| 1. Job Costing (OPTIONAL Module) |

| 1.1. Prerequisites for Job Costing | ||||||||||||||||||||||

Prerequisites for Running a New Job Costing:

ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. The Job Costing Module is used to record the details of the costs associated with a particular job or work order. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com\contactus.aspx After activation, "Job Costing" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.2. Introduction for Job Costing |

The Job Costing Module is used to record the details of the costs associated with a particular job or work order. The actual material(actual can be standard, Purchase Order allocated to the specific Work Order or the Weighted Purchase Cost of the last 5 Purchase Orders) and labor costs are compared with the standard or “budgeted” costs and provision is made to include miscellaneous charges. The user may also compare the standard (budget 0 to items purchased specifically for the Work Order (please see the Purchasing Management procedures) or to the weighted average of the last 5 purchases. A variance is calculated and also the variance %. Once a Work Order is created, the user may preview the “budget” information for both material and labor. Time card information and kitting forward into Job Costing. As each component of the Work Order is completed, the Job Costing Module captures the required information. Please refer to the Time Card and Time & Attendance Management procedures. |

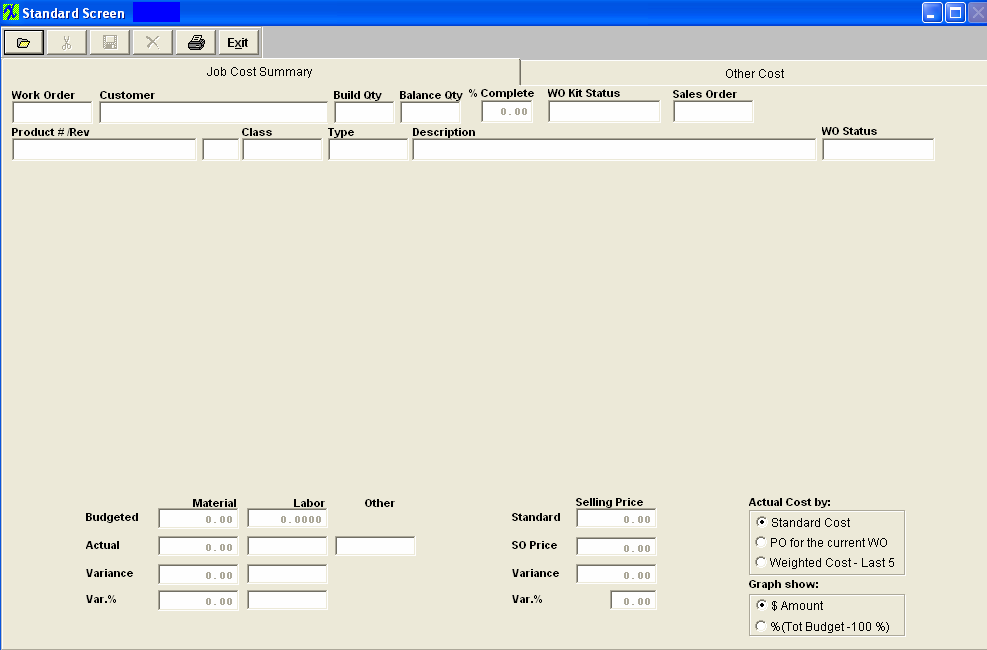

| 1.3. Fields & Definitions for Job Costing |

| 1.3.1. Job Cost Summary | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Job Cost Field Definitions

Budgeted

Actual - The actual is taken from the first time the parts are issued to the kit. The cost is gathered from inventory issue table

Variance

Var%

Selling Price

Actual Costed By:

Graph show:

|

| 1.3.2. Other Costs | ||||||||||

Other Cost Field Description

|

| 1.4. How To ...... for Job Costing |

| 1.4.1. Find a Job Cost Record | ||||

|

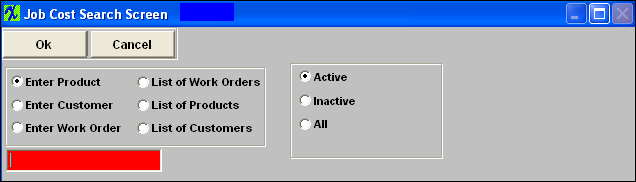

The following screen will appear:

