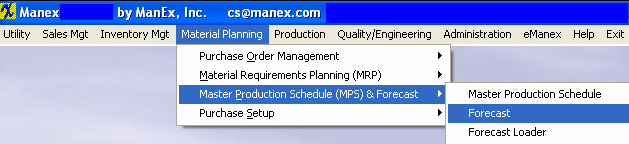

| 1. How To ..... Forecast |

| 1.1. Find a Forecast | ||||

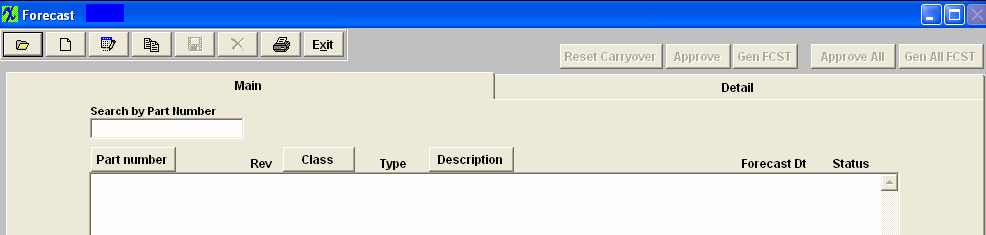

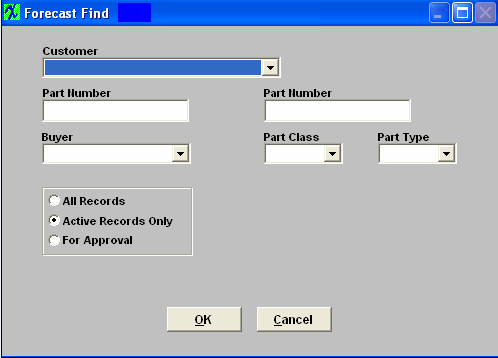

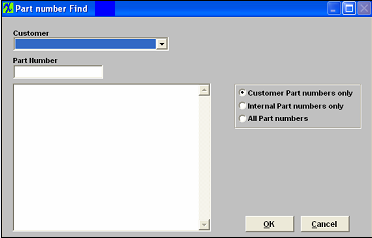

The following screen will appear:

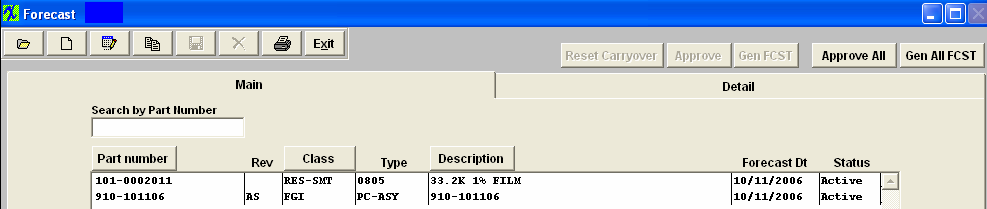

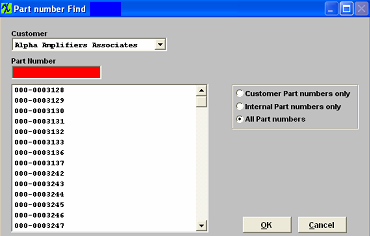

After depressing the OK button the following screen will appear:

