| 1. Quotation & Estimating |

| 1.1. Prerequisties |

ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. This module allows the user to create a new assembly number for a proposed or current customer, and identify each of the parts used in the assembly. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com\contactus.aspx

After activation, "Sales Quotation & Estimating" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

Customer

|

The Customer database must be established for current and prospective customers in the Customer Information module. |

| Number System Setup |

If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will automatically assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, user will need to manually assign a part number and revision to the item added in the material 2 screen. ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers |

| Class & Type |

The Inventory Class and Type must be setup in the Inventory Part Class Setup module. |

| Part Number in Item Master |

The part number must exist for the components for existing inventory in the Inventory Control module. |

| Supplier |

The current or prospective Supplier must be setup in the Supplier Information module.

|

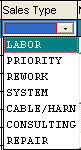

| Sales Types & Sales Price Itemization |

The Sales Type & Sales Price Itemization must be setup in Sales Type & Price Itemization module. |

| Supplier Line Card Info |

The Supplier Line Card Information must be setup in the Supplier Line Card Information module.

|

| Part Manufacturer Setup |

The Part Manufacturer must be setup in the Part Manufuacturer Setup module.

|

| Tools |

The Tools descriptions must be setup in the Tools Setup module. |

| Customer Quote |

The Customer Quote defaults must be setup in the Quote Defaults module.

|

| Quote Setup |

The approvals required must be set up in the Quote Setup module.

|

|

| 1.2. Introduction | The Customer Quotation Module is used to estimate the cost of new assemblies so that the user may respond to RFQs they receive from their customers. The module allows the user to create a new assembly number for a proposed or current customer, and identify each of the parts used in the assembly. Existing BOM’s may be copied and then edited or a quote already created may be copied and edited or the user may just start from scratch. Parts which already exist in the user’s database (already entered in the Inventory Control module) may be entered by part number. The user has the option to auto or manual number new inventory parts created in the Material 2 screen. (If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will automatically assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, user will need to manually assign a part number and revision to the item added in the material 2 screen. ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers.

The user has the option of using the standard cost, the weighted average cost, or a manually entered cost for existing parts. New parts (not already in inventory) may be added to the quote. The user may elect up to seven quantity pricings. The user defines the markups to be used for each of four categories: Material, Labor, Non-recurring expenditure and Miscellaneous. The user completes the information for the materials and labor required, non-recurring expenditure charges and miscellaneous charges. When the user has completed all of the data, a roll-up of all of the costs is calculated for each quantity pricing. Then, the program will compile the requirements and reports are generated to mail, fax or email to proposed suppliers for quotation. Upon receipt of the supplier’s response, the user may then identify which suppliers (and prices) are to be used for the final customer quotation and can update the quote for this information.

Once the quotation has become a real product, the user, with the appropriate approval, may transfer Standard Cost, Labor and Serial Number information into the appropriate Inventory record.

The Component Quote Management module may also be used as a stand alone RFQ for a request for quote from the user to their supplier.

|

| 1.3. Fields & Definitions |

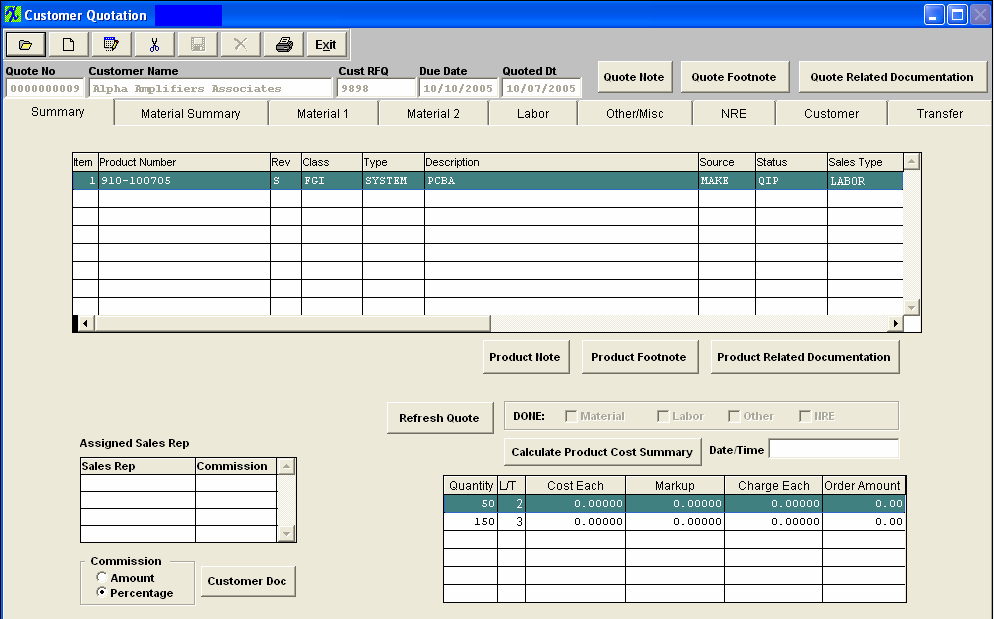

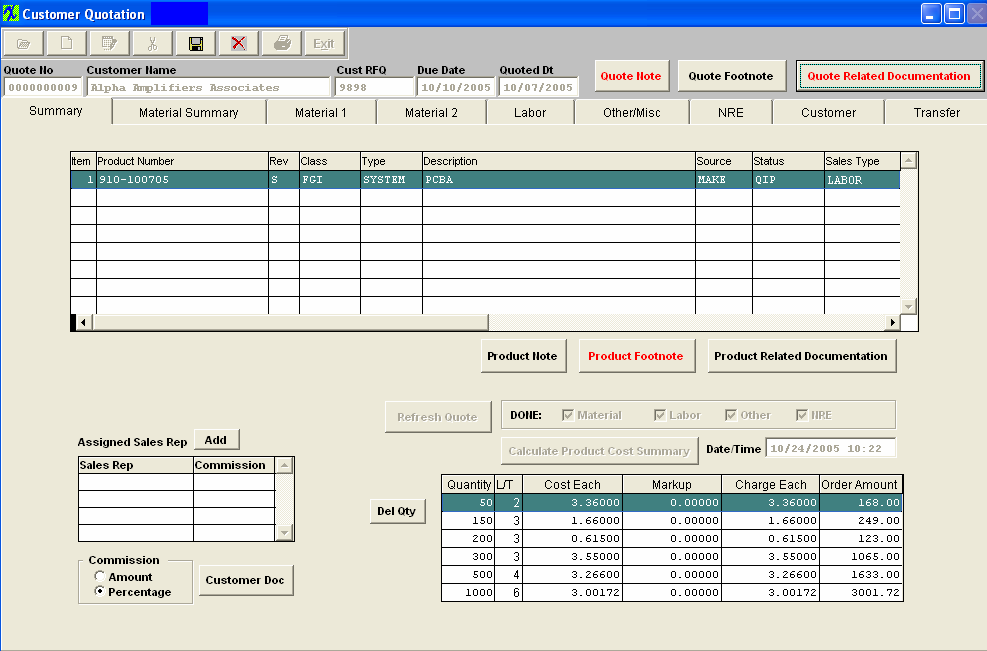

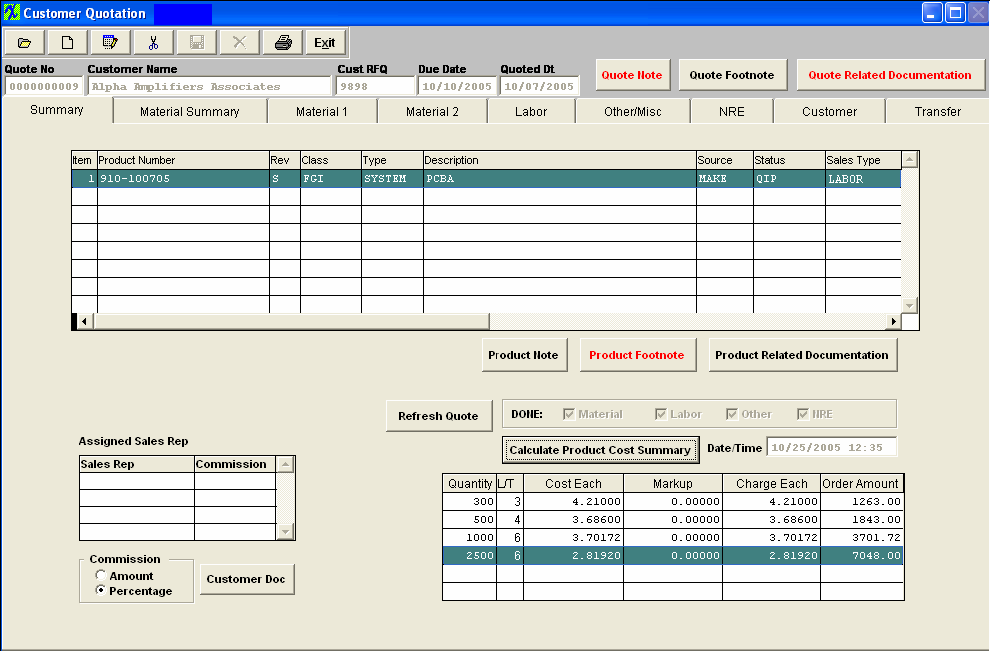

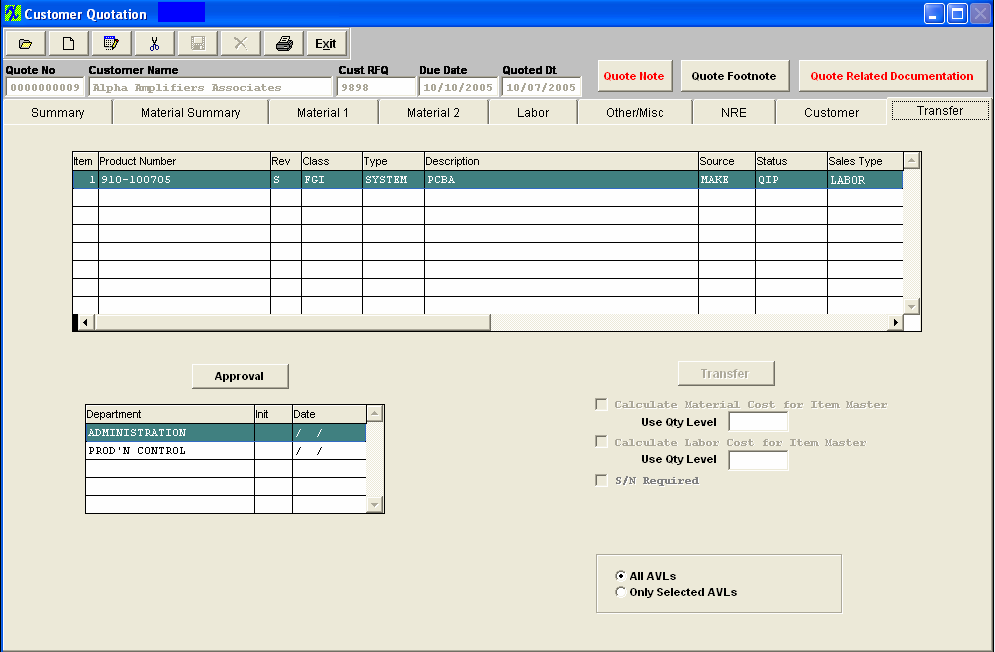

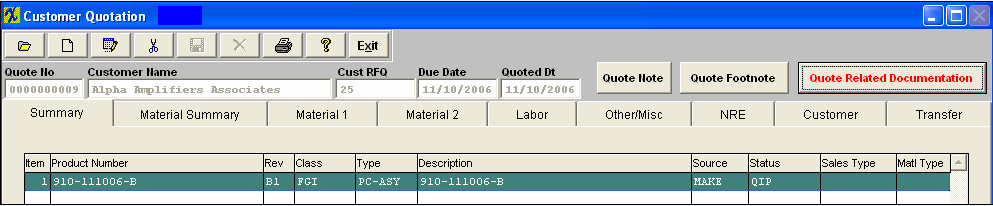

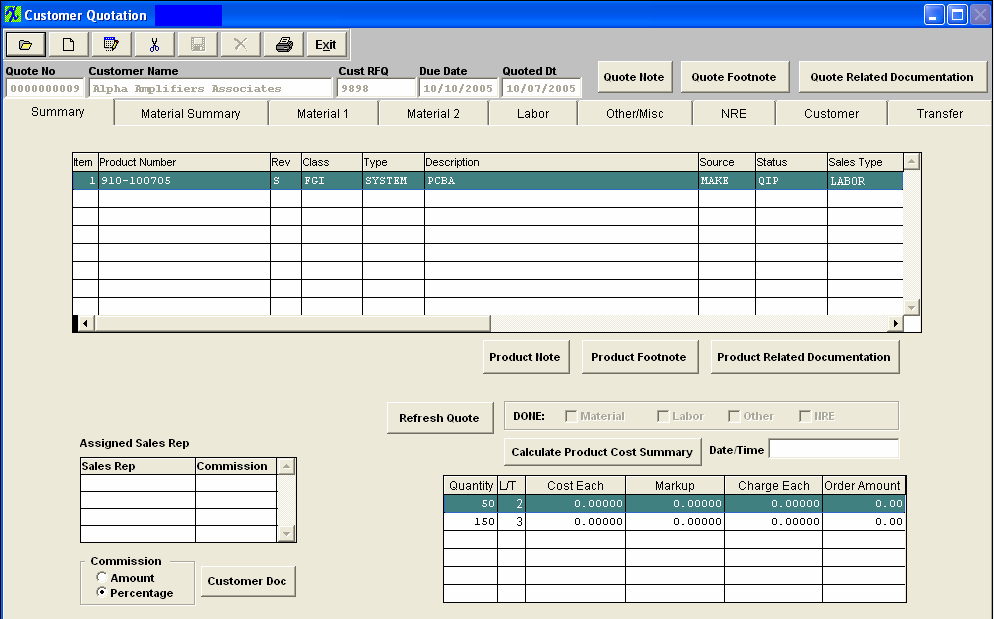

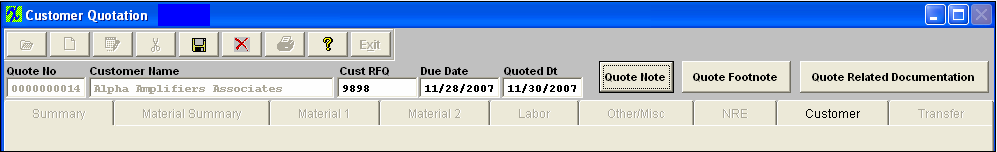

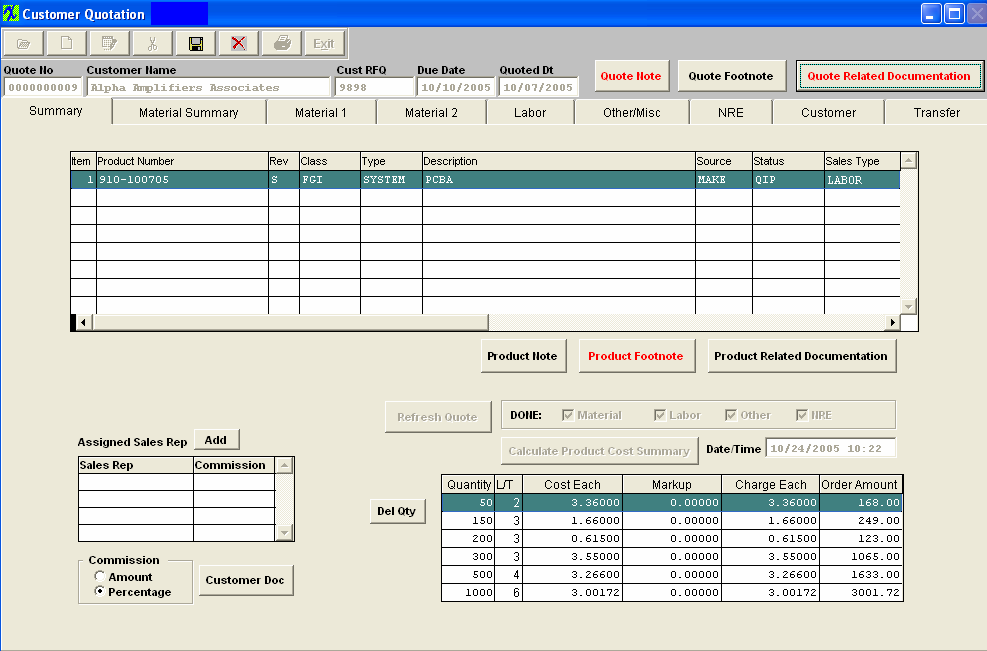

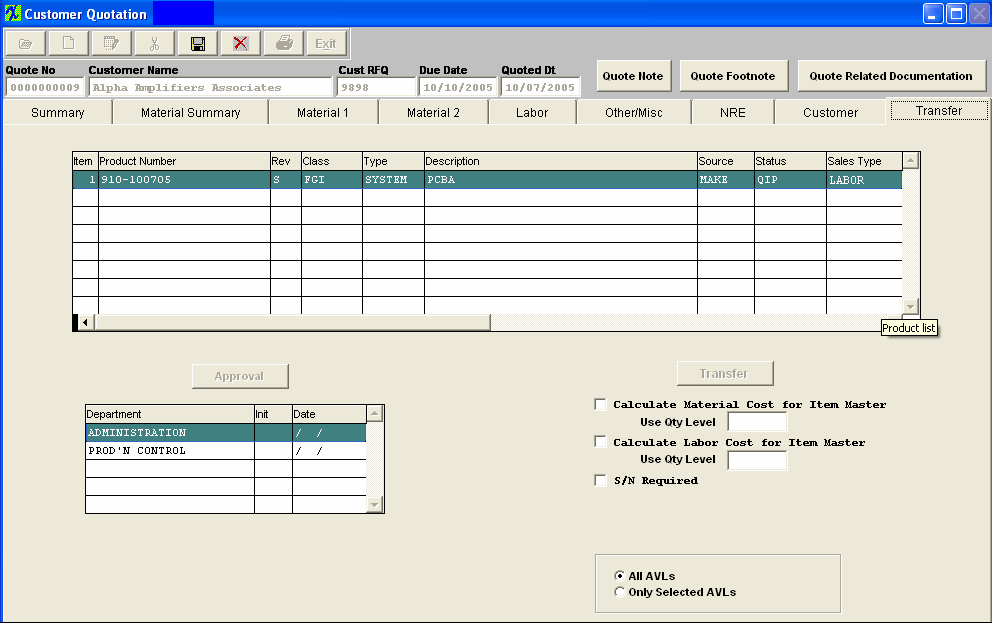

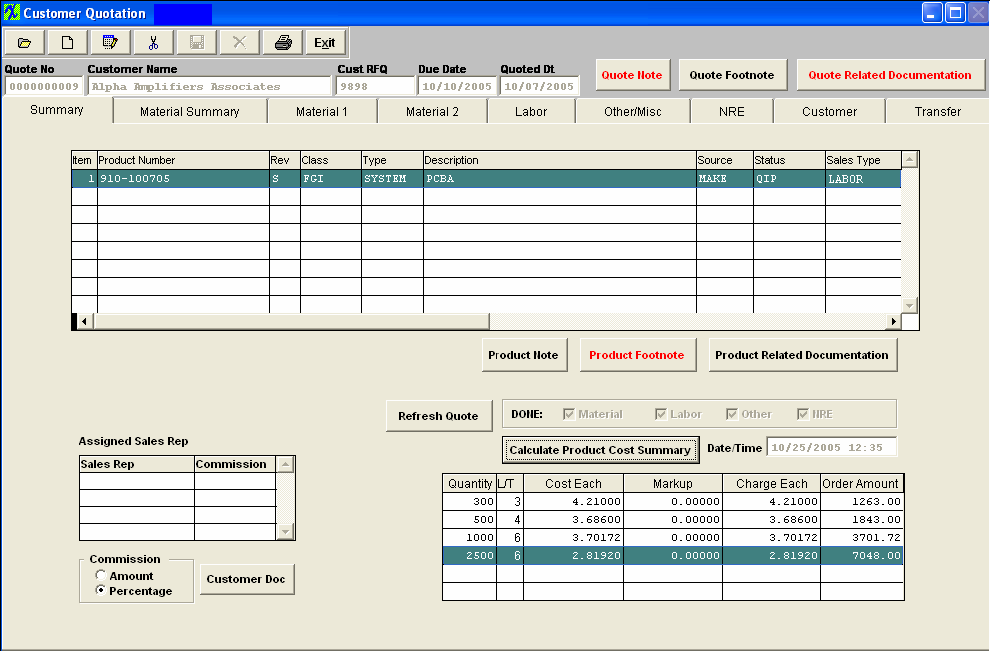

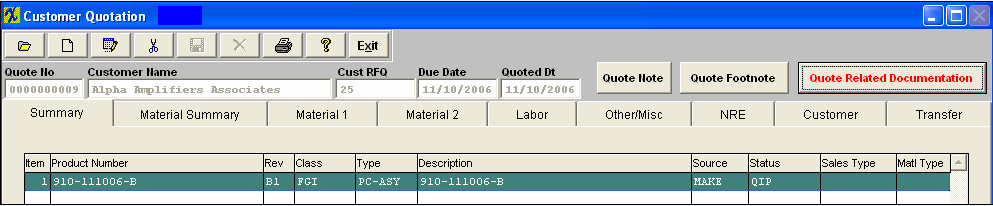

| 1.3.1. Summary Tab | The summary tab contains all of the summary information pertaining to the quote. For each product number, quantity, cost, markup, charge to customer and order amount are displayed in summary fashion.

Summary tab field definitions

| Quote Number |

The number the system has assigned to the quotation (if auto numbeirng is setup). (If manual numbering is setup user must assign the number). This number can not be changed after the quote has been created. |

| Customer Name |

The name of the customer for which this quote was prepared. |

| Customer RFQ |

The number the customer assigned to the request for quote. |

| Due Date |

The date by which the quote is due to the customer. |

| Quoted Date |

The date the quote was actually sent to the customer.

|

|

Depress this button to enter any notes that pertain specifically to this quote. This button will be displayed in RED when notes exist pertaining to this quote. |

|

Depress this button to enter any footnotes that pertain specifically to this quote. This button will be displayed in RED when footnotes exist pertaining to this quote. |

|

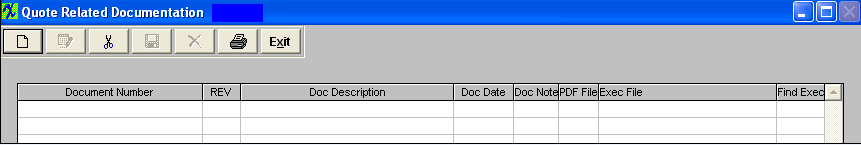

Depressing this button will give the users the ability to scan any related documents directly into the ManEx system and attached the document directly to the quote in the Customer Quotation module. For further detail see Article #2396. This button will be displayed in RED when Related documents are attached. |

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product.

|

| Rev |

The revision number assigned to the product.

|

| Class |

The classification of the product. |

| Type |

The type within the classification pertaining to this product |

| Description |

The description of the product.

|

| Source |

The source of the product, either Make or Phantom. MAKE is for an item made in-house (assemblies and sub-assemblies) and PHANTOM is for a number used to define a collection of items that does not exist as a separate assembly built on a Work Order (ship kits, upgrade packages, spares kits, etc.). |

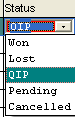

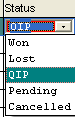

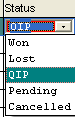

STATUS

This is for the status of the highlighed line item.

|

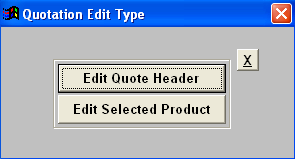

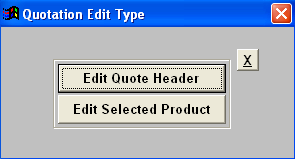

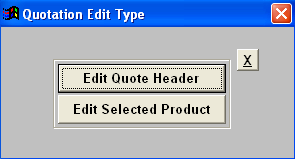

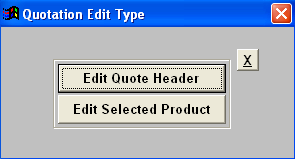

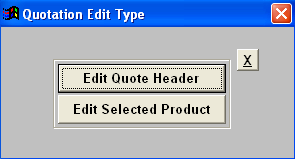

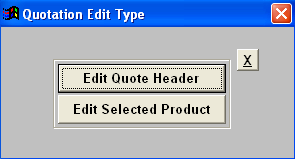

To change Quote Status, while in the Summary tab, depress the Edit button.

Type in the password. The following selection will appear:

Depress "Edit Selected Product".

Type in your password.

|

|

|

Highlight the Status section and select the appropriate new status from the drop down list.

