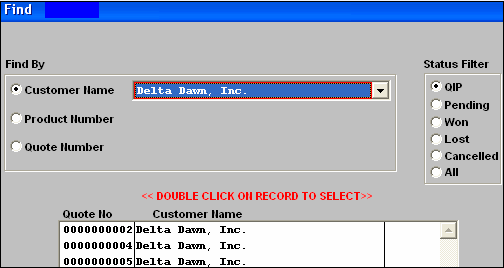

| 1. How To ..... |

| 1.1. Find a Customer Quotation | ||||||||||||||

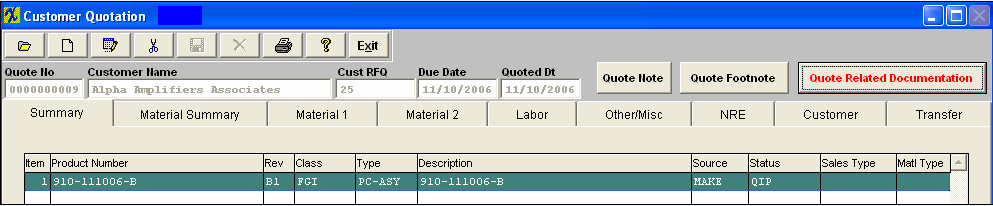

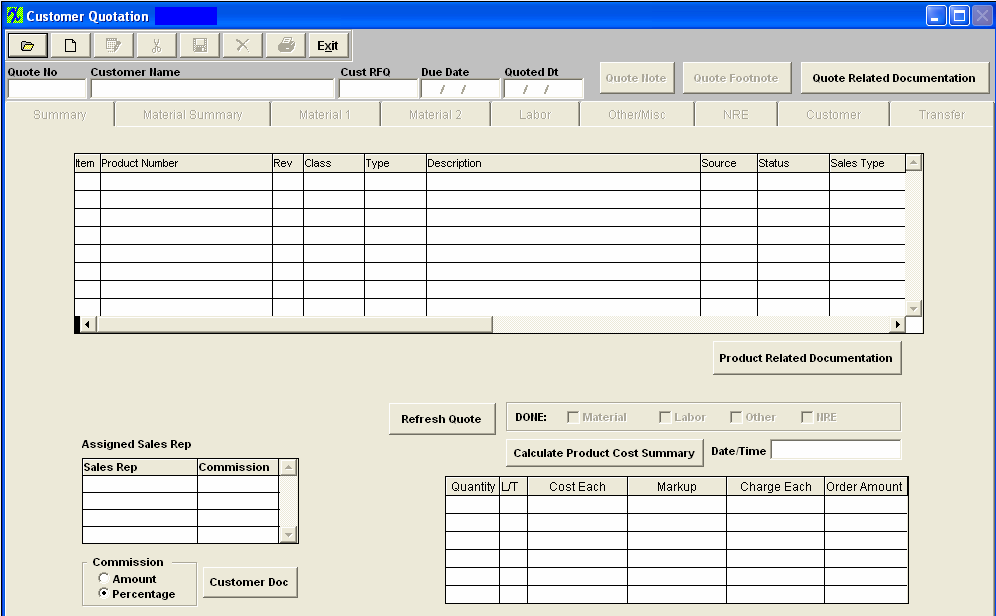

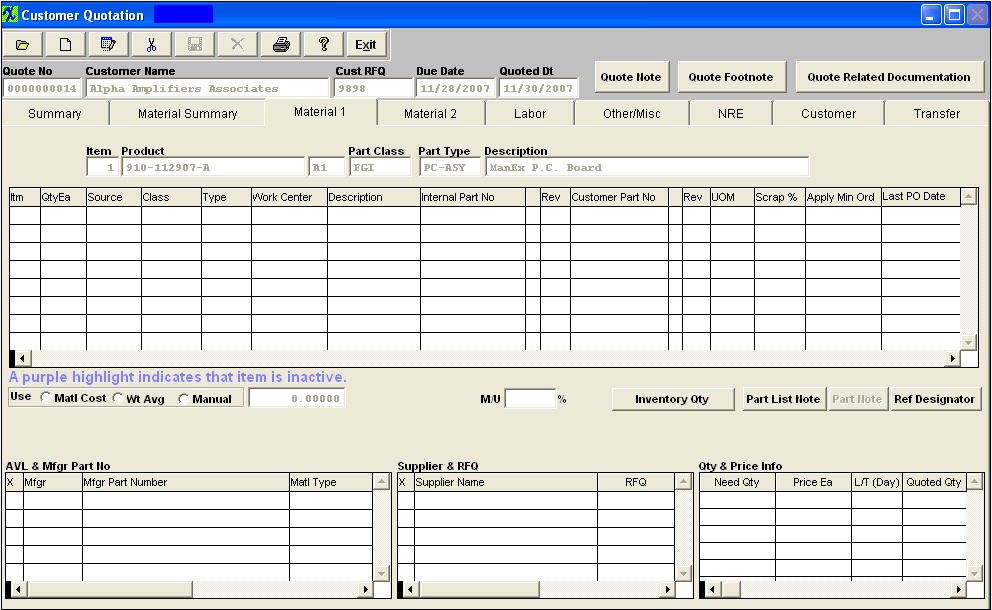

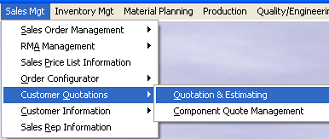

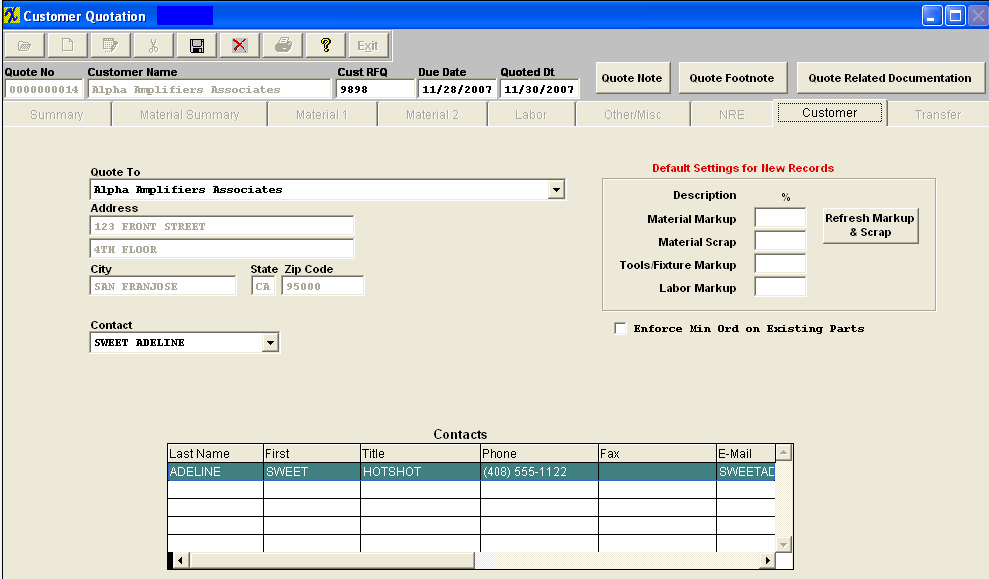

The following screen will be displayed: Within this screen, an estimate is created select the Add action button to create a new record or the Find action button for viewing and editing an existing quote. Find an EstimateDepressing the Find action button displays the following sequences:

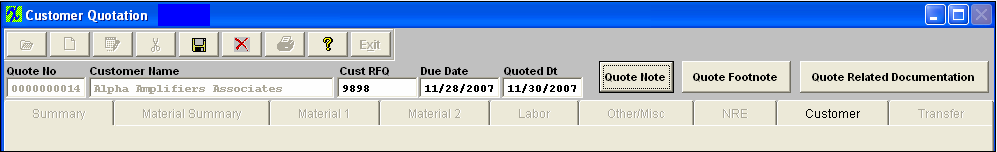

Once you have made your choice, the information regarding that quote populates the screen.

|

| 1.2. Create a Quote | |||||||||||||||||||||||||||||||||||||||||

The following screen will appear:

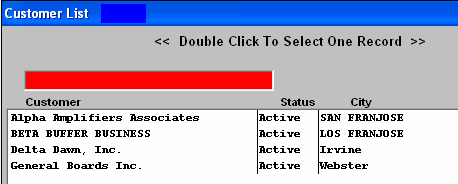

The following Customer List will appear: Highlight the desired customer and double click. The Customer name will transfer onto the screen. Enter in the Customer RFQ Number, Due Date, and Quoted Date.

