| 1. Purchase Order Management |

| 1.1. Purchase Order Management |

| 1.1.1. Prerequisties - PO Mgmt |

After activation, "Purchase Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

Supplier

|

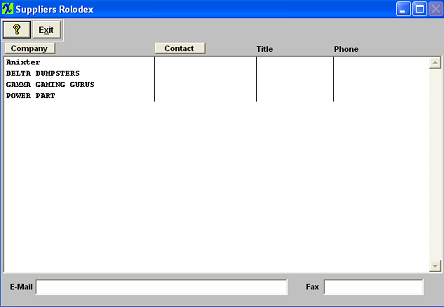

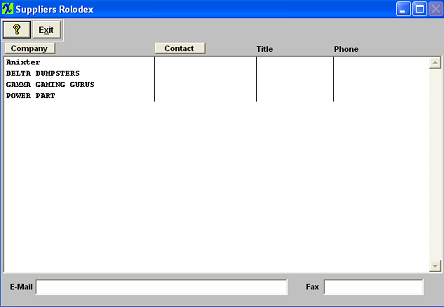

The Supplier must be setup in the Supplier Information module. |

| Part number in Item Master |

The part number must exist for a product or part in the ICM module. |

| AVL |

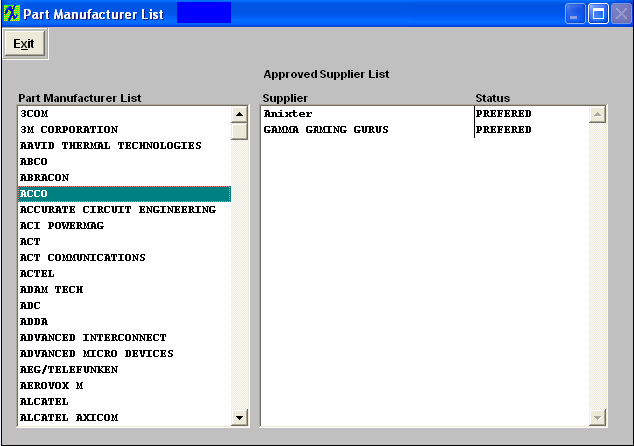

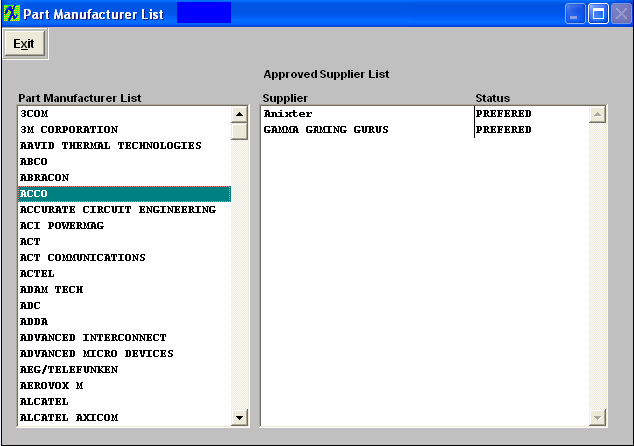

The Manufacturer Names must have been set up in Part Manufacturer Setup module. |

| Buyer Codes |

The Buyer codes must be established in the Inventory Buyer Setup module. |

| Purchasing Approvals |

A list of employees and their approval authorizations must exist in Purchase Setup module. |

Optional Prerequisites for Entering a New PURCHASING

|

| 1.1.2. Introduction for PO Mgmt |

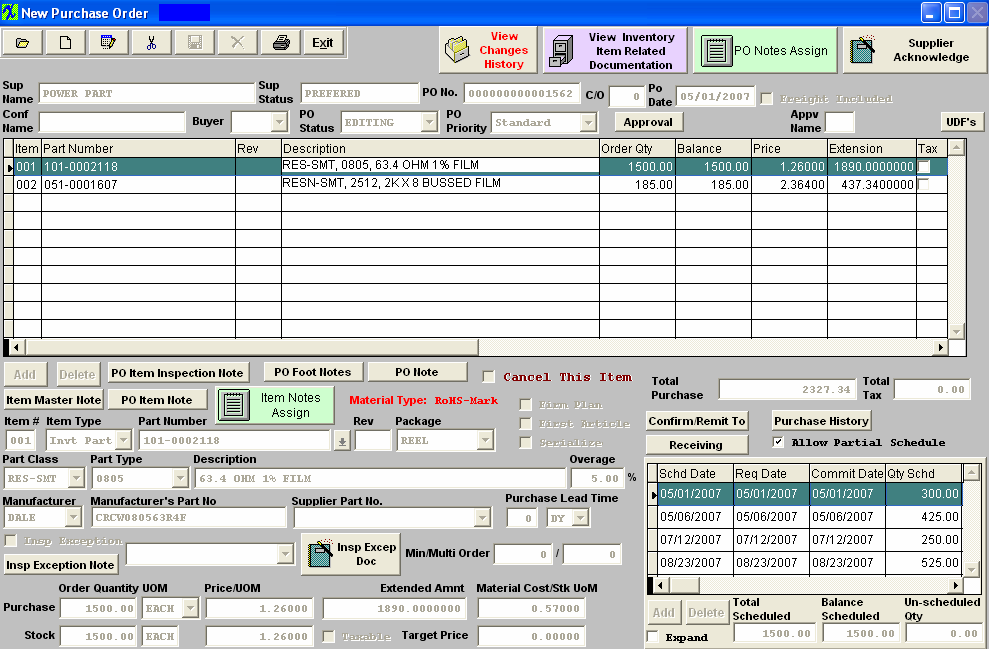

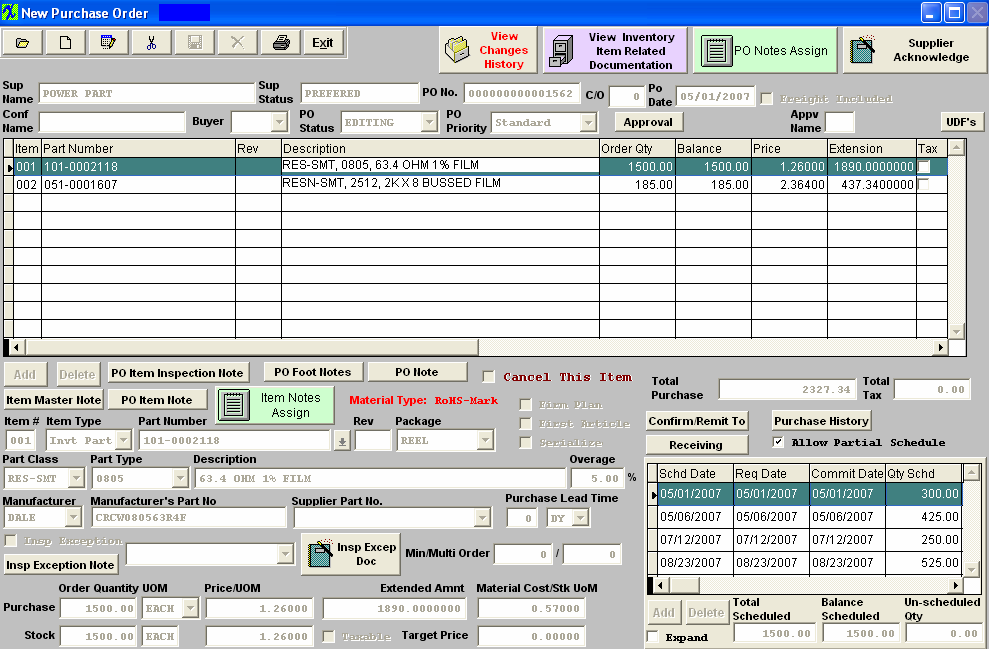

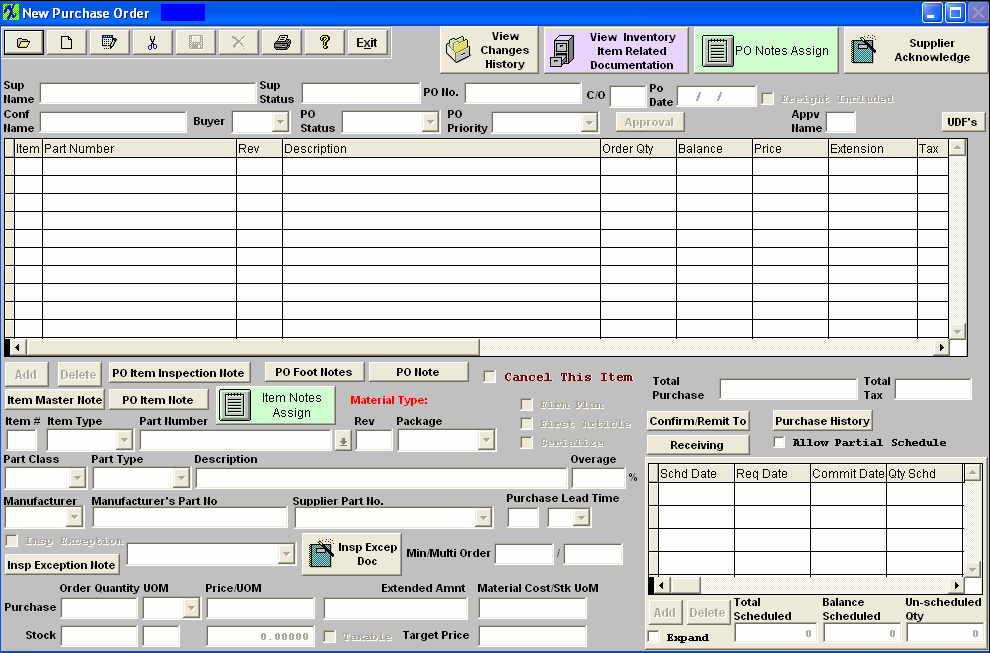

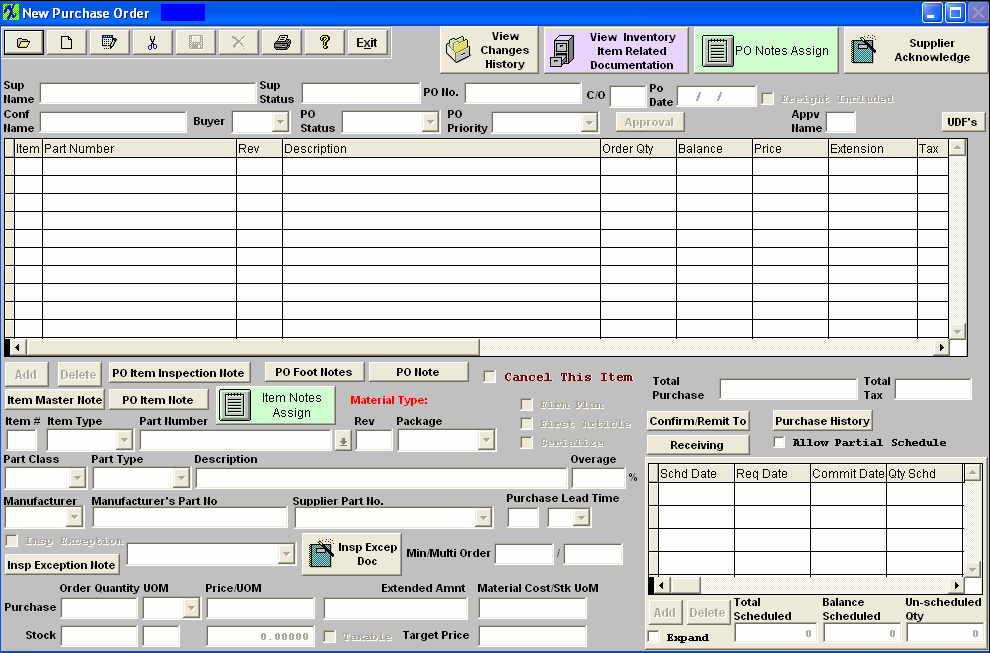

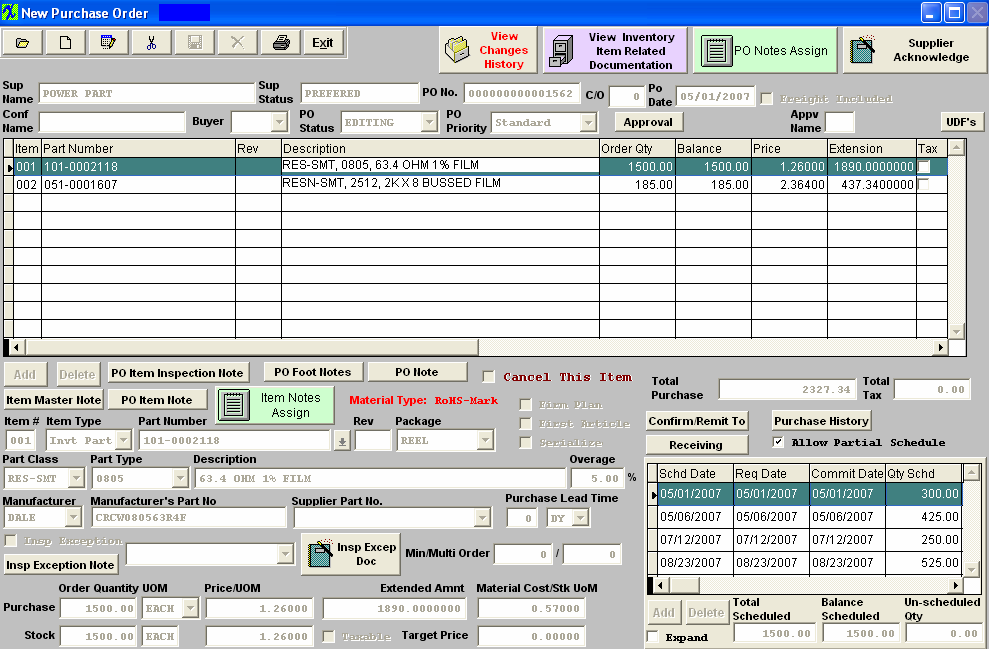

The PURCHASING Module is the place where all procurement is done. This module allows the user to add purchase orders to the system, and to add items to each purchase order. Edit functions are available both at the purchase order level and at the item level.

The process begins by selecting a Regular PO or an In-Store PO, then selecting a supplier for the order. The supplier is selected from a list of suppliers established in the Supplier Information module.

After selecting a supplier, the user may enter orders for various types of material. Inventory material is ordered to be placed in on hand inventory and used in the making of product. The user may also select MRO parts, parts which are not kept in inventory, but are expensed as they are purchased and distributed to the requester when they are received. (MRO parts may be defined in the item master and kept in inventory, if desired.) There is also a selection for Services.

The user may add a new part by selecting the part class and type, then choosing from a part matching that criteria, or go directly to the part number edit box and enter the part number without visiting the class and type box.

The buyer may have entered a specific manufacturer of the item, providing that the manufacturer and the part number have been entered in the inventory item master. If there is only one manufacturer, that manufacturer will be the default manufacturer entered in the purchase order.

If the user is adding an inventory item to the order, the system will add in the details from the item master once the part number is established.

Purchased items may have the delivery schedule established for one or more deliveries. The delivery date entered in the purchase order is meant to be the date the material lands on the user’s dock.

The user may enter either the stocking quantities based on the stocking unit of measure or the purchasing quantities, based on the purchase unit of measure. If the units of measure are different, the user must have defined the relationship between the different units in the Unit of Measure Conversion. Entering one quantity will automatically calculate and enter the other quantity.

The user enters the unit price and whether or not the item is taxable. If it is taxable, the tax percentage will be supplied based on the data entered in the Tax &Shipping Mode tab. The system will display the extended amount of the item on the order based on the quantity and price. Note: If the Tax Information has not been filled in, the Purchase Order will NOT calculate any sales tax. Therefore, it is important that the user set this up properly.

The user may define the quantity that may be received over the amount of the order by entering an overage percentage. This will allow incoming receiving to accept quantities up to the amount of overage specified for the order.

The user may enter specific notes about the item on the purchase order, to be printed on the order. They may also view and edit any item master notes that may exist for the part, and may also view the procurement history for the part.

Once entered, all orders require an approval. The approval authority established in the Purchase Order Authorization tab is used to determine whether or not an individual may approve an order. It is possible to allow two approvals to orders, and to set different approval limits for each of them.

Orders will be identified as temporary orders until approved, after which they will have a permanent number assigned.

Change orders to purchase orders must also be approved in the same manner. Once an order is changed, it cannot be printed or acted upon until it is approved again.

Details about the remittance, delivery point, billing etc. will be completed with Supplier default information, and may be reviewed for the order if necessary.

In-Store purchasing overview: In-Store is the situation where the Supplier has placed raw materials in the user’s warehouse. The Supplier still owns the raw materials. When the user is ready to use the Supplier’s raw materials, he/she issues an In-Store Purchase Order. For In-Store POs, the user may select by Supplier or by Part Number. Then the user may find records according to the selection. Once found, the user may create a PO for the In-Store Consumption. In-Store Purchasing also includes receiving.

|

| 1.1.3. Fields & Definitions - PO Mgmt |

| Sup Name |

The supplier or vendor with whom the order was placed. |

| Sup Status |

The status of the Supplier, whether Approved, Inactive, etc. |

| PO Number |

The Purchase Order number of the order. If PO Numbering is set to Auto (in Number System Setup ) the system automatically places a "T" in the PO number to flag it as a temporary number. Then upon approval the system auto finds and replaces that "T" with a "0". Note: If PO Numbering is set to manual, users enters a PO number manually using a "T", then changes the numbering to Auto, if this PO is edited and approved the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change.

|

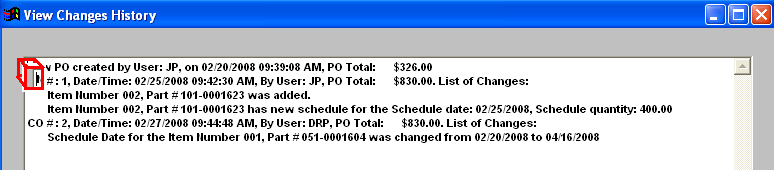

| CO |

The Change Order revision status of the order. This field can be automatically increased upon approval or controlled by the user and is only changed if the user manually assigns a Change Order number. (This is setup in the Purchase Order Setup module). Change Order History is tracked under the View Changes History screen automatically. NOTE: If auto assign the next change order will be referenced in the change history but the PO change order will not increase until PO has been approved. If not auto assigned the change order will be referenced to what ever change order user enters.

|

| Po Date |

The date the purchase order was created. |

| Freight Included |

If this box is checked, the vendor has agreed to pay the freight. "Freight Included" will be added to the print out of the PO form and will be displayed in PO Reconciliation module for reference. If this box is not checked "Freight Not Included" will be displayed on PO Reconciliation module. |

| Conf Name |

The contact at the supplier who confirmed the purchase order. |

| Buyer |

The initials of the buyer for the order. |

| PO Status |

The status of the purchase order. Indicates if the order is new, being edited, is open, closed or cancelled. |

| PO Priority |

The status of the purchase order.Indicate if the order is standard, priority, or hot. |

| Approval |

When the purchase order is approved, the "T" in the Purchase Order number will be replaced with a "0" and the initials of the person who approved the order will be displayed. (Note: The PO must be approved before being able to create a PO Dock receiver). |

| Final Approval |

When two approvals are required, and both are granted, the initials of the second person approving the purchase order will be displayed in this field. |

| UDF |

(User Define Field) has been added for future use and is not functional at this time. |

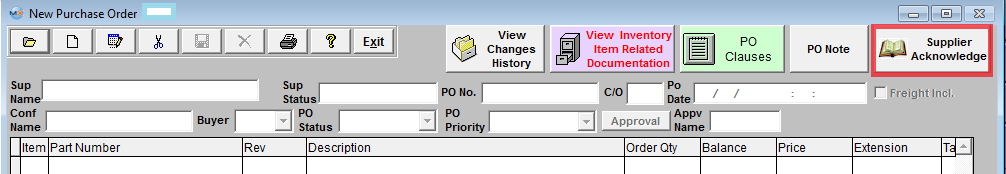

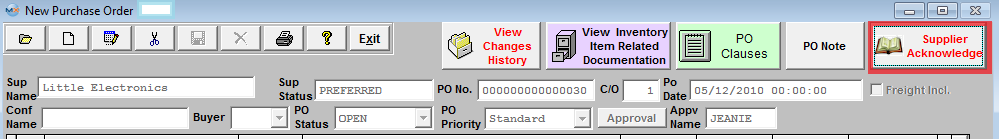

| Supplier Ack |

Load supplier acknowledgement documents received from supplier. |

Purchase Order Items

| Item |

The purchase order item number of an item being purchased. |

| Part Number |

The part number of the item being purchased. |

| Rev |

The revision of the part number being purchased. |

| Description |

The Description of the part number. |

| Order Qty |

The quantity of parts being ordered. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. |

| Balance |

The un-received balance of the item. |

| Price |

The agreed upon price for the items being ordered. |

| Extension |

The extension of the price and quantity. |

| Tax |

Indicates whether or not the item is taxable. |

|

This will allow user to cancel an individual item on a PO. Since the system does not allow you to delete a line item that has had any kind of transaction, we needed a way for users to cancel individual line items without having to cancel the entire order within the system. If any parts have been accepted, it cannot be cancelled. Once a part has any receipts the user cannot delete the line, so if they reject the total received qty they can cancel the line to prevent it from affecting the PO, or PO history for the other line items. If they do not want to reject the entire qty then their only option is to reduce the balance qty to the accepted qty. Cancelled line items will be excluded from the Purchase Order reports within the module.

