| 1. Shop Floor Tracking Defaults |

| 1.1. Prerequisites for SFT Defaults |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-f" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.2. Introduction for SFT Defaults |

There are a number of functions within MANEX that the user may establish as default conditions during operations. Each function relating to this setup screen is described in the Fields & Definitions article. |

| 1.3. Fields & Definitions for SFT Defaults |

Interval for Refreshing Shop Floor When the user is in the Shop Floor module, and has information displayed on the screen (for example, the wip status of a work order). The user then leaves the screen up and alone to do another task (say breaks for lunch). Then the data represented by the screen may actually undergo changes by other employees. If the user does not use the screen in the meantime, when they return from their alternate task, the information on the screen would be incorrect (because someone else moved material). ManEx performs a periodic update (refresh) to Shop Floor screens when the user has information displayed on the screen, but has not performed any functions in the meantime. The period of the refresh rate is initially set to every two and a half minutes by ManEx. So, if the user has a work order tracking screen displayed with a work order showing wip, and does not perform any transaction for 2-1/2 minutes, ManEx will automatically update the information on the screen. This timing is initially set at 2-1/2 minutes, but the user may change this period in this setup. However, the trade-off for shorter periods is increased network traffic, and setting too many workstations to be refreshed every few seconds will seriously impact the server’s ability to deliver data. Use Work Order Check List User MUST check this box to activate the Unreleased Work Order List module. Work Order Preparation Check List If user has selected to use the "Work Order Check List" they must create a Work Order Preparation Check List. These items will be defaulted into the Work Order Release Check List (within the Work Order Traveler Setup module). Then they will be able to create a checklist for a product (within the Work Order Traveler Setup module), selecting one or more from this table, and it/they will be used to record that an action was taken for the work order, by whom and when it occurred within the Unreleased Work Order List module. Examples of check lists might be: Verify product revision, perform tooling setup, complete first article, deburring, or any other critical function for which the user wishes to have a verifiable record of being accomplished. The description of the checklist item may be up to 20 characters in length. Note: In order to complete the Unreleased Work Order List user MUST also have the Product Data Management (PDM) optional module. Work Whenever a product is moved from one work center to another, the user has the option to print a move ticket (like a traveler) for each transaction. This move ticket may be printed and accompany the material to the next work center, identifying the work order, product date, work center, etc. The user may choose to turn this feature off by selecting the “Printer OFF” button in the setup. If the printer is turned on (“Printer ON”), then a sheet with the details will be printed for every product movement. FGI Label Printing Defaults Whenever a product is moved from one work center to the Print Work Instructions on Move Tickets If the user chooses to print move tickets, then they may also choose whether or not work instructions and work order notes are included in the printing.

Pop up Default Printer Selection Dialog

If the user wishes to move material by the panel, sheet or roll, they may select “Default to PANEL” as the method of tracking quantities. This requires the user to define in the product definition the number of products contained in a panel/sheet/roll. Then, if this method is chosen, the user moves panels and ManEx keeps track of the number of units. If the user chooses to identify material movement by quantity of product, then the “Default to Quantity” button should be selected. If the user is tracking serial numbers through the production process, and is using the ManEx bar code tracking module, then they have the option of defining a default method for picking up the bar-coded serial numbers. One option is to scan one serial number at a time, and collect those serial numbers for processing a transaction. Another option is to enter the beginning and ending serial number of a series of serial numbers and allow ManEx to fill in all of the serial numbers in between for processing a transaction. The third option is for the user to manually enter the quantity of boards to be moved. If the boards are serialized, then a list of serial numbers is presented to the user from which to select the serial numbers being moved with the quantity of parts. The user has the option to change any of these defaults at the time of entry. Please refer to the Shop Floor Tracking Management manual. The ManEx Manufacturing System Software has bar code scan and print capability which is designed primarily for transfer of products in Shop Floor Tracking and input of inspection data by serial number and defect code. Installation: Bar Code Shop Floor Tracking is an OPTIONAL module; it is NOT a part of the Core ManEx MES modules. · Upon purchase of this module, ManEx will send a soft-key to activate the module · After activation, Bar Coding access for each user must be setup in the ManEx Security module. Users with “Supervisor’s Rights” will automatically have access.

· Each client workstation (individual PC) which will be printing Reports, Travelers, Labels, Serial Tags, Physical Inventory Tags and Defect Lists with Bar Coding must have the font installed as an active Windows font.

