| 1. Master Production Schedule |

| 1.1. Prerequisites for MPS & Forecast | ||||||

Prerequisites Required for Entering a New Master Production Schedule:

ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. The forecast module is designed to be the controlling factor for a product when it is used. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com\contactus.aspx After activation, "Master Production Schedule" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.2. Introduction for MPS & Forecast |

| ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. The forecast module is designed to be the controlling factor for a product when it is used. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com\contactus.aspx |

| 1.3. Fields & Definitions for MPS & Forecast |

| 1.3.1. Forecast | ||||||||||||||||||||||||||||||||||||||

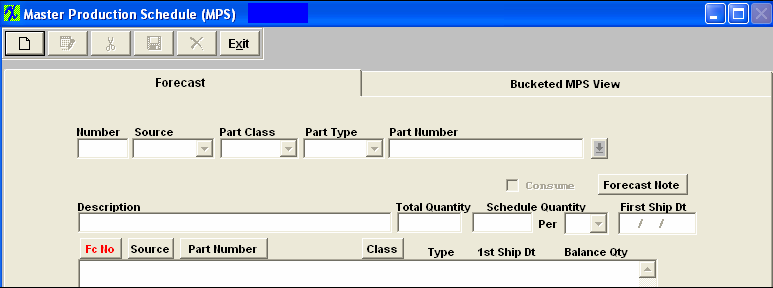

Master Production Schedule Forecast tab Field Definitions: Header Portion of Screen

The number assigned to the forecast. The classification of the Part. The Type assigned to the part number. The unique number assigned to the part. The box is checked if the user expected to ship eventually under a Sales Order. The description of the part. Total Quantity The total quantity of the Forecast. The portion of the total quantity scheduled and the frequency of the schedule. First Ship Date The Date the schedule quantity displayed is expected to ship. Body of Screen

The number assigned to the forecast for the part listed. Whether the forecast involves a Make or Buy Part. The unique number assigned to the part. The revision character assigned to the part Number, if such exists. The classification of the Part. The Type assigned to the part number. First Ship Date The Date the schedule quantity displayed is expected to ship. Balance Quantity The unshipped quantity amount.

|

| 1.3.2. Bucketed MPS View | ||||||||||||||||||||||||||||||

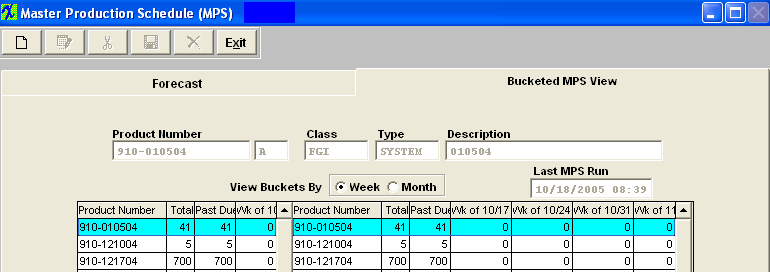

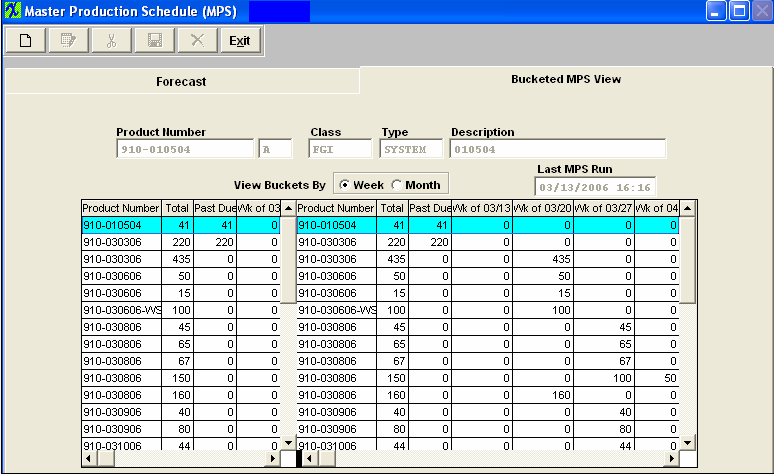

Bucketed Master Production Schedule tab Field Definitions: Top of Screen:

The unique number assigned to the product. The description of the Product Number highlighted. The radial selection dictates how the buckets are viewed, by Week or by Month. Last (MPS) Material Requirements Planning Run This is the date of the last Material Requirements Planning run.

Left Side of Screen:

Week of or Month of Displays the quantity of the amount scheduled, by week or by month. This column indicated the quantity scheduled beyond the Weeks or Months displayed.

Right Side of Screen:

Week of or Month of Displays the quantity of the amount scheduled, by week or by month. This column indicated the quantity scheduled beyond the Weeks or Months displayed. |

| 1.4. How To ..... for MPS & Forecast |

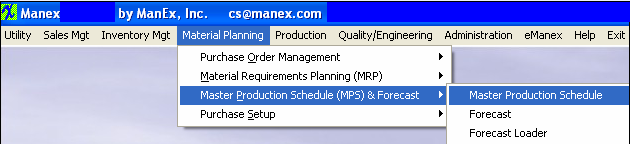

| 1.4.1. Adding A New Master Production Schedule | ||

|

The following screen will appear:

To ADD a new Master Production Schedule, depress the Add action button. Enter your password. Select the Source from the Drop down menu. Select the Part Class from the Drop down menu. Select the Part Type from the Drop down menu. Select the Part Number from the Drop down menu. Either type the Part Number into the red box or scroll down until the part number is located.Then, double click to select. On the main screen, type in the total forecasted quantity for the part.Type in the scheduling parameters.For example, if the forecasted need is 1000 and your plant has the capacity to make 250 units per week, schedule 250 over the next 4 weeks. Type in the first ship date or type a ? in the First Ship Date box and a calendar will appear on the screen: Click on the date of interest.To advance into the next month, depress the right hand > button.To advance into the same month next year, depress the right hand >> button. To go back to last month, depress the left hand < button.To go back a full year, depress the << button. Click on the date desired. Check the consume box if the forecast will eventually be replaced by a Sales Order. If you want to add a Forecast note, depress that button.The following Forecast Item Note screen is available: Depress the Edit button.Type in the note.Depress the Save button.Exit. Once you’ve finished the data entry in this screen, depress the Save button |

| 1.4.2. Bucketed Master Production Schedule Tab | ||||||||||||||||||||

Depress the Bucketed Master Production Schedule tab.The following screen will appear:

This screen displays the results of the latest Material Requirements Planning run. Highlight the Product Number of Interest. Bucketed Master Production Schedule tab Field Definitions: Top of Screen:

The unique number assigned to the product. The description of the Product Number highlighted. The radial selection dictates how the buckets are viewed, by Week or by Month. Last Material Requirements Planning Run This is the date of the last Material Requirements Planning run. Left Side of Screen:

Right Side of Screen:

Week of or Month of Displays the quantity of the amount scheduled, by week or by month. This column indicated the quantity scheduled beyond the Weeks or Months displayed. Once a new Material Requirements Planning run is made, this screen will update

|