Depress the Save button.

|

|

|

Depress this button to add or edit notes pertaining to this specific product, the notes added will be carried over into the Inventory Control module, when the quote is transfered and the Product number is created on the Inventory Control module. If an existing product number is entered and there are existing notes for this specific product within the Inventory Control Module, they will be defaulted in. This button will be displayed in RED when notes exist for the product. Depress this button to view any notes pertaining to this product. |

|

Depress this button to add or edit footnotes pertaining to this specific product. This button will be displayed in RED when footnotes exist for the product. Depress this button to view any notes pertaining to this product |

|

Depress this button to load a Product Related Document. For further detail see Article #2396. If this button is displayed in RED there is a Product Related Document attached. |

|

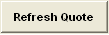

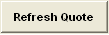

Depress this button to refresh pricing, due date, Last PO Dates, standard cost and customer part numbers. This way if the customer part number is added or the standard cost is changed mid quote, they can update the quote with that info. The system will calculate the longest leadtime from selected mfgr and selected supplier to update product leadtime. |

|

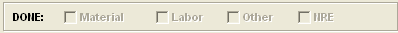

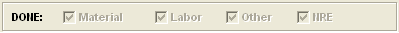

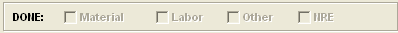

If these boxes are checked, it denotes that the information has been forwarded from the required summary tabs.

|

|

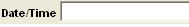

This button will cause the module to update the summary of the product costs, and update the Date/Time field. The Cost Each, Markup, Charge Each and Order Amount will automatically update.

|

|

This is the date and time (24 hour clock) of the creation of the Product Cost Summary. This field is only updated when user clicks the "Calculate Product Cost Summary" button. |

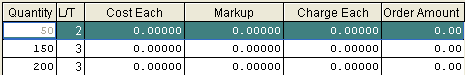

For the Item Number highlighted:

| Quantity |

This column displays the quantity pertaining to the Product Cost Summary.

|

| L/T |

This column displays the lead time pertaining to the Product Cost Summary. |

| Cost Each |

This column displays the cost each for the quantity listed on the left.

|

| Markup |

This column displays the markup in dollars and cents for the quantity listed.

|

| Charge Each |

This is the total of the cost each plus the markup |

| Order Amount |

This is the total of the quantity multiplied by the charge each.

|

| Sales Representative |

For the product highlighted, the Sales Representative selected and the applicable commission expressed either in percentage or dollar amounts per the radials.

|

|

Depress this button to load a Customer Document. For further detail see Article #2823 If this button is displayed in RED there is Customer documents attached. |

|

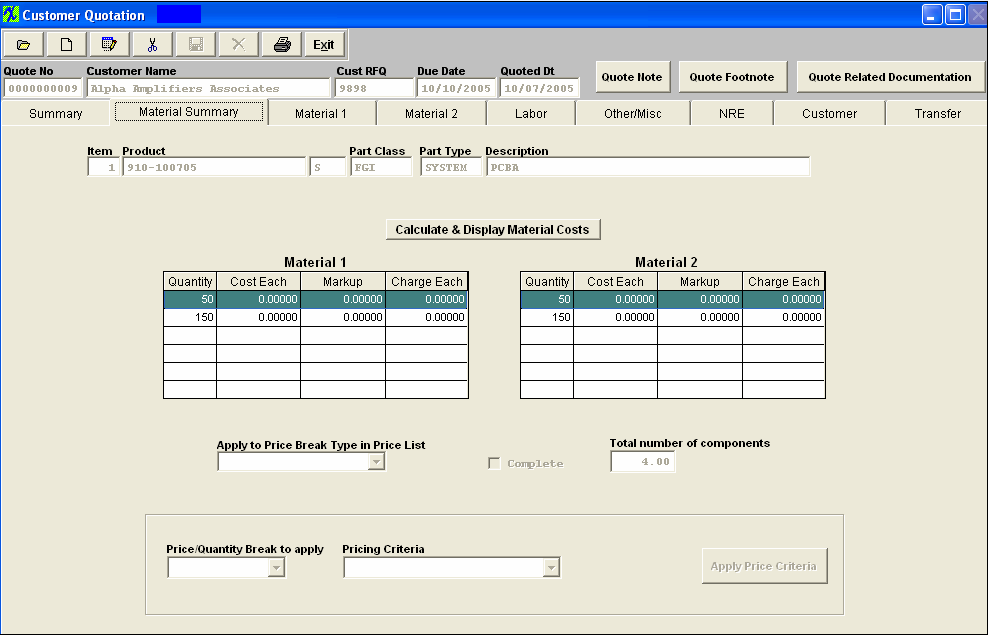

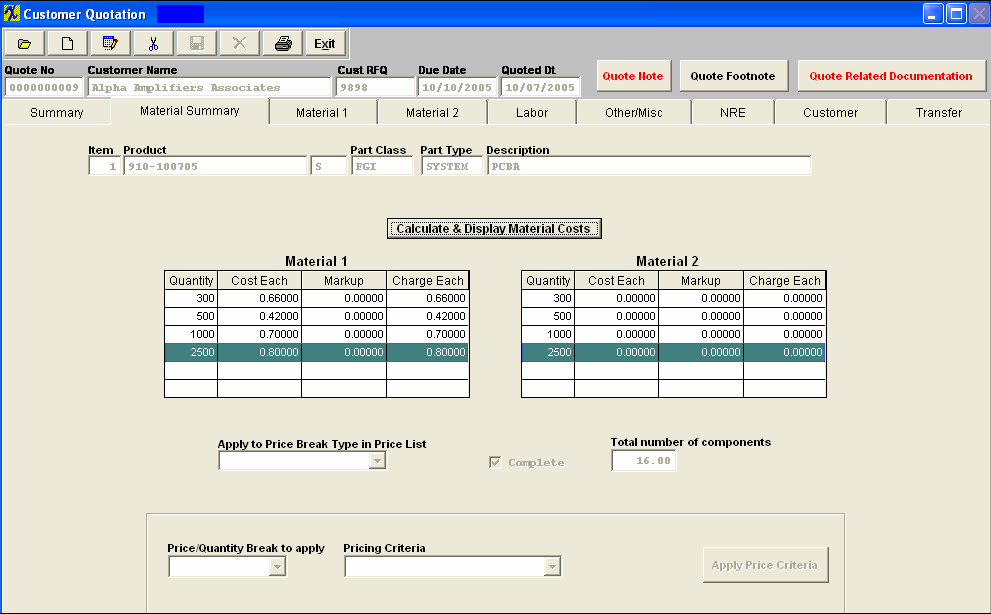

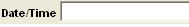

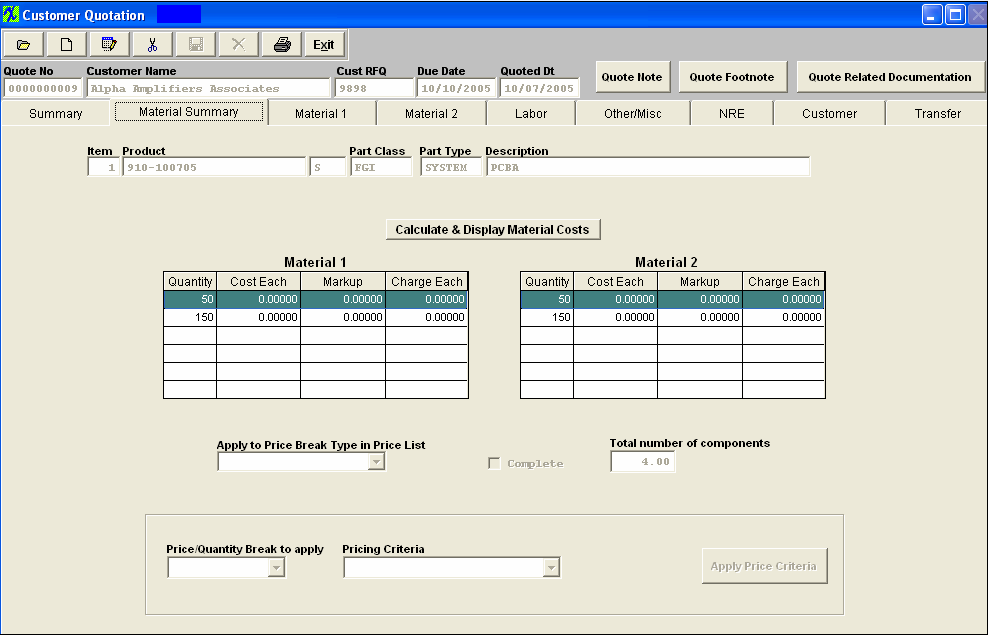

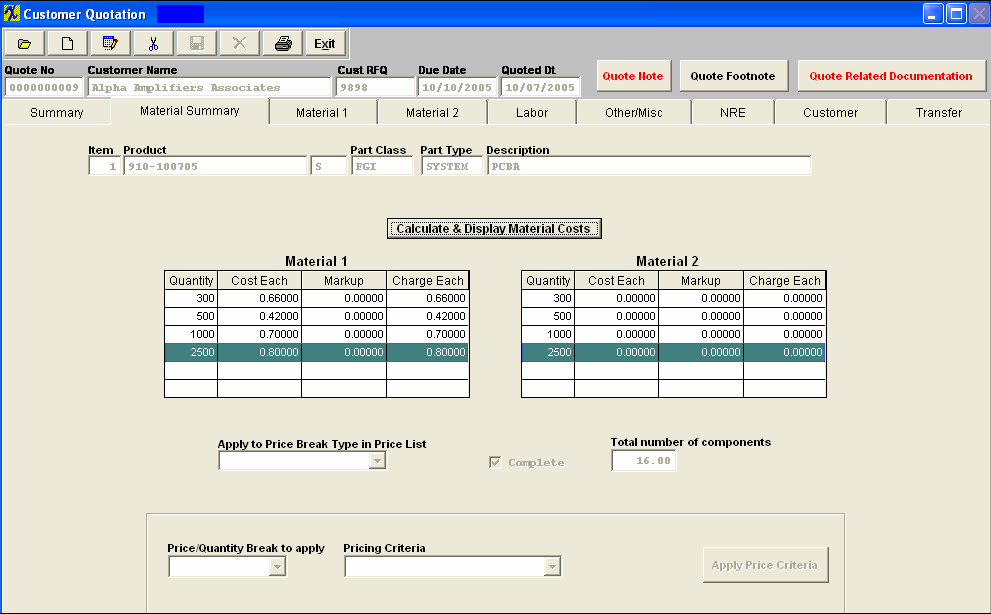

| 1.3.2. Material Summary Tab | The material summary tab displays the quantity, cost each, markup and charge forwarding from both Material 1 tab and Material 2 tabs and displays the quantity pricings. This information will be forwarded into the summary tab.

Material Summary tab field definitions

| Item |

The line number. |

| Product Number |

The unique number assigned to the product.

|

| Rev |

The revision number assigned to the product.

|

| Class |

The classification of the product. |

| Type |

The type within the classification pertaining to this product.

|

| Description |

The description of the product.

|

|

The Markup and Charge Each will automatically update for items included in the Inventory Master for the Material 1 tab and any manually added costs in the Material 2 tab once this button is depressed. |

For both the Material 1 and 2 sections:

| Quantity |

This column displays the quantity pertaining to the Product Cost Summary.

|

| Cost Each |

This column displays the cost each for the quantity listed on the left.

|

| Markup |

This column display the markup in dollars and cents for the quantity listed.

|

| Charge Each |

This is the total of the cost each plus the markup.

|

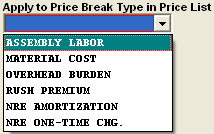

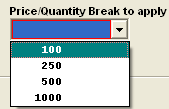

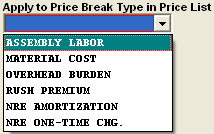

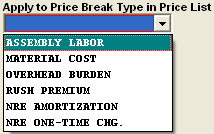

Apply to Price Break Type in Price List

| Complete |

A check in this box denotes that this screen has been completed and is available to forward into the Summary tab. |

| Total Number of Components |

This field calculates the total number of components being used for each product. |

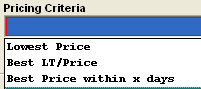

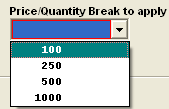

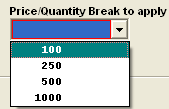

| Price/Quantity Break to apply |

This would be used to either select the price break you expect the customer to buy or the price break that you would like to build. This field works together with the Apply Pricing Criteria field.

|

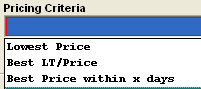

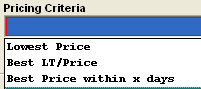

| Pricing Criteria - This field is to allow the users to select which calculation they wish for the system to do. |

|

| Apply Pricing Criteria |

Depress this button once you have made your selection and the system will calculate based on the selection made. |

|

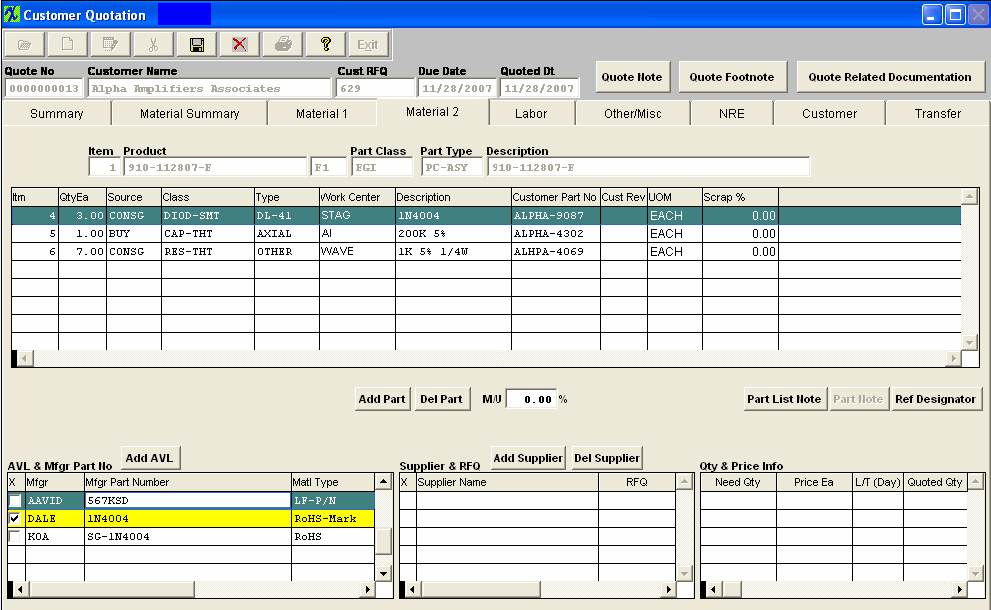

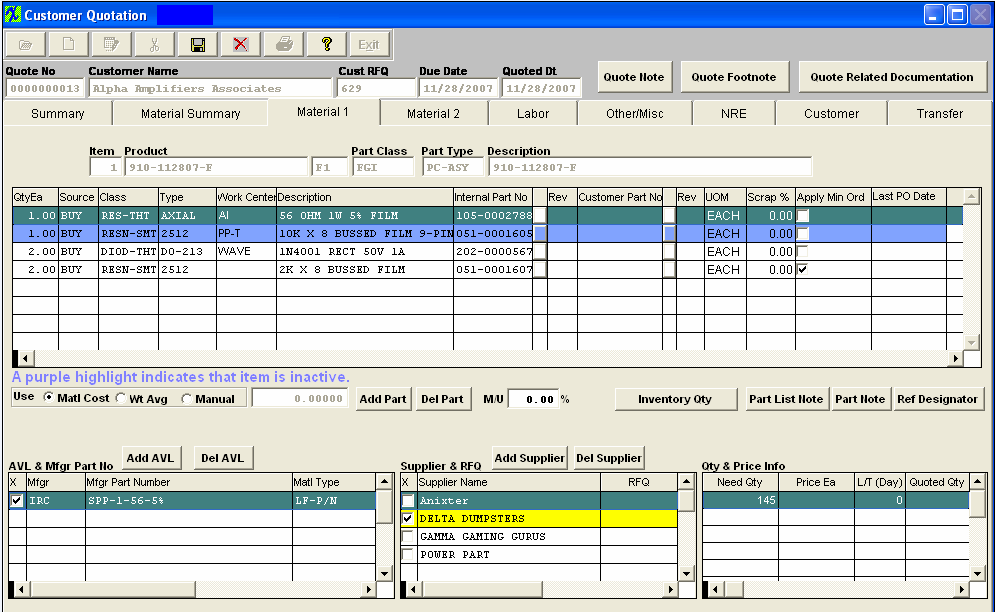

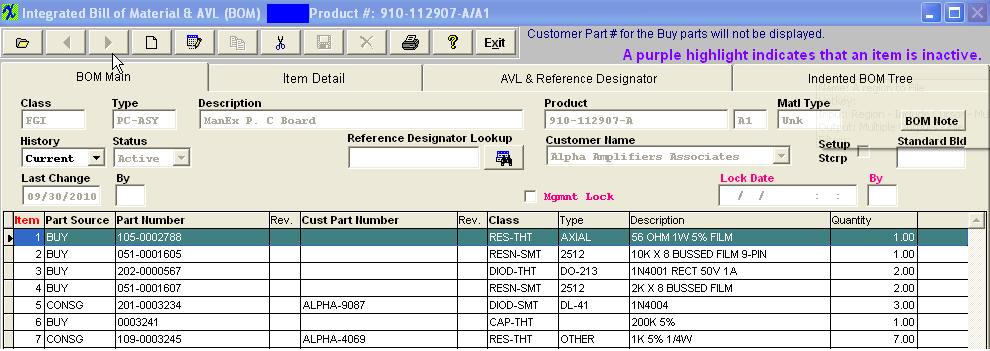

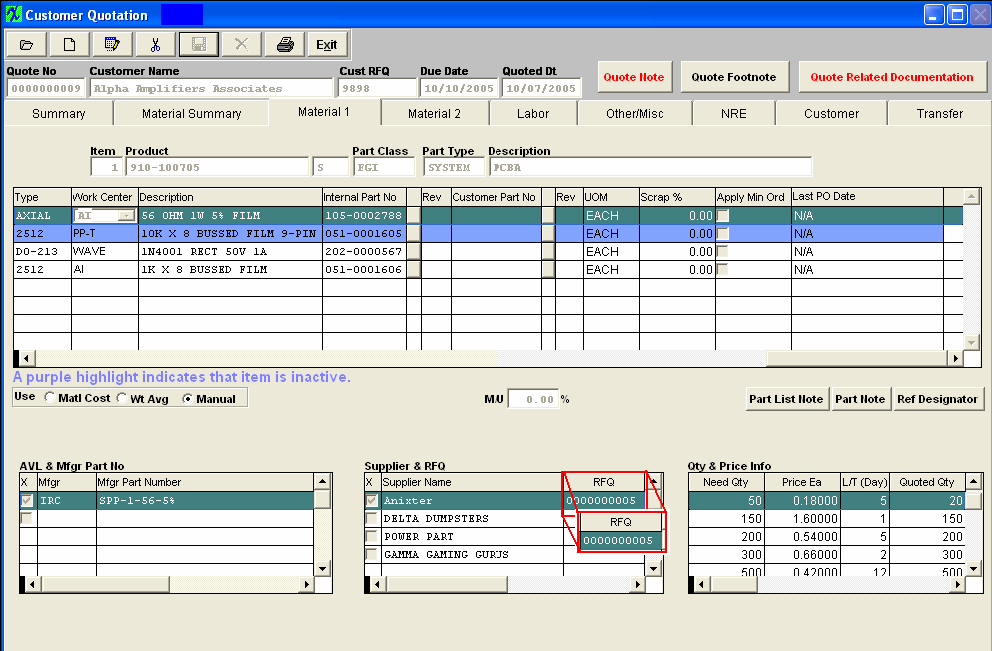

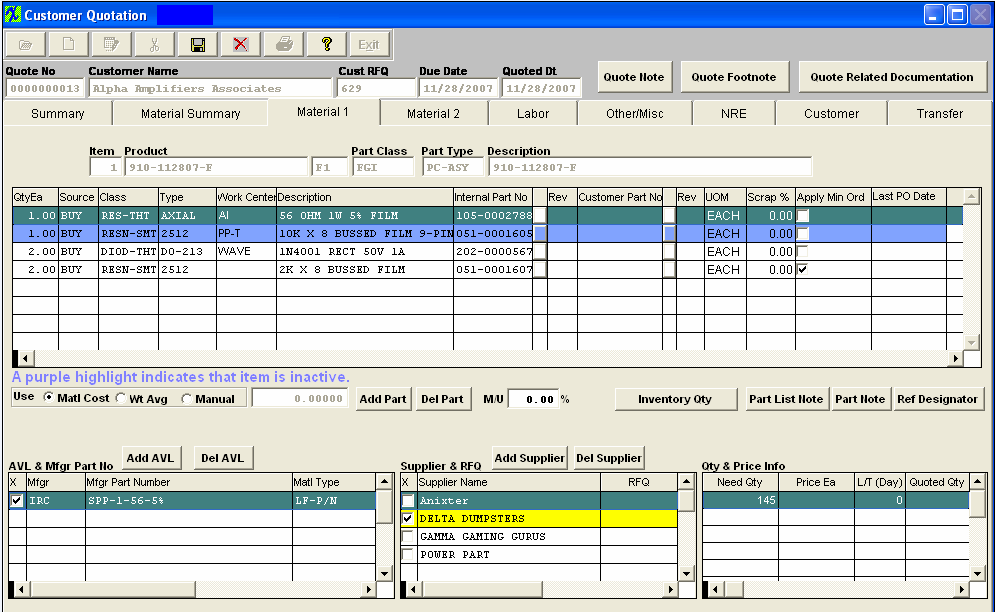

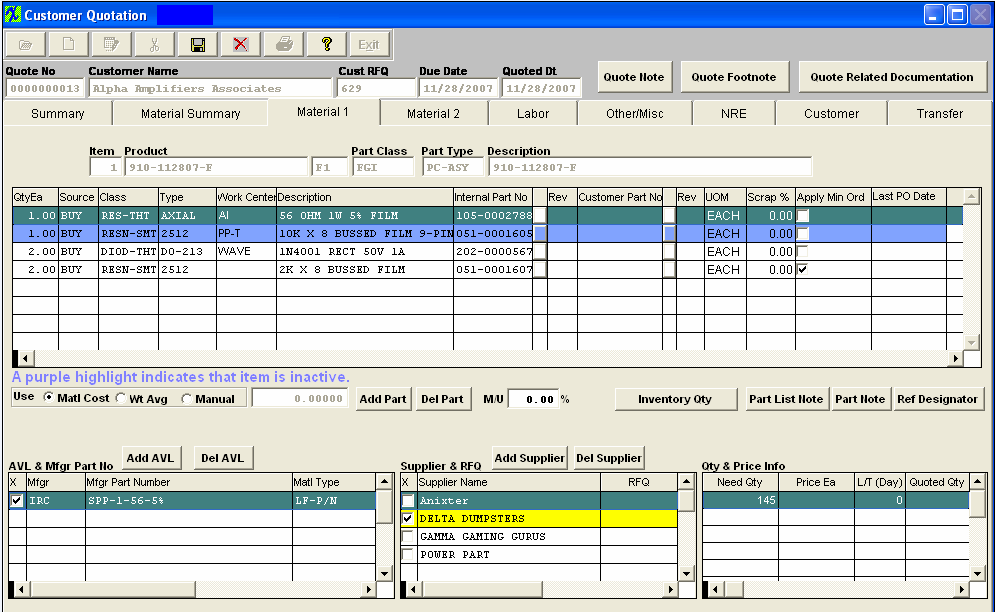

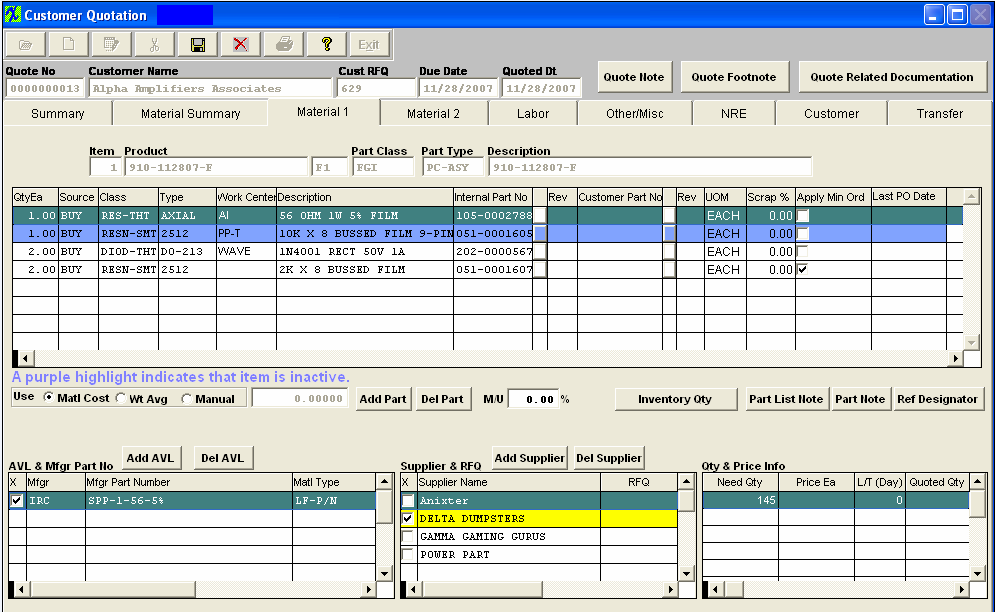

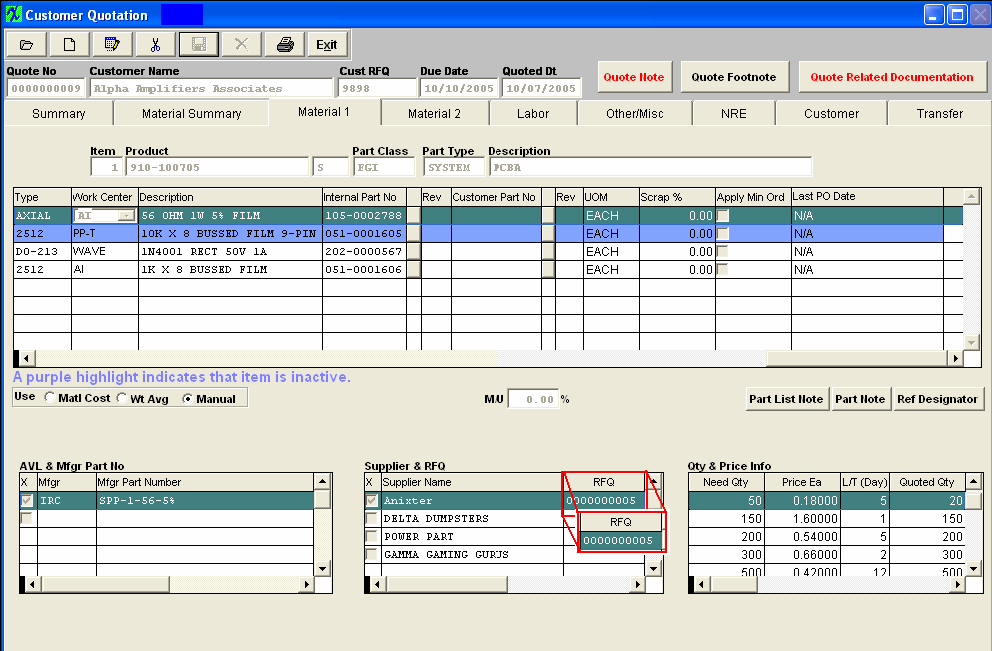

| 1.3.3. Material 1 Tab | The material 1 tab displays the details of components which are currently identified in the Inventory Control Item Master . For each line item, the quantity, source, class, type, description, internal part number, revision number, customer part number, customer revision number, unit of measure, scrap %, whether or not the minimum order is to be applied, and Last PO Date is displayed. Additionally, the costing method is displayed together with the approved manufacturer and the manufacturers part number. It also displays the supplier for that component and the request for quote number as assigned in the Component Quote Management module. The need quantity, price each, lead time, quoted quantity, order multiple, minimum order the price source are also displayed. This information forwards into the Material summary tab. The purple highlighed item indicates that the item is inactive.

