Prerequisites for Calendar Setup |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-b" before continuing the setup. User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.3.2. Introduction for Calendar Setup |

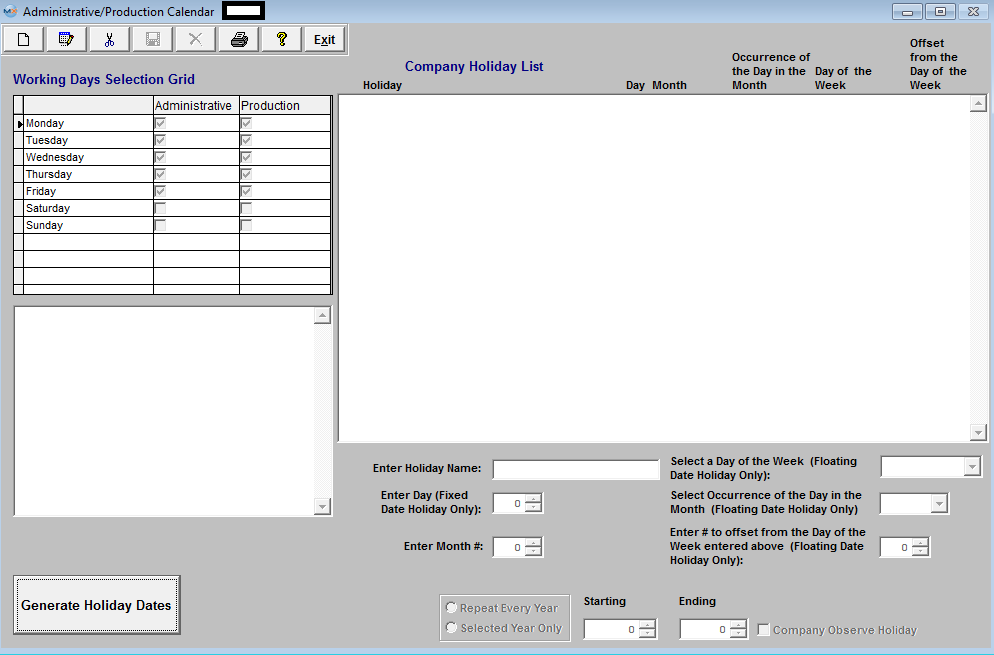

Administrative and Production calendar sections consist of three parts. They are: Company Holiday setup, Work Days setup, and

ManEx recommends that the user maintain a minimum of at least two years of calendar data ahead of the current date. If the user places a purchase order a year in advance and the generated calendar range is not enough to cover the range, then the system will generate an incorrect schedule. Likewise, the user should have at least six months in the past, otherwise any MRP actions that show up as being required beyond that date will provide erroneous information. However ManEx recommends that the user does NOT setup an extensive amount of calendar years. Having extensive calendars (both accounting and production) will slow down operations in each. More specifically, MRP has to determine from the production calendar all of the possible dates necessary for production schedules. With larger files, it takes a little longer to find the target information. In accounting, each time they post and close, accounting makes a record for every account, for every period in the accounting calendar. So the fewer periods set up, the faster the process of updating the accounting records. |

| 1.1.3.3. Fields and Definitions for Calendar Setup | ||||||||||||||||||||||||||||||

Working Days Selection Grid - This section is to tell the system how many standard work days are available each week (exclusive of holidays) for all functioning operations. All computations for deliveries, action dates and resource availability are based on this information.

Company Holiday List

|

| 1.1.3.4. How To ..... for Calendar Setup |

| 1.1.3.4.1. Setup the Admin/Production Calendar | ||||

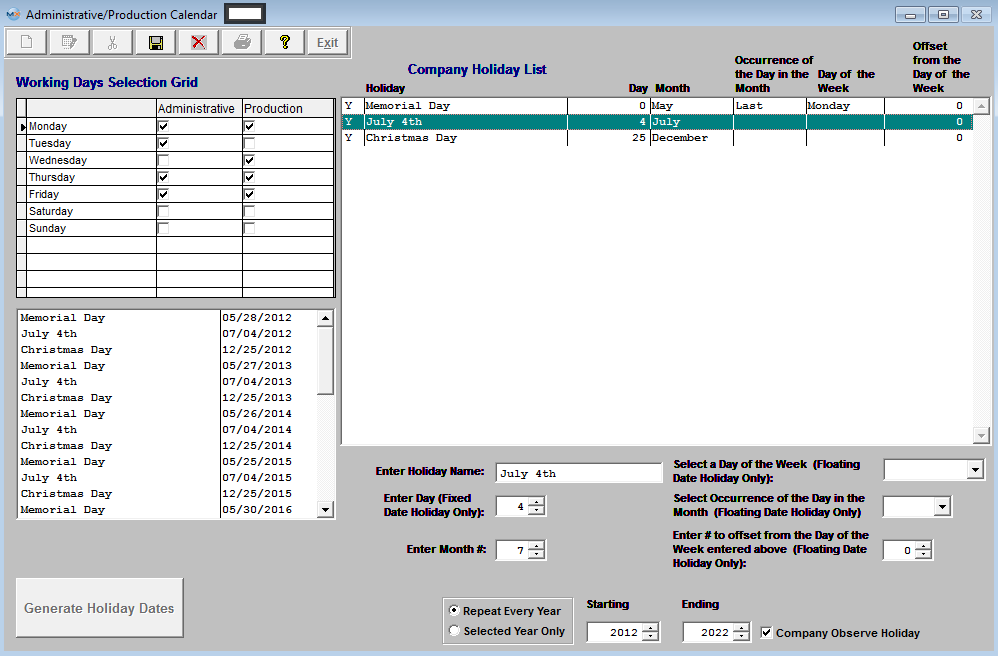

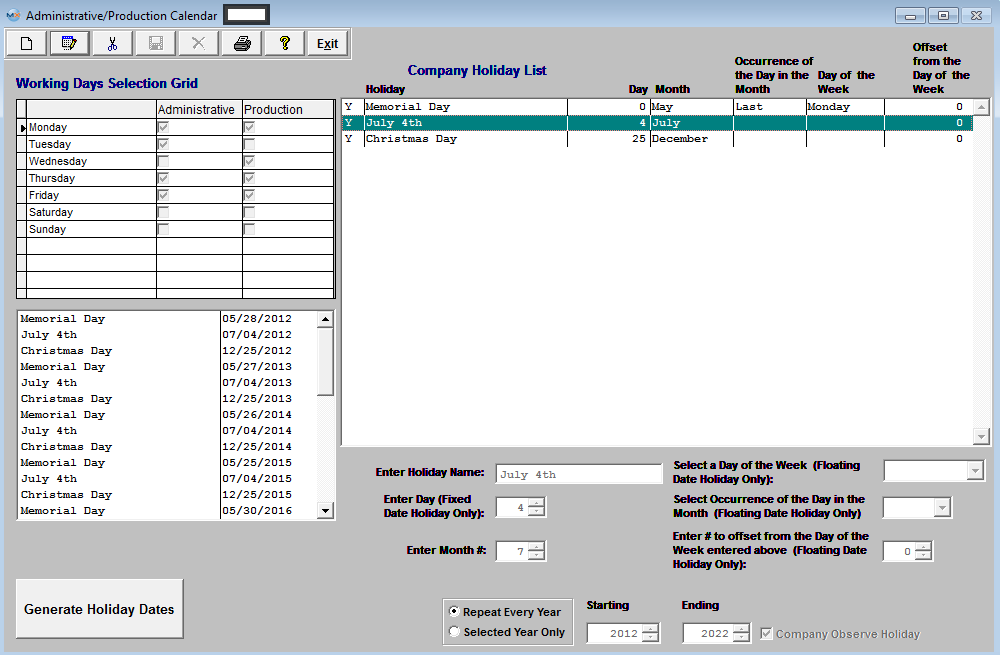

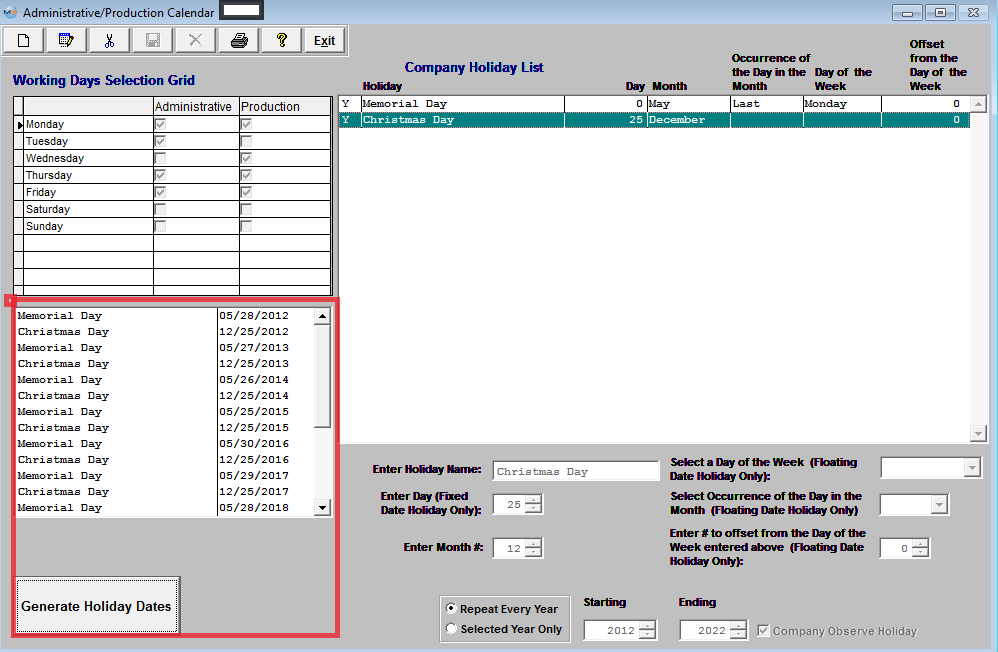

The following screen wiil be displayed:

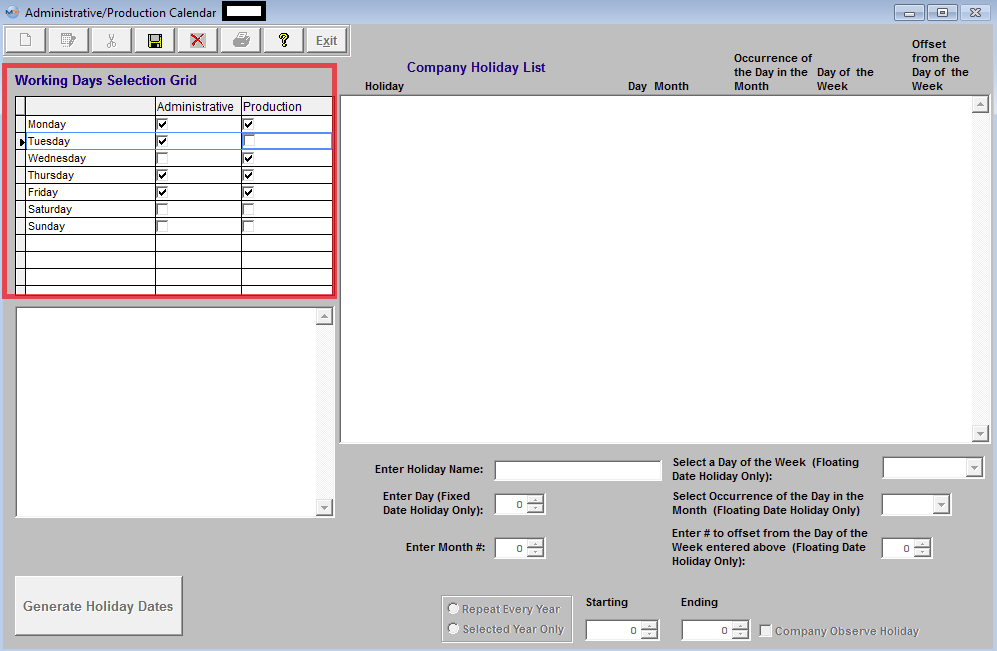

Working Days Selection Grid

To modify this screen, the user must click on the Edit button and supply the password. That action will enable the screen. This screen determines which weekdays will be considered as available for resources for the Administrative and/or Production. User may check the box if the day should be considered or is available or leave it unchecked of the day should NOT be considered or will NOT be available.