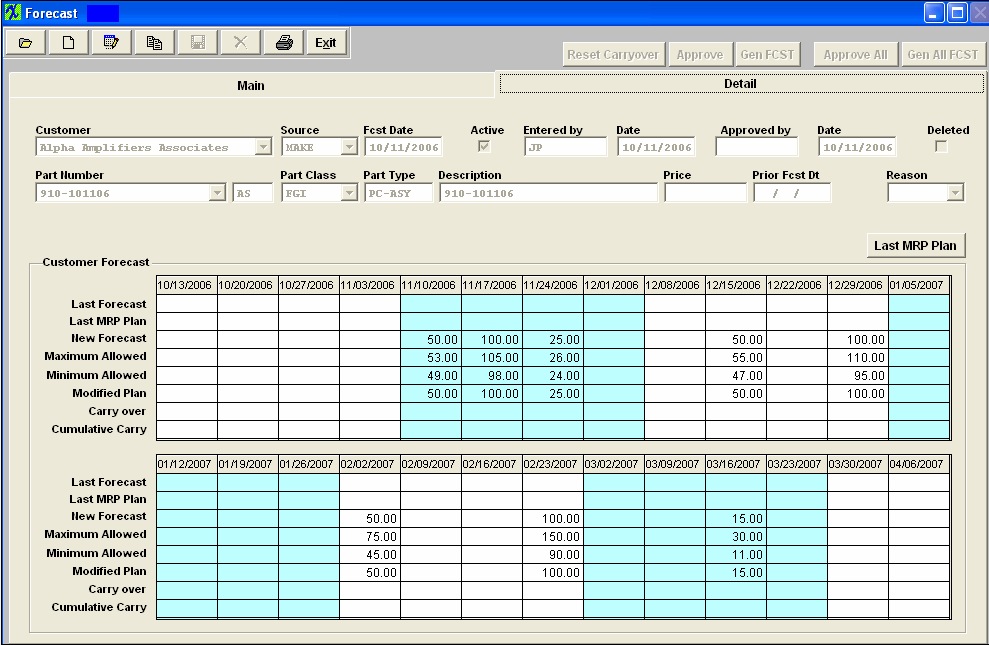

Highlight the PN of interest, then click on the Detail tab and the forecast detail for that PN will be displayed

