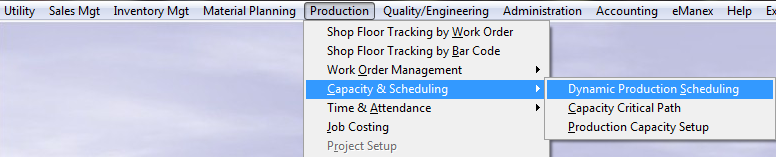

| 1. How To ...... for Dynamic Production Scheduling |

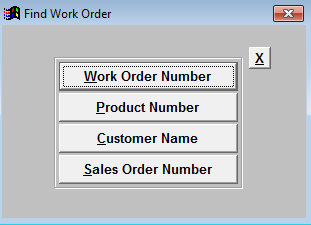

| 1.1. Find Work Order | ||||||

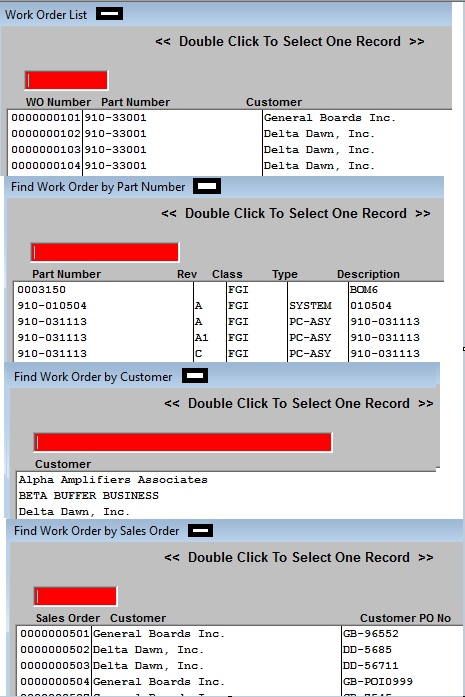

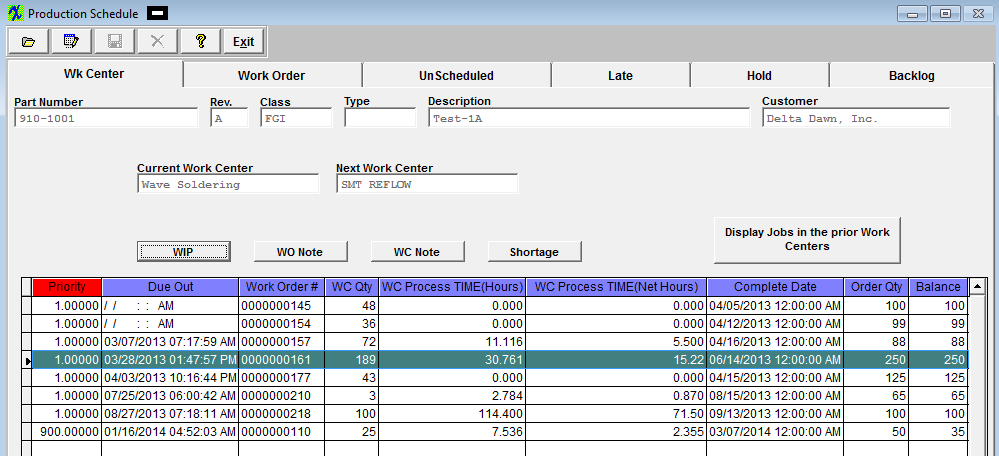

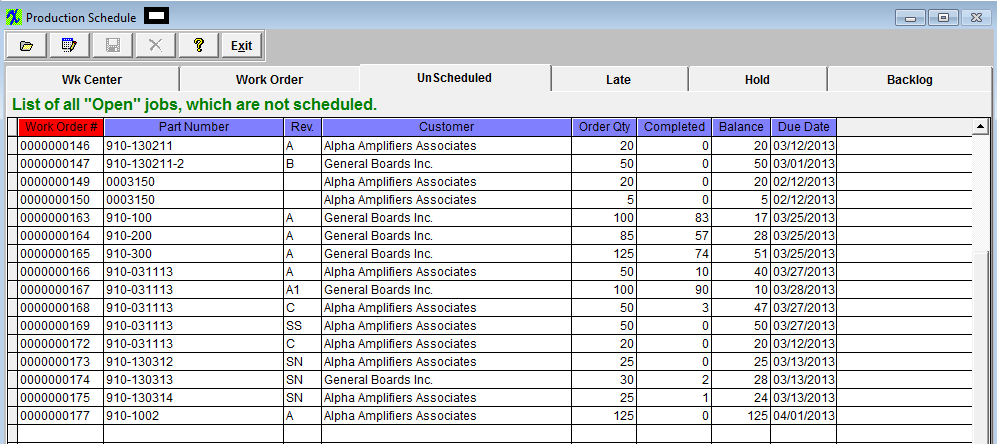