|

| Total Purchases |

The total amount of all items on the purchase order (excluding taxes). |

| Total Tax |

The total tax amount of all items on the purchase order. |

Detail Definitions

| Item # |

The purchase order item number of an item being viewed. |

| Item Type |

The type of inventory being purchased (Inventory, MRO, or Services) Inventory is for a part that exists in the ICM module. MRO stands for Management Required Options. Generally this is used for supplies, purchases. Services items are for those instances where the assembly is outsourced. |

|

Part Number

|

The internal part number of the item being purchased. |

|

Rev

|

The revision of the part number. |

|

Package

|

The packaging method used to package the parts.

|

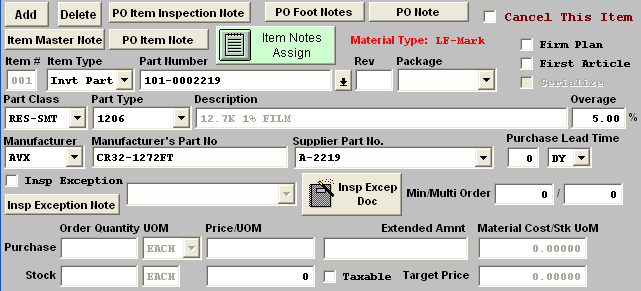

| Material Type |

The material type (per AVL level) will be displayed in Red once user selects the mfgr and mfrg PN. |

| Firm Plan |

If this box is checked, the MRP module will NOT try to override the purchasing decision. For example: If the need is for 100 parts per month for the next six months. But the user makes a decision to block order 600 parts and marks the PO as Firm Planned. Without any Firm Plan command, the MRP module would instruct the user to cancel the PO for 600 quantity and re-issue for 6 separate purchases of 100 each. But since the PO is marked as Firm Planned this tells MRP that the purchasing decision was intentional and NOT to override. So MRP will work around this PO

|

|

First Article

|

If this box is checked, this part requires a first article inspection and the users will be required to check off the First Article Done box within PO receiving (This information is usually defaulted from the ICM module, but can be edited within the PO module also).

|

|

Allow Partial Schedule

|

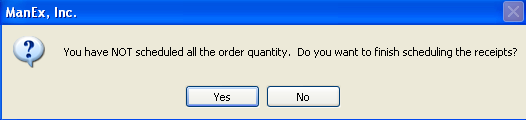

This will default in from the Purchase Order Setup module, but user can change it any time while in the PO module. If un-checked user will receive the popup warning them that they have not scheduled all the order qty and ask if they want to finish scheduling the order qty, upon saving a PO with only a partial schedule. If the box is checked the system will not ask any questions when saving a po with only partial schedule. (Note: MRP will NOT acknowledge qty's that are not scheduled).

|

|

Serialized

|

If this box is checked, the user will be required to enter serial numbers at time of Purchase Order Receipt and Inspection. (This information is defaulted from the ICM module).

|

|

Part Class

|

The Part Class of the part number.

|

|

Part Type

|

The Part Type of the part number.

|

|

Description

|

The Description of the part type.

|

|

Overage

|

The percentage of parts allowed to be received over the ordered quantity.

|

|

Manufacturer

|

The manufacturer for the part.

|

|

Manufacturer Part Number

|

The commercial part number.

|

|

Supplier Part No.

|

If the Mfgr AVL has a Supplier and Supplier PN associated within the ICM module, the Supplier PN will be displayed in this field as additional reference.

|

|

Purchase Lead Time

|

The time between the Supplier receipt of the PO and receipt at the users dock.

|

|

Insp Exception

|

Checking this box will allow the receiver to receive the parts for this Purchase Order Only without inspection. Upon checking this box the Insp Exception Note Field and the Insp Excep Doc will become available for use and then user must then select an Insp Exception Type from the pull down screen. User MUST have special rights within the Security module or supervisor rights to edit this field.

|

|

The Insp Exception box MUST be checked for this field to become available. This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system. |

|

|

The Insp Exception box MUST be checked for this field to become available. This will allow users to attached documents. This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system.

|

|

Min/Multi Order

|

The Min/Multi order quantities are defaulted in from the Inventory Control module (MRP Info tab) to display the minimum quantity that must be ordered for this part and the increments this part must be purchased in. (If this information is edited within the Purchase Order Module, it will be updated to the ICM module upon saving). For Example: if the Min order qty is 500 and the order multi is 100 and the order is for 515, then the order will need to be rounded up to 600.

|

|

Purchase Order Qty

|

The quantity of parts being ordered based on the purchasing units of measure.

|

|

UOM

|

The Purchased unit of measure. (May be different than stocking unit of measure).

|

|

Price/UOM

|

The agreed upon unit price for the items being ordered.

|

|

Extended Amt

|

The extension of the price and quantity.

|

|

Standard Cost/Stock UOM

|

This field displays the Standard MATERIAL Cost. (This is defaulted in from the ICM module, if no standard material cost is found in the ICM module the user will be allowed to enter in a standard material cost at the time of purchase). For a BUY part, this is the value against which PPV should be calculated, and the value the user should expect to pay for the part.

|

|

Stock/Order Qty

|

The quantity of parts ordered based on the stocking unit of measure.

|

|

Stock UOM

|

The stocking unit of measure.

|

| Stock Price/UOM |

The stocking price.

|

|

Taxable

|

Indicates whether or not the item is taxable.

|

|

Target Price

|

The target price is a reference for the buyers to use. (This information is defaulted from the ICM module).

|

D

T

Directive Buttons

The following buttons are displayed on the Purchase Order screen.

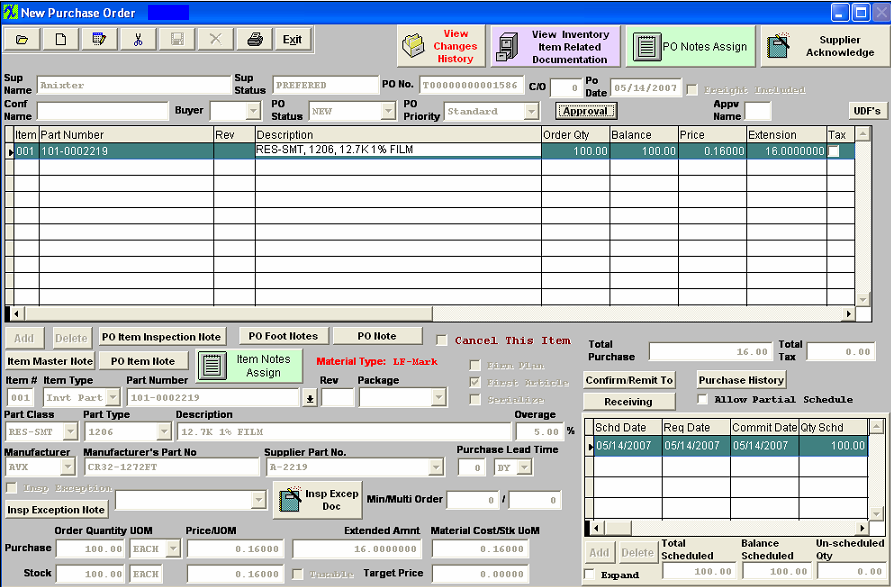

After a purchase order is created or edited, it must be approved before it can be printed and issued to a supplier. Certain employees may be granted authority to approve purchases up to a certain total dollar value. Those authorized personnel may approve purchase orders under that amount. If only one signature is required, the order will be finalized and released. If it is a new order, and automatic PO numbering is enabled, Manex will assign the next available number to the order. The action is taken by clicking on the Approval button and responding with an authorized password.

If two signatures are required in order to release a purchase order, then a second person with approval authority for the amount of the order must approve the order, by clicking on the Final Approval button and responding with an authorized password.

|

If this button is displayed in Red related documents have been attached to this item in the ICM module and may be viewed by depressing the "View Inventory Item Related Documentation" button. For further detail see Article #2396. |

|

Depressing this button will display the note for that part per the Item Master (It will be shown in red as displayed) This button will only be editable if that user has "Edit" rights for the Inventory Control Module. |

|

Depressing the button will bring up a screen where the user can enter a special note pertaining to the particular line item. Depress the Edit button. Type in the note. Depress the Save button. Exit. |

|

Depressing the button will bring up a screen where the user can enter special notes pertaining to the entire PO. Depress the Edit button. Type in the note. Depress the Save button. Exit.

|

|

If this button is displayed in Red, user will be able to view the inspection notes that have been recorded within the PO Receiving module. These notes will also be displayed in all of the PO Detail reports (except detail by due date report). |

|

Depressing the button will bring up a screen where the user can enter additional PO foot notes pertaining to the entire PO. (This will not replace the standard foot notes defaulted from the system set-up.) Depress the Edit button. Type in the note. Depress the Save button. Exit.

|

|

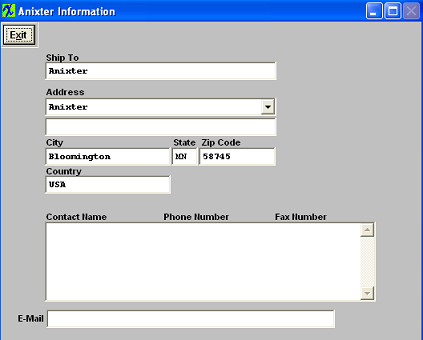

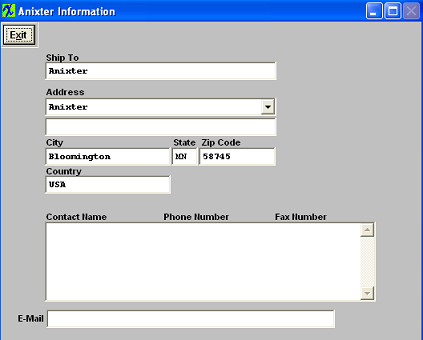

Depressing this button will open up address information regarding the supplier. |

|

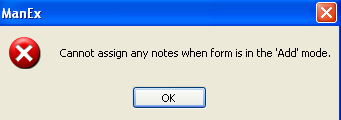

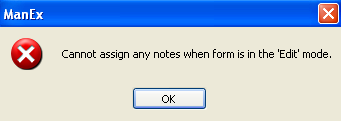

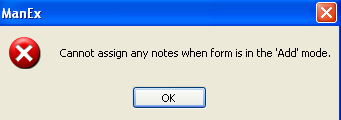

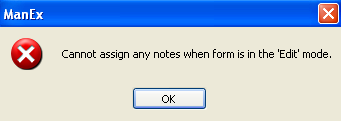

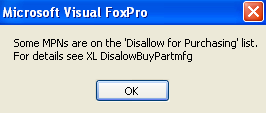

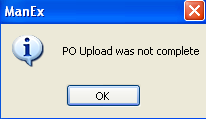

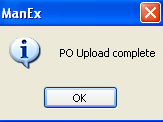

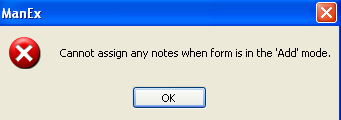

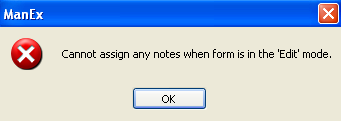

Depressing this button will bring up a screen listing note templates from System Setup and you may select the desired template(s) you would like added at the Item level. Any Note Templates added will be listed as an attachment to the normal PO and this button will be displayed in RED. By design this button is ONLY editable in the view mode (See Article #3432 for further detail). If user trys to use this button in the add or edit mode the system will display one of the following warnings.

|

|

Depressing this button will bring up a screen listing note templates from System Setup and you may select the desired template(s) you would like added at the PO level. Any Note Templates added will be listed as an attachment to the normal PO and this button will be displayed in RED. By design this button is ONLY editable in the view mode (See Article #3432 for further detail). If user trys to use this button in the add or edit mode the system will display one of the following warnings.

|

|

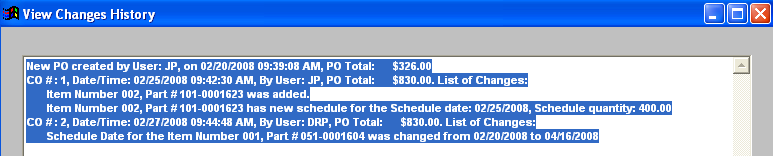

Depressing this button will display the complete history of all changes made to this order, if an approval is required for the change, with the exception of checking or unchecking the Freight Included box. It will list the CO # (if applicable), Date/Time of Change, By User, PO Total at time of change, and List of Changes recorded. NOTE: The system will record the fact that notes have been changed (PO Note, POItem Note, PO Foot Notes)(only if an approval is required which is setup in the Purchase Setup module), but will NOT record the differences between them. This will be the users responsibility to record and track the modifications within the note fields. |

|

Load supplier acknowledgement documents received from supplier. See Article #5137 for further information on How to Load a Document. |

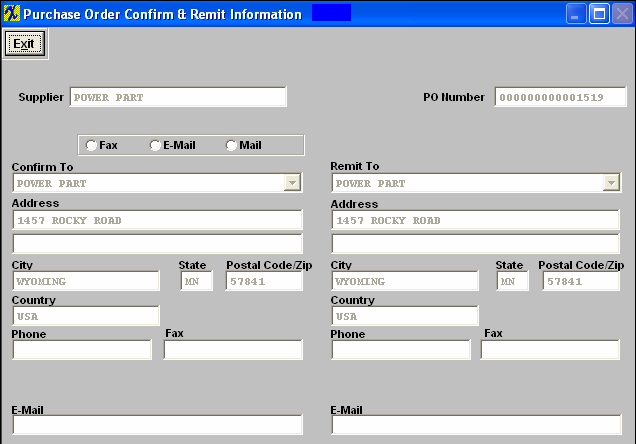

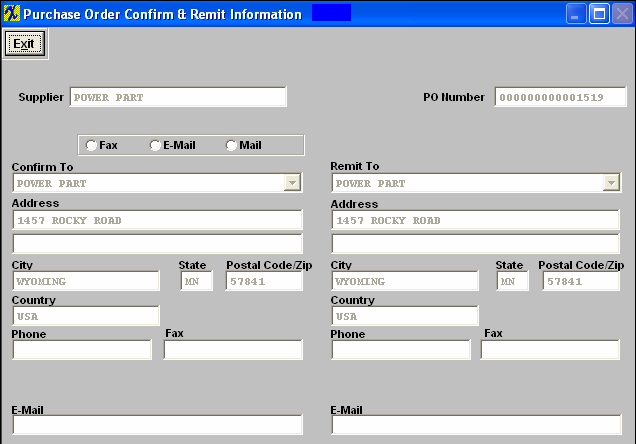

Confirm/Remit Screen Field Definitions

| Supplier |

The supplier or vendor with whom the order was placed. |

| PO Number |

The Purchase Order number of the order. New purchase orders that have not been approved will display a temporary number until approved. |

| Fax, eMail, Mail |

How to communicate with the supplier. |

CONFIRM TO

| Confirm To |

The name of the supplier. |

|

Address, City, State, Postal Code, Country

|

The address of the supplier to which the order is sent. |

| Phone, Fax |

How to communicate with the supplier. |

| E-Mail |

Email address enter within the Supplier Setup module. |

REMIT TO

| Remit To |

The name of the supplier or their agent. |

| Address, City, State, Postal Code, Country |

The address of the supplier to which the payment is sent. |

| Phone, Fax |

How to communicate with the supplier accounting department. |

| E-Mail |

Email address enter within the Supplier Setup module. |

|

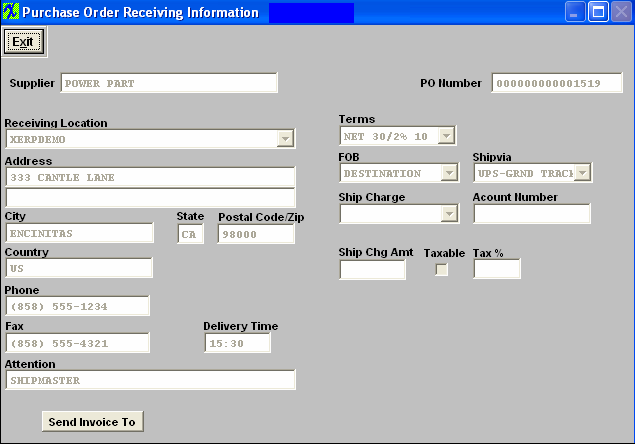

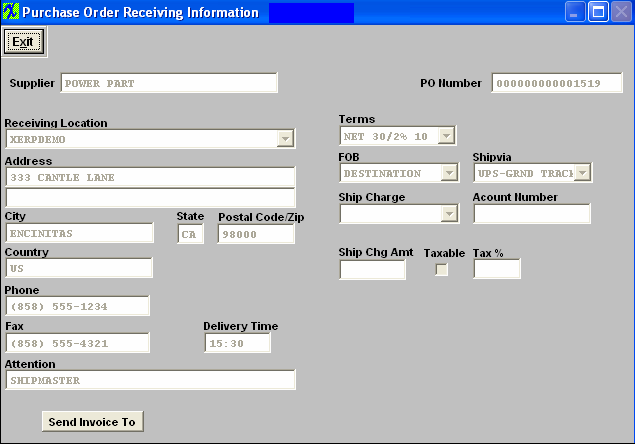

When the user has displayed a purchase order with items on the Purchase Order screen, pressing on the Receiving button will display information about where the supplier is to ship the material on the purchase order, and the terms and conditions of the order. |

Receiving Screen Field Definitions

| Supplier |

The supplier or vendor with whom the order was placed. |

| PO Number |

The Purchase Order number of the order. New purchase orders that have not been approved will display a temporary number until approved. |

| Receiving Location |

The company and address to which the order is to be shipped. |

| Terms |

The terms of the purchase order. |

| FOB |

The FOB point for the order. |

| Ship via |

The preferred shipping carrier for the order. |

| Ship Charge |

How the freight costs are to be paid. |

| Account Number |

If needed, the freight company account number for the carrier to charge. |

| Ship Chg Amt |

The shipping charge cost for the order. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

| Taxable |

Indicates if the freight charges are taxable. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

| Tax % |

The tax rate for the shipping charges. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

| Delivery Time |

The preferred delivery time for receipts. |

| Attention |

The name of the person to whom the shipment is directed. |

DIRECTIVE BUTTONS

|

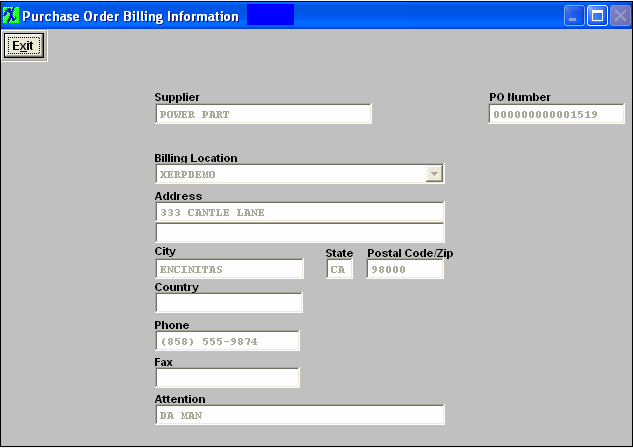

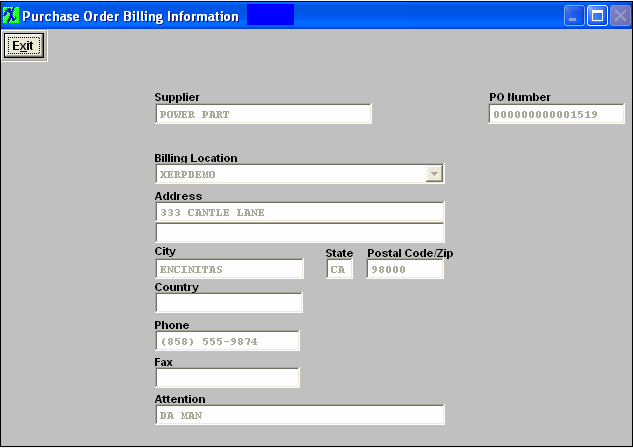

When the user has displayed a purchase order with items on the Purchase Order screen, pressing on the Send Invoice To button will display the billing information for the supplier. This button is displayed on the Purchase Order Receiving Information screen. |

