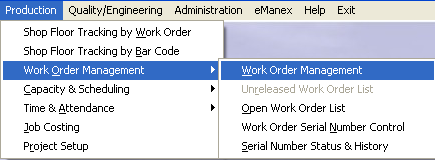

| 1. Production |

| 1.1. Shop Floor Tracking by Work Order |

| 1.1.1. Prerequisties for SFT by WO | ||||||||||||

Prerequisites Required for Shop Floor Tracking:

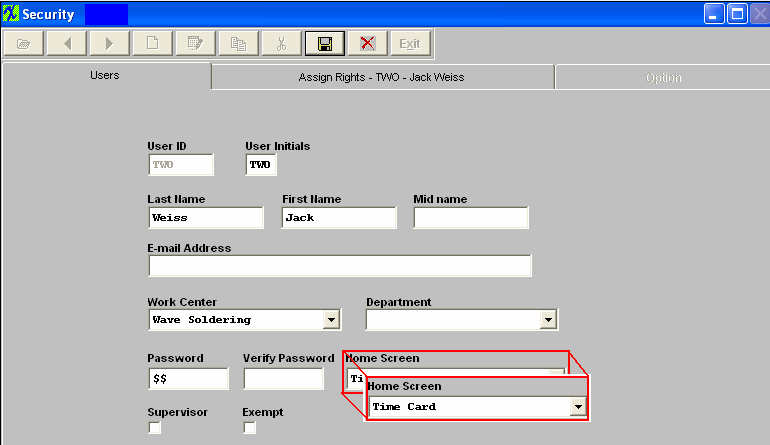

After activation, "Work Order Shop Tracking" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

The SHOP FLOOR TRACKING must refer to a Work Order, which includes the part numbers and description of the product being built. Note: If the "Status" field in the Work Order is set to Manufacturing Hold, the user will NOT be able to transfer product for that Work Oder. If the “Status” field in Sales Order or RMA is set to Administrative Hold, the user may finish transfering the product, but a Packing List can not be issued. The Routing must exist for the product, which includes the work centers and activities for the product being built. Optional Prerequisites for Shop Floor Tracking:

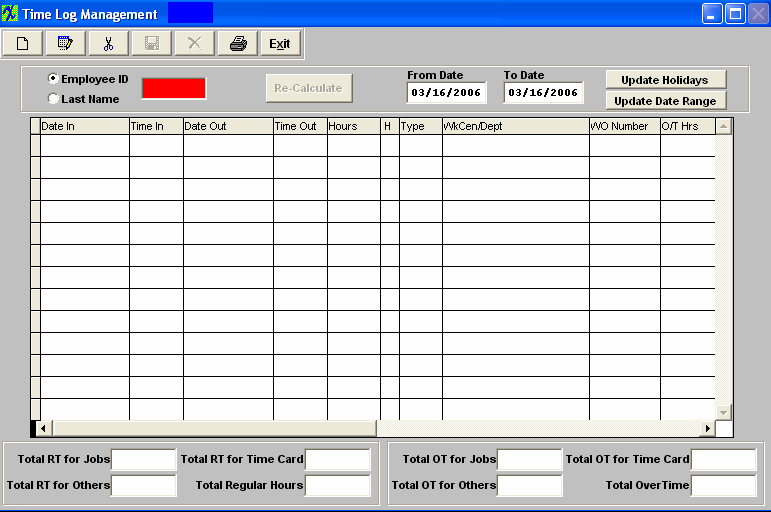

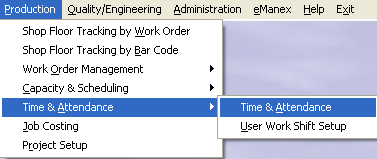

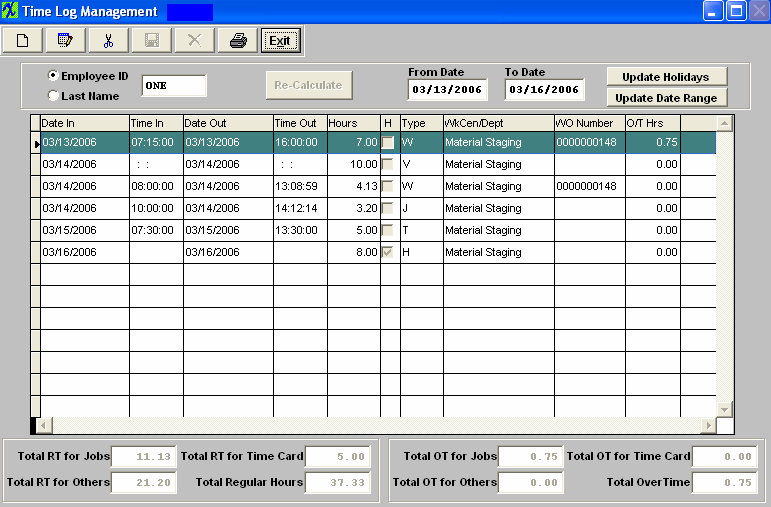

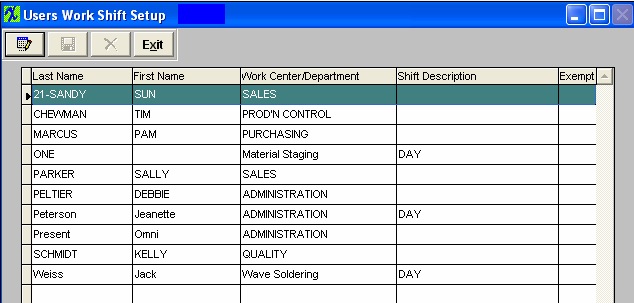

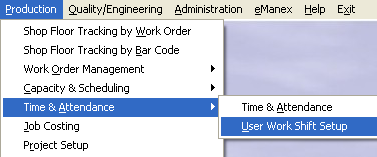

Required if Inspection data is to be entered. Work Instructions should be established if the user wishes to utilize setup and work instructions. The System Setup must define whether or not serialization is required for the part type. User Work Shift information and Time & Attendance features must be installed before you will be able to use the “Time Log” button within the Shop Floor Tracking module. |

| 1.1.2. Introduction for SFT by WO | ||||||||||||||||||||||||||||||||||||||||||||

The Shop Floor Tracking Module is used to record detailed transactions of all of the user’s Work In Process (WIP) activity. This screen is a critical piece in the communication process. This allows production to update the system as products move through the shop floor. Production can add notes and indicators to identify current issues and delays. This information is readily available for program managers and others so they have important information when it is needed and without chasing it down in production. From within this module, the following functions are available, depending on the user’s configuration:

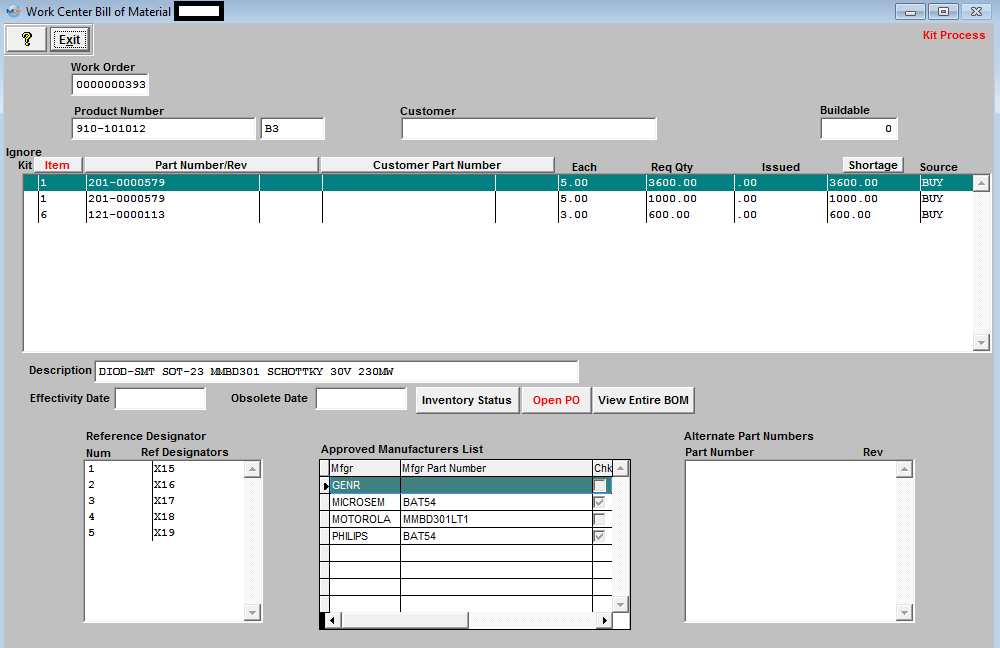

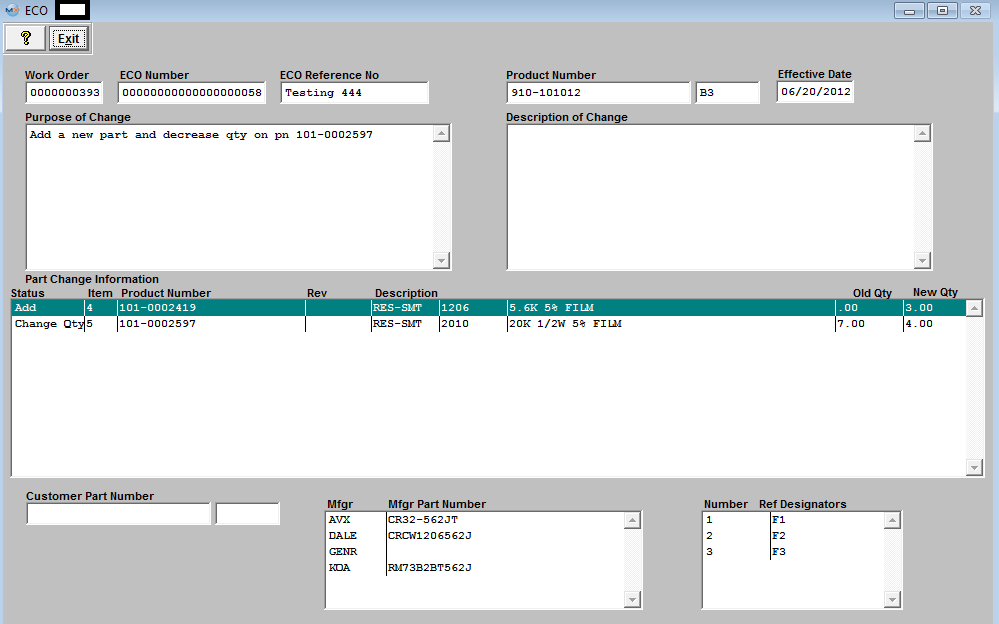

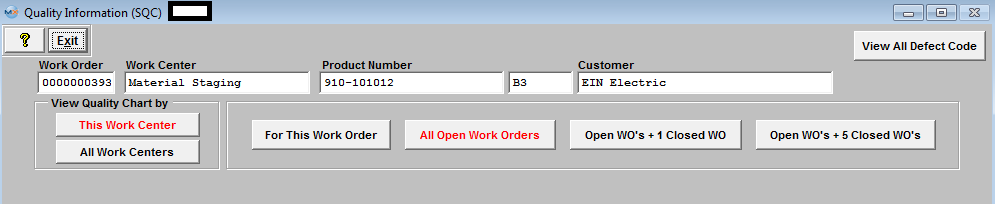

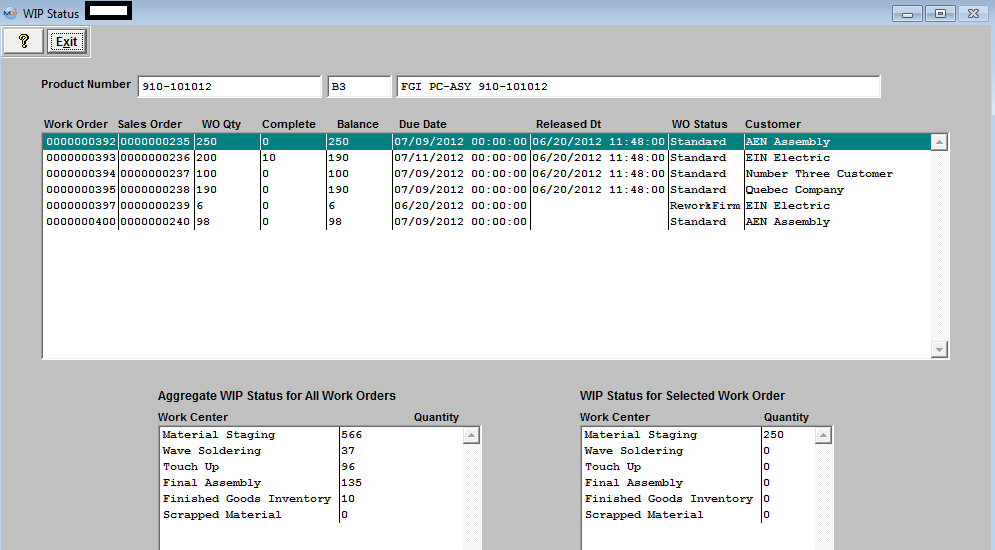

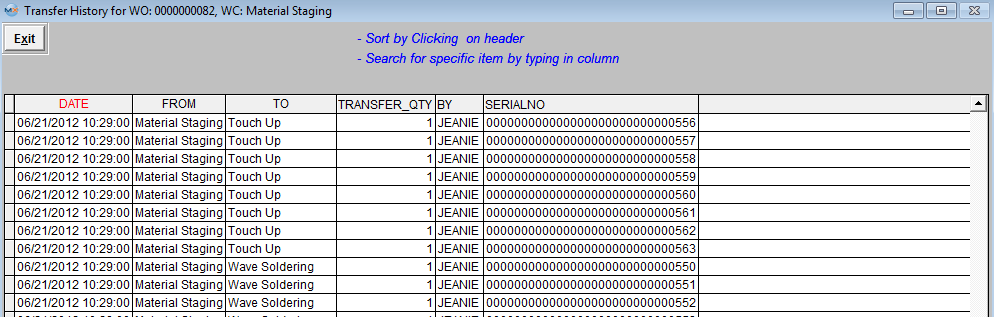

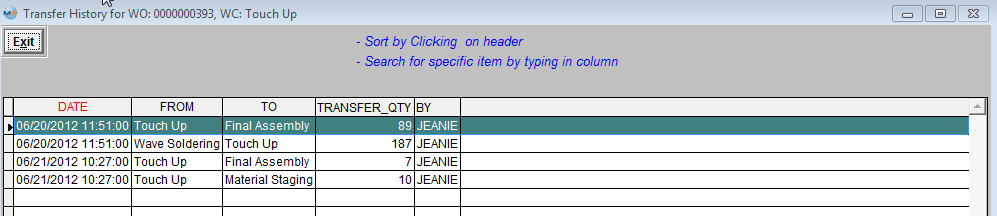

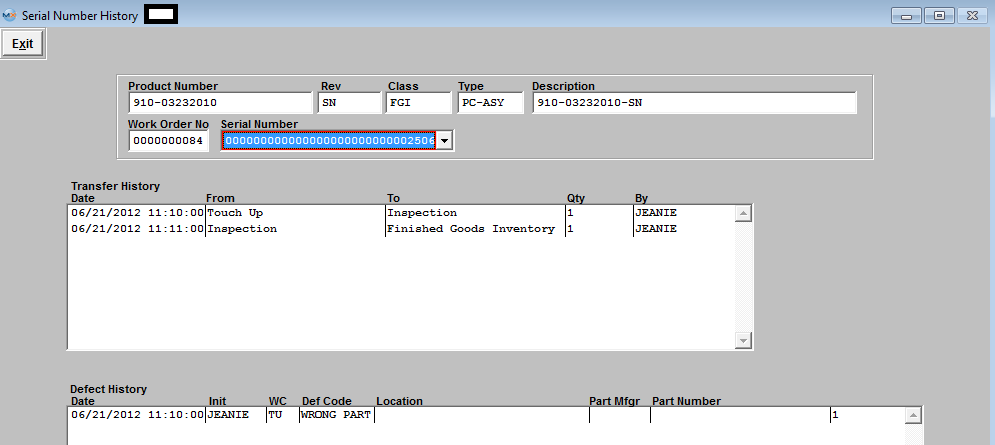

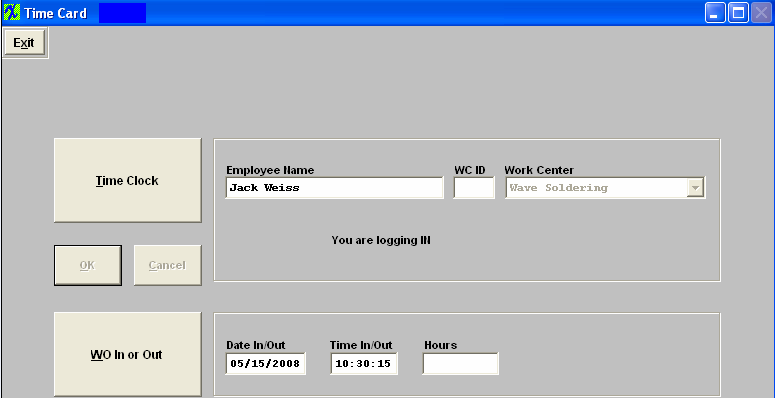

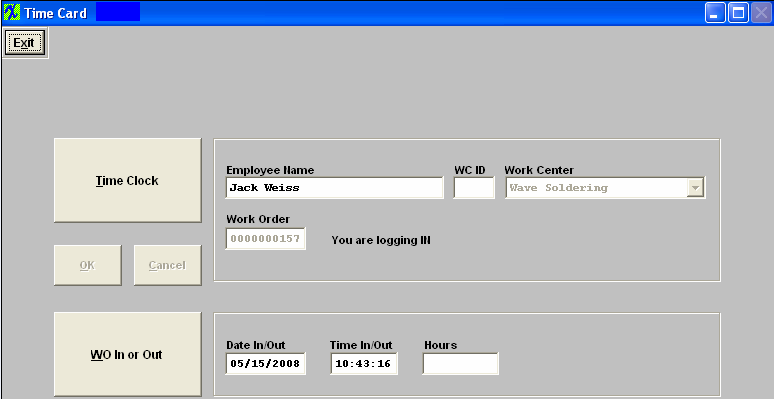

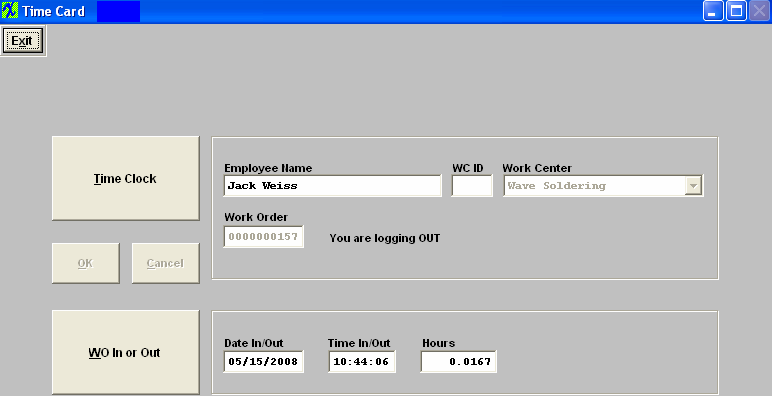

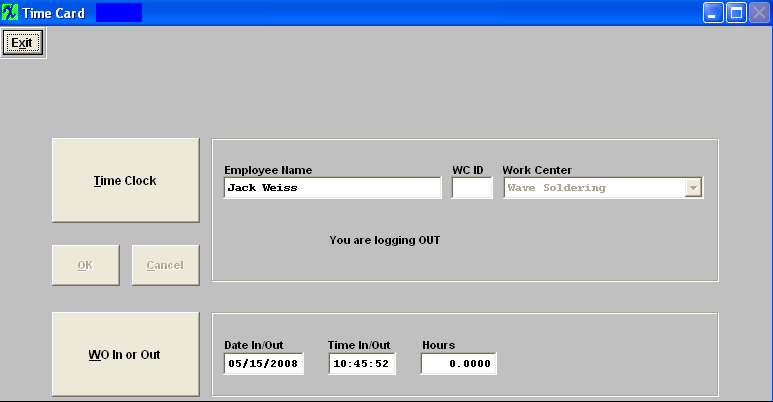

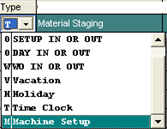

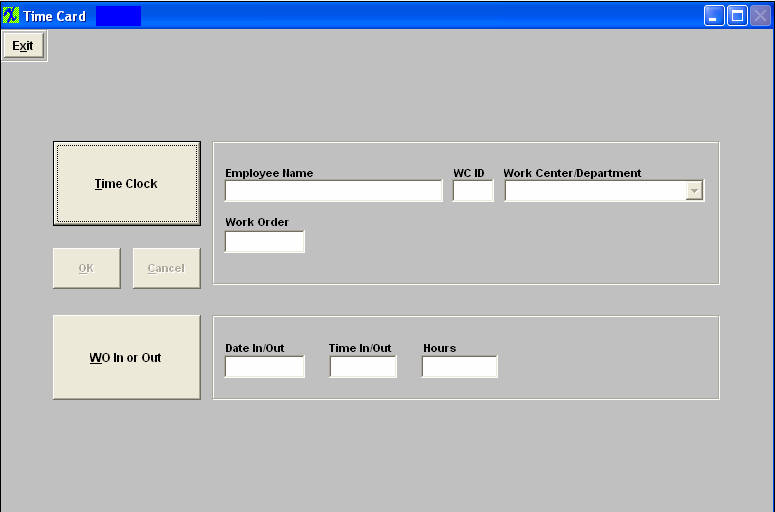

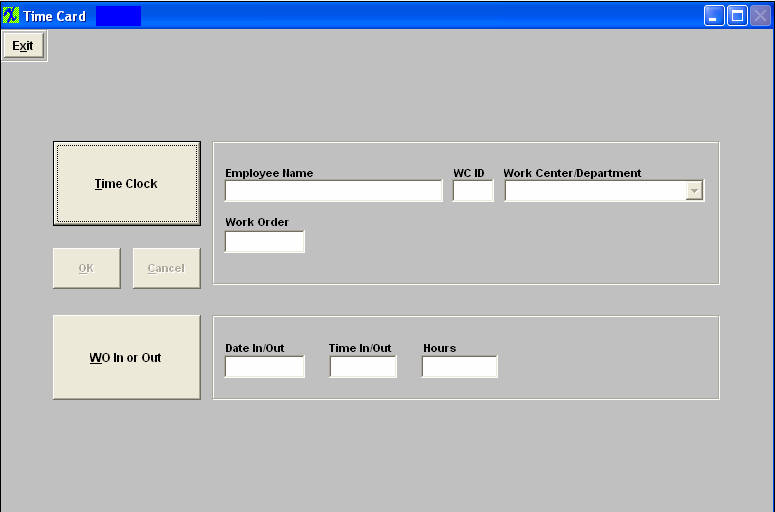

The Time Card module has two functions:1) to enter the worker coming in at the first of the shift and exiting for the day, and 2) to track time spent by each worker on each Work Order (Job), by date and time.This information will forward to the Time and Attendance module. A function for entering quality inspection results. Data may be used to track line quality based on customer, work center, product, location, etc. All Statistical Quality Control information and graphics are based on data entered here. A list of items defined to be checked as completed