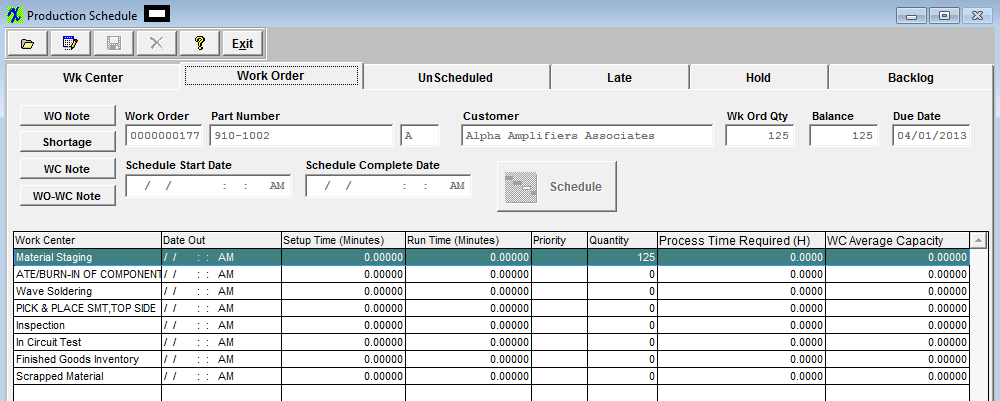

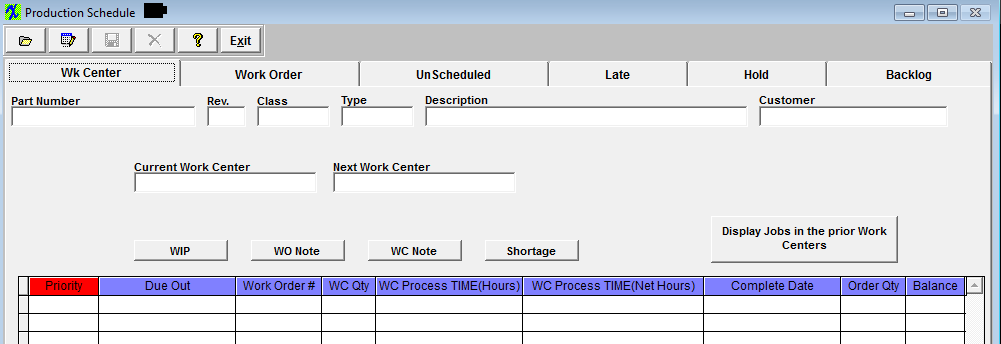

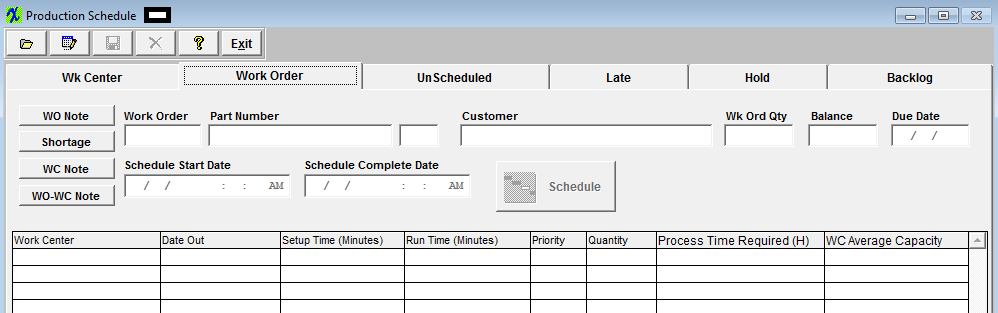

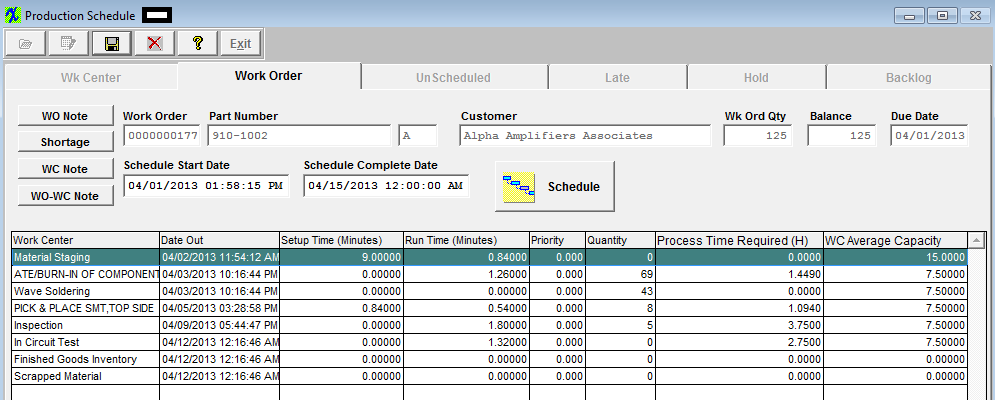

The following screen will appear:  Depress the Work Order tab. The following screen will appear:

Depress the Find button.