Material 1 tab field definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product |

| (Rev) |

The revision number assigned to the product |

| Class |

The classification of the product.

|

| Type |

The type within the classification pertaining to this product |

| Description |

The description of the product.

|

| Internal Part Number |

This is the number the user has assigned to the component. |

| Rev |

This is the revision number pertaining to the internal part number.

|

| Customer Part No |

This is the number which the customer has assigned to the component.

|

| Rev |

This is the revision number which pertains to the Customer Part number.

|

| UOM |

The unit of measure which is used for this component.

|

| Scrap % |

This amount is added to the exact quantity used on an assembly to provide an overage to cover losses during running due to predictable machine and human losses. If the part number already has scrap entered in ICM, the system will use this default. If no scrap has been entered within Inventory, the system will then use the scrap that has been entered within the Quote screen.

|

| Apply Min Ord |

This is smallest number of the item that can be ordered from the vendor in one PO.For instance, Surface Mount components on a reel usually have a minimum order of 1000 items or more.

|

| Last PO Date |

Displays the date of the last PO placed for this component. This field will only populate if the "Refresh Quote" button is depressed which is located on the Summary Tab. |

|

The radials, Matl Cost, Wt Avg and Manual pertain to the type of cost pertaining to the component.The field denotes the dollar amount. Material Cost is per the Inventory Master. Weighted Average is the weighted average of the last five Purchase Orders processed for that part number. (Please refer to the Inventory Control Management manual.) Manual cost is per the user. |

|

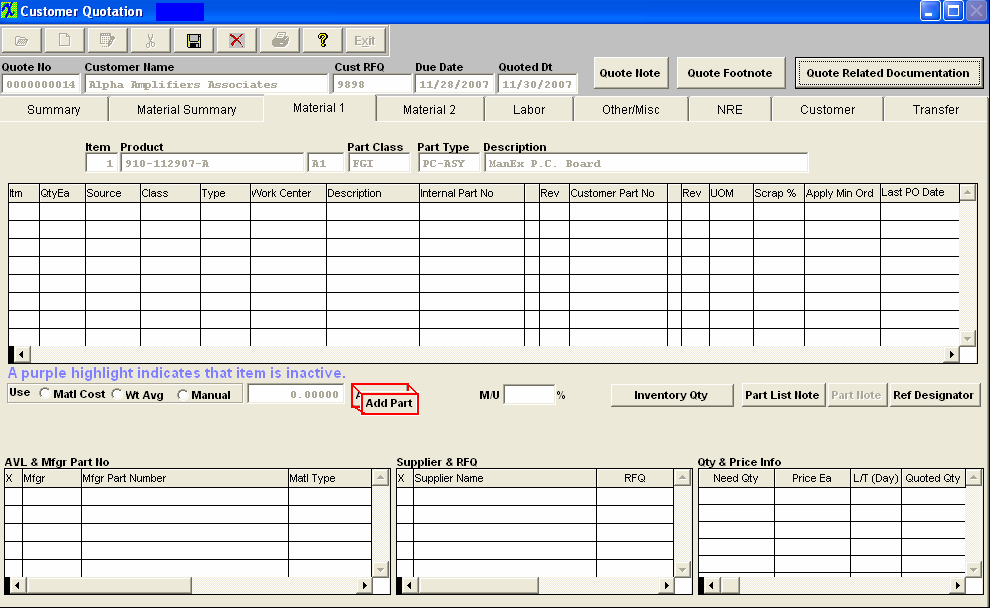

This button is used to add an item to the list of components needed for the assembly.

|

|

This button is used to delete an item from the list of components needed for the assembly.

|

|

This field displays the mark up percentage which the user will be charging their customer. |

|

This button will be displayed in RED when notes exist pertaining to the list of parts. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when notes exist pertaining to the highlighted part. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when reference designators for the highlighted part exist. Depressing this button will allow the user to view these reference designators.

|

|

AVL stands for (Approved Vendor List).This button is used to add an approved manufacturer.

|

|

This button is used to delete an approved manufacturer. |

|

This button is used to add a supplier.

|

|

This button is used to delete a supplier. |

For the Line Item highlighted:

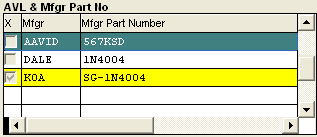

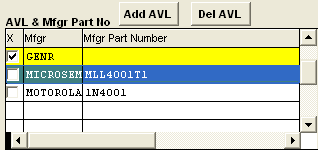

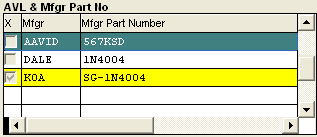

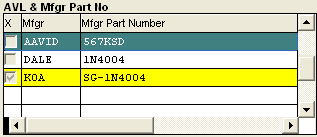

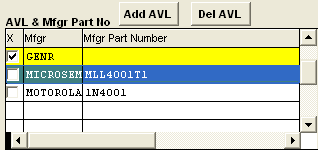

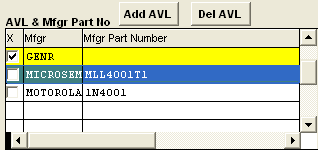

AVL & Mfgr Part No section

|

When you add a part to the material 1 screen from inventory, if the customer on the quote is linked to that internal part number the AVL’s will be pulled from the consigned side, if that customer is NOT linked to that internal part number then the AVL’s will be pulled from the internal side. System WILL allow users to enter NEW mfgr's part numbers, but NOT new mfgr's. The mfgr's from inventory will be the ONLY ones listed on the pull down to select from.

X - A check in this box is NOT for the approval of AVL's on BOM. This box is used when transfering quote to inventory and/or BOM. There is an option located on the "Transfer Tab" to select to transfer "ALL AVL's" or "Only the selected AVL's". If the user chooses to transfer "Only theSelected AVL's", this box MUST be checked on the NEW mfgr part numbers added, then upon transfer the new mfgr part numbers will be transfered to inventory along with the existing mfgr and mfgr part numbers. If this box is NOT checked for the new mfgr part numbers added, when the quote is transfered and the option to add "Only theSelected AVL's" is marked, the new Mfgr part numbers will NOT be transfered to inventory and/or BOM. When a quote is transfered All AVL's transfered will be checked as Approved on the new BOM.

NOTE: When adding a new quote by "ADD Existing Product from Inventory to this Quote" only the AVL's marked as approved on the existing BOM will be transfered to quote.

If more than one manufacturer is displayed, highlight the manufacturer desired before selecting the Supplier name. The mfgr and mfgr part number selected will be highlighted in yellow.

Mfgr - This is the name of the manufacturer assigned to the component.

Mfgr Part Number - This is the number which the manufacturer has assigned to the component.

|

|

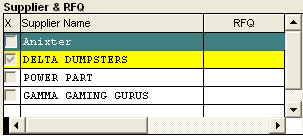

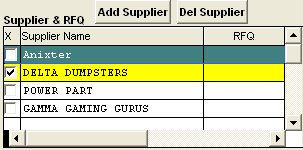

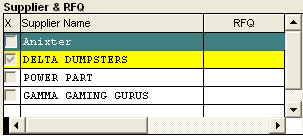

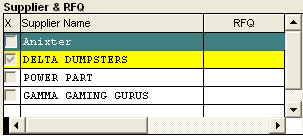

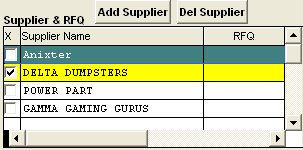

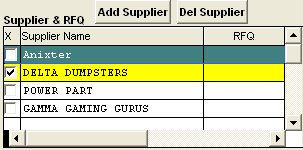

Supplier & RFQ section

|

X - A check in this box denotes that the supplier has been selected. The selected supplier will be highlighted in Yellow.

Supplier Name - The name of the supplier.

RFQ - This is the Request for Quotation number as assigned in the Component Quote Management portion of Customer Quotations.

|

|

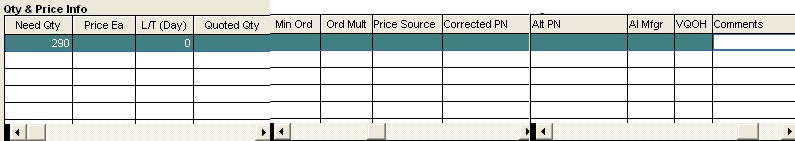

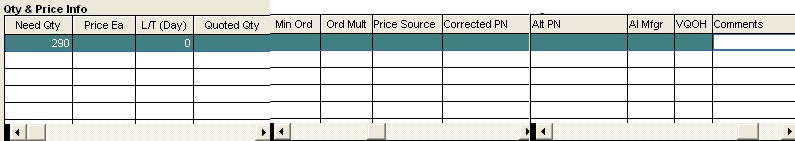

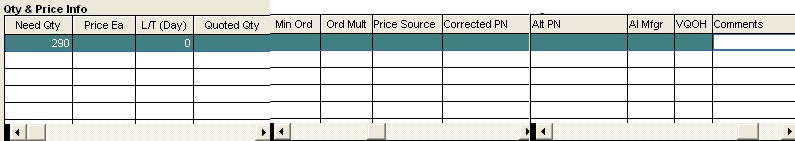

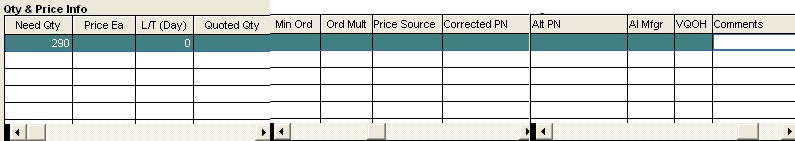

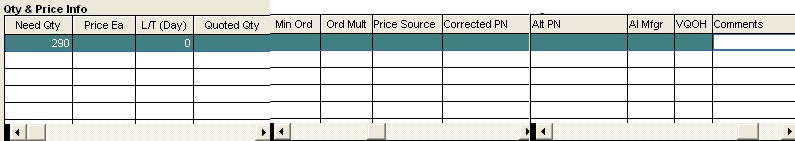

| Need Qty |

The amount required for the quantity represented. |

| Price Ea |

The dollar amount which the Supplier charges the user. |

| L/T (Day) |

The lead time will use inventory leadtime to calculate and will be displayed in the number of days between placement of the order and receipt. |

| Quoted Qty |

The number of units quoted by the supplier. |

| Min Ord |

The supplier requirement for the minimum quantity per order.

|

| Order Multiple |

This field defines the even multiples of the Unit of Measure in which an item must be purchased.For example, 16AWG Wire might be only available in even hundreds of feet on a spool. |

| Price Source |

The source of the pricing such as Manual, a Request for Quote, etc.

|

| Corrected PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Alt PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| AI Mfgr |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| VQOH |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Comments |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

|

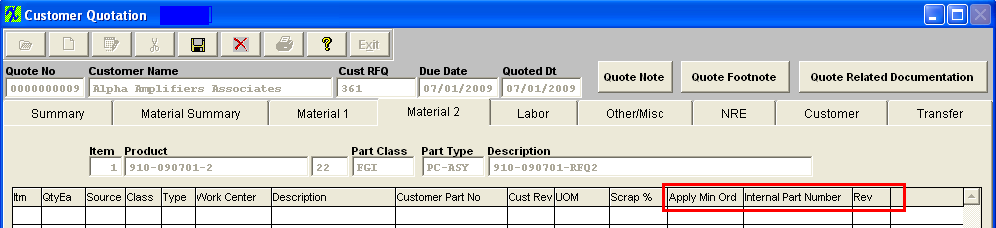

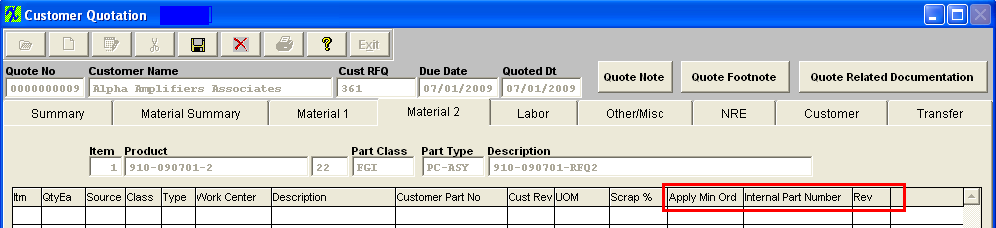

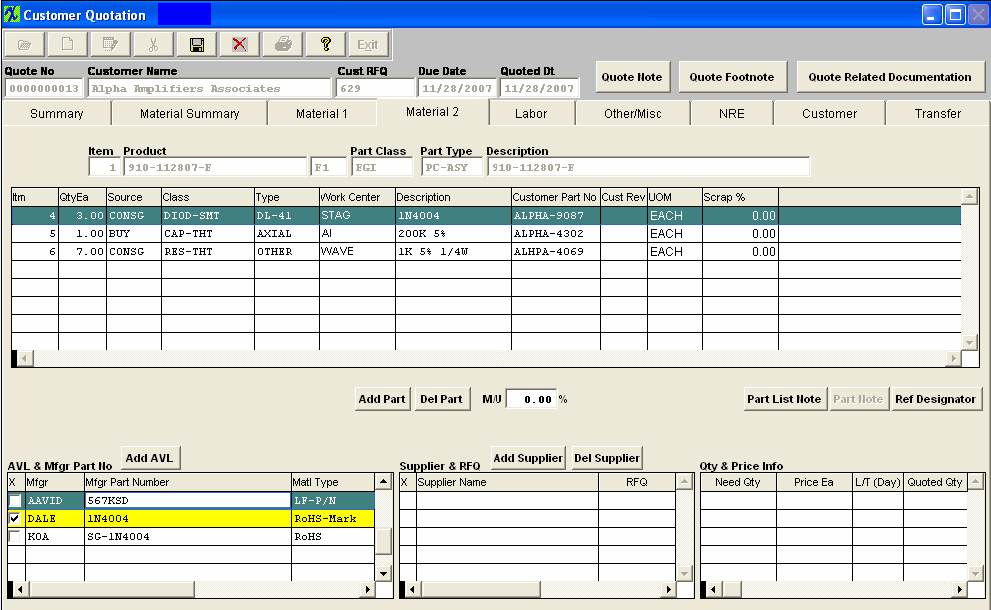

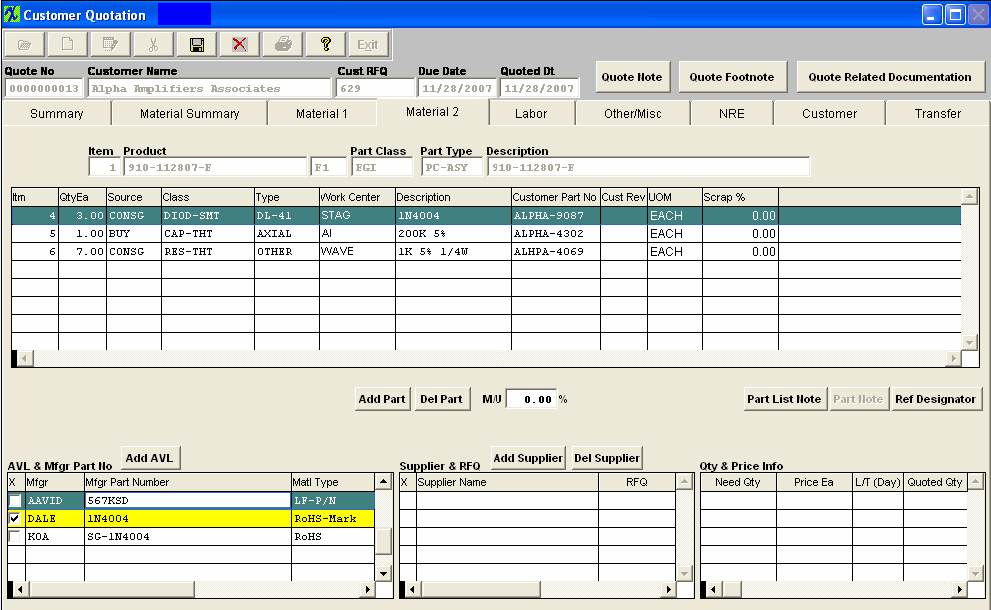

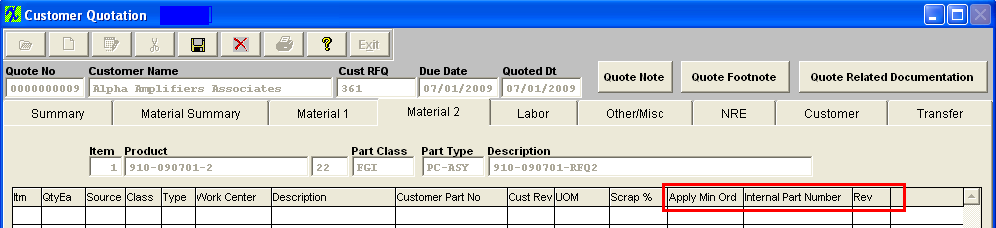

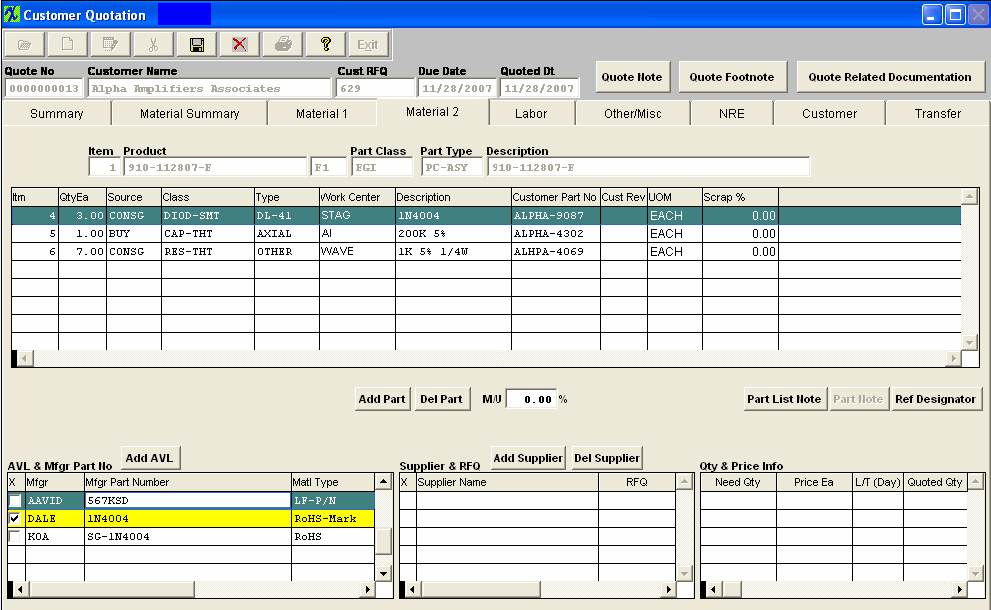

| 1.3.4. Material 2 Tab | |

The material 2 tab displays the details of components which are NOT identified in the Inventory Control Item Master. For each line item, the quantity, source, class, type, description, customer part number, customer revision number, unit of measure, and scrap % is displayed. Additionally displayed is the approved manufacturer and the manufacturer’s part number. It also displays the supplier for that component and the request for quote number as assigned in the Component Quote Management module. The need quantity, price each, lead time, quoted quantity, order multiple, minimum order and the price source are also displayed. This information forwards into the Material Summary tab. NOTE: When the parts from Material 2 screen are transferred from quote to BOM, inventory item master part numbers are created for each item. The system does NOT search the inventory item tables for an existing part number and will create new item master part numbers, even if the manufacturers and part numbers are the same.

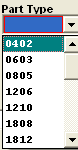

NOTE: If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, the Material 2 screen will display three additional fields shown below in Red box: ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers.

Material 2 tab field definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product |

| (Rev) |

The revision number assigned to the product.

|

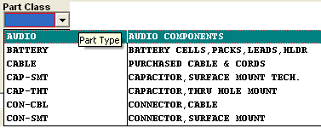

| Class |

The classification of the product.

|

| Type |

The type within the classification pertaining to this product |

| Description |

The description of the product.

|

| Customer Part No |

This is the number which the customer has assigned to the component.

|

| Rev |

This is the revision number which pertains to the Customer Part number.

|

| UOM |

The unit of measure which is used for this component.

|

| Scrap % |

This amount is added to the exact quantity used on an assembly to provide an overage to cover losses during running due to predictable machine and human losses.

|

| Apply Min Order |

This is smallest number of the item that can be ordered from the vendor in one PO.For instance, Surface Mount components on a reel usually have a minimum order of 1000 items or more. This field will only be enabled if the Number System is set to "Manual" for Inventory Parts.

|

| Internal Part Number |

Manually assign an internal part number to the item. This field will only be enabled if the Number System is set to "Manual" for Invventory Parts. |

| Rev |

Manually assign a revision to the item. This field will only be enabled if the Number System is set to "Manual" for Invventory Parts |

|

This button is used to add an item to the list of components needed for the assembly.

|

|

This button is used to delete an item from the list of components needed for the assembly.

|

|

This field displays the mark up percentage which the user will be charging their customer. |

|

This button will be displayed in RED when Part List Notes exist. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when notes exist pertaining to the highlighted part. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when reference designators exist pertaining to the highlighted part. Depressing this button will allow the user to view the reference designators.

|

|

AVL stands for (Approved Vendor List).This button is used to add an approved manufacturer.

|

|

This button is used to delete an approved manufacturer. |

|

This button is used to add a supplier.

|

|

This button is used to delete a supplier.

|

For the Line Item highlighted:

AVL & Mfgr Part No section

X -A check in this box is NOT for the approval of AVL's. When transfering quote there is an option located on the "Transfer Tab" to select to transfer "ALL AVL's" or "Only the selected AVL's". If user chooses to transfer "Only the Selected AVL's", this box MUST be checked, if this is one of the selected AVL's you want transfered to inventory and/or BOM. If user chooses to transfer All AVL's then this box does NOT need to be checked. When a quote is transfered All AVL's transfered will be checked as Approved.