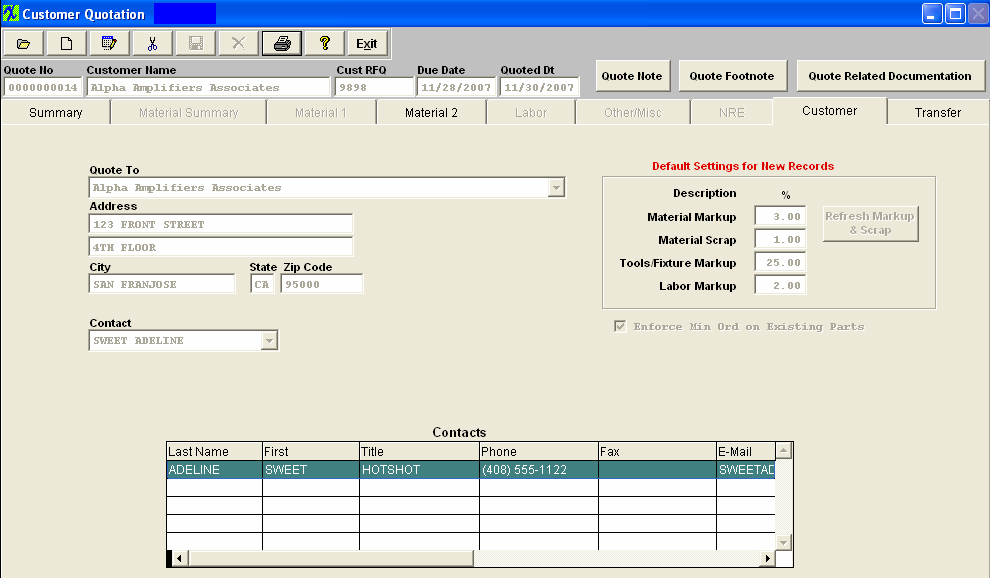

Enter the Customer Tab Select the desired Quote To address, (if different from the default) by depressing the down arrow next to the Quote To box. Enter the Default Settings for New Records. Check the box to Enforce Minimum Order on Existing Parts. Depress the Save button. The completed screen will appear:

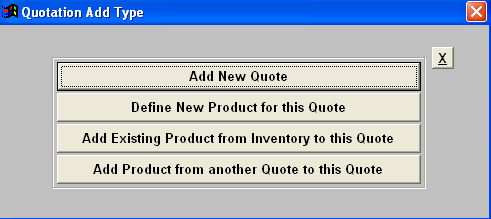

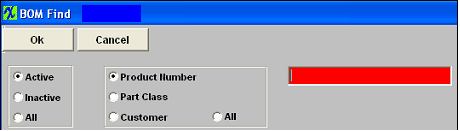

The selection to Add a New Quote will allow the user to start the new quote from scratch. The selection to Define New Product for this Quote will allow the user to add a product from scratch to the Quote.(Detailed below) The selection to Add Existing Product from Inventory to this Quote will bring up the following BOM Find screen:

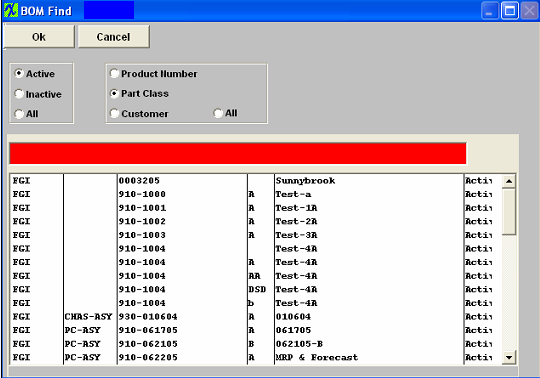

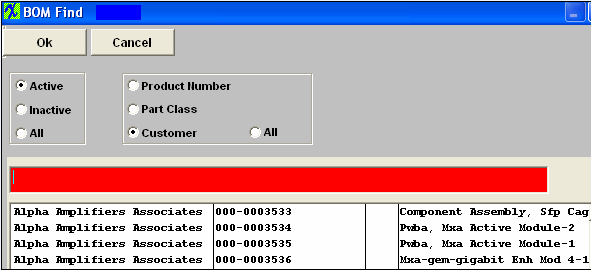

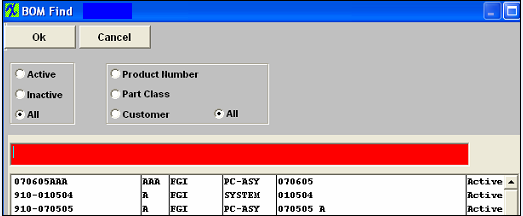

Select the BOM status, Active, Inactive or All, then select the BOM by Product Number; Part Class, Customer, or All by clicking on the appropriate radial.

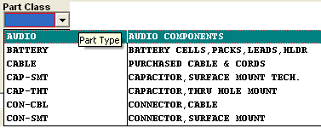

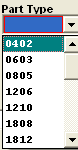

To select by Part Class, click on that radial and type the Part Class into the red box. Depress the OK button. The following screen will appear: Type in the Product Number and revision number if applicable

To select by Customer, depress the radial for Customer. Place the cursor in the red box. Type in the 1st letter of the customer. The following list will appear:

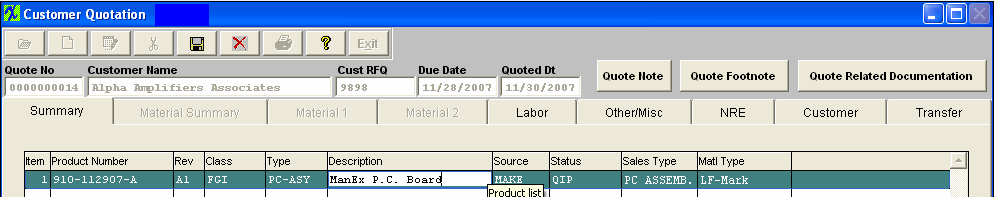

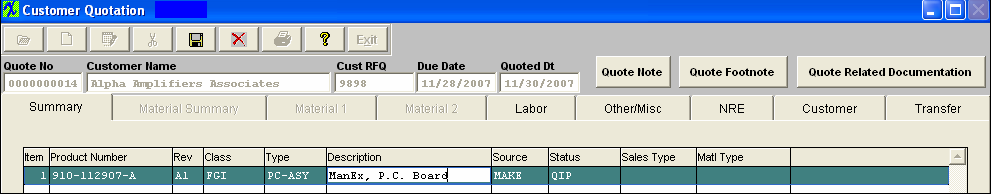

The Summary screen will display the product, as follows:

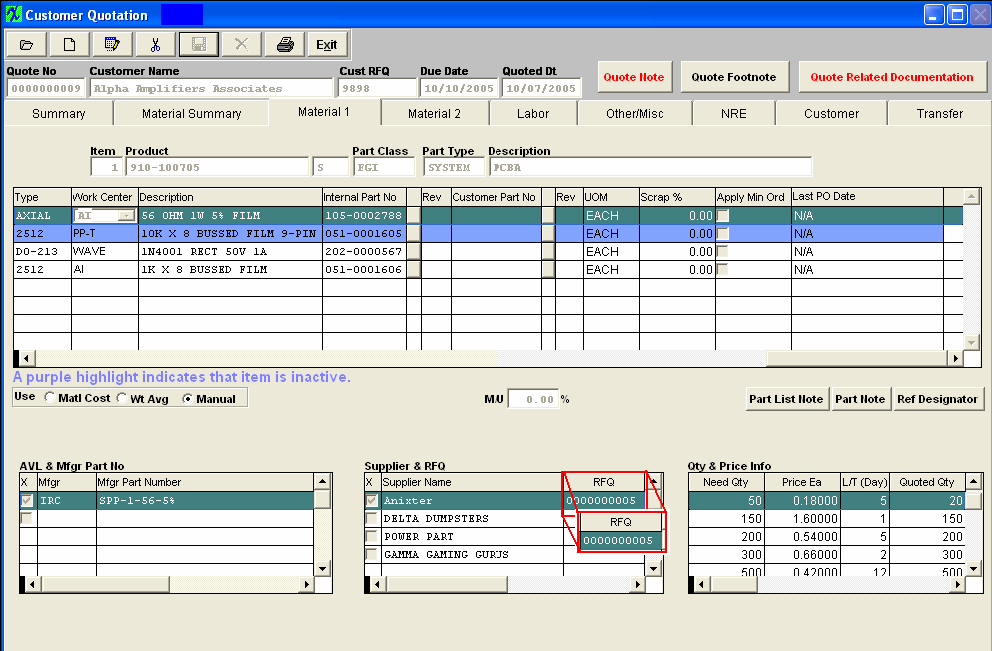

The components for that Product will appear in the Material 1 window, as illustrated below: Note: If you Add existing product from Inventory to quote, quote having same customer as existing product, only the approved AVL’s in existing product will copy over. If you Add existing product from Inventory to quote, quote having different customer than the customer linked to the existing product or the existing product not linked to a customer, then the system will pull AVL’s from consigned data if that customer is linked to that part. If customer is not linked to the part then the AVL’s will be pulled from the Internal data.

Edit the Material 1 screen as desired. The user may add new components, delete existing components and/or change quantities. Finish off the other screens, as detailed in Article #911 .