Depress the Find button.The following screen will appear:

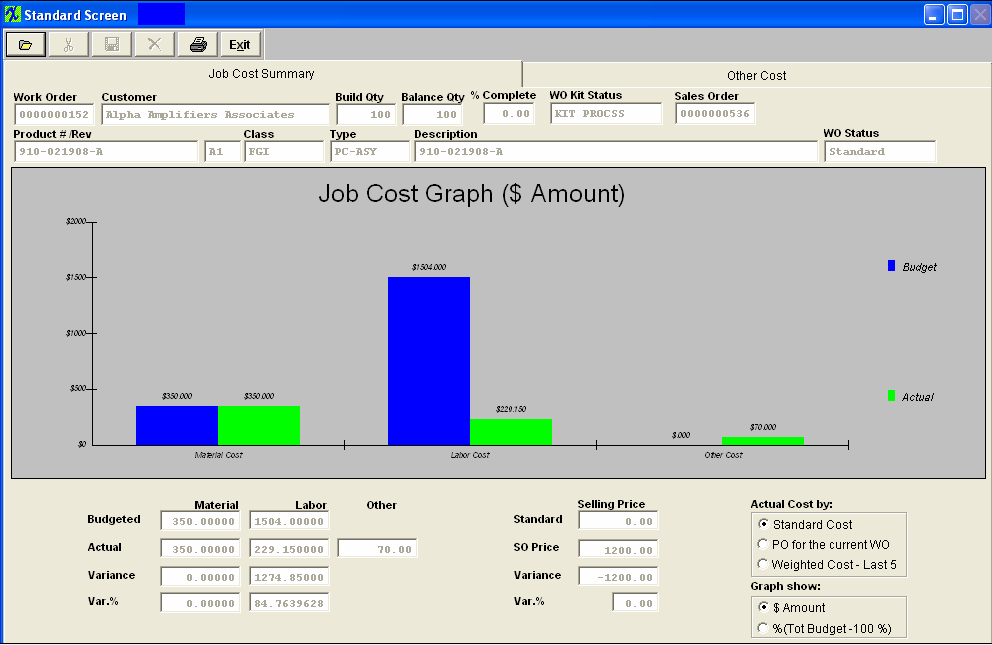

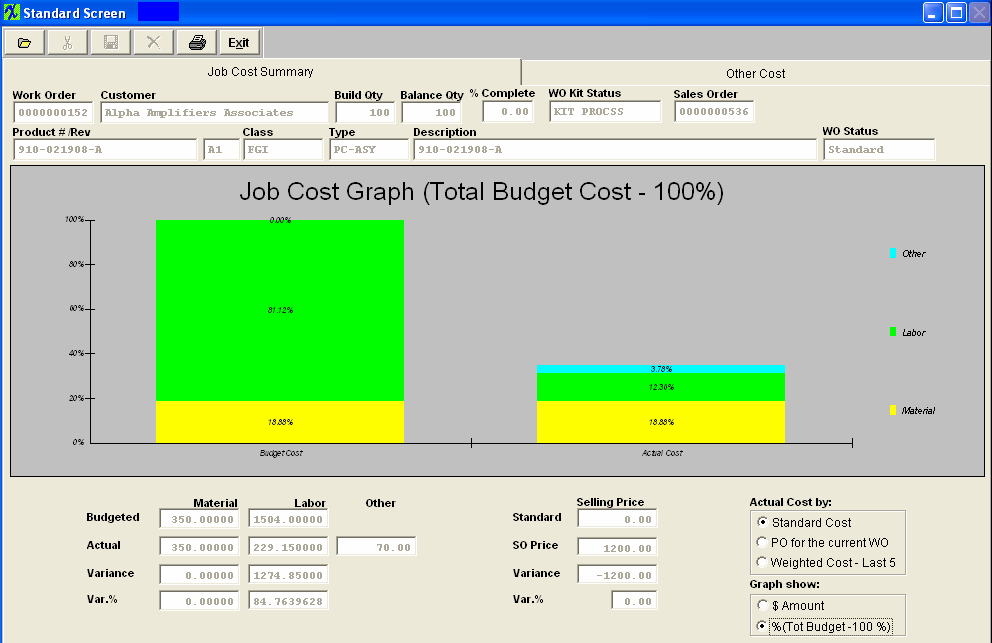

Select the desired Search by method by clicking on the applicable radial. The graphics for that Work Order will appear:

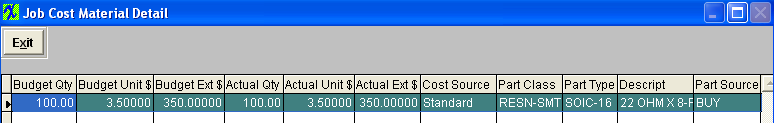

Select between Standard Cost, PO for the Current WO or Weighted Cost – Last 5. The actual material cost display will change. Job Cost Material Detail To view the Job Cost Material Detail, highlight the green graph bar display and click. The following detail will become available: If you would like to see the formula's used to calculate the budget information see Article 2159.

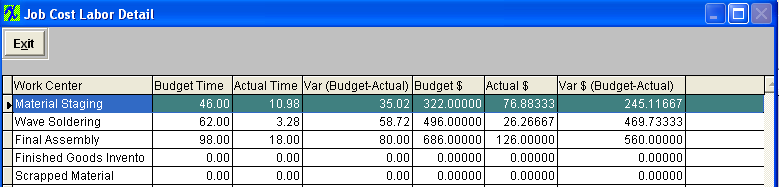

Job Cost Labor Detail To view the Job Cost Labor Detail, highlight the green graph bar display and click.The following detail will become available:

Percentage Radial To see percentages rather than dollars display, select the Percentage radial in the Graph View section. The following view will become available:

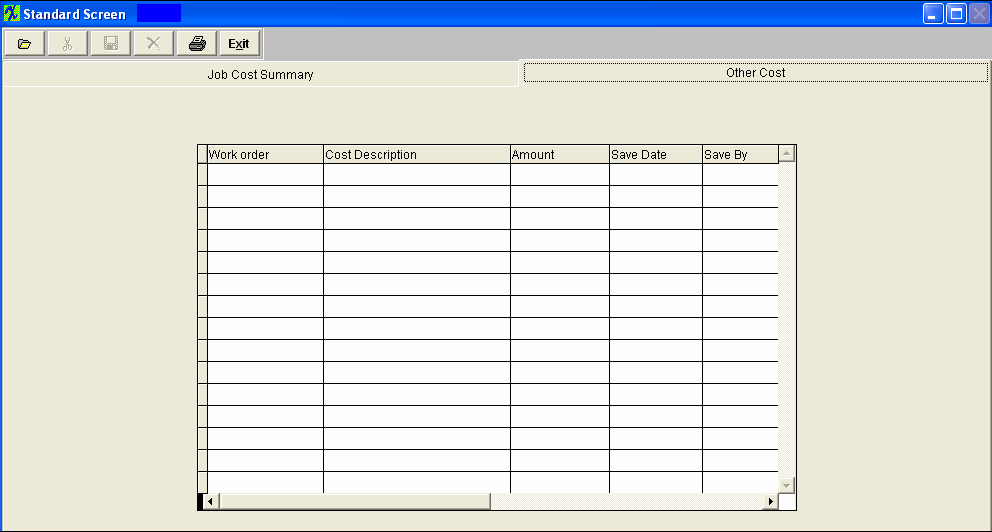

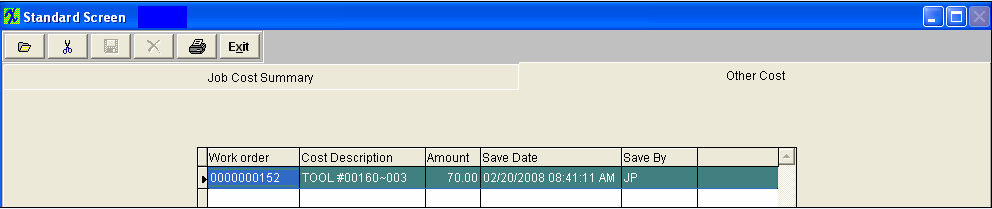

Other Cost To enter an Other Actual Cost, depress the Other Cost tab. The following will open:

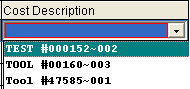

To add a cost, highlight the Cost Description Field. Select from among the following: This selection is setup within the Quote Defaults module. Enter in the amount.