· If Bar Coding of Serial Numbers is desired, the Serial Number tracking must be setup in Shop Floor Tracking Defaults . Specification: · ManEx uses the Microsoft Truetype BC C39 Narrow Font. See Article #1225 for the installation procedure. · Use of a Y-Type keyboard-emulation scanner is supported by ManEx. The scanner output goes into ManEx via the keyboard-input cable. Bar code fields may be scanned or manually entered with the scanner installed. · Most scanners require ¼” of white space surrounding the bar code. Laser and inkjet printed labels must have adequate resolution, contrast and clarity to print barcodes that are readable. · ManEx recognizes a bar code by an asterisk (*) at the beginning and end of the bar coded field. Serial Number Tracking Method At the beginning of a ManEx implementation, the user must decide a method for tracking Serial Numbers. THIS DECISION, ONCE STARTED, IS IRREVOCABLE. The decision to be made is:

1, Do NOT use Serial Number tracking. If this box is checked users will NOT be allowed to check the serialized box within the ICM module, and they will receive a warning message. 2, Serial Number will always be unique. This will insure that a serial number is unique throughout the company; (meaning once used, can NEVER be used again, no matter what product). 3, Serial Number will be unique by Product. This will allow duplicate serial numbers to be used throughout the company, but they must be unique for a given product, (can be used for other products, but never again for the same product). If Serial Numbers are NOT to be used, then the option will NOT appear when creating new part numbers within the ICM module. If Serial Numbers ARE used, then the user will have the option when creating parts within the ICM module to either serialize the part or leave it unserialized. If Serial Numbers are used on a part, then the user MUST enter Serial Numbers in order to move product through the SFT for shipment. The user will also need to define whether Serial Numbers are to be transferred by Work Center or by Activity within a Work Center. For further detail on why the system enforces the uniqueness per Product rule and will not base the uniqueness on SN that exist in the Qty at that time see Article #2495.

Avg Hrs/Work Day (For Cap Plng)

The system assigns the Average Hrs/Work Day as 24 hours. This field is for reference only.

|

| 1.4. How To ..... SFT Defaults |

| 1.4.1. Setup the Shop Floor Tracking Defaults | ||

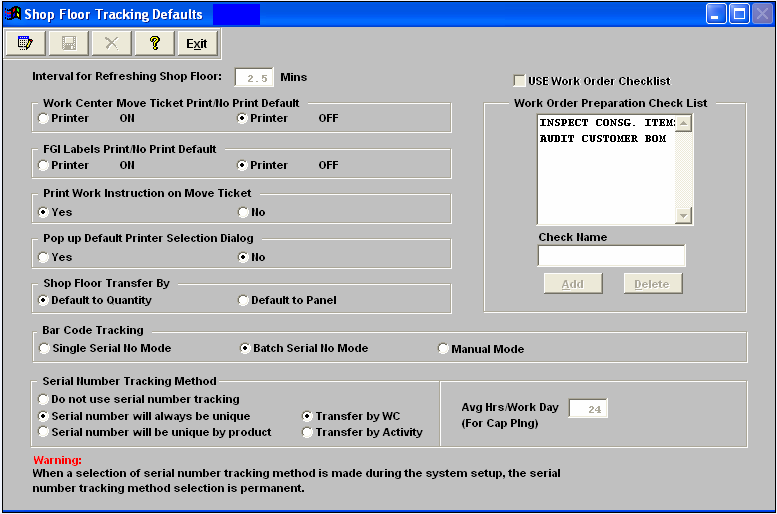

The following screen will appear:

The user may edit any of the defaults by clicking on the Edit button and selecting the default to be changed. Check List items may be added by clicking on the Add button and entering the description of the item to be listed.

Use Work Order Check List User MUST check this box to activate the Unreleased Work Order List module. Work Order Preparation Check List If user has selected to use the "Work Order Check List" they must create a Work Order Preparation Check List. These items will be defaulted into the Work Order Release Check List (within the Work Order Traveler Setup module). Then they will be able to create a checklist for a product (within the Work Order Traveler Setup module), selecting one or more from this table, and it/they will be used to record that an action was taken for the work order, by whom and when it occurred within the Unreleased Work Order List module. Examples of check lists might be: Verify product revision, perform tooling setup, complete first article, deburring, or any other critical function for which the user wishes to have a verifiable record of being accomplished. The description of the checklist item may be up to 20 characters in length. Note: In order to complete the Unreleased Work Order List user MUST also have the Product Data Management (PDM) optional module. Serial Number Tracking Method can NOT be changed once a selection has been made at the beginning of a ManEx implementation. THIS DECISION, ONCE STARTED, IS IRREVOCABLE. The decision to be made is:

1, Do NOT use Serial Number tracking. If this box is checked users will NOT be allowed to check the serialized box within the ICM module, and they will receive a warning message. 2, Serial Number will always be unique. This will insure that a serial number is unique throughout the company; (meaning once used, can NEVER be used again, no matter what product). 3, Serial Number will be unique by Product. This will allow duplicate serial numbers to be used throughout the company, but they must be unique for a given product, (can be used for other products, but never again for the same product). If Serial Numbers are NOT to be used, then the option will NOT appear when creating new part numbers within the ICM module. If Serial Numbers ARE used, then the user will have the option when creating parts within the ICM module to either serialize the part or leave it unserialized. If Serial Numbers are used on a part, then the user MUST enter Serial Numbers in order to move product through the SFT for shipment. The user will also need to define whether Serial Numbers are to be transferred by Work Center or by Activity within a Work Center. For further detail on why the system enforces the uniqueness per Product rule and will not base the uniqueness on SN that exist in the Qty at that time see Article #2495.

When the user has completed the changes they must press the Save or Abandon button, before exiting. Where Used: In all shop floor functions for a product’s work orders.

Mark as Completed in RoadMap Section B Item 3 |