| 1. How To ..... for SO Mgmt |

| 1.1. Find A Sales Order | ||||||||||||||||||

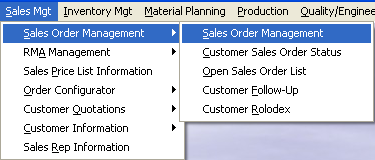

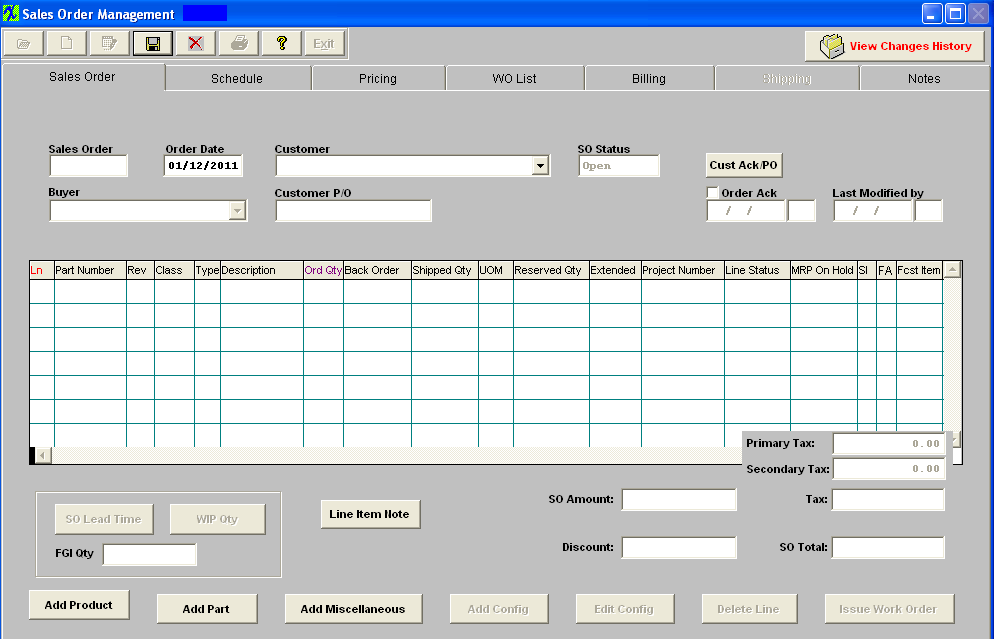

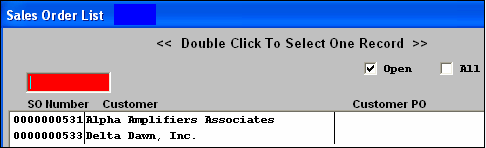

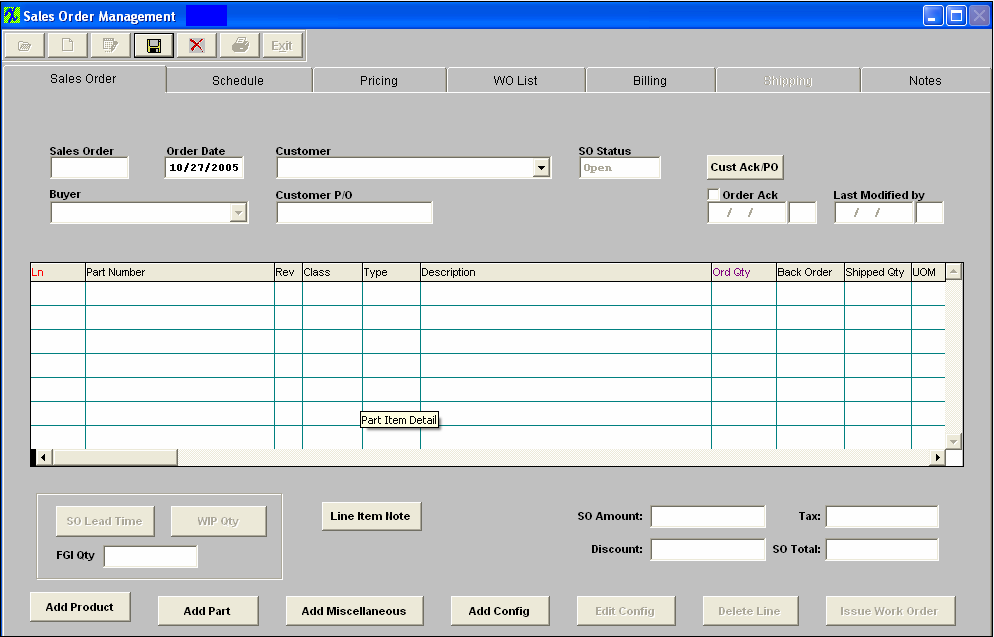

The following screen will appear:

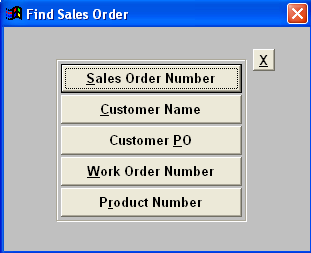

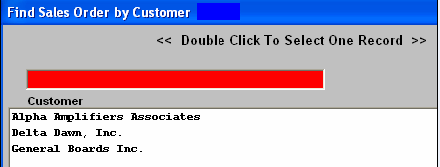

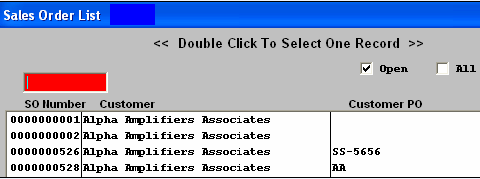

Depress the Find action button. The following selection screen will be displayed. To find an existing order select one of the following: Sales Order Number, Customer Name, Customer P.O., Work Order Number, or by Product Number. The user may exit the selection screen without a selection by selecting the X button.

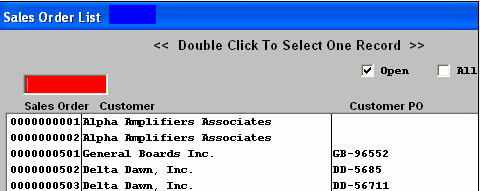

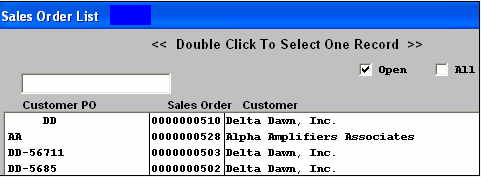

When the user elects to find an order by the Customer Purchase Order Number, a screen appears listing open Purchase Orders in numerical order, along with the Sales Order. The user may elect to show only open orders, or all orders. The user selects the Purchase Order by either entering it into the red box, or scrolling down the list and clicking on the selected order.

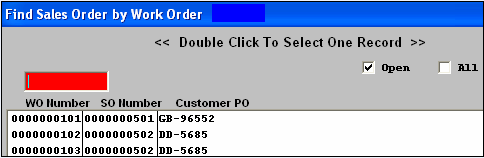

When the user elects to find an order by the Work Order Number, a screen appears listing Work Orders in numerical order, along with the Sales Order and Customer Purchase Order. The user may elect to show only open orders, or all orders. The user selects the Work Order by either entering it into the red box, or scrolling down the list and clicking on the selected order.