If you want to copy from another quotation, select the Add Product From Another Quote To This Quote:

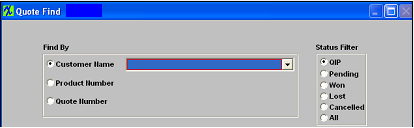

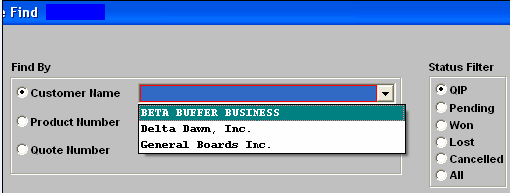

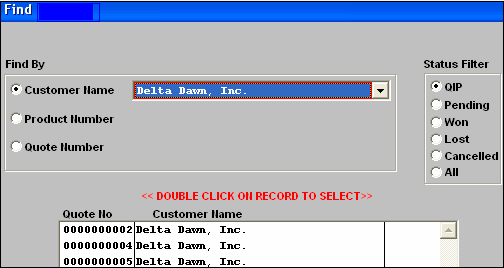

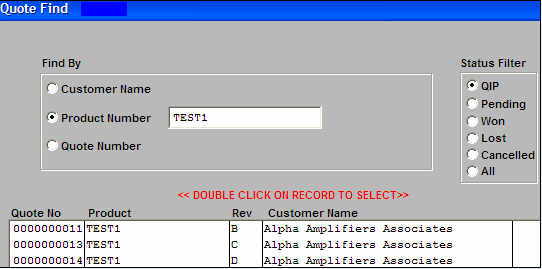

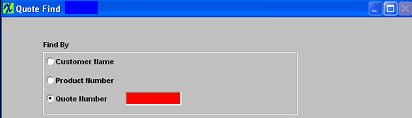

A Quotation Find screen will appear. The user may find by Customer, by Product Number or by Quote Number. The user may select the appropriate Status Filter radial button, to filter by Quotation in Process, Pending Quotation, Won Quotation, Lost Quotation, Cancelled Quotation or All.

If the user selects Find by Customer Name, depressing the down arrow produces a list of Customer names from which to choose, as displayed in the screen above.If the customer has more than one quote, the user will be presented with the following screen. Select the appropriate quote number and double click:

Once the previous quote is selected and the product number is amended to make it unique, the user may edit any of the applicable screens as detailed below.

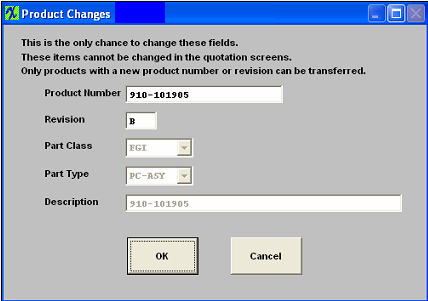

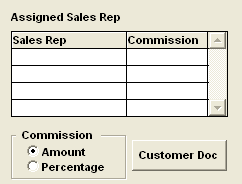

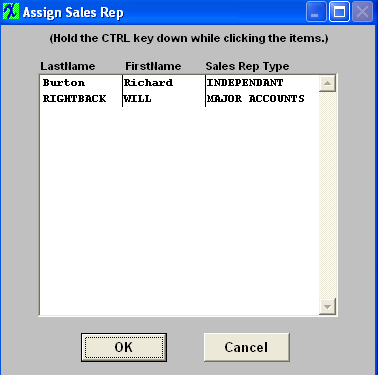

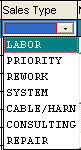

Depress the Ctrl key and click on the representative(s) of choice. Depress the OK button. Click on the appropriate Commission radial, either Amount or Percentage.Enter the number in the Commission column opposite the Sales Rep. If you selected Define New Product for this Quote. Enter the Product Number, Revision Number, if applicable. Select Class, Type, Source, Sales Type, and Material Type from the drop down lists.

Enter the description:

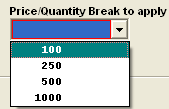

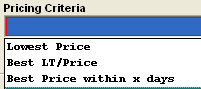

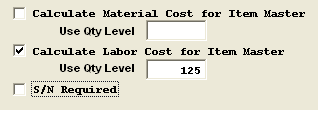

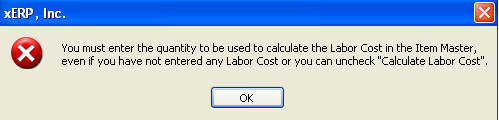

The user may elect up to seven quantity pricings. Depress the

The following two screens will appear. Fill in the Lead Time Days and the quantity and depress the enter key. Thelead times are being imported into the system/quote by Days. When all of the quantities have been entered, depress the Save button.

|

| 1.3. Add Materials To Quote & Transfer to Inventory | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

There are two tabs in which to add components to the assembly. The Material 1 tab is for those inventory items which currently exist in the user’s Inventory Master. The second tab is for items which are not identified in the user’s Inventory Master. The user may use a combination of the two. For both tabs, the Mark Up Percentage will automatically bring up the default percentage from the customer tab, but it may be edited by the user.

Material 1 Tab These are the components for the new assembly when the item is included in the Inventory Master.

Depress the Material 1 tab; The following screen will appear:  Depress the Edit button, enter password.

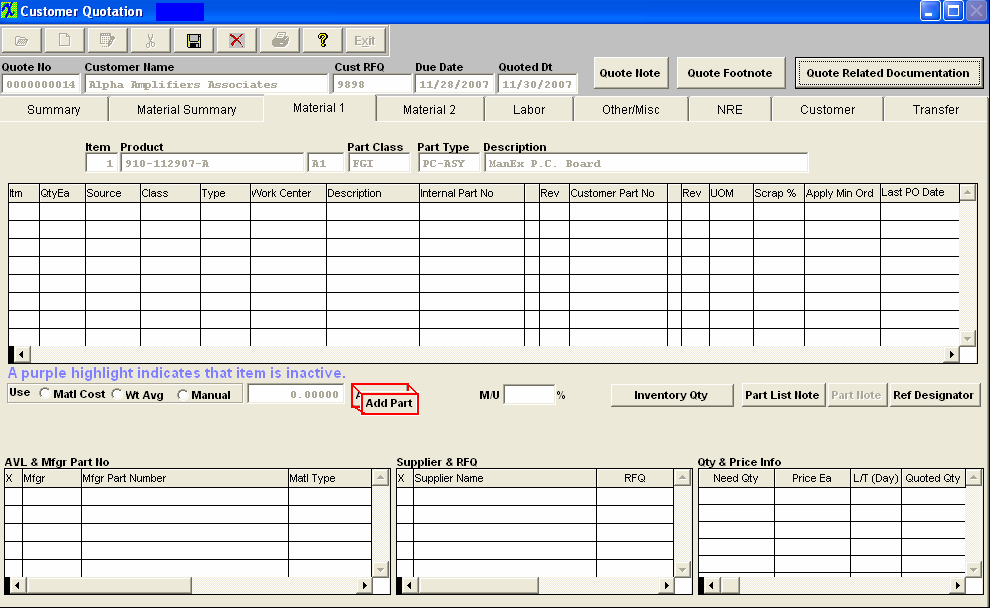

The following screen will appear:

Depress the

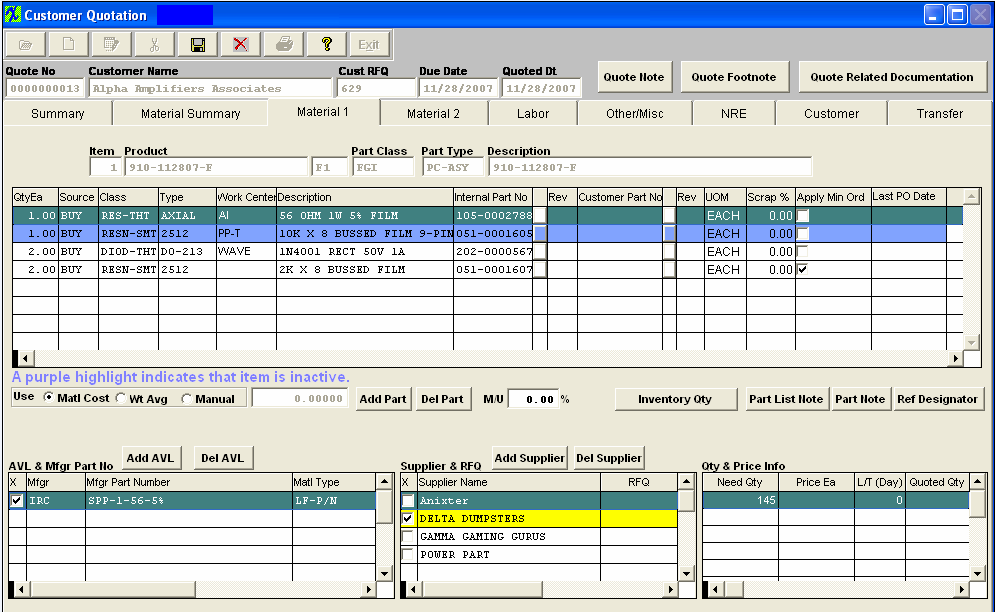

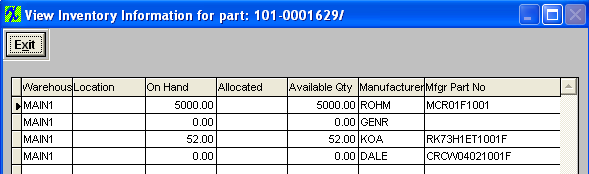

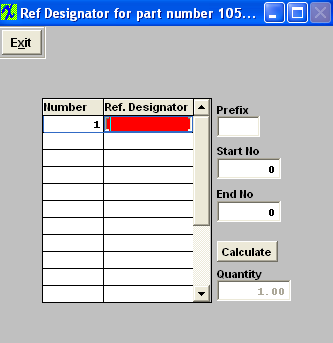

Depress the OK button. Enter the Item number, Quantity each, select the Part Source, and enter the internal part number. If the Part List has more than one available, a selection screen will appear. Double Click to Select the part you want to consider. The following columns will fill in automatically: Class, Type, Description, Revision number, Scrap %,(If applicable), AVL's, and customer PN (if part source is CONSIGNED). User may enter the customer part number and applicable revision number if part number exists in Inventory records. Check the Apply Minimum Order, and select a Work Center, if desired.