COMPANY HOLIDAYS

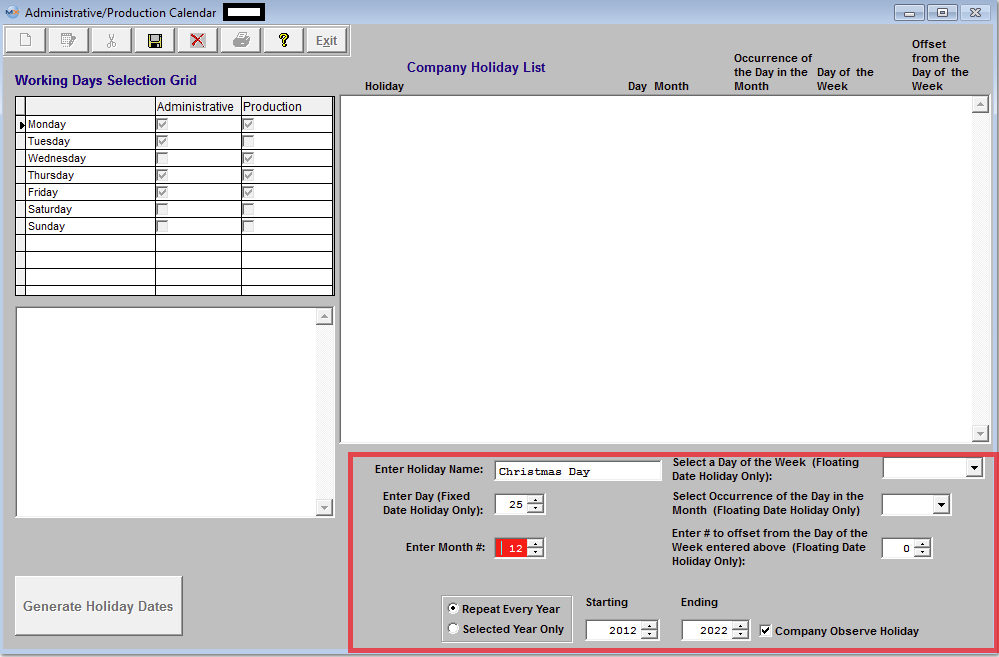

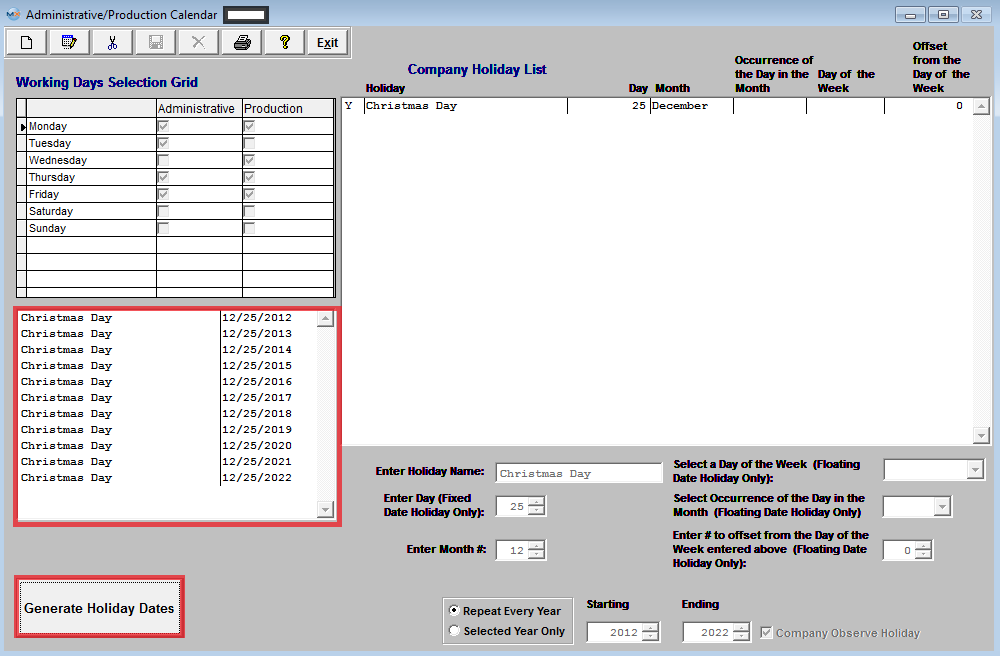

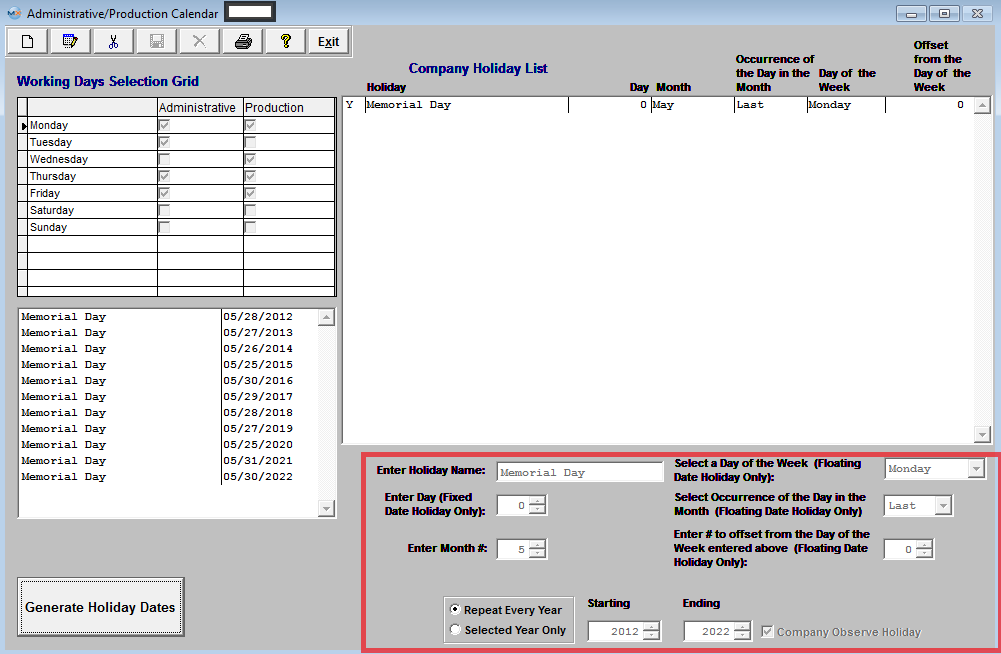

The user may Add, Edit or Delete holidays by using the action buttons. To ADD a holiday user must click on the ADD action button and supply the password. That action will enable the Holiday Information fields.  Enter the Holiday Name, if the Hoilday is the same date every year (Fixed Date Holiday) and NOT based on the same day of the year, user would enter in the date of the holiday and the Month of the holiday. Select to "Repeat Every Year" or "Selected Year Only". Select the Starting Year and Ending Year. Check if the Company is to Observe the Holiday being entered. Once all this has been completed depress the "Save" changes or "Abandon Changes" action button. If changes have been saved the "Generate Holiday Dates" button will become available. Depress the "Generate Holiday Dates" button and the Holiday dates will be created as displayed below:  If the Holiday is the same day of the year so the date fluctuates then the user would select a day of the week fron the pull down, select the Occurrence of the Day in the month (such as First, Second, Third, Fourth, or Last) and enter the Month the Holiday is in. Select to "Repeat Every Year" or "Selected Year Only". Select the Starting Year and Ending Year. Check if the Company is to Observe the Holiday being entered. Once all this has been completed depress the "Save" changes or "Abandon Changes" action button. If changes have been saved the "Generate Holiday Dates" button will become available. Depress the "Generate Holiday Dates" and holiday dates will be created as displayed below:  To EDIT Holiday Information Highlight the holiday you want to edit, depress the Edit button and the Holiday information will become editable

Once user has made the changes, depress the Save action button and depress the "Generate Holiday Dates" button to refresh the screen with the changes.

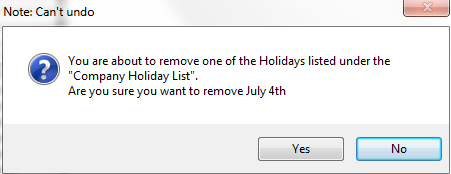

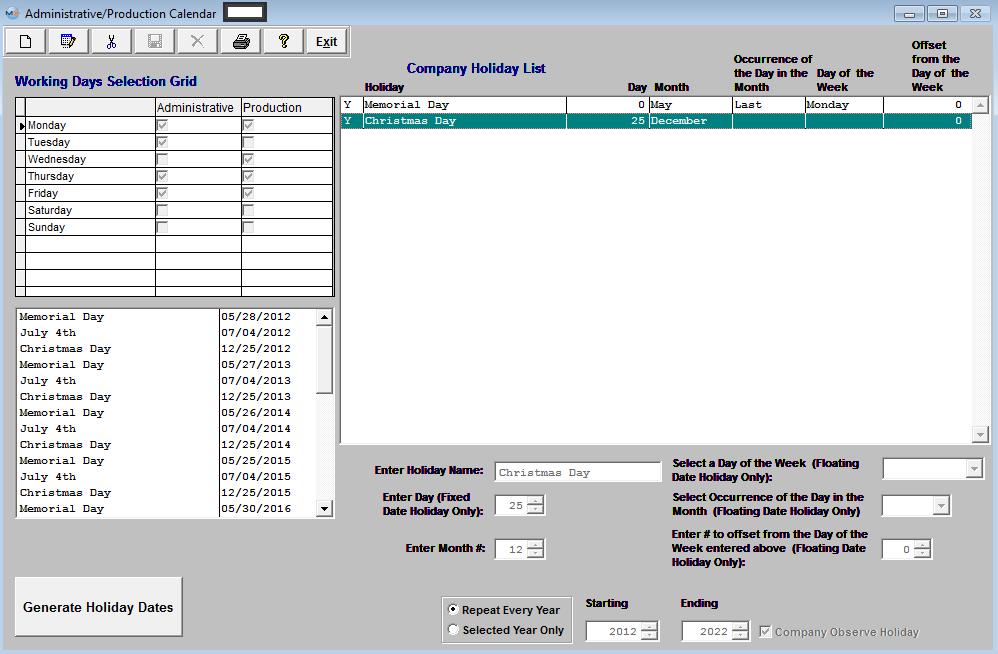

To DELETE a Holiday Highlight the holiday you want to remove or delete (Example July 4th)  Depress the Delete action button the following message will be displayed:  Depress Yes to Continue (notice that the Holiday (July 4th) has been removed from the Company Holiday List screen to the right but has NOT been removed from the Holiday Dates screen to the left)  User MUST depress the "Generate Holiday Dates" to refresh the Holiday Dates screen. Once this button has been depressed the (July 4th) dates will be removed from this screen also, as displayed below.  Where Used: All activities that consider available work days.

|

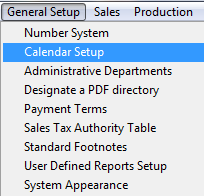

| 1.1.3.5. Reports for the Calendar Setup |

To obtain the AP

Aging Reports within the Web, select the WEB Print button from the ManEx action buttons at the top

of the screen. For further detail on How the Reports work within the Web refer

to Article #5477.

Select the Report Type: HOLIDAYS - A List of Reports will be displayed that are available on the Web

for HOLIDAYS

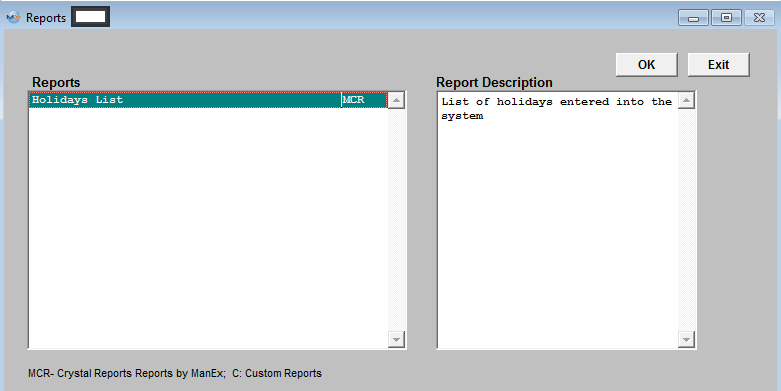

To obtain the Holiday Reports within the desktop, select the Print button from the ManEx action buttons at the top of the screen.

The following reports screen

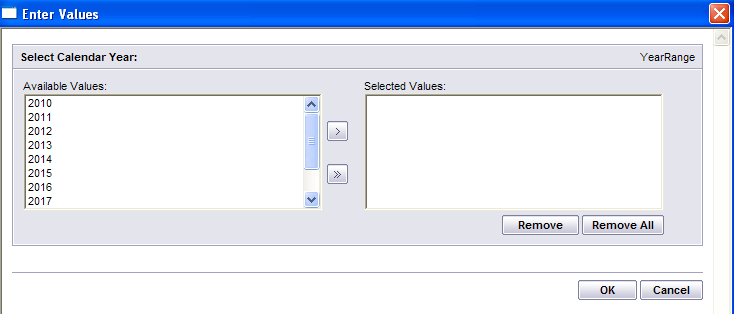

will display a list of reports that are available on the ManEx Desktop:  Highlight the Holiday List Report and depress the OK button, the following screen will appear:  Highlight the Calendar Year and depress the > button. To select All of the Calendar Years listed, depress the >> button.

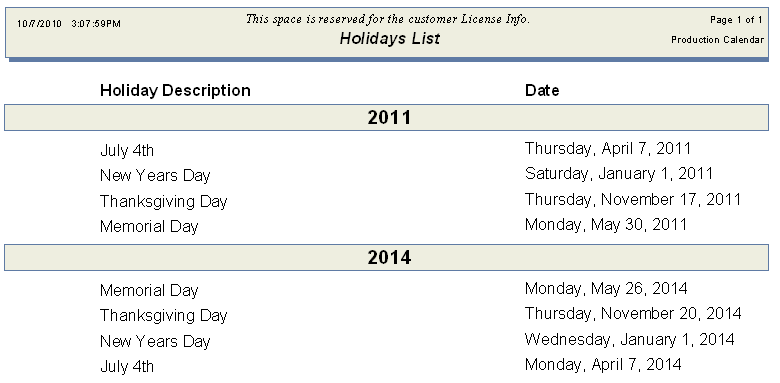

Depress the OK button. The following report is available:

|

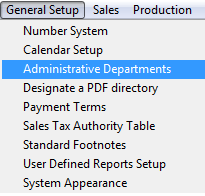

| 1.1.4. Administrative Departments |

| 1.1.4.1. Prerequisites for Administrative Departments |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-c" before continuing the setup. User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.4.2. Introduction for Administrative Departments |

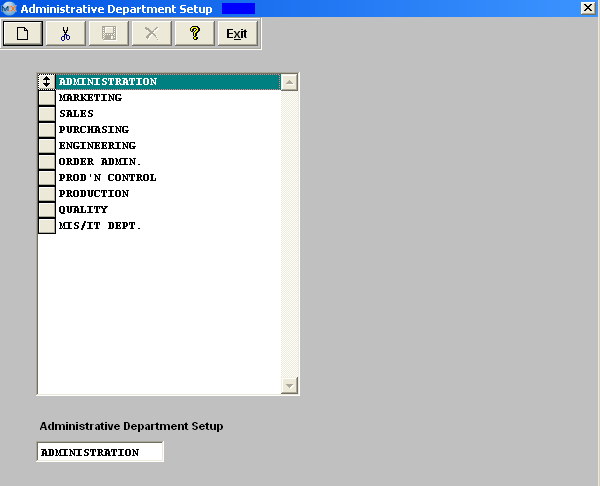

This screen is used to establish the different administrative departments within the company. |

| 1.1.4.3. Fields & Definitions for Admin Departments Module |

The ManEx System will use this information as a means for traceability. Do not use this screen for entering Production Department or Work Centers. Production departments are set up in the Production Work Centers & Activities setup. The Administrative Department is only used in System Security to assign user to either "work center" or "department"

The user may enter as many departments as desired. |

| 1.1.4.4. How To ..... for Administrative Department |

| 1.1.4.4.1. Setup the Adminstrative Departments | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add or Delete button and supply the password. That action will enable the screen. The user may either add or delete department names to the list. After adding or deleting a department name, the user must Save or Abandon changes.

These items may be rearranged in any order by clicking on and dragging the box to the left side to the (vertical) position desired. This order will be the order the user sees when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: When assigning non-production users to an administrative department, and in establishing accounts for the departments. «Mark as Completed in RoadMap Section B Item 1-c» |

| 1.1.5. Designate a PDF directory |

| 1.1.5.1. Prerequisites for Designate a PDF Directory |

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.5.2. Introduction to Designate a PDF Directory |

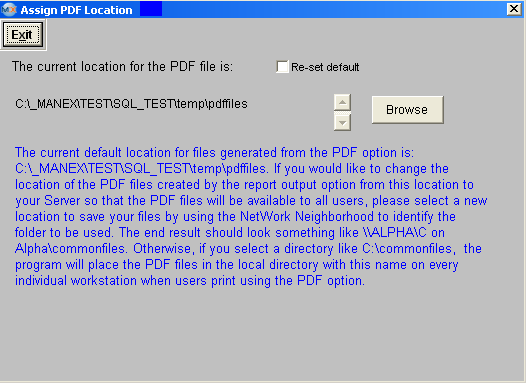

| This is the current default location for files generated from the pdf option. |

| 1.1.5.3. Fields & Definitions for Designate a PDF Directory |

|

| 1.1.6. Payment Terms |

| 1.1.6.1. Prerequisites for Payment Terms |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-e" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

| 1.1.6.2. Introduction for Payment Terms |

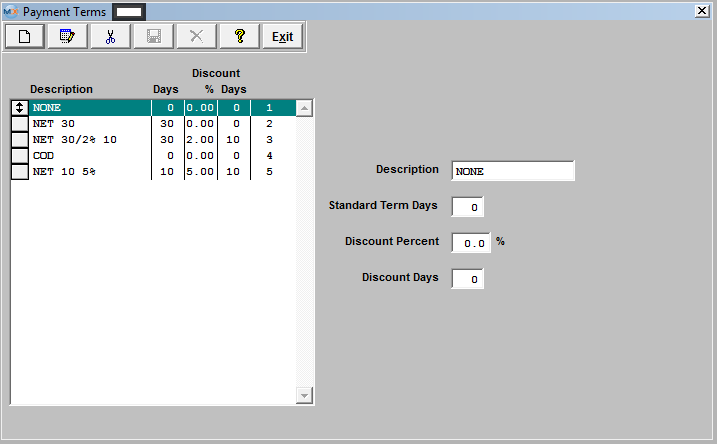

This is where the user sets up Payment Terms (used in Customer Information, Sales Order, Quotation, Invoicing, Supplier Information, Purchase Order and Accounts Payable). The description is a free text field to describe the payment terms as the user wishes to see it, i.e.: 2% 10 Days, N30 etc. This is provided for the user to select payment terms based on the description. |

| 1.1.6.3. Fields and Definitions | ||||||||

In the example Net 30/2% 10, if the buyer pays the invoice within ten days of the invoice date, they are entitled to take a two percent (2%) discount on the amount of the invoice. After the ten days have passed, the buyer has up to thirty days from the date of the invoice to pay. Payments made after that time may be charged other fees. |

| 1.1.6.4. How To ..... Payment Terms |

| 1.1.6.4.1. Setup Payment Terms | ||||

|

The following screen will be displayed:

Pressing the Add button will enable the data entry boxes at the left of the screen for the user to enter new data. Selecting an existing Payment Term and pressing the Edit button will bring the selected information to the data entry box to be modified. Selecting an existing Payment Term and pressing the Delete button will remove the selected information. The user enters in the Description, standard days, discount (as a percent) and discount days. These items may be rearranged in any order by clicking on and dragging the box to the left side to the (vertical) position desired. This order will be the order the user sees when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In the Customer Setup, Sales Orders, Packing Lists, Invoicing, Supplier Setup, and Accounting.

«Mark as Completed in RoadMap Section B Item 1-e» |

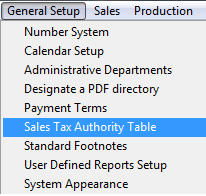

| 1.1.7. Sales Tax Authority Table |

| 1.1.7.1. Prerequisites for Sales Tax Authority Table |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-f" before continuing the setup. If Accounting is used, the appropriate General Ledger numbers must have been set up in the Accounting Set Up section.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.7.2. Introduction for Sales Tax Authority Table |

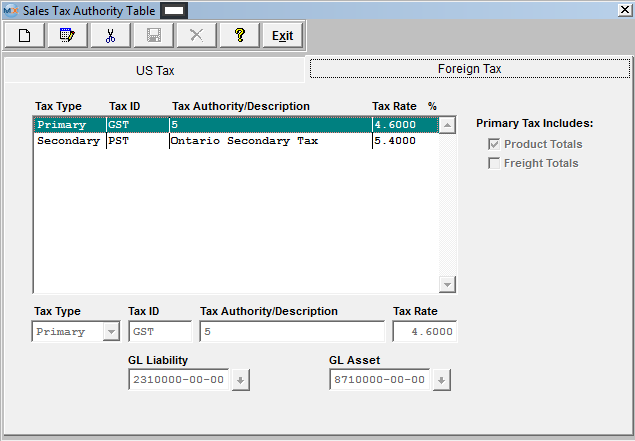

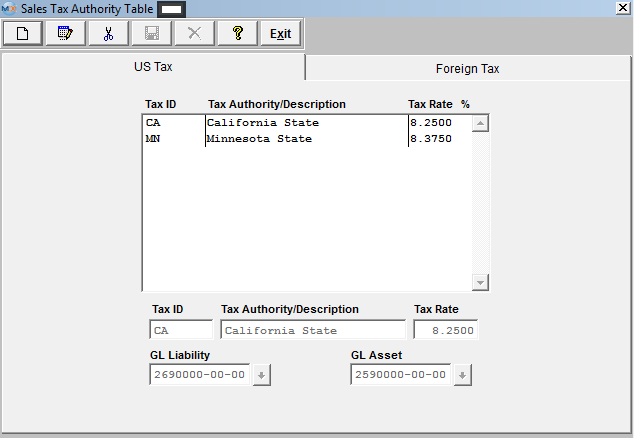

This is where the user must enter all sales tax information. The tax ID, Tax Authority description, and rates for various city, county, state, province, etc. are entered. This information is used in Customer Shipping Information and Material Receiving Location default tables. This default setting assigned to each shipping address for each customer will be entered in orders automatically when a new order is added, if the Tax Box is checked. The tax ID is also associated with the user’s Bill-to / Ship to address for purchases, and added to taxable items on a purchase order. The default information in the invoice and purchase order can be modified during the entry process for a new order. This section may not apply to states that do not have local or state sales tax or states with manufacturing local & state sales exemption.