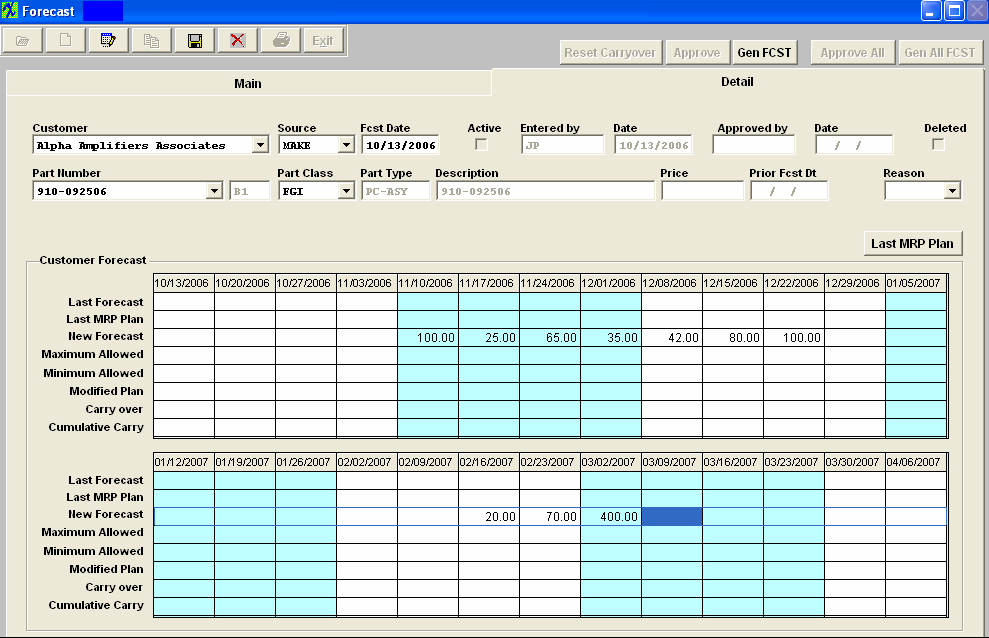

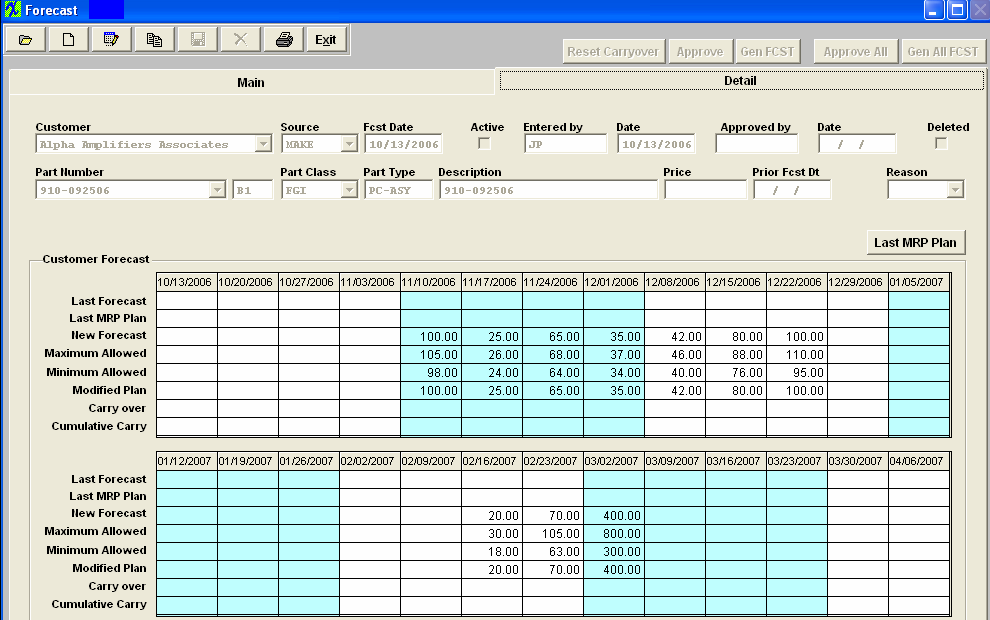

The weekly buckets are established as of the end date of the current week. Any data loaded from an excel sheet will aggregate the data by these week end dates. The Maximum Allowed and Minimum Allowed rows of data are calculated based on the tolerances provided for the customer in the Forecast Setup module.

|

| 1.2. Add a Forecast | ||||||

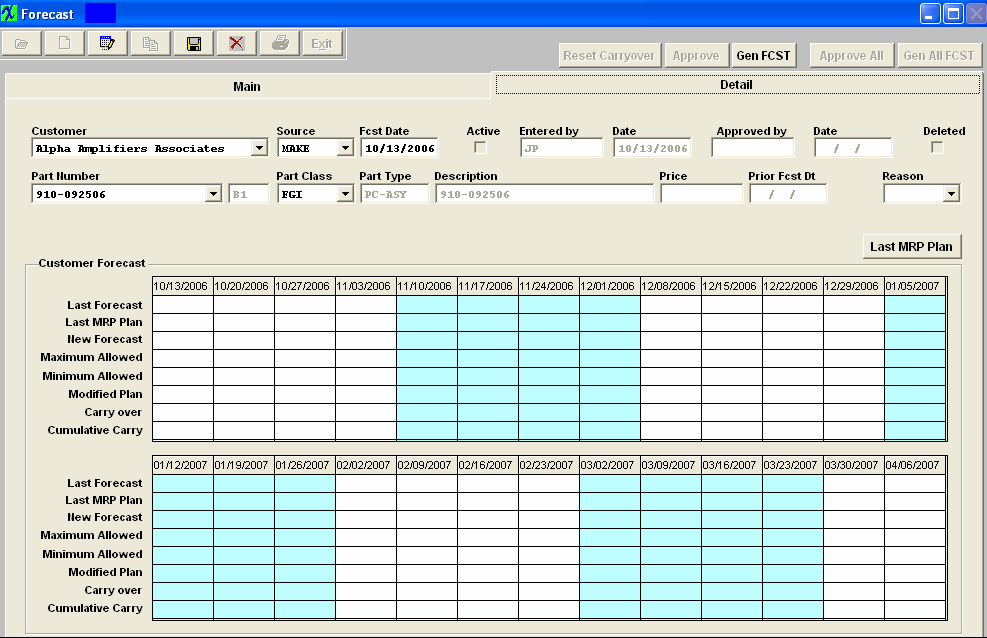

The following screen will appear:

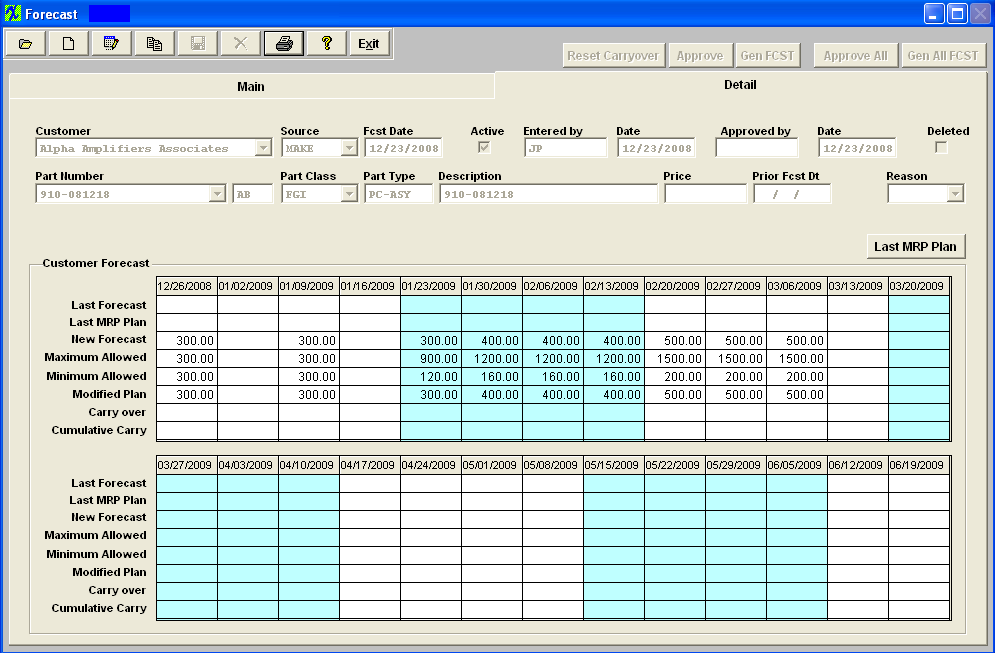

Go to the Detail Tab Screen. The header information will deafult in;

Enter in the new forecast;

Once the forecast is entered, the User should save the information by depressing the Save record action button, and/or depress the GenFCST button to extend the Original forecast to the Planned Forecast, based on the system setup for the customer. The user may also approve the forecast, if they have the authority. If the Forecast Setup indicates that approval is NOT required, the Approval button will be inactive, and saving the forecast will automatically make it active.  |

| 1.3. Edit a Forecast | ||

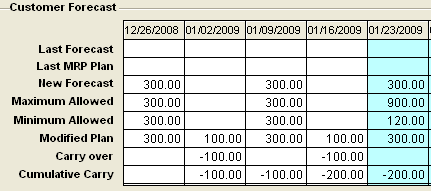

Depress the Edit button. Then the NEW FORECAST line can be edited. If there was a previous forecast, it will be shown on the top line. In order to move forward with the forecast, the ACTIVE checkbox needs to be unchecked (in edit). After saving the changes and checkbox, then re-entering the same forecast in edit mode will activate the Approval and Gen FCST buttons. (If approvals are not required in the system setup, the Approval buttons will not be displayed.) The Reset Carryover button can be used but as mentioned earlier, needs to have an approval entered in the system setup. The purpose of this button is to allow the user to eliminate any items carried over from previous or unfulfilled forecasts. When activated and password entered, the prompt is for a date on which the carryover will be eliminated.

|