Select the Costing radial to use – Matl Cost, Wt Average or Manual. Material Cost is per the Inventory Master. Weighted Average is the weighted average of the last five Purchase Orders processed for that part number. Manual cost is per the user.

Select AVL

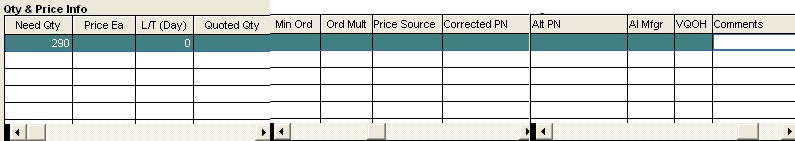

There are two ways to fill in this information: 1. The Quantity and Price information sections are forwarded by depressing the Update Quote button in the Component Quote Management module. To view after the Update, highlight the selected Supplier and the quote information will appear. 2. If you selected Manual costing radial, you may enter the price each in the Quantity & Price Information section in this screen.

To add a Part List Note, or a Part Note.

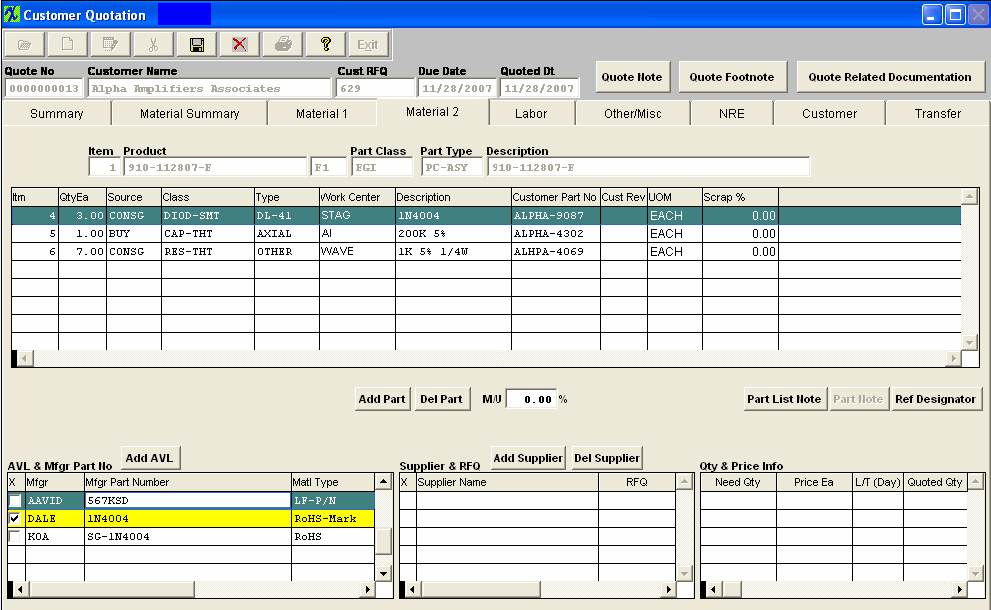

Material 2 Tab These are the components for the new assembly when the item is NOT included in the Inventory Master. NOTE: When the parts from Material 2 screen are transferred from quote to BOM, inventory item master part numbers are created for each item. The system does NOT search the inventory item tables for an existing part number and will create new item master part numbers, even if the manufacturers and part numbers are the same.

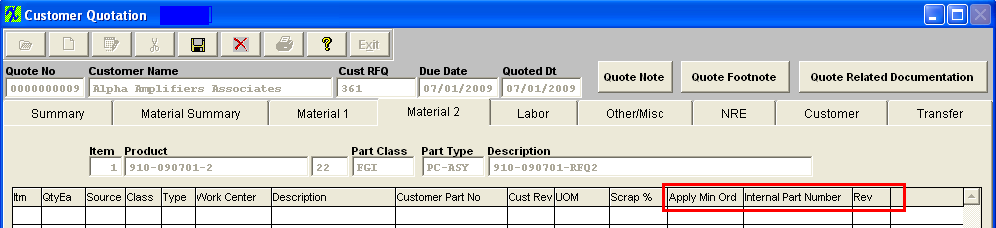

The user has the option to auto or manual number new inventory parts created in the Material 2 screen. (If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will automatically assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, user will need to manually assign a part number and revision to the item added in the material 2 screen. ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers. Depress the Material 2 tab. Depress the Edit button, enter password.

The following screen appears:

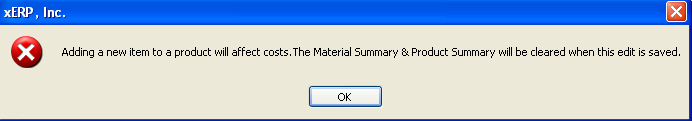

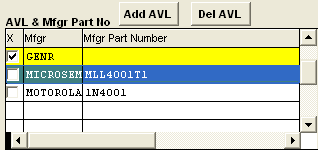

Depress the The following message will appear:  Depress the OK button. Enter the Item number, Quantity each, select the Source, Class, Type, and Work Center from the pull downs. Enter the Description, Customer PN and Rev (if applicable), select Unit of Measure from pull down, and enter scrap % if applicable. If "MANUAL" numbering is selected in the Number System screen for Inventory parts, the Material 2 screen will display three additional fields shown below in Red box:  Select AVL

Highlight the Part Added. Depress the Add AVL button.

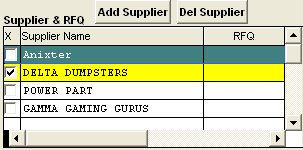

The Supplier for that Inventory Class will appear if added in the Supplier Line Card Information. The Supplier Request for Quote number will display to the right of the Supplier, once a quote has been requested in Component Quote Management. Once the supplier has been checked it will be highlighted in yellow. Quantity and Price Information

There are two ways to fill in this information: 1. The Quantity and price information sections are forwarded by depressing the Update Quote button in the Component Quote Management module. To view, highlight the selected Supplier and the quote information will appear.

2. You may enter the price each in the Quantity & Price Information section in this screen. The price source will display as manual. Continue to Add parts,AVL & Manufacturer’s Part Number, Supplier Name and Quantity & Price information until all components (not included in Inventory Master) are included. Depress the Save button. The completed screen will appear as follows:

To add a Part List Note or a Part Note.

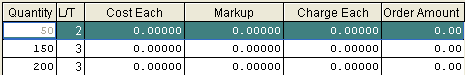

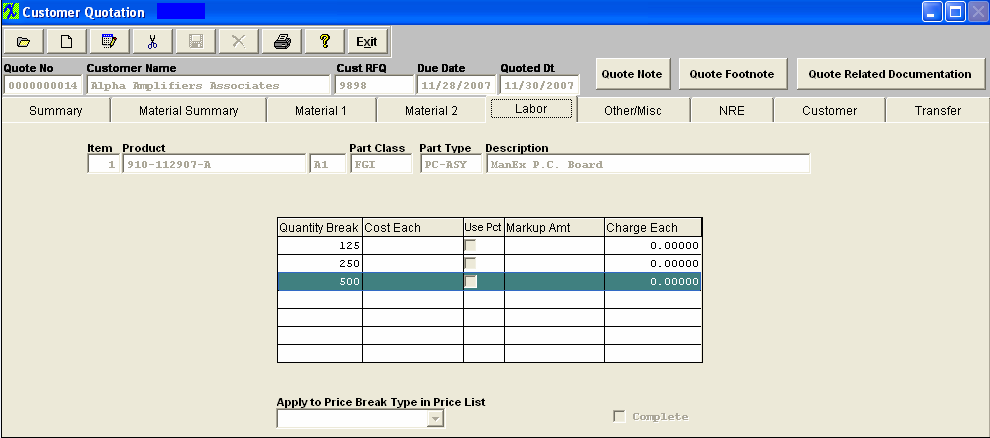

Labor Tab Depress on the Labor tab and the following screen will appear:

Depress the Edit Button, enter password.

