|

When a buyer generates a purchase order, it is created as a temporary order until it is approved. These orders will be created with a prefix to distinguish them as temporary until approved. As a temporary order, the document cannot be printed, nor will the order be considered as supply for Material Requirements Planning considerations. When a purchase order undergoes a revision, changing schedules, quantities and/or pricing, the order returns to a temporary status until approved. Note: These changed orders are not changed back to a prefix.

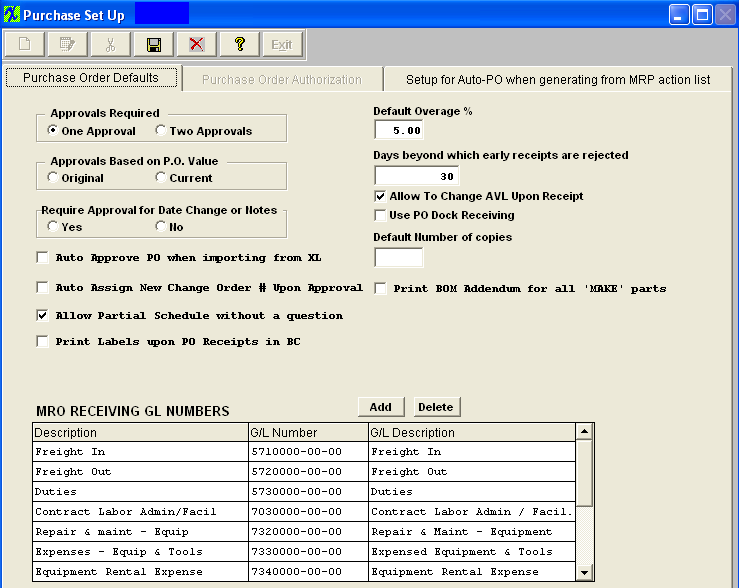

| Approvals Required |

The company has the option to declare whether one or two approvals are required in order for a purchase order to be approved. If the user chooses to have two approvals, then one of the approval-users must have final approval authority.

|

| Approvals Based on P.O. Value |

This will allow the PO to be approved based on the PO value |

| Require Approval For Date Change or Notes |

This gives the user the option to require approvals or NOT to require approvals when Date Changes or Note Changes are made. If "No" is checked user can edit the notes without going into edit mode on the PO record. NOTE: If "No" is checked any changes made to the notes will NOT be recorded in the "View Changes History" screen. (This includes PO Item Master Notes, PO Item Notes, PO Notes, and PO Footnotes). If "neither" option is selected or "YES" is selected approvals WILL be required when there are Date Changes or Note Changes made. |

| Default Overage % |

This is a default percentage applied to each order as it is placed, but may be over-ridden at the time the order is created. If material is received that exceeds in quantity the ordered amount by this percentage, then the receiving department cannot receive the material until the order is modified by purchasing.

|

| Days beyond which early receipts are rejected |

Enter the number of days allowed for early receipt (from the PO Scheduled Date) based on work days. This is a provision for the restriction for PO early receipt. The default for this field is 30 days. |

| Allow to Change AVL Upon Receipt |

This will allow the users within Purchase Order Receiving to change the AVL selection (based on the available AVL's that currently exist within Inventory Control for that part) upon accepting the parts into inventory. |

| Use PO Dock Receiving |

This will allow users to decide if they want to use the two-step receiving procedure (Dock Receiving & PO Receiving) or if left un-checked just the one step (PO Receiving Only) |

| Default Number of Copies |

Enter in the number of copies you want the system to create per PO |

| Auto Approve PO when Importing from XL |

Default is un-checked. If the user checks this box the system will automatically approve all the POs uploaded. If this box is not checked then all the POs will be uploaded as "NEW" and users will be required to approve within the Purchase Order Management module. |

| Auto Assign New Change Order # Upon Approval |

Default is un-checked. If un-checked when user makes changes the CO# will stay the same, the system will prompt the reminder, and user may manually assign a change order number if applicable. If checked, the reminder will not be issued and CO # field becomes not editable. When the user approves the change the Change Order number will be increased. NOTE: If auto assign the next change order will be referenced in the change history and the PO change order will not increase until approved. If not auto assigned then the change order will be referenced to what ever change order user enters. |

| Allow Partial Schedule without a question |

Default is un-checked. If un-checked user will receive the popup warning them that they have not scheduled all the order qty and ask if they want to finish scheduling the order qty, upon saving a PO with only a partial schedule. If the box is checked the system will not ask any questions when saving a po with only partial schedule. |

| Print Labels upon PO Receipts in BC |

Default is un-checked. If checked it will default into the PO Bar Code Receiving Module and may be unchecked within the module if necessary. If checked the receiving label will be printed upon Receipt using the PO Bar Code Receiving module. |

| Print BOM Addendum for all "MAKE" parts on the Selected PO |

Default is unchecked. If checked it will default into the PO Reports /PO Form Report Options. If this option is checked when the users add a Make/Buy part to a Suppliers PO, and checks this option the system will then print a "BOM Indented with AVL" report as an addendum to the PO form. Each BOM will be printed as a separate report and will reference PO and item on the PO. If the AVL on the approve vendor list for any of the items on the BOM happens to be checked as "disallow to buy" this AVL will not be included within the addendum to the PO. |

When a non-inventory item is being purchased, the user must indicate the General Ledger MRO receiving numbers, if Accounting is used.

|