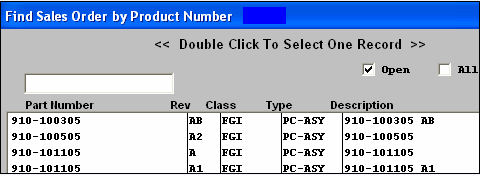

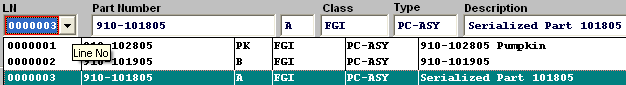

When the user elects to find an order by the Product Number, a screen appears listing part numbers in numerical order, along with the revision, Class, Type and Description.The user selects the Product by either entering it into the red box, or scrolling down the list and clicking on the selected product.

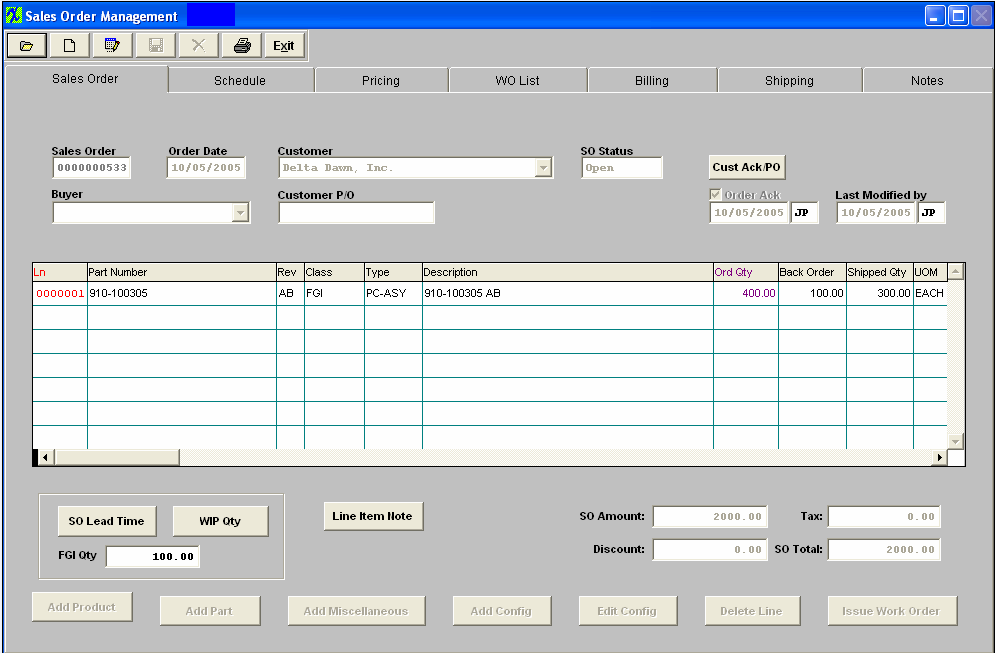

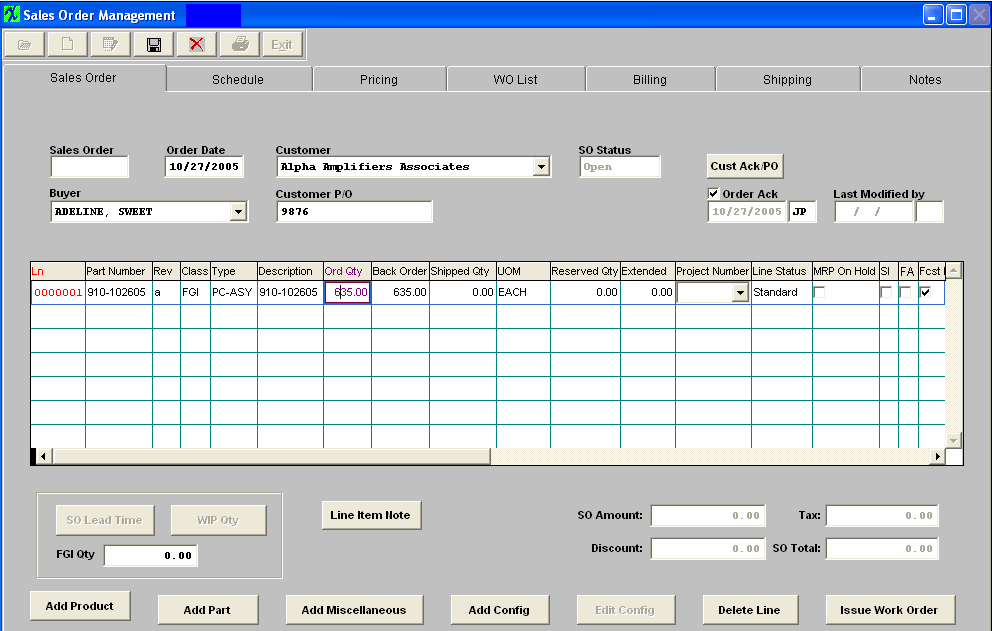

Once you have made your choice, the information will be displayed as follows:

|

| 1.2. Edit A Sales Order |

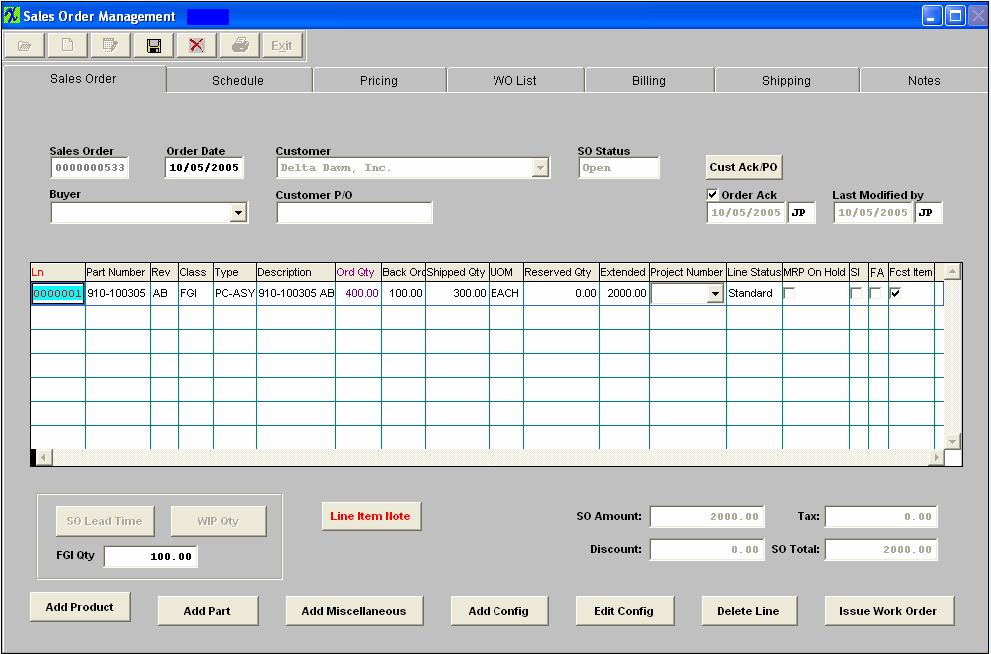

Find a Sales Order, it may be edited by selecting the Edit Action button, then entry of the password. All fields available for editing will be enabled for modification. Sales Order tab - The user may add a new product, part or miscellaneous item. The user may delete an entire line item. The user may change the quantity ordered, add or change the amount reserved or change the line status. To remove a project number from the project field,by right clicking on the field. (Note: If a SO for example has three line items and user deletes only line item 01 user will NOT be able to re-use this line item when adding a new line item to this SO. The system will use the next line item which would be line item number 04 in this example).

