| 1. Fields & Definitions |

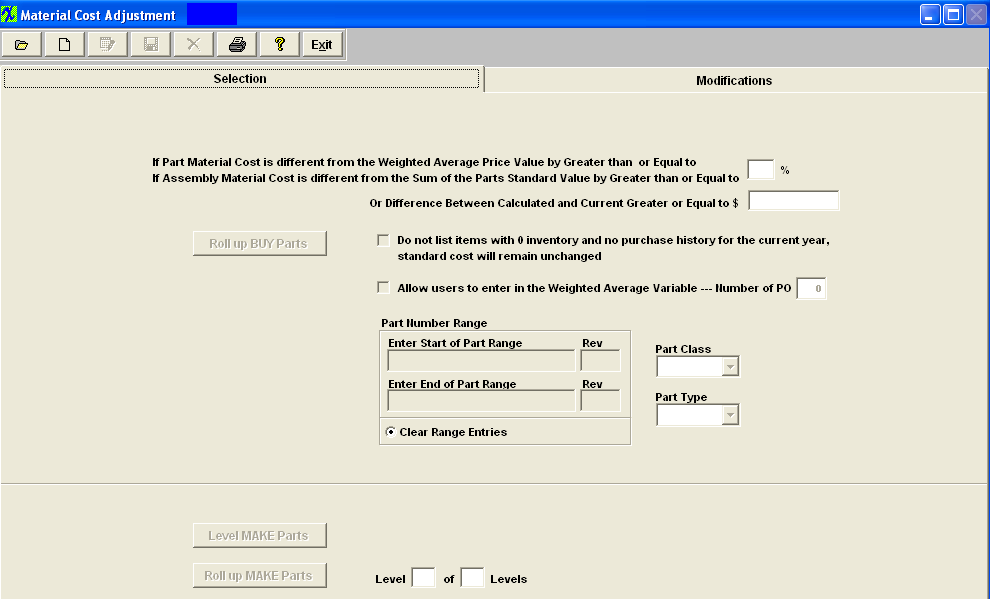

| 1.1. Selection Tab |

Enter the percentage to use if the part material cost is different from the Weighted Average Price Value by Greater than or Equal to or if the assembly material cost is different from the Sum of the parts standard value by Greater than or Equal to Or Difference between Calculated and Current Greater or Equal to $

Example: if there is a $2000.00 assembly in stock, and users apply the 1% criteria, a $19.00 difference won't be brought into the matrix to be checked. On the other users enter 0%, then every single part will be included. A Minimum dollar value has been added to the Standard Cost Adjustment screen that will be used to determine whether or not an item is included in the matrix. If left blank then the percentage rules. If value entered then it becomes the criteria for inclusion in the matrix.

Check box if you "Do not want items listed with 0 inventory and no purchase history for the current year", then the standard cost will remain unchanged Check this box if you want to "Allow user to enter in the Weighted Average Variable". Once this has been checked the users can then enter in the number of the most recent Purchase Orders they wish to have included in the Weighted Average Calculation. This give the user the option to eliminate the Quick Turn buys that may throw the calculations off. User also has the option to select the part number range , class, or type, on which part(s) to process. This will complete the adjustment process faster and user will be able to maintain more accurate records and also allow the users the ability to narrow the resulting filter of the Buy parts. NOTE: The Part Number range selection is available for only BUY parts. ManEx does not offer it for MAKE parts, because the system needs to roll ALL sub assemblies up to determine the top level costs. However, in the modifications tab, it is possible to sort by part number or class, to make it easier for the user to find specific items of interest.

To roll up the Buy Parts, depress the Roll up BUY Parts button. To roll up Make Parts, depress the Roll up MAKE Parts button. To Level Make Parts depress the Level MAKE Parts button.