The user may also define the GL accounts to be used for taxes in this section, if the accounting module is active. |

| 1.1.7.3. Fields & Definitions for Sales Tax Authority Table |

| 1.1.7.3.1. US Sales Tax | ||||||||||

|

| 1.1.7.3.2. Foreign Tax | ||||||||||||||||

|

| 1.1.7.4. How To ..... for Sales Tax Authority Table |

| 1.1.7.4.1. Setup the US Sales Tax | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add, Edit, or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry boxes at the bottom of the screen for the user to enter new data. Selecting an existing Tax ID and pressing the Edit button will bring the selected information to the data entry box to be modified. Selecting an existing Tax ID and pressing the Delete button will remove the selected information. The user enters in the Tax ID, Description, Rate, the GL Liability Account and the GL Asset Account. Pressing on the down-arrow keys will display the GL account numbers, if the user is using the accounting module. The user must Save or Abandon changes when finished adding or editing screen. Where Used: In the Customer Setup, Sales Orders, Packing Lists, Invoicing, Purchase Setup Receiving and Billing Information, and Accounting.

«Mark as Completed in RoadMap Section B Item 1-f» |

| 1.1.7.4.2. Setup the Foreign Sales Tax | ||||

|

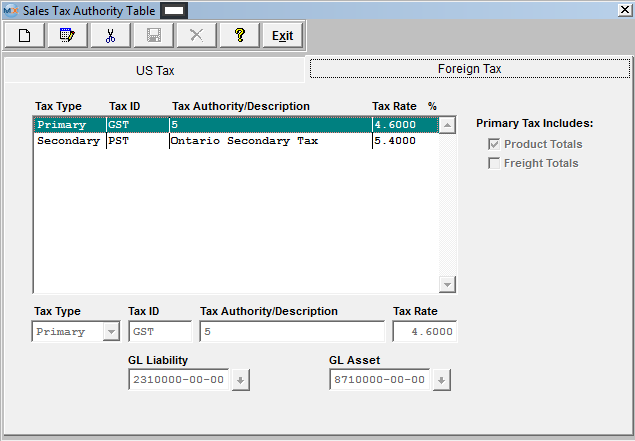

The following screen will be displayed:  Depress the Foreign Tax tab

To modify this screen, the user must click on the Add, Edit, or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry boxes at the bottom of the screen for the user to enter new data. Selecting an existing Tax ID and pressing the Edit button will bring the selected information to the data entry box to be modified. Selecting an existing Tax ID and pressing the Delete button will remove the selected information. The user selects the Tax Type from the pull down, enters in the Tax ID, Description, Rate, the GL Liability Account and the GL Asset Account. Pressing on the down-arrow keys will display the GL account numbers, if the user is using the accounting module.

If user selects "Primary" tax type, this tax will be calculated first, the calculation will be based on what user checks for Primary Tax to include Product Totals, and/or Freight Totals. If user selects "Secondary" tax type, this tax will be calculated after primary tax, and the calculation will be based on what boxes are checked, Product Totals, and/or Freight Totals, and/or Primary Tax Totals. If user checks "Primary Tax Totals", the tax calculated will be based on only the "Primary Tax Total". The user must Save or Abandon changes when finished adding or editing screen. For examples see the "Foreign Tax Examples.xlsx" or the "canadian provice vats.xls" attached.

Where Used: In the Customer Setup, Sales Orders, Packing Lists, Invoicing, Purchase Setup Receiving and Billing Information, and Accounting.

«Mark as Completed in RoadMap Section B Item 1-f» |

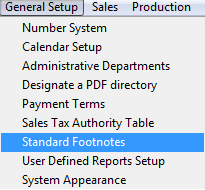

| 1.1.8. Standard Foot Notes |

| 1.1.8.1. Prerequisites for Standard Footnotes |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-g" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.8.2. Introduction for Standard Footnotes |

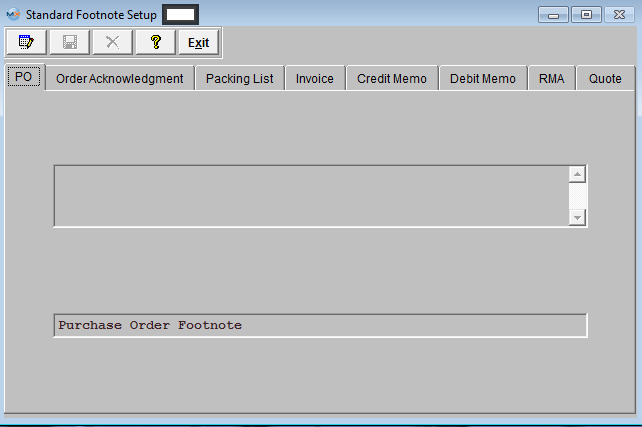

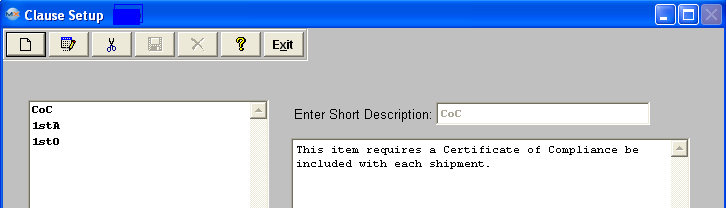

The foot note section is used to set up standard system level messages that will print on the foot note section of the various type of forms. Whenever any of the forms listed are printed, the setup message will automatically appear on the foot note section of the form. Enter messages in the space provided. Sample verbiage provided is for reference only, and is not intended to be a suggestion for the user to adopt for their own use. |

| 1.1.8.3. Fields & Definitions for Standard Footnotes |

The foot note section is used to set up standard system level messages that will print on the foot note section of the various type of forms listed below. Whenever any of the forms listed below are printed, the setup message will automatically appear on the foot note section of the form. Enter messages in the space provided. Sample verbiage provided is for reference only, and is not intended to be a suggestion for the user to adopt for their own use.

|

| 1.1.8.4. How To ..... for Standard Footnotes |

| 1.1.8.4.1. Setup Standard Footnotes | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Edit button and supply the password. That action will enable the screen. This will allow the user to click on the tabs for the documents displayed. The user may enter text in each of these screens, but the text will be limited to the amount of space reserved on each of the documents for such notes. The user must Save or Abandon changes after entering the Edit mode.

Where Used: In ALL documents named on the screen.

«Mark as Completed in RoadMap Section B Item 1-g» |

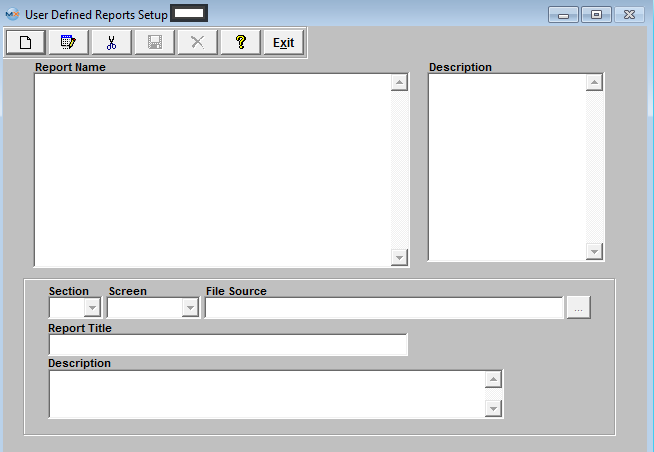

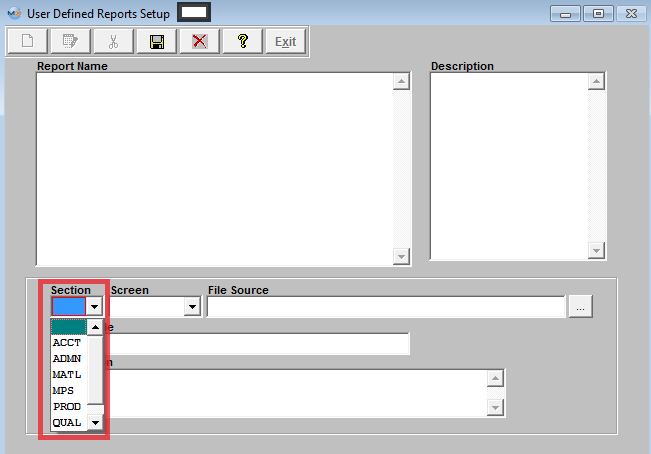

| 1.1.9. User Defined Reports Setup |

| 1.1.9.1. Prerequisites for User Defined Reports Setup |

A Crystal Report Interface is available. This function allows the user to view any custom Crystal Report that has been compiled into an Executable and loaded into the "User Defined Report Setup" screen. WITHOUT having to have any Crystal Report software loaded on this machine.

To view the Custom Crystal Reports once they have been linked in ManEx user must have the VFPODBC Drivers installed. For further detail on how to install these drivers see Article #3072 .

We are currently using CR XI Developer, but our new Library files should work with previous versions. You no longer need to compile your reports using Crystal Reports Designer software. You can now attach your Crystal Report in the User Defined Reports Setup and run them in ManEx. PRECAUTIONS WHEN USING CRYSTAL REPORTS AND CRYSTAL REPORT DESIGNER WITH THE MANEX DATABASE ManEx does not provide training on the use of Crystal Reports software. It is not our product. To arrange for training, call Seagate Software at 1-800-877-2340. If you do not have anyone on your staff who can do the reports and you want an outside designer, there are independent software consultants who do this type of work. In the Silicon Valley area, one of these consultants is Wisdom Technology. The number is 408-997-7165. The contact’s name is Bob Shatzer. ManEx can provide you or your designer with the database information for the reports you are trying to create. We will charge you phone support hours your company purchased for the time we spend. Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 1-h" before continuing the setup.

Rights to "System Setup" in the System Security module. Users with "Supervisor Rights" will automatically have access.

|

| 1.1.9.2. Introduction for User Defined Reports Setup |

This module will allow each end workstation the ability to view(desktop only) any custom Crystal Report that has been compiled in .rpt format and loaded into the "User Defined Report Setup" screen. ManEx includes the Crystal Reports viewer so custom reports created in Crystal Reports can be controlled and distributed through the software, WITHOUT having to have any Crystal Report software loaded on that machine.

For Manexcloud custom reports users can create custom Quick View reports. See article here. Article 5816 For full report options on Manexcloud you can use Stimulsoft software Once setup you can configure to work with SQLManex Configure Stimulsoft To Work With SQL Data |

| 1.1.9.3. Fields & Definitions for User Defined Reports Setup |

|

1. Crystal Reports must NOT be designed using "live" MANEX DBFS tables. Data will be corrupted in MANEX if any of the tables used for the design are accessed and changed while the design is in progress. To use Crystal Report Designer, create a copy of the DBFS and use the copy to design the report. 2. MANEX has no reason to believe that running a previously designed Crystal Report using live MANEX files will cause any problems. It does not matter if the report was designed using Crystal Report Designer or written as a custom executable.

3. However, when using Crystal Report Designer or running a pre-existing Crystal Report, the user's workstation should be using "absolute" NOT "relative" paths to the DBFS files in use (ie. X:\Manex\DBFS\xyz.dbf NOT \\Manex\DBFS\xyz.dbf), where “X” is the absolute drive letter. Therefore, workstations setup with shortcuts to MANEX using relative addressing (for security reasons*) shouldn't be used to run Crystal Reports.

* Normally MANEX suggests that users use the MANEX shortcuts with relative addressing (not mapped to the server) to keep users from accessing the MANEX Server files in Windows Explorer. 4. If you accidentally corrupt the MANEX DBFS files using Crystal Report Designer or relative addressing, get all users off of MANEX and reindex TWICE. The first time clears the incorrect End of File table and the second time writes a corrected index. So in conclusion, as long as you don't design on the live database and you use "absolute" mapping to the server, using Crystal Reports to look at the live data after the report is designed should not be a problem.

|

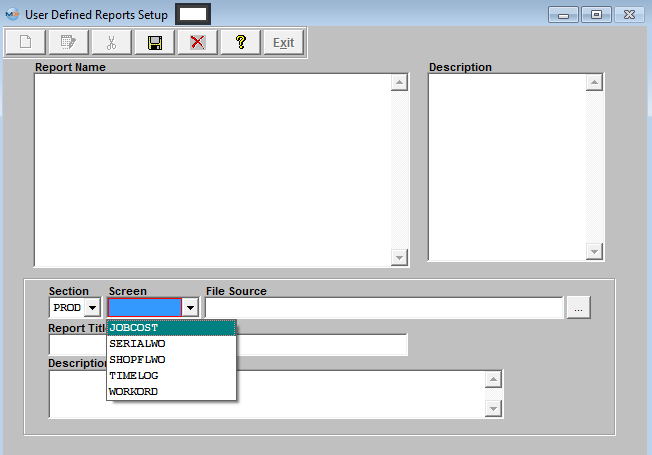

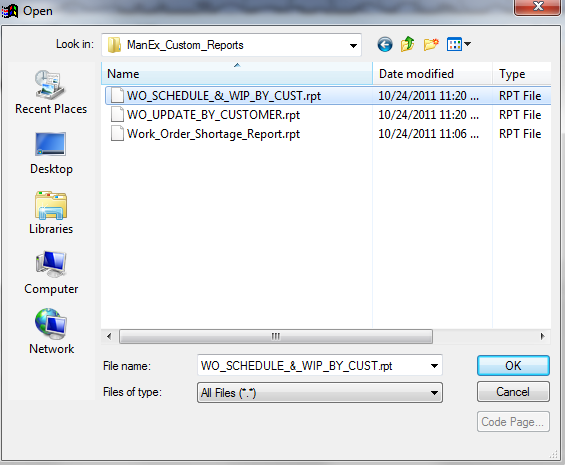

| 1.1.9.4. How To ..... for User Defined Reports Setup |

| 1.1.9.4.1. Setup the User Defined Reports | ||||||||||||||||||||

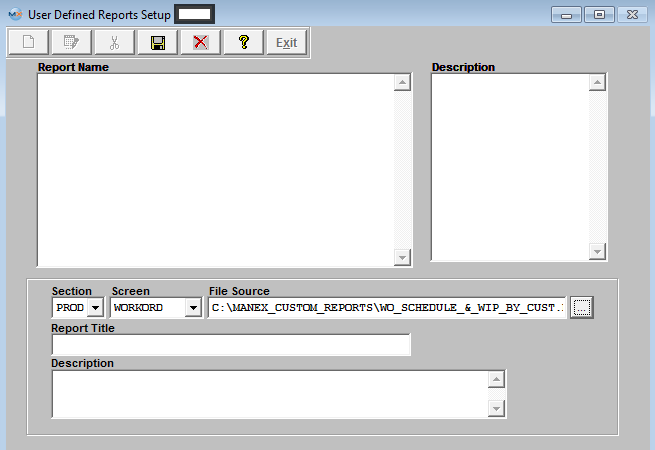

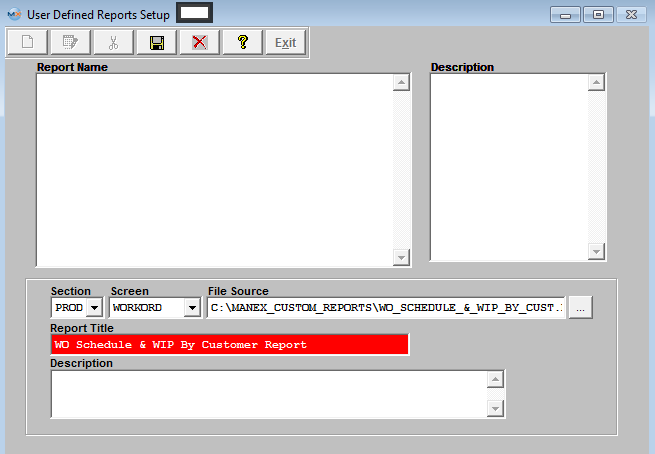

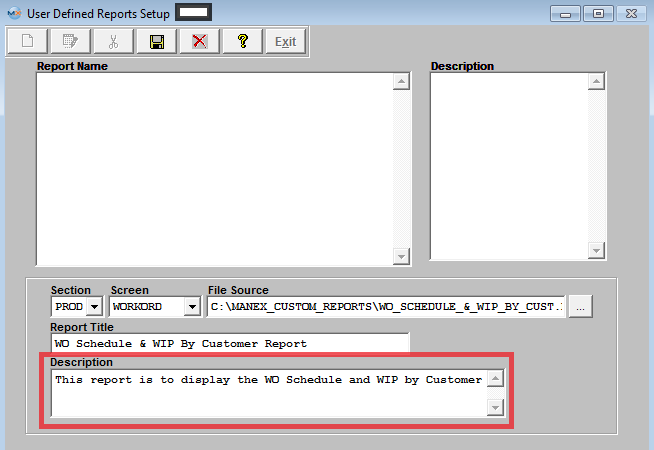

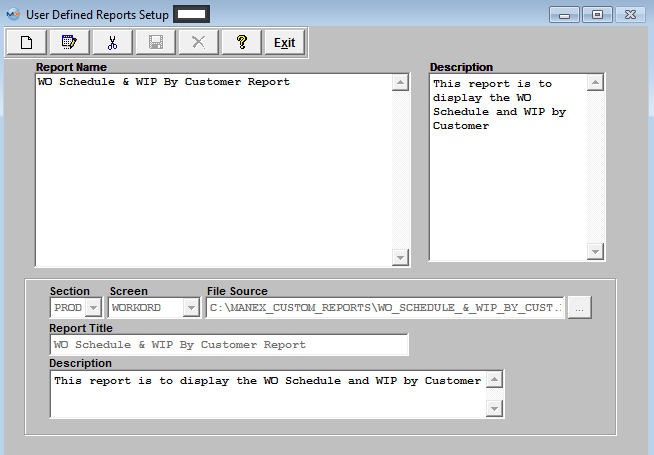

|

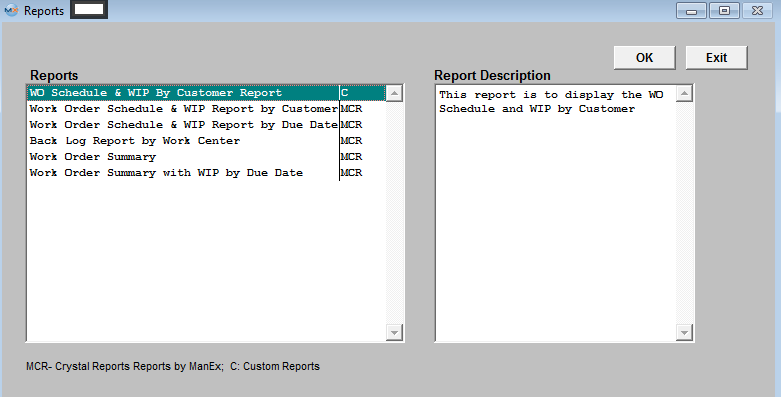

The following screen will be displayed:

When you visit the applicable module, the report you created will appear in the Reports Selection window, as illustrated:

1. Crystal Reports must not be designed using "live" ManEx DBFS tables. Data will be corrupted in ManEx if the any of the tables used for the design are accessed and changed while the design is in progress. To use Crystal Report Designer, create a copy of the DBFS and use the copy to design the report.

3. However, when using Crystal Report Designer or running a pre-existing Crystal Report, the user's workstation should be using "absolute" not "relative" paths to the DBFS files in use (ie. X:\Manex\DBFS\xyz.dbf NOT \\Manex\DBFS\xyz.dbf). Therefore, workstations setup with shortcuts to ManEx using relative addressing (for security reasons*) shouldn't be used to run Crystal Reports.

* Normally ManEx suggests that users use the ManEx shortcuts with relative addressing (not mapped to the server) to keep users from accessing the ManEx Server files in Windows Explorer. 4. If you accidentally corrupt the ManEx DBFS files using Crystal Report Designer or relative addressing, get all users off of ManEx and reindex TWICE. The first time clears the incorrect End of File table and the second time writes a corrected index.

So in conclusion, as long as you don't design on the live database and you use absolute mapping to the server, using Crystal Reports to look at the live data after the report is designed should not be a problem.

|

| 1.1.10. System Appearance |

| 1.1.10.1. Prerequisites for System Appearance |

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.1.10.2. Introduction for System Appearance |

| This is to setup the System Appearance on screens and Setup the Connection to WebManEx. |

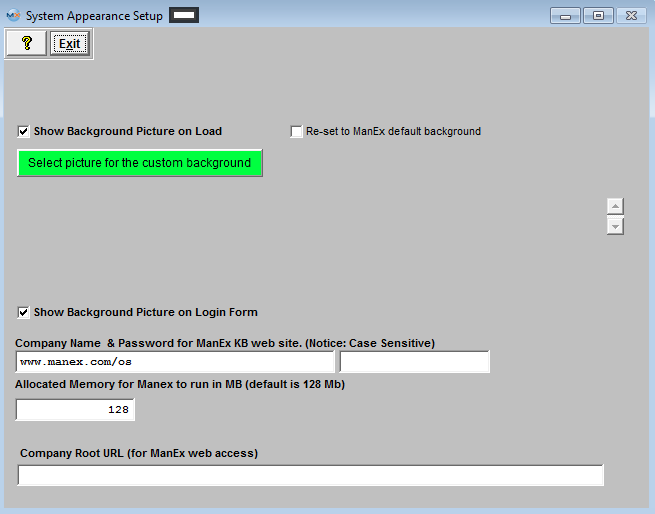

| 1.1.10.3. Fields & Definitions for System Appearance | ||||||||||||||

|

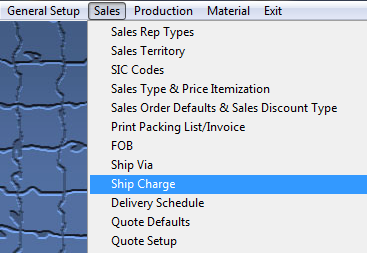

| 1.2. Sales |

| 1.2.1. Prerequisites |

The Sales module setup section allows the user to prepare tables for most of the modules your company has purchased.Once the items are setup in the system, the user will be able to use these tables and/or perform certain functions automatically.

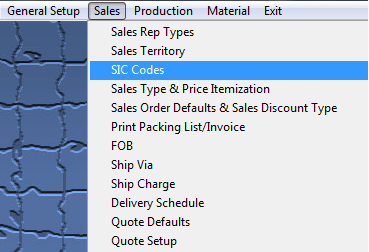

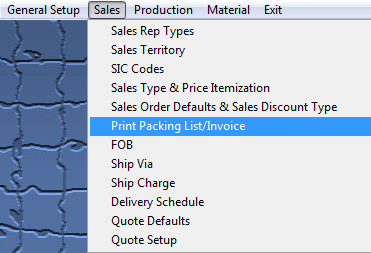

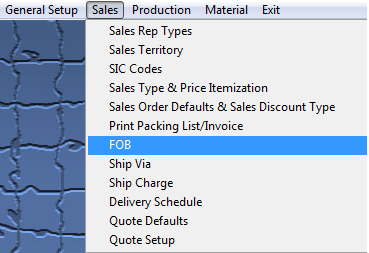

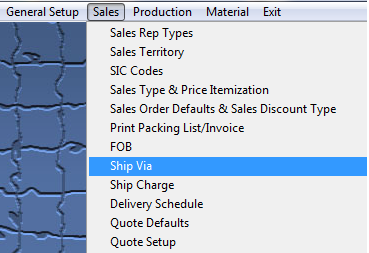

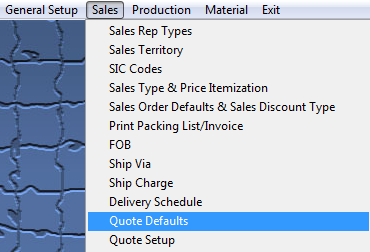

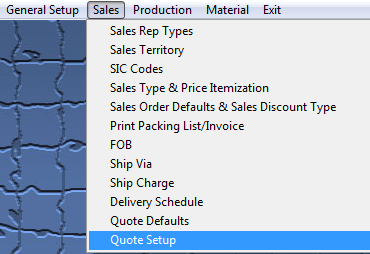

The Sales Setup section worksheets cover the following modules: Sales Rep Types, Sales Territory, SIC Codes, Sales Type & Price Itemization, Sales Order Defaults & Sales Discount Type, Print Packing List/Invoice, FOB, Ship Via, Ship Charge, Delivery Schedule, Quote Defaults, and Quote Setup. This section will first define the nature of each of the Sales Setup screens, then describe how to fill out the work sheets.

User MUST have full rights to the "System Setup" in System Security to setup these modules. Users with “Supervisor Rights” will automatically have access.

|

| 1.2.2. Sales Rep Types |

| 1.2.2.1. Prerequisites for Sales Rep Types |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-a" before continuing the setup.

A Sales Rep Type that is used to describe an active sales rep may NOT be deleted.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

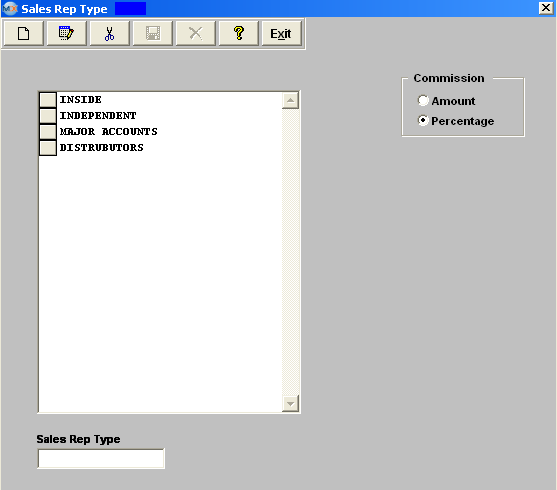

| 1.2.2.2. Introduction for Sales Rep Types |

This section is to establish different types of sales reps, and it is required in order to use the Sales Rep Information setup. Some examples are: Inside Sales, Outside Sales, Independent Rep, etc. This feature will allow the user to analyze data based on the type of representatives entered here. The user also may select the Commission Type, either a stated dollar amount or a Percentage of the |

| 1.2.2.3. Fields & Definitions for Sales Rep Types |

This feature will allow the user to analyze data based on the type of representatives entered here. The user also may select the Commission Type, either a stated dollar amount or a Percentage of the |

| 1.2.2.4. How To ..... for Sales Rep Types |

| 1.2.2.4.1. Setup a Sales Rep Type | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add, Edit or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry box at the bottom of the screen for the user to enter new data. Selecting an existing Sales Rep Type and pressing the Edit button will bring the selected information to the data entry box to be modified. Selecting an existing Sales Rep Type and pressing the Delete button will remove the selected information. The user must Save or Abandon changes after adding or editing the record.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In the Sales Rep setup screen.

«Mark as Completed in RoadMap Section B Item 2-a» |

| 1.2.3. Sales Territory |

| 1.2.3.1. Prerequisites for Sales Territory |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-b" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

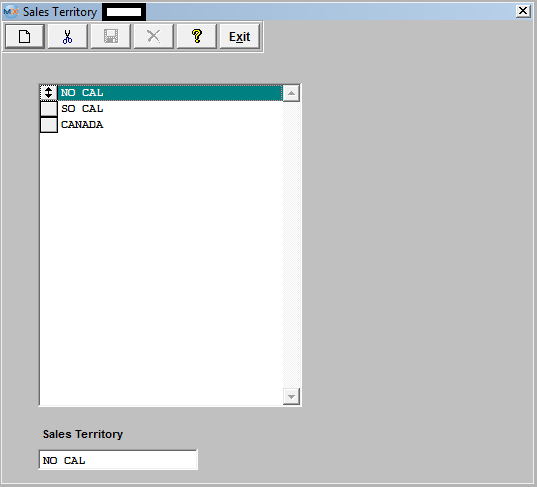

| 1.2.3.2. Introduction for Sales Territory |

This screen is used to assign geographical sales territories and is used in the Customer Information Module. Some examples are: The user may optionally assign a territory to a customer for purposes of grouping sales and other business considerations. |

| 1.2.3.3. Fields & Definitions for Sales Territory |

This screen is used to assign geographical sales territories and is used in the Customer Information Module. Some examples are: The user may optionally assign a territory to a customer for purposes of grouping sales and other business considerations. |

| 1.2.3.4. How To ..... for Sales Territory |

| 1.2.3.4.1. Setup Sales Territory | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry box at the bottom of the screen for the user to enter new data. Selecting an existing Sales Territory and pressing the Delete button will remove the selected information. The user must Save or Abandon changes after adding a Sales Territory.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used:I n the Sales Rep setup screen and the Customer Information screen.

«Mark as Completed in RoadMap Section B Item 2-b» |

| 1.2.4. SIC (Standard Industrial Codes) |

| 1.2.4.1. Prerequisites for SIC Codes |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-c" before continuing the setup.

User MUST have full rights to the System Setup in Security . Users with “supervisor’s rights” will automatically have access. |

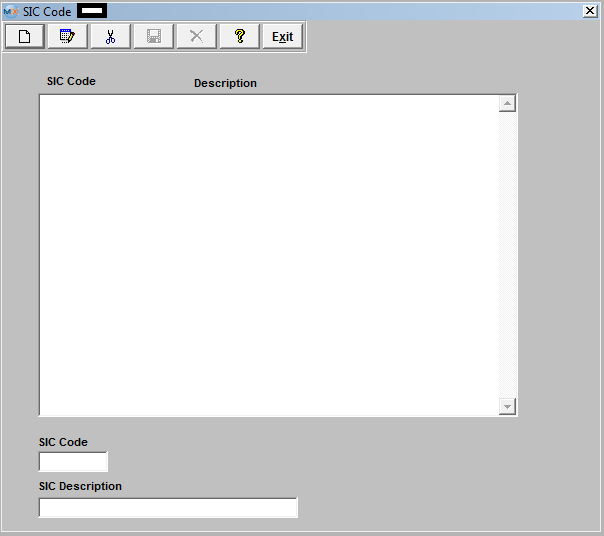

| 1.2.4.2. Introduction for SIC Codes |

Use this screen to setup the different Industrial codes that pertain to the user’s customers. The SIC codes are nation-wide standard industrial classifications given to each industry type. In some cases, the user may wish to deal with multiple industries. This is also useful for the user who wants to track business conditions by the type of businesses served. |

| 1.2.4.3. Fields & Definitions for SIC Codes |

Use this screen to setup the different Industrial codes that pertain to the user’s customers. The SIC codes are nation-wide standard industrial codes given to each industry type. In some cases, the user may wish to deal with multiple industries. This is also useful for the user who wants to track business conditions by the type of businesses served. |

| 1.2.4.4. How To ..... for SIC Codes |

| 1.2.4.4.1. Setup the SIC Codes | ||||

|

The following screen will be displayed:  To modify this screen, the user must click on the Add, Edit or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry box at the bottom of the screen for the user to enter new data. Selecting an existing SIC code and pressing the Edit button will bring the selected information to the data entry box to be modified. Selecting an existing SIC code and pressing the Delete button will remove the selected information. The user must Save or Abandon changes after adding or editing the record.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In the Customer Setup. «Mark as Completed in RoadMap Section B Item 2-c» |

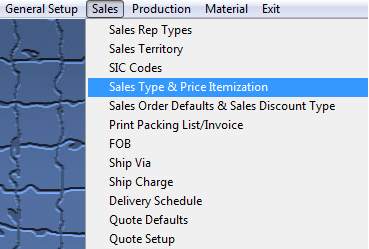

| 1.2.5. Sales Type & Price Itemization |

| 1.2.5.1. Prerequisites for Sales Type & Price Itemization |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-d" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2.5.2. Introduction for Sales Type & Price Itemization |

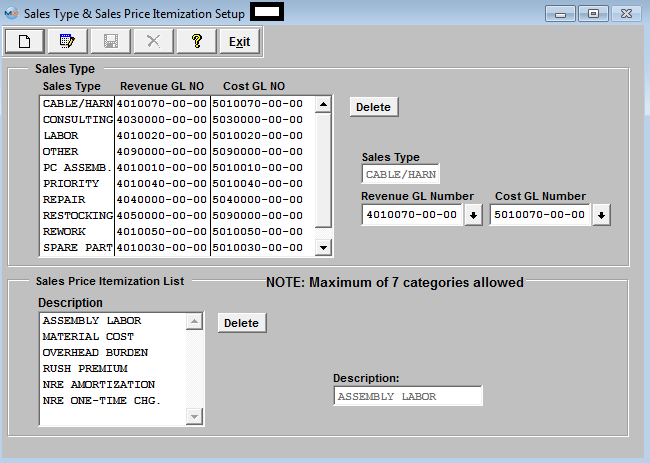

This section is to prepare information to be used in the Sales Price List module in the Sales main menu. The Sales Type portion is used when adding Sales Orders. The Sales Price Itemization List is used in the Sales Price List Information module. |

| 1.2.5.3. Fields and Definitions for Sales Type & Price Itemization |

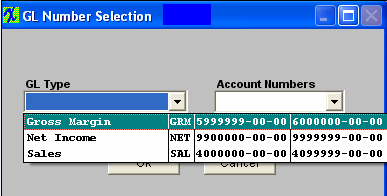

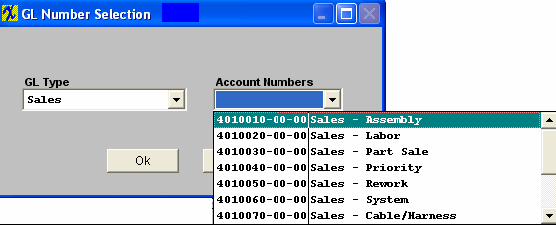

The user may define a sales type, to be used to associate the revenues, and related costs with a specific market sector and general ledger account (assuming the accounting module is installed).