Schedule tab - For the Line Item selected, the user may add or delete a scheduled delivery, change the 1st Due Date, or the Transit Days.

Pricing tab - For the Line Item selected, the user may edit the Price, Sales Type, Tax, Lot Charge, Commissions info, Add or Delete a line. The Price Markup field is NOT editable within the Sales Order screen. This information defaults in from the Sales Price List Information module. The Customer Sales Discount field is NOT editable within the Sales Order screen. This information defaults in from the Customer Information module.  WO List - This screen is view only.  Billing tab - The user may change the Customer address and/or add a Credit Note.

Shipping tab - The user may edit or Add a New Ship To address, select a different Attention, FOB, Ship Via, and/or select a different Delivery Time from the pull down. Note: The user is able to edit or change the Cust Account No to match any special Ship Via pertaining to the specific order within the SO Shipping screen without the changes affecting the Customer Information module or any other pre-existing orders.

Notes tab - The user may add or change the Sales Order Note and/or the Sales Order Acknowledgement Footnote.

At the conclusion of the modification process, the user may either depress the Save action button to save the changes or depress the Abandon changes action button to cancel changes, located at the top of the screen.

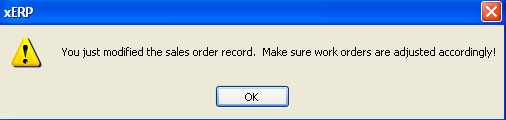

The following message will be displayed to the user if a WO is linked to the SO:

NOTE: The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. |

| 1.3. Add A Sales Order | |||||||||||||||||||||||||||||||||||

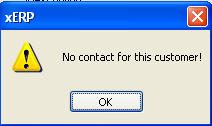

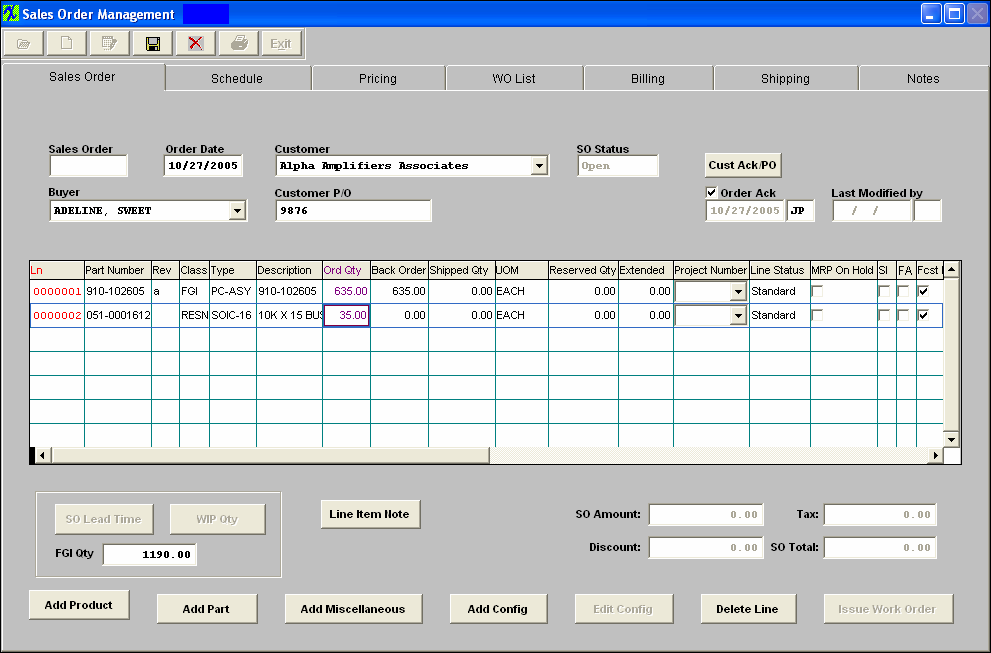

Adding a sales order is accomplished by first selecting the customer, then a product and quantity. Then the user visits additional tab/screens to add more information about the order. The first of these is the Schedule Screen, where the user defines the delivery requirements for the product, then the Pricing Screen. The user should visit the Billing Screen and the Shipping screen to ensure that the defaults established for the customer are appropriate to the order being entered. If the user is visiting this screen to view an existing sales order, they may tab to the WO List screen and view current work orders in process. Depress the Add action button. Enter your password. And the Sales Order Screen will appear. The current calendar date will default in the Order Date field. This may be changed if desired.

If the user is using auto-numbering for sales orders, the Sales Order field will be completed by ManEx when the order is saved.

The next field to enter is the CUSTOMER. The user may begin entering the name, and ManEx will immediately begin tracking the key-entry to bring up the customer with as few keystrokes as necessary to identify the customer. Or, you may press on the down arrow adjacent to the field and ManEx will display all of the customers from which to choose for the order.

The SO Status is defaulted to the OPEN status during entry of a new sales order.

Next, a customer Purchase Order number is entered. This is a free-form field, and up to twenty of any normal characters(any combination of alphabet or numbers) may be entered. If the user has a purchase order from the customer, or a confirmation of the order from the customer, then the ORDER ACK box can be checked. If this box is NOT checked, the user will NOT be able to create a packing list for the order when it comes time to ship. If this box IS checked, then the date and initials of the user accepting responsibility for the order are recorded. The next step is to use the Directive Buttons to add information into the sales order. |

|

The "Add Product" button adds products or assemblies to the order. Pressing this button produces a list of products that have been established for the customer selected for the sales order. The user selects the product number being ordered by entering it in the red box, or scrolling down the list and double-clicking on the assembly.

Note: If the user enters specific customers in the Customer List within the Sales Price List Information module, then that product will only be available for that customer when creating a Sales Order. |

|

After selecting a part number, ManEx requests the quantity to be ordered.

The user enters the Ord Qty (The quantity being ordered by the customer for the part number and the system automatically displays the Back Order, which is the quantity still due to be shipped for the order).

Once this quantity is entered, ManEx populates the first open line in the sales order with the data from inventory tables.

You may view additional information about the part by sliding the scroll bar at the bottom of the grid to to the right.