Mfgr - This is the name of the manufacturer assigned to the component.

Mfgr Part Number - This is the number which the manufacturer has assigned to the component.

|

|

Supplier & RFQ section

|

X – a check in this box denotes that the supplier has been selected.

Supplier Name – The name of the supplier.

RFQ – This is the Request for Quotation number as assigned in the Component Quote Management portion of Customer Quotations.

|

|

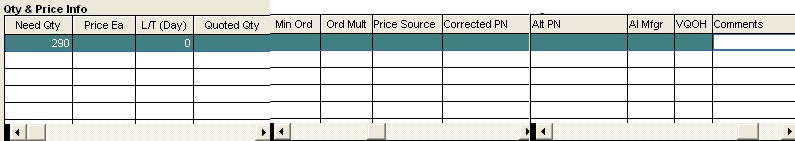

| Need Qty |

The amount required for the quantity represented. |

| Price Ea |

The dollar amount which the Supplier charges the user. |

| L/T |

The lead time will use part class/type setup default leadtime to calculate and is displayed in the number of days between placement of the order and receipt. |

| Quoted Qty |

The number of units quoted by the supplier. |

| Min Ord |

The supplier’s requirement for the minimum quantity per order.

|

| Order Multiple |

This field defines the even multiples of the Unit of Measure in which an item must be purchased.For example, 16AWG Wire might be only available in even hundreds of feet on a spool. |

| Price Source |

The source of the pricing such as Manual, a Request for Quote, etc.

|

| Corrected PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Alt PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| AI Mfgr |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| VQOH |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Comments |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

|

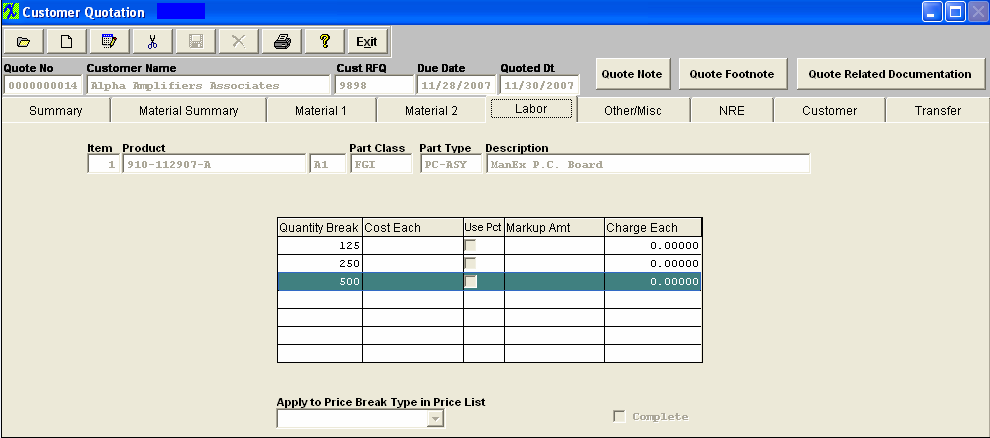

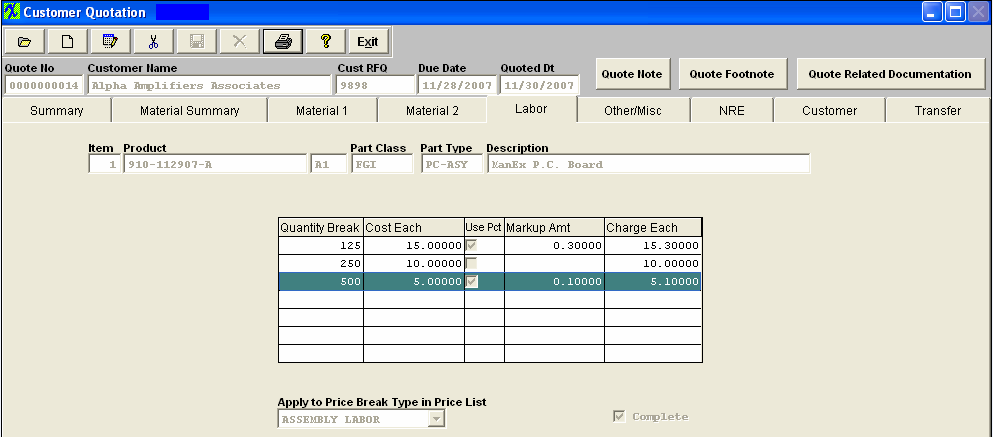

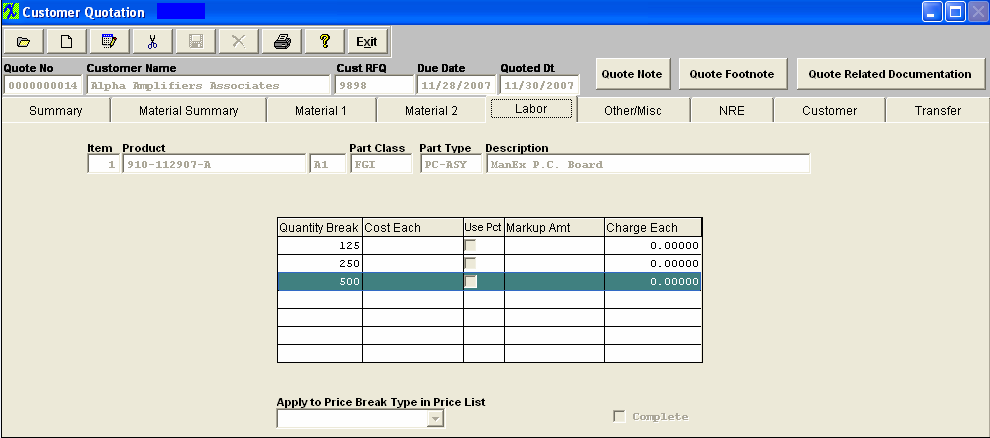

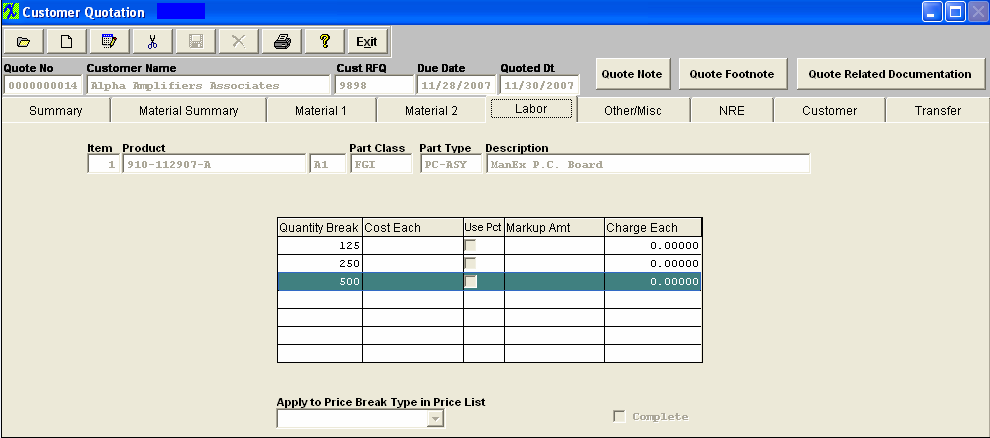

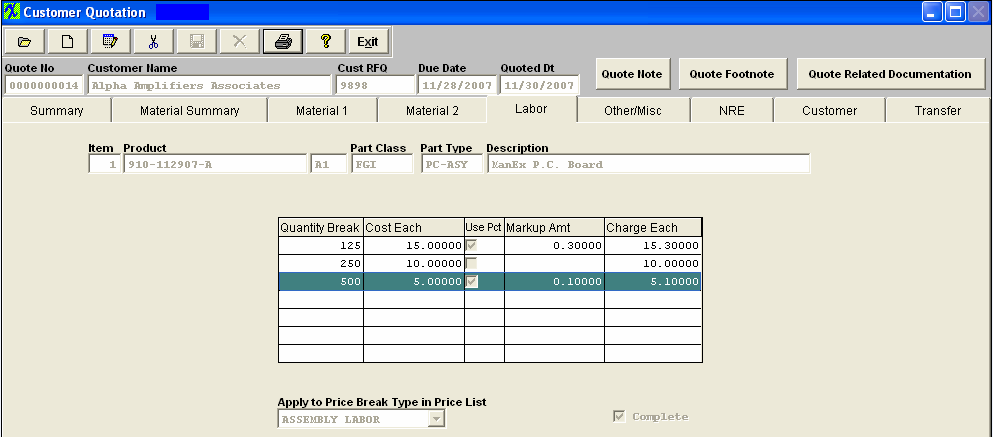

| 1.3.5. Labor Tab | The labor tab displays the labor costs for each, markup amount and charge for each for each quantity break.Also displayed is the quantity pricing.This information forwards into the Summary tab.

Labor tab field definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product.

|

| (Rev) |

The revision number assigned to the product.

|

| Class |

The classification of the product. |

| Type |

The type within the classification pertaining to this product.

|

| Description |

The description of the product.

|

| Quantity Break |

This column displays the quantity pertaining to the Product Cost Summary.

|

| Cost Each |

This column displays the labor cost each for the quantity listed on the left.

|

| Use Pct |

Check this column if the percentage is to be used.

|

| Markup |

This column displays the markup in dollars and cents for the quantity listed.

|

| Charge Each |

This is the total of the cost each plus the markup.

|

| Complete |

A check in this box denotes that this screen has been completed and is available to forward into the Summary tab.

|

|

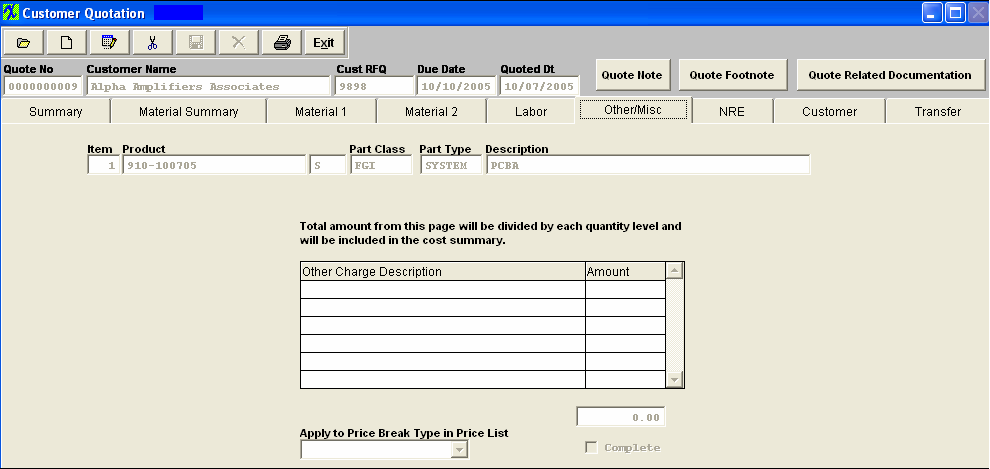

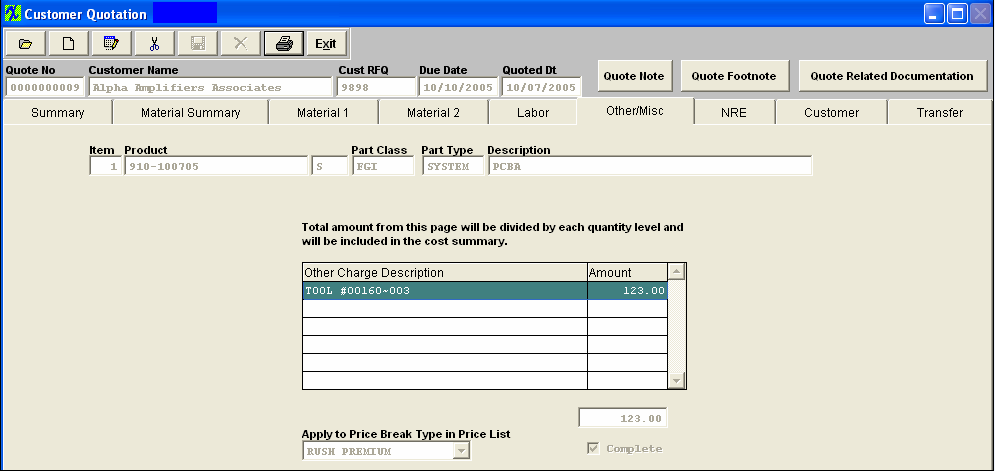

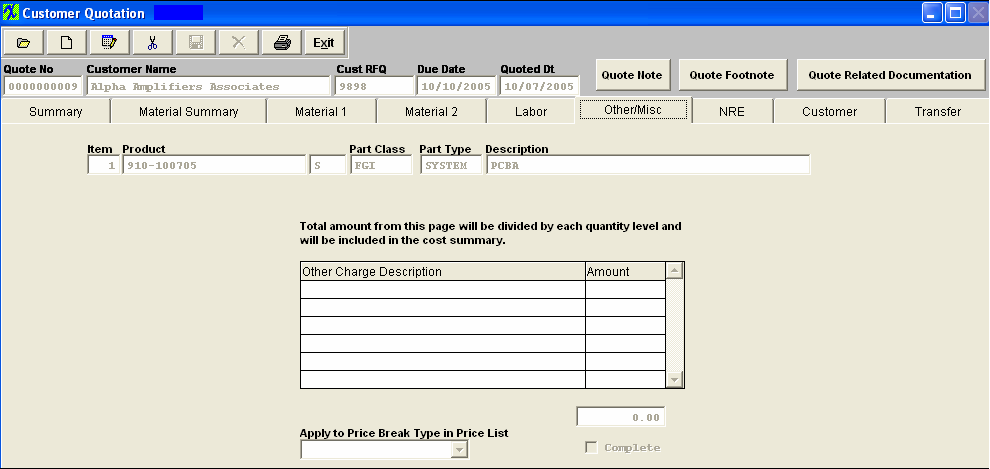

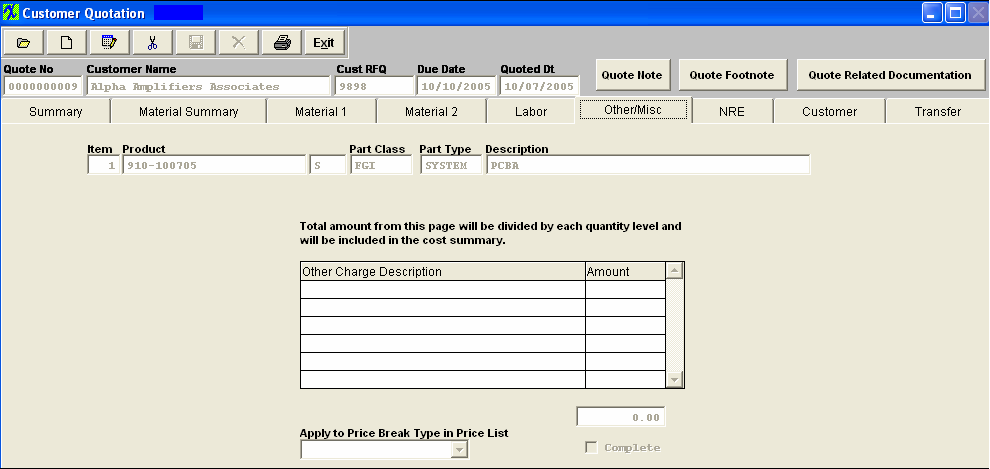

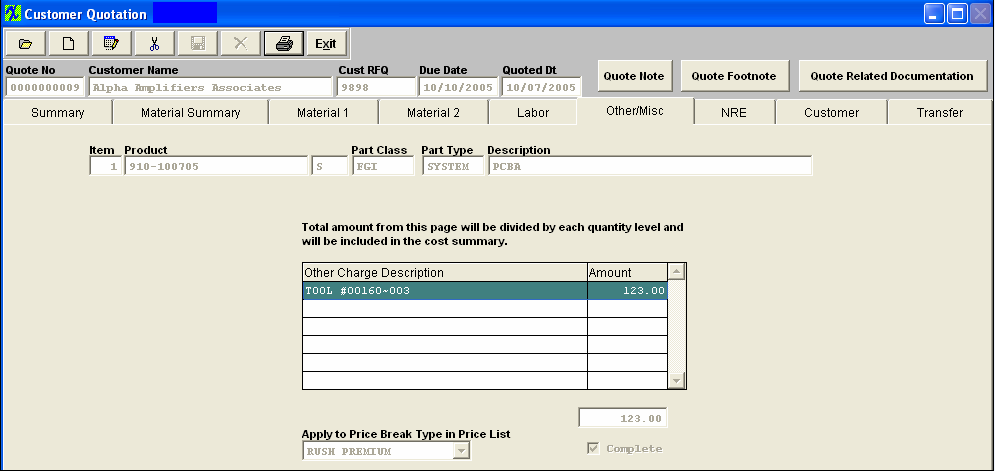

| 1.3.6. Other/Misc. Tab | The Other/Miscellaneous tab displays the description and amount of the other charges. The charge amount is divided by each quantity level and will be included in the cost summary. This information forwards into the Summary tab.

Other/Misc Tab Definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product.

|

| (Rev) |

The revision number assigned to the product. |

| Class |

The classification of the product.

|

| Type |

The type within the classification pertaining to this product.

|

| Description |

The description of the product.

|

| Other Charge Description |

This is the description to be applied to the other charge amount. The user selects for the table provided in System Setup Quote Defaults.

|

|

| Amount |

The charge amount is divided by each quantity level and will be included in the cost summary.

|

| Complete |

A check in this box denotes that this screen has been completed and is available to forward into the Summary tab.

|

|

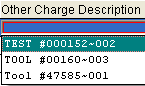

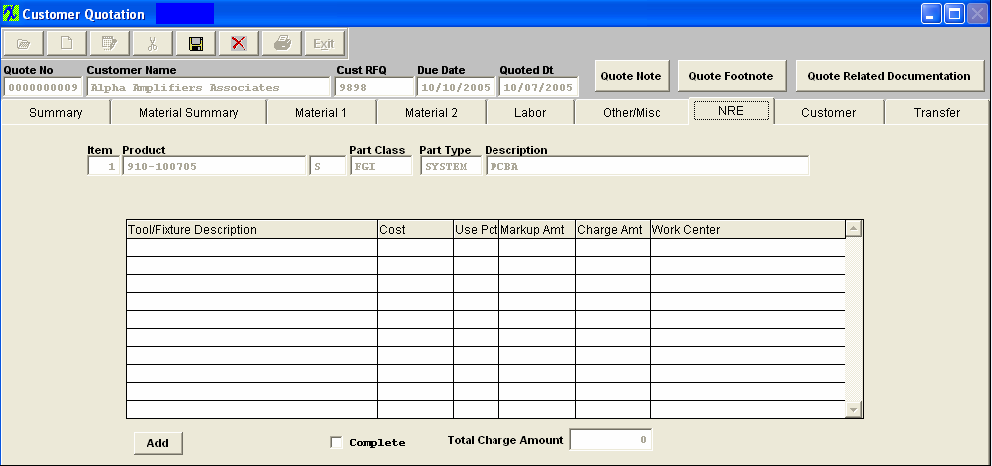

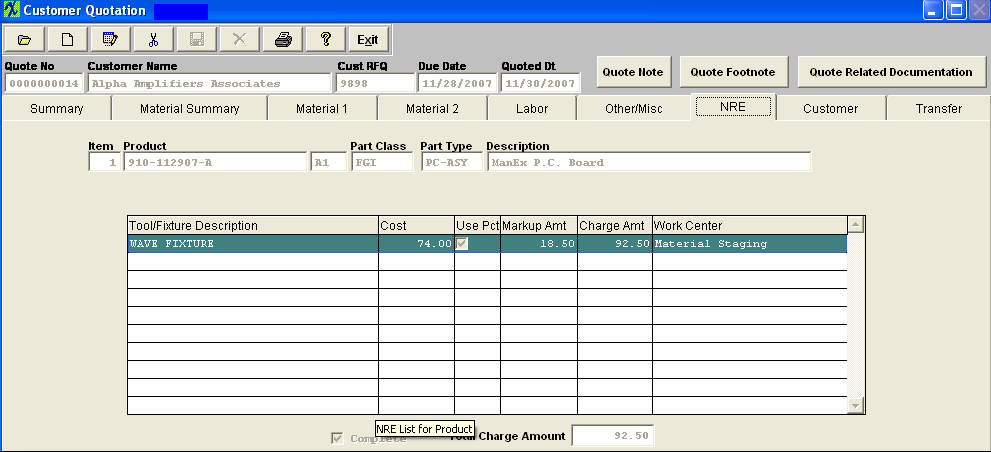

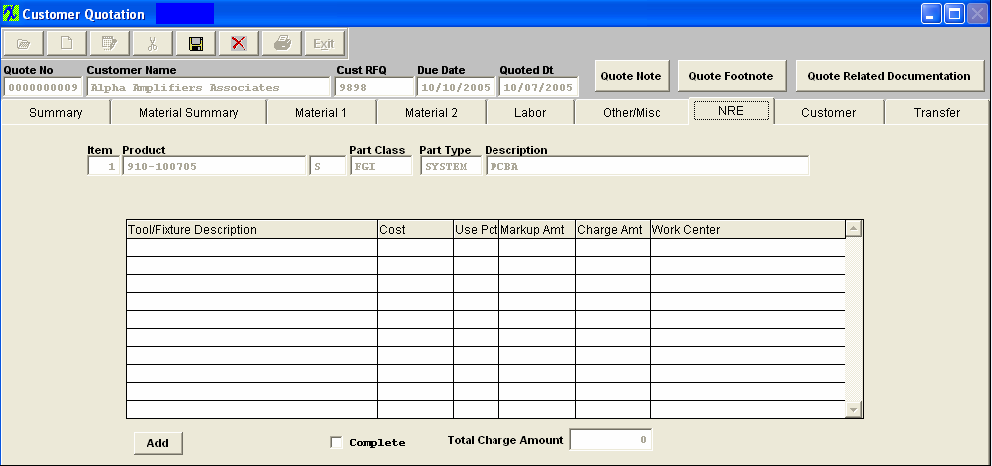

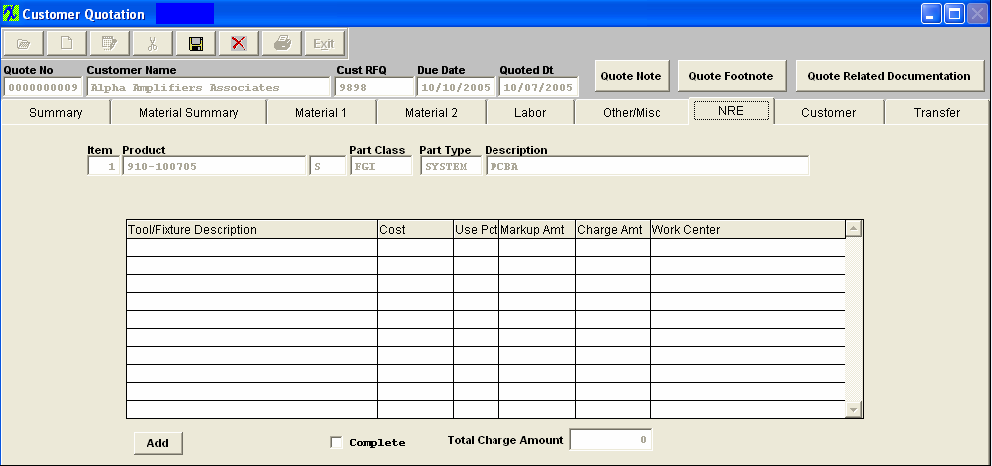

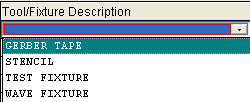

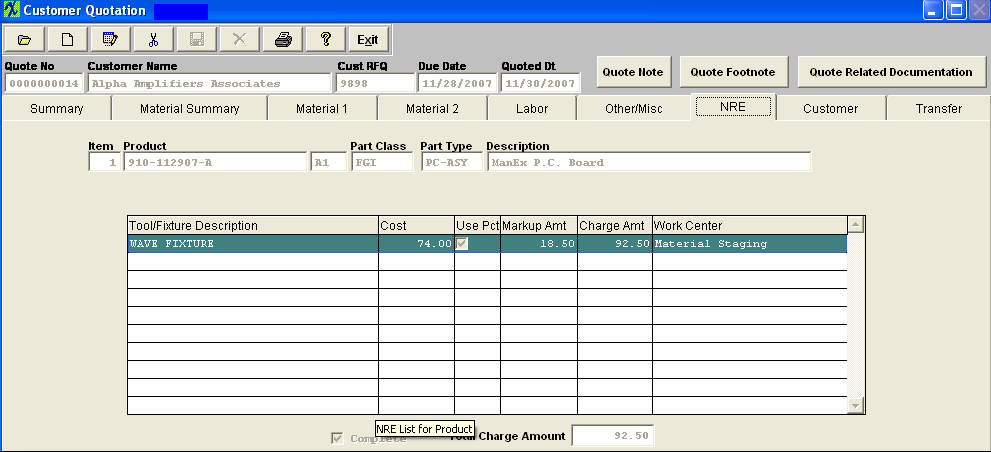

| 1.3.7. NRE Tab | The NRE – non-recurring expenditure tab is to identify and cost tools/fixtures which the user intends to pass on to the customer. This screen displays the NRE description, cost, markup amount, charge amount and the applicable work center. This information forwards into the Summary screen.