Send Invoice To Screen Field Definitions

| Supplier |

The supplier or vendor with whom the order was placed. |

| PO Number |

The Purchase Order number of the order. New purchase orders that have not been approved will display a temporary number until approved. |

| Remittance Location |

The users company and address to which the order is to be billed. |

|

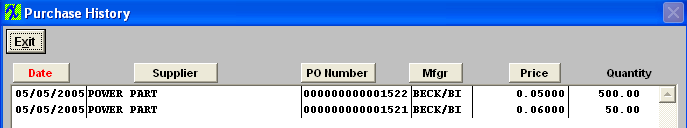

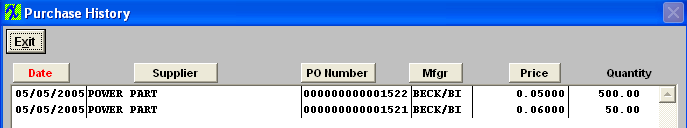

Depressing the Purchase History button will display the purchase history for that line item. The user may sort by Date, Supplier, PO Number, Mfgr. or Price by depressing the appropriate button. Note: If an order has status “EDITING” it will not be displayed on the history list. Once the order is approved and the status is changed to "Open" or "Closed" the order will then be displayed on the purchase history list. |

|

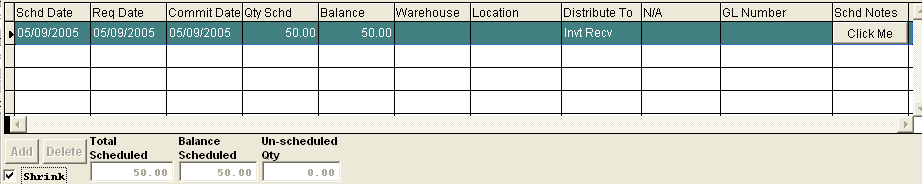

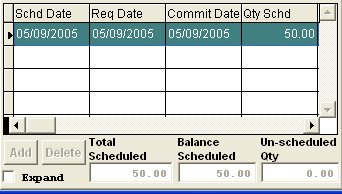

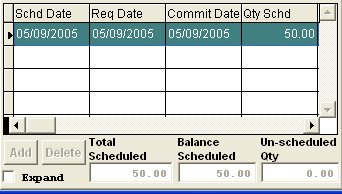

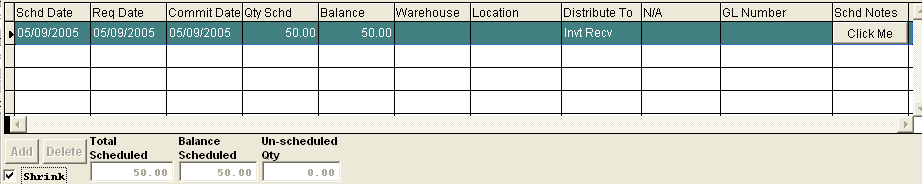

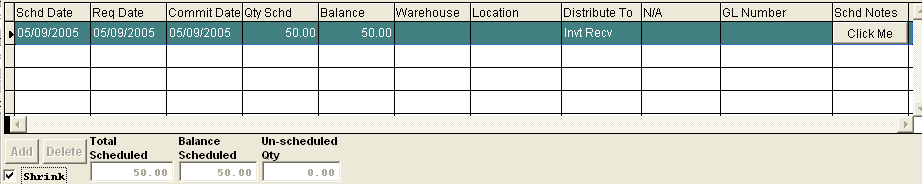

When the user has displayed a purchase order with items on the Purchase Order screen, and has highlighted one of the line items, checking the Expand box will display the schedule information about the item being purchased. |

|

When the user has finished viewing the schedule information about the item, the user may check the Shrink box and the scheduleinformation will shrink down. |

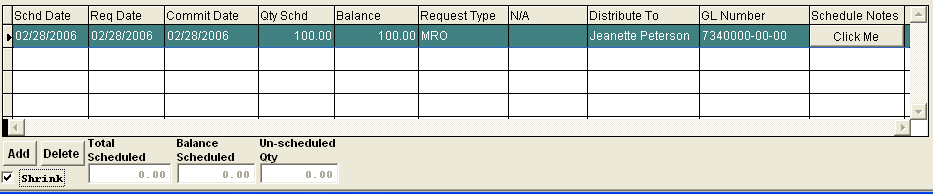

Schedule Field Definitions

| Schd Date |

The date the material is due to land on the users dock. This is the date MRP uses. |

| Req Date |

This is the internally required or desired date. It is not used for the supplier or MRP. |

| Commit Date |

The commit date is a reference field for the buyer. |

| Qty Schd |

The quantity scheduled for the due date. |

| Balance |

This will display the balance left to receive from the Qty scheduled.

|

| Warehouse |

The User can choose the Warehouse from the pulldown or leave it blank. The Y next to the Warehouse location indicates that, that Warehouse is set-up in the AVL. The N next to the Warehouse location indicates that, that Warehouse is not set-up in the AVL. If the warehouse field is left blank then the warehouse can then be assigned at PO Receiving Management. Once the record has been saved within the PO Receiving this information will then be updated within the Inventory Control Management under the Qty info screen. |

| Location |

The Location field will update automatically from the Inventory Control Management module. The user can edit this field in the scheduling detail. This will not change the location in the Inventory Control Management module under the quantity info screen. |

| Distribute To |

This is classification of the distribution of the item when received, either to regular Inventory Receiving or to Allocate to Special Work Order or Project |

| N/A |

This Field is for future use, it is non-applicable at this time.

|

| GL Number |

The General Ledger number where the purchase order will post. |

| Schd Notes |

Depressing on the  button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit |

|

When Creating a new PO or Editing an existing PO this button will be enable. Depressing this button will allow the user to add additional scheduled deliveries.

|

|

When Creating a new PO or Editing a existing PO this button will be enabled. Highlight a scheduled delivery then depressing this button will delete that delivery from this screen

|

| Total Scheduled |

This field will display the total qty scheduled for the highlighted item.

|

| Balance Scheduled |

This field will display the Balance left to receive from the qty scheduled for the highlighted item. |

| Un-scheduled Qty |

This field will display the qty un-scheduled for the highlighted item.

|

|

| 1.1.4. How To ..... for PO Mgmt |

| 1.1.4.1. Find a Purchase Order |

|

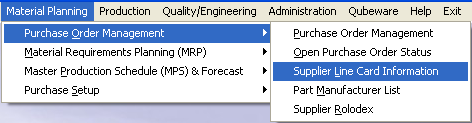

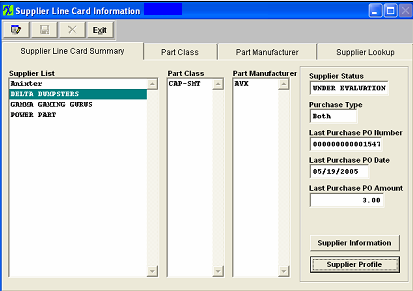

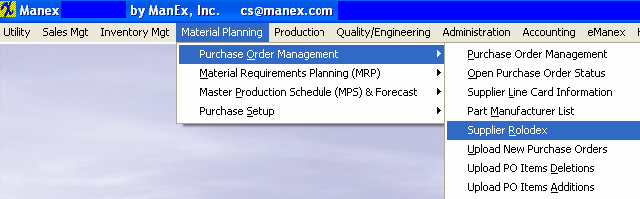

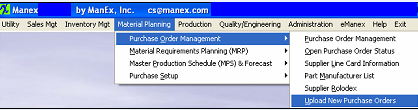

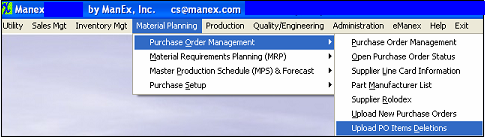

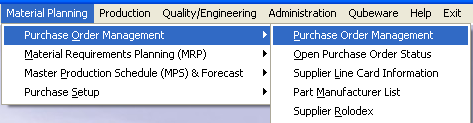

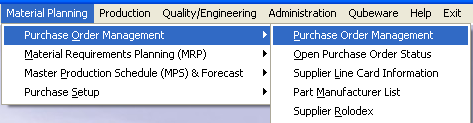

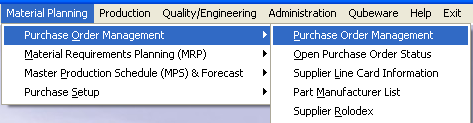

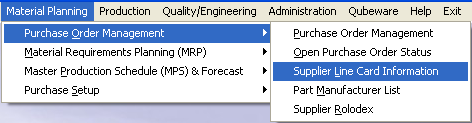

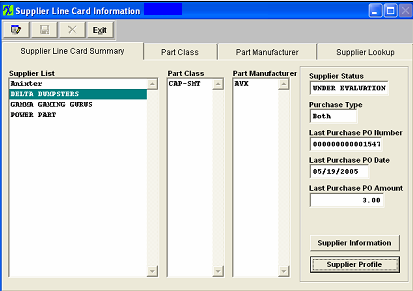

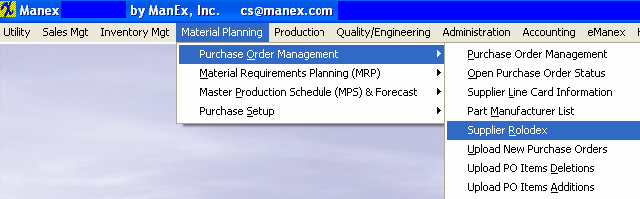

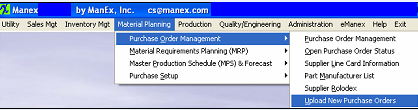

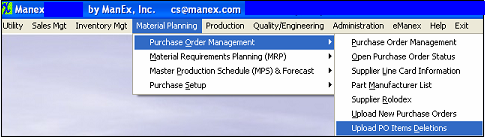

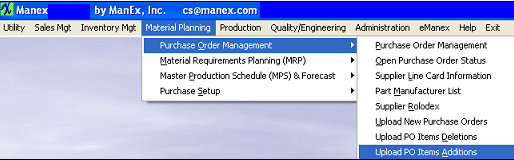

Depress Material Planning/Purchase Order Management/Purchase Order Management. The main screen will appear.

|

|

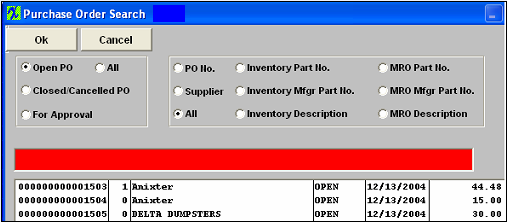

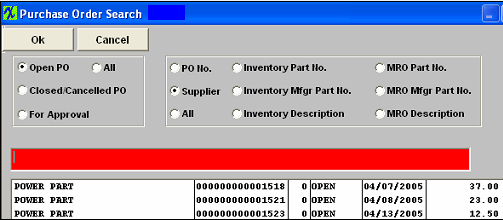

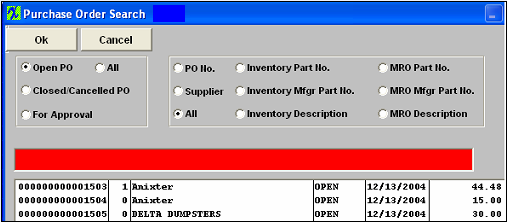

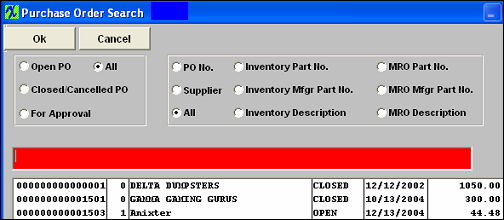

1. Depress the Find Record icon.The following screen will be displayed.

2. On the left hand side of the screen, choose what you’re looking for – either Open PO, All, Closed/Cancelled PO or For Approval, by clicking on the appropriate radial.

|

|

3. Once you’ve made your “search for” choice, determine the search method by choosing between PO Number, Inventory Part Number, MRO Part Number, Supplier, Inventory Manufacturer Part Number, MRO Manufacturer Part Number, All, Inventory Description, or MRO Description.

| 4a. For example, a selection on the left for an Open PO, and a selection of ALL on the right will produce the following screen, listing all open purchase orders.

Double click on the Open PO displayed to make your selection.

|

|

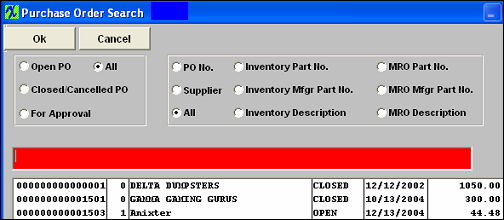

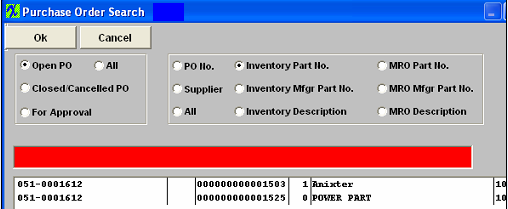

| 4b. A selection on the left for All and a selection of All on the right will produce a list of all purchase orders, open, closed, etc. |

|

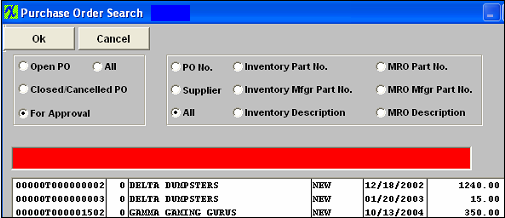

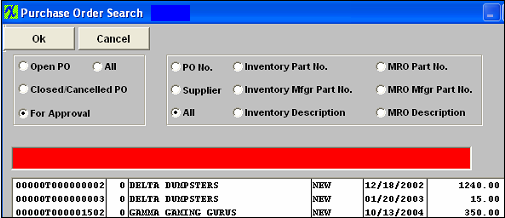

| 4c. A selection on the left of For Approval and a selection on the right for All will produce the following selection. (Pending, Editing, New, etc.)

|

|

| 4d. If you are searching for a specific PO, select All on the left and PO No. on the right.Then type in the purchase order number and hit enter.The PO record will pull onto screen. |

|

|

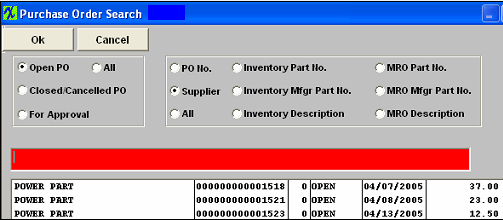

4e. If you are interested in a specific supplier with open POs, mark the left hand side Open PO and the right as Supplier.Type in the Supplier Name.

A list of all of the Open POs for that Supplier will appear, as shown.

|

|

|

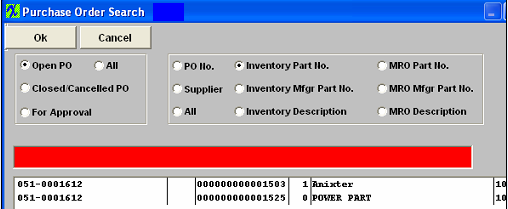

4f. If you are interested in a specific part number on Open POs, select Open PO on the left and Inventory Part No. on the right.Type in the Part Number.

Any open POs containing this part number will appear, as shown.

|

|

The rest of the right hand selections are essentially the same as for those illustrated above.

5. After finding the Purchase Order, the Purchase Order screen appears, populated with any parts on order.

|

| 1.1.4.2. Add A Purchase Order |

|

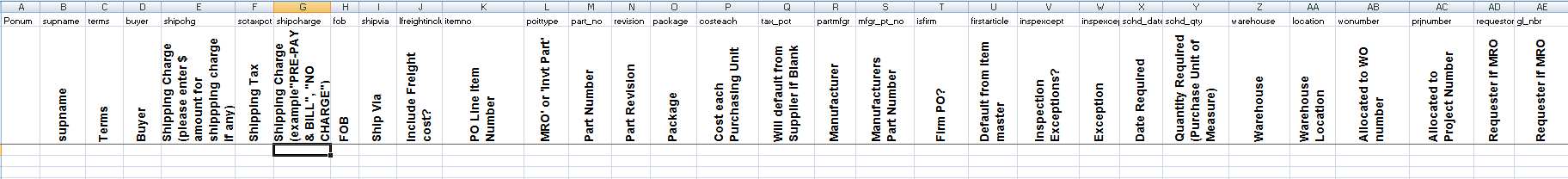

Enter Manex.exe

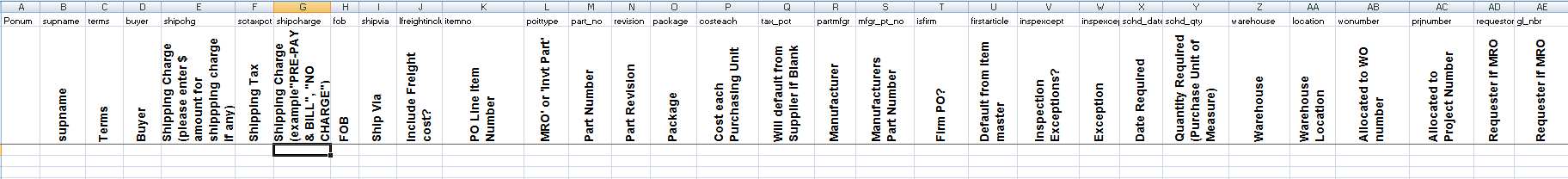

Material Planning/Purchase Order Management/Purchase Order Management

|

|

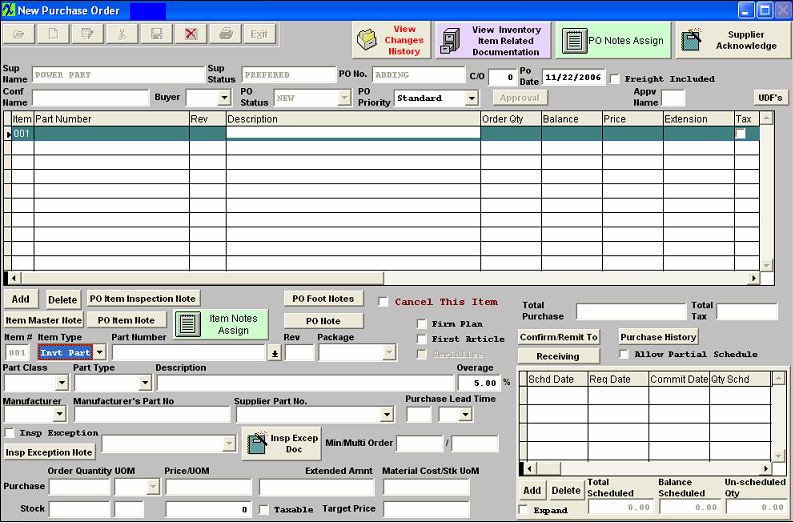

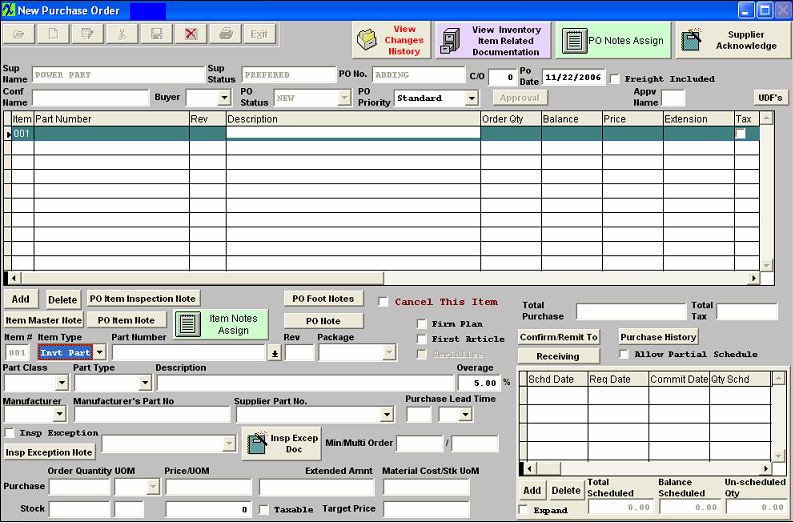

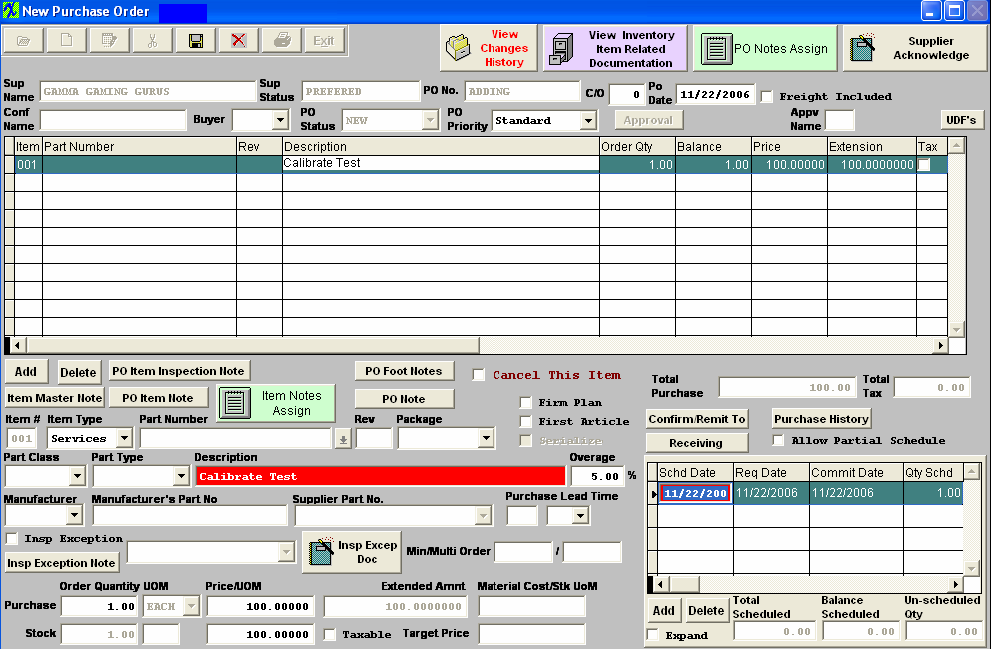

The following screen will appear:

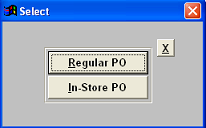

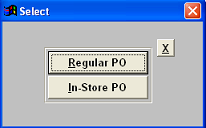

Depress the Add Record Button (in the Purchase Order Tab screen) displays the following sequences:

The user will be prompted for the password. The first step is to Select Regular PO or In-Store PO

|

|

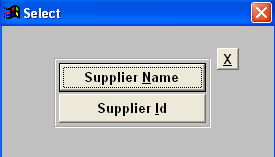

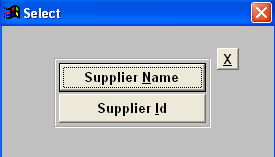

| If Regular PO is selected then another Selection box will appear. The user must define the supplier for the purchase order.

