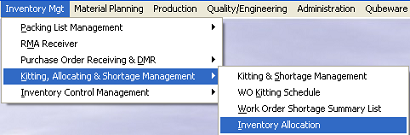

| 1. How To ..... for Inventory Allocation |

| 1.1. Find an Inventory Allocation | ||||

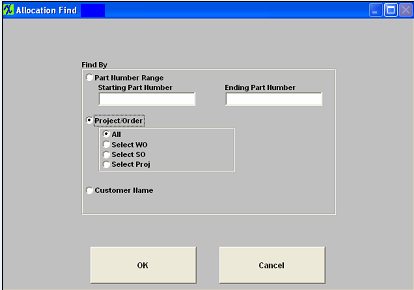

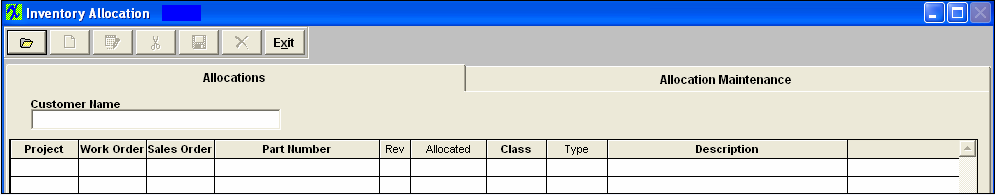

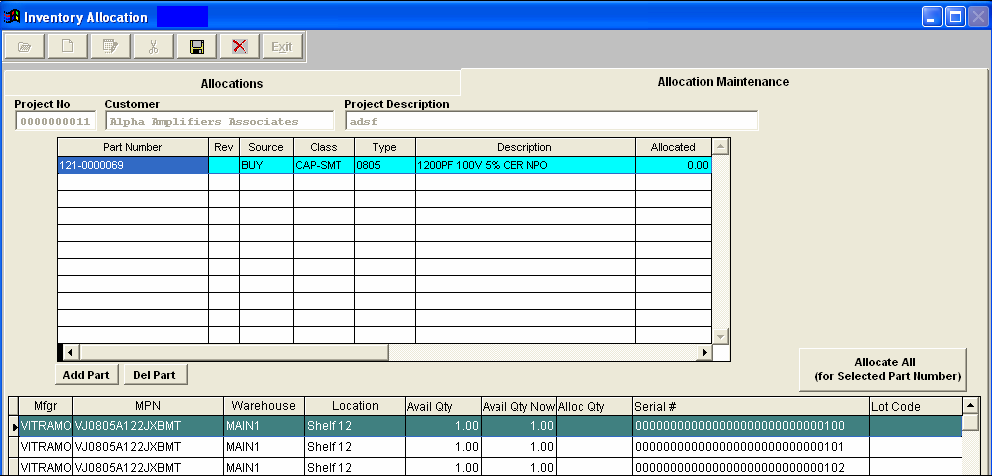

The main screen will appear:  Find an Inventory Allocation

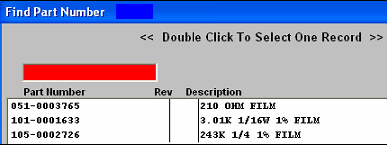

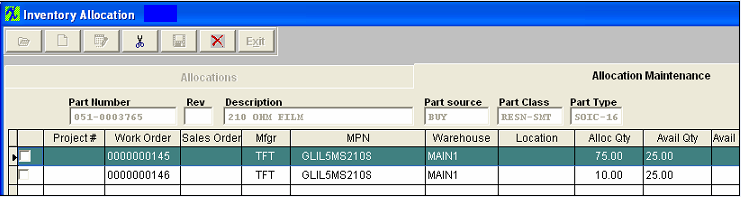

Depress the Find button . The following selection will be presented: If you now the specific part number or range of numbers you are interested in, enter it into the Part number Range fields. For the selections entered into the find criteria screen, the allocations will display in the bottom of the screen for the highlight part number.