The user may also customize the itemization used in the pricing module by establishing different categories for collecting pricing information details. For example, the user may wish to break out the pricing for materials, for labor, for engineering costs, for out-sourcing, and anything else imaginable.

In the pricing module, each unit can itemize it up to seven categories for breaking down the unit price. In the setup, as many different pricing categories may be set up as desired. These price categories will NOT show on any printed information that is available to the user’s customer.

Please review the attached <<How GL #'s from Sales Type setup will be used in GL Trans>> for example of how the GL #'s used within this Setup screen will be generated within the Resulting GL Transactions. |

| 1.2.5.4. How To ..... for Sales Type & Price Itemization |

| 1.2.5.4.1. Setup the Sales Type & Price Itemization | ||||||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Edit button and supply the password. That action will enable the screen. Then the user may address either the Sales Type or Price Itemization List. The user may Add, Edit or Delete a Sales Type by pressing the appropriate buttons. This will activate the data entry boxes for addition or modification of data. However, the user is cautioned to not remove sales types that have already been assigned to orders. To select the Revenue GL Number and the accompanying Cost GL Number, depress on the down arrows next to the appropriate field, as illustrated below:

Then, select the Account Number. The user may Add, Edit or Delete a Price Itemization by pressing the appropriate buttons. This will activate the data entry boxes for addition or modification of data. The user must Save or Abandon the changes after adding or editing the record.

Where Used: In the Pricing Module, revenue analysis for Accounting.

«Mark as Completed in RoadMap Section B Item 2-d» |

| 1.2.6. Sales Order Defaults & Sales Discount Type |

| 1.2.6.1. Prerequisites for Sales Order Defaults & Sales Discount Type |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-e" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2.6.2. Introduction for Sales Order Defaults & Sales Discount Type |

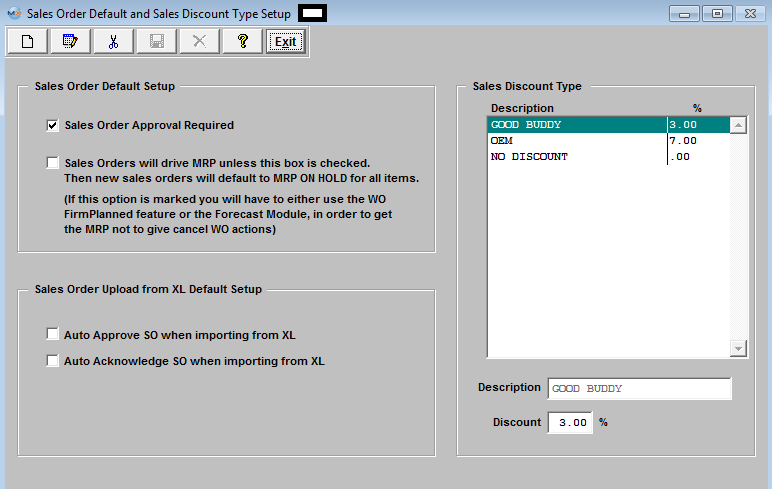

In this set up screen, the user enters customer’s discount terms and applicable percentages which will be used at the time of Sales Order data entry. This data could be used for discount coupons, promotional discount, quantity discounts and wholesale discounts, etc.

|

| 1.2.6.3. Fields and Definitions for Sales Type & Price Itemization | ||||||||||||

Sales Order Default Setup

Sales Order Upload from XL Default Setup

Sales Discount Types In this set up screen, the user enters discount terms and applicable percentages which will be used at the time of Sales Order data entry.

|

| 1.2.6.4. How To ..... for Sales Order Defaults & Sales Discount Type |

| 1.2.6.4.1. Setup the Sales Order Defaults & Sales Discount Type | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add, Edit, or Delete button and supply the password. That action will enable the screen.

The user must Save or Abandon changes after modifying the screen. Where Used: In the Customer Set Up, Sales Orders, Invoices and Accounting.

|

| 1.2.7. Print Packing List and Invoice |

| 1.2.7.1. Prerequisites for Print Packing List/Invoice |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-f" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2.7.2. Introduction for Print Packing List/Invoice |

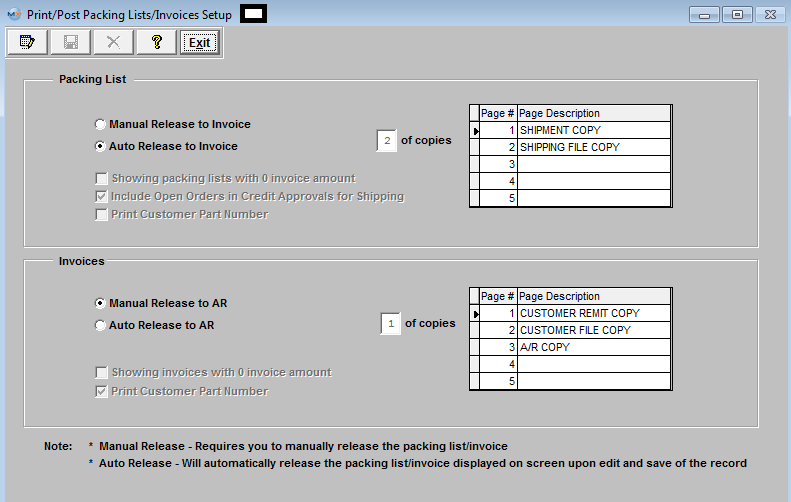

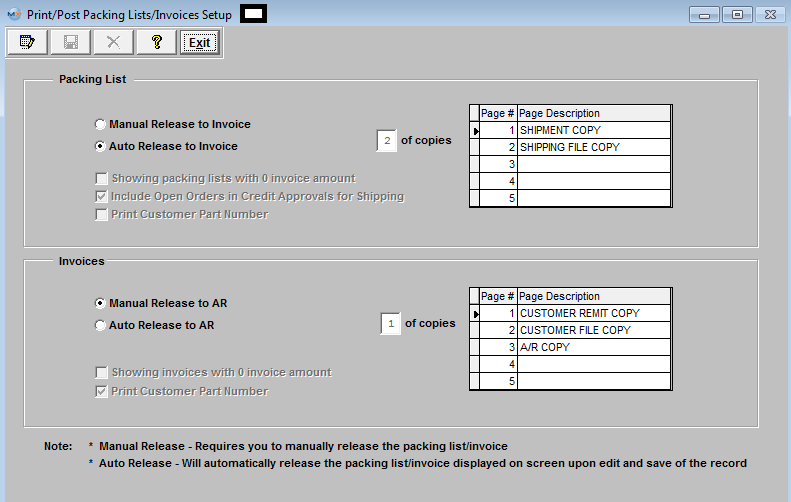

This is where the user determines whether they want to set the Packing List and Invoice to Auto Release or Manual Release, what type of form to use for printing, how many forms to print, option to show Packing Lists and Invoices with 0 invoices amounts, and/or Print Customer part numbers when printing Packing Lists and/or Invoices. Manual Release to Invoice - will require user to Print the Packing List before it will be released to Invoice. Auto Release to Invoice - will automatically release the Packing List being displayed on screen to Invoice upon edit and save of the record. The ManEx system will update the records even if the user does not print the record. The system will maintain the records for history information and management reports Manual Release to AR - will require user to depress the "Release to AR" button available on screen to release Invoice to AR. Auto Release to AR - will automatically release the Invoice being displayed on screen to AR upon edit and save of the record. The ManEx system will update the records even if the user does not print the record. The system will maintain the records for history information and management reports. |

| 1.2.7.3. Fields & Definitions for Print Packing List & Invoice | ||||||||||||||||||||||||||

Packing List

Invoices

Hold for Credit Limit Overview If the user has elected “Enforce Credit Limit at Shipment” feature in AR-AP Acct Default Setup, the following message will appear if a non-supervisor attempts to ship:

Depress the OK button and try to add the Packing List with a Supervisor’s password. The Supervisor will receive the following warning:

|

| 1.2.7.4. How To ..... for Print Packing List/Invoice |

| 1.2.7.4.1. Setup Print Packing List/Invoice Module | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Edit button and supply the password. That action will enable the screen. The user clicks on the button desired to either Manual or Auto Release Packing Lists and Invoices.

Enter the number of copies and the Description to be printed on each copy.

The user may also check the following: A check box for showing of invoices with a zero dollar amount is available. A check box to elect to include open orders in credit approvals for shipping is available. To exclude, leave the box unchecked.

The user must Save or Abandon changes after modifying the screen.

«Mark as Completed in RoadMap Section B Item 2-f» |

| 1.2.8. Freight On Board (FOB) |

| 1.2.8.1. Prerequisites for FOB |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-g" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

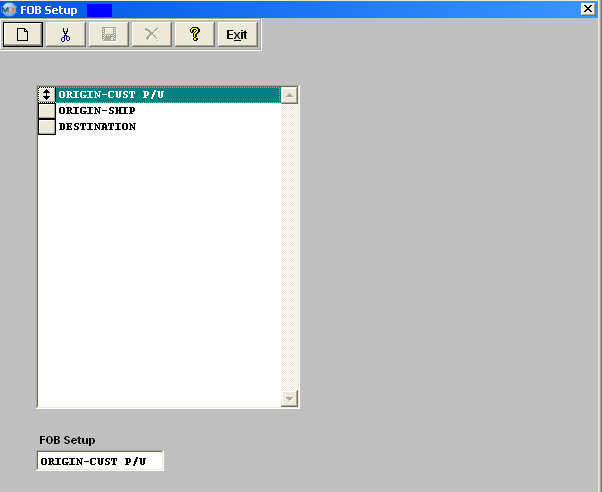

| 1.2.8.2. Introduction for FOB |

FOB (Freight On Board) defines the point of ownership of the product as it is transferred from one business to another. If the FOB is Origin, it usually means that the customer pays for freight and insurance from the seller’s dock, and assumes ownership at the time the product leaves the seller’s dock. FOB Destination would usually mean the seller is responsible for the product until it is accepted at the buyer’s dock. FOB types are used in the Customer Shipping Information, Order Management, Packing List, Purchase Order Receiving, and Purchase Order. |

| 1.2.8.3. Fields & Definitions for FOB |

FOB (Freight On Board) defines the point of ownership of the product as it is transferred from one business to another. If the FOB is Origin, it usually means that the customer pays for freight and insurance from the seller’s dock, and assumes ownership at the time the product leaves the seller’s dock. FOB Destination would usually mean the seller is responsible for the product until it is accepted at the buyer’s dock. FOB types are used in the Customer Shipping Information, Order Management, Packing List, Purchase Order Receiving, and Purchase Order. |

| 1.2.8.4. How To ..... for FOB |

| 1.2.8.4.1. Setup the FOB Module | ||||

|

The following screen will be displayed:  To modify this screen, the user must click on the Add or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry box at the bottom of the screen for the user to enter new data. Selecting an existing FOB and pressing the Delete button will remove the selected information. The user must Save or Abandon changes after modifying the screen.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list.

Where Used: In the Customer Setup, Sales Orders, Packing Lists, Invoicing, Receiving and Billing Information.

«Mark as Completed in RoadMap Section B Item 2g» |

| 1.2.9. Ship Via |

| 1.2.9.1. Prerequisites for Ship Via |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-h" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

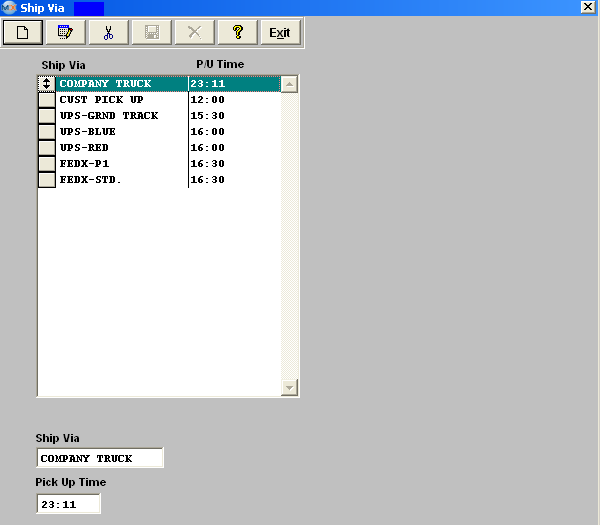

| 1.2.9.2. Introduction for Ship Via |

Ship Via is a term used to describe the freight carrier or method of shipping product to a customer. Some customers, because of FOB origin considerations, may prescribe their preferred delivery system. The Ship Via is entered as a preference for each ship-to destination, and guides the shipping department in which carrier to use for a shipment. The delivery system may also be US Mail, a company truck, will-call, etc. |

| 1.2.9.3. Fields & Definitions for Ship Via |

Ship Via is a term used to describe the freight carrier or method of shipping product to a customer. Some customers, because of FOB origin considerations, may prescribe their preferred delivery system. The Ship Via is entered as a preference for each ship-to destination, and guides the shipping department in which carrier to use for a shipment. The delivery system may also be US Mail, a company truck, will-call, etc. |

| 1.2.9.4. How To ..... for Ship Via |

| 1.2.9.4.1. Setup the Ship Via Module | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add, Edit or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry boxes at the bottom of the screen for the user to enter new data. Selecting an existing Ship Via and pressing the Edit will populate the data entry boxes at the bottom of the screen and allow a change. Selecting an existing Ship Via and pressing the Delete button will remove the selected information. These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list.

Where Used: Customer Setup, Sales Orders, Packing Lists, Invoicing, Purchase Setup Receiving and Billing Information. "Mark as Completed RoadMap Section B Item 2-h"

|

| 1.2.10. Ship Charge |

| 1.2.10.1. Prerequisites for Ship Charge |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-i" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2.10.2. Introduction for Ship Charge |

This information is also used for the User’s own Receiving Tax and Shipping mode as entered in Purchasing setup. |

| 1.2.10.3. Fields & Definitions for Ship Charge |

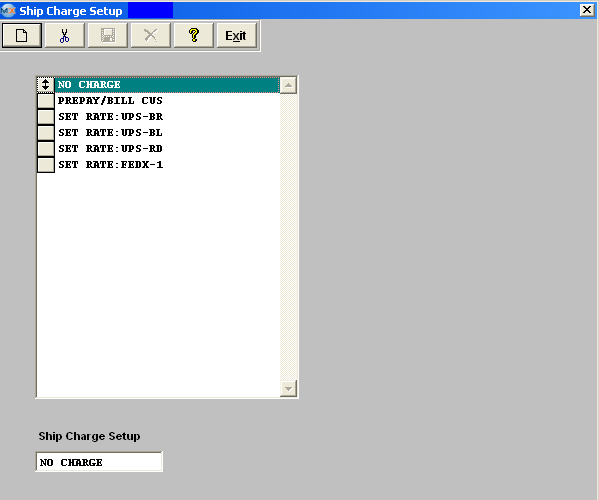

This section is to set up the types of shipping charges assessed the customer. This data is used in the Customer and Packing List Modules. Types of shipping charges could be Standard, No Charge, Overnight, Premium, etc. This information is also used for the User’s own Receiving Tax and Shipping mode as entered in Purchasing setup. |

| 1.2.10.4. How To ..... for Ship Charge |

| 1.2.10.4.1. Setup the Ship Charge Module | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Add or Delete button and supply the password. That action will enable the screen. Pressing the Add button will enable the data entry boxes at the bottom of the screen for the user to enter new data. Selecting an existing Ship Charge and pressing the Delete button will remove the selected information. The user must Save or Abandon changes after modifying the screen.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In the Customer Setup, Sales Orders, Packing lists, Invoicing, Purchase Setup Receiving and Billing Information.