![]()

|

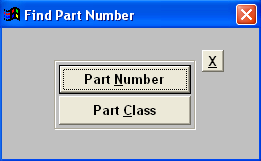

The "Add Part" button is to add a part from inventory to the sales order. This is material that is sold out of the stockroom, rather than material assembled to order. It may include any part carried in ManEx inventory, with a source as “Buy”. Pressing this button brings up the following dialogue box: The user is prompted to search for a part to enter either by the Part Number or by the Part Class. |

|

|

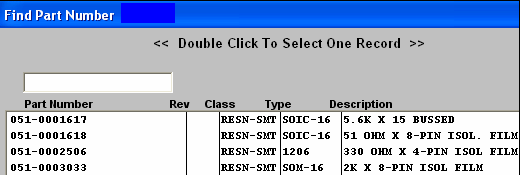

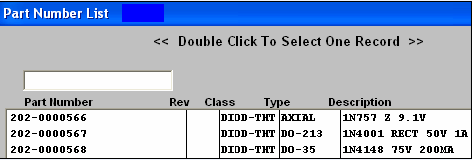

Clicking on Part Number brings up the query screen for a part number. In this screen, the Part Number, the Part Revision, the Class, the Type and the Description are all displayed. In this screen, the user may enter the part number directly, in the red box, or scroll down the part numbers until the correct part is found. The red box will cause the list to scroll to the closest match to the data entered. For each additional character entered, the cursor will move to a matching entry until the final part number is found. |

|

|

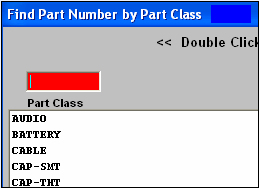

If the user elects to search for a part by the Part Class, then the following screen appears: Clicking on Part Class brings up the query screen for a Part Class. In this screen, the Part Class is displayed, and the user may enter the part class directly, in the red box, or scroll down the part classes shown until the correct class is found. The red box will cause the list to scroll to the closest match to the data entered. For each additional character entered, the cursor will move to a matching entry until the final part class is found. |

|

| After finding the correct class, the user is presented with the following screen which includes parts that belong to the selected class type. |  |

If a part is reserved in SO, and also reserved to a project that's linked to the SO, the system should pick the parts that are reserved by the SO first, if not enough to ship, then take the parts that are reserved by the project.

If parts are allocated to a project and the project is selected in SO for the SO item, when the part is shipped, those allocated to that project parts will be available to be shipped. After the project is selected in SO, the new created WO will link to that project.

|

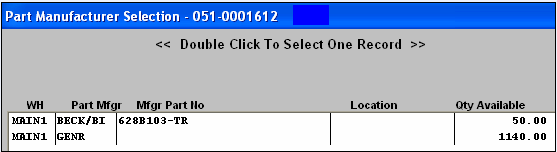

Once the order quantity is entered, the following selection screen will appear: This screen allows the user to select the desired manufacturer. Displayed will be the Warehouse, Part Mfgr, Mfgr Part Number, Warehouse Location and the Quantity Available. Highlight and double click on the desired Part Manufacturer. |

|

![]()

The "Add Miscellaneous" button is to add any miscellaneous items to the sales order. This may be prototype items, engineering charges, or any item that is not manufactured nor is it in inventory. Pressing this button adds a line to the Sales Order and moves the cursor to the description field. The user enters the description, quantity and may then move to the pricing screen to complete the data.

The user is reminded that the scroll bars at the right side and bottom of the information box allow the information to be scrolled sideways and up or down to see additional information.

![]()

The "Delete Line" button is to delete a line already entered from the Sales Order. The user selects the line to be deleted from the Sales Order tab, and presses the button.

|

Pressing this button brings up the following dialogue box: The user confirms the deletion and the deletion is complete. |

|

Highlight the Assembly line item first before you depress the button.

Highlight the Assembly line item first before you depress the button.

Important Note: This action is taken AFTER the Scheduling tab is completely filled in for all add Products (assemblies). So, first go to the Schedule tab (instructions below). Schedule the product and then return to this tab.

| If user has the "SO Approval Required" box check in Sales Order Defaults & Sales Discount Type module checked, then user will be required to check the "SO Approved" box before being able to Issue a Work Order. If the "SO Approved" box is NOT checked user will receive the message located to the right. |  |

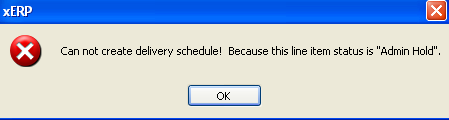

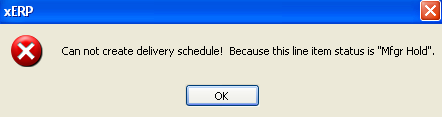

| If line item is on Admin Hold or Mfgr Hold user will receive one of the following messages and will be unable to Auto create a WO until the status has been changed for this specific line item. User will be able to manually add a Work Order for this product in the Work Order Management module. |

|

|

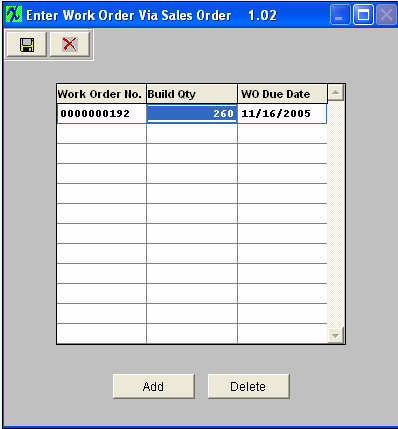

If there is only one delivery scheduled for the sales order, and the work order setup is established as automatic numbering, then the following screen appears:

Keep in mind though that even if you have the SO linked to a WO does not mean that the quantities will always be the same. The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. A message is displayed to the users that they will have to make the same changes to the WO. |

|

|

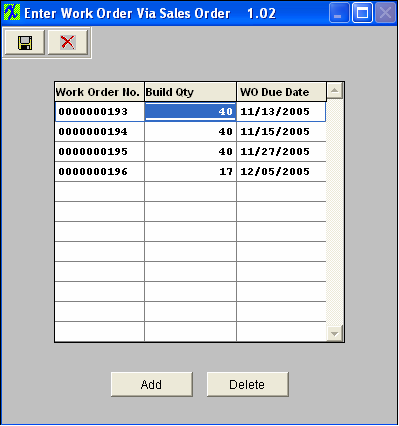

If the user has established more than one delivery date for the sales order, then pressing this button brings up the following: |

|

Depress the Save action button to finish creating the Work Order(s).

After completing all of the Sales Order data, the Sales Order must be saved. Then pressing the WO List tab will display all of the work orders created for the current sales order.