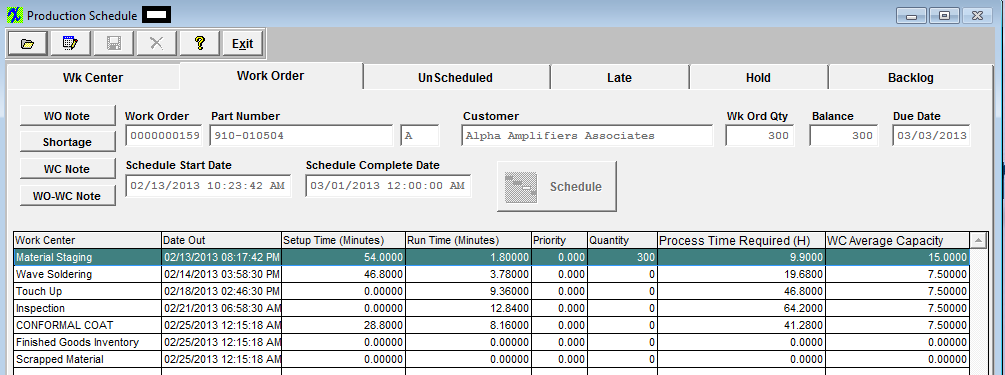

The Work Order selected will appear on the screen:

|

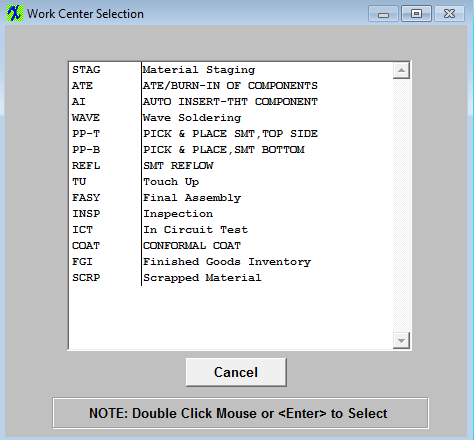

| 1.2. Find Work Center | ||||||||

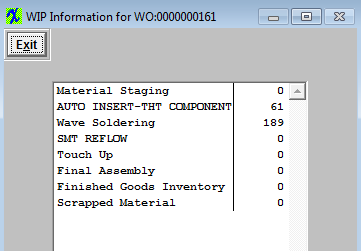

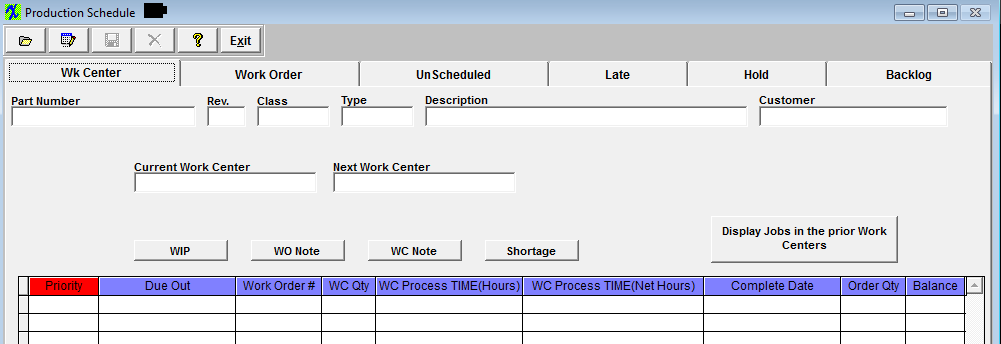

Clicking on the

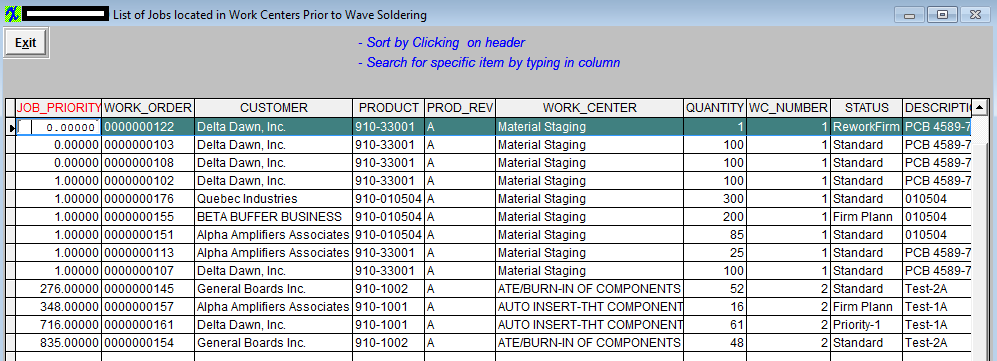

Depress the Find button and the following

The following will appear for all of the Work Orders listed in the Work Order tab. The user may sort on any of the following buttons: Due Out, Work Order #, Priority, WC Qty, WC Process Time, Complete Date, Order Qty, or Balance.

Depressing the WO Note button will bring up the Notes entered in the Work Order Screen. To add a note, depress the Edit button, type in the note and depress the Save button.

Depress the WC Note button will bring up the notes entered in SFT per work center, for the Work Order highlighted. To add a note, depress the Edit button, type in the note and depress the Save button.

|

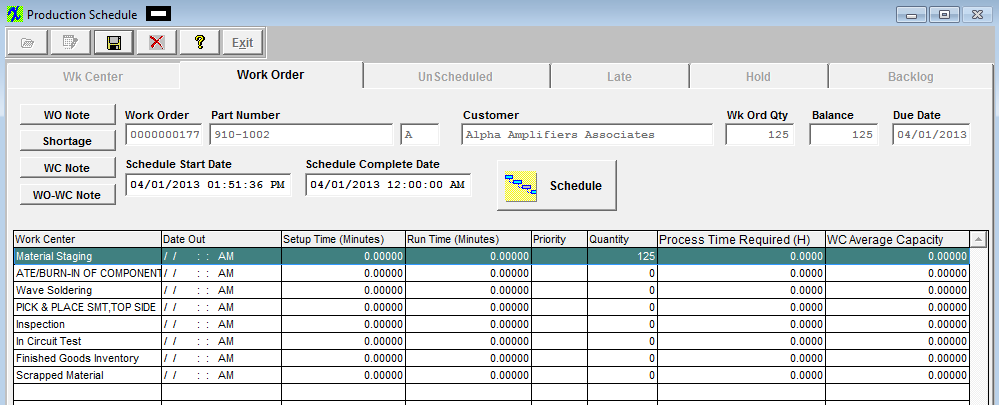

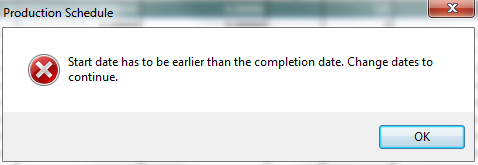

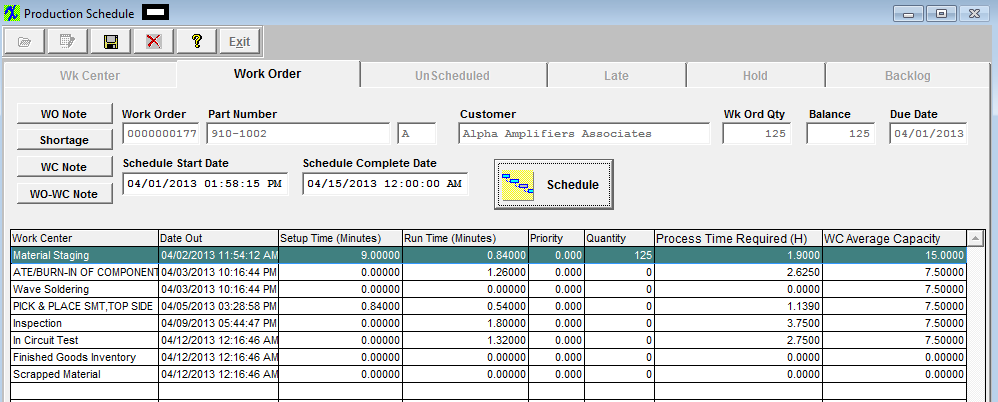

| 1.4. Re-Schedule a Work Order |

Find a Scheduled Work Order, depress the Edit Button, and enter your password.   Depress the Exit button. Once user has completed the changes they may depress the Save button, to save the changes or the Abandon changes button to abandon the changes.

NOTE: There is also a Capacity Planning Trigger option that my be setup to re-schedule all of the jobs that were scheduled and still open automatically. When the trigger runs, it will recalculate the "In" and "Out" date/time for the Work Centers so the capacity view is current.

|