| 1. Rejecting Quantity in PO Receiving & Inspection |

|

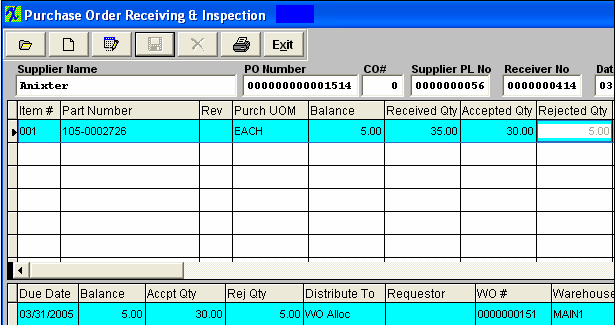

| 1.1. Rejecting Items if Accounting has Processed the Invoice |

|

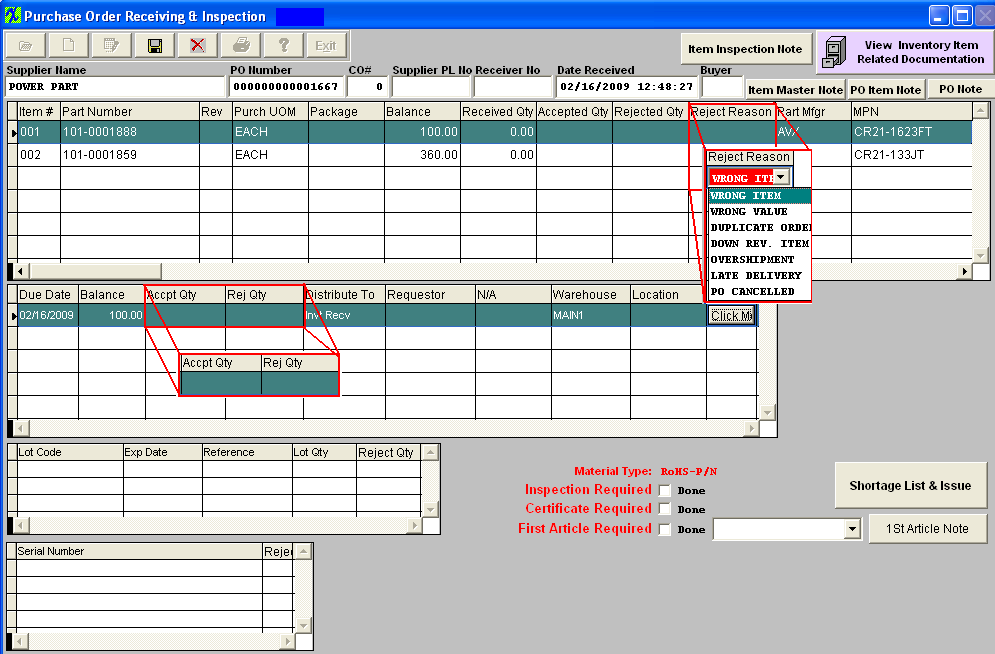

| 1.2. Rejecting Items if Accounting hasn't Processed the Invoice |

Introduction After the user has accepted all of the items on a Closed Purchase Order and then subsequently it’s discovered that the material received is discrepant, do the following if Accounting hasn’t already processed the Supplier’s Invoice for payment:

|