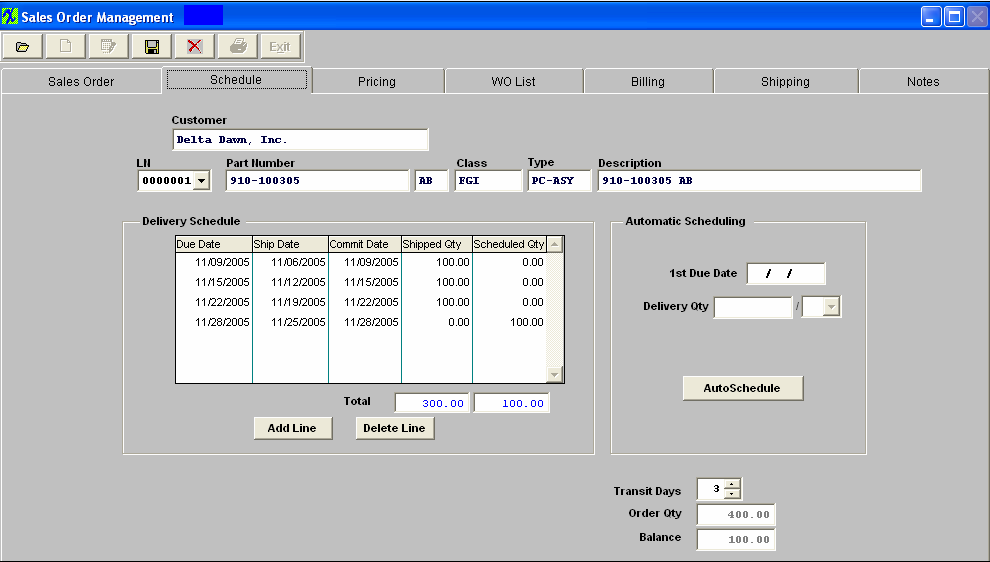

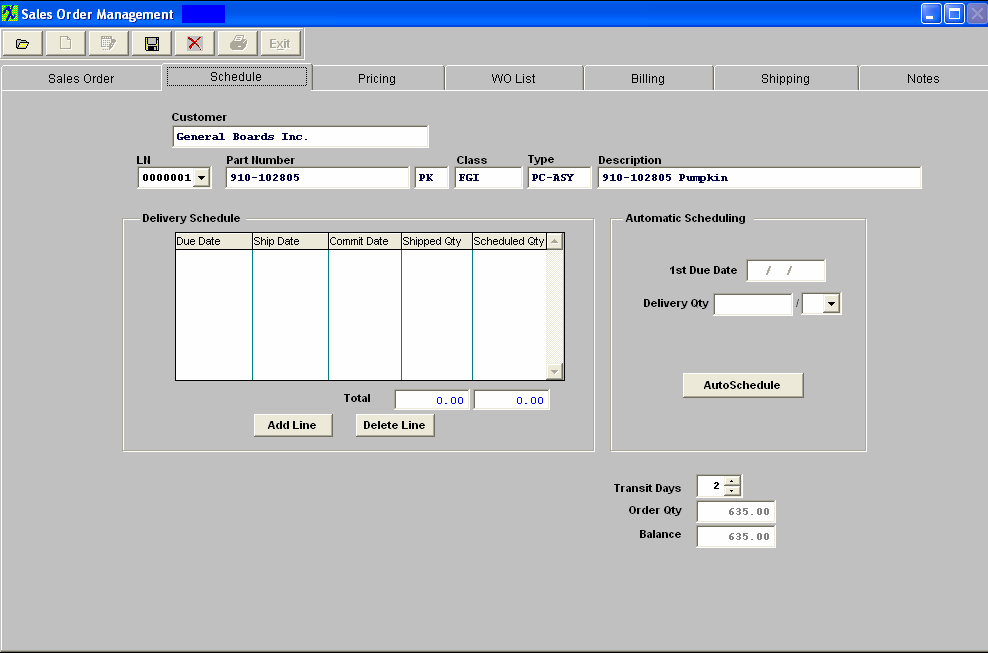

Schedule Tab

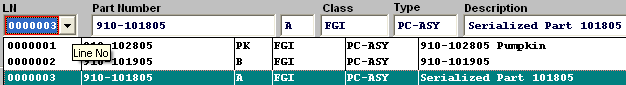

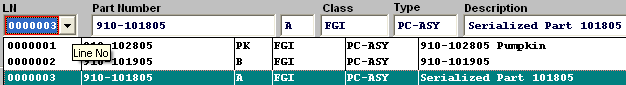

Sales Order Line number: Select the line number by depressing the LN down arrow. The following selection will appear:

The first line is populated with the data from the part number entered on the previous screen.

The following activities are available:

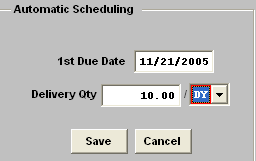

| Automatic Scheduling |

Pressing this button enables the scheduling box and places the default lead time date in the Due Date box. (The user may establish a default number of days in the Delivery Schedule Default Setup module). The user can then use that date, or enter the first (beginning delivery) date the customer expects to receive the order. The Delivery Qty screen allows the user to divide the shipment into multiple deliveries of equal parts. For example, if the order is for a total of 100 pieces, and the customer wishes delivery to be at the rate of 10 units each day, then the delivery quantity should be entered as 10. The next box allows the user to select the delivery intervals. The options are by day (DY), week (WK) (7 days) or month (MO) (30 days).

Note: In using the term Weekly and Monthly, it doesn't matter what the holidays or what the weekends are (i.e. that they are not excluded from the total time of a week or month), but are considered when the final date is calculated. |

|

|

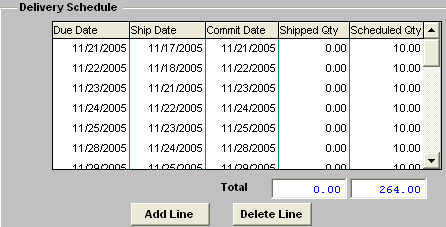

After selecting the delivery interval, pressing the SAVE button creates a line for each delivery date in the sequence requested, as illustrated:

In this Delivery Schedule screen, the user may further edit, delete or add lines.

|

|

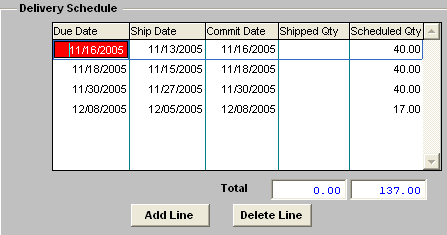

| Manual Scheduling |

Pressing the Add Line button enables the delivery schedule box and places the cursor in the Due Date box. The user can then enter the first (beginning delivery) date the customer expects to receive the order. Next, the Ship Date (the date the order is to leave the user’s dock) will be entered by ManEx based on the transit days entered. This date can then be modified by the user if a different date is desired. Then the scheduled quantity is entered. The Shipped quantity will be completed by ManEx when the line has material shipped against it. Additional lines may be added or deleted by pressing the appropriate button. The total number of units scheduled will be displayed at the bottom of the box, so the user can verify all units have been scheduled. |

|

After you’ve scheduled all assemblies, you may go back into the Sales Order tab and issue the Work Orders for those assemblies. Please refer to the instructions above regarding the Issue Work Order button.