«Mark as Completed in RoadMap Section B Item 2-i» |

| 1.2.11. Delivery Schedule |

| 1.2.11.1. Prerequisites for Delivery Schedule |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-j" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

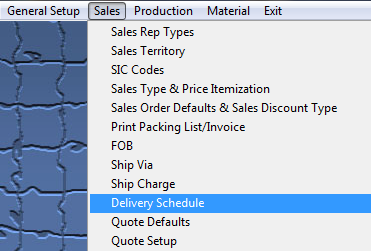

| 1.2.11.2. Introduction for Delivery Schedule |

|

| 1.2.11.3. Fields & Definitions for Delivery Schedule |

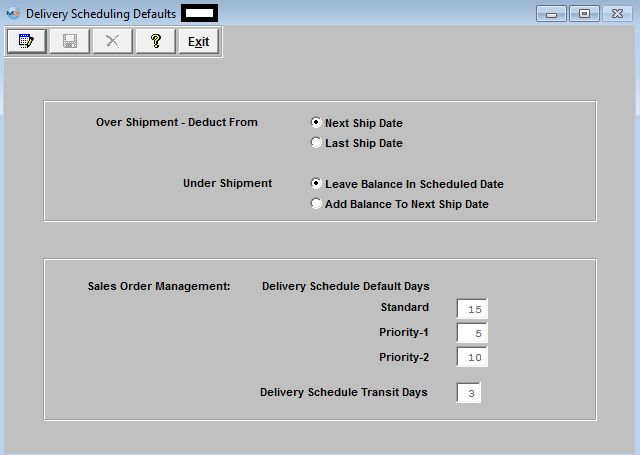

Over/Under Shipment Management

OVER SHIPMENT-DEDUCT FROM: Next Shipment Date: If the user wants over shipment quantities to be deducted from the next scheduled delivery for the same sale order and product. OVER SHIPMENT DEDUCT FROM: Last Shipment Date: If the user wants the over shipment amount to be deducted from the last scheduled delivery for the same sales order and product. UNDER SHIPMENT: Leave Balance in Scheduled Date: If the user wants to leave the back order quantity at the originally scheduled delivery date for the product on the same sales order. UNDER SHIPMENT: Add Balance To Next Ship Date: If the user wants to add the remaining back order to the next scheduled delivery date for the product on the same sales order. Sales Order Schedule Delivery Management When the user enters a new order, the system will default delivery due dates to a certain number of days from the date of the entry. The number of days is defined by the job type and the numbers in this setup screen. STANDARD: the number of days beyond the current date that MANEX will default a new sales order due date. PRIORITY1: the number of days beyond the current date that MANEX will default a new sales order due date. PRIORITY2: the number of days beyond the current date that MANEX will default a new sales order due date DELIVERY SCHEDULE TRANSIT DAYS: enter the number of days the user wants deducted from sales order delivery date, to account for freight delivery and to establish the dock shipment date. |

| 1.2.11.4. How To ..... for Delivery Schedule |

| 1.2.11.4.1. Setup the Delivery Schedule Module | ||||

|

The following screen will be displayed:

To modify this screen, the user must click on the Edit button and supply the password. That action will enable the screen. This will allow the user to click on the radio button desired for over and under shipments. The days may be entered into the data entry boxes for the default due dates and ship dates for sales order. The user must Save or Abandon changes after modifying screen.

Where Used: In Sales Orders, Packing Lists and Invoicing.

«Mark as Completed in RoadMap Section B Item 2-j» |

| 1.2.12. Quote Defaults |

| 1.2.12.1. Prerequisites for Quote Defaults |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-k" before continuing the setup. User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

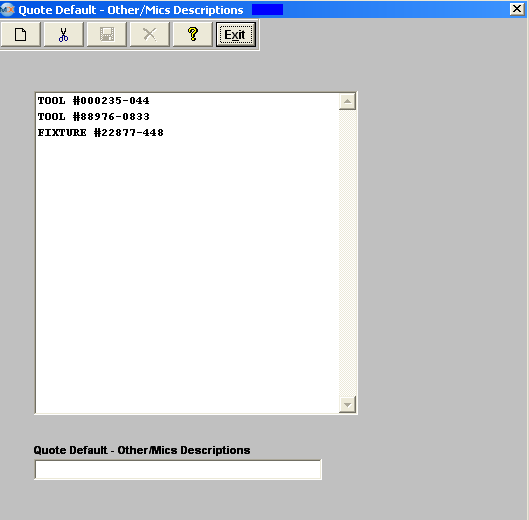

| 1.2.12.2. Introduction for Quote Defaults |

The Quote Defaults setup screen is used to quote the other/miscellaneous description prices on assemblies. These descriptions are used in the Customer Quotation module in the Sales section. Types of descriptions could be Tooling, Non Recurring Expense, Burden, etc. |

| 1.2.12.3. Fields & Definitions for Quote Defaults |

|

The Quote Defaults setup screen is used to quote the other/miscellaneous description prices on assemblies. These descriptions are used in the Customer Quotation module in the Sales section. Types of descriptions could be Tooling, Non Recurring Expense, Burden, etc. |

| 1.2.12.4. How To ..... for Quote Defaults |

| 1.2.12.4.1. Setup the Quote Defaults Module | ||||

|

The following screen will be displayed:

To Add a Customer Quote Default, depress the Add button. Enter your password. Type in the desired description for Other or Miscellaneous descriptions to be used in the Customer Quote module. To Edit a Customer Quote Default, depress the Edit button. Highlight the description to be changed. Type in the desired changes. To Delete a Customer Quote Default, depress the Delete button .Highlight the description to be deleted. The user must Save or Abandon changes after modifying the screen. "Mark as Completed RoadMap Section B Item 2-k"

|

| 1.2.13. Quote Setup |

| 1.2.13.1. Prerequisites for Quote Setup |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 2-l" before continuing the setup. The Departments must have been set up in Administrative Departments in the General Setup.

User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access.

|

| 1.2.13.2. Introduction for Quote Setup |

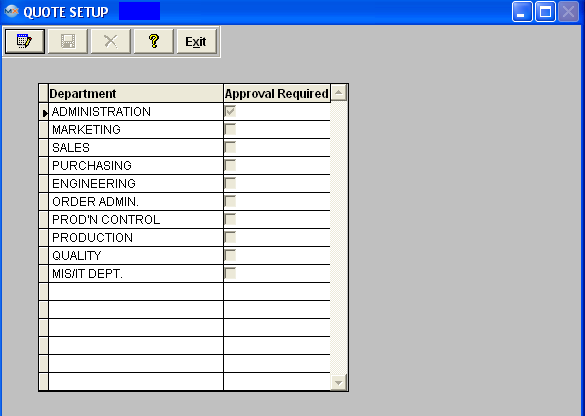

This setup screen is used in the Customer Quote modules in ManEx Sales section. Check off the department(s) which must approve a Customer Quote before the Inventory, BOM and Pricing tables can be updated by the use of “Transfer” on the Customer Quote module. |

| 1.2.13.3. Fields & Definitions for Quote Setup |

This setup screen is used in the Customer Quote modules in ManEx Sales section. Check off the department(s) which must approve a Customer Quote before the Inventory, BOM and Pricing tables can be updated by the use of “Transfer” on the Customer Quote module. |

| 1.2.13.4. How To ..... for Quote Setup |

| 1.2.13.4.1. Setup the Quote Setup Module | ||||

|

The following screen will be displayed:

To modify the quote setup screen, depress the Edit button. Check off the department(s) which must approve a Customer Quote by clicking in the Approval Required box. The user must Save or Abandon changes after modifying the screen. Where Used: This setup screen is used in the Customer Quote modules in MANEX Sales section.

"Mark as Completed RoadMap Section B Item 2-l"

|

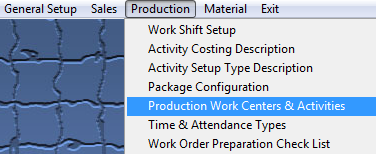

| 1.3. Production |

| 1.3.1. Prerequisties for Production Setup |

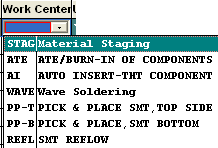

In general, the production work is divided up among several departments. Some products may require that some work that is done in each of these departments. Other products may require that work be done in only a few of all the departments in operation. In order to identify the work processes for each product, ManEx allows the user to define Work Centers. These Work Centers describe a physical aspect (usually) of production operations that applies a specific type of labor to the product. Examples of work centers may be: SMT - where the product is assembled on a surface mount line; AI - where parts are Auto-Inserted into the product; Wave - where the parts are wave soldered; Cleaning; Inspection; Test; etc. Each of these work centers contains within it, a common aspect of production. For example, in SMT, the surface mount operator’s pay scale is probably higher than other parts of production, the parts are all contained within one area, the setup time is appropriate to one lot of a given product, and the parts are contained within the work area. If inventory counting is necessary, the user can identify that the parts are in the work center.

The user may create as many work centers as necessary to define the production activities that occur within the operation. Within a work center, the user may establish additional definitions, called Activities. These activities may be set up separately from the work centers, and then used as needed within individual work centers. The activities may be assigned their own hourly charge rate. And within an Activity, there is yet another classification called sub-activities, which have activity costs associated with them. These activity costs are established in the Activity Cost & Volume Type setup. Also, in this section the setups for Quality items are accomplished, and will be discussed in each setup. Outside Program Calls Setup is also available.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.3.1.1. Manex Notes Matrix |

See the word attachement <Notes Matrix.doc>> for a table which shows the cross-reference for all ManEx Notes.

|

| 1.3.2. Introduction for Production Setup |

This section covers the production setup to be used in all production related modules. Please take time to think about how you want to use these tables for best production management. Some sample data is provided with this setup as a guideline. These tables are used in various modules throughout the system. The production application module setup section allows you to prepare tables for specific production related modules your company has purchased. Once setup in the system, you will be able to use these tables and/or perform certain functions automatically. These tables are completed by preparing worksheet tables and/or setting certain switches.

