| 1. Return/Shortage Reasons |

| 1.1. Prerequisites for Return/Shortage Reasons |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 4-p" before continuing the setup. User MUST have full rights to the "System Setup" in System Security . Users with “Supervisor Rights” will automatically have access. |

| 1.2. Introduction for Return/Shortage Reasons |

Throughout the operation, there will be instances where material has been rejected in the course of business. Examples of these places are Purchasing Receiving, Kit Preparation, Material Shortages, Shipping, etc. It is useful to have a common terminology to choose from, and avoid development of similar nomenclature that mean the same thing. To aid in focusing terms for reason codes, this setup area is established to be used whenever material is rejected. The available number of reasons for rejection is unlimited, but the user must have at least one entered in order to reject material in operations. |

| 1.3. Fields & Definitions for Return/Shortage Reasons |

Throughout the operation, there will be instances where material has been rejected in the course of business. Examples of these places are Purchasing Receiving, Kit Preparation, Material Shortages, Shipping, etc. It is useful to have a common terminology to choose from, and avoid development of similar nomenclature that mean the same thing. To aid in focusing terms for reason codes, this setup area is established to be used whenever material is rejected. The available number of reasons for rejection is unlimited, but the user must have at least one entered in order to reject material in operations. |

| 1.4. How To ..... for Return/Shortage Reasons |

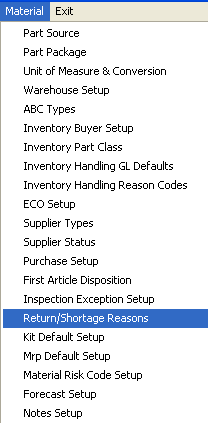

| 1.4.1. Setup the Return/Shortage Reasons | ||

|

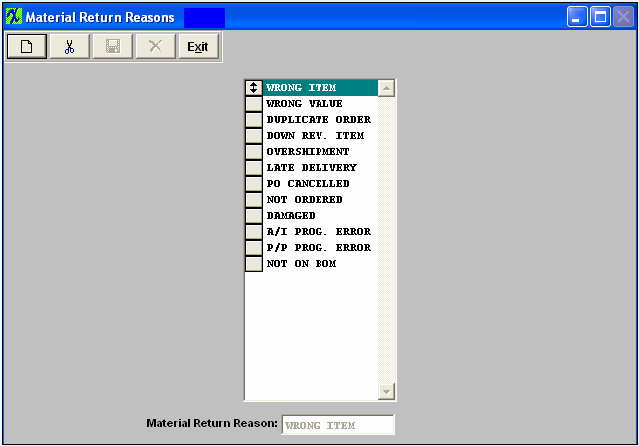

The following screen will appear:

To Add a reason, depress on the Add button and enter the reason in the highlighted field. To Delete a reason, highlight the reason you would like to delete, and depress the Delete button. These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: Used by Purchase Receiving, Kit Preparation & Audit and Material Shortage Management. «Mark as Completed in RoadMap in Section B Item 3-p» |