Enter the Cost Each of labor, then check the "Use Pct" box if the percentage is be used, do this for each quantity break.

Thereafter, changing the “Cost Each” will NOT change to the markup amount. This is so that users may manually change the mark up to whatever they want, without having the default percentage override it. If the user wants to have the percentage create a new markup, go to the customer screen and depress the "Refresh Markup & Scrap" button and the new percentages will be applied to all existing parts for all Products within that quote.

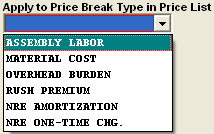

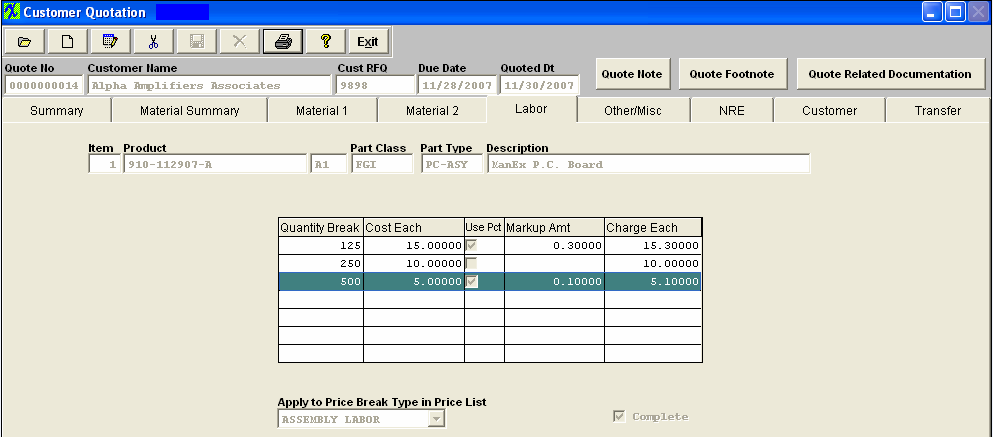

Press the down arrow for" Apply to Price Break Type" in Price List. Select the type pertaining to Labor.

Check the Complete box. Depress the Save button. The completed screen will look like this.

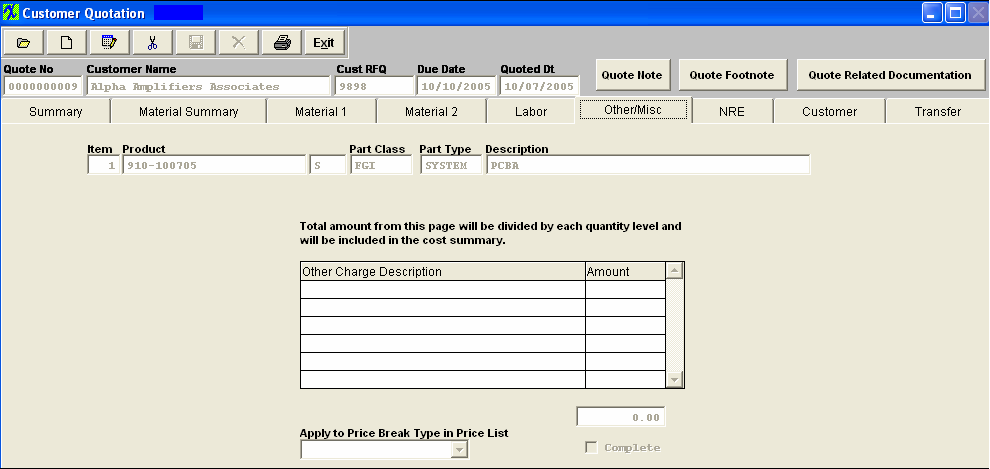

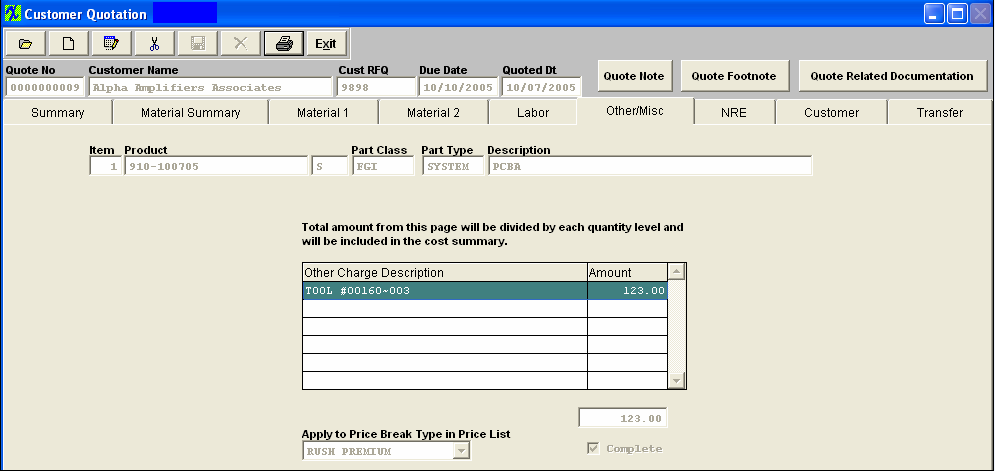

Other/Misc. Tab Depress the Other/Misc. Tab and the following screen will appear:

Depress the Edit button, enter password.

Depress the Add button. The following message will appear:

5. Depress the OK button.

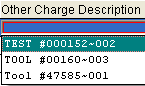

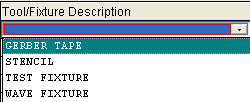

6. Depress the down arrow in the Other Charge Description section. A listing of Other Charge Descriptions will appear. Select the pertinent one. 7. Type in the amount pertaining to that charge.

The completed screen will look like this:

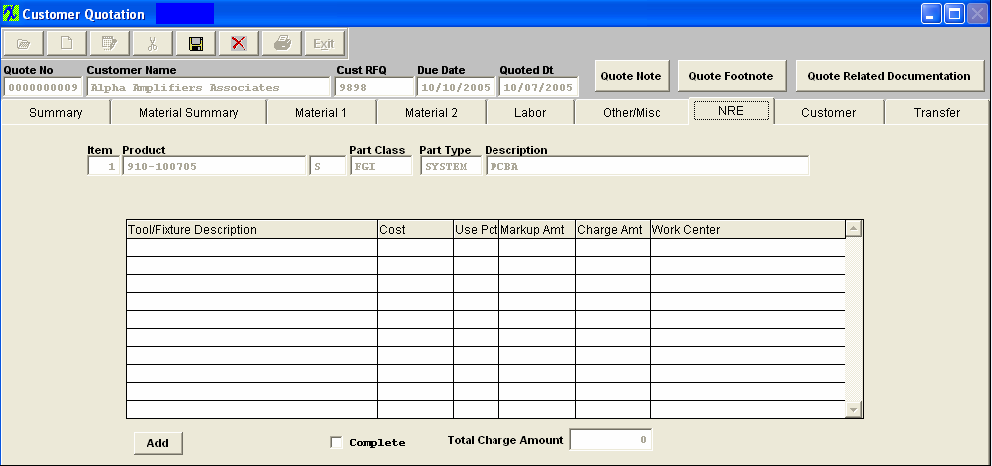

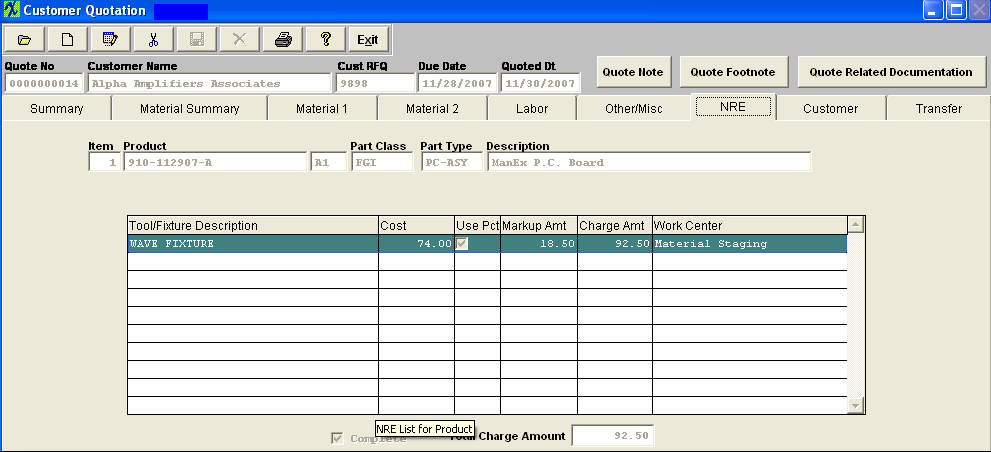

Note: That any amounts entered here are amortized over the quantity quoted. NRE Tab Depress the NRE tab and the following screen will appear:

Depress the Edit button, enter password.