NRE tab field definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product.

|

| (Rev) |

The revision number assigned to the product.

|

| Class |

The classification of the product.

|

| Type |

The type within the classification pertaining to this product.

|

| Description |

The description of the product.

|

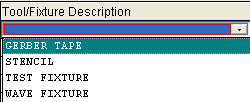

| Tool/Fixture Description |

This is the description of the NRE charge as set up in Production Setup, Tools setup.Please refer to the Implementation – Production manual.

|

| Cost |

This column displays the NRE cost.

|

| Use Pct |

Check this column if the percentage is to be used.

|

| Markup Amt |

This column displays the markup in dollars and cents.This column will update only if the column is left blank.

|

| Charge Amt |

This is the total of the cost plus the markup.

|

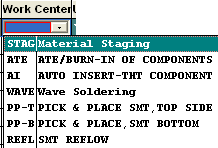

| Work Center |

This is the name of the Work Center where the NRE item will be used.

|

|

Depressing this button will allow the user to add additional NRE charges.

|

|

Depressing this button will allow the user to highlight and delete an NRE charge.

|

| Total Charge Amount |

This field displays the sum of all of the items listed in the Charge Amount column.

|

| Complete |

A check in this box denotes that this screen has been completed and is available to forward into the Summary tab.

|

|

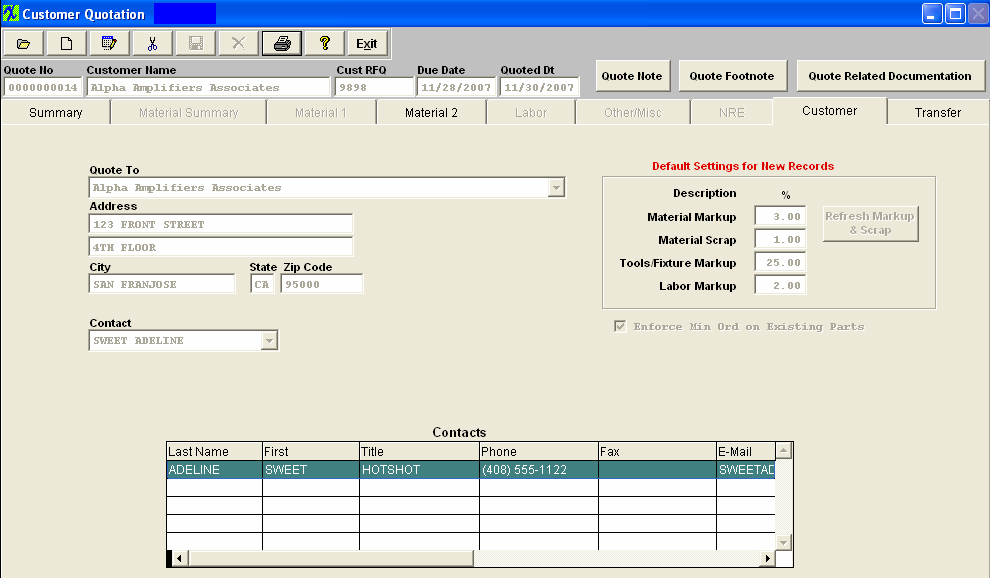

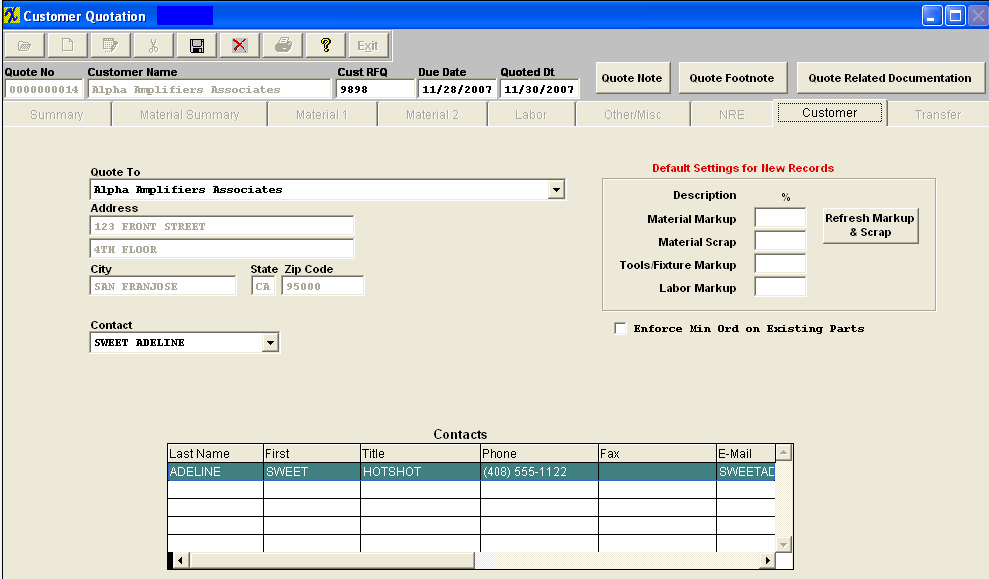

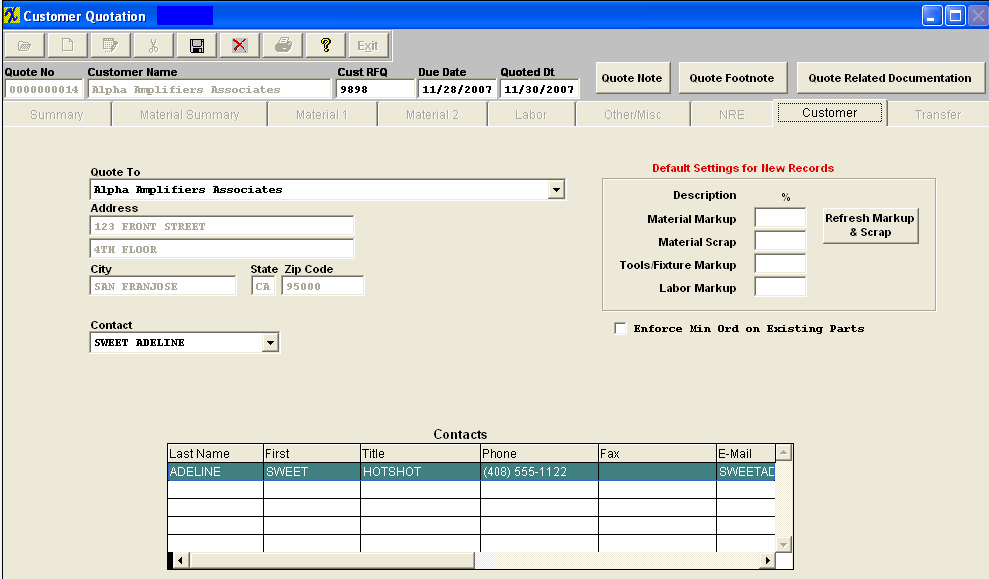

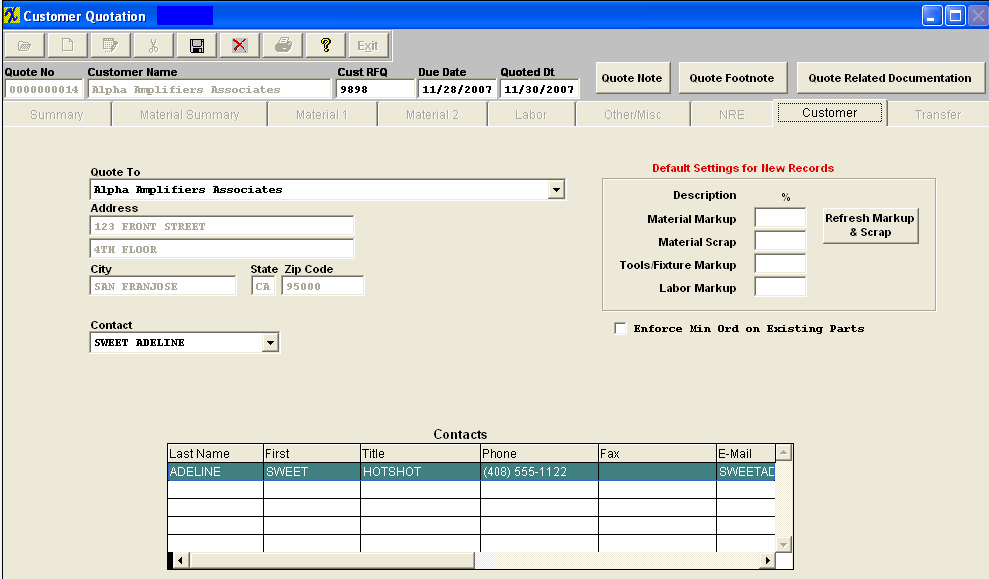

| 1.3.8. Customer Tab | The customer tab contains billing information, the default settings for new records and the contact list. The mark up percentages forward into the respective other tabs for material summary, NRE, and labor. The option to enforce minimum order quantities forwards into the Material 1 tab.

Customer tab field definitions

| Quote To |

This is defaulted in from the Bill To default address setup in the Customer Information module. The user may change the address by depressing the down arrow next to the Quote To box, and making another selection. |

Default Settings for New Records

| Material Markup |

The markup percentage which will forward to the Material Summary tab. |

| Material Scrap |

The percentage of the component for scrap.(If there is a scrap percentage in the customer setup section, that scrap will be applied to all of the items in the Material 2 tab. The Material 1 tab will first look at the inventory master and if the scrap is NOT zero, place the item master scrap in the quote line item. If it is zero in the item master, the scrap value in the customer setup section of the quote will be used.) |

| Tools/Fixture Markup |

The markup percentage which will forward to the NRE tab.

|

| Labor Markup |

The markup percentage which will forward to the Labor tab.

|

| Refresh Markup & Scrap |

When any of the Markup fields are changed, depress this button and the new percentages will be applied to all existing parts for all Products within that quote. |

| Enforce Min Ord on Existing Parts |

Minimum Order is the smallest number of the item that can be ordered from the supplier in one PO.For instance, Surface Mount components on a reel usually have a minimum order of 1000 items or more.Checking this box will enforce the minimums. This forwards to the Material 1 tab.

|

| Contacts |

The name and phone information for the contacts setup for this specific customer in the Contacts Information module.

|

|

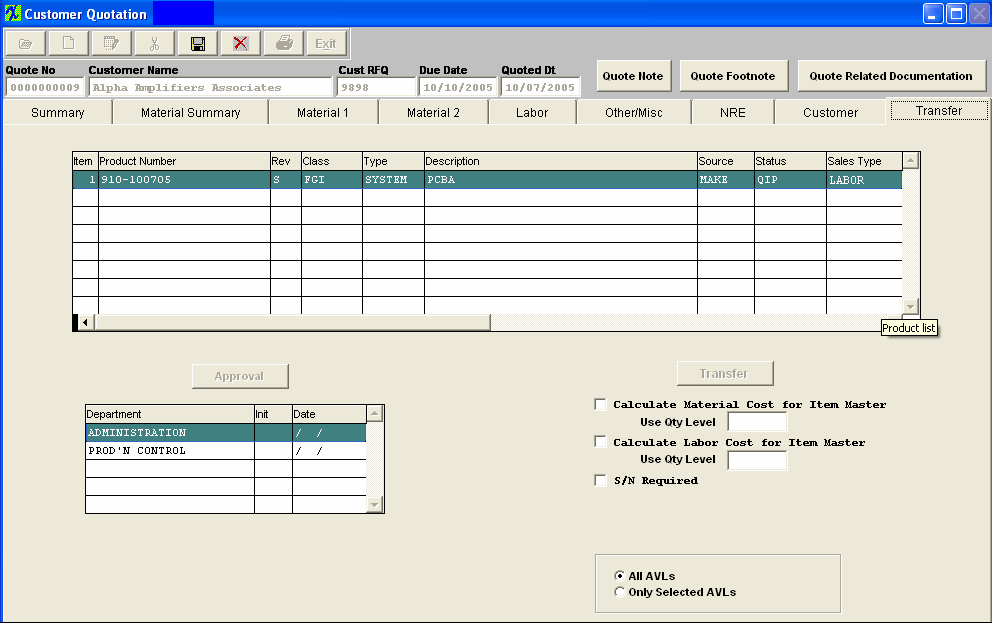

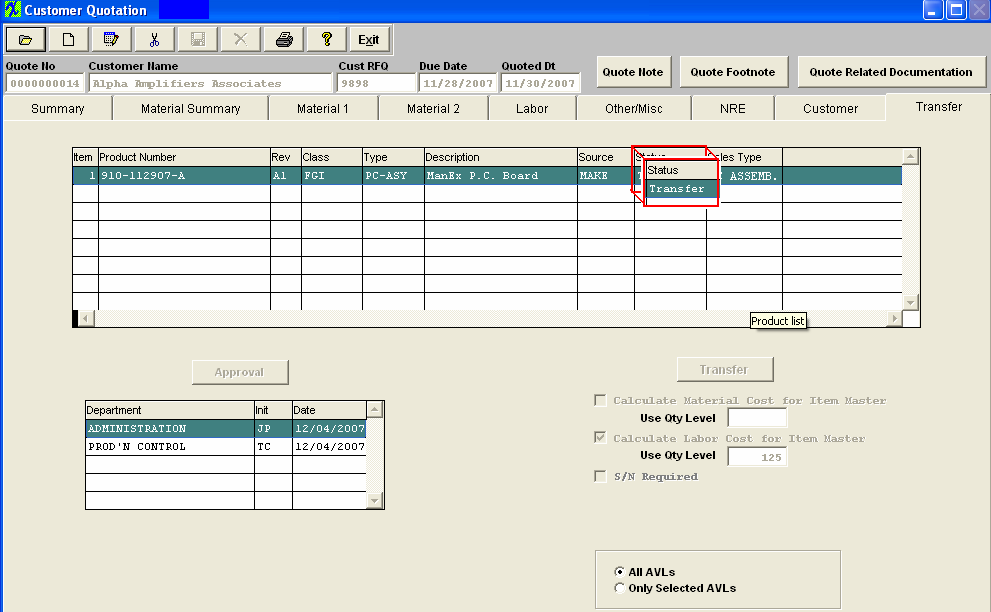

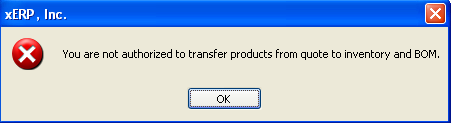

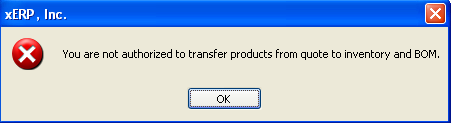

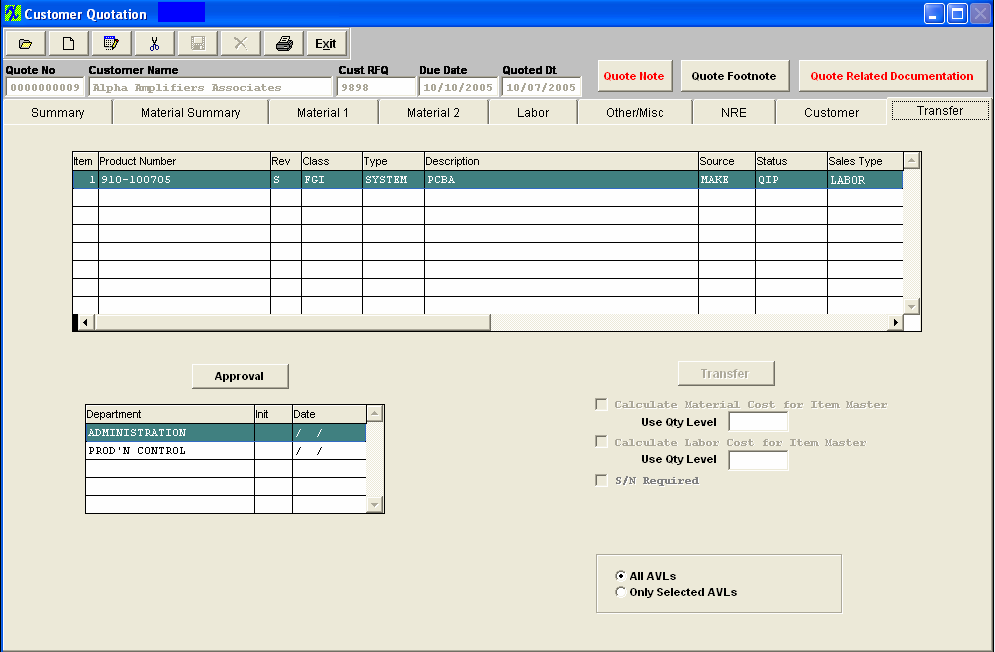

| 1.3.9. Transfer Tab | The transfer tab is used once the request for quote information has been uploaded from the Component Quote Management module. First the user must enter the required approvals as set up in Quote Setup. A user must have been assigned to a department in Security Setup. Then for each department listed, an approval must take place. Once the necessary approvals have been obtained, the user may transfer information regarding the standard cost, labor cost, AVL's, and whether a serial number is required into the Inventory Control Item Master, the Bill of Materials or the Work Order Traveler Setup.

Note: Users MUST have special rights within the Security module to perform a Quote transfer. Users with “supervisor’s rights” will automatically have access. If users do not have the "Quote Transfer" box checked within the Security module they will receive the following warning:

|

|

| Item |

The line number. |

| Product Number |

The unique number assigned to the product. |

| (Rev) |

The revision number assigned to the product. |

| Class |

The classification of the product. |

| Type |

The type within the classification pertaining to this product. |

| Description |

The description of the product. |

| Source |

The source of the product, either Make or Phantom. MAKE is for an item made in-house (assemblies and sub-assemblies) and PHANTOM is for a number used to define a collection of items that does not exist as a separate assembly built on a Work Order (ship kits, upgrade packages, spares kits, etc.). |

|

This is for the status of this line item. If the Quotation has been transferred, the Status will display as transferred.

|

|

|

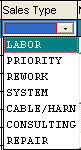

This is for the type of sale which pertains to the product, as setup in System setup Sales Type & Price Itemization |

|

|

Once this button is depressed, the system will prompt for the appropriate departmental password.

|

| Init |

The initials of the approver.

|

| Date |

The date of approval.

|

|

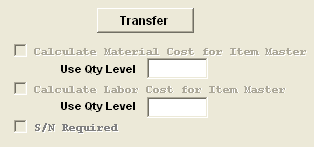

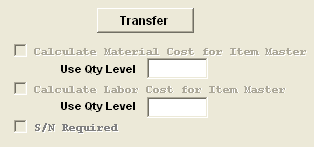

This button is used AFTER marking whether to update standard costs for materials and labor.Note that one of the quantities as stated in the summary tab must be entered in the box. The user must also pre-select whether or not serial numbers are to be used.

|

|

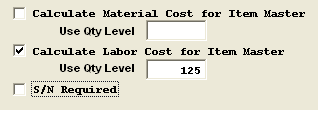

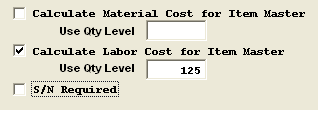

Calculate Material Cost for Item Master

|

If this option is checked, the cost for the materials will forward to the Inventory Master. Note that one of the quantities as stated in the summary tab must be entered in the Use Qty Level box.

|

|

Calculate Labor Cost for Item Master

|

If this option is checked, the cost for the labor will forward to the Inventory Master. Note that one of the quantities as stated in the summary tab must be entered in the Use Qty Level box.

|

| S/N Required |

This box is checked if serial numbers are required for the product.

|

| All AVL's |

Transfer all the AVL's listed on the quote to inventory. When adding AVL's on Material 2 page, because it is a new part, the system will add all or selected, based on what is checked, on material 1 page, it will transfer all existing AVL's plus add any new AVL's based on what is check. |

| Only Selected AVL's |

Transfer just the selected AVL's listed on the quote to inventory. When adding AVL's on Material 2 page, because it is a new part, the system will add all or selected, based on what is checked, on material 1 page, it will transfer all existing AVL's plus add any new AVL's based on what is check. |

|

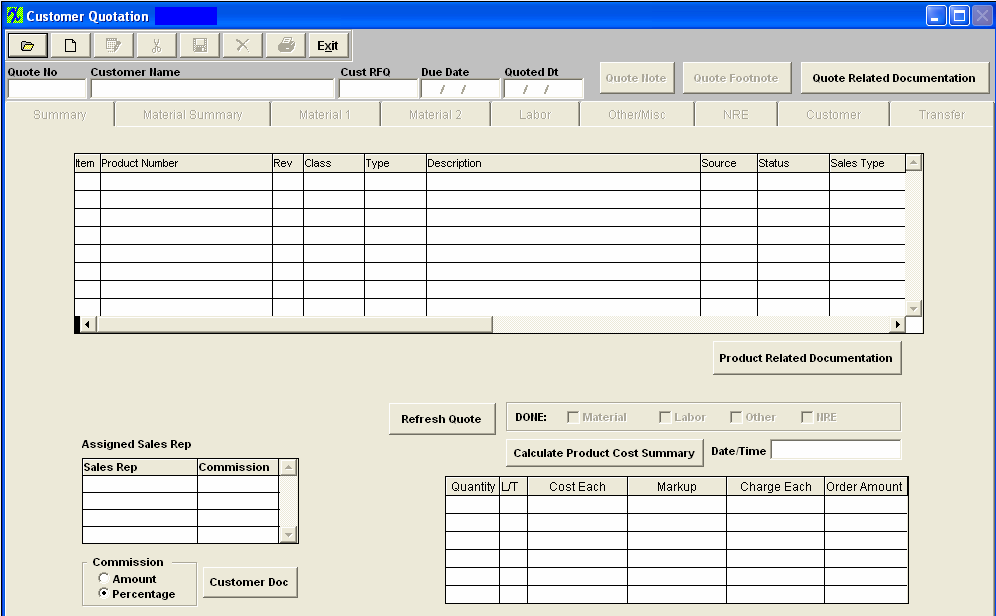

| 1.4.1. Find a Customer Quotation |

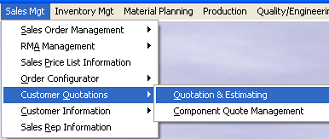

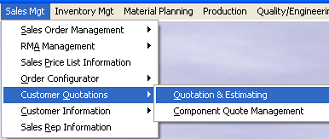

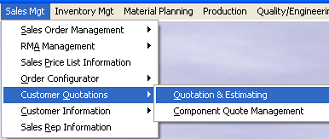

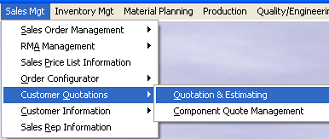

| Enter Sales Mgt/Customer Quotations/Quotation & Estimating |

|

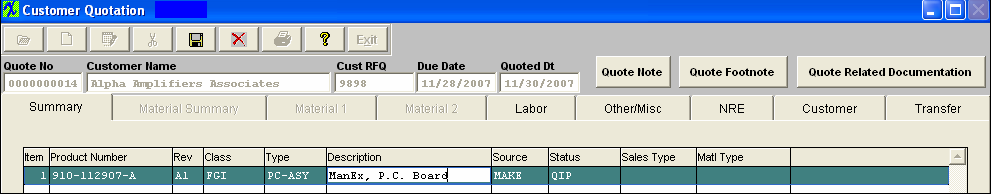

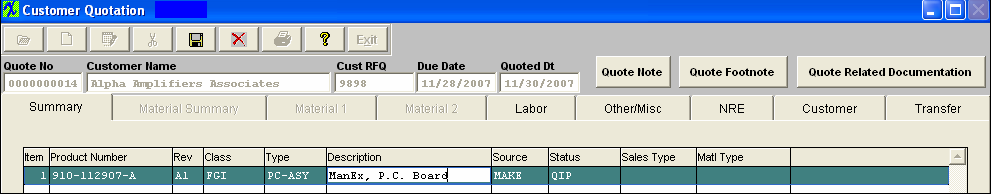

The following screen will be displayed: Within this screen, an estimate is created select the Add action button to create a new record or the Find action button for viewing and editing an existing quote.