for the work order and work center. The users visit this screen, identify the items completed, and enter their password, marking the check list with their initials and date completed. Ths is the key function of this module. This is where the users identify the number of products being transfered from one work center to another during the production of the work order. When the Work Center Activity Setup and Run is entered in System Setup, clicking in this area will provide the user with both text and pictorial instructions for setting up the work center. Depressing this button will display any Tool/Fixture information which has been assigned to the Product through the Routing or Product Data Management (PDM) Module. When the PDM module is used, clicking in this area will provide the user with both text and pictorial instructions for processing the product in the work center. When the PDM module is used, clicking in this area will provide the user with both text and pictorial instructions for the product and work center. Identifies standard specifications relating to this product per the Standard Process Specification module. Provides a list of documents relating to the product being assembled. Displays the document number, revision, document date, and notes about the document. Will list all part number assigned to the specific Work Center within the BOM module. It will also allow the user to view the entire BOM if desired. This screen will list the detailed information pulled forward from the ECO Control Management module. This screen will list the detailed information pulled forward from the ECO Control Management module pertaining to any approved Deviations for the selected product. Will display the Quality information for the selected Work Center based on the information entered within the Inspection module. Show all the open work orders for this product and show where the quantities are in the shop floor This is an outside call program that ManEx has implemented into the system. The Users can have their own program to run when they scan their serial number inside of shop floor tracking by using the “User defined” button. Within the Outside Program Call Setup module, the user will have the ability to change the button name of the “User Defined” button and select which program (EXE) they want to run after the users scans specific Serial Numbers. Any notes entered for the work order on the shop floor tracking screen will cause the button to turn Red. Any comments in this area will be visible to all work centers which are included in the work order routing. Any notes entered specifically for the work order and the work center being viewed will cause the button to turn Red, calling the user’s attention to review notes that are applicable to the order. This button is sensitive to the work center being highlighted on the shop floor tracking screen. Any notes entered for the work center highlighted on the shop floor tracking screen will cause the button to turn Red. Any comments in this area will be visible to all products which include the work center in the routing. This button lists the history of transfers. This button will display Transfer History and Defect History by specific serial numbers. This is simply a note screen that may be used to record information about the product during the course of manufacturing. For further detail of these functions see Article #3107 . |

