| 1. Fields and Definitions for RMA Receiver |

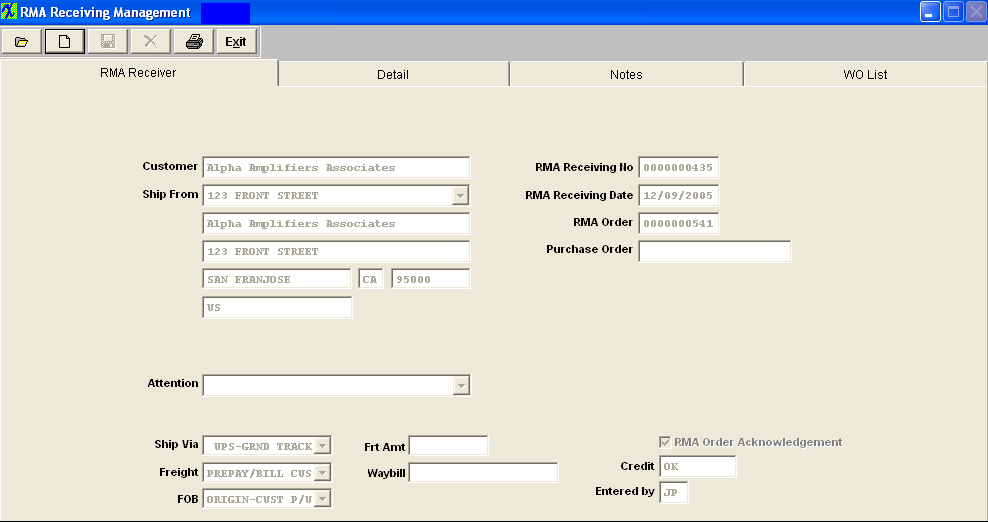

| 1.1. RMA Receiver Tab | ||||||||||||||||||||||||||||||

RMA Receiver Tab Field Definitions

|

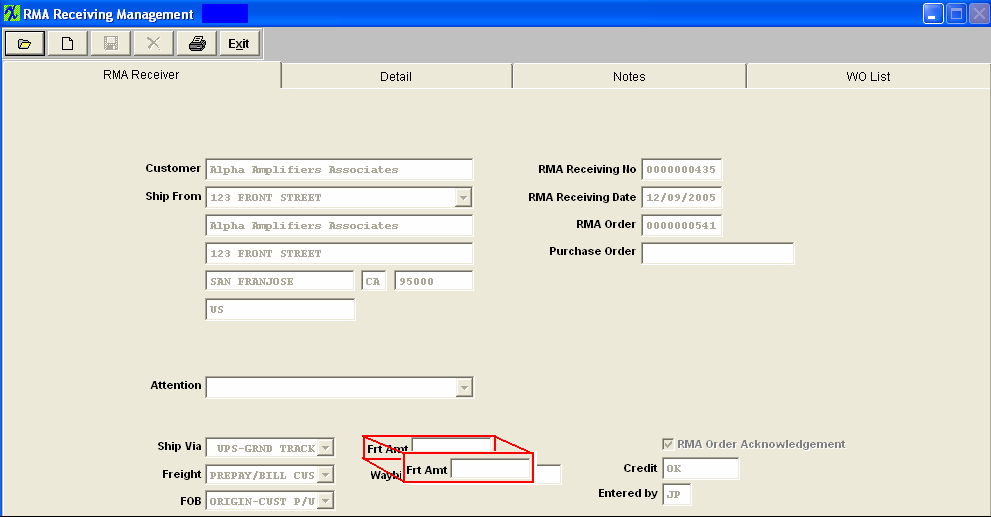

Customer

| This is the name of the Customer who returned the material.

|

RMA Receiving Number

| This is the unique number assigned to the RMA Receiver.

|

Ship From

| This is the Customer’s address from which the material was returned.

|

RMA Receiving Date

| This is the date the user’s Receiving Department received the returned material.