To add another Cost, depress the "down arrow" key and the program will add a new record automatically. Once all changes and adds are complete, depress the Save record icon to save changes, or depress the Abandon changes icon to abandon changes. |

| 1.4.2. Formula's used to Calculate Information |

IF Exclude Scrap and Setup Scrap QtyReqTotal= WoBldQty x BomQty ELSE QtyReqTotal = WOBldQty x BomQty+(WoBldQty*BomQty*BomScrap)/100 ENDIF Ext_cost_total=QtyReqTotal X Stdcost IF Exclude Scrap and Setup Scrap SetupScrap_cost = 0 ELSE SetupScrap_cost = Setupscrap/StdBldQty x Stdcost ENDIF Total Budget cost = SUM of Ext_cost_total + (SUM of SetupScrap_cost x WoBldQty) How is the Actual Labor time calcualated within the Job Costing Module - It is actually controlled from the Prod WC/Activity Setup screen. Here you assign a hourly rate to each work center. Then within the T&A log the users can select the Work order and therefore the WC from the routing. The Job Costing will then take the hours entered * WC hourly rate. The T&A Setup Types do not have an option to assign any value to it – so this does not dictate any Value within the Job costing module.

|

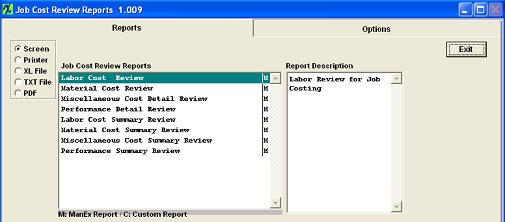

| 1.5. Reports - Job Costing | ||||||||||

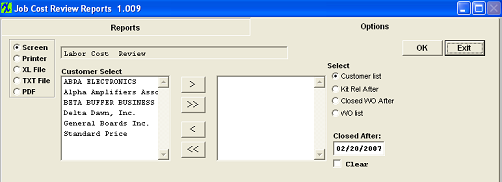

Labor Cost Review Rpt

Depress the Ok button. The following report will be displayed.

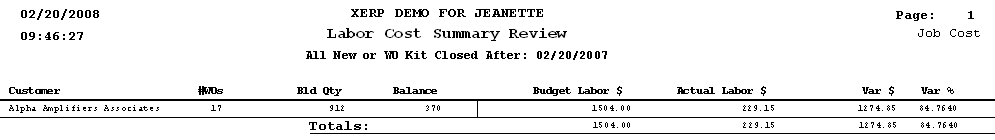

There is also a Labor Cost Summary Review Rpt available:

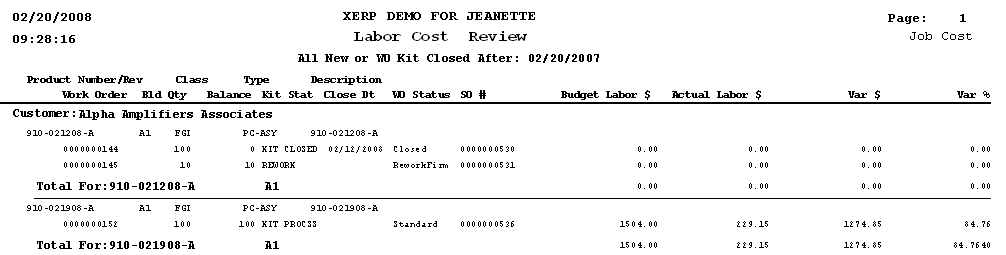

Material Cost Review Rpt

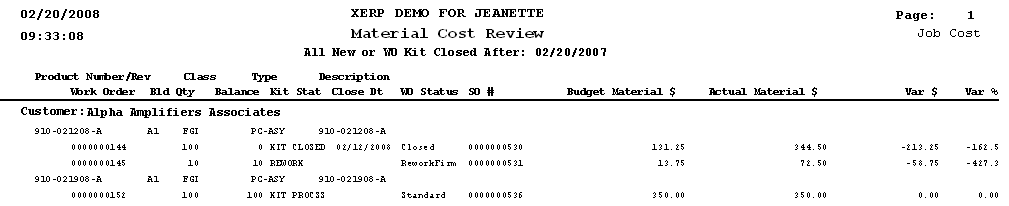

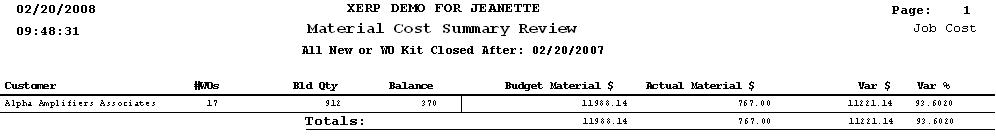

Depress the Ok button. The following report will be displayed.  There is also a Material Cost Summary Review Rpt available:

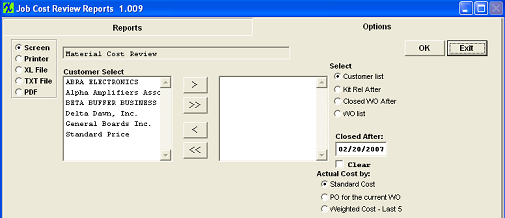

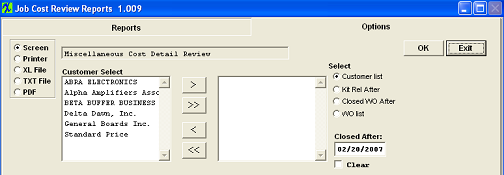

Miscellaneous Cost Detail Review Rpt

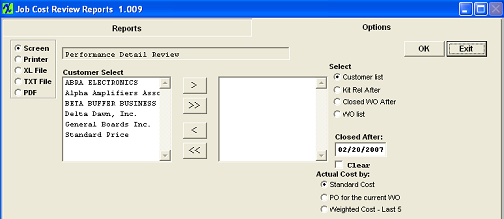

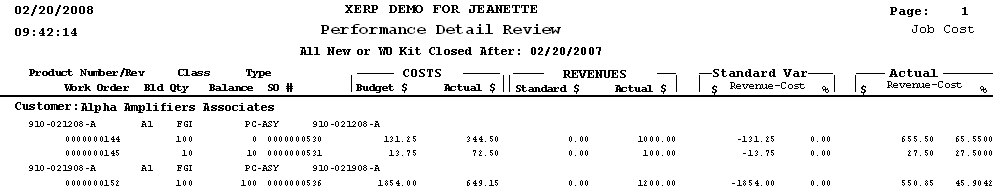

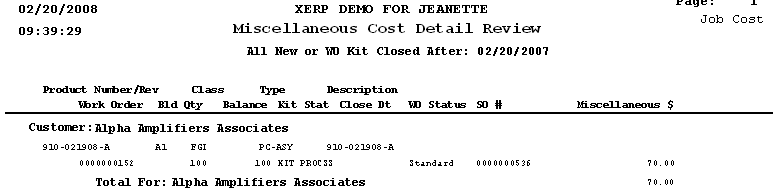

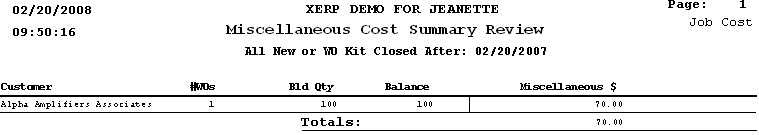

Depress the Ok button. The following report will be displayed.  There is also a Miscellaneous Cost Summary Review Rpt available:  Performance Detail Review Rpt

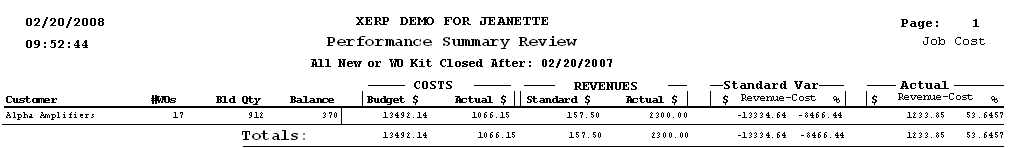

Depress the Ok button. The following report will be displayed. There is also a Performance Summary Review Rpt available:

|

| 1.6. ManEx Minutes (JC) |