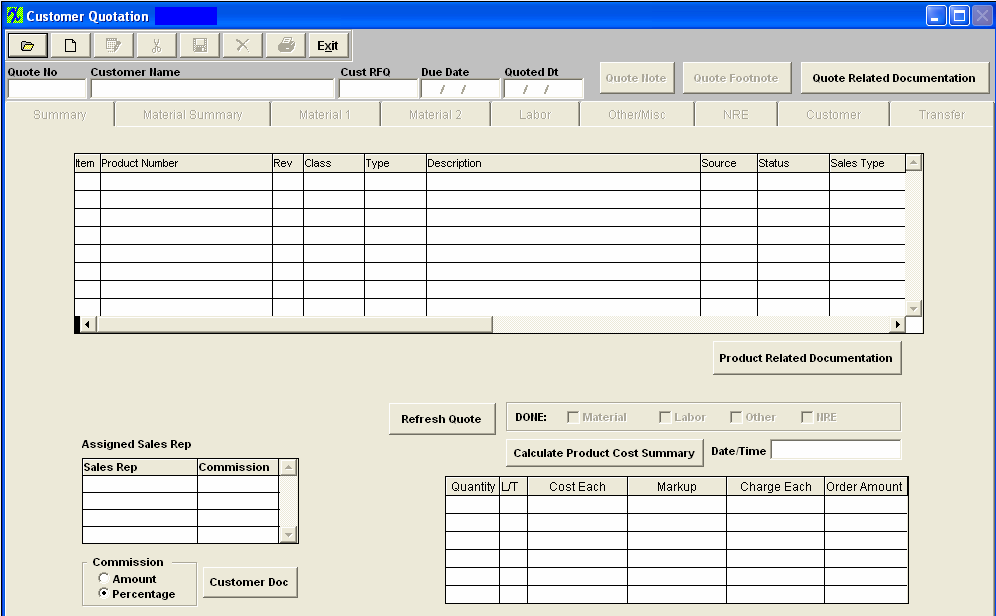

Find an Estimate

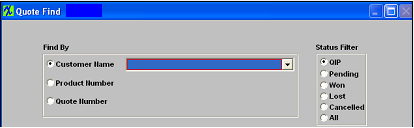

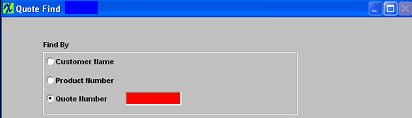

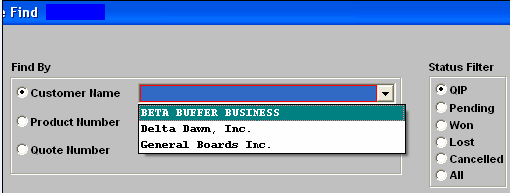

Depressing the Find action button displays the following sequences:

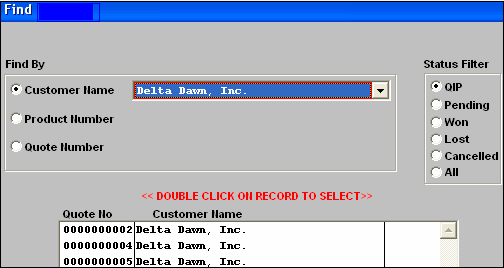

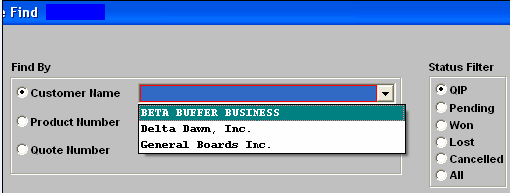

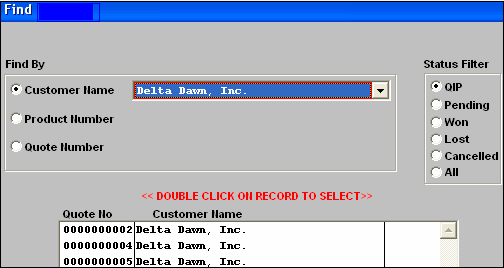

|

The user may find by Customer, by Product Number or by Quote Number.

The user may select the appropriate Status Filter radial button, to filter by: QIP (Quotation in Process), Pending Quotation, Won, Lost, Cancelled, or All.

|

|

|

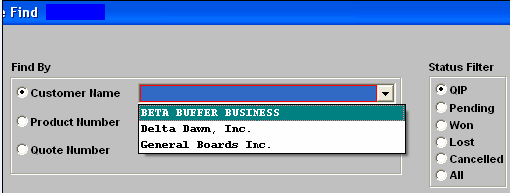

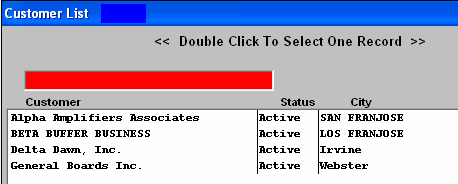

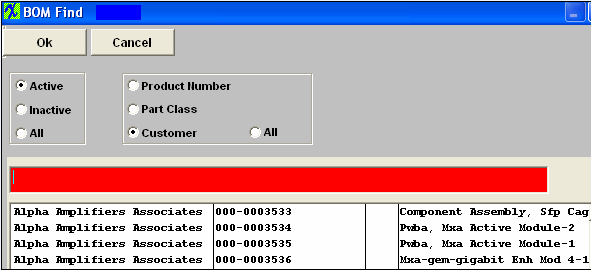

If the user selects Find by Customer Name, depressing the down arrow produces a list of Customer names from which to choose, as displayed:

|

|

|

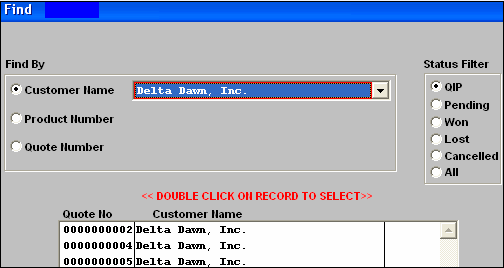

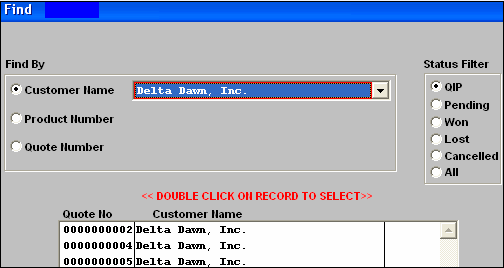

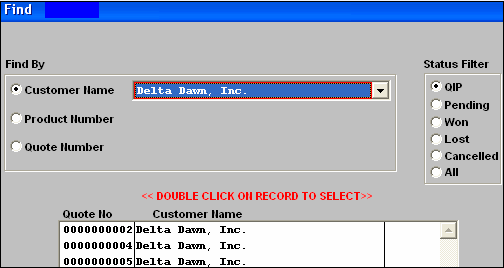

If the customer has more than one quote, the user will be presented with the following screen:

Select the appropriate quote number and double click.

|

|

|

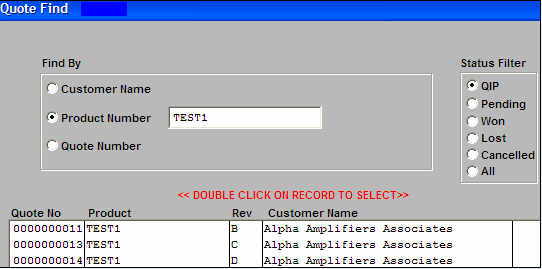

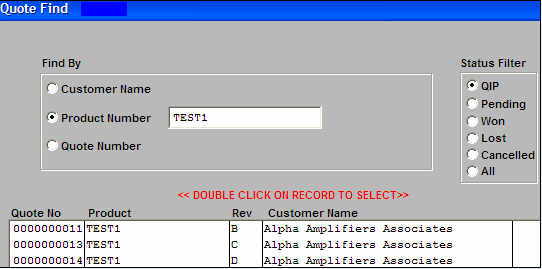

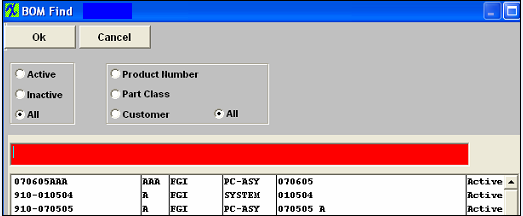

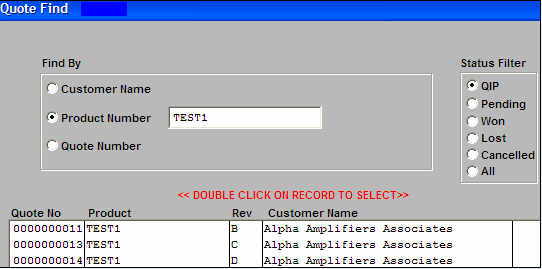

If the user selects Find by Product Number the following screen appears:

Type the Product Number in the red box:

|

|

|

The user is then presented with another selection screen.

This screen displays the Quote Number, Product and Revision and the Customer name.

Double click on the record you want to select.The information for that quote will populate the screen |

|

|

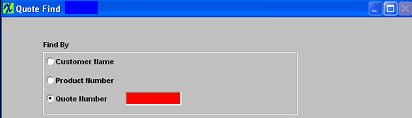

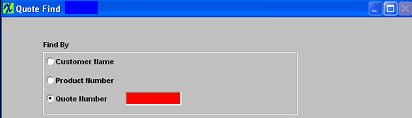

If the user selects Find by Quotation Number the following screen appears:

Once the number is typed in, the information regarding to that quote populates the screen.

|

|

Once you have made your choice, the information regarding that quote populates the screen.

|

| 1.4.2. Create a Quote | |

| Enter Sales Mgt/Customer Quotations/Quotation & Estimating |

|

The following screen will appear:

Depress the Add button, and enter password

|

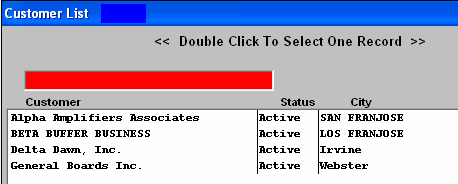

The following Customer List will appear:

Highlight the desired customer and double click.

The Customer name will transfer onto the screen.

|

|

Enter in the Customer RFQ Number, Due Date, and Quoted Date.

Enter the Customer Tab

Select the desired Quote To address, (if different from the default) by depressing the down arrow next to the Quote To box. Enter the Default Settings for New Records. Check the box to Enforce Minimum Order on Existing Parts. Depress the Save button. The completed screen will appear:

|

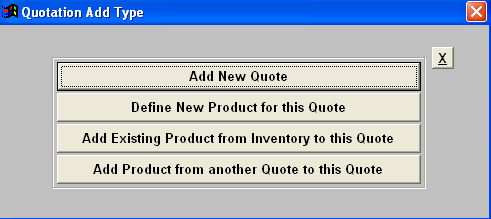

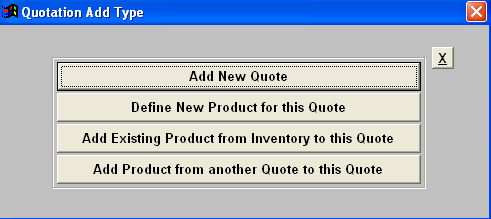

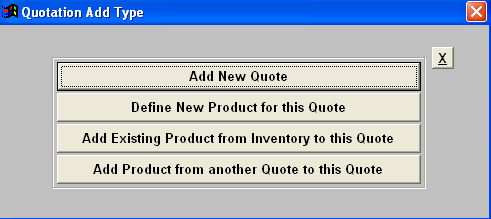

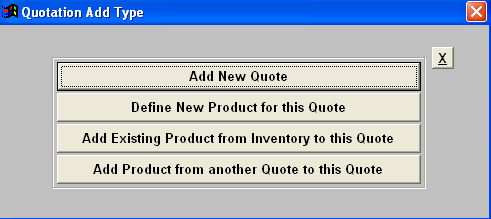

Depress the Add button, enter password and the "Quotation Add Type" selection screen will appear:

Quote functions allow users to: Add New Quote; Define New Product for this Quote; Add Existing Product from Inventory to this Quote; or Add Product from another Quote to this Quote.

|

|

The selection to Add a New Quote will allow the user to start the new quote from scratch.

The selection to Define New Product for this Quote will allow the user to add a product from scratch to the Quote.(Detailed below)

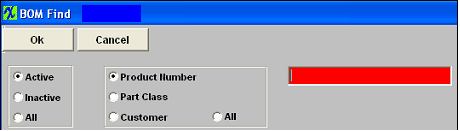

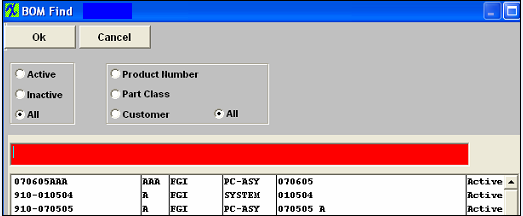

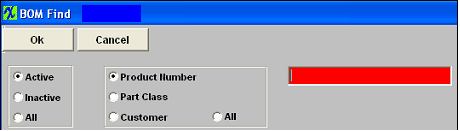

The selection to Add Existing Product from Inventory to this Quote will bring up the following BOM Find screen:

|

Select the BOM status, Active, Inactive or All, then select the BOM by Product Number; Part Class, Customer, or All by clicking on the appropriate radial.

If you know the product number type it into the red box. |

|

|

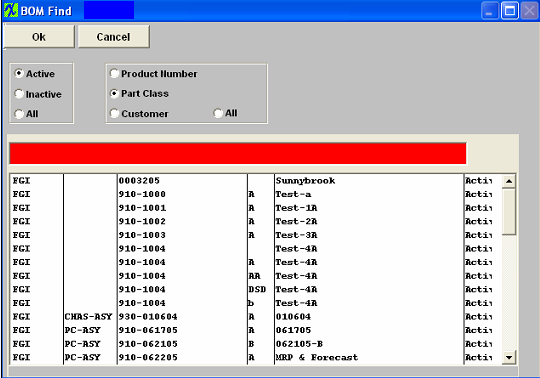

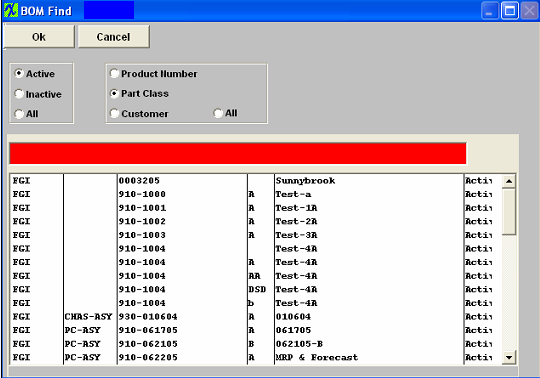

To select by Part Class, click on that radial and type the Part Class into the red box. Depress the OK button. The following screen will appear:

Type in the Product Number and revision number if applicable

|

|

|

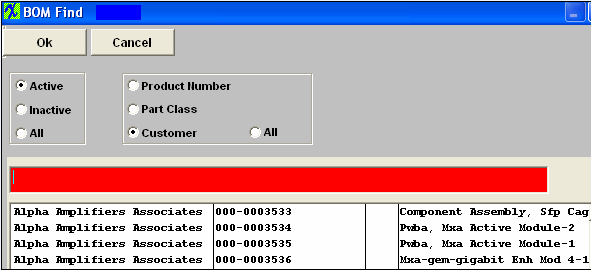

To select by Customer, depress the radial for Customer. Place the cursor in the red box. Type in the 1st letter of the customer. The following list will appear:

|

|

| To select by All, click on the All radial. The following list will appear:

If you know the product number type it into the red box. The following screen will appear:

|

|

|

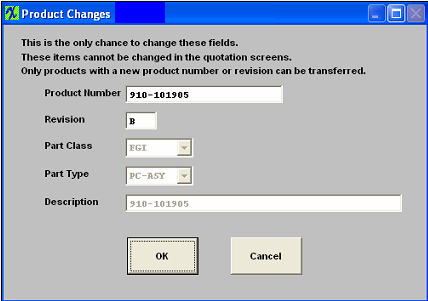

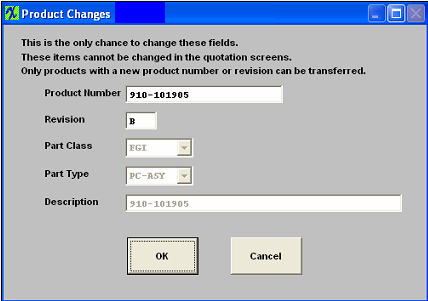

The following screen will appear. Once you have made your selection using one of the procedures above.

Type in any changes to the Product Number and or revision. Note: You must make the new product unique! Depress the OK button.

|

|

The Summary screen will display the product, as follows:

The components for that Product will appear in the Material 1 window, as illustrated below: Note: If you Add existing product from Inventory to quote, quote having same customer as existing product, only the approved AVL’s in existing product will copy over. If you Add existing product from Inventory to quote, quote having different customer than the customer linked to the existing product or the existing product not linked to a customer, then the system will pull AVL’s from consigned data if that customer is linked to that part. If customer is not linked to the part then the AVL’s will be pulled from the Internal data.

Edit the Material 1 screen as desired. The user may add new components, delete existing components and/or change quantities. Finish off the other screens, as detailed in Article #911 .

|

If you want to copy from another quotation, select the Add Product From Another Quote To This Quote:

|

|

|

A Quotation Find screen will appear.

The user may find by Customer, by Product Number or by Quote Number.

The user may select the appropriate Status Filter radial button, to filter by Quotation in Process, Pending Quotation, Won Quotation, Lost Quotation, Cancelled Quotation or All.

|

|

|

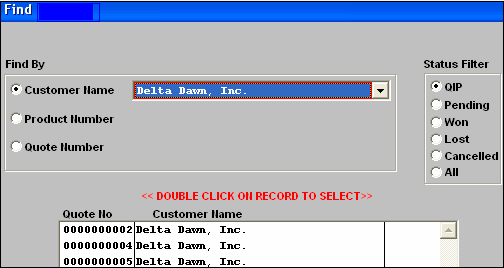

If the user selects Find by Customer Name, depressing the down arrow produces a list of Customer names from which to choose, as displayed in the screen above.If the customer has more than one quote, the user will be presented with the following screen. Select the appropriate quote number and double click:

|

|

|

Find by Product Number prompts the user to enter the appropriate number.

|

|

|

Once the Product number is typed in, the user is presented with another selection screen.

This screen displays the Quote Number, Product and Revision and the Customer name.

Double click on the record you want to select.The information for that quote will populate the screen.

|

|

|

Find by Quotation Number prompts the user to enter the EXACT Quotation Number.

Once the number is typed in, the information regarding that quote populates the screen.

|

|

Once the previous quote is selected and the product number is amended to make it unique, the user may edit any of the applicable screens as detailed below.

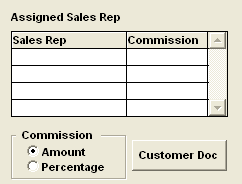

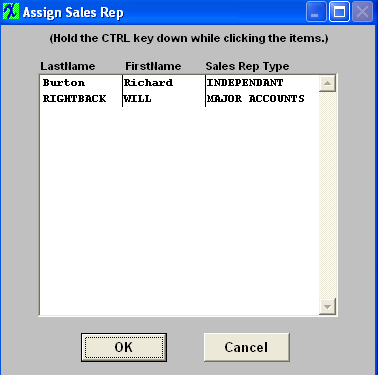

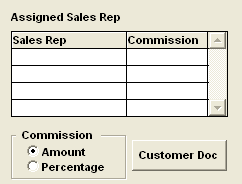

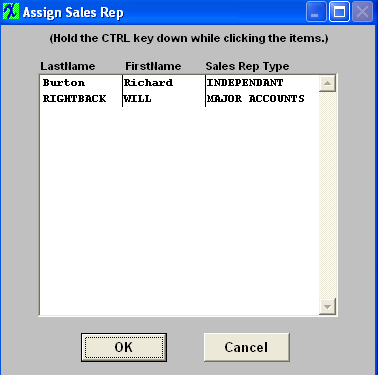

| The Customer Quotation Summary tab allows the addition of a sales representative, as illustrated. |

|

| To add the Sales Representative, depress the Add button near the Assigned Sales Rep section. The following list of representatives will appear: |

|

Depress the Ctrl key and click on the representative(s) of choice.

Depress the OK button.

Click on the appropriate Commission radial, either Amount or Percentage.Enter the number in the Commission column opposite the Sales Rep.

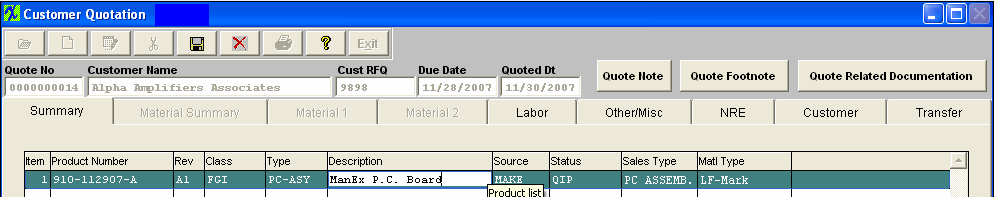

If you selected Define New Product for this Quote.

Enter the Product Number, Revision Number, if applicable. Select Class, Type, Source, Sales Type, and Material Type from the drop down lists.

Add Lead Time & Quantity

The user may elect up to seven quantity pricings.

Depress the  button. button.

|

The following two screens will appear. Fill in the Lead Time Days and the quantity and depress the enter key. Thelead times are being imported into the system/quote by Days.

|

|

When all of the quantities have been entered, depress the Save button.

|

The Quantities and Lead Times will appear in the Quantity Table.

|

|

|

| 1.4.3. Add Materials To Quote & Transfer to Inventory | There are two tabs in which to add components to the assembly. The Material 1 tab is for those inventory items which currently exist in the user’s Inventory Master. The second tab is for items which are not identified in the user’s Inventory Master. The user may use a combination of the two. For both tabs, the Mark Up Percentage will automatically bring up the default percentage from the customer tab, but it may be edited by the user.

Material 1 Tab

These are the components for the new assembly when the item is included in the Inventory Master.

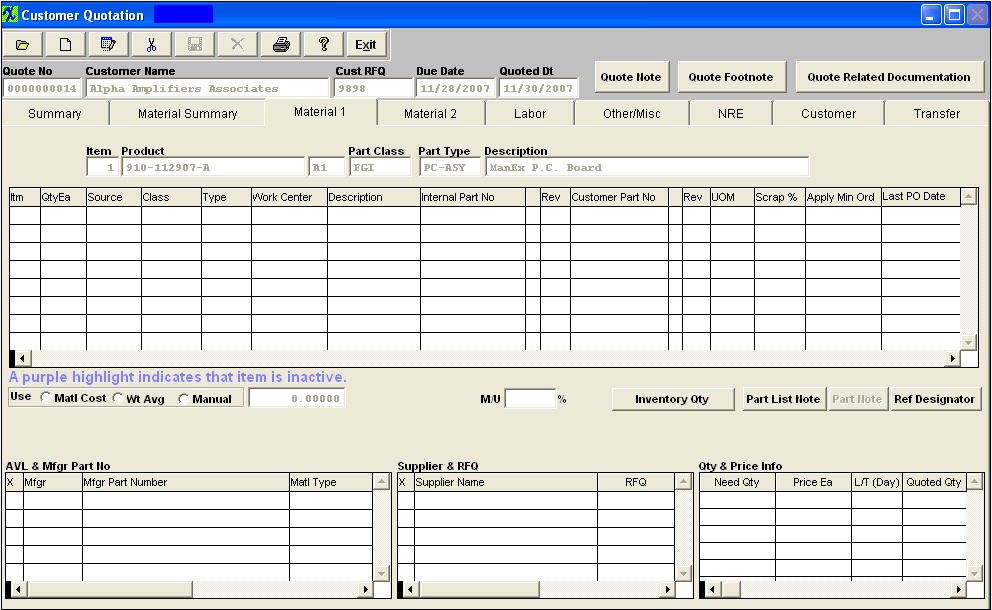

Depress the Material 1 tab; The following screen will appear:

Depress the Edit button, enter password.

|

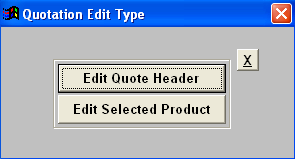

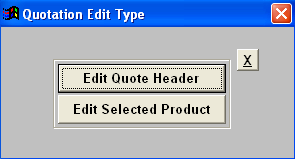

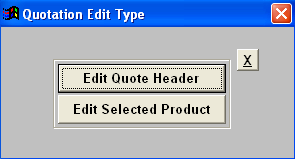

The following Quotation Edit Type selection will appear.