|

RMA Order Number

| This is the RMA Order Number assigned in the RMA Management module.See above.

|

Purchase Order

| The was the customer’s original purchase order number for the original Sales Order.

|

Attention

| This is the contact name at the Customer.

|

Ship Via

| This is the original carrier for the original Sales Order.

|

Freight Amount

| This is the freight originally charged the customer on the original Sales Order.

|

RMA Order Acknowledgement

| This box is checked in the RMA Management module, as explained above.

|

Freight

| This is the freight arrangement per the original Sales Order.

|

Waybill

| This is the Waybill number pertaining to the original Sales Order.

|

Credit

| This is the Customer’s Credit Status with the user.

|

FOB

| This is the original FOB terms pertaining to the original Sales Order.

|

Entered By

| These are the user’s initials authorizing the material return in the RMA Management module. |

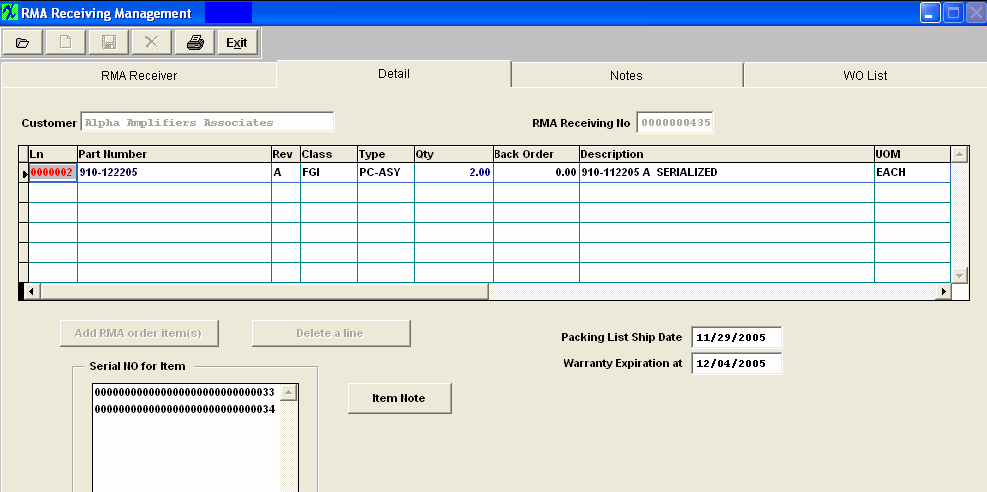

| 1.2. Detail Tab | ||||||||||||||||||||||||||||||||||

RMA Receiver Detail Tab Field Definitions

|

|

Customer |

This is the name of the Customer who returned the material |

|

RMA Receiving Number |

This is the unique number assigned to the RMA Receiver. |

|

Ln |

The line number of the Return Material Authorization or the line member of the order to be re-worked/replaced and returned to the customer. |

|

Part Number |

The user’s internal number for the part or assembly. |

|

Rev |

The revision number pertaining to the Part Number. |

|

Class |

The user’s classification covering the Part Number. |

|

Type |

The type within the classification covering the Part Number. |

|

Qty |

It’s the amount of the original order which the customer is returning. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. |