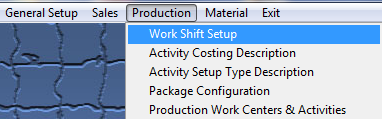

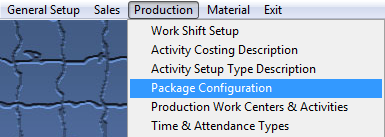

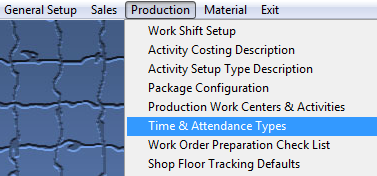

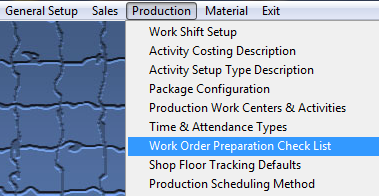

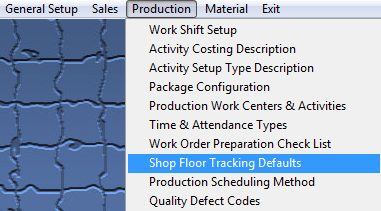

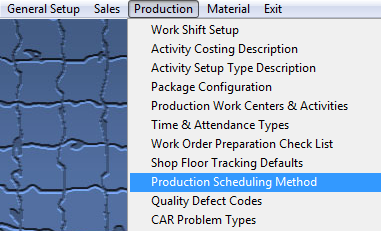

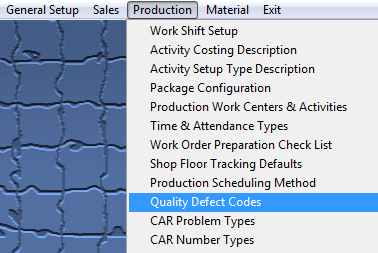

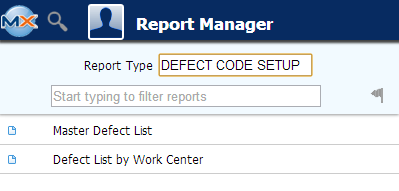

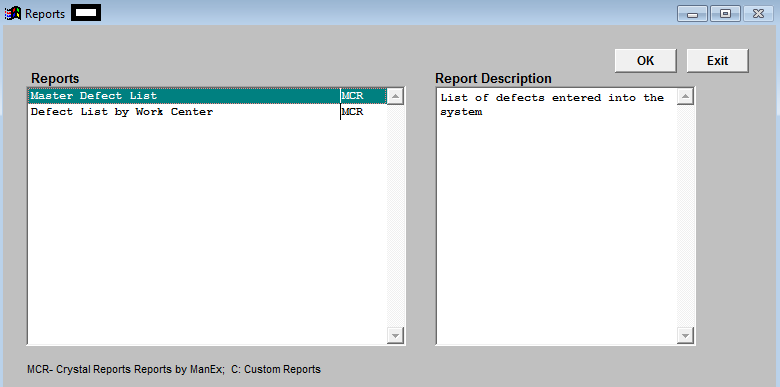

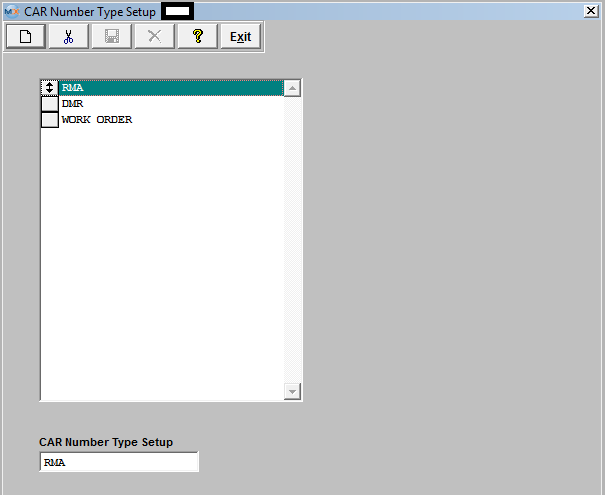

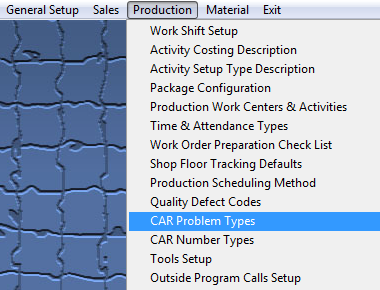

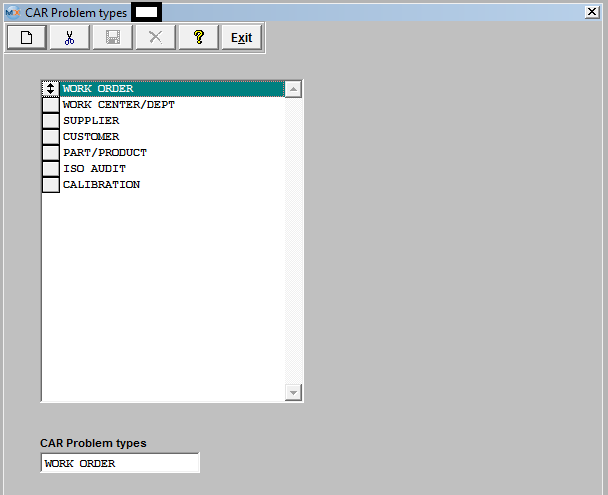

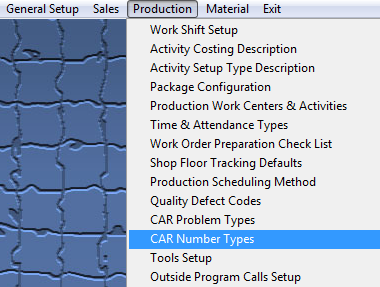

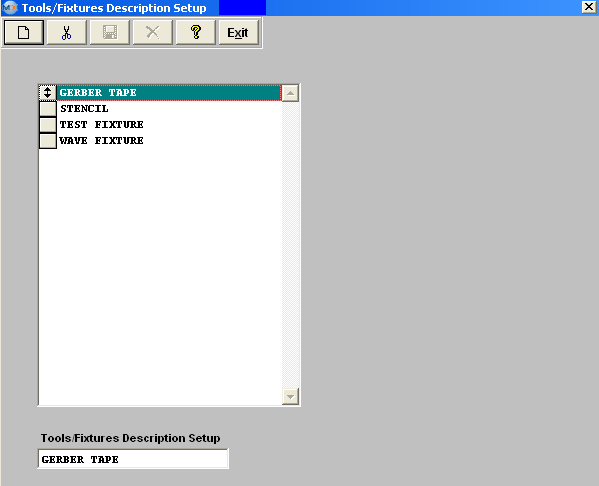

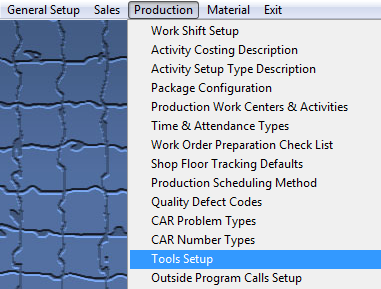

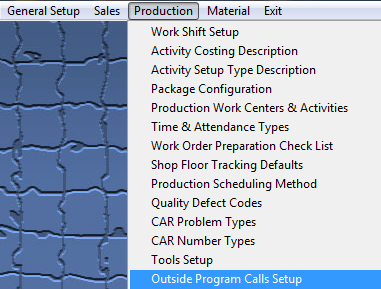

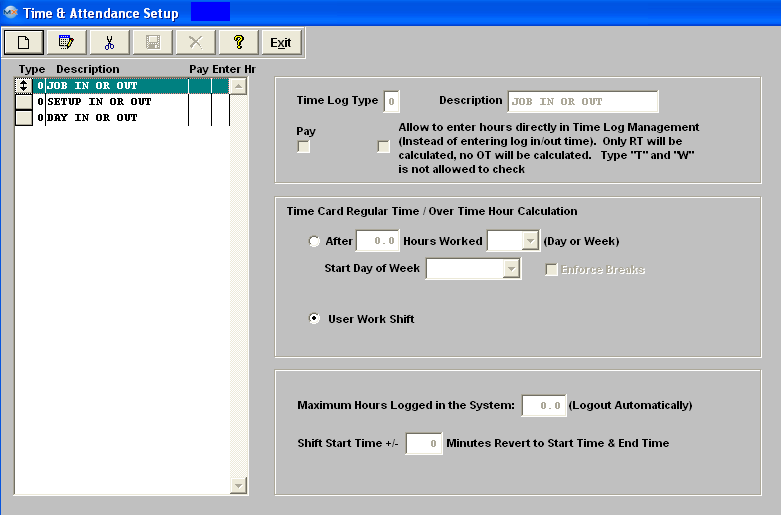

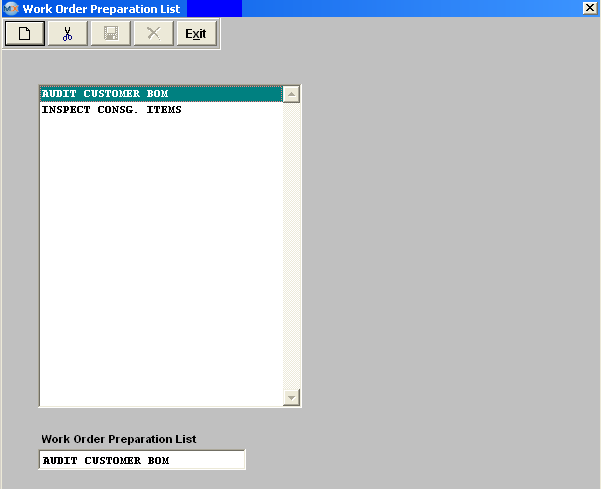

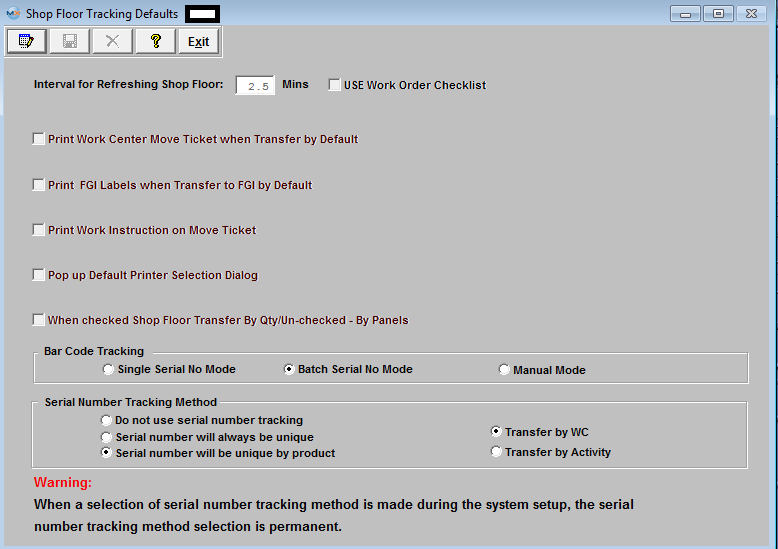

Production System worksheet covers the following modules: Work Shift Set Up, Activity Costing & Volume Type Set Up, Package Configuration, Production Work Centers & Activities, Time & Attendance Types, Shop Floor Tracking Defaults, Production Scheduling Method, Quality Defect Codes, CAR Problem Types, CAR Number Types, Tools Setup and Outside Program Calls Setup.

|

| 1.3.3. Work Shift Setup |

| 1.3.3.1. Prerequisites for Work Shift Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-a" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.3.3.2. Introduction for Work Shift Setup |

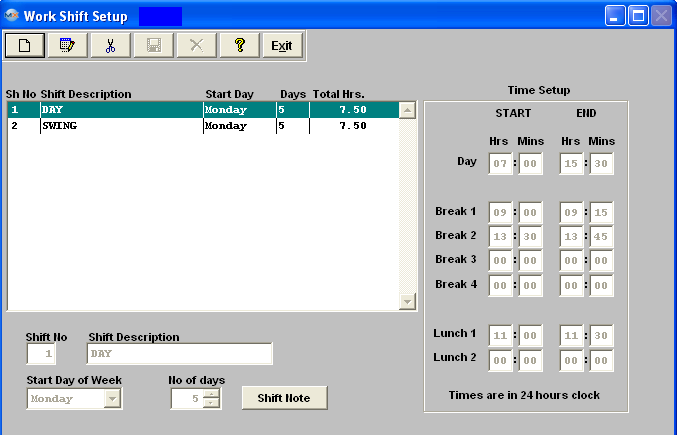

| 1.3.3.3. Fields & Definitions for Work Shift Setup | ||||||||||||||||

|

| 1.3.3.4. How To ..... for Work Shift Setup |

| 1.3.3.4.1. Setup the Work Shift Module | ||||

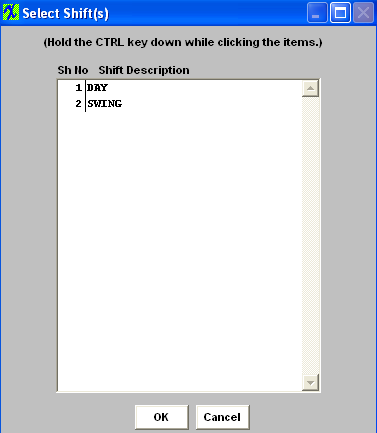

|

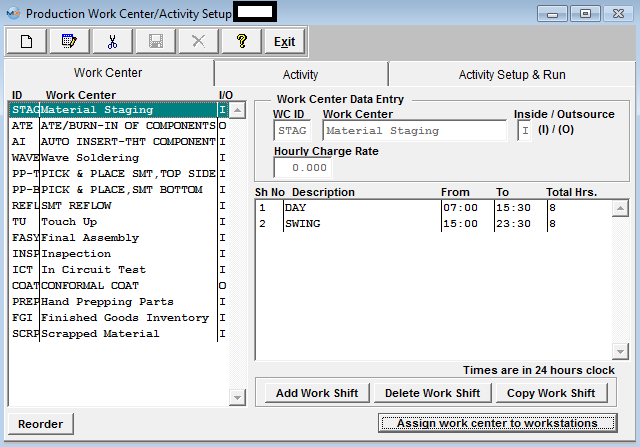

The following screen will be displayed:

The user may Add new or Edit and Delete existing shifts. The user must either Save or Abaondon to close the screen. Where Used: In the job routing functions for a product. «Mark as Completed in RoadMap in Section B Item 3-a» |

| 1.3.4. Activity Costing and Setup Type Setup |

| 1.3.4.1. Prerequisites for Activity Costing & Setup Type Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-b" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.3.4.2. Introduction for Activity Costing & Setup Type Setup |

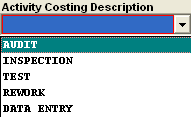

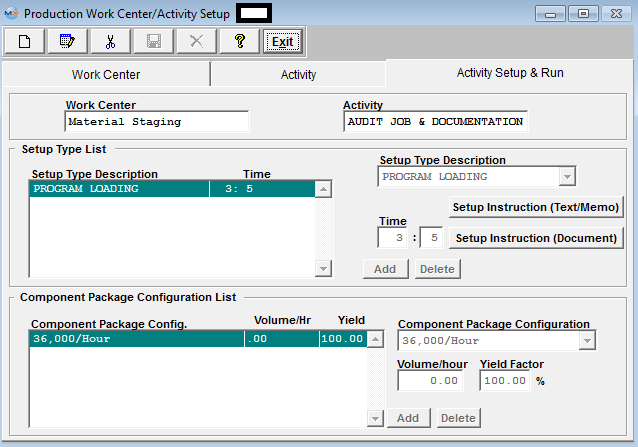

This module is essential if you are using Activity Based Cost (ABC) methodology for managing the production floor. The information entered here forwards to Production Work Center/Activity Setup. Then both setups are used in the MANEX Capacity Planning module.

Activity Costing and Activity Volume Type Description setup is a requirement only if your company is employing Activity Based Cost (ABC) methodology for managing the production floor. The Activity Costing and Activity Volume Type Descriptions are used in Production Work Center/Activity setup to assign Activity Costs and Activity Volume Types to a production Work Center/Activity. The Activity Volume Type Description is a pre-requisite for Production Work Centers & Activities / Activity Setup & Run tab. Your company should become knowledgeable about the principles of ABC prior to using Activity Costing and Activity Volume Type Descriptions.Activity Cost and Volume types allow the users to define the costs and capacity for individual activities within a work center. It is used in the capacity planning module to determine available and required capacities. It is also used to assign costs of operation. For example, there may be several machines that can do the same job in a work center. However, one may have a higher operating cost, but also greater capacity. Both machines can be displayed as a resource. The selection of the machine is performed in the routing and capacity modules. |

| 1.3.4.3. How To ..... for Activity Costing & Setup Type |

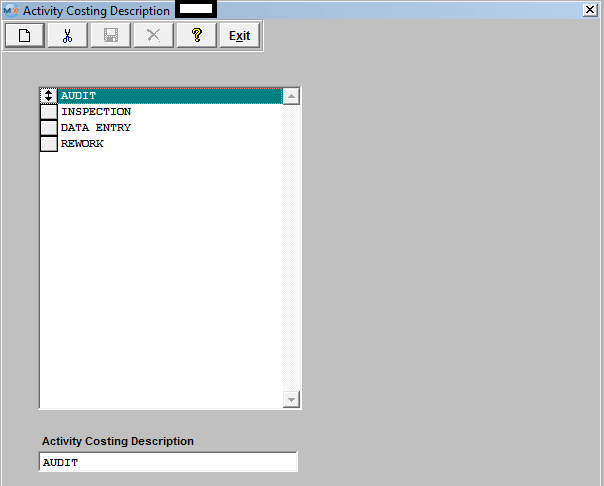

| 1.3.4.3.1. Setup the Activity Costing | ||||

The following screen will be displayed:

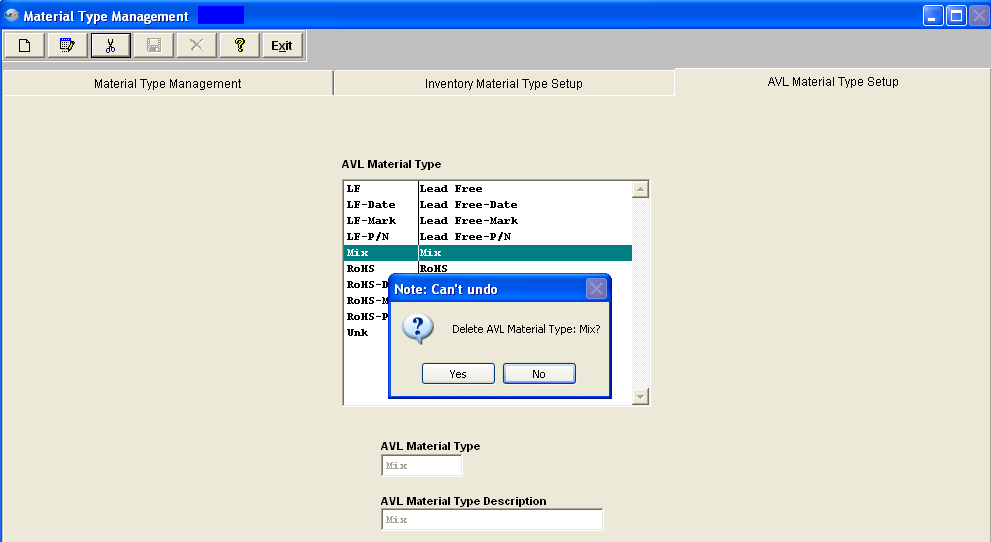

To ADD new Costing descriptions, depress on the ADD button, enter the description. When complete depress the Save or Abandon changes button. To DELETE existing descriptions, highlight the description you want to delete, depress the Delete button. The following popup screen will appear:

Depress "Yes" to Continue or "No" to abandon changes.

To REORDER descriptions, click and drag the activities to the desired order. When exiting the re-order changes will be saved.

Where Used: In the Production Work Center/Activity Setup.

«Mark as Completed in RoadMap in Section B Item 3-b» |

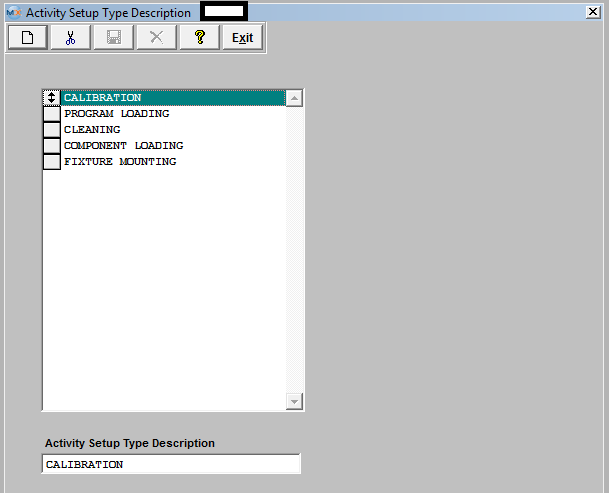

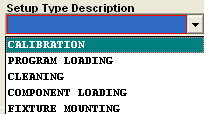

| 1.3.4.3.2. Setup the Activity Setup Type Description | ||||

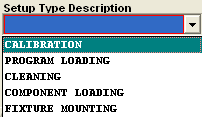

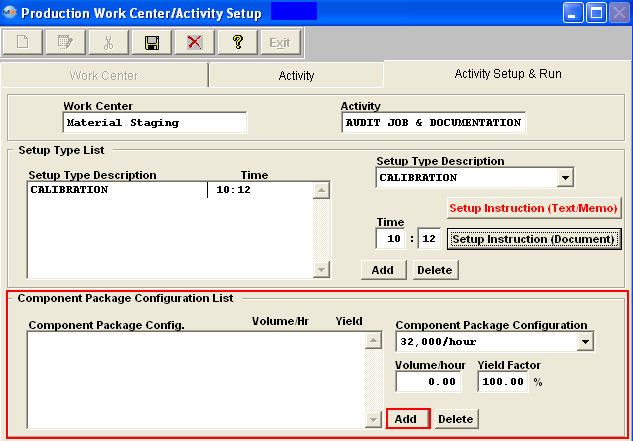

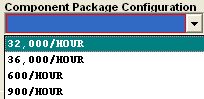

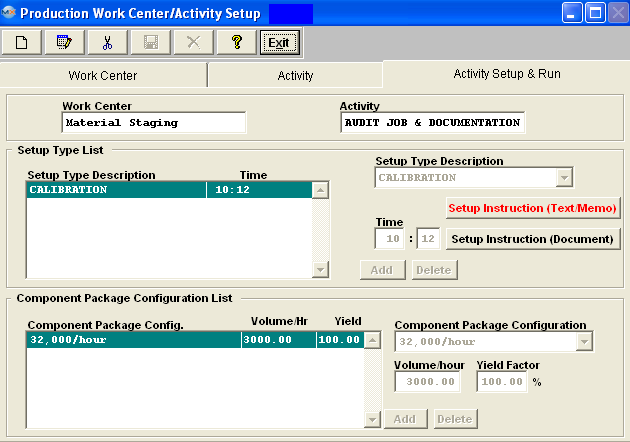

The following screen will be displayed:

To ADD new Activity Setup Type descriptions, depress on the ADD button, enter the description. When complete depress the Save or Abandon changes button. To DELETE existing Activity Setup Type descriptions, highlight the description you want to delete, depress the Delete button. The following popup screen will appear:

Depress "Yes" to Continue or "No" to abandon changes.

To REORDER descriptions, click and drag the activities to the desired order. When exiting the re-order changes will be saved.

Where Used: In the Production Work Center/Activity Setup.