| 1.1.3. Fields & Definitions for SFT by WO |

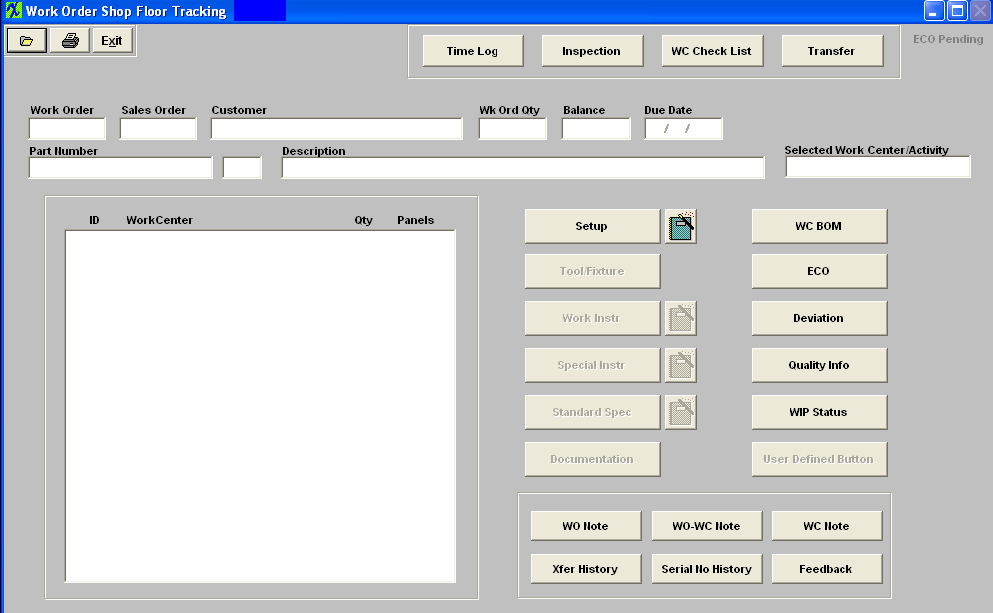

| 1.1.3.1. Work Order Shop Floor Tracking | ||||||||||||||||||||||||||||

Work Order Shop Floor Tracking Fields and Definitions

See Article #3107 for the Directive Buttons fields and definitons

|

| 1.1.3.1.1. Directive Buttons | ||||||||||||||||||||||||||||||||||||||||||||

SFT by WO Directive Buttons

|

| 1.1.3.2. Transfer Screen | ||||||||||||||||||

|

| 1.1.4. How To ..... for SFT by WO |

| 1.1.4.1. Finding A Work Order | ||||

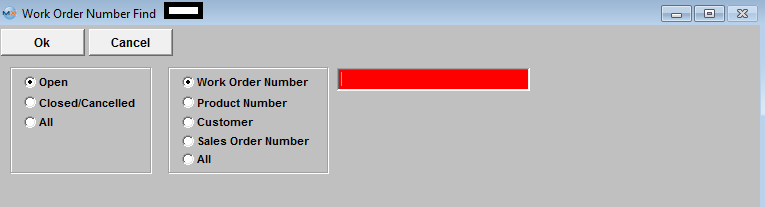

The Main Screen will appear.

Select the desired Work Order record. The Shop Floor Tracking screen is then populated with the appropriate data.

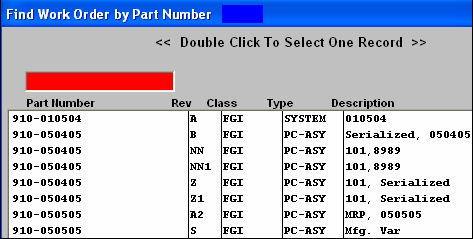

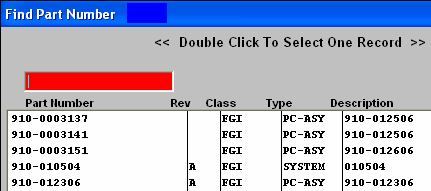

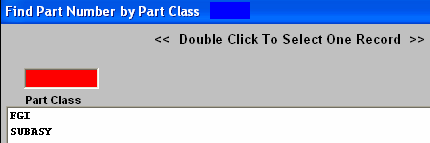

The Products will be listed in alpha-numerical order, along with the Revision, Class, Type and Description. Select the desired Product Number.

|

| 1.1.4.2. Shop Floor Tracking - Transfer | ||||||||

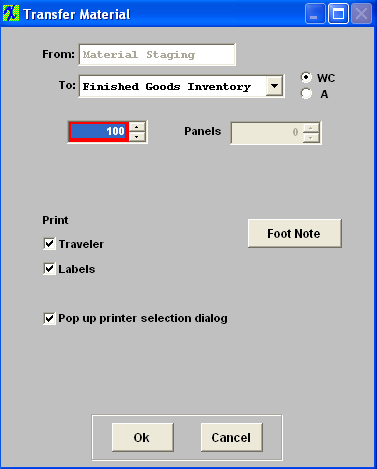

Find the desired Work Order record within the system.