|

Back Order |

The amount of product still expected to be returned by the customer. |

|

Description |

The user’s description covering the Part Number. |

|

UOM |

The unit of measure pertaining to the product. |

|

|

This button allows the user to add items from the RMA Management module. |

|

|

This button allows the user to delete the highlighted line. |

|

Packing List Ship Date |

The date the Original Packing list was created. |

|

Warranty Expiration |

The date the warranty originally extended to the customer expires. |

|

Serial Number Entry |

The serial numbers pertaining to the items returned. |

|

|

The note pertaining to the Part Number as entered in the Inventory Master. |

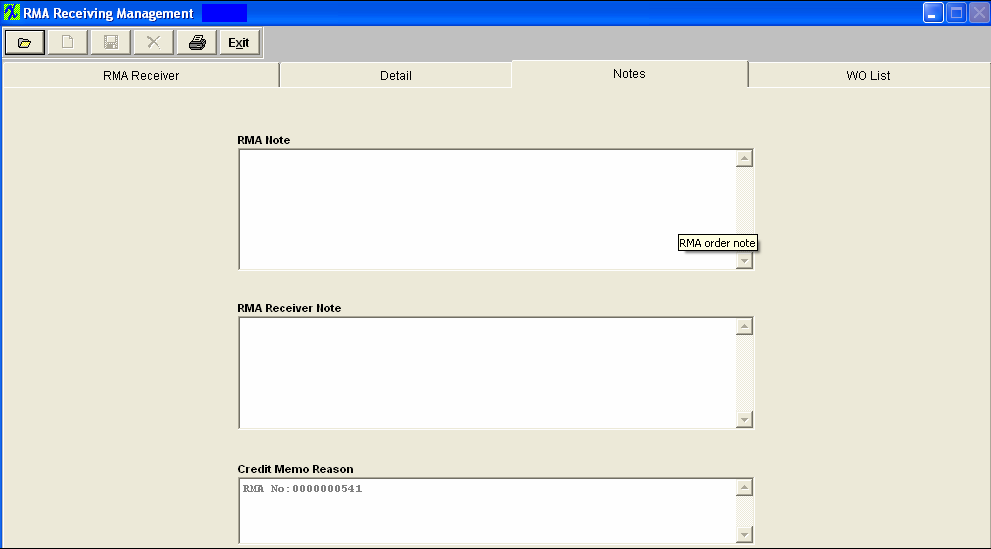

| 1.3. Notes Tab | ||||||

RMA Receiver Notes Tab Field Definitions

|

RMA Note

|

This is the internal note used by the user regarding the Return Material Authorization as entered in the RMA Management module. RMA Receiver Note |

|

This is a note that will be displayed on the RMA Packing List.

|

Credit Memo Reason

|

This is the note created when the Credit Memo was created. |

| 1.4. WO List Tab | ||||||||||||||||||||||||

RMA Receiver Work Order List TabIf the RMA Management module called for a re-work or replacement in addition to authorization of the return of material, the system will have created a Work Order. Information regarding any such Work Order will appear in this tab. RMA Receivng Work Order List Tab Field Definitions