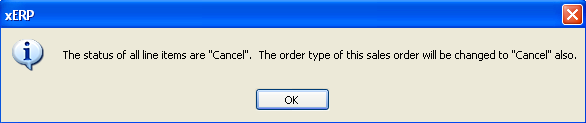

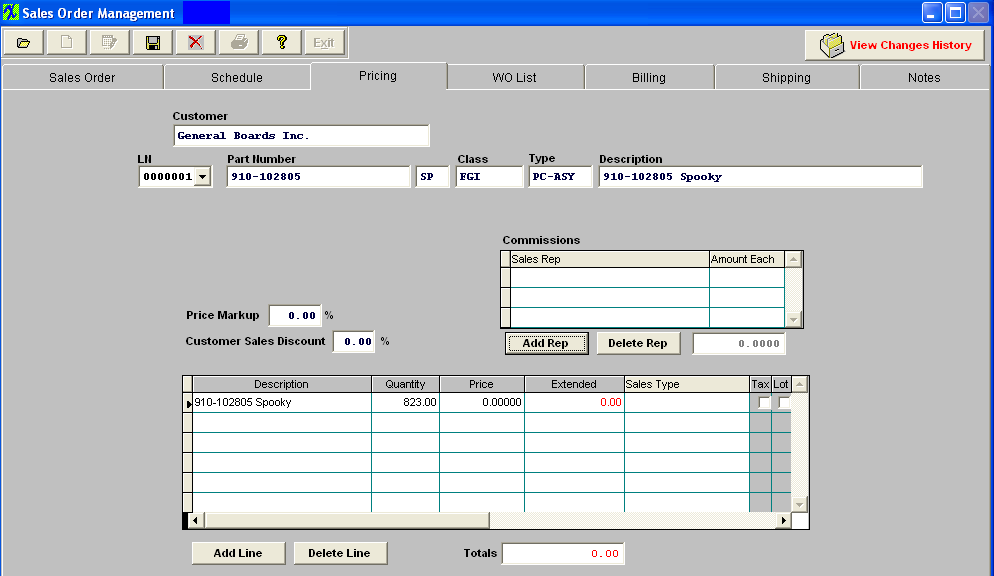

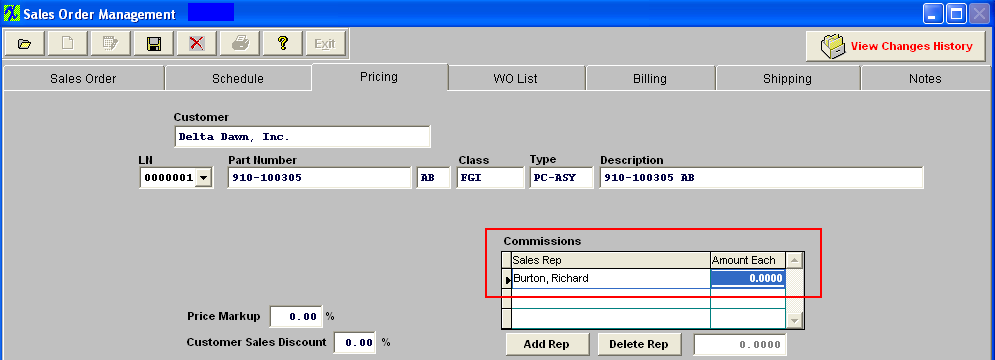

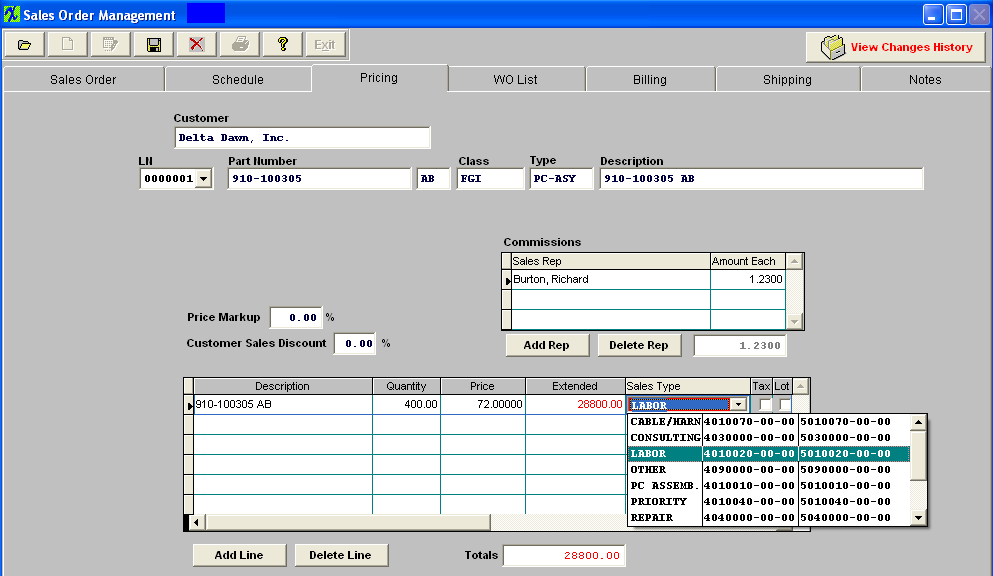

Pricing Tab

Clicking on the Pricing screen brings up the following screen:

Depress the down arrow next to the LN field. The following list will appear:

Select the desired line number.

|

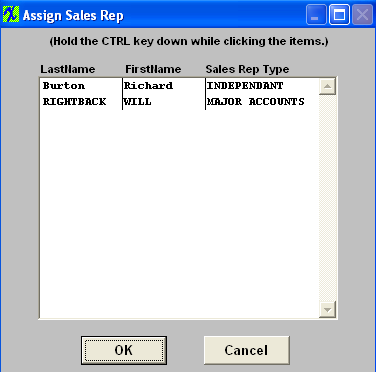

Depress the "Add Rep" button to add a Sales Rep. The following screen will appear listing all the Sales Rep's setup in the Sales Rep Information module.

Highlight the Sales Rep or Reps, then depress the OK button and they will appear in the commissions box as displayed below.

|

|

Enter in the commission amount for that specific Sales Rep.

If accounting is installed,the user selects the Sales Type. The user can select the Sales Type from the drop down list:

The first column of account numbers are for the posting of the sale. The 2nd column of account numbers are for the posting of the Cost of Goods Sold entry. Once the Invoice is printed the account entry will become available.

If the user has completed the Pricing Screen for the product, then the pricing will be automatically entered. See Article #766 for more detail.

The user may select if the unit is taxable by clicking on the appropriate box on the right side of the screen.

For Sales Order Items with no Tax, leave the Tax box unchecked. No further action is required.

Adding a US Sales Tax or a US Shipping Charge Tax in Customer Information requires that those items added be entered in System Setup under Sales Tax Authority Table.

If a particular Customer Ship To Address has more than one US Tax (such as a Sales, Use, Excise, etc. tax), then the taxes may be entered in System Setup individually and added individually to the appropriate Customer Ship To addresses.

User CANNOT manually add Foreign tax to Sales Orders or Invoices. The Foreign tax box must be checked for the Shipping Address for the particular Customer selected in the Sales Order Header.

If the Foreign tax box is checked for the Shipping Address for the particular Customer selected in the Sales Order Header. Pricing will be listed as follows on the Sales Order Acknowledgement, Invoice, RMA, and Credit Memo: First the Product Sub-tot AMT, the Sales Discount (if applicable), the Freight AMT (if applicable), a SUB-TOTAL, the GST TAX (Primary tax) (Note: the Primary tax will always be displayed even if it is zero, if a Secondary Tax is present), then a second Sub-Total, PST TAX (secondary tax), and last the TOTAL. If no PST tax (secondary Tax), Sales Discount, or Freight is involved, then no lines would print for these items. See the Foreign Tax Examples.xls attachment to see how the Primary and Secondary taxes are calculated.

The Primary tax and Secondary tax is divided into the Sales tax and Shipping tax on the Sales Tax reports.

For Example:

Primary Tax (GST): 144*10% (sales tax) + 0 (no freight tax is calculated) =$14.40

Secondary Tax (PST): 144*8% (sales tax) + 12*8% (Freight tax) = $12.48

Divided into sales tax and freight tax:

Sales Tax: 144*10% (sales tax) + 144*8% (sales tax) = $25.92

Freight Tax 0 (from primary tax) + 12*8% (from secondary tax) = $0.96

If the user wants to use a Lot Charge instead of unit pricing, click on the Lot box. This will take the unit cost as a lot charge for the item without extending the units by the price. This may be used if a flat fee is charged for a number of parts.

Clicking on the Add Line button may enter additional charges for the product. These charges may carry a different unit price, and may be of any description. A Non-inventory line added on this screen will be invoiced on the first shipment made for this sales order.