«Mark as Completed in RoadMap in Section B Item 3-b» |

| 1.3.5. Package Configuration |

| 1.3.5.1. Prerequisites for Package Configuration |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-c" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.3.5.2. Introduction for Package Configuration |

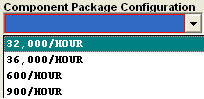

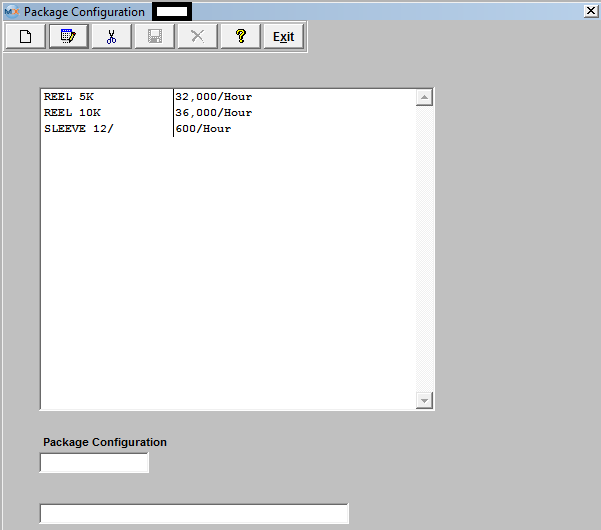

Package configuration setup is provided so that the user may define a machine’s Units Per Hour. This definition can then be accessed in the Production Work Centers & Activities setup/Activities Setup & Run tab. |

| 1.3.5.3. Fields and Definitions for the Package Configuration | ||||

|

| 1.3.5.4. How To ..... for Package Configuration |

| 1.3.5.4.1. Setup the Package Configuration Module | ||||

The following screen will be displayed:

To ADD a record, depress the Add button, type in the Package Configuration and description. To EDIT a record, depress the Edit button, edit the Package Configuration and/or description. To DELETE a record, highlight the Package Configuration and description you wish to delete, depress the Delete button. "Mark as Completed RoadMap Section B Item 3-c"

Where Used: In the Production Work Center/Activity Setup. |

| 1.3.6. Production Work Center & Activity Setup |

| 1.3.6.1. Prerequisites for Production Work Centers & Activities |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-d" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

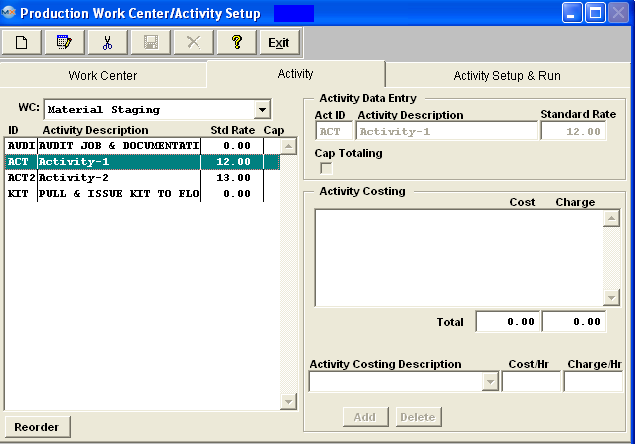

| 1.3.6.2. Introduction for Production Work Centers & Activities |

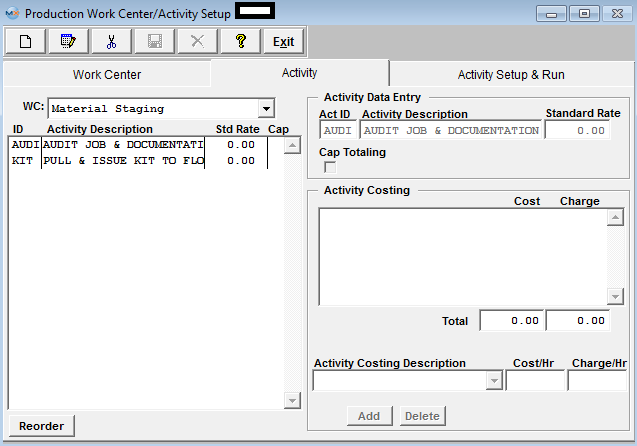

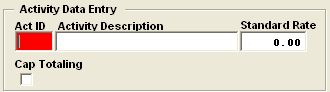

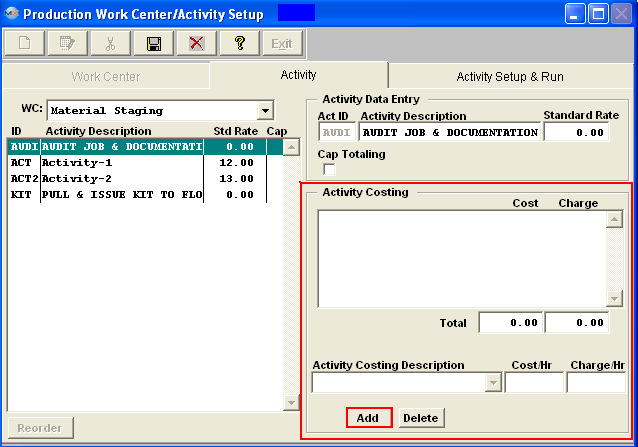

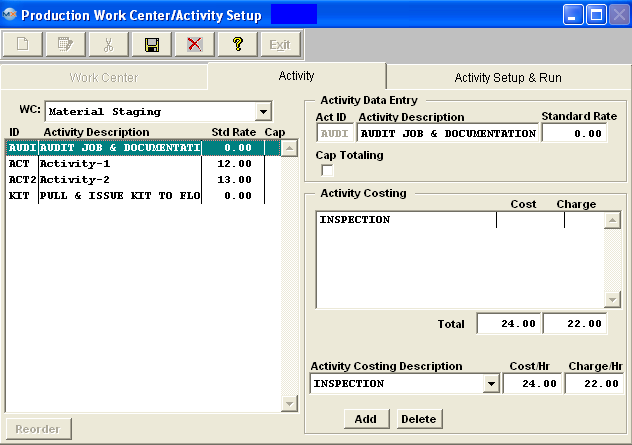

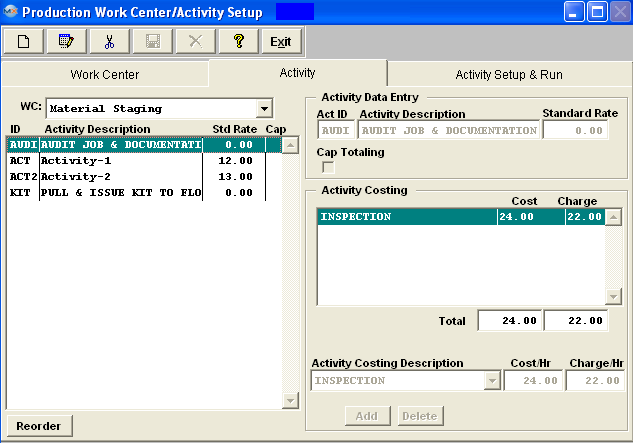

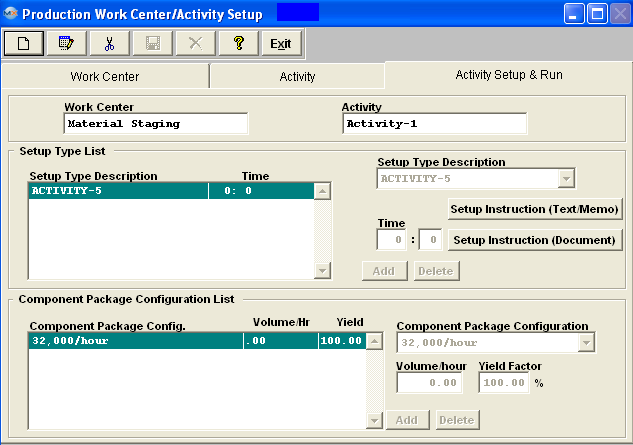

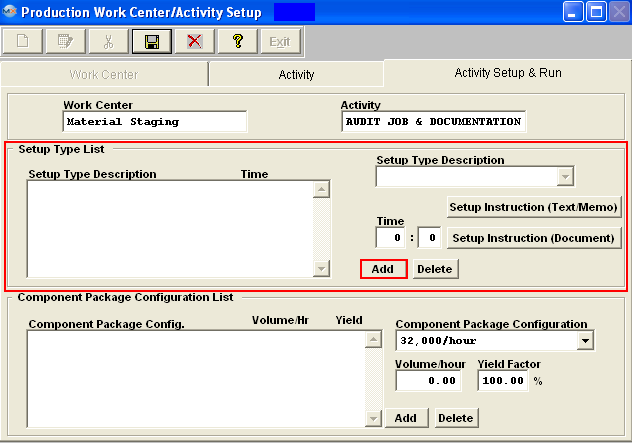

| Production Work center activities are optional sub-sets of work center departments. Activities may be defined prior to establishing work centers, and then used as more detailed actions within a work center. Each of these activities may be assigned a separate hourly charge rate.

Please note: As of 03/03/2016: We are actually in the process of implementing optional routing steps in place of activities. We are working to simplify and flatten the process to make it easier for everyone. Presently, you can still choose to setup activities if desired and then decide if you want to track production through activities or not. With the current activity setup this decision is universally applied for all work centers and work orders. With the optional routing steps that we are implementing, you would still have to decide if you want to add activities or not (optional steps), but now you would be able to decide on the fly if you want to track production through those steps. It also means that you would have fewer places to maintain in setup. |

| 1.3.6.3. Fields & Definitions for Production Work Centers & Activities |

| 1.3.6.3.1. Work Center Tab | ||||||||||||||||||

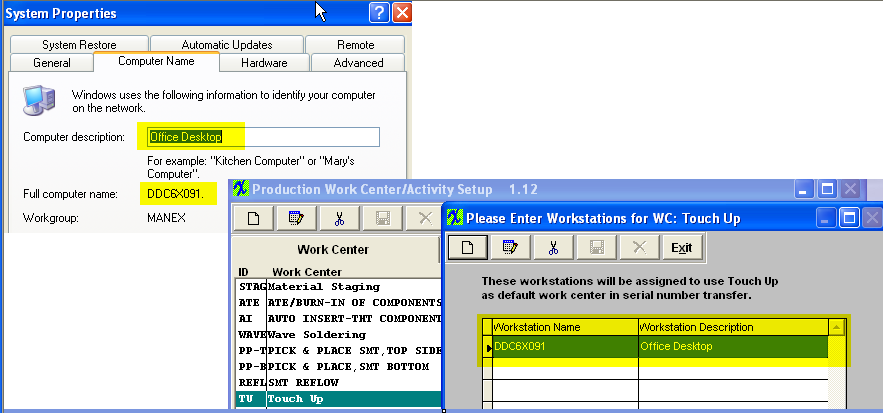

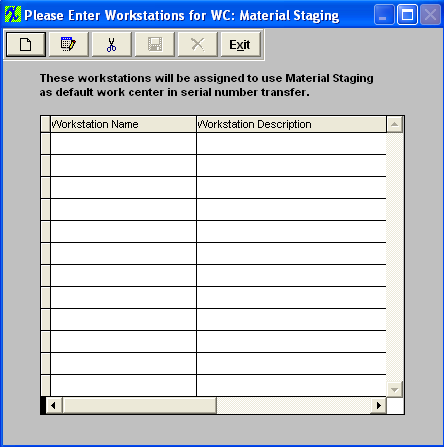

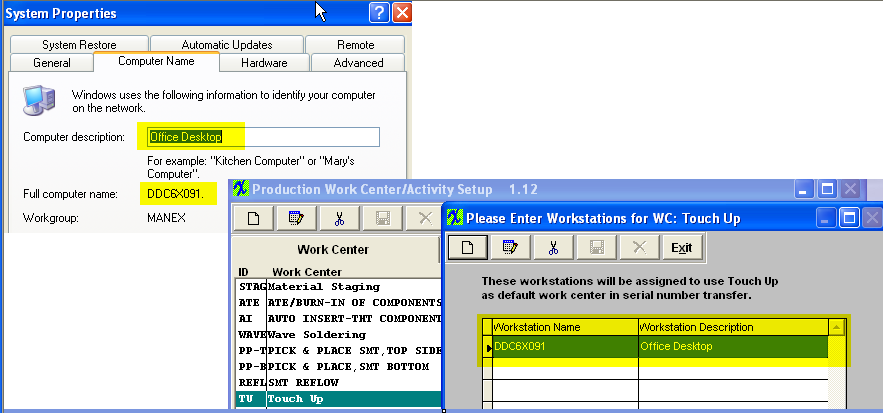

Assign work center to workstations (button)

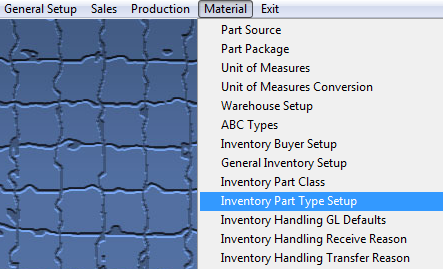

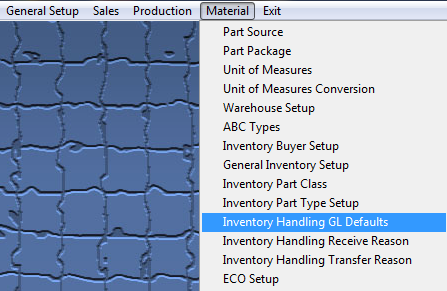

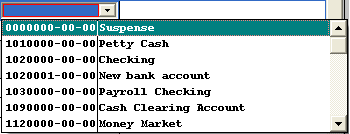

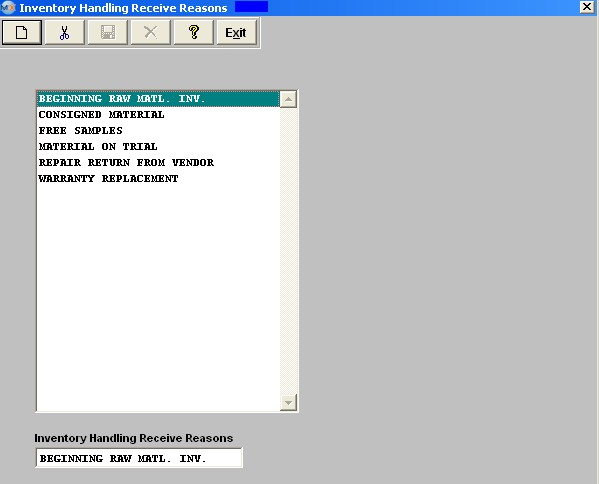

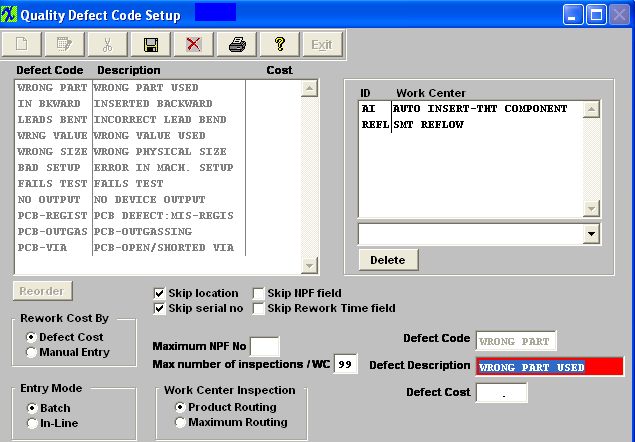

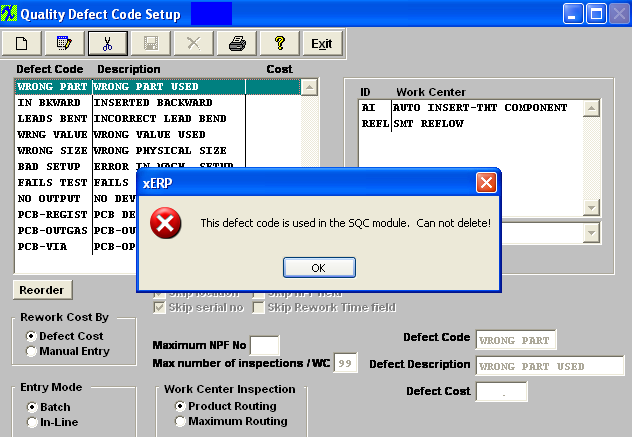

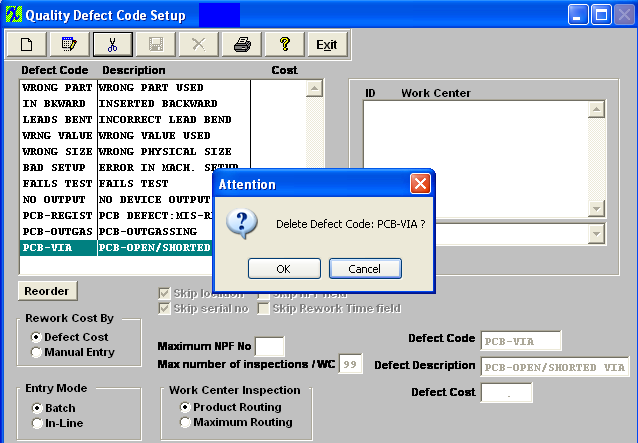

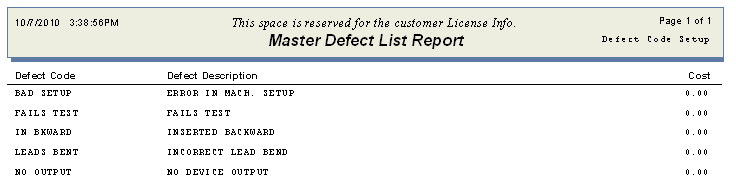

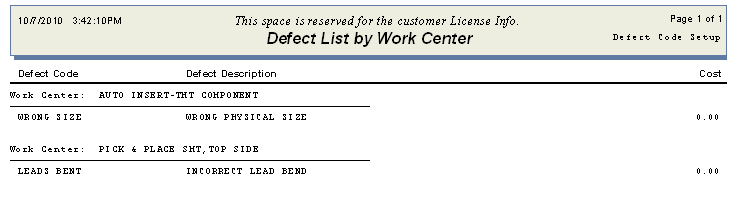

If a customer wants to install workstations along the production line, with scanners to read serial numbers as they passed down the line, this button provides the ability to limit a work station (specific computer) to be able to only transfer material “FROM” a certain Work Center. So, when a user first opens the "SFT by WO" or "Shop Floor Tracking by Bar Code" module, the module will use the default work center assigned for this workstation, but if user chooses to use a different work center, supervisor approval or a user that has the option "Allow Changing Default Work Center for Serial Number Transfer" box checked within the Security module is required to continue. After a supervisor's or user with this option’s password is entered, the default work center will be changed to the one that the supervisor entered password for. For Example: the workstation is assigned to use “TU” as default work center, now if user chooses to use “AI” to transfer, the system will ask for supervisor’s password, if user cancels the password, the default work center will still be “TU”, but if the supervisor enters his/her password on this machine, the default work center will be changed to “AI”. If now the user tried to transfer from “TU” again, the system will ask for supervisor’s password again. If user exits the module and come back, the default work center will be “TU” again.