|

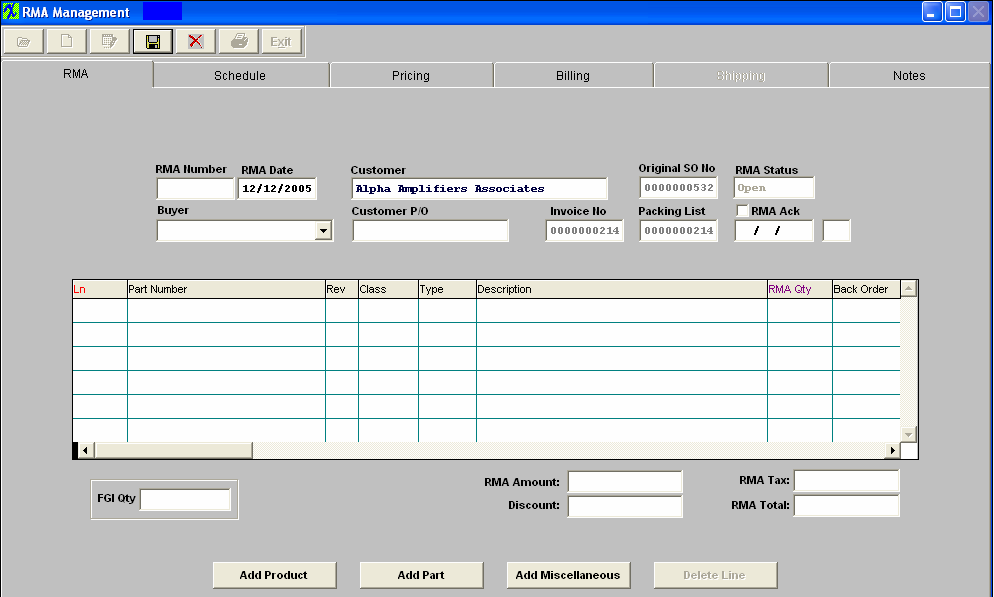

| 1.5. Overview Regarding Return Material Authorization Accounting |

No Journal Entry is created in the RMA module, however the system was collecting the JE components from that module as follows: Assume that the original sale was for 10 units @ $100.00 each, with a standard cost of $80.00 each and freight charged the customer of $15.00. At the time the user selects the original Invoice number in the Return Material Authorization module, the system “remembers” the original accounting entry that was created at the time the original Invoice was printed, which was: Debit Accounts Receivable – Trade $1,015.00 Debit Cost of Goods Sold $800.00 Credit Sales $1,000.00 Credit Finished Goods Inventory $800.00 Credit Freight Income $15.00

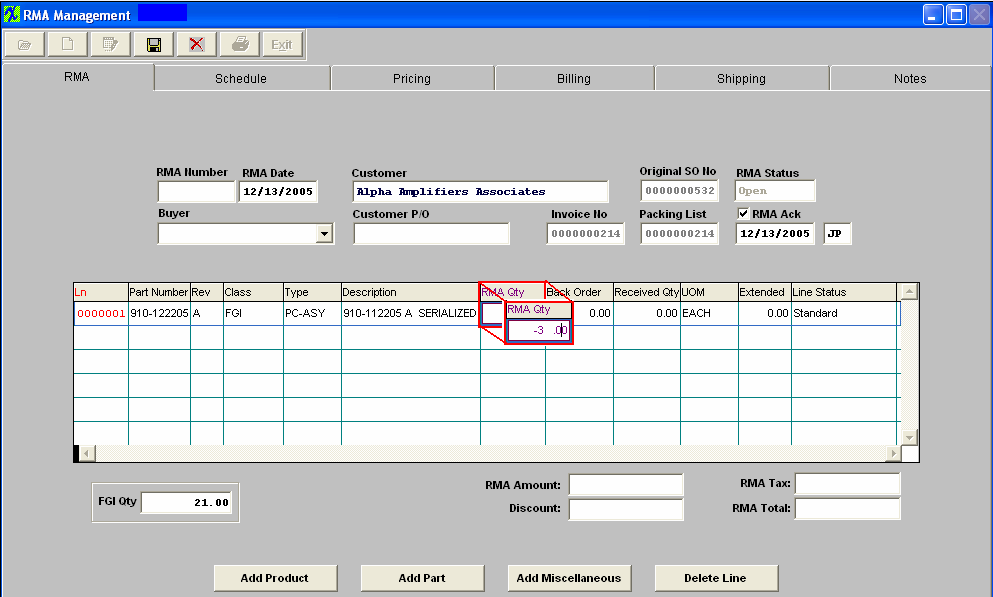

When the user enters the “return quantity” (the one entered as a negative quantity), the system will remember that the original cost of sales was $80.00 per unit.

