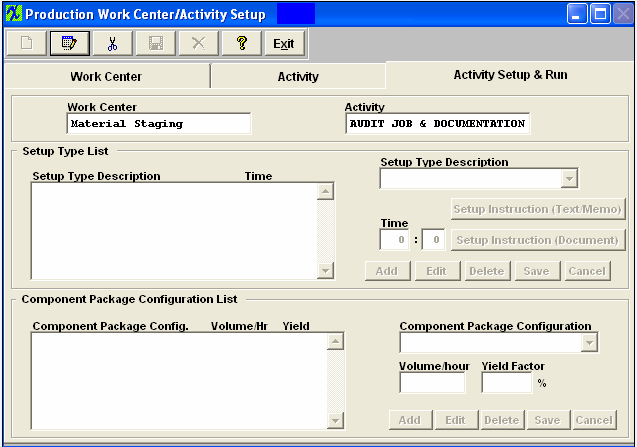

| Activity Setup & Run Tab | ||||||||||||

The information set up in this screen will be used in Capacity Planning & Dynamic Scheduling modules. Setup Type List The Setup Type description is input into a previous screen “Activity Costing & Setup Type Setup/Activity Setup Type Description”.

Component Package Configuration List The Component Package Configuration is set up in a prior screen. See Setup Package Configuration.

Note: In order to add Times in Routing, the Run and Setup Time MUST be selected in the Production Schedule Setup module.

Using Run and Setup Times in the Production Schedule Setup module is preferred when there is great variability in the products produced and the setup and run rates in each Work Center.

Using the Run and Setup Times in System Setup under this module, Work Center Setup, is preferred when the product flow is uniform, the machine rates are well established and the setup times very uniform regardless of product. Use of Run and Setup Times in the Production Schedule Setup module is optional unless either Job Costing or Capacity Planning Modules are in use. |