|

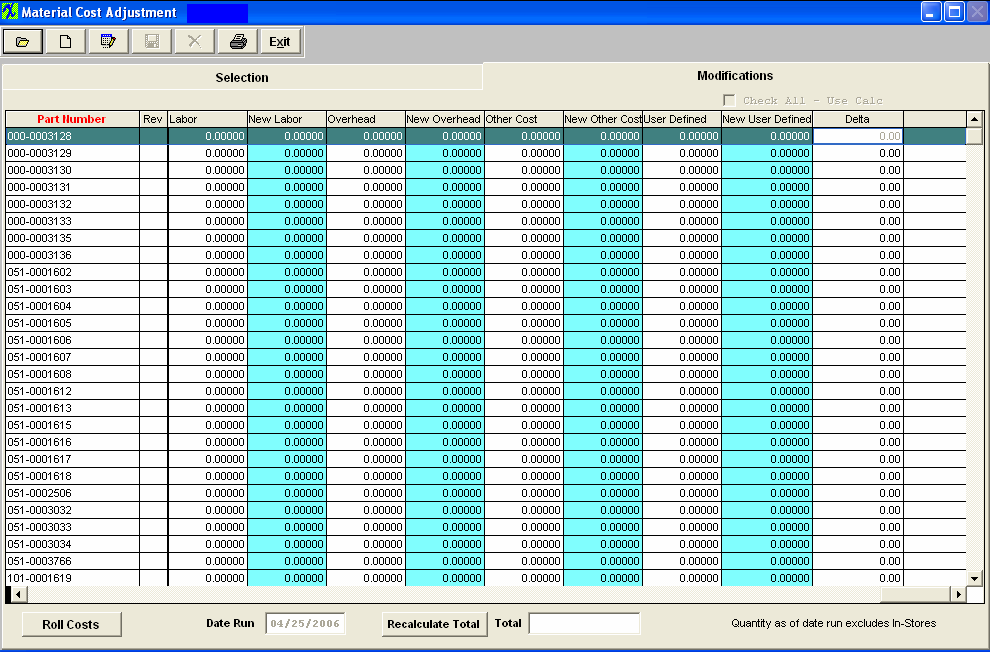

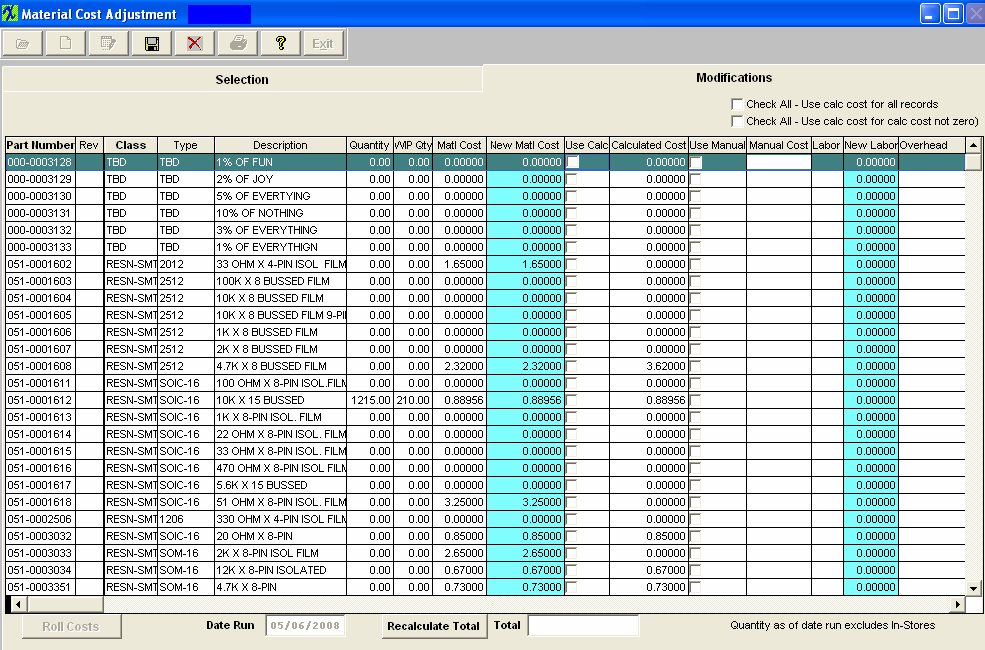

| 1.2. Modification Tab | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Modifications tab field definitions

The number the user has assigned to the part within the ICM module. The revision number assigned to the Part Number within the ICM module. The classification to which the part belongs. The type within the classification to which the part number belongs. The description assigned to the Part Number within the ICM module. The quantity is the number of units currently owned. This excludes all un-purchased In-Stores Inventory. ( for explanation on In-Store Inventory See Purchasing Manual) See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. This cost is defaulted in from the cost currently assigned to the part number through ICM or PO . ·Important Note - If accounting is installed: For all buy parts, the standard cost field must have data entered. If this data is missing (or wrong), the Raw Materials Inventory and the Work In Process (WIP) will be incorrect for the accounting records. All make parts which are not labor only (the customer brings you the kit and all you do is apply the labor), must have data entered in the standard cost field. Additionally, the data entered in the standard cost field for the make part must equal the sum of the Bill of Materials components.(Please refer to Bill of Materials Reports – Bill of Material With Standard Cost.) If the data is missing or wrong on a Make Part, the Work In Process, Cost of Goods Sold and Finished Goods Inventory will be wrong for the accounting records. If the sum of the Bill of Materials components does not equal the standard cost per the Item Master, a configuration variance will generate.

By moving the arrows (at the bottom of the screen) to the right the following fields are also available

|