Work Order List Tab

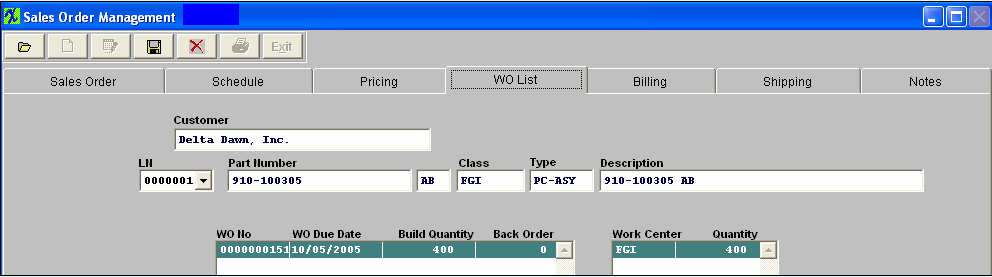

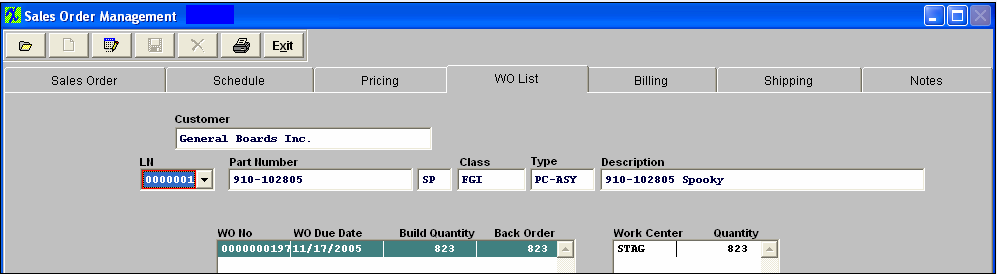

Clicking on the Work Order List tab brings up the following:

Depress the down arrow next to the LN field. The following will display:

Select the line item containing an assembly for which Work Orders have been created.

This screen is for information only, providing the user with status of work orders created for the current sales order. The user has the option of creating multiple work orders for a sales order line item. To see the Work Orders for the next line item, depress the LN down arrow and select the desired line item.

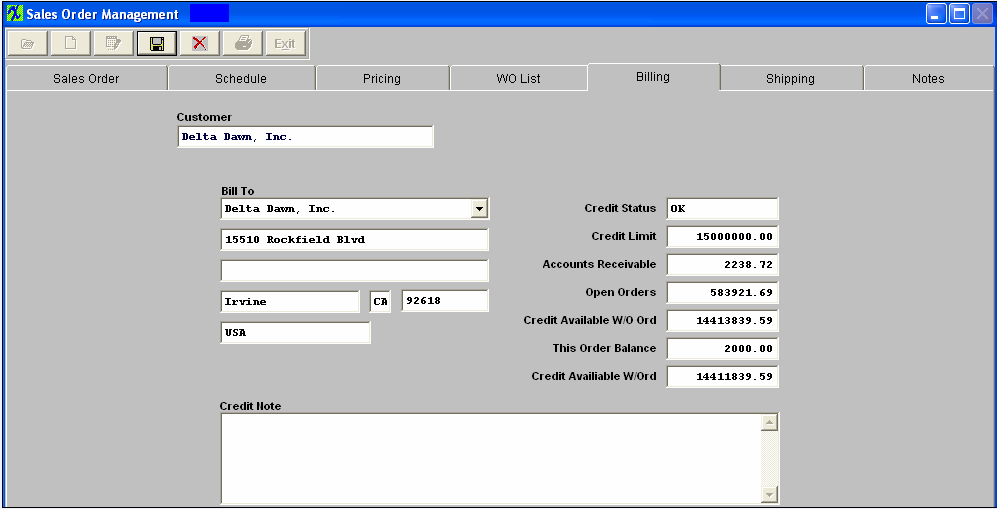

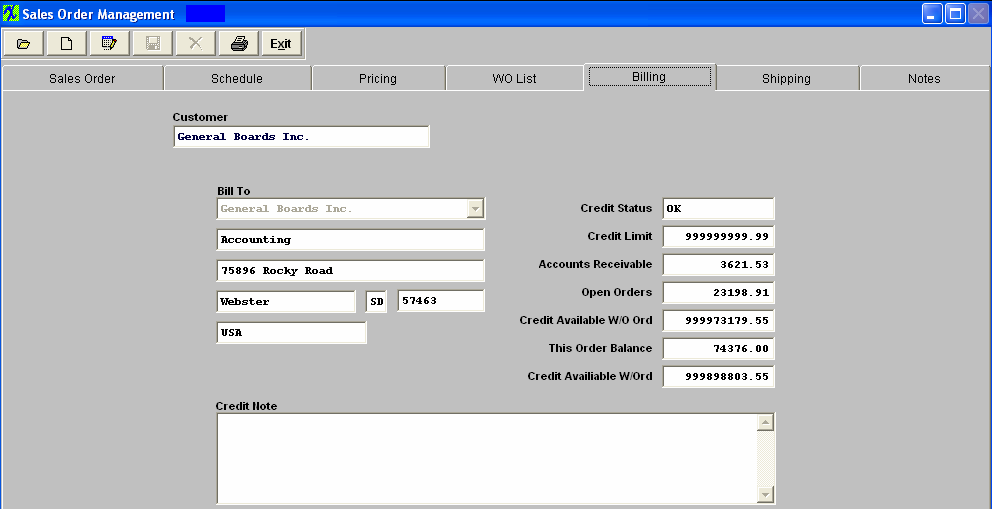

Billing Tab

Clicking on the Billing screen tab brings up the following:

In this screen, a Bill-to address will be completed with the default address established in the Customer Information Module. The Bill-to address also may be selected from any other addresses entered in the Customer Information Module. The first prompt is to enter the Bill-to address. The user may accept the default address, or select from any address established in the Customer Information Module. All address information in the set up will be displayed when the down-arrow is pressed at the right side of the field:

After selecting the appropriate bill-to address, the information fields on the screen are populated with the correct data.

