| 1. FAQ for Sales Mgmt Modules |

| 1.1. FAQ- Sales Order Management (SO) |

| 1.1.1. How do I determine if an order can be shipped sooner than the scheduled due date? |

Question: What reports or screens can we view to see the material status, so we can determine whether or not we can change the Sales Order Schedule Due Date in order to ship it earlier? Answer: First check the Customer Order Status screen by customer PO and/or Sales Order number. From this screen you will be able to determine the status of any work order(s) in progress and if there are any shortages. Second you may run a Kit Material Availability W/AVL Detail (Simulation) report, by product number and revision. This report will display the Quantity on Hand and the Quantity Available for each part used on that product. Third you can check the MRP status of the product for proposed work orders and purchase orders. This will inform you if the scheduled delivery date (s) will be met. |

| 1.1.2. How is the SO Lead Time Calculated? |

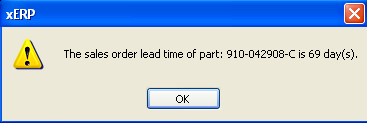

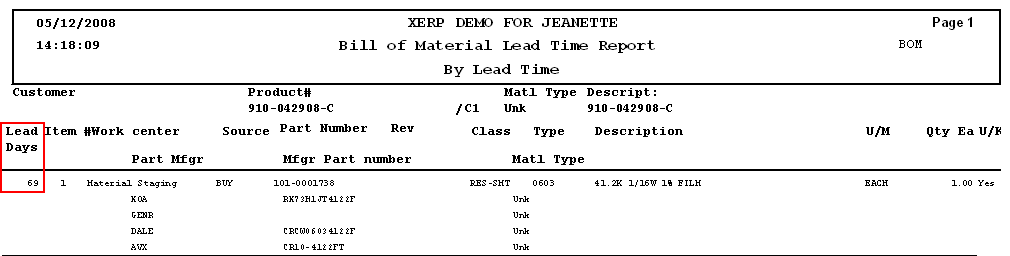

Within the Sales Order module there is a button called “SO Lead Time.”This button will display the Longest Lead Time based on the following: Component Purchase Lead Time 12 weeks (60 days) Product Kitting Lead Time 2 days Product Production Lead Time 7 days Total Sales Order Lead Time 69 days  This should match the Lead Times from the Bill of Material Lead Time report.

Note: The SO lead-time does NOT calculate the purchase lead-times of buy parts associated to sub assemblies. It will consider the kitting and production lead-times of the make part itself along with any buy components on the top level assembly in calculating the longest lead-time. The system assumes that the sub-assembly is complete at the time your kitting it for the top assembly.

|

| 1.1.3. Where Are The Seven Price List Cost Catagories And Sales Types Setup? |

The seven Cost Categories are setup in the Sales Type & Price Itemization module and are typically: Material Cost, Assembly Labor, Documentation, Overhead Burden, Rush Premium, NRE Amortization, and NRE One Time Chg. Price List information is is displayed in the Sales Price List Information screen. |

| 1.1.4. Reports |

Can a Crystal Report be used to show Cost Category information not available in MANEX reports?

In the RMA module, there are no reports for RMA back logs. The RMAs should be showing up on the back log report with a negative number for the returns due back and a positive number for the shipments due out. |

| 1.2. FAQ - RMA Mgmt Module |

| 1.2.1. How do I Create an RMA to Refund the Customer their Money rather than Fixing and Returning the Product? |

|

| 1.2.2. How Do I Handle the Shipping Cost on a Returned Item? |

How do I handle the Shipping Cost that the Customer Paid to Return the Board??? We sold 100 boards @ 62.00 each. (No Shipping Cost on Invoice) Problem: Customer returned one of the boards and took credit for the cost of the board which was $62.00 + $7.49 for the shipping cost that the customer paid to return the board (which was not part of the original Invoice) = $69.49 Resolution: Create a Standard RMA for the Cost of the board $62.00 and since the shipping was not part of the invoice you will NOT be able to included that cost on the RMA, so you will then need to Create a General Credit Memo for the shipping cost of $7.49 and then use that CM in the AR Offset module to apply against the Invoice.

|

| 1.2.3. How Does Processing an RMA with $$ Amount affect the GL? |

Q. - How does Processing an RMA with $$ amounts affect the GL?

A. - The user may enter full price for both the return and re-work. The Prints Screens attached below <<RMA_With_$$$.docx>> displays the basic procedure followed for processing an RMA through the system where both of the items have a $$ associated with them and how it affects the GL accounts.

|

| 1.2.4. How Does Processing an RMA with no $$ amount affect the GL? |

Q. - How does Processing an RMA with $$ amounts affect the GL? A. -A. - The user may enter zero for both the return and re-work. The Prints Screens attached below <<RMA_Without_$$$.docx>> displays the basic procedure followed for processing an RMA through the system where both of the items DO NOT have $$ associated with them and how it affects the GL accounts. |

| 1.2.5. Why is FGI credited and WIP debited when an RMA is received? |

Q - Why is FGI credited and WIP debited when an RMA is received?

A - When an RMA is received, it is first received to inventory, then issued to the RMA as some kind of credit is issued to the customer, depending on the amount entered in the RMA module. The Credit Memo is automatically created, accounting may be notified automatically that it was created, and they approve the transaction. Additionally, WIP is debited, because the material is NOT consigned, but valued inventory.

|

| 1.2.6. How does an RMA impact MRP? |

How does an RMA impact MRP?

If the user enters a scheduled delivery for both the returning item(s) (a minus quantity, those coming back to the user) and the reship items (a positive quantity, returning the items to the customer) on the RMA. MRP will display a demand for a Rework Firm Order for their replacements, to satisfy the return to customer requirements based off the scheduled delivery date entered in the RMA. Note: When the RMA Receiver is created the Work Order due dates are generated automatically based on the date the RMA was created. This date may need to be reviewed and adjusted to match the RMA reshipment date. MRP will NOT instruct you to reschedule a rework firm work order, so it is important to make sure these two dates match.

RMA's will NOT drive MRP:

If the RMA only has the return to User, (a minus quantity), but not a return to the customer(a positive quantity), then the product will become available for other orders, if it makes it to FGI. If the user scraps it in this case, there is NO impact to MRP, as there is no requirement to replace the items. If there are other requirements for the same item, however, then MRP will use the rework order as a source for additional demands.

There would be no reason to create an RMA to ship only, without the return to our user. We would call that a Sales Order. Which would be visible anywhere. The Word attachment <<RMA Orders Affect MRP.docx>> will display how MRP works if the RMA's are properly processed through the system.

|

| 1.3. FAQ - Customer Information |

| 1.3.1. What is the Credit Limit Restrictions based on? |

Question: What is the Credit Limit Restrictions based on? Answer: The Credit Limit check takes place within the Packing List. The program gets the total Accounts Receivable (AR Aging) + Not Posted Invoice (invoice not printed out of the Admin/Invoice module) + Open SO Amounts. Compares it to the Credit Limit setup in the Customer Information module. This is based on having the "Include Open Orders for Credit Approvals for Shipping" option checked, (within the Print PL/Invoice setup module) (if you do not want to include open Sales Orders you would want to uncheck this option) and the "Enforce Credit Limit at Shipment" option checked, (within the Sales-A/R setup module)(uncheck this option if you do not want to Enforce the Credit Limit at Shipment). You also have the ability, to authorize a user to approve the credit limit exceed message or not (within the Security module, Packing List option screen). Make sure that these options are marked properly to get the results you are expecting. |

| 1.4. FAQ- Quote Management (QOT) |

| 1.4.1. QOT Total Part Demands Question | |||||||

|