The user is asked if they wish to locate the supplier by the name or supplier ID code.

|

|

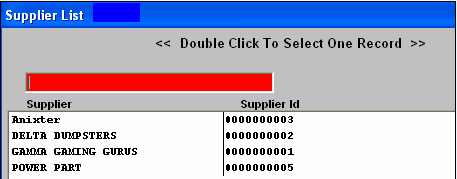

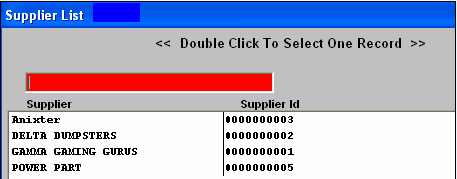

| If the user selects to find a supplier by the name, a screen is presented listing all of the suppliers in alphanumeric order |

|

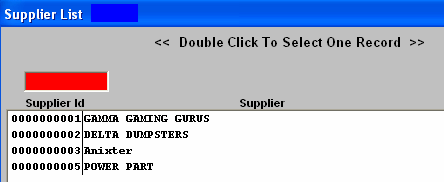

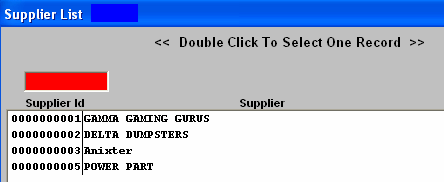

| If the user selects to find a supplier by the ID code, a screen is presented listing all of the supplier ID codes in alphanumeric order |

|

The user may enter the number or name in the red edit box above the Supplier or Supplier ID label, or scroll down to select a supplier. Double clicking on a supplier or pressing the ENTER key on a highlighted supplier selects the supplier and displays the Purchase Order screen with the supplier included.

Once a supplier is identified, the remaining information fields become active. The user can CANCEL the action if needed.

The user then may fill in the Confirm Name, Buyer and add items to the purchase order.

Entering Item Detail Information

|

The user must first select the Item Type to be entered as a line item. Item types include Inventory Parts (parts to be delivered to on hand inventory), MRO (expensed items) or Services .

|

|

|

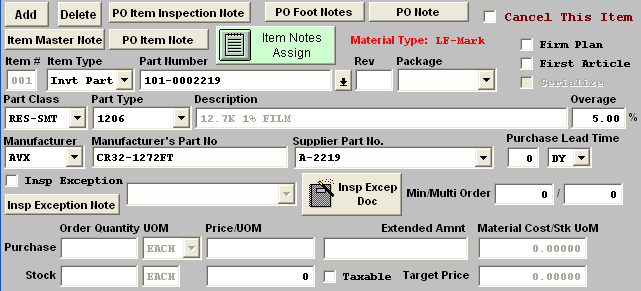

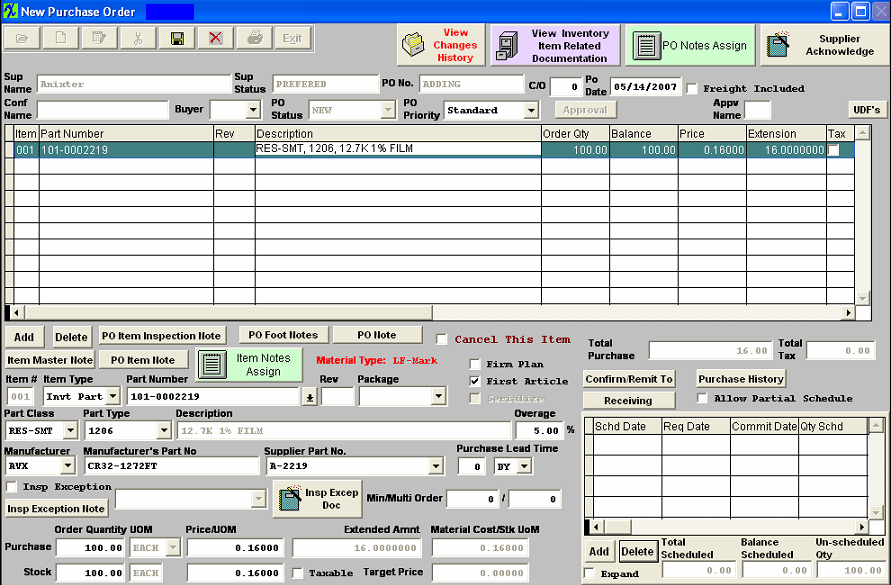

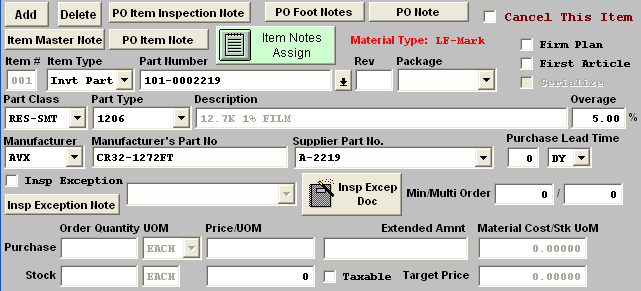

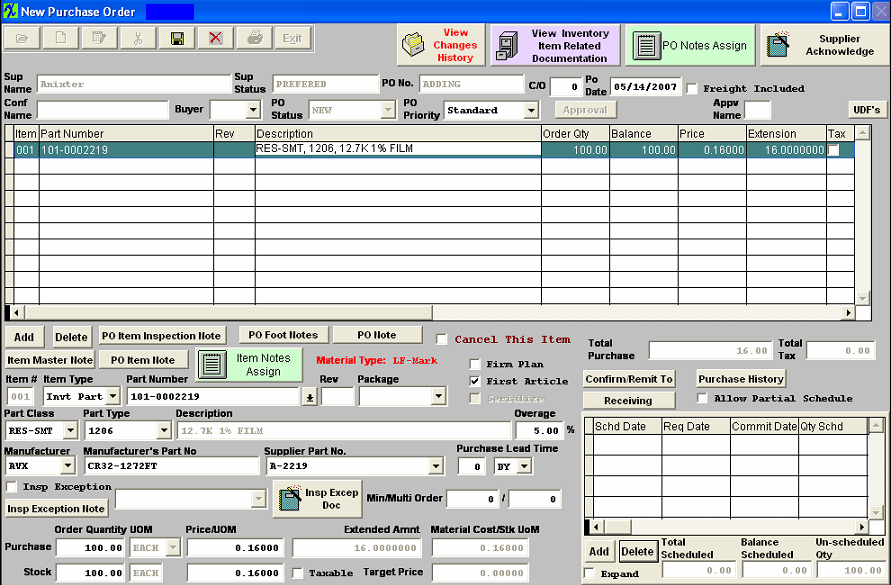

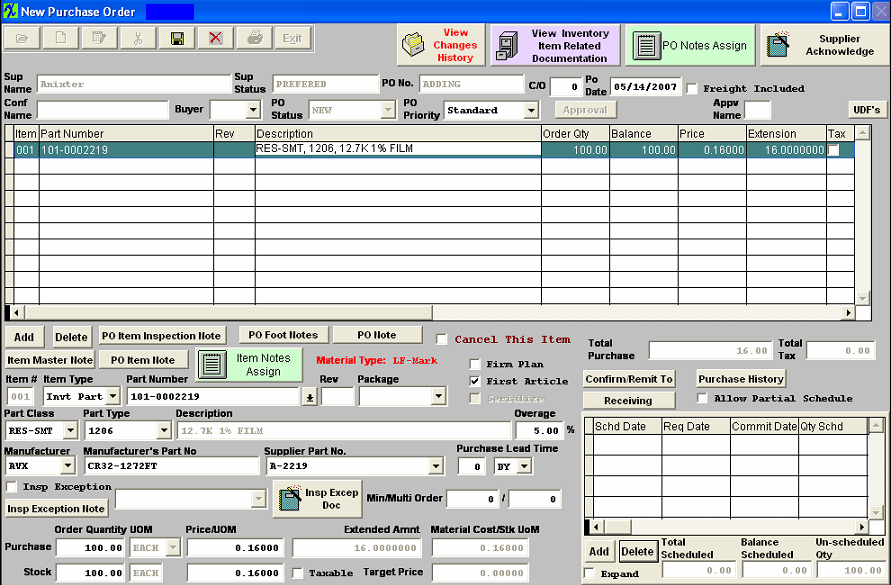

| 1.1.4.2.1. Inventory Part | Selecting Inventory Parts as the item type, the user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. Once a part number from Inventory has been entered, ManEx completes the boxes associated with the item master.

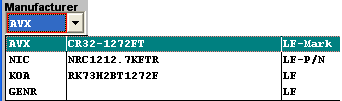

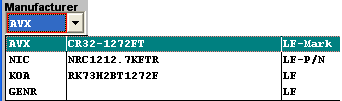

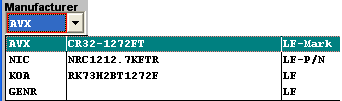

| If more than one manufacturer exists for the part, the user may click on the down-arrow next to the manufacturer edit box and select the appropriate manufacturer for the order. The Material type will be displayed in the pulldown next to the Mfg. and Mfgr. PN. |

|

|

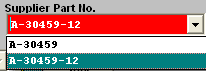

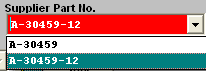

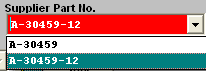

If more than one supplier part number exists for the part, the user may click on the down-arrow next to the supplier part no. edit box and select the appropriate supplier part no. for the order.

The system will look for the preferred supplier part number and if found will show it as a display. At this time the user can leave the part number as is or select a different one if available. After a user will save the PO, the supplier part number will be saved and next time you will see the selected suppler part number when viewing the same PO.

No history will be saved because this field is for the information only.

|

|

| Firm Plan |

If this box is checked, the MRP module will not try to override the purchasing decision. For Example: The user makes a decision to block order 600 parts, but the need is only for 100 parts per month for the next six months. Without the Firm Plan command, the MRP module would tell the user to cancel the PO for 600 quantity and re-issue for 6 separate purchases of 100 each. With the Firm Plan command, this tells MRP that the purchasing decision was intentional. (Please refer to the Material Requirements Planning article).

|

| First Article |

This box will be checked if set-up in the Inventory Control Management Module. You may uncheck it or check it if user has been instructed that it may be changed for this item only. This information will be carried forward to the PO Receiving screen for reference. |

| Serialized |

This box will be checked if set-up in the Inventory Control Management Module and will not be editable within the Purchase Order Management. This indicates to the user that this BUY part has been marked as Serialized and any product coming in or out of the system will require serial number tracking. |

The user may edit or add a percentage amount of extra material that will be allowed to be shipped against the order. By entering a percentage in the OVERAGE field, receiving will be allowed to receive extra parts up to the limit imposed in this field.

The user may also edit or add in purchasing lead time and min/mult order quantities through the Purchase Order Management module.Once the record has been saved this information will then be updated within the Inventory Control Management under the MRP Info screen.

The user may check the box for Inspection Exception and select from the Inspection Exception Pulldown (which is established in the Inspection Exception Setup module). The user will then also be allowed to enter any Inspection Exception Notes and/or Load Insp Excep doc that pertain to that PO line item. This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system.

The user is then prompted for the purchase order quantity of parts to be ordered. The user may enter either the Purchase Quantity or the Stocking Quantity, and ManEx will complete the other field based on the purchase/stocking unit of measure and conversion field.

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter qty of 24 into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

Then the unit price is entered (Price Each). The extended amount is shown, calculated by extending the quantity by price. (If the inventory part that you are creating a line item for currently has a standard cost of 0.00 within inventory control the system will prompt the user if you wish to take that Purchase Order Price entered and use it as the standard cost for that item within inventory control). This can not be controlled by the Security level due to the fact that it is better practice to have a $$ assigned to the ICM record before the Purchase Order Receipt is accepted into the system. Otherwise you will have stock that is not valued properly, accounting records that will not be correct, etc. . . . So this is why ManEx allows any Purchase Order user to populate the STD cost field for that record with the purchase $ that you are loading. BUT . . Once a Std Cost is associated with the ICM record - the users within Purchase Order Management should no longer be able to change that value through the PO module.

The user may then indicate that the items are taxable by clicking on the Taxable check box.

The Stock/BOM field will update automatically based upon the conversion table defined in setup. The completed screen should appear as follows:

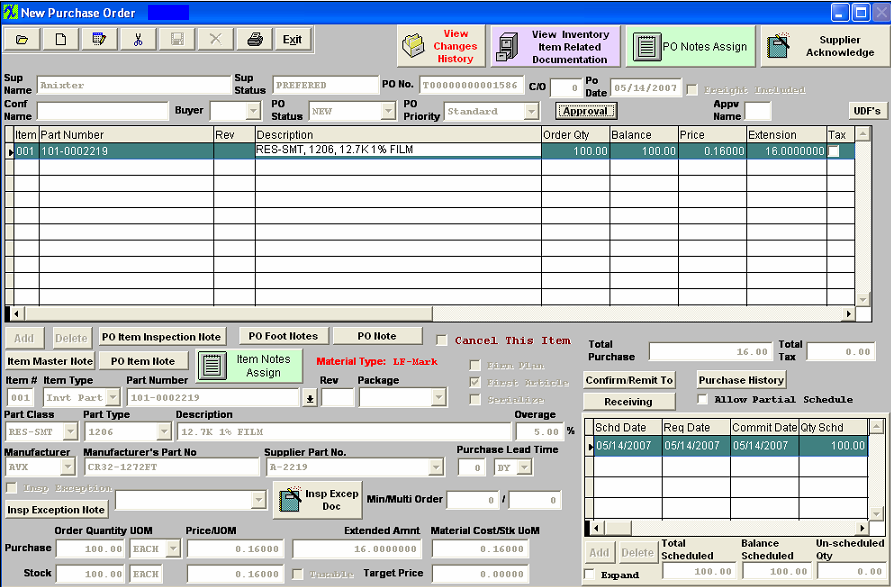

Before saving the order you will need to check the expand box and enter the Schedule detail information.

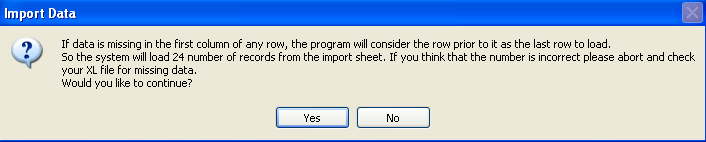

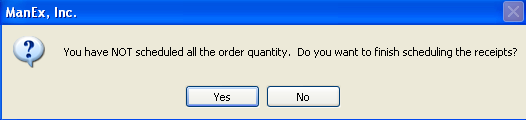

There are situations when the users will either not enter a schedule or enter a partial schedule at time of creating PO. If the scheduled qty does not match the order qty or the "Allow Partial Schedule" box is unchecked, upon depressing the Save button the following message will be displayed. This gives the user the option to stop the save process and return to the item and schedule or continue on and save without scheduling. Some users may not know an exact date for scheduling at the time of the PO creation and just create the PO to get the part on order. Then upon the supplier response add the scheduled dates to the PO at a later time. This is why we do not enforce the scheduling at the time of the PO creation.

If the "Allow Partial Schedule" box is checked upon saving the PO without a schedule or a partial schedule this message will not be displayed.

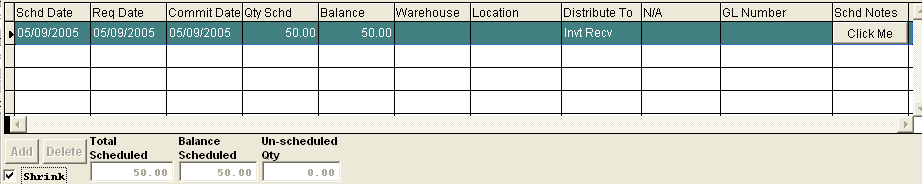

Entering Schedule Detail Information

The item will schedule automatically by adding the lead time to todays date and schedule the entire order amount. (Note: MRP will NOT acknowledge qty's that are not scheduled).

At this time the user has the option to change the Schd date/Req date/commit date information and also the Qty Schd.

Note: If user is not following MRP suggestions when creating POs they need to keep in mind inspection time when entering a schedule for a PO.

|

If the user wants to modify the automatic scheduled date, they can either manually adjust the Date information by highlighting the field and typing in the new date, or place the cursor in the Due Date field.Type in a ?. A calendar will appear.

Depress the desired delivery date.To advance into the next month, depress the > button.

|

|

Schedule Field Definitions

| Schd Date |

The date the material is due to land on the users dock. This is the date MRP uses. |

| Req Date |

This is the internally required or desired date. It is not used for the supplier or MRP. |

| Commit Date |

The commit date is a reference field for the buyer. |

| Qty Schd |

The quantity scheduled for the due date. |

| Warehouse |

The User can choose the Warehouse from the pulldown or leave it blank. The Y next to the Warehouse location indicates that, that Warehouse is set-up in the AVL. The N next to the Warehouse location indicates that, that Warehouse is not set-up in the AVL. If the warehouse field is left blank then the warehouse can then be assigned at PO Receiving Management. Once the record has been saved within the PO Receiving this information will then be updated within the Inventory Control Management under the Qty info screen. |

| Location |

The Location field will update automatically from the Inventory Control Management module. The user can edit this field in the scheduling detail. This will not change the location in the Inventory Control Management module under the quantity info screen. |

| Distribute To |

This is classification of the distribution of the item when received, either to regular Inventory Receiving or to Allocate to Special Work Order or Project |

| GL Number |

The General Ledger number where the purchase order will post. |

| Schd Notes |

Depressing on the  button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit |

Pressing the Save button at the top of the screen saves the order and item(s) entered, and assigns a temporary number to the order. After adding items to the purchase order and saving them, the Purchase Order will display all items added to the order.

The user may use the scroll bars at the right and bottom of the items listed to scroll over additional information.

The user may modify the column widths in the current view by placing the cursor on the right border of the column in the column header, and pressing the left mouse button. Moving the border while holding the mouse button then releasing at the new location resizes the columns.

|

| 1.1.4.2.1.1. Allocate to Special Work Order or Project | Introduction

Inventory Allocation is used to allocate (reserve) quantities of existing items in stock or future Purchase Order deliveries to a Work Order or Project Number.This allocation prevents issuing the quantity reserved to any other use except the Work Order or Project Number specified. Purchase Order Line Item allocations may be removed prior to receipt of the parts by editing the Purchase Order.After receipt of parts allocated by Purchase Order, the allocation may only be removed after the parts are in stock, by using the Inventory Allocation module.

ALLOCATION OF PURCHASE ORDER DELIVERIES

Allocating a PO Line Item is used to make sure that the item will be reserved for a particular Work Order or Project Number when it is received.PO line item allocation is generally used when allocating to a Work Order or Project Number for which the items are not available in stock.Line Shortages of items not on the BOM, which are not in stock, are an example of typical PO Line Item Allocations.To allocate Purchase Order Line Item Deliveries to a Work Order or Project Number:

- A Work Order or Project Number must be open for the product.

- The Item to be allocated must be entered in the Inventory Control Item Master.

- The quantity allocated must equal the quantity ordered. ie. The total quantity ordered on a line item may be allocated to multiple Work Orders or Project Numbers through the schedule screen.

PROCEDURES

To Allocate a PO Line Item to a Work Order or Project Number:

- Allocate to a new or existing PO.

- Select the desired PO in Article #153.

- Highlight the line item you want to allocate.

- (If it is an existing PO) Depress the Edit action button.