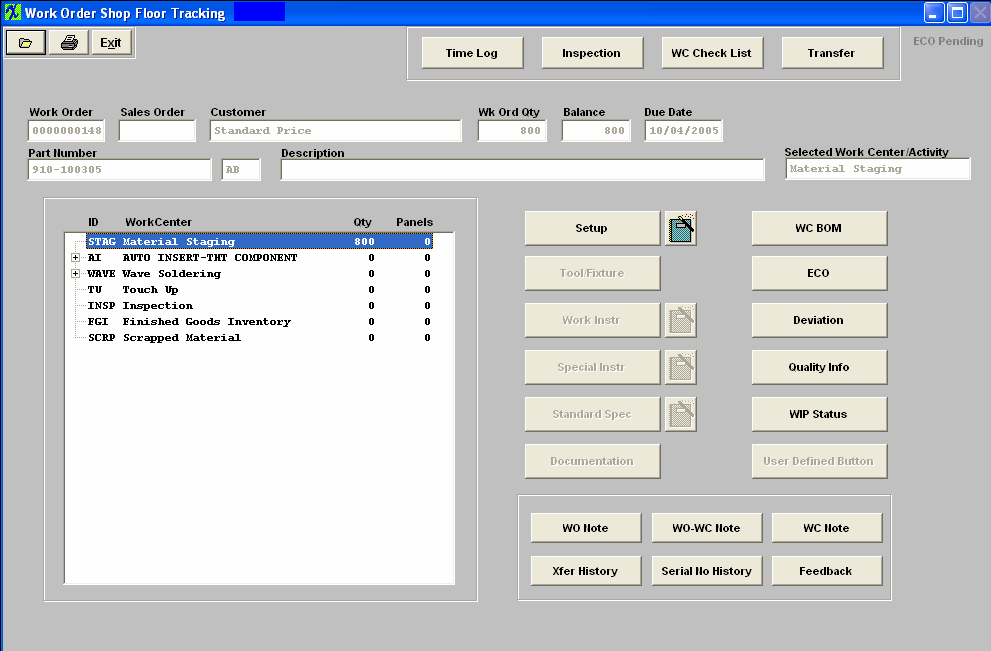

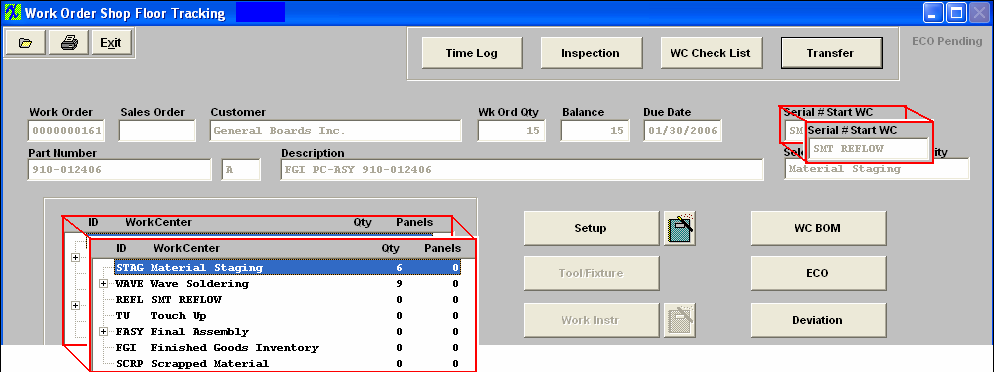

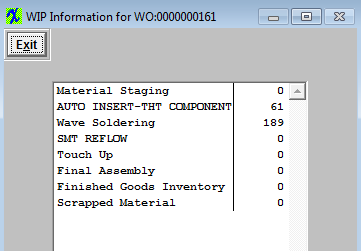