|

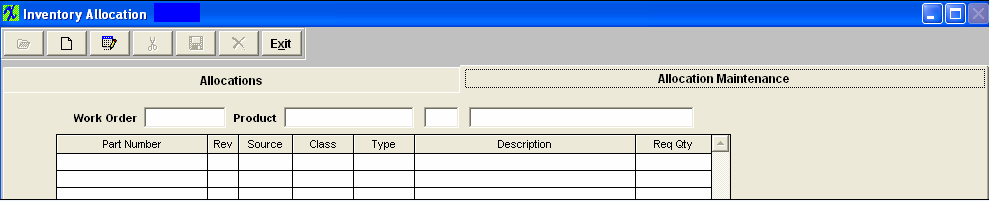

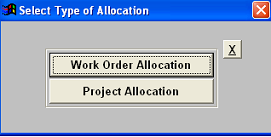

| 1.2. Add a New Inventory Allocation | ||||||||

|

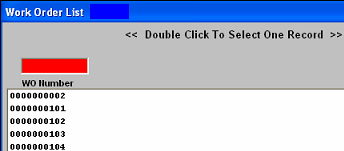

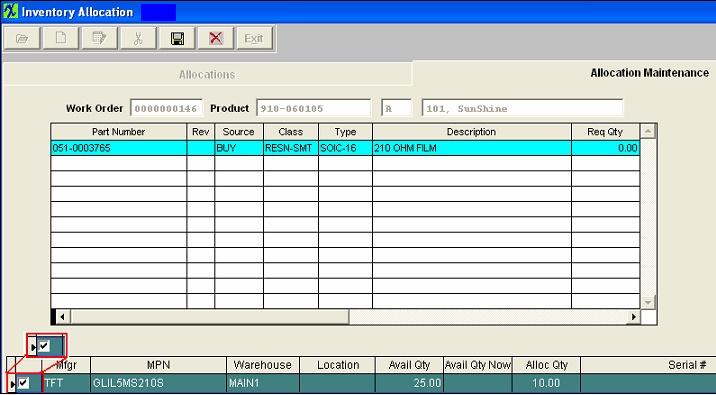

The following screen will appear:

Depress the Allocation Maintenance tab

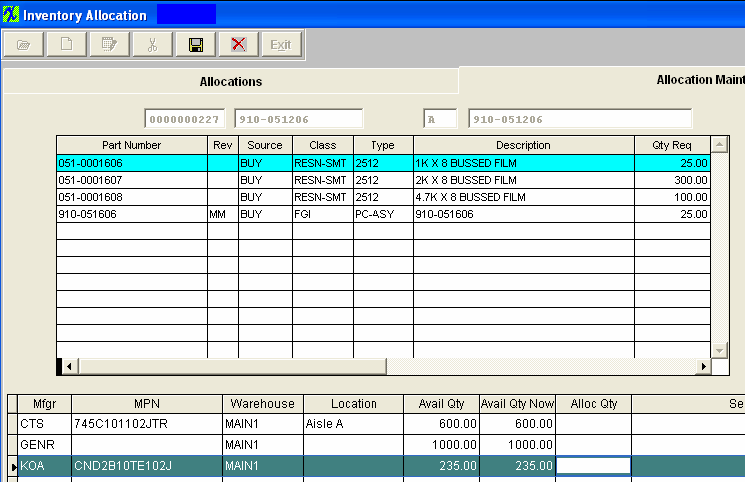

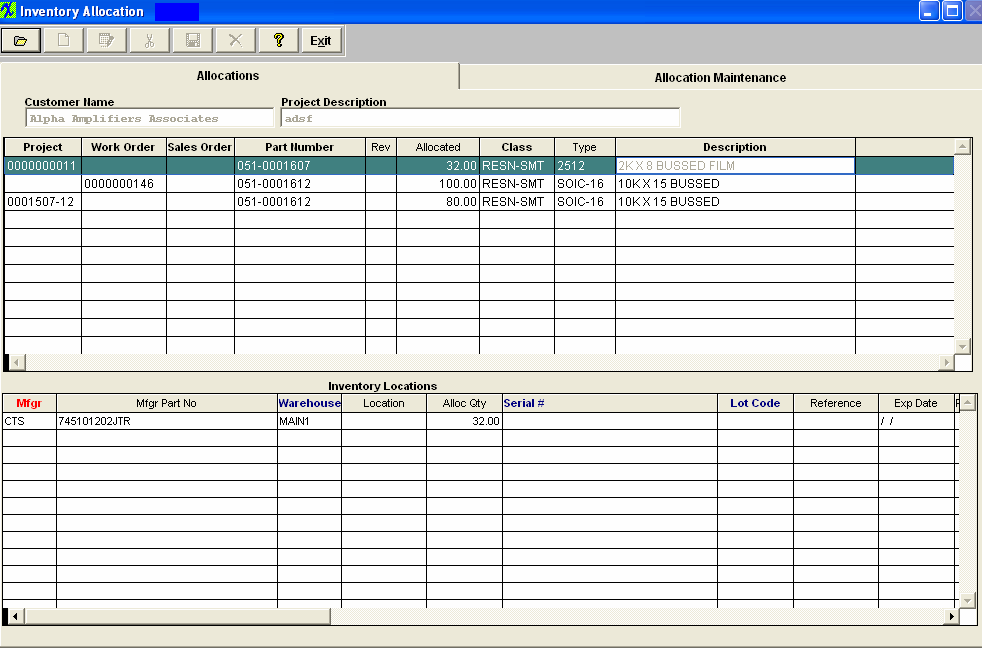

Particulars regarding that Work Order will populate the screen as displayed below:

Note that the Avail Qty column has updated to reflect the amount allocated. The Inventory Master has also automatically updated, and will now display the amount allocated (“reserved”). |

| 1.3. Change the Allocation Quantity | ||||

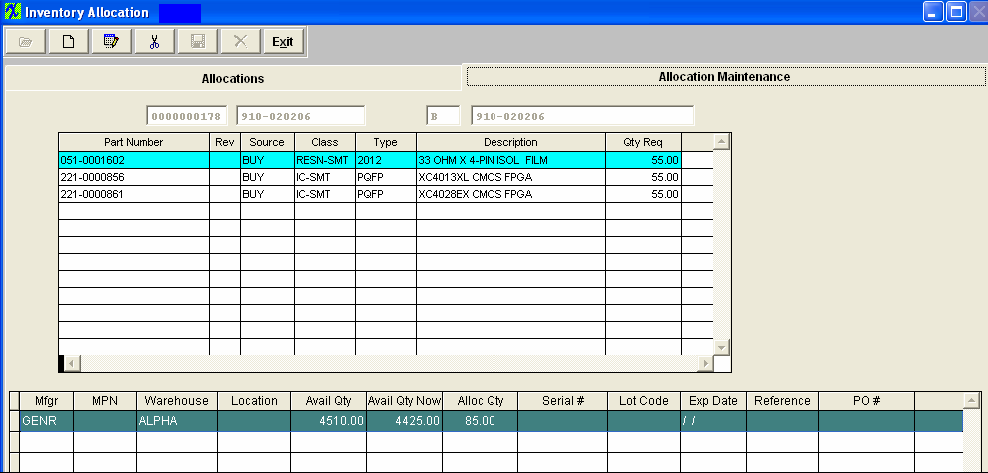

The following screen will appear, and the user will be allowed to modify the Alloc Qty.

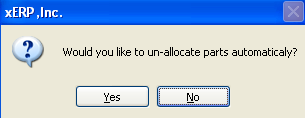

Highlight the desired part number and modify the Alloc Qty. Depress the Save record action button. The program will unallocate all original qty and allocate the new quantity again. This will create two records in the Inventory Transaction report |

| 1.4. Un-Allocate an Allocation | ||||||||||

|

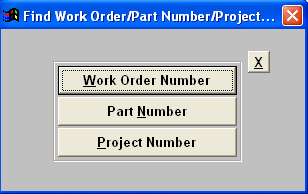

To Un-allocate an allocation, thus freeing up the amount allocated to a Work Order or Project, first go to the Allocation Maintenance screen. Depress the Edit Record button. The following find record options will be displayed

Highlight the desired part number and then Check mark which items you wish to un-allocate. Depress the Save record action button and any marked item should now be unallocated and be considered available inventory.

Highlight the desired part number and then Check mark which items you wish to un-allocate. Depress the Save record action button and any marked item should now be unallocated and be considered available inventory. The Inventory Control Item Master will update automatically. Note: For reports on Allocated Inventory, please refer to the ICM reports |