- Expand the Schedule Screen, tab or click on the "Distribute to" field.

- Select WO Alloc or Prj Alloc, enter the Work Order number or Project number to allocate to in the WO # field or Project # field.

- Follow normal PO Mgmt procedures to save and approve.

NOTE:The user may wish to allocate a line item to multiple Work Orders and/or Project Numbers. In the schedule for an item, the user can create as many schedule lines as required. Each schedule line can have a different allocation. If the user had a requirement for 5 Work Orders and/or Project Numbers of 100 parts for each Work Order and/or Project Number, the user would add a line to the PO for 500 parts, then in the schedule, the user can add a line for each Work Order and/or ProjectNumber to which the parts are allocated. The schedule dates can be the same or different. The supplier will see only the total quantity required by the schedule date and is not bothered with the individual allocations.

To Un-allocate a PO Line Item that has not yet been Dock Received:

- Select the desired PO in Article #153.

- Highlight the line item you want to un-allocate.

- Depress the Edit action button.

- Expand the Schedule Screen, tab or click on the "Distribute to" field.

- Select Inv Recv.

- Follow normal PO Mgmt procedures to save and approve.

To Un-allocate a PO Line Item that has already been Dock Received:

-

-

|

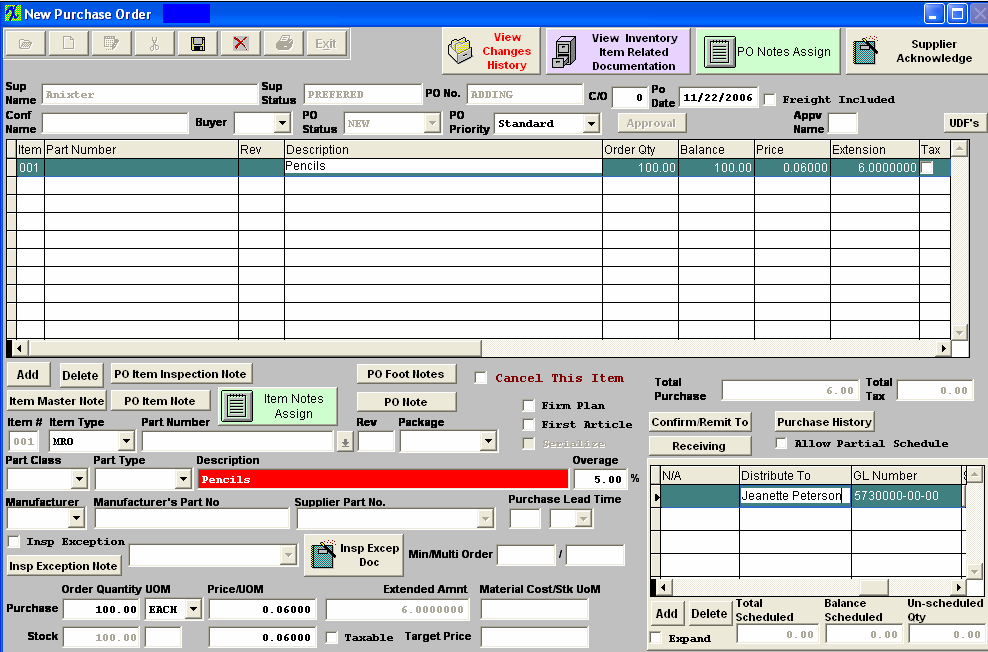

| 1.1.4.2.2. MRO Items | MRO stands for Maintenance, Repair and Operations. Generally this is used for supplies, etc. purchases.

After selecting the Item Type to be "MRO"

If the MRO item is included in inventory

a. The user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow

the focus and then select a part from the desired part type.

b. Fill in the quantity and unit price.

If the MRO item is NOT included in inventory

a. The user may enter in the Suppliers part number manually (or leave blank) and then jump to the description field and enter the description.

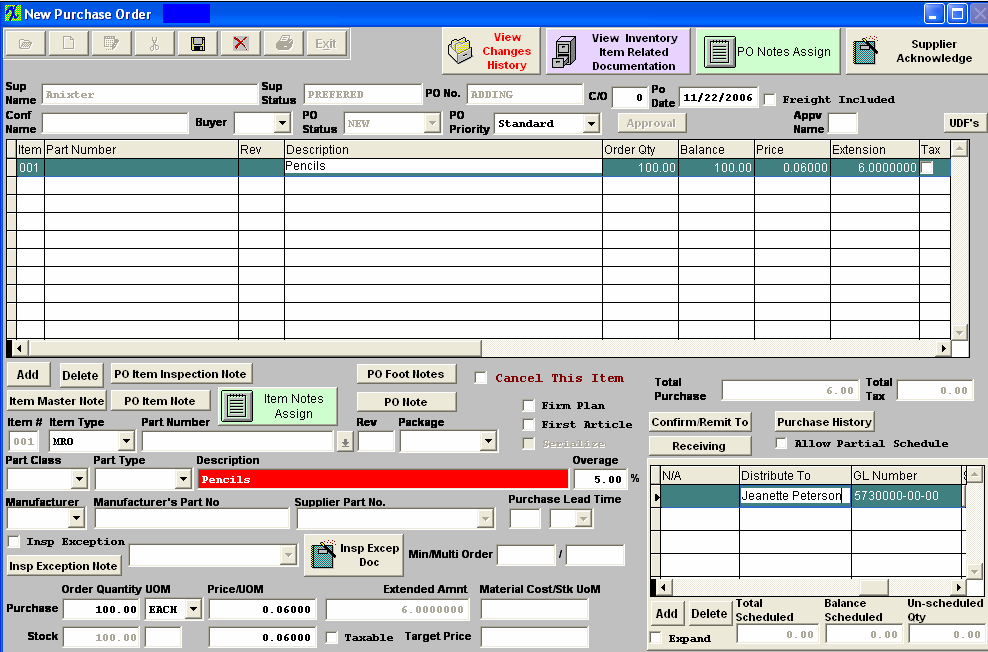

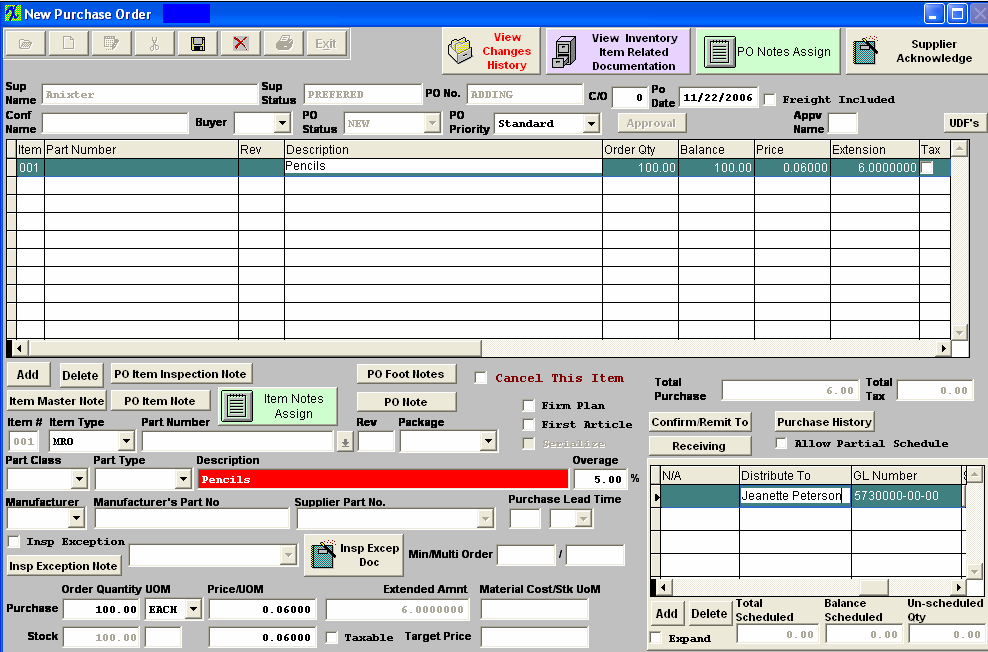

The finished screen should look like the screen displayed:

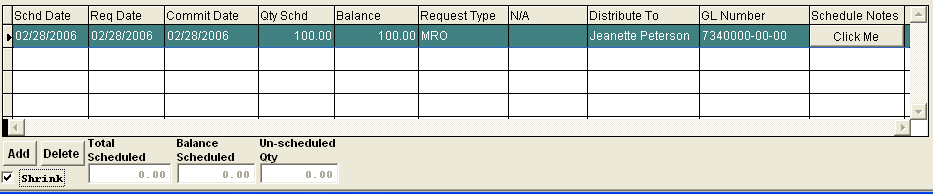

- Check the Expand box in the Schedule screen.

- Enter schedule dates and quantity scheduled.

- Type in the title or name of the person requesting the item in the “Distribute To” field.

- Enter a General Ledger account number in the GL Number field.

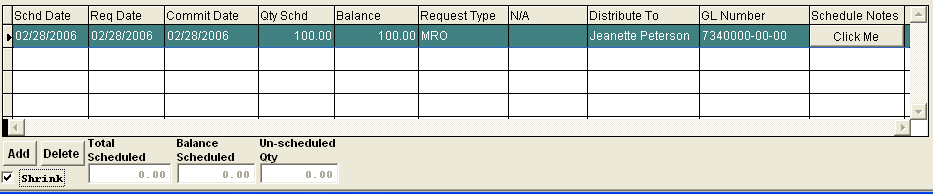

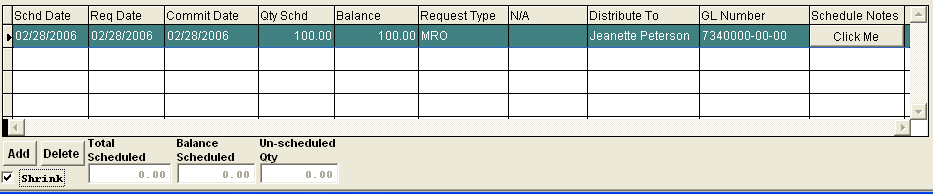

The completed Schedule screen will appear as follows:

- At the conclusion of entry for the item, the user may depress the Save record action button or the Abandon record action button.

- Approve record.

|

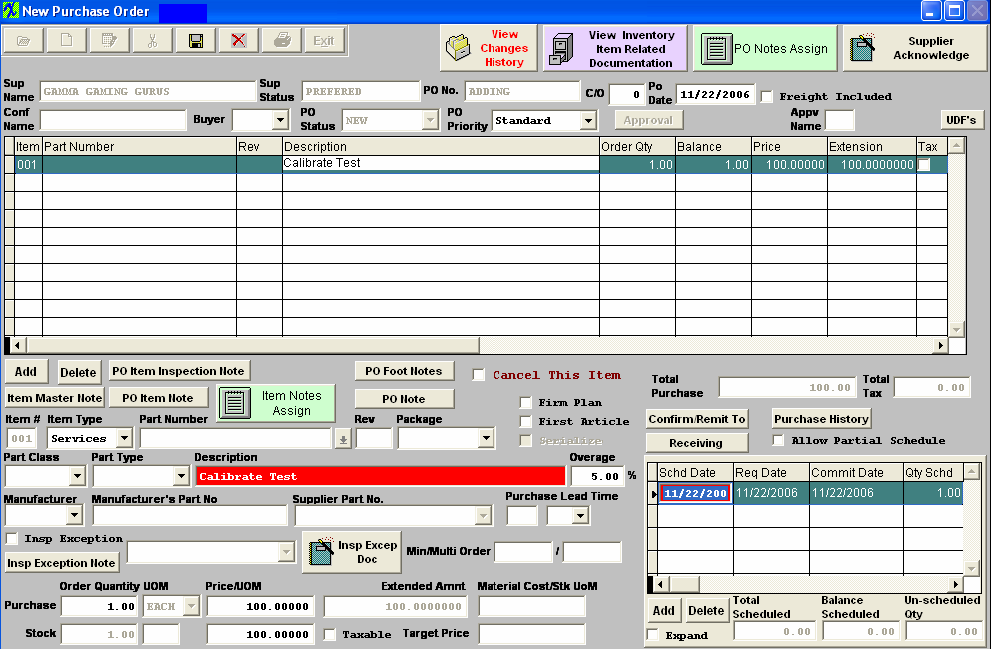

| 1.1.4.2.3. Service Items | Service items are for those instances where the assembly is outsourced.

After selecting the Item Type to be "Service"

- The user may enter the supplier Part number manually (or leave blank) and then go to the description field and enter the description.

- Fill in the quantity and unit price.

The finished screen should look like the screen displayed:

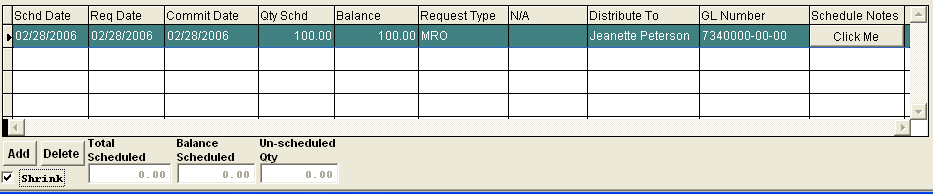

- Check the Expand box in the Schedule screen.

- Enter schedule dates and quantity scheduled.

- Type in the title or name of the person requesting the item in the “Distribute To” field.

- Enter a General Ledger account number in the GL Number field.

The completed Schedule screen will appear as follows:

- At the conclusion of entry for the item, the user may depress the Save record action button or the Abandon changes action button.

- Approve record. Please note upon approval the service item is marked as received and balance updated to 0.

|

| 1.1.4.3. Edit, Cancel, or Close a Purchase Order | Find the Purchase Order that you would like to edit.

Pressing the Edit record action button in the Purchase Order screen will allow the user to modify all the following information:

- The Confirmation Name, Buyer, PO Priority, Supplier Ack., check or uncheck Freight Included box.

- The Status field will only be enabled in the edit mode for users with approval rights. User MUST have approval rights to Modify the PO Status.

- Order quantity and unit price, min/multi qty, purchase lead time, overage amount, Firm Plan or First Article.

- Add or Deletion of a Line Item

- By depressing the Add button allows the user to add additional items to the PO.

- By depressing the Delete button you can delete an existing line Item from the PO.

- Highlight the line item that you wish to delete, then depress the Delete button .

- The user will be asked to validate the deletion before proceeding.

- If you select OK the item will be deleted from the order.

- Information about the terms, FOB, Ship Via, Ship Charge, and Account number, Ship Charge Amount, whether taxable, the tax %

- Schd Date, Requested Date, Commit Date, Quantity Scheduled, Warehouse, Location, Distribute To and Schd Notes.

- Modify or add any information in the Item Master Notes, PO Item Notes, PO Notes, and PO Foot Notes. (Depending on how the user has Purchase Setup module marked depends on whether user can edit the notes without going into edit mode on the PO record. If the "Require approvals for Date changes and Notes" is marked as "Yes" then it will force the users to first put the PO in edit mode before they will be allowed to edit any notes and the note changes will be recorded in the "View Changes History" screen. But if it is marked "No" then the notes become editable without the actual record in Edit mode and the note changes will NOT be recorded in the "View Changes History" screen).

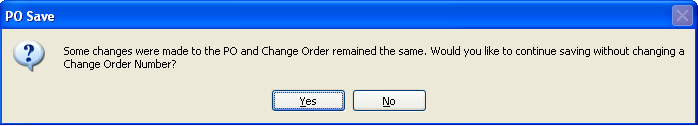

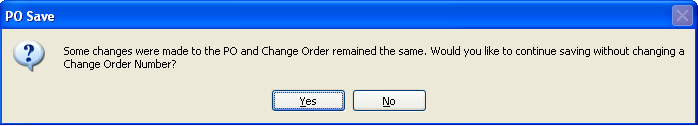

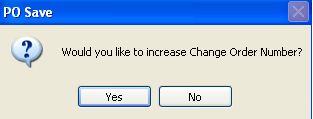

Depress the Save record action button after you have finished with editing the record. The user will then need to approve the order. If user has the "Auto Assign new Change Order # Upon Approval" box checked within the Purchase Setup module, the reminder will NOT be issued and CO# field becomes NOT editable. When the user approves the change the Change Order number will be automatically increased. If user has the "Auto Assign New Change Order # Upon Approval" box unchecked within the Purchase Setup module when user makes changes the CO# will stay the same, the system will prompt the reminder, and user may manually assign a change order number if applicable.

There are situations when an item may not have a schedule or may have a partial schedule. If the "Allow Partial Schedule" box is checked within the Purchase Setup module, the system will NOT ask any questions when saving a po with only partial schedule. (Note: MRP will NOT acknowledge qty's that are not scheduled). If the " Allow Partial Schedule" box is unchecked within the Purchase Setup module , user will receive the following popup warning when editing and saving that line item or any other line item on that same purchase order:

NOTE: If the "Auto Assign new Change Order # Upon Approval" box is checked, and PO is new and the user goes into the "Edit" mode prior to approval, no changes will be made to the CO# on screen or in the "View Changes History" screen. If PO has been approved and the user goes into the "Edit" mode the next CO# will be referenced in the "View Changes History" screen but will NOT increase on screen until PO has been approved. If the user goes to the "Edit" mode more than once before approving the change the CO# will only increase once in the "View Changes History" screen.

NOTE: If users enter a PO number manually using a "T", then changes the numbering to Auto, and later edits and approves this PO the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change.

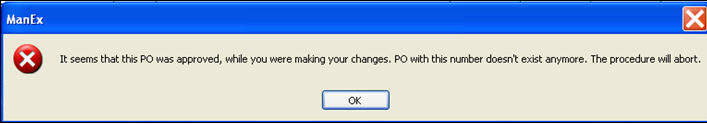

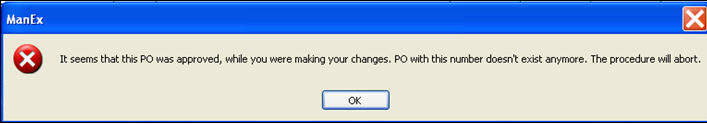

If multiple users are editing the same PO and the PO has not been approved yet, so it still has a temp # and the 1st users approves the PO, while the 2nd user is still making their changes, when the 2nd user goes to exit and save their changes they will receive the following message:

Manex tracks all revisions of a Purchase Order and each receipt against each revision of the order. The system will NOT allow any changes to a Purchase Order which has parts in Dock Receiving that have not yet been processed in the Purchase Order Receiving & Inspection module. Cancel a Purchase Order

Find the Purchase Order you want to cancel. Press the Edit record action button in the Purchase Order screen this will allow the user to change the PO status from Open to Cancel. Note: User MUST have approval rights to Modify the PO Status.

Each line item will need to be deleted using the instructions above. Once all line items have been deleted from the PO. The status on the PO will show cancel.

Closing out a Purchase Order

At times, the user may wish to close out a PO to suppliers who have either shipped short or overages of ordered components. For example, say a user has a Purchase Order for 100 components. 100 units are received with 5 rejections. (See the DMR procedures). This would show the Purchase Order showing a quantity of 5 for a balance. What if the user informs the supplier that they do not want the last 5 pieces.

In the above set of circumstances, the user will be allowed to change the ORIGINAL order quantity by removing the rejected quantity via the DMR procedure. When the Received quantity PLUS the DMR quantity is LESS than the order quantity, the user will be allowed to decrease the order quantity by that many. Original Order 100; Received quantity 100; Rejected quantity 5. Returned to supplier via DMR 5. At this point, the user may reduce the quantity ordered, AND the accompanying amount scheduled to 95. This action will close out the Purchase Order.

The user must depress the Edit button. Change the Purchase Order Quantity, then change the Quantity Scheduled so that the total of the schedule dates exactly equals the new quantity. Depress the Save button. Approve the PO and the PO status will change to close.

|

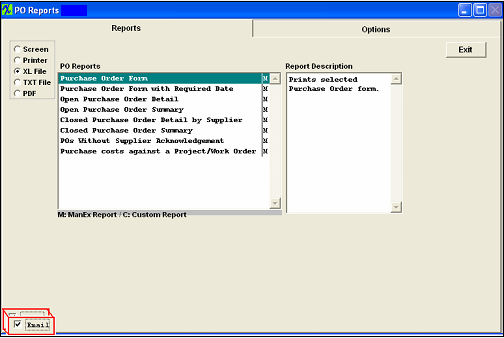

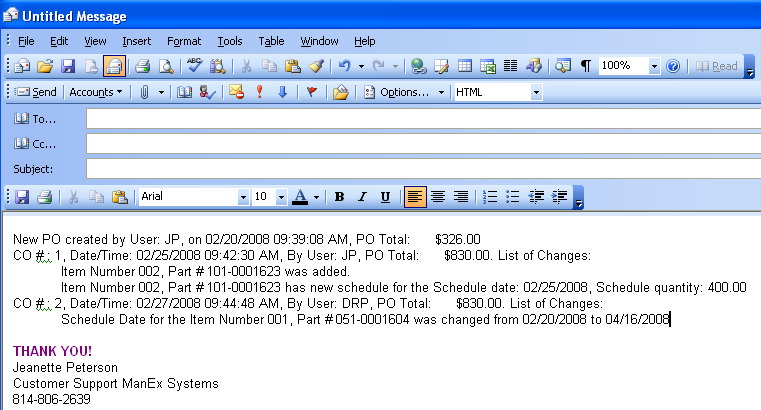

| 1.1.4.4. E-mail Purchase Order(s) | To e-mail a Purchase Order report(s), depress the Reports button.