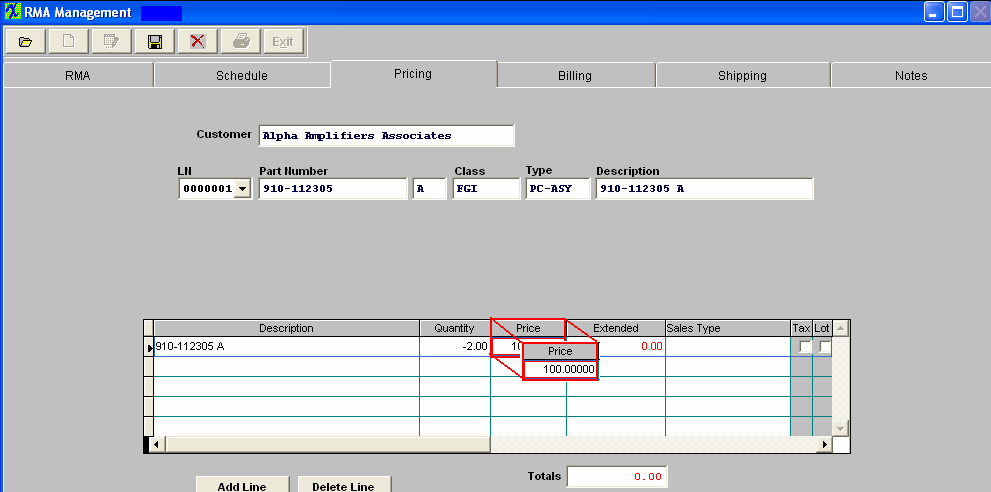

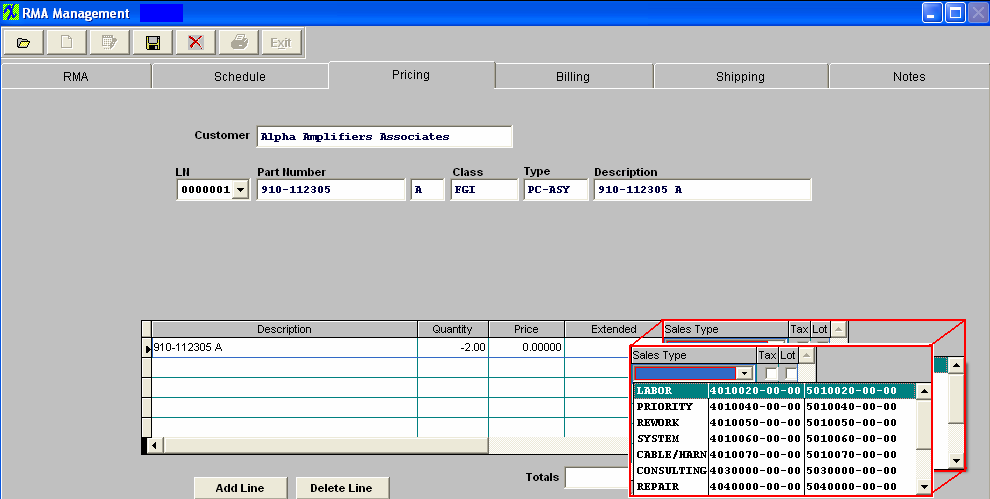

The user then enters the pricing on the item to be returned on the Pricing page of the RMA module.

The pricing entered can be any amount up to the amount of the original pricing of $100.00 per unit. And so the journal entry component for the debit to the sales account is 2X $100.00 = $200.00, in this example. The user selects the sales and cost of goods general ledger accounts to be used per the Sales Type column:

And so, the sales account number selected will be debited for $200.00 once the journal entry is created, upon the actual receipt of the returned item.And the related Cost of Goods sold account will be credited for the $160.00. If the return is to be reworked and then returned back to the customer, the user creates a second line item on the RMA using a positive quantity which is in actuality creating the RMA Sales Order and an eventual invoice upon shipment. The journal entry and the applicable Credit Memo for the returnis created in this Return Material Authorization Receiving module.On this screen, the user indicates the amount of freight to be credited, such as a pro rata 2/10 of $15.00, or $3.00, for example:

After the user types in the quantity received on the Detail page and depresses the Save button, several things happen all at once: The Journal Entry is created as follows and forwards to the Release to General Ledger module: Debit Sales $200.00 Debit WIP $160.00 Debit Freight $3.00 Credit Accounts Receivable $203.00 Credit COGS $160.00

Once the Rework Work order is released, the user may opt to go into kitting and add line shortages which will be included in the Material Variance once the Kit is closed.Please refer to the Kitting and Shortage Management manual. From this point forward, the accounting is the same as for a regular order. |