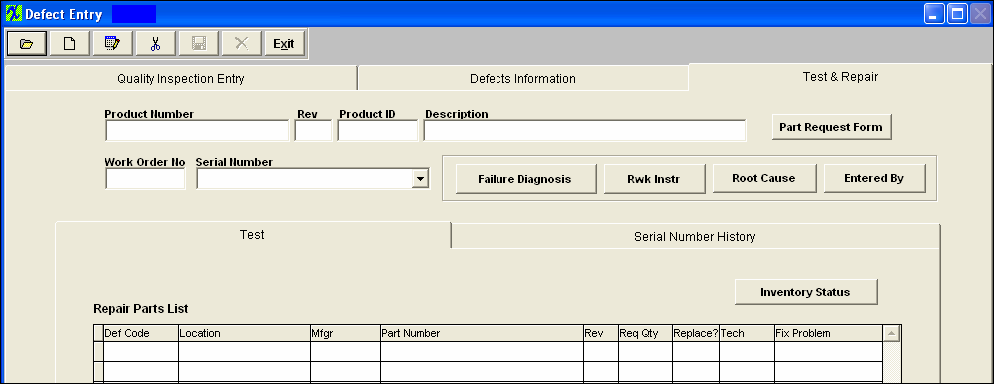

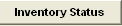

Test & Repair Screen Field Definitions

The Test & Repair is actually a separate OPTIONAL module, but has been included into the Defect Entry screen for ease of use for the operators.

| Product Number |

The internal number assigned to the assembly.

|

| Rev |

The revision number associated with the Product Number.

|

| Product ID |

This field is no longer used and will be left blank.

|

| Description |

The description of the Product Number.

|

|

If the component part is to be replaced, this button will be available to view and print the request for replacement. This request/form should be sent to the stockroom showing them that replacements are needed for the components identified as failing inspection or test. If the part is issued, it will be charged to the work order.

|

| Work Order Number |

The number of the work order which was inspected.

|

| Serial Number |

The serial number of the assembly which failed inspection.

|

|

|

These three buttons are for viewing notes on the topics of diagnosis of failure, instruction for reworking and the cause of the defect |

|

This button will open up a screen which will display the initials of the user who entered the failure: |

Test Tab Field Defintions

Repair Parts List

| Def Code |

The code assigned to the defect.

|

| Location |

The Reference Designator as set up in the assembly’s Bill of Materials.

|

| Mfgr |

The name of the manufacturer of the failed part.

|

| Part Number |

The internal number assigned to the failed component.

|

| Rev |

The revision number assigned to the internal part number.

|

| Req Qty |

The number rejected of the assembly.

|

| Replace ? |

If this box is checked, the user intends to replace the rejected component.

|

| Tech |

This field will display the name of the technician who fixed the defect. To get the name to display user must double click in the field. This is a read only field and can NOT be edited.

|

| Fix Problem |

If the user decides to fix the problem, he/she may choose one of the following selections:

|

|

Depressing this button will bring up the following information:

|

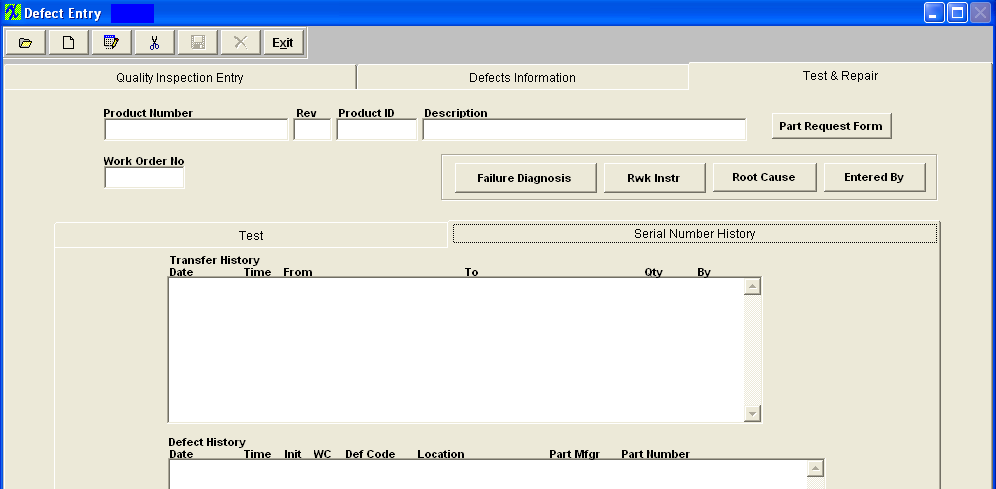

Serial Number History tab

Transfer History Section

| Date & Time |

The date and time (24 hour clock) the assembly was transferred to the Work Center.

|

| From/To |

The Work Centers involved in the transfer.

|

| Qty |

The quantity transferred.

|

| By |

The initials of the user who recorded the transfer.

|

Defect History Section

| Date & Time |

The date and time (24 hour clock) the assembly was rejected.

|

| Init |

The initials of the user who recorded the rejection.

|

| WC |

The Work Center where the failure was noted.

|

| Def Code |

The code relating to the defect.

|

| Location |

The Reference Designator as set up in the assembly’s Bill of Materials.

|

| Part Manufacturer |

The name of the manufacturer of the failed component.

|

| Part Number |

The internal number assigned to the component.

|

|