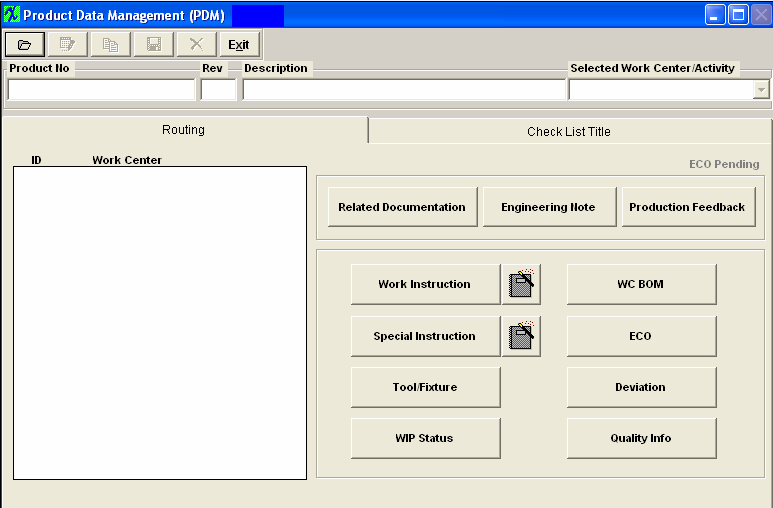

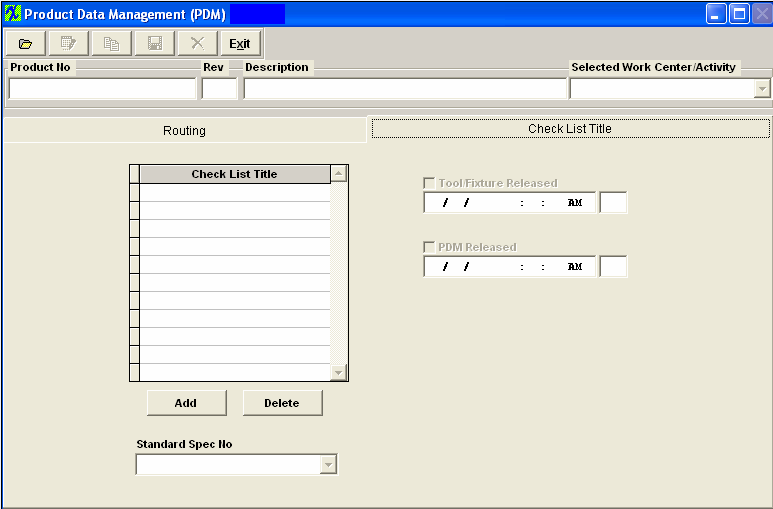

This screen allows the user to establish check lists for each PRODUCT. Note that this is a different check list than the one for Work Order which is set up in Shop Floor Tracking Defaults . Items may be added to the check list in the edit mode.

| Check List Title |

Description of the Check to be Performed |

| Tool/Fixture Released |

Check this box to release the Tool Fixture. This box MUST be check when usiing the Unreleased Work Order List and/or for the Tool/Fixture button to be enabled in the Shop Floor Tracking module..

Note: Users MUST have special rights within the Security module to check this box. Users with “supervisor’s rights” will automatically have access.

|

|

This box will display the date and time of when the Tool/Fixture was Released and will also display the initials of the user that checked the box. |

| PDM Released |

Check this box to release the PDM. This box must be check when usiing the Unreleased Work Order List .

Note: Users MUST have special rights within the Security module to check this box. Users with “supervisor’s rights” will automatically have access.

|

|

This box will display the date and time of when the PDM was Released and will also display the initials of the user that checked the box. |

|

Pressing the ADD button opens another field in which information may be placed in the Check List. |

|

Pressing the DELETE button deletes the item from the Check List that the cursor is on when the delete button is pushed.

|

| Standard Spec No |

Select the Standard Specification Number from the pull down list displaying after depressing the down arrow. These are defaulted in from the PDM Standard Process Specification module. |

This information will be carried forward into the Shop Floor Tracking module for the highlight Work Center.

|