Depress the OK button.

Depress the Add button.

Enter in the Cost, then check the "Use Pct" box if the percentage is be used. The Markup Amount and Charge Amount will update automatically.

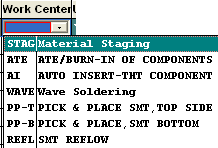

Select the Work Center pertaining to the non-recurring expense from the drop down menu.

The completed screen will look like this:

Note: That any amounts entered here represent a one time cost.(The quantity of units to be made, have no bearing on this number.) To setup information in the Customer tab see Article #622 .

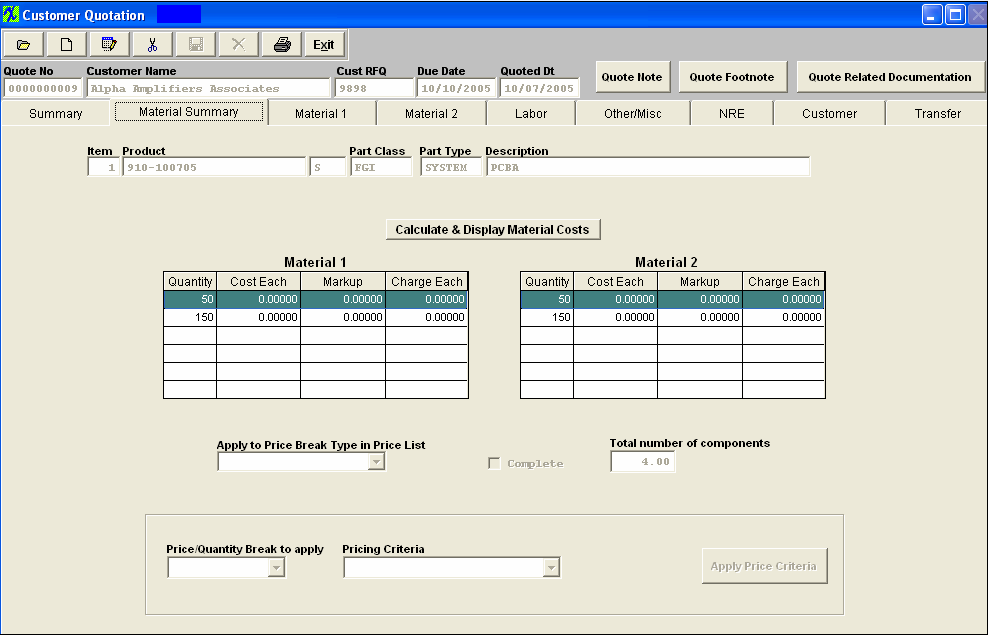

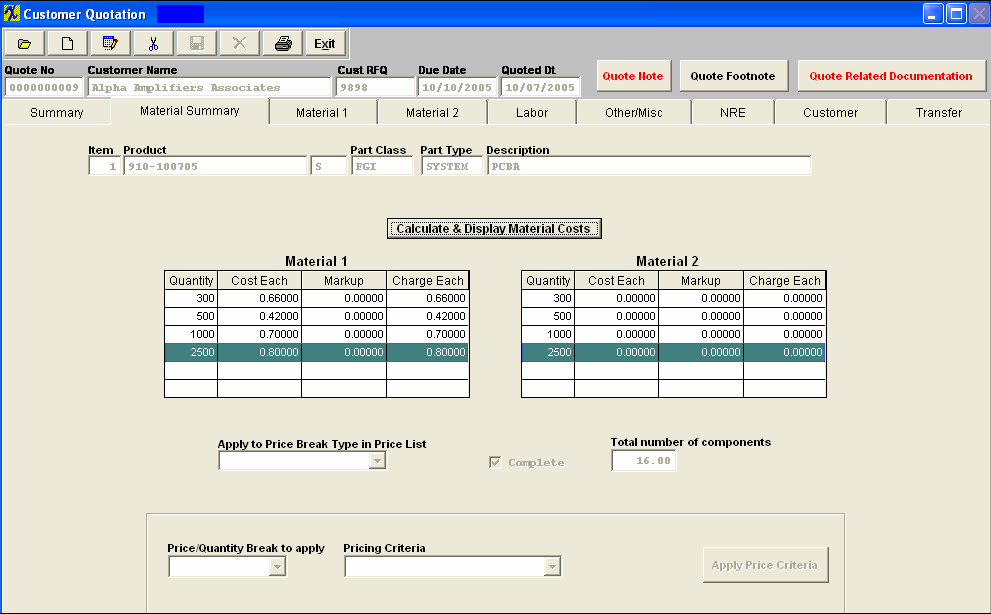

Before entering the Transfer tab, user will want to complete the Material Summary tab and Summary Tab.

Material Summary Tab If you are NOT going to update costs from the Component Quote module and have entered all of the pertinent costs manually, depress the Material Summary tab. Depress the Calculate & Display Material Costs button. The Markup and Charge Each will automatically update for items included in the Inventory Master for the Material 1 tab and any manually added costs in the Material 2 tab. The total number of components is calculated from the qty each column in Material 1 and Material 2.

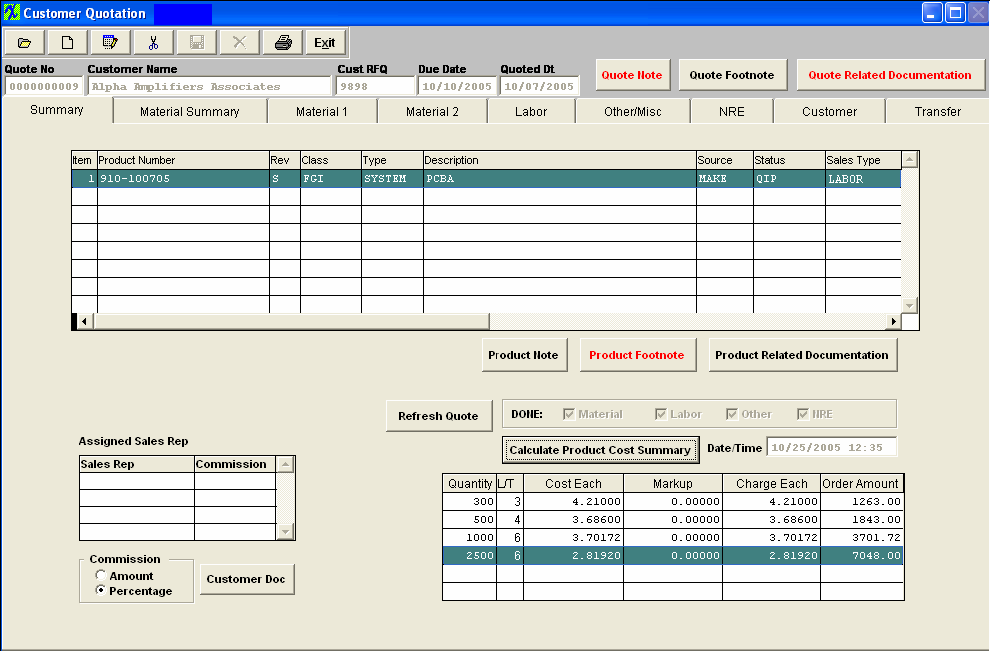

Summary Tab If you are NOT going to use the Component Quote Management module and have entered all of the material costs manually, return to the Summary Tab.

Depress the Quote Note or the Quote Footnote button.

Depress the Edit button in the Note screen.

Type in your note.

Depress the Save button.

Exit.

If you want to add a product note:

Highlight the product.

Depress the Edit button.

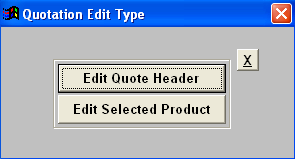

The following Quotation Edit Type selection will appear: Select Edit Selected Product. Depress the Product Note button or the Product Footnote button.

Depress the Edit button.

Type in the note.

Depress the Save button.

Depress the Exit button.

Depress the Save button.