Select Edit Selected Product.

|

|

The following screen will appear:

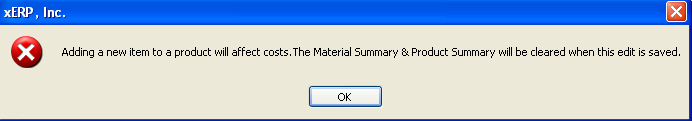

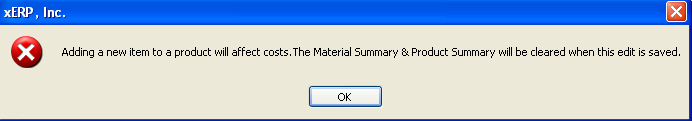

Depress the  button, t he following message will appear:

Depress the OK button. Enter the Item number, Quantity each, select the Part Source, and enter the internal part number. If the Part List has more than one available, a selection screen will appear. Double Click to Select the part you want to consider. The following columns will fill in automatically: Class, Type, Description, Revision number, Scrap %,(If applicable), AVL's, and customer PN (if part source is CONSIGNED). User may enter the customer part number and applicable revision number if part number exists in Inventory records. Check the Apply Minimum Order, and select a Work Center, if desired.

Select the Costing radial to use – Matl Cost, Wt Average or Manual. Material Cost is per the Inventory Master. Weighted Average is the weighted average of the last five Purchase Orders processed for that part number. Manual cost is per the user.

Select AVL

|

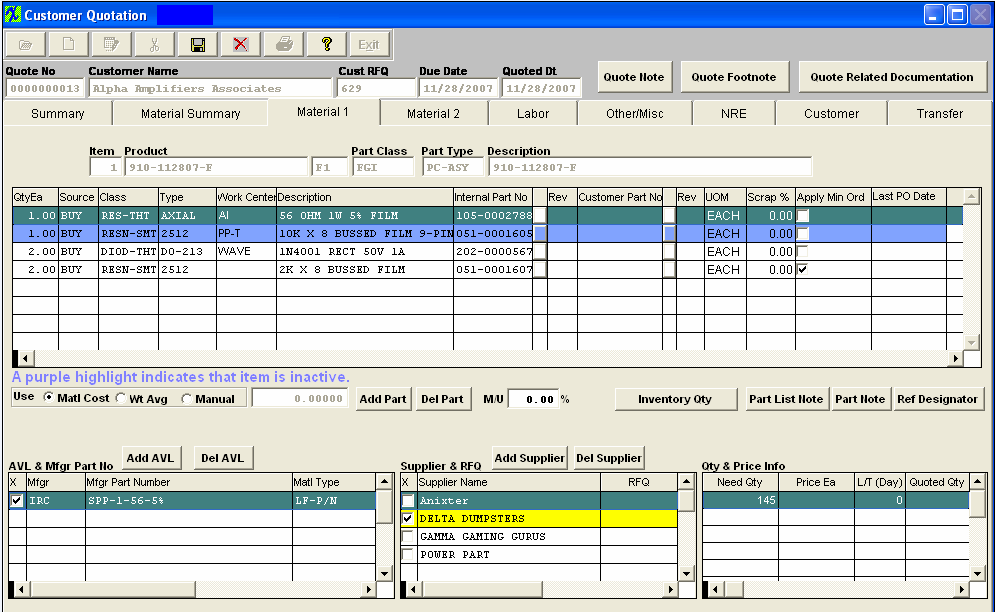

Highlight the Part Added, the Manufacturer and the Manufacturer’s Part Numbers are displayed per the Inventory Item Master.

When you add a part to the material 1 screen from inventory, if the customer on the quote is linked to that internal part number the AVL’s will be pulled from the consigned side, if that customer is NOT linked to that internal part number then the AVL’s will be pulled from the internal side. System WILL allow users to enter NEW mfgr's part numbers, but NOT new mfgr's. The mfgr's from inventory will be the ONLY ones listed on the pull down to select from.

X - A check in this box is NOT for the approval of AVL's on BOM. This box is used when transfering quote to inventory and/or BOM. There is an option located on the "Transfer Tab" to select to transfer "ALL AVL's" or "Only the selected AVL's". If the user chooses to transfer "Only the Selected AVL's", this box MUST be checked on the NEW mfgr part numbers added, then upon transfer the new mfgr part numbers will be transfered to inventory along with the existing mfgr and mfgr part numbers. If this box is NOT checked for the new mfgr part numbers added, when the quote is transfered and the option to add "Only the Selected AVL's" is marked, the new Mfgr part numbers will NOT be transfered to inventory and/or BOM. When a quote is transfered All AVL's transfered will be checked as Approved on the new BOM.

NOTE: When adding a new quote by "ADD Existing Product from Inventory to this Quote" only the AVL's marked as approved on the existing BOM will be tranfered to quote.

If more than one manufacturer is displayed, highlight the manufacturer desired before selecting the Supplier name. The mfgr and mfgr part number selected will be highlighted in yellow.

|

|

| The Supplier for that Inventory Class will appear if added in Supplier Line Card Information. The Supplier Request for Quote number will display to the right of the Supplier, once a quote has been requested in Component Quote Management. Once the supplier has been checked it will be highlighted in yellow. |

|

Quantity and Price Information

There are two ways to fill in this information:

1. The Quantity and Price information sections are forwarded by depressing the Update Quote button in the Component Quote Management module. To view after the Update, highlight the selected Supplier and the quote information will appear.

2. If you selected Manual costing radial, you may enter the price each in the Quantity & Price Information section in this screen.

Continue to Add parts, indicate AVL & Manufacturer’s Part Number, Supplier Name and Quantity & Price information until all components (in Inventory Master) are included.

Depress the Save button.

The completed screen will appear as below:

To add a Part List Note, or a Part Note.

- Depress the Edit button.

- Enter password.

- Select Edit Selected Product.

- Depress the Part List Note or Part Note button. A Note window will appear.

- Depress the Edit button.

- Type in the note.

- Depress the Save button.

- Exit.

- Depress the Save button.

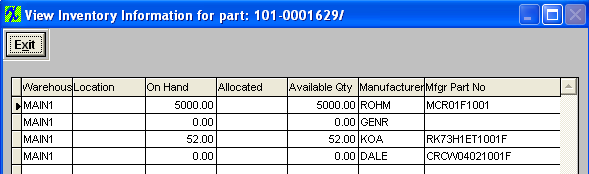

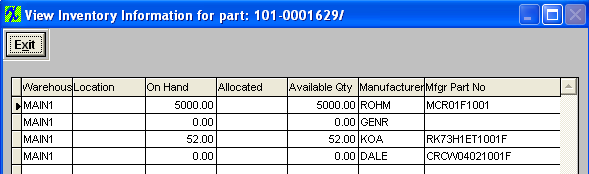

To view the Inventory on Hand, highlight the Part number of interest, depress the Inventory Qty button and the following screen will appear:

|

|

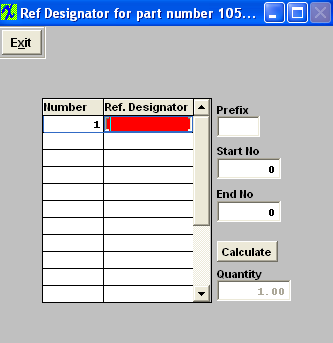

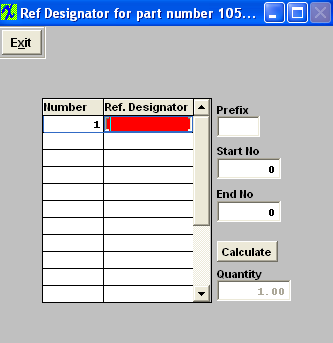

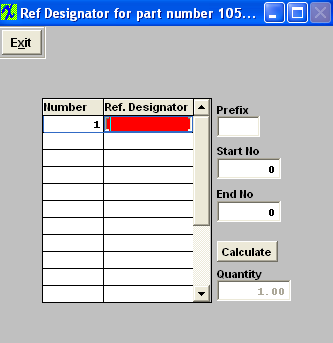

To Enter Reference Designators, depress the Edit button, depress the Ref Designator button and the following screen will appear:

|

|

Material 2 Tab

These are the components for the new assembly when the item is NOT included in the Inventory Master. NOTE: When the parts from Material 2 screen are transferred from quote to BOM, inventory item master part numbers are created for each item. The system does NOT search the inventory item tables for an existing part number and will create new item master part numbers, even if the manufacturers and part numbers are the same.

The user has the option to auto or manual number new inventory parts created in the Material 2 screen. (If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will automatically assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, user will need to manually assign a part number and revision to the item added in the material 2 screen. ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers.

Depress the Material 2 tab. Depress the Edit button, enter password.

|

The following Quotation Edit Type selection will appear:

Select Edit Selected Product.

|

|

The following screen appears:

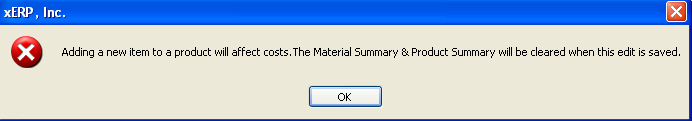

Depress the  button. button.

The following message will appear:

Depress the OK button. Enter the Item number, Quantity each, select the Source, Class, Type, and Work Center from the pull downs. Enter the Description, Customer PN and Rev (if applicable), select Unit of Measure from pull down, and enter scrap % if applicable.

If "MANUAL" numbering is selected in the Number System screen for Inventory parts, the Material 2 screen will display three additional fields shown below in Red box:

Select AVL

|

Highlight the Part Added. Depress the Add AVL button.

Select the manufacturer from the drop down list, all the part mfgr's from system setup will be available to select. Enter in the Manufacturer’s Part Number.

X - A check in this box is NOT for the approval of AVL's. When transfering quote there is an option located on the "Transfer Tab" to select to transfer "ALL AVL's" or "Only the selected AVL's". If user chooses to transfer "Only the Selected AVL's", this box MUST be checked, if this is one of the selected AVL's you want transfered to inventory and/or BOM. If user chooses to transfer All AVL's then this box does NOT need to be checked. When a quote is transfered All AVL's transfered will be checked as Approved.

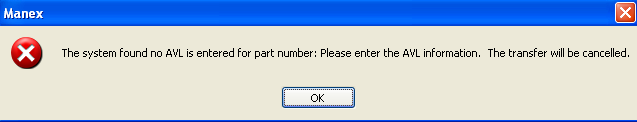

At least one AVL MUST be entered or the quote will NOT transfer to BOM.

If more than one manufacturer is displayed, highlight the manufacturer desired before selecting the Supplier name. The mfgr and mfgr part number selected will be highlighted in yellow. |

|

|

The Supplier for that Inventory Class will appear if added in the Supplier Line Card Information. The Supplier Request for Quote number will display to the right of the Supplier, once a quote has been requested in Component Quote Management. Once the supplier has been checked it will be highlighted in yellow.

|

|

Quantity and Price Information

There are two ways to fill in this information:

1. The Quantity and price information sections are forwarded by depressing the Update Quote button in the Component Quote Management module. To view, highlight the selected Supplier and the quote information will appear.

2. You may enter the price each in the Quantity & Price Information section in this screen. The price source will display as manual.

Continue to Add parts,AVL & Manufacturer’s Part Number, Supplier Name and Quantity & Price information until all components (not included in Inventory Master) are included.

Depress the Save button. The completed screen will appear as follows:

To add a Part List Note or a Part Note.

- Depress the Edit button.

- Type in your password.

- Select Edit Selected Product.

- Depress the Part List Note or the Part Note button. A Note window will appear.

- Depress the Edit button.

- Type in the note.

- Depress the Save button.

- Exit.

- Depress the Save button.

To Enter Reference Designators, depress the Edit button, depress the Ref Designator button and the following screen will appear:

|

|

Labor Tab

Depress on the Labor tab and the following screen will appear:

Depress the Edit Button, enter password.

|

The following Quotation Edit Type selection will appear:

Select Edit Selected Product.

|

|

Enter the Cost Each of labor, then check the "Use Pct" box if the percentage is be used, do this for each quantity break.

- The Markup Amount and Charge Each will update automatically, on the initial data entry.

Thereafter, changing the “Cost Each” will NOT change to the markup amount. This is so that users may manually change the mark up to whatever they want, without having the default percentage override it. If the user wants to have the percentage create a new markup, go to the customer screen and depress the "Refresh Markup & Scrap" button and the new percentages will be applied to all existing parts for all Products within that quote.

|

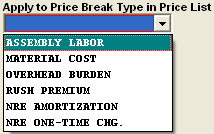

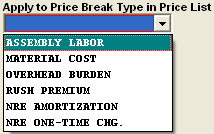

Press the down arrow for" Apply to Price Break Type" in Price List. Select the type pertaining to Labor.

|

|

|

Check the Complete box.

Depress the Save button.

|

|

The completed screen will look like this.

Other/Misc. Tab

Depress the Other/Misc. Tab and the following screen will appear:

Depress the Edit button, enter password.

|

The following Quotation Edit Type selection will appear:

Select Edit Selected Product.

|

|

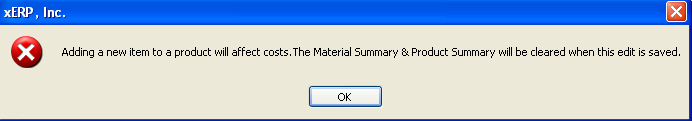

Depress the Add button. The following message will appear:

5. Depress the OK button.

|

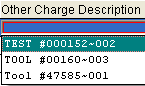

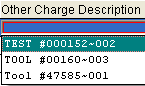

6. Depress the down arrow in the Other Charge Description section. A listing of Other Charge Descriptions will appear. Select the pertinent one.

7. Type in the amount pertaining to that charge.

|

|

| 8. Depress the down arrow for "Apply to Price Break in Type List". Select one pertaining to the other or miscellaneous charge. |

|

|

9. Check the Complete box.

10. Depress the Save button.

|

|

The completed screen will look like this:

Note: That any amounts entered here are amortized over the quantity quoted.

NRE Tab

Depress the NRE tab and the following screen will appear:

Depress the Edit button, enter password.

|

The following Quotation Edit Type selection will appear:

Select Edit Selected Product.

|

|

The following message will appear:

|

Select the preferred Tool/Fixture description from the drop down list.

|

|

Enter in the Cost, then check the "Use Pct" box if the percentage is be used. The Markup Amount and Charge Amount will update automatically.

|

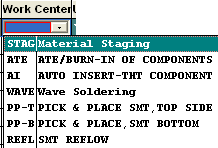

Select the Work Center pertaining to the non-recurring expense from the drop down menu.

|

|

Check the Complete box.

Depress the Save button.

|

|

The completed screen will look like this:

Note: That any amounts entered here represent a one time cost.(The quantity of units to be made, have no bearing on this number.)

Before entering the Transfer tab, user will want to complete the Material Summary tab and Summary Tab.

Material Summary Tab

If you are NOT going to update costs from the Component Quote module and have entered all of the pertinent costs manually, depress the Material Summary tab. Depress the Calculate & Display Material Costs button. The Markup and Charge Each will automatically update for items included in the Inventory Master for the Material 1 tab and any manually added costs in the Material 2 tab. The total number of components is calculated from the qty each column in Material 1 and Material 2.

Depress the Edit button, and enter password, the following Quotation Edit Type selection will appear:

Select "Edit Selected Product" if you would like to:

|

|

|

This gives the user the option to Apply a Price Break Type to the Price List to the existing quote

|

|

| This gives the user to option to Apply a Price/Quantity Break to the existing quote |

|

|

This gives the user the option to Apply a Pricing Criteria to the existing quote

|

|

|

Once all the selections have been made depress this button to apply them and prices will be updated

|

|

Check the Complete box.

Depress the Save button.

|

|

Summary Tab

If you are NOT going to use the Component Quote Management module and have entered all of the material costs manually, return to the Summary Tab.

|

To add a Quote Note or a Quote Footnote.

The following Quotation Edit Type selection will appear:

Select Edit Quote Header.

|

|

Depress the Quote Note or the Quote Footnote button.

Depress the Edit button in the Note screen.

Type in your note.

Depress the Save button.

Exit.

|

Check to be sure that Material, Labor, Other and NRE boxes are checked.

|

|

If you want to add a product note:

Highlight the product.

Depress the Edit button.

|

The following Quotation Edit Type selection will appear:

Select Edit Selected Product.

|

|

Depress the Product Note button or the Product Footnote button.

Type in the note.

|

Depress the Calculate Product Cost Summary button.The Cost Each, Markup, Charge Each and Order Amount will automatically update.

|

|

The completed screen will appear as follows:

Add another product number, if desired.

|

To ADD a new product, depress the Add button.

The Quotation Add Type Selection will appear:

Select Define New Product for this Quote.

Follow the "Define New Product for this Quote" procedures, but skipping over the Customer Tab procedures.

|

|

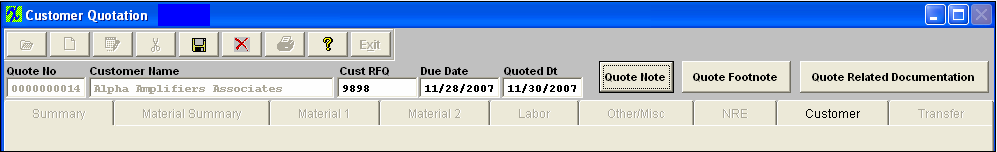

Transfer tab

If the user did NOT use the Component Quote Management module, once the customer has accepted the quotation and the user now wants to add the new product to the Inventory Master and create a new Bill of Materials for the new product, the user may accomplish this by depressing the transfer tab. Note: Once the Transfer process is completed, no further changes are allowed to the Quote and that the status of the quote will change to Transferred.

NOTE: For this tab, a serial of approvals must be entered. In this example, approvals are required by a user assigned to the departments listed. Depress the Approval button. Have a user from engineering (for example) type in his/her password. Continue down the list until every department has the initials and date displayed. Once all the approvals have been entered the Transfer button will become available. The approvals will need to be re-entered after every Edit.

Depress the Edit button, and enter password to select any of the following options:

To select "Calculate Material Cost for Item Master, check that box and indicate the Quantity Level which is to be selected.

To select "Calculate Labor Cost for Item Master, check that box and indicate the quantity level.

To mark this product as serialized, check the "S/N Required" box.

|

|

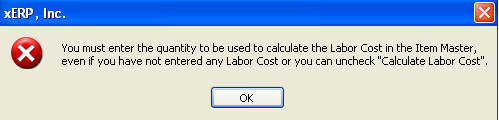

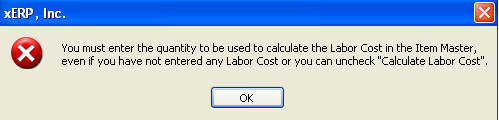

| If either "Calculate Material Cost for Item Master" or "Calculate Labor Cost for Item Master" and the quantity level field is left blank the following prompt will be displayed. Depress the OK button and the transfer will abort, allowing user to enter the Qty level. |

|

Select the radial to either transfer "All AVLs" or "Only Selected AVLs" to BOM and item master.

When adding AVL's on Material 2 page, because it is a new part, the system will add all or selected, based on what is checked, on material 1 page, it will transfer all existing AVL's plus add any new AVL's based on what is check. For more detail see Select AVL section above.

ALL AVL's transfered will be check as approved on the BOM.

|

|

Depress the Save button. Note: Once the Edit button has been depressed the Approvals will clear and need to be re-entered again.

Depress the Transfer button, enter password.

The Status of the Quote will be updated to Transfered, as displayed below:

The system will run several validations at this point these are a few:

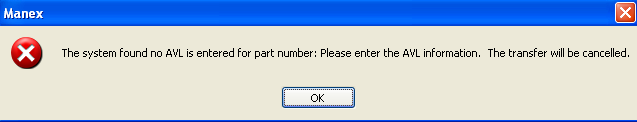

| If there are No AVL's listed for a part in the Material 2 screen, or no AVL's selected as approved on each item the following prompt will be displayed. Depress the OK button and the transfer will abort, allowing user to correct the missing AVL. |

|

|

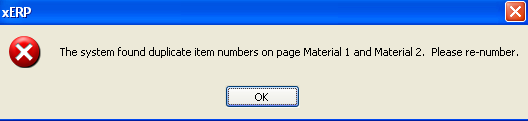

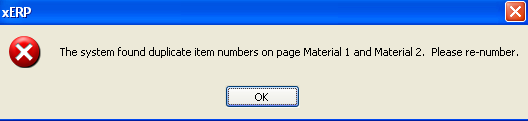

If there are duplicate item numbers within the Material 1 and Material 2 tab the following prompt will be displayed. Depress the OK button and the transfer will abort, allowing user to correct the duplicate item numbers.

|

|

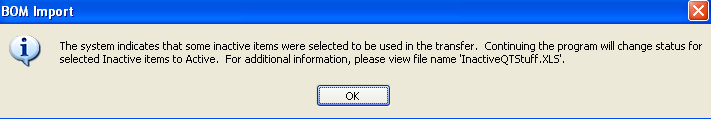

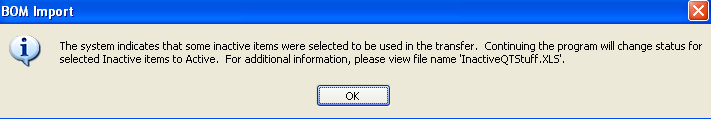

| If there are inactive items selected to be used in the transfer the following prompt will be displayed. Depress the OK button to continue the transfer. |

|

Once all the validations have been ran the BOM will be created with a Status of "Active:

|

| 1.4.4. Quotation and Estimating Completion |

| To finalize the Customer’s quote, return to the Quotation and Estimating module. |

|

Find the Customer Quote using the procedures above. You will note that the information from the Component Quote Management module has forwarded into the Quotation and Estimating module, as illustrated below:

If you are NOT going to update costs from the Component Quote module and have entered all of the pertinent costs manually, depress the Material Summary tab. Depress the Calculate & Display Material Costs button. The Markup and Charge Each will automatically update for items included in the Inventory Master for the Material 1 tab and any manually added costs in the Material 2 tab. The total number of components is calculated from the qty each column in Material 1 and Material 2.

Depress the Edit button if you would like to:

| This gives the user the option to Apply a Price Break Type to the Price List to the existing quote |

|

| This gives the user to option to Apply a Price/Quantity Break to the existing quote |

|

| This gives the user the option to Apply a Pricing Criteria to the existing quote |

|

| Once all the selections have been made depress this button to apply them and prices will be updated. |

|

Depress the Summary tab.

Depress the Product Cost Summary button. The screen will update as displayed:

Now the user may print out the Customer Quotation and related reports.

Transfer tab

Once the customer has accepted the quotation and the user now wants to add the new product to the Inventory Master and create a new Bill of Materials for the new product, the user may accomplish this by depressing the transfer tab. Note that once the Transfer process is completed, no further changes are allowed to the Quote and that the status of the quote will change to Transferred.

NOTE: For this tab, a serial of approvals must be entered. In this example, approvals are required by a user assigned to the departments listed. Depress the Approval button. Have a user from engineering (for example) type in his/her password. Continue down the list until every department has the initials and date displayed.

Depress the Edit button. Type in the password.

|

The Transfer button and the check boxes will be available:

If you want Standard cost calculated for the Item Master, check that box and indicate the Quantity Level which is to be selected.

If you want the Labor cost calculated and transferred to the Item Master, check that box and indicate the quantity level.

If you want to mark that for this product, a serial number is required, check the box.

|

|

| Check the radial to transfer All AVLs or Only Selected AVLs |

|

Depress the Transfer button, enter password and Quote status will change to Transfer, when the transfer is complete.

Note: If new part numbers are created within the Inventory Control module via the quote transfer all the defaults will be carried forward for the new part from the Part Class/Type Setup screen.

|

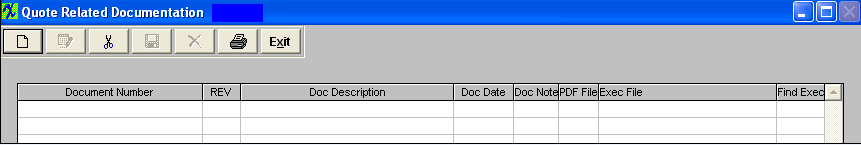

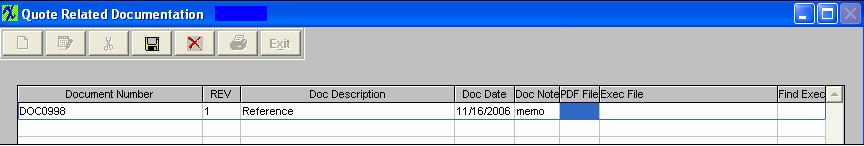

| 1.4.5. Attach a Related Document | Find an existing Quote Record, or Add a new Quote record.

Depress the  button, and enter password. button, and enter password.

The following screen will appear:

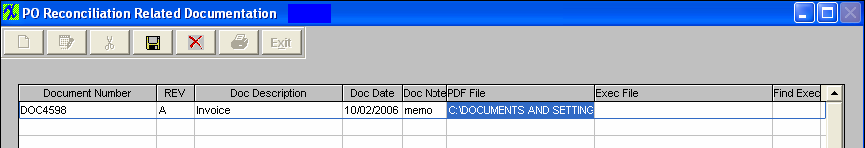

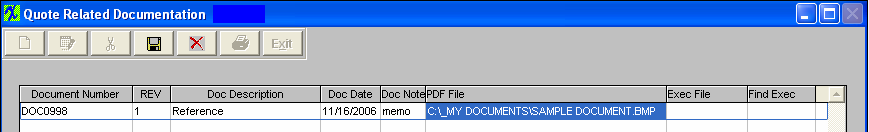

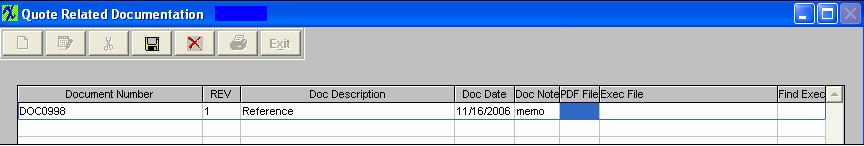

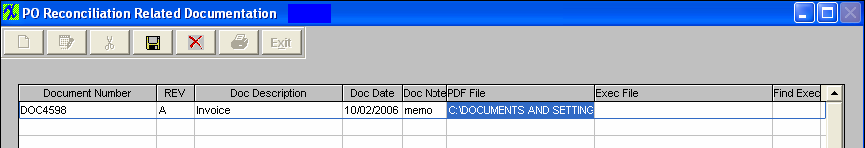

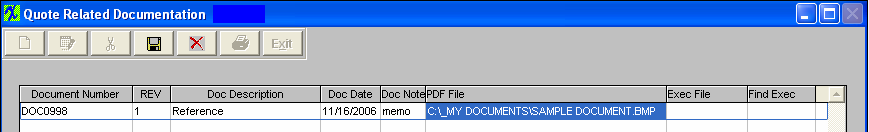

Depress the Add record icon, enter in a Document Number, REV, Doc Description, Doc Date, Doc Note;

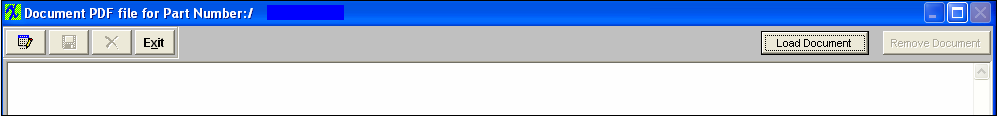

To load a document double click in the PDF File field and the following screen will appear:

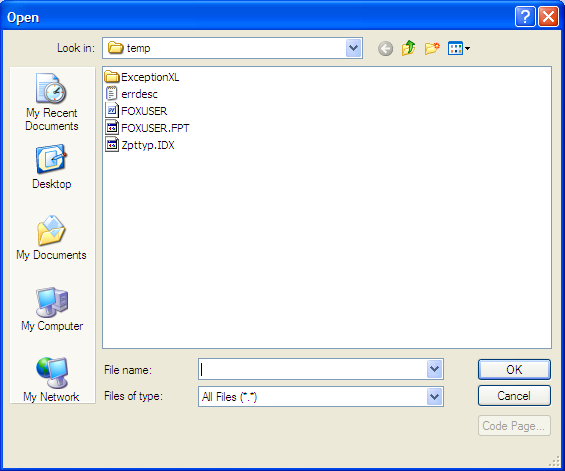

Depress the Load Document button and the following screen will appear: The PDF screen will allow you to load almost any type of document; (Word, Excel, pdf, Images, etc .... )

Locate the document and double click on it and the document will populate screen.

Depress the Save record icon to save or depress the Abandon changes icon to abandon changes. The following screen will appear:

Depress the Save record icon to save or depress the Abandon changes icon to abandon changes.

Once documents are saved the "Quote Related Documentation" button will display in Red.

|

| 1.5. Customer Quotation Reports | If the user has not used the Component Quote Management module to update the costs, the user may print out the reports, as desired.

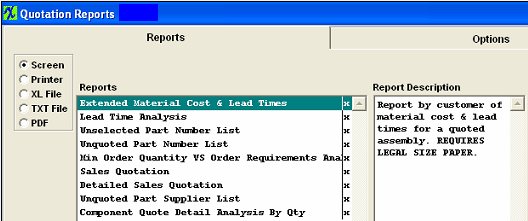

To obtain the Quotation reports, select the Print button from the ManEx action buttons at the top of the screen.

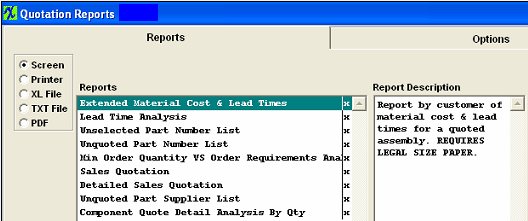

The following screen will appear:

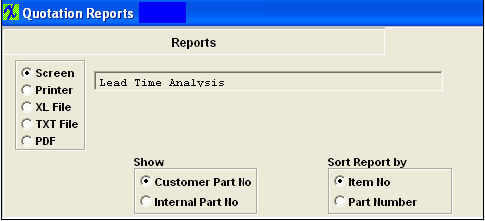

|

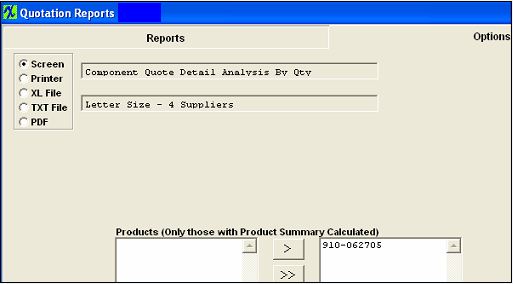

Select the appropriate radio for the output format you desire: Screen, Printer, XL File, TXT File, or PDF.

Highlight the desired report and then depress the Option tab if applicable.

|

|

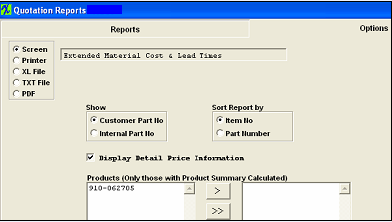

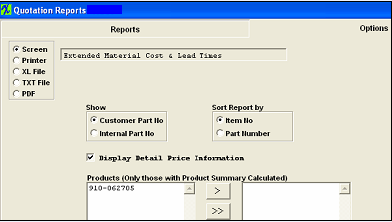

Extended Material Cost & Lead Times

|

Choose to view by Customer Part No. or Manufacturer Part No.

Highlight the product of preference and depress the > button.If you want all products depress the >> button.

Depress the OK button.

|

|

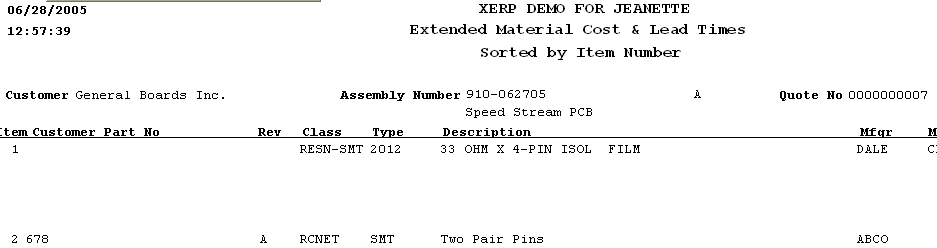

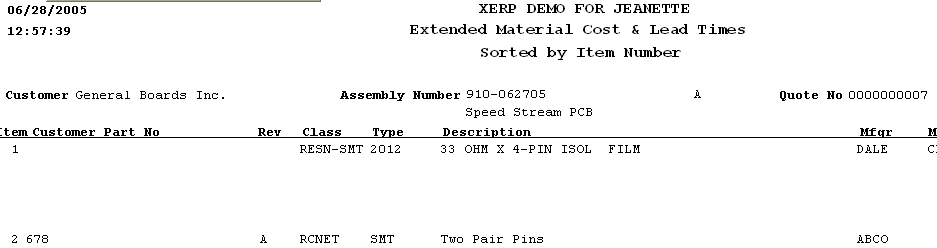

The following is printed:

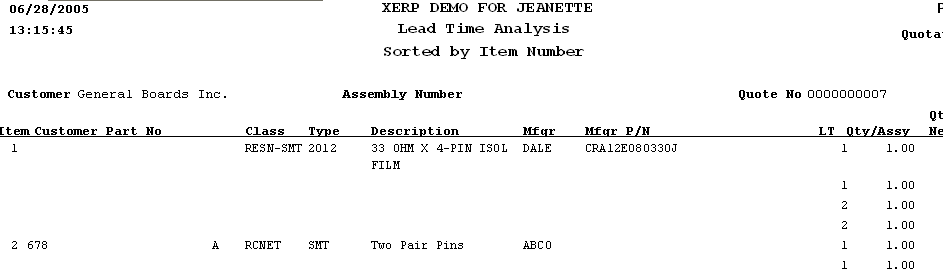

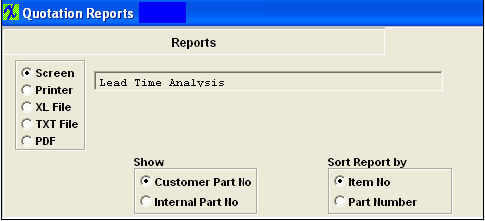

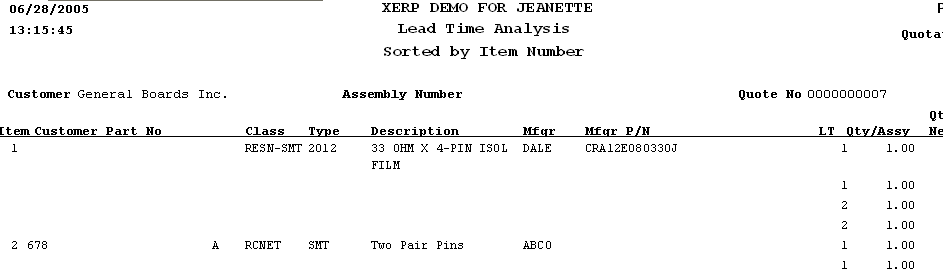

Lead Time Analysis

|

Choose to view by Customer Part No. or Manufacturer Part No.

Depress the OK button.

|

|

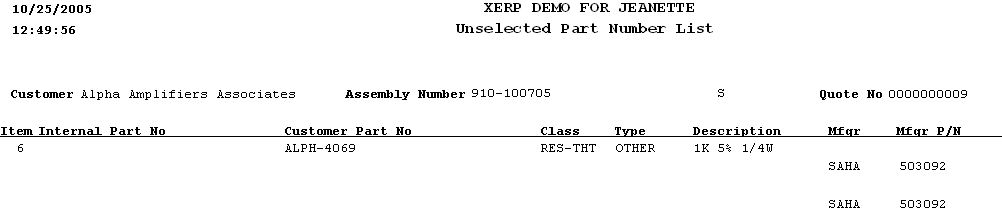

The following is printed.

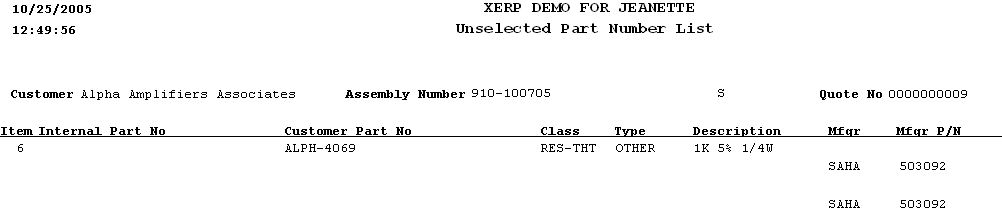

Unselected Part Number List reportHighlight the Unselected Part Number List report. Depress the OK button.

The following is printed

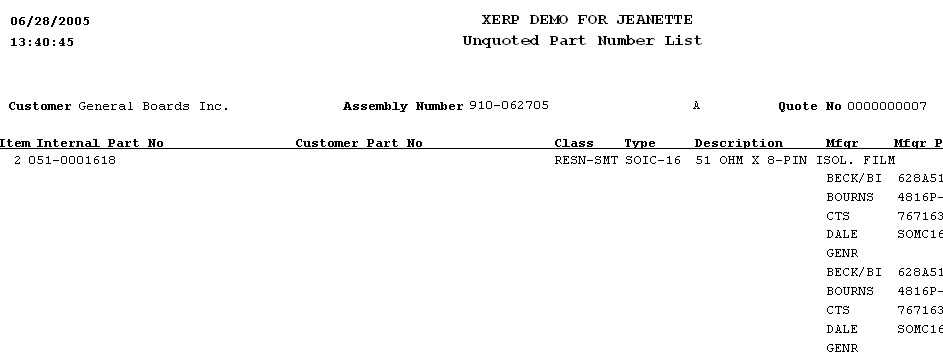

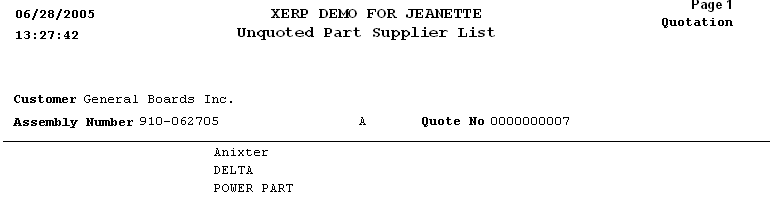

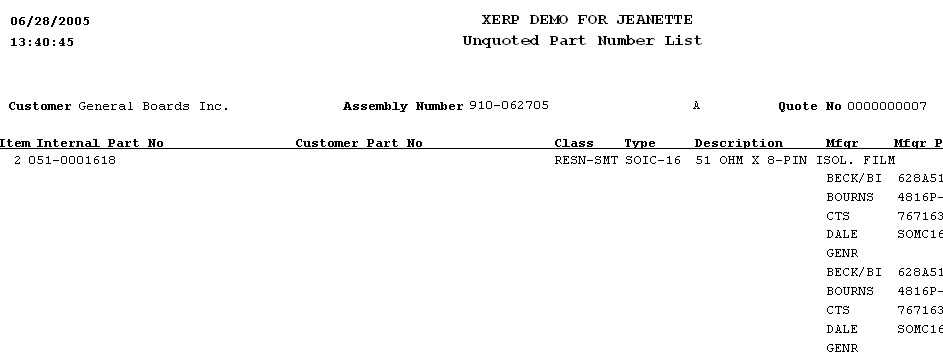

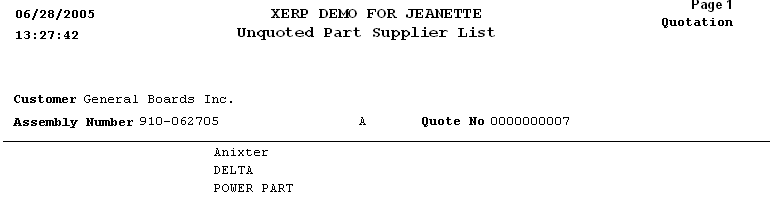

Unquoted Part Number List report

Highlight the Unquoted Part Number List report. Depress the OK button.

The following is printed:

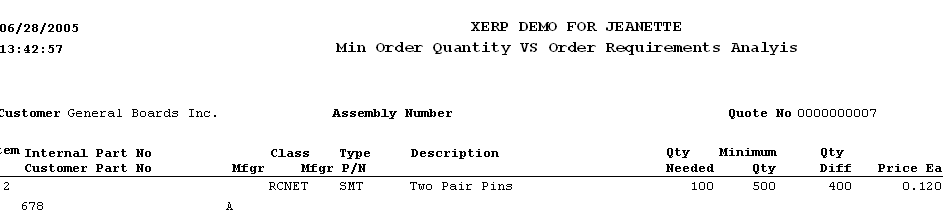

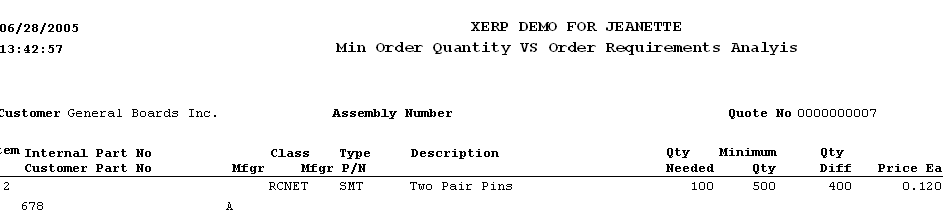

Min OrderQuantity VS OrderRequirements Analysis reportHighlight the Min Order Quantity VS Order Requirements Analysis report.

Depress the OK button.

The following isl printed.

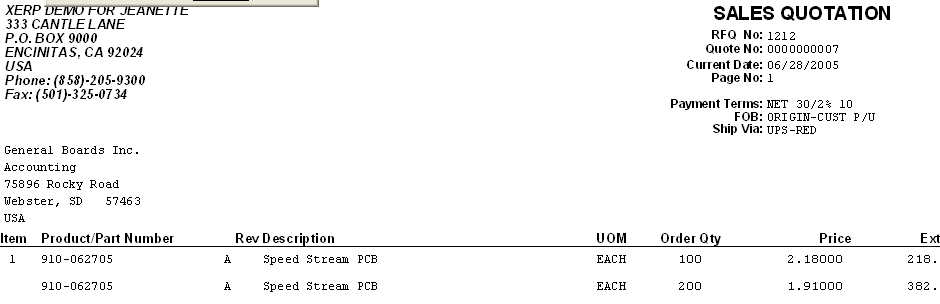

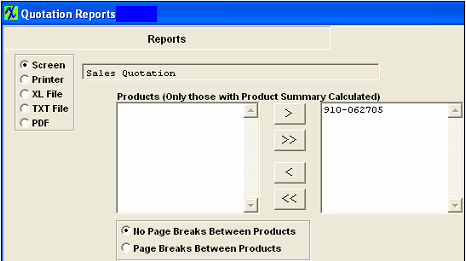

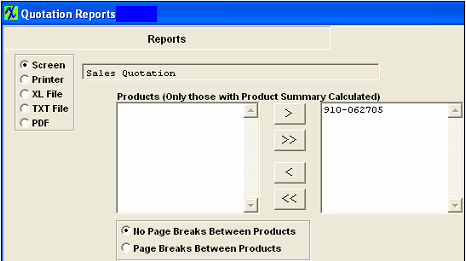

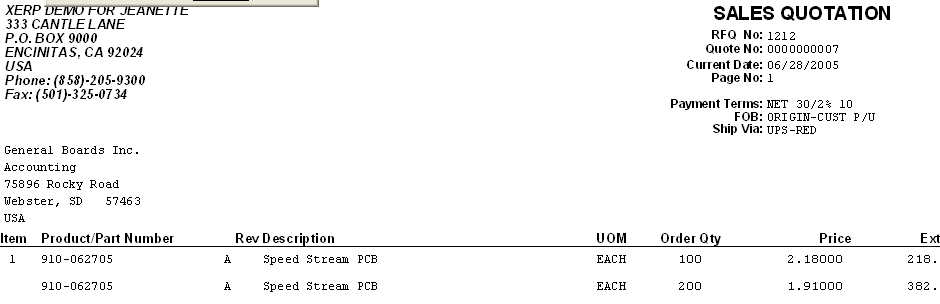

Sales Quotation report

|

Highlight the product of preference and depress the > button.If you want all products depress the >> button.

Depress the OK button.

|

|

The following is printed.

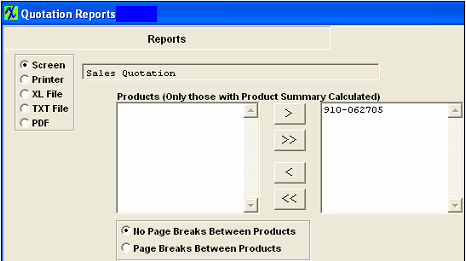

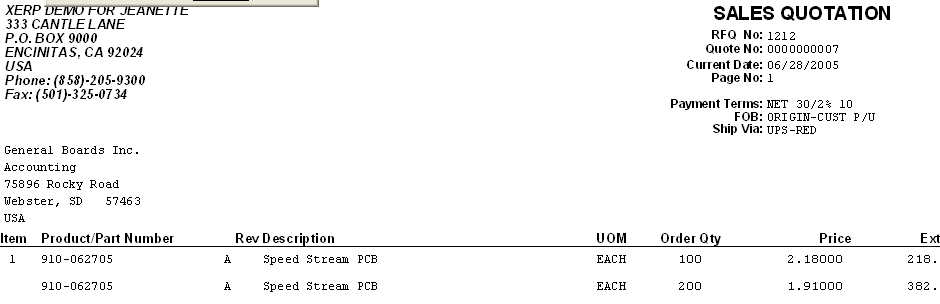

Detailed Sales Quotation report

|

Highlight the product of preference and depress the > button.If you want all products depress the >> button.

Depress the OK button.

|

|

The following is printed

Unquoted Part Supplier List report

Highlight the Unquoted Part Supplier List report.

Depress the OK button.

The following will print:

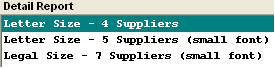

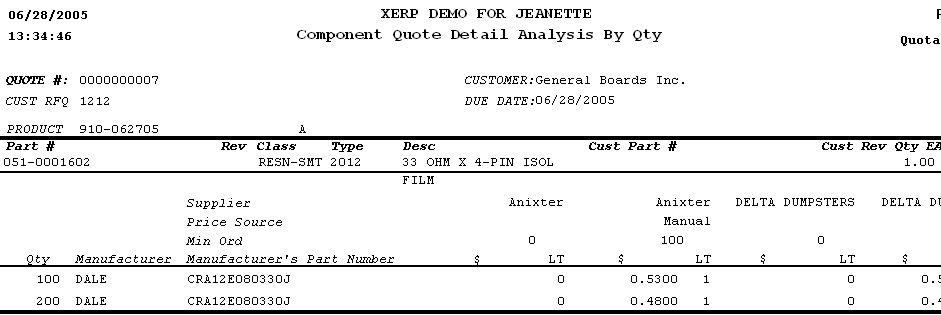

Component Quote Detail Analysis by Qty report

|

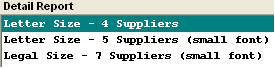

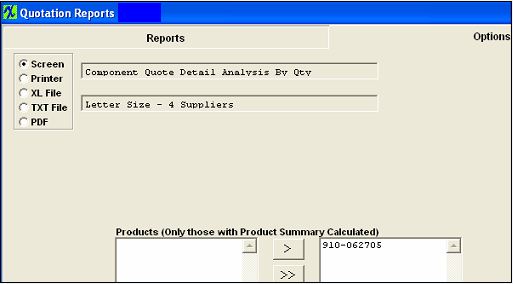

Highlighting the Component Quote Detail Analysis by Qty report will bring up a selection of reports to print.

Highlight the report of your choice and depress the option tab.

|

|

|

Highlight the product of preference and depress the > button. If you want all products depress the >> button.

Depress the OK button.

|

|

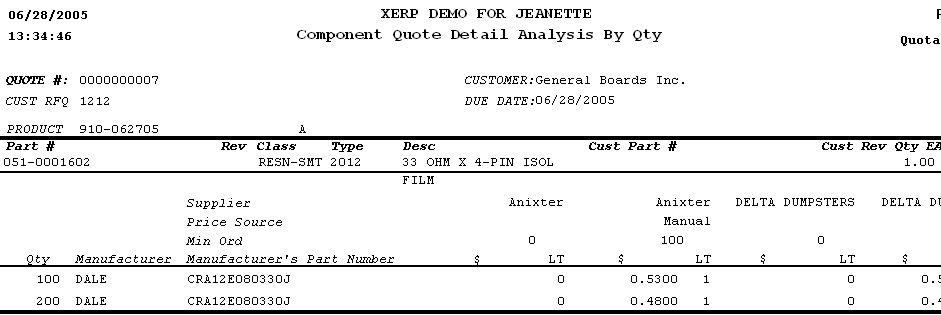

The following is printed

|

|