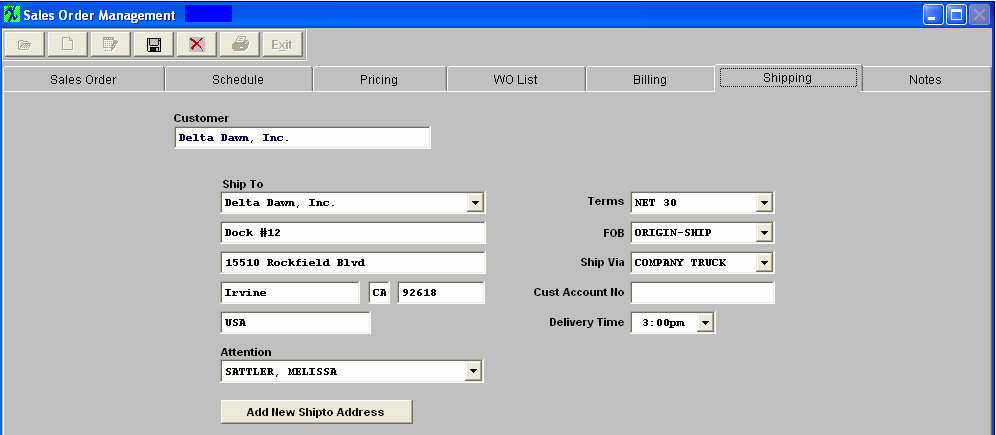

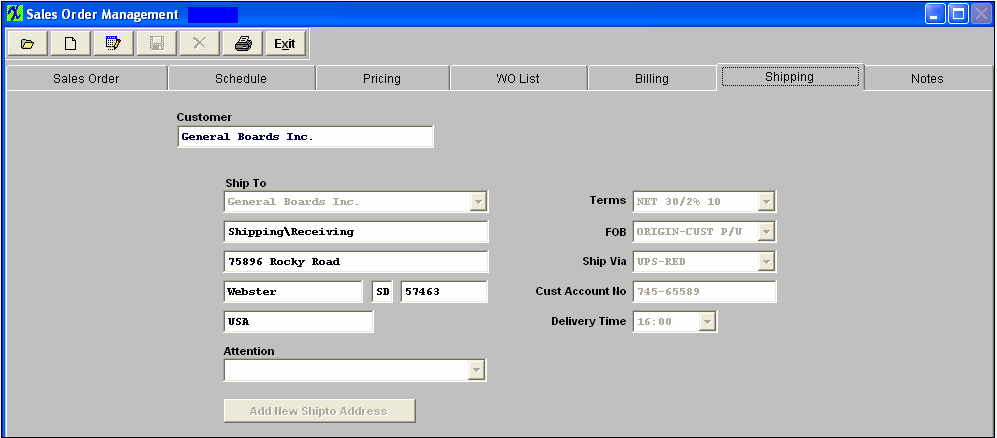

Shipping Tab

Clicking on the Shipping screen tab brings up the following:

As in the Billing screen, the user may select from established ship-to addresses by pressing on the down-arrow key at the right of the first field:

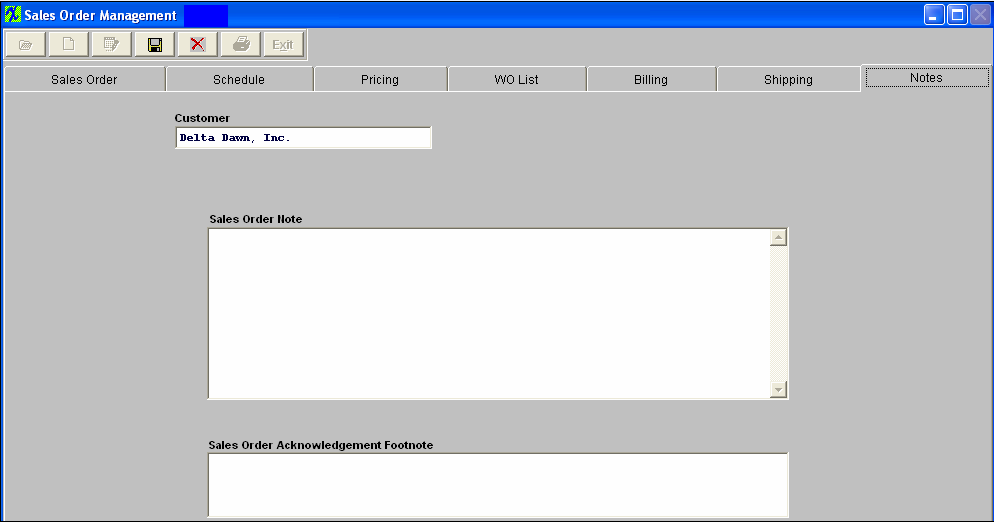

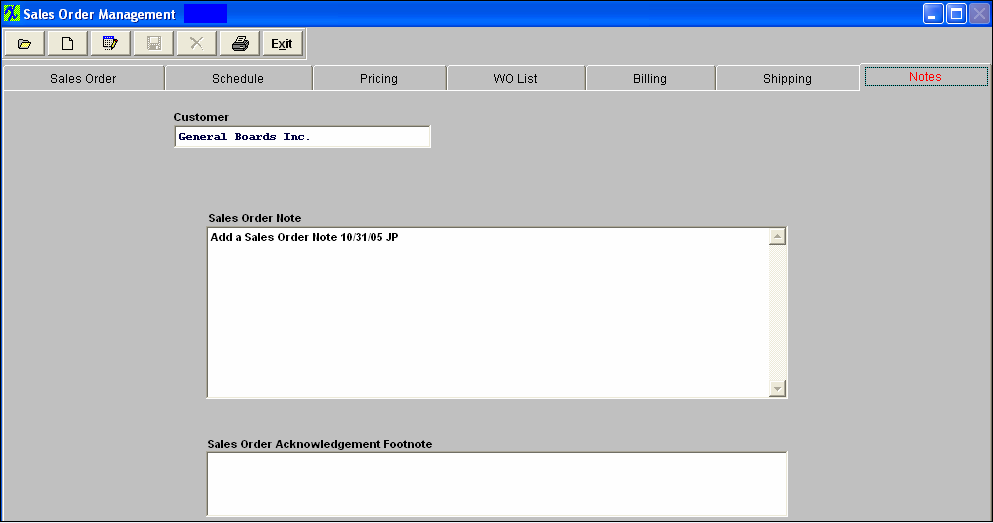

Notes Tab

The last screen, the NOTES screen, provisions are made to establish Sales Order Notes and/or Sales Order Acknowledgment Footnotes. These notes are available on their respective screens.

Note that when any note is entered on this screen, the screen tab NOTES turns red to indicate there is data in the notes.

Once all Tabs have been complete Depress the Save action button to save changes or the Abandon changes action button to abandon changes.

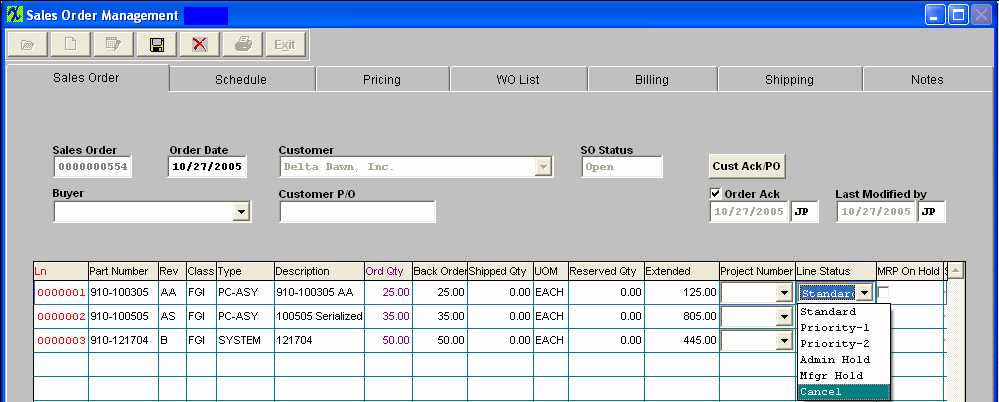

| 1.4. Cancel a Sales Order |

To cancel a Sales Order

Once you have cancelled all line items on PO the following message will appear:

Depress Ok and the Sales Order status will be changed to "Cancel" Depress the Save action button, to save changes. Press the Red "X" to abandon changes. Depress the Exit action button to exit the current screen and returns the user to the previous screen. |

| 1.5. Delete a Sales order |

A sales order may be deleted using the Delete Unwanted Sales Order in the System Utility Module. This utility will allow users to delete any Sales Order record within the system as long as there are no shipments or reserved qty against it. In addition to deleting the Sales order, the utility will also check to see if there were any linked Work Orders to that Sales Order, if any were found it will display a warning and then also generate a XLS spreadsheet for the users to review and re-establish links to new Sales Orders if desired. |