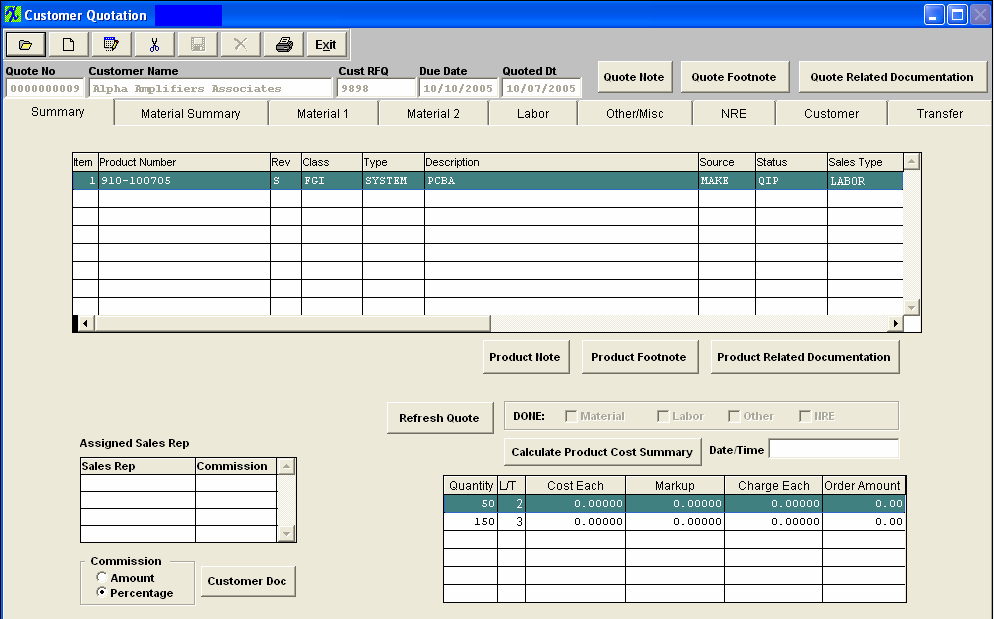

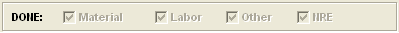

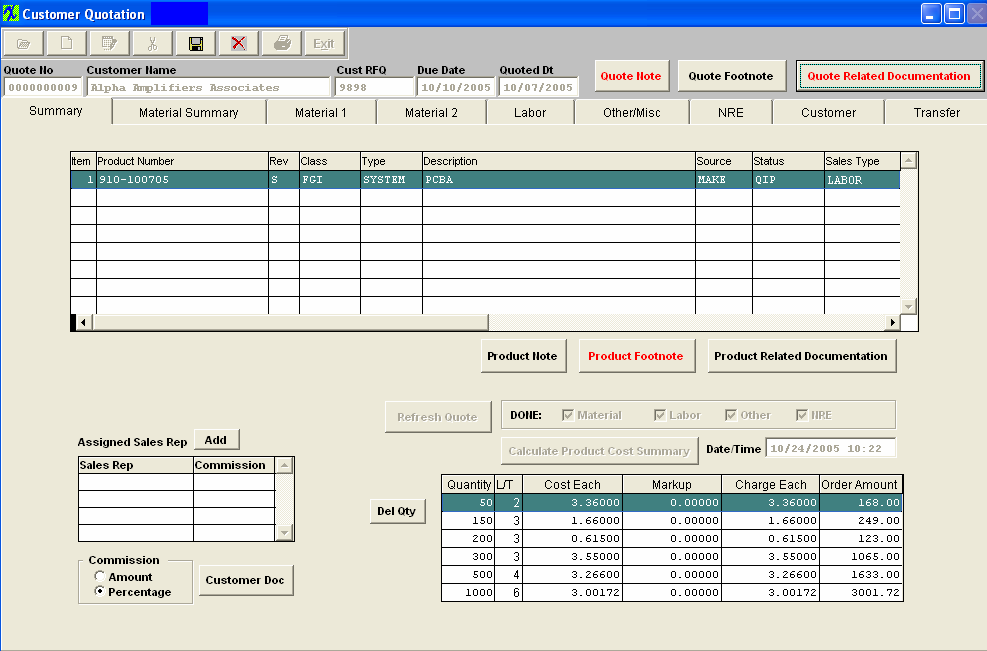

Depress the Calculate Product Cost Summary button.The Cost Each, Markup, Charge Each and Order Amount will automatically update. The completed screen will appear as follows:

Add another product number, if desired.

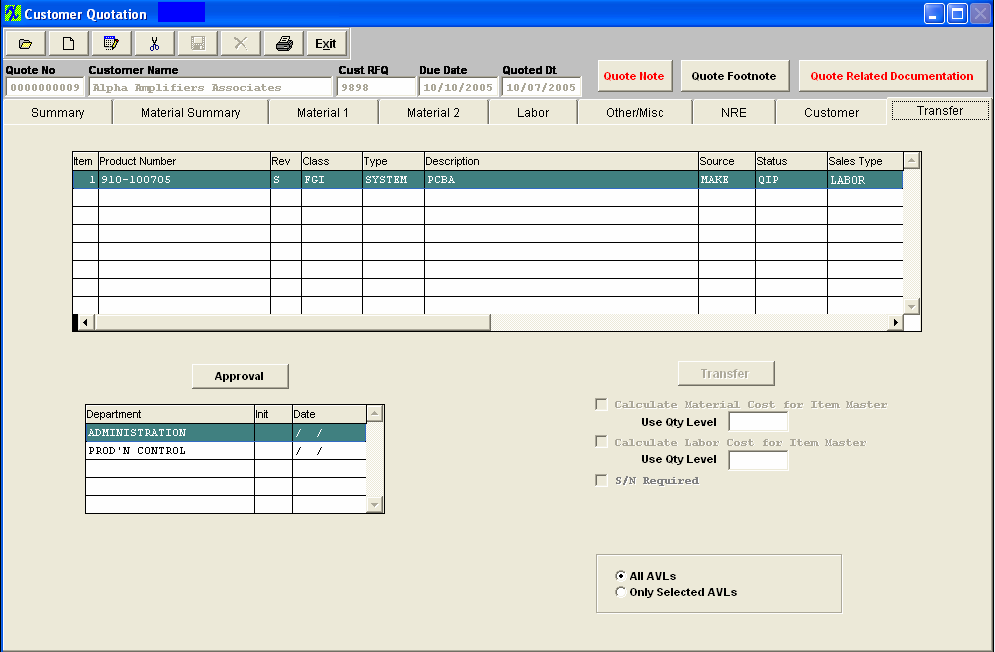

Transfer tab

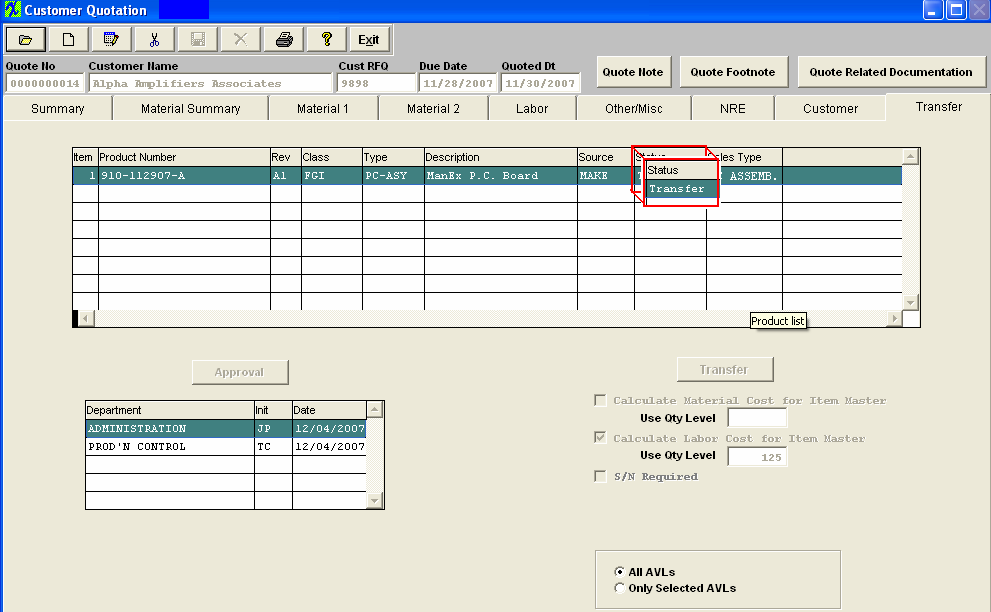

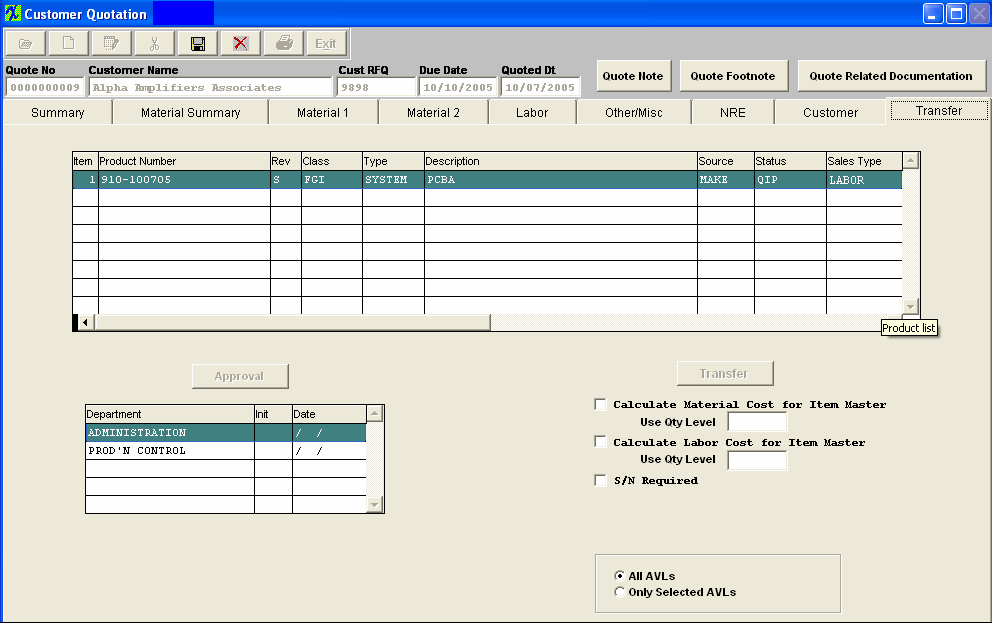

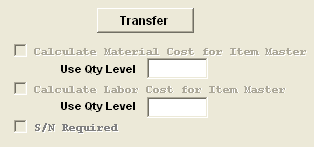

If the user did NOT use the Component Quote Management module, once the customer has accepted the quotation and the user now wants to add the new product to the Inventory Master and create a new Bill of Materials for the new product, the user may accomplish this by depressing the transfer tab. Note: Once the Transfer process is completed, no further changes are allowed to the Quote and that the status of the quote will change to Transferred.

