| 1. Production Scheduling Method |

| 1.1. Prerequisites for Production Scheduling Method |

|

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.2. Introduction for Production Scheduling Method |

In this setup, the user defines the method to be used by ManEx to determine the capacities and scheduling in the Capacity Planning module. |

| 1.3. Fields & Definitions for Production Scheduling Method |

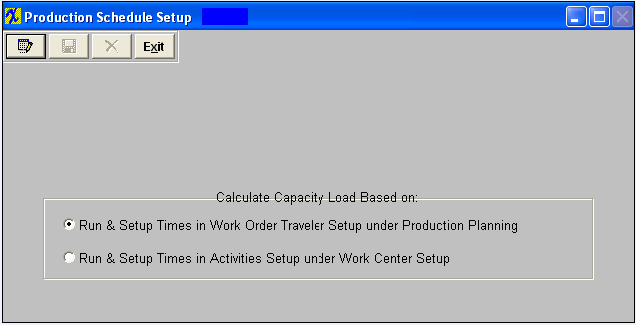

The default, “Run & Setup Time” will calculate the resources and costs associated with those entered in the work center setups and activities for the product. The costs will be based on the work center rates, and the capacity on the product routing information. The Activities Drivers option may be used in conjunction with the Job Planning module, and will calculate the costs and durations based on parameters entered by the users in the planning module.Normally, the Run & Setup time option is used.However, once the system has an active capacity planning module in place, the user may use Activities Drivers to schedule priorities in the Dynamic Scheduling Module. No change is required in this setup unless the user is going to make extensive use of the job planning module. Note: In order to add Times in Routing, the Run and Setup Time MUST be selected in this module. |

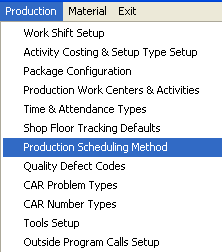

| 1.4. How To ..... for Production Scheduling Method |

| 1.4.1. Setup Production Scheduling Method | ||

|

The following screen will appear:

The user may click on the Edit button to change the defaults. The user must Save or Abandon changes after entering the Edit Mode. Where Used: In all shop floor functions defining labor costs, and for Capacity Planning Modules. «Mark as Completed in RoadMap in Section B Item 3-g» |