Note: You MUST have the e-mail setup within the Trigger.exe setup and working before the PO e-mail will work.

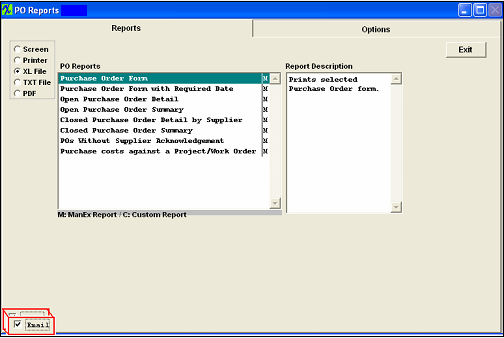

The reports screen will appear:

|

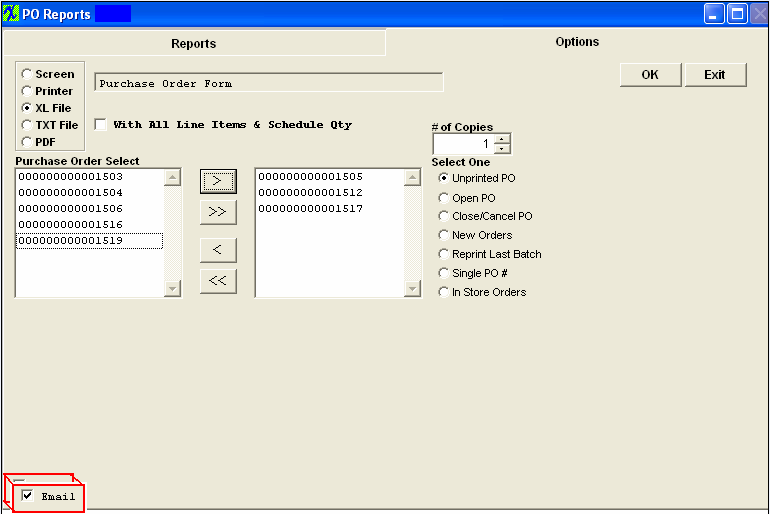

Select the output XL File, TXT File, or PDF by clicking on the radial.

Check the Email box located int he left hand corner of the Reports Tab.

Highlight the report you want to Email.

Depress the option tab.

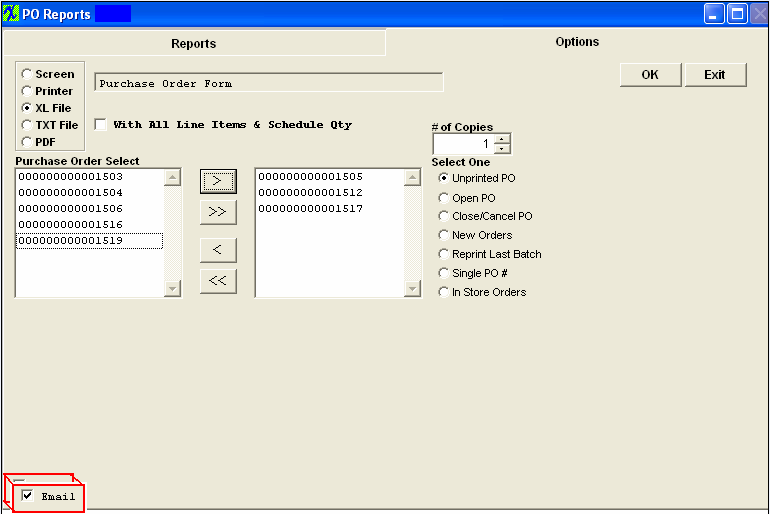

|

|

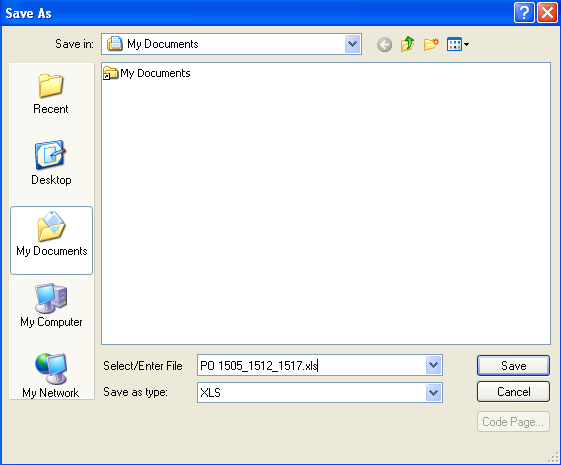

Complete the Option tab with the information required: Note: User has the option to check the Email box on the Options screen also.

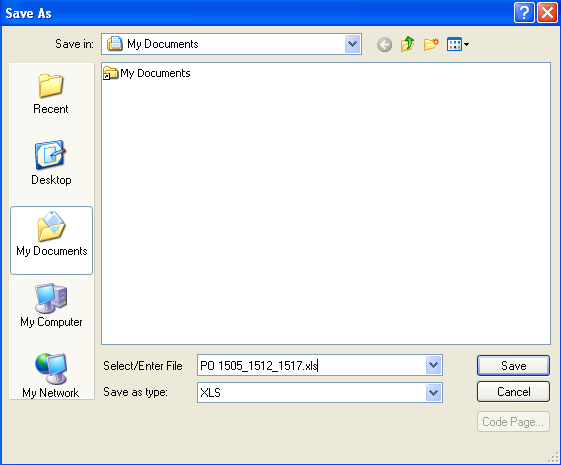

Depress OK. The following screen will appear. Select or Enter File Name.

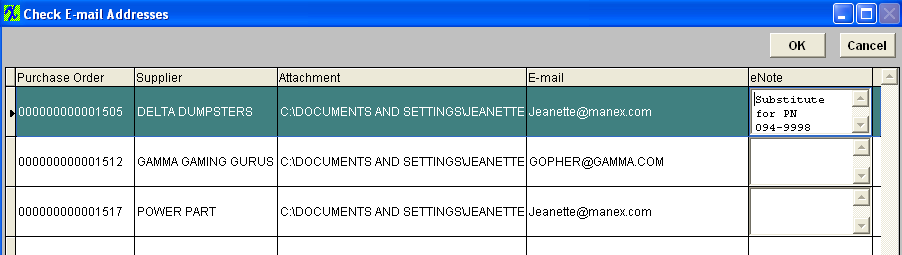

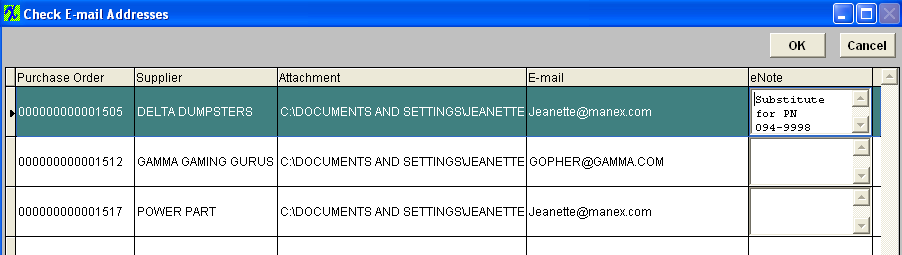

Depress Save, the following Check Email Addresses screen will appear. Within this screen you can enter an e-mail address or add any special notes needed:

Depress OK and documents will be sent to e-mail addresses assigned.

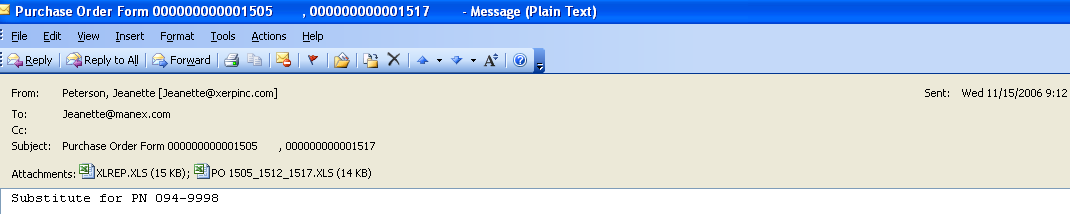

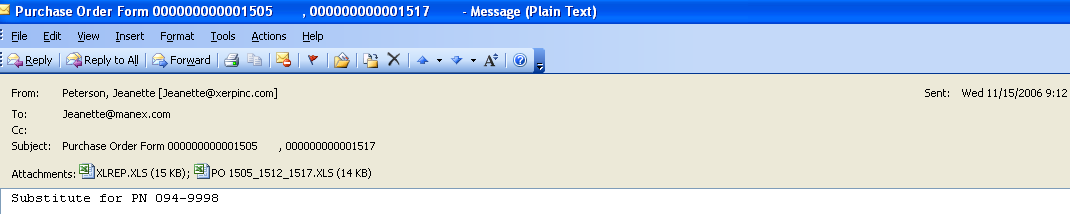

The following is what the receiver will receive:

|

| 1.1.4.5. Approve a Purchase Order |

|

Material Planning/Purchase Order Management/Purchase Order Management

|

|

The following screen will appear:

Depress the Find record button and follow the Find a PO procedures to find a PO for Approval.

Approve PO

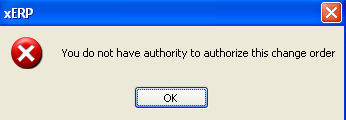

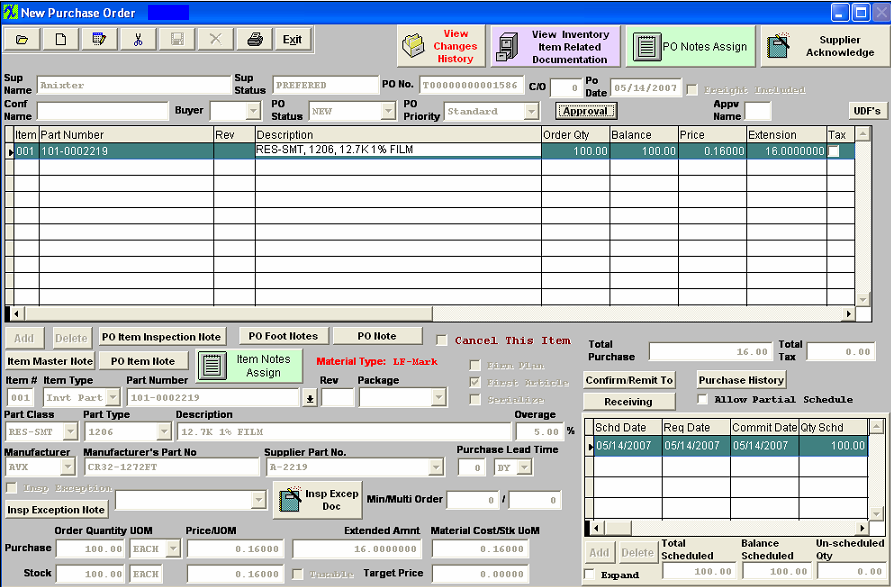

Pressing the Approval button in the Purchase Order module will ask for the user’s password. The user must enter a password that has been authorized (within the Purchase Setup module) to approve the dollar amount of the order.

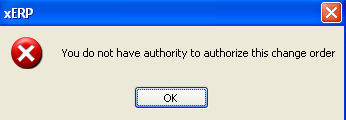

| Entry of an un-authorized password will receive the following message:

|

|

Entry of an authorized password and approval will inactivate the 1st approval button and place the initials of the person approving the order next to the approval button , (If in the Purchase Setup , the company has selected to allow one approval of purchase orders). Then upon approval the temporary Purchase Order number will be replaced with a permanent PO number (replacing the "T" with a "0").

If in the Purchase Setup , the company has selected requiring two approvals, then the process must be repeated for the second approval, and the temporary Purchase Order number will be replaced with a permanent PO number (replacing the "T" with a "0") once both approval are granted.

Note: That if the Purchase Order is an Service or In-store order, once the PO has received it’s final approval the temporary Purchase Order number will be replaced with a permanent PO number (replacing the "T" with a "0") and the PO Status marked as closed.

If the user has elected to use manual purchase order number,the screen will prompt the user for an order number to be applied to the purchase order. Note: If users enter a PO number manually using a "T", then changes the numbering to Auto, and later edits and approves this PO the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change.

|

| 1.1.4.5.1. Inventory Part | Selecting Inventory Parts as the item type, the user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. Once a part number from Inventory has been entered, Manex completes the boxes associated with the item master.

| If more than one manufacturer exists for the part, the user may click on the down-arrow next to the manufacturer edit box and select the appropriate manufacturer for the order. The Material type will be displayed in the pulldown next to the Mfg. and Mfgr. PN. |

|

|

If more than one supplier part number exists for the part, the user may click on the down-arrow next to the supplier part no. edit box and select the appropriate supplier part no. for the order.

The system will look for the preferred supplier part number and if found will show it as a display. At this time the user can leave the part number as is or select a different one if available. After a user will save the PO, the supplier part number will be saved and next time you will see the selected suppler part number when viewing the same PO.

No history will be saved because this field is for the information only.

|

|

| Firm Plan |

If this box is checked, the MRP module will not try to override the purchasing decision. Lets take a test case. The user makes a decision to block order 600 parts, but the need is only for 100 parts per month for the next six months. Without any Firm Plan command, the MRP module would instruct the user to cancel the PO for 600 quantity and re-issue for 6 separate purchases of 100 each. Firm Plan tells MRP that the purchasing decision was intentional and no action is required. (For further detail see Article #1080 ).

|

| First Article |

This box will be checked if set-up in the Inventory Control Management Module. You may uncheck it or check it if user has been instructed that it may be changed for this item only. This information will be carried forward to the PO Receiving screen for reference. |

| Serialized |

This box will be checked if set-up in the Inventory Control Management Module and will not be editable within the Purchase Order Management . This indicates to the user that this BUY part has been marked as Serialized and any product coming in or out of the system will require serial number tracking. |

The user may edit or add a percentage amount of extra material that will be allowed to be shipped against the order. By entering a percentage in the OVERAGE field, receiving will be allowed to receive extra parts up to the limit imposed in this field.

The user may also edit or add in purchasing lead time and min/mult order quantities through the Purchase Order Management module.Once the record has been saved this information will then be updated within the Inventory Control Management under the MRP Info screen.

The user may check the box for Inspection Exception and select from the Inspection Exception Pulldown (which is established in the Inspection Exception Setup module).The user will then also be allowed to enter any Inspection Exception Notes and/or Load Insp Excep doc that pertain to that PO line item.This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system.

The user is then prompted for the purchase order quantity of parts to be ordered. The user may enter either the Purchase Quantity or the Stocking quantity, and Manex will complete the other field based on the purchase/stocking unit of measure and conversion field.

Then the unit price is entered (Price Each). The extended amount is shown, calculated by extending the quantity by price. (If the inventory part that you are creating a line item for currently has a standard cost of 0.00 within inventory control the system will prompt the user if you wish to take that Purchase Order Price entered and use it as the standard cost for that item within inventory control). This can not be controlled by the Security level due to the fact that it is better practice to have a $$ assigned to the ICM record before the Purchase Order Receipt is accepted into the system. Otherwise you will have stock that is not valued properly, accounting records that will not be correct, etc. . . . So this is why ManEx allows any Purchase Order user to populate the STD cost field for that record with the purchase $ that you are loading. BUT . . Once a Std Cost is associated with the ICM record - the users within Purchase Order Management should no longer be able to change that value through the PO module.

The user may then indicate that the items are taxable by clicking on the Taxable check box.

The Stock/BOM field will update automatically based upon the conversion table defined in setup. The completed screen should appear as follows:

Before saving the order you will need to check the expand box and enter the Schedule detail information.

Entering Schedule Detail Information

The item will schedule automatically by adding the lead time to todays date and schedule the entire order amount.

At this time the user has the option to change the Schd date/Req date/commit date information and also the Qty Schd.

Note: If user is not following MRP suggestions when creating POs they need to keep in mind inspection time when entering a schedule for a PO.

|

If the user wants to modify the automatic scheduled date, they can either manually adjust the Date information by highlighting the field and typing in the new date, or place the cursor in the Due Date field.Type in a ?. A calendar will appear.

Depress the desired delivery date.To advance into the next month, depress the > button.

|

|

Schedule Field Definitions

| Schd Date |

The date the material is due to land on the users dock |

| Req Date |

This is the internally required or desired date.It is not used for the supplier |

| Commit Date |

The commit date is a reference field for the buyer |

| Qty Schd |

The quantity scheduled for the due date |

| Warehouse |

The User can choose the Warehouse from the pulldown or leave it blank. The Y next to the Warehouse location indicates that, that Warehouse is set-up in the AVL. The N next to the Warehouse location indicates that, that Warehouse is not set-up in the AVL. If the warehouse field is left blank then the warehouse can then be assigned at PO Receiving Management. Once the record has been saved within the PO Receiving this information will then be updated within the Inventory Control Management under the Qty info screen. |

| Location |

The Location field will update automatically from the Inventory Control Management module. The user can edit this field in the scheduling detail. This will not change the location in the Inventory Control Management module under the quantity info screen. |

| Distribute To |

This is classification of the distribution of the item when received, either to regular Inventory Receiving or to Allocate to Special Work Order or Project |

| GL Number |

The General Ledger number where the purchase order will post |

| Schd Notes |

Depressing on the  button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit button will bring up a screen where the user can enter in specific notes that pertain to that one schedule, item, and date. Type in the note. Depress the Save button. Exit |

Pressing the Save button at the top of the screen saves the order and item(s) entered, and assigns a temporary number to the order. After adding items to the purchase order and saving them, the Purchase Order will display all items added to the order.

The user may use the scroll bars at the right and bottom of the items listed to scroll over additional information.

The user may modify the column widths in the current view by placing the cursor on the right border of the column in the column header, and pressing the left mouse button. Moving the border while holding the mouse button then releasing at the new location resizes the columns.

|

| 1.1.4.5.1.1. Allocate to Special Work Order or Project | Introduction

Inventory Allocation is used to allocate (reserve) quantities of existing items in stock or future Purchase Order deliveries to a Work Order or Project Number.This allocation prevents issuing the quantity reserved to any other use except the Work Order or Project Number specified. Purchase Order Line Item allocations may be removed prior to receipt of the parts by editing the Purchase Order.After receipt of parts allocated by Purchase Order, the allocation may only be removed after the parts are in stock, by using the Inventory Allocation module.

ALLOCATION OF PURCHASE ORDER DELIVERIES

Allocating a PO Line Item is used to make sure that the item will be reserved for a particular Work Order or Project Number when it is received.PO line item allocation is generally used when allocating to a Work Order or Project Number for which the items are not available in stock.Line Shortages of items not on the BOM, which are not in stock, are an example of typical PO Line Item Allocations.To allocate Purchase Order Line Item Deliveries to a Work Order or Project Number:

- A Work Order or Project Number must be open for the product.

- The Item to be allocated must be entered in the Inventory Control Item Master.

- The quantity allocated must equal the quantity ordered. ie. The total quantity ordered on a line item may be allocated to multiple Work Orders or Project Numbers through the schedule screen.

PROCEDURES

To Allocate a PO Line Item to a Work Order or Project Number:

- Allocate to a new or existing PO.

- Select the desired PO in Article #153.

- Highlight the line item you want to allocate.

- (If it is an existing PO) Depress the Edit action button.

- Expand the Schedule Screen, tab or click on the "Distribute to" field.

- Select WO Alloc or Prj Alloc, enter the Work Order number or Project number to allocate to in the WO # field or Project # field.

- Follow normal PO Mgmt procedures to save and approve.

NOTE:The user may wish to allocate a line item to multiple Work Orders and/or Project Numbers. In the schedule for an item, the user can create as many schedule lines as required. Each schedule line can have a different allocation. If the user had a requirement for 5 Work Orders and/or Project Numbers of 100 parts for each Work Order and/or Project Number, the user would add a line to the PO for 500 parts, then in the schedule, the user can add a line for each Work Order and/or ProjectNumber to which the parts are allocated. The schedule dates can be the same or different. The supplier will see only the total quantity required by the schedule date and is not bothered with the individual allocations.

To Un-allocate a PO Line Item that has not yet been Dock Received:

- Select the desired PO in Article #153.

- Highlight the line item you want to un-allocate.

- Depress the Edit action button.

- Expand the Schedule Screen, tab or click on the "Distribute to" field.

- Select Inv Recv.

- Follow normal PO Mgmt procedures to save and approve.

To Un-allocate a PO Line Item that has already been Dock Received:

-

-

|

| 1.1.4.5.2. MRO Items | MRO stands for Management Required Options. Generally this is used for supplies, etc. purchases.

After selecting the Item Type to be "MRO"

- If the MRO item is included in inventory

- The user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type.

- Fill in the quantity and unit price.

- If the part is not in inventoryThe user may enter in the Suppliers part number manually (or leave blank) and then jump to the description field and enter the description.

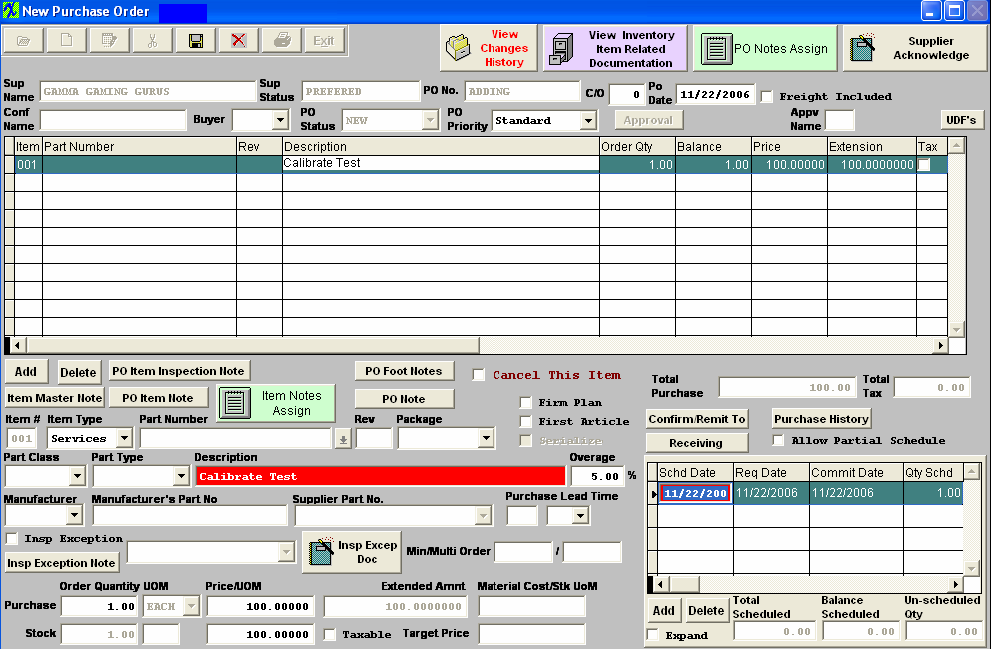

The finished screen should look like the screen displayed:

- Check the Expand box in the Schedule screen.

- Enter schedule dates and quantity scheduled.

- Type in the title or name of the person requesting the item in the “Distribute To” field.

- Enter a General Ledger account number in the GL Number field.

The completed Schedule screen will appear as follows:

- At the conclusion of entry for the item, the user may depress the Save record action button or the Abandon record action button.

- To complete see Add a PO .

|

| 1.1.4.5.3. Service Items | Services items are for those instances where the assembly is outsourced.

After selecting the Item Type to be "Service"

- The user may enter the supplier Part number manually (or leave blank) and then go to the description field and enter the description.

- Fill in the quantity and unit price.

The finished screen should look like the screen displayed:

- Check the Expand box in the Schedule screen.

- Enter schedule dates and quantity scheduled.

- Type in the title or name of the person requesting the item in the “Distribute To” field.

- Enter a General Ledger account number in the GL Number field.

The completed Schedule screen will appear as follows:

- At the conclusion of entry for the item, the user may depress the Save record action button or the Abandon changes action button.

- Approve record.

|

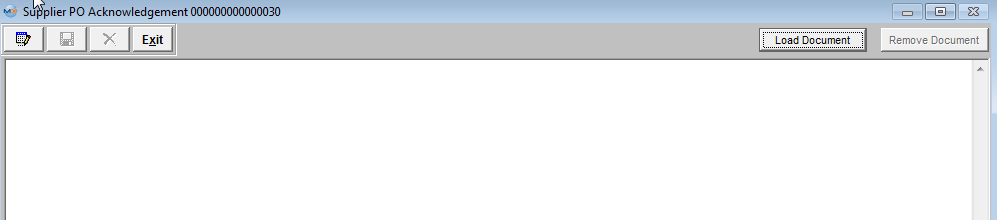

| 1.1.4.6. Load Supplier Acknowledgement |

How to attach or load a Supplier Acknowledge document to a PO. Note: User is only allowed to load one document per Purchase order.

Depress the "Supplier Acknowledge" button and the following screen will appear:

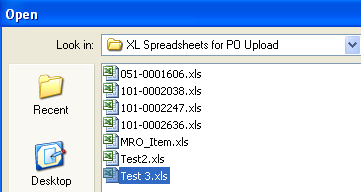

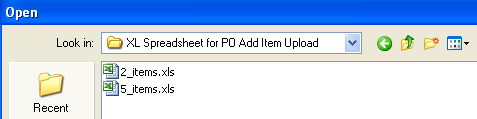

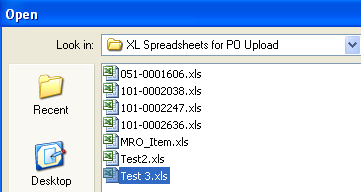

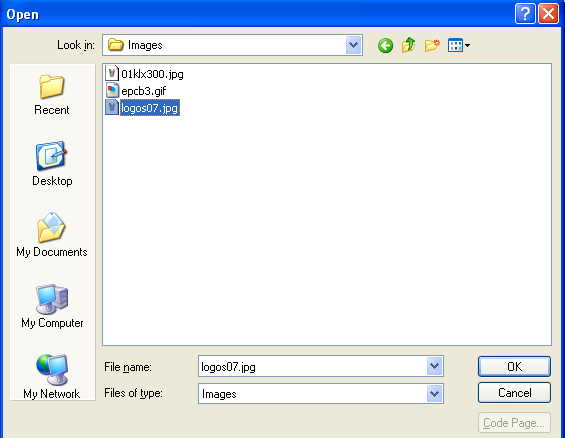

To load images or documents, depress the "Load Document" button, up in the right hand corner of the screen. A browser screen will appear similar to the one below:

Find and highlight the desired Image file, as illustrated.

Once the file name appears, depress the Ok button.

Note: that the user can also load other document types by changing the File of Type to ALL

The file will appear in the screen as displayed:

Depress the Save action button to save the changes or depress the Abandon changes action button to abandon changes. Exit will bring the user back to the Purchase Order Management module. If user selected to Save the Supplier Acknowledge button will be displayed in Red as shown below.

|

| 1.1.4.7. Copy "View Change History" Notes | Find the Purchase Order you want to Copy the "View Changes History" notes on.

Depress the "View Changes History" button, When in the “Change PO history” screen, click on the vertical scroll (on your keyboard), you will see the cursor appeared on the top inside the window with the text.

Depress the "CTRL" button + the vertical scroll buttons to highlight the information you wish to copy;

Depress the "CTRL + C" to copy, then paste to a document, e-mail, etc....

|

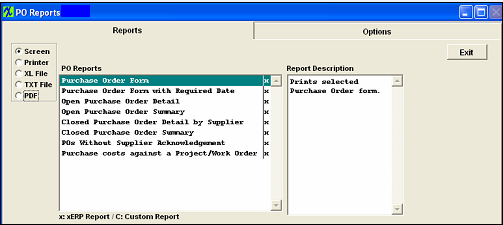

| 1.1.5. Reports - PO Mgmt |

|

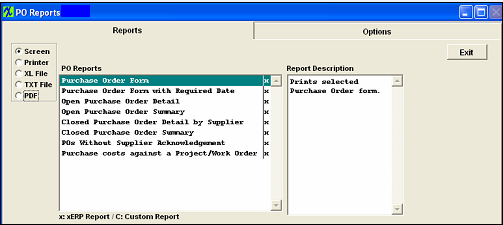

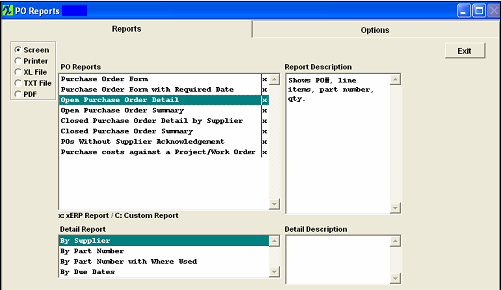

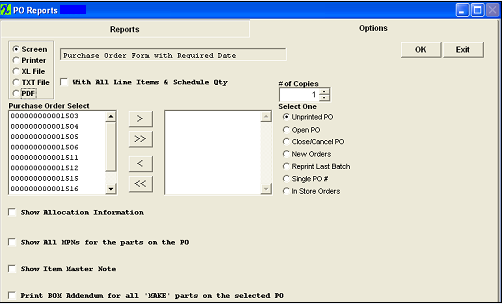

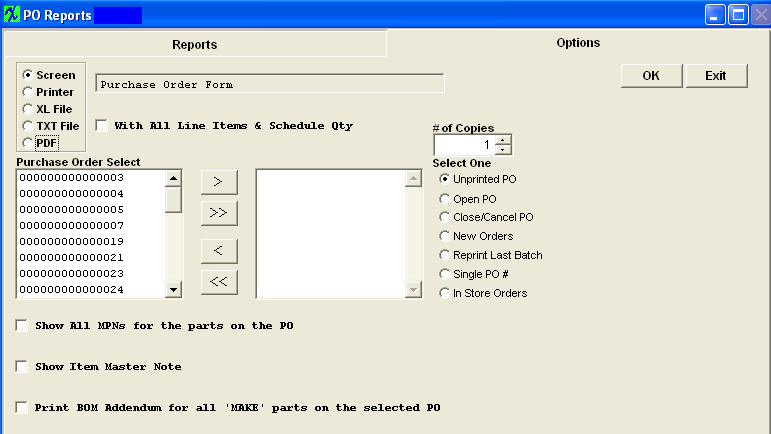

1. To access the reports, depress the Print button at the top of the screen. The report screen will appear.

2. Select the output you desire by selecting one of the output radial selections at the top left of the screen, Screen, Printer, XL File, TXT File, or PDF.

3. Highlight the report desired and click on the option tab.

|

|

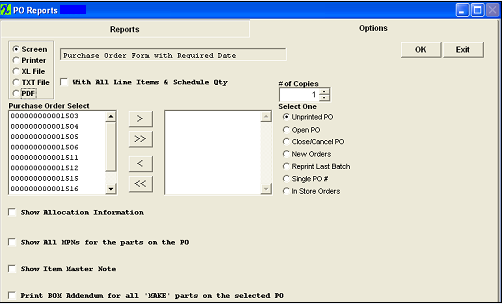

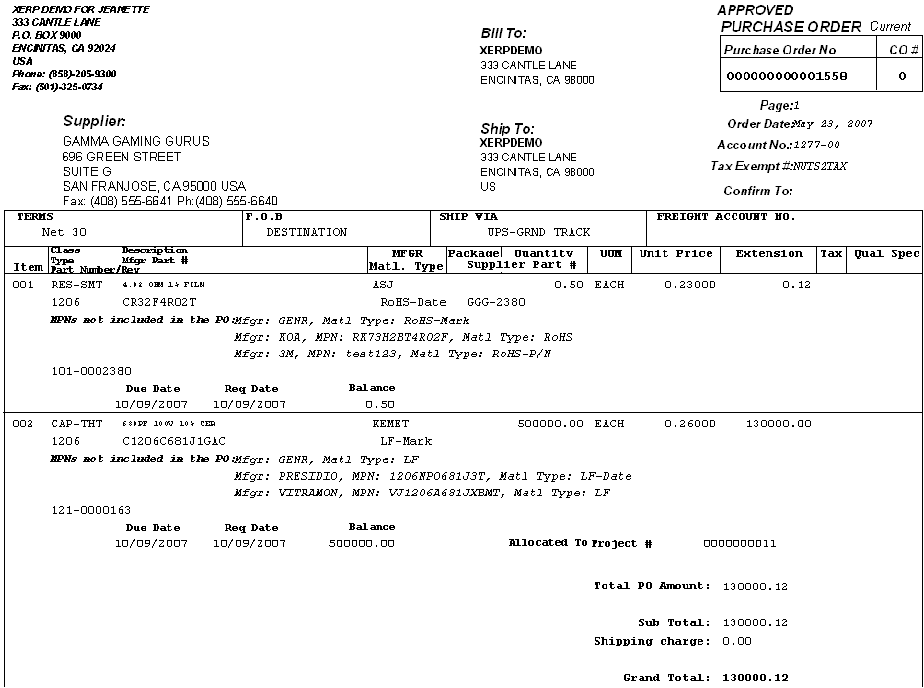

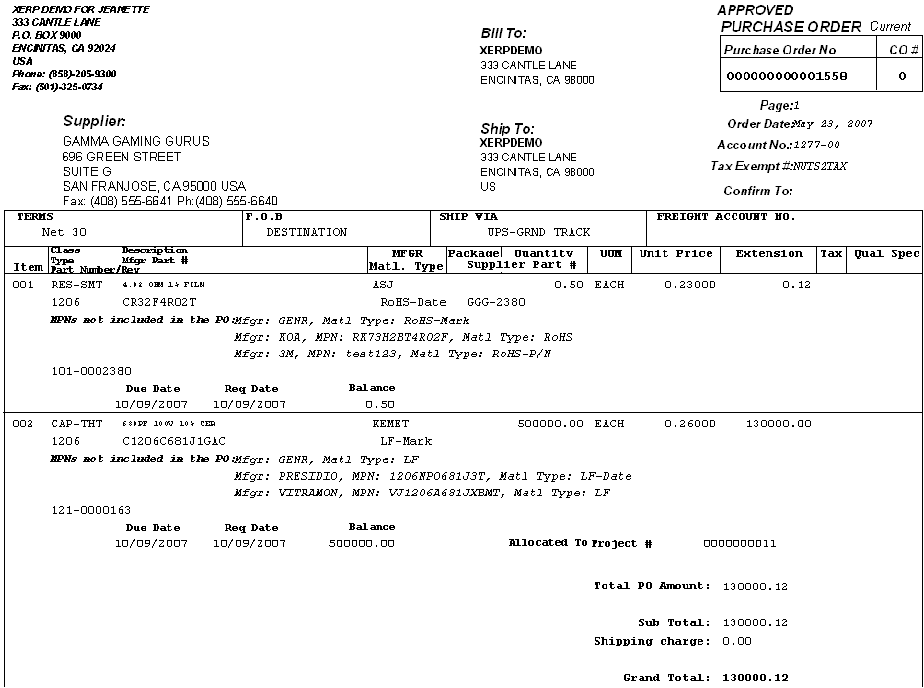

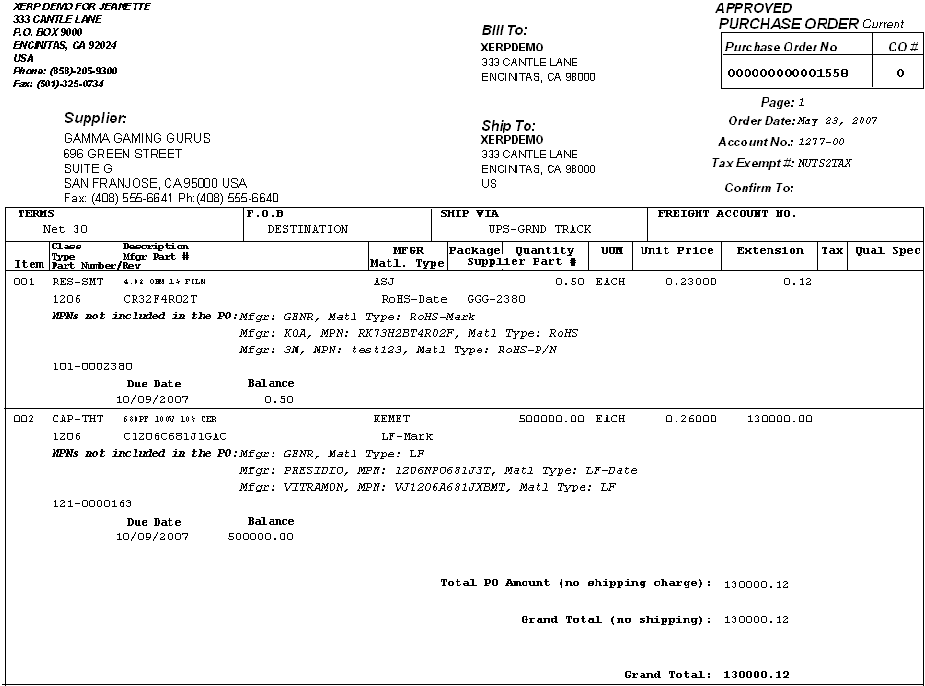

PURCHASE ORDER FORM report

If you want all line items & scheduled quantities to print, check that box.

Select the number of copies you want by toggling the up and down arrows.

Select one of the following options: Unprinted PO, Open PO, Close/Cancel PO, New Orders, Reprint Last Batch, Single PO #, In Store Orders by clicking on the radial.

NOTE: Depending on which one of these options you select will depend on what will be displayed on the report. For Example: If User selects Open/Active the report will have "APPROVED" at the top of the report (as displayed below) and prints out the Purchase Order form AFTER some receiving has occurred against that PO, then ONLY the un-received still open amounts will print on this form. Any line items COMPLETELY RECEIVED or CANCELED will NOT display on the PO form. If User selects Close/Cancel PO the report will have "CLOSED" at the top of the report and will display the original scheduled balance.

Highlight the PO of interest and depress the > button. To select all POs, depress the >> button.

Check the "Show All MPNs for the Parts on the PO" box if you want all MPNs listed on the report.

Check the "Show Item Master Note" box if you would like the Item master notes to be displayed on the report.

Check the "Print BOM Addendum for all "MAKE" parts on the Selected PO" When the users add a Make/Buy part to a Suppliers PO, and checks this option the system will then print a "BOM Indented with AVL" report as an addendum to the PO form. Each BOM will be printed as a separate report and will reference PO and item on the PO. If the AVL on the approve vendor list for any of the items on the BOM happens to be checked as "disallow to buy" this AVL will not be included within the addendum to the PO.

Depress the OK button

When this report is printed is will display the Approval status of the order, it will also display the Supplier Part Number if entered in the ICM module.

-

If purchase order status is "NEW" report will print "NOT APPROVED"

-

If purchase order status is "OPEN" and has been approved, report will display "APPROVED"

-

If purchase order status is "EDITING" meaning order was once approved but now in edit status, the report will display "EDITING PENDING APPROVAL"

The following report will be displayed:

PURCHASE ORDER FORM with REQUIRED DATE report

|

This report is exactly the same as the Purchase Order Form report above, except that this report will also show the Required Date information.

If you want all line items & scheduled quantities to print, check that box.

Select the number of copies you want by toggling the up and down arrows.

Select one of the following options:Unprinted PO, Open PO, Close/Cancel PO, New Orders, Reprint Last Batch, In Store Orders by clicking on the radial.

Highlight the PO of interest and depress the > button.To select all POs, depress the >> button.

Check the "Show Allocation Information" if you want this information printed on the PO

Check the "Show All MPNs for the Parts on the PO" box if you want all MPNs listed on the Report.

Check the "Show Item Master Note" box if you would like the Item master notes to be displayed on the report.

Depress the OK button.

This report will display the Supplier Part Number if entered in the ICM module.

|

|

The following report will be displayed:

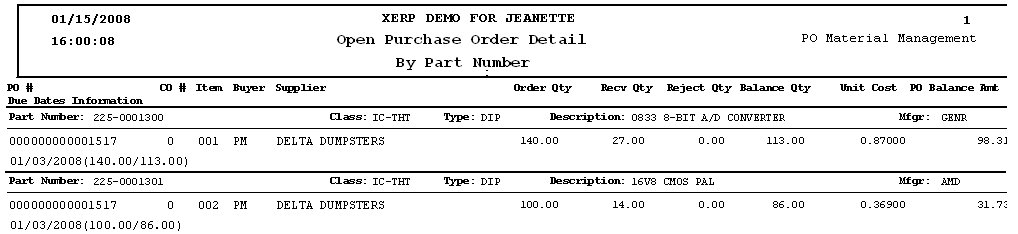

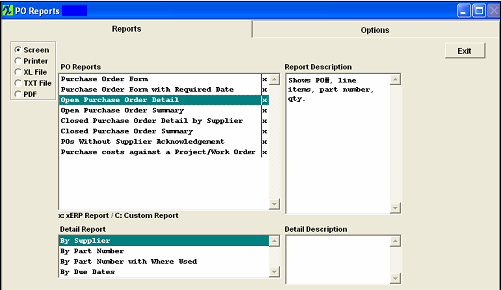

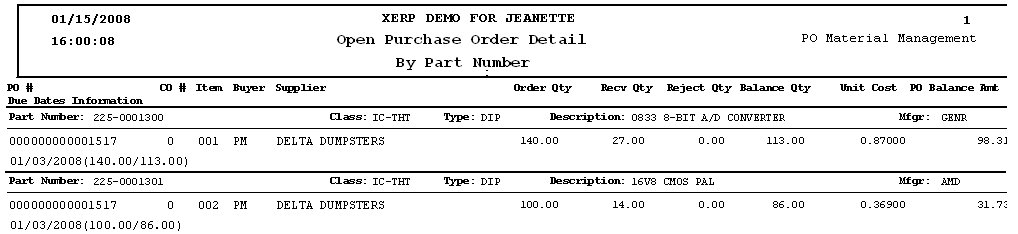

OPEN PURCHASE ORDER DETAIL report

|

At the bottom of the screen, highlight the Detail Report, By Supplier, By Part Number, By Part Number with Where Used or By Due Dates.

Note: If you select ANY of the Detail selects other than “By Supplier” then you can click directly on the OK button and ALL open PO's will be displayed.

The “Open Purchase Order Detail” report shows only items that still have balance. So if you have an open PO with three items and only one of those items have a balance the report will only show the one item with the balance.

Note: When exporting to Excel there will be an additional column displaying the Unique ID #.

|

|

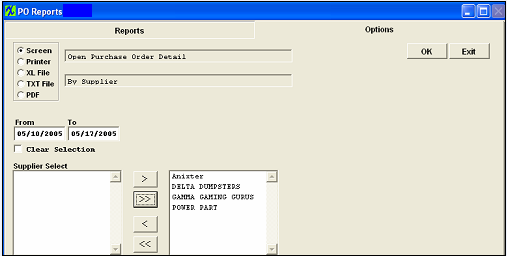

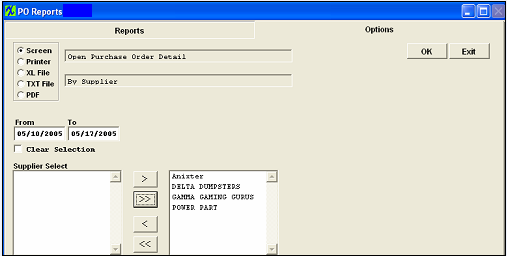

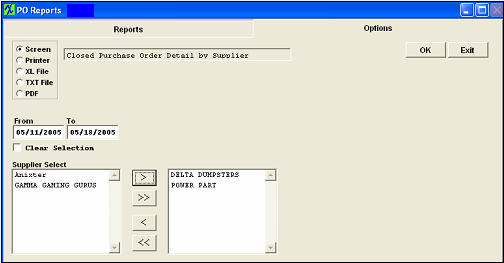

| If user selects “By Supplier”, the Options screen becomes enabled.

Enter the desired Date Range to filter the search more.

Highlight the Supplier of interest and depress the > button. To select all Suppliers, depress the >> button.

Depress the OK button.

|

|

The following report will be displayed:

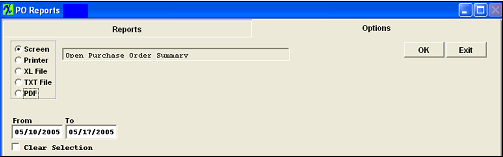

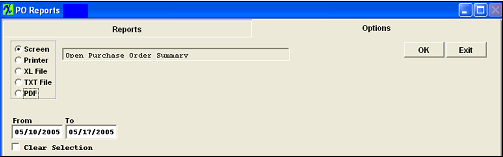

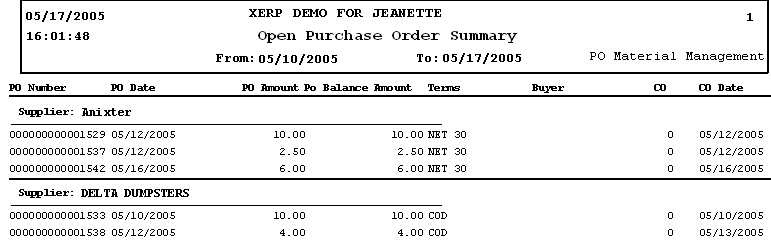

OPEN PURCHASE ORDER SUMMARY report

|

Enter in the desired Date Range.

Depress the OK button.

The “Summary” report shows all open orders based on the status of the PO. If the open PO has no items with balance left the "Open Purchase Order Detail" report will not show this PO at all, but the "Open Purchase Order Summary "report will.

|  |

The following report will be displayed

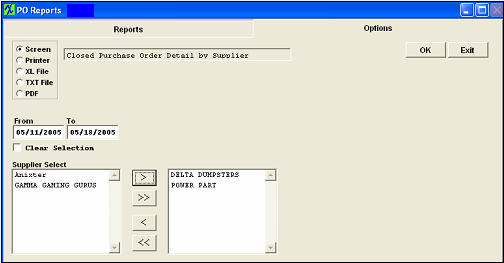

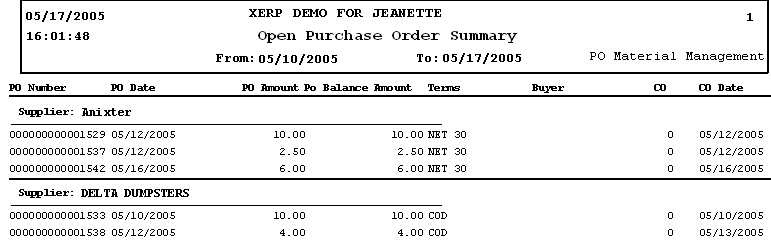

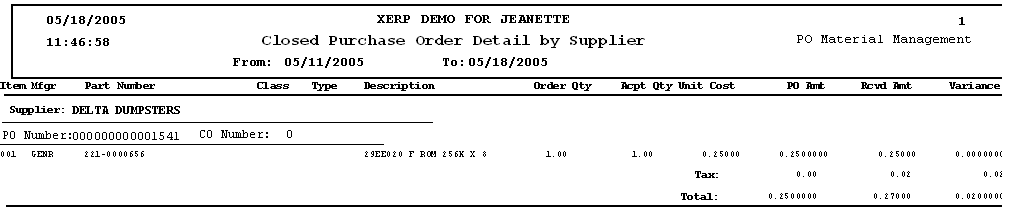

CLOSED PURCHASE ORDER DETAIL BY SUPPLIER report

|

Enter in the desired Date Range.

Highlight the Supplier and select by using the > button.For All Suppliers, depress the >> button.

Depress the OK button.

Note: When exporting to Excel there will be an additional column displaying the Unique ID #.

|

|

The following report will be displayed

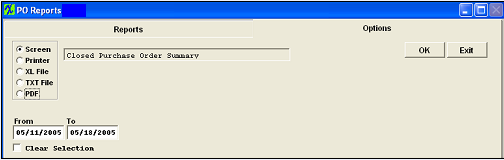

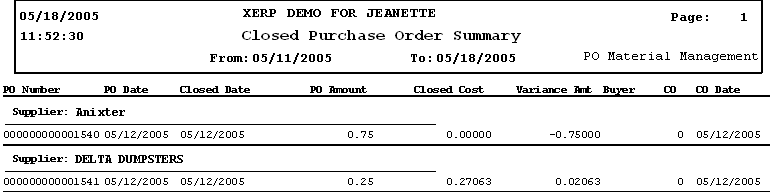

CLOSED PURCHASE ORDER SUMMARY report

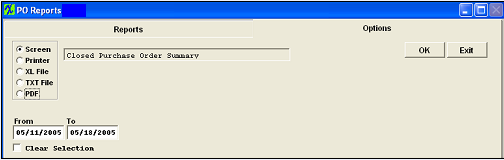

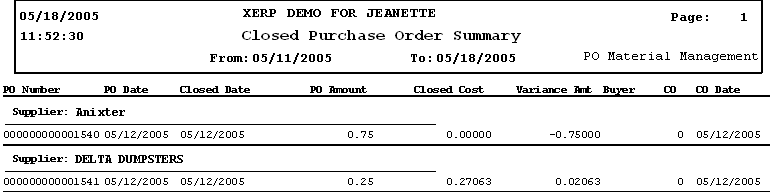

|

Enter in the desired Date Range.

Depress the OK button.

|

|

The following report will be displayed

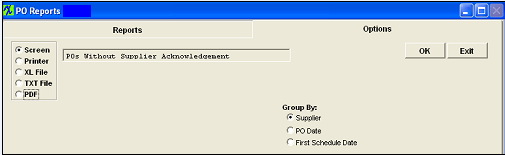

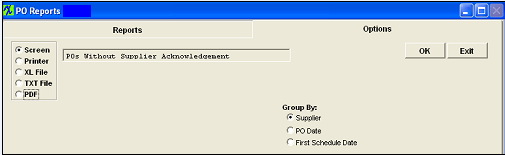

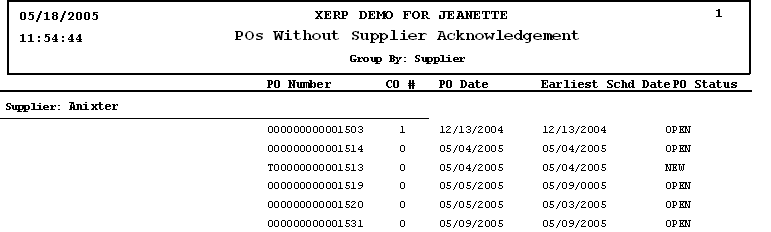

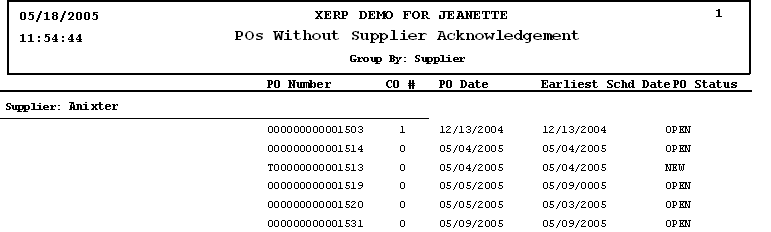

POs WITHOUT SUPPLIER ACKNOWLEDGEMENT report

|

Select one of the Group By options: Supplier, PO Date, First Schedule Date by clicking on the radial.

Depress the OK button.

|

|

The following report will be displayed

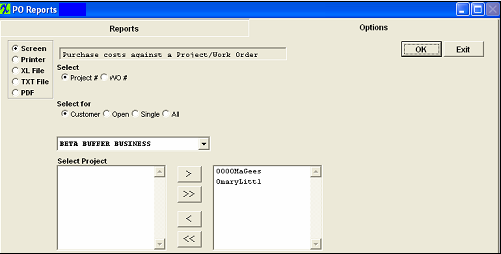

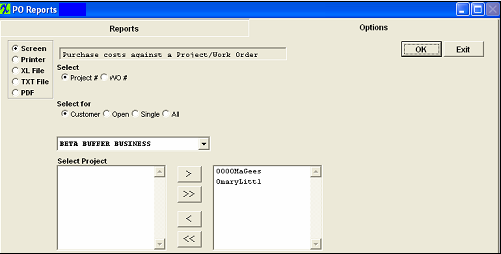

PURCHASE COSTS against a PROJECT/WORK ORDER report

|

Select Project # or Work Order # by clicking on the radial.

Select for: Customer, Open, Single, or All by clicking on the radial

If select by customer, then choose the customer from the pull down menu.

Highlight the Project and select by using the > button. For All Suppliers, depress the >> button.

Depress the OK button.

|

|

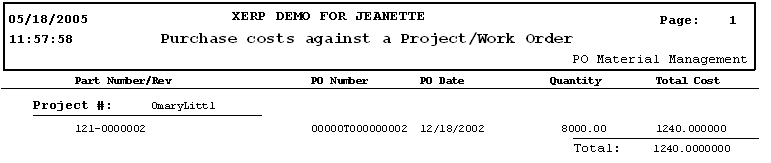

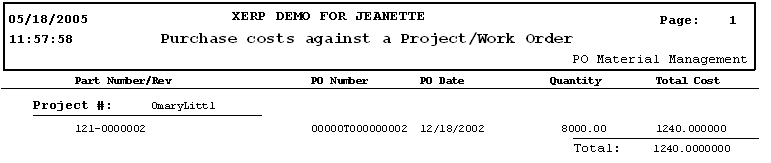

The following report will be displayed

|

| 1.1.6. FAQs - PO Mgmt | | Facts and Questions for the Purchase Order Module |

| 1.1.7. ManEx Minutes (PO) |

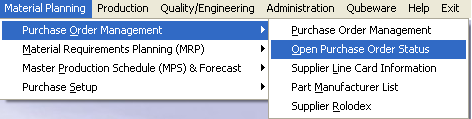

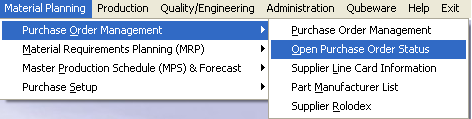

| 1.2. Open Purchase Order Status |

| 1.2.1. Open Purchase Order Status |

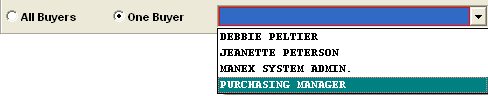

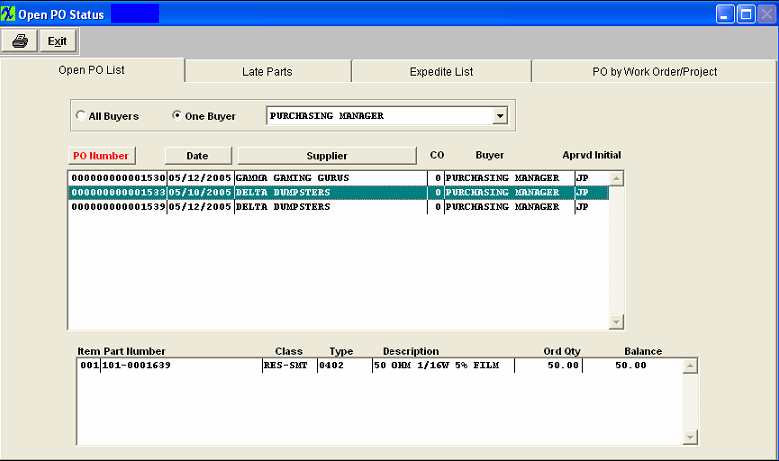

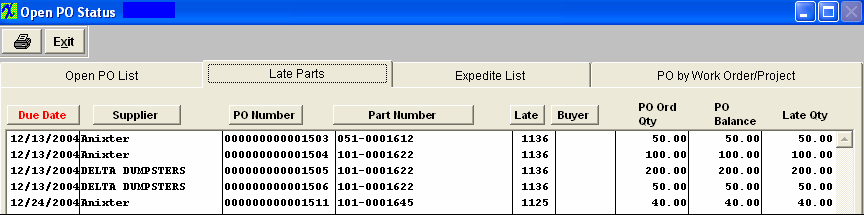

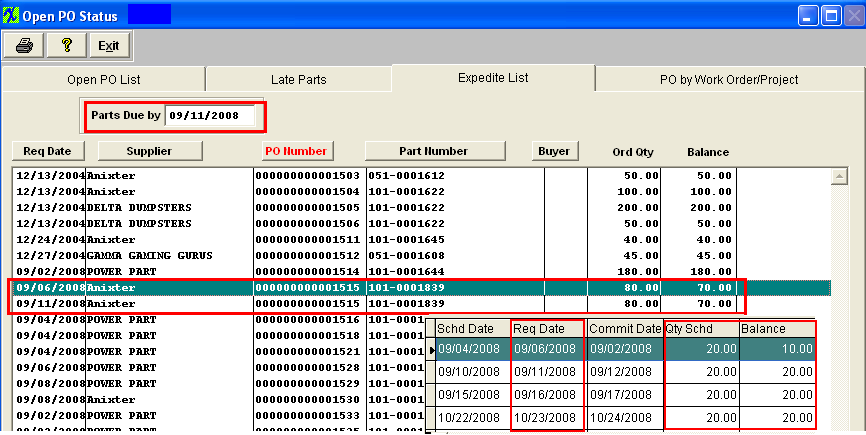

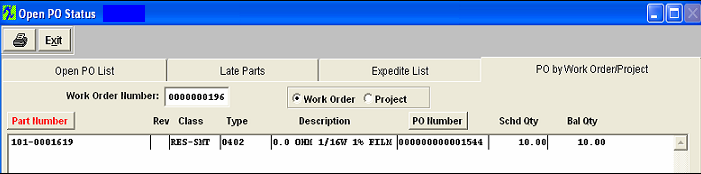

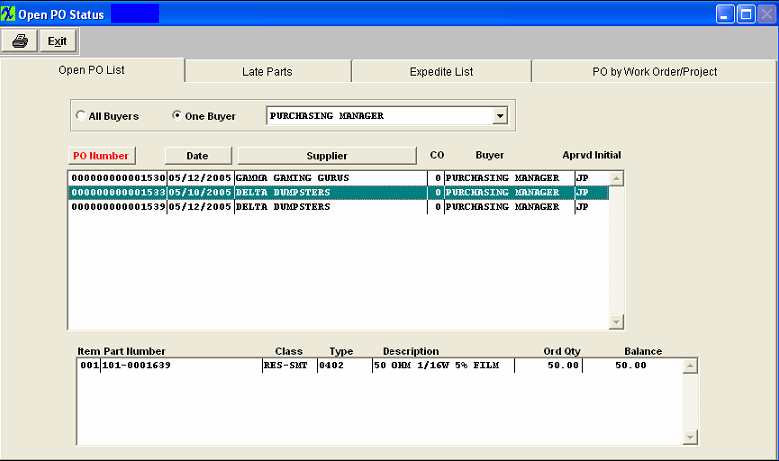

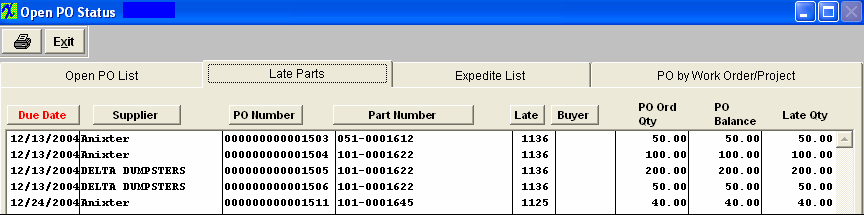

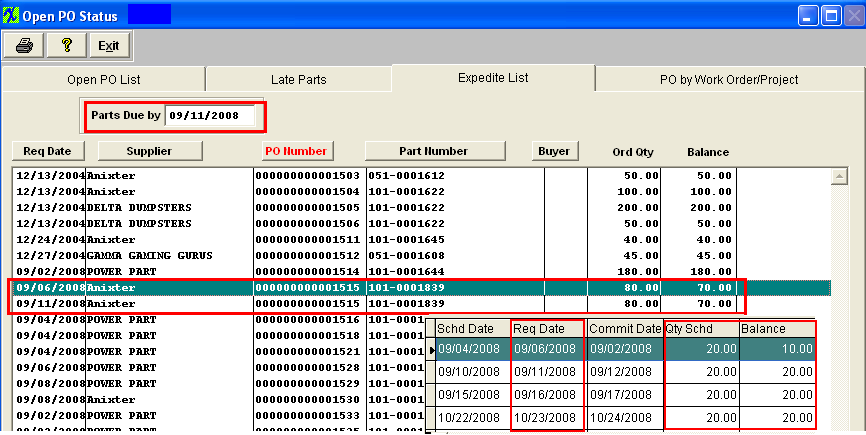

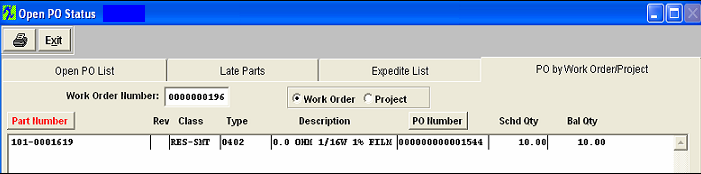

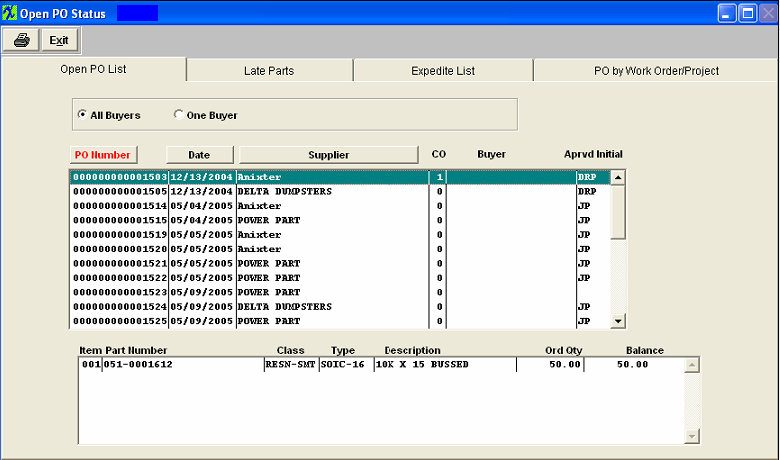

Material Planning/Purchase Order Management/Open Purchase Order Status

This screen allows users to closely monitor and manage parts currently on order. Users are able to see all parts currently past due, all parts due by a specific date (useful for planning for upcoming jobs), and parts allocated to a specific job or work order. This provides greater control over critical components and can reduce or prevent instances of unexpected production delays due to missing components.