NOTE: For this tab, a serial of approvals must be entered. In this example, approvals are required by a user assigned to the departments listed. Depress the Approval button. Have a user from engineering (for example) type in his/her password. Continue down the list until every department has the initials and date displayed. Once all the approvals have been entered the Transfer button will become available. The approvals will need to be re-entered after every Edit.

Depress the Save button. Note: Once the Edit button has been depressed the Approvals will clear and need to be re-entered again.

Depress the Transfer button, enter password. The Status of the Quote will be updated to Transfered, as displayed below:

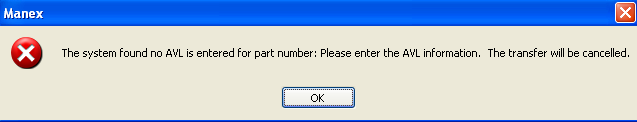

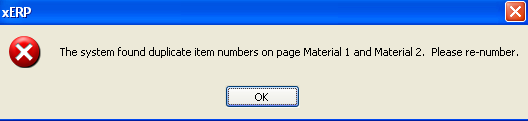

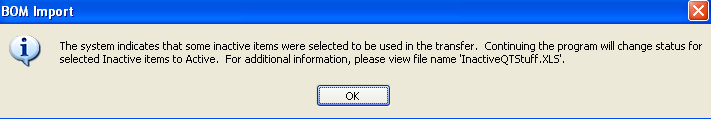

The system will run several validations at this point these are a few:

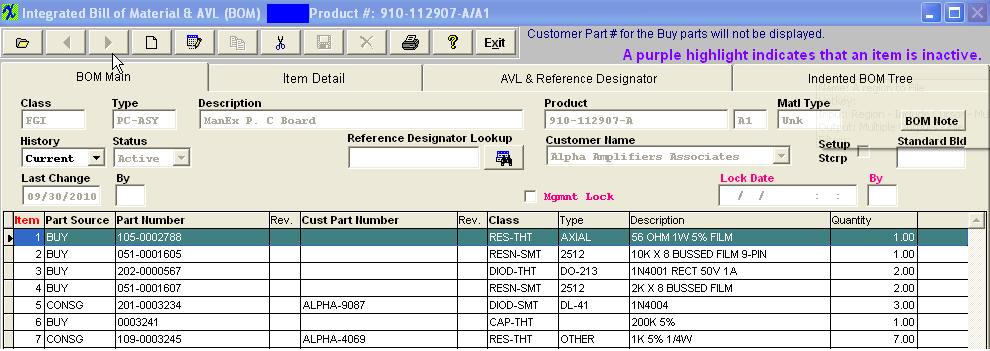

Once all the validations have been ran the BOM will be created with a Status of "Active:

|

| 1.4. Quotation and Estimating Completion | ||||||||||||||

Find the Customer Quote using the procedures above. You will note that the information from the Component Quote Management module has forwarded into the Quotation and Estimating module, as illustrated below:

If you are NOT going to update costs from the Component Quote module and have entered all of the pertinent costs manually, depress the Material Summary tab. Depress the Calculate & Display Material Costs button. The Markup and Charge Each will automatically update for items included in the Inventory Master for the Material 1 tab and any manually added costs in the Material 2 tab. The total number of components is calculated from the qty each column in Material 1 and Material 2.

Depress the Edit button if you would like to:

Depress the Summary tab.

Depress the Product Cost Summary button. The screen will update as displayed:

Now the user may print out the Customer Quotation and related reports. Once the customer has accepted the quotation and the user now wants to add the new product to the Inventory Master and create a new Bill of Materials for the new product, the user may accomplish this by depressing the transfer tab. Note that once the Transfer process is completed, no further changes are allowed to the Quote and that the status of the quote will change to Transferred.

NOTE: For this tab, a serial of approvals must be entered. In this example, approvals are required by a user assigned to the departments listed. Depress the Approval button. Have a user from engineering (for example) type in his/her password. Continue down the list until every department has the initials and date displayed. Depress the Edit button. Type in the password.

Depress the Transfer button, enter password and Quote status will change to Transfer, when the transfer is complete.

Note: If new part numbers are created within the Inventory Control module via the quote transfer all the defaults will be carried forward for the new part from the Part Class/Type Setup screen. |

| 1.5. Attach a Related Document |

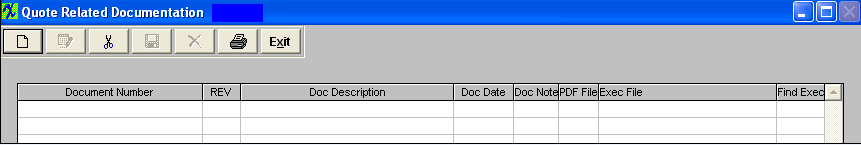

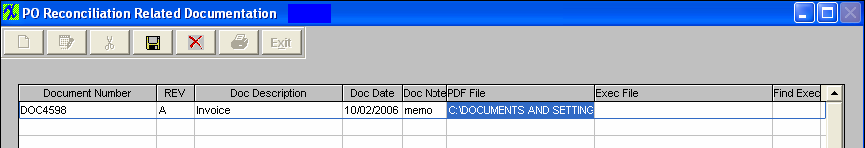

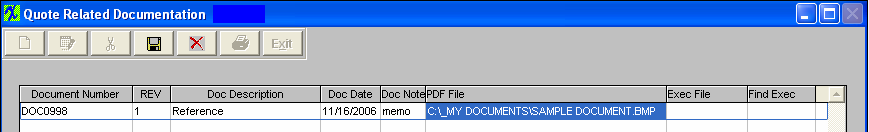

Find an existing Quote Record, or Add a new Quote record. Depress the The following screen will appear:

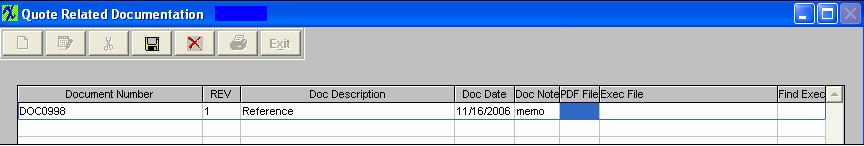

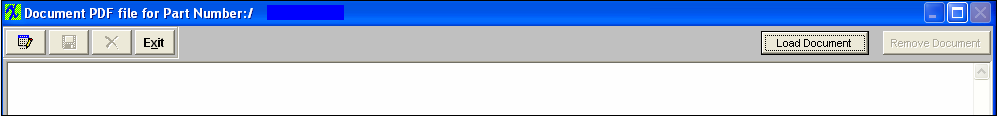

Depress the Add record icon, enter in a Document Number, REV, Doc Description, Doc Date, Doc Note; To load a document double click in the PDF File field and the following screen will appear:

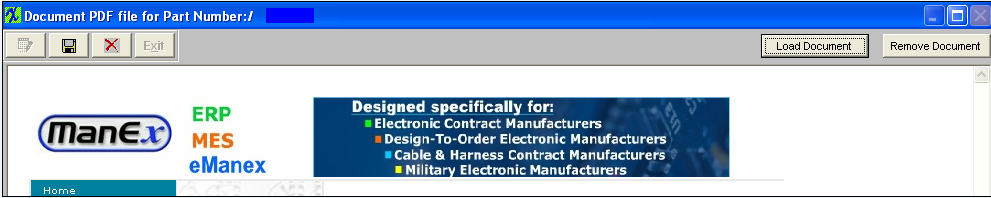

Depress the Load Document button and the following screen will appear: The PDF screen will allow you to load almost any type of document; (Word, Excel, pdf, Images, etc .... ) Locate the document and double click on it and the document will populate screen.

Depress the Save record icon to save or depress the Abandon changes icon to abandon changes. The following screen will appear:

Depress the Save record icon to save or depress the Abandon changes icon to abandon changes.

Once documents are saved the "Quote Related Documentation" button will display in Red.

|

button, and enter password.

button, and enter password.