| 1. FAQ for Production Modules |

| 1.1. FAQ- Work Order Management (WO) |

| 1.1.1. FAQs for the Work Order |

| 1.1.1.1. I have an order already kitted to WIP and I need to get it transferred to MRB |

| Question: I have an order already kitted to WIP and I need to get it transferred to MRB

Answer: If you’ve already started up the production line in Shop Floor Tracking , back it down to the |

| 1.1.1.2. How do I serialize Work Orders which are partially done? |

Q. How do I serialize Work Orders which are partially done?

A. In order to invoke serialization for a product, it has to be an all-or-nothing situation. You can’t have some parts serialized and some not, otherwise there would be no way to enforce serialization tracking through the Shop Floor Tracking module and then the Packing List module. If the user has Work Order(s) that have product BELOW the If the user has already shipped product out of Finished Goods, then receive it back in via Inventory Handling . Move it back in the Shop Floor Tracking module to a Locate the product number in Inventory Control Mgmt module and check the serialized box for that product. The user can then go into the WO Traveler Setup for the product and setup the Work Center in which serialization is required. After completing that process, update the Work Order(s) in process. (This action may reset the quantities in the Work Order back to the

The user must then enter the WO Serial Number Control module to assign serial numbers to the Work Order before you will be able to move parts past the Work Center in which serialization is required.

Enter the Shop Floor Tracking module, move the parts back down to their respective position, including any in Finished Goods.

If the user did have to use the Inventory Handling to put the shipped product back into Finished Goods, they will have to use the Inventory Handling Issue screen to remove them from Finished Goods again. The same change number used in receiving should be used for the issuing.

|

| 1.1.1.3. Why are my Work Order Numbers out of Sequence? |

Q. Why are my Work Order Numbers out of Sequence?

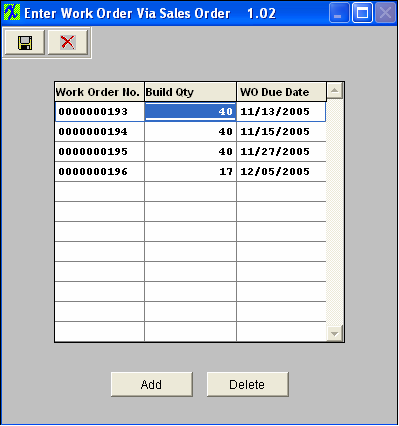

A. When users create a Sales Order they have the option at this time to issue the Work Order(s). If they choose this option the Work Order(s) are created, within this screen the user then has the option to "Add" more Work Order(s), or "Delete" the Work Order(s) that were created. If the user chooses to "Delete" the Work Order(s) that were created, these Work Order numbers will be removed from the Sequence. Also, at this time the user can "Save" or "Abandon Changes" if the user selects to "Abaondon Changes" the Work Order numbers will be removed from the Sequence.

|

| 1.1.2. Why does the system force individual entry for serial numbers with prefixes or characters? |

Q Why does the system force individual entry for serial numbers with prefixes or characters? A If user enters both character and number in one field, then it is hard to know which part (character or number) needs to be increased first. So the system cannot predict how the range is intended to increment: For Example if user enters a SN range of A101 to Z110. The system does not know how the user wants the range setup A101, B101, C101 or A101, B102, C103, etc. |

| 1.2. FAQ - Capacity & Scheduling |

| 1.2.1. Is the capacity set at units per hour? |

Q. Is the capacity set at units per hour?

A. Yes, Capacity is at units/hour/operator-machine. Capacity then depends on the number of resources available, and that includes the number of shifts available. The program determines the duration of the job based on the resources, shifts, and active time during shifts (breaks and meals are excluded). The capacity planning module will stack up the requirements for multiple jobs on the same day and either require the user to add resources, or extend the completion time.

|

| 1.3. FAQ - Shop Floor Tracking (SFT) |

| 1.3.1. Why are we unable to transfer to Activities within the Shop Floor Tracking by Barcode module? |

Q. Why are we unable to transfer to Activities within the Shop Floor Tracking by Barcode module?

A. There is an option within the Shop Floor Tracking Defaults to Transfer Serial Numbers by Work Center or Activities. If you are trying to transfer by activities you may want to check this option to be sure it is setup to transfer by Activities rather than Work Center.

|

| 1.3.2. Why did the Quantities in Other Work Centers revert back to Material Staging? |

Q. Why did the Quantities in Other Work Centers revert back to Material Staging?

A. If the starting SN work center is removed, when user clicks “Update WO” button, all the WC qty and SN (if any) except for FGI and SCRP work centers will be moved back to STAG work center because the system will treat the STAG as the starting tracking SN work center.

|

| 1.3.3. Why doesn't the Qty in the Transfer History Screen Match the Qty in the WO Screen? |

Q. Why doesn't the Qty in the Transfer History Screen Match the Qty in the WO Screen? A. ECO changes will cause this situation. The qty in the transfer history screen may be different then the actual qty transfered due to the fact that the product has changed revisions from the ECO module. The SFT module will see it as a different product and no longer display the transfer history information on screen for the old revision.

Resolution - ManEx is considering improvements to the SFT module, where the transfer history in the work order inlcudes the revision, and all items transferred out of the work order regardless of the rrevision. We will be looking into these changes more once the SQL and IPKEY projects are completed.

|

| 1.3.4. SYSTEM LOCK ERROR-What to do if system SFT Lock Appears |

|

Issue: Unable to move product through Shop Floor Tracking due to the following message:

User will receive this message after one of the workstations that was in the process of moving product through Shop Floor Tracking had experienced lost connection to the Network, or their workstation had actually crashed. The system will then place this lock on the table to prevent any possible corruption. Resolution: There should already be a file called <<RESETSHOPFLAG9.EXE>> located within the Manex Root Directory. (if this file is missing please download the attached) Running this executable will reset the lock within the shop floor tracking tables. This executable does not require you to stop the TrigTimer. |

| 1.3.5. SQL - -SYSTEM LOCK ERROR-What to do if system SFT Lock Appears |

|

Issue: Unable to move product through Shop Floor Tracking due to the following message:

Resolution: There is a SFT_lock.sql attached below and/or there is a stored procedure sp_unlockSFTFlag as part of the database. Go into the SQL Server Management and run the attached script, this will remove the SFT Lock placed on your tables.

Reason: User will receive this message after one of the workstations that was in the process of moving product through Shop Floor Tracking had experienced lost connection to the Network, or their workstation had actually crashed.The system will then place this lock on the table to prevent any possible corruption. Prevention: If users see a message that the file is currently in use have them wait a few minutes and try again, not to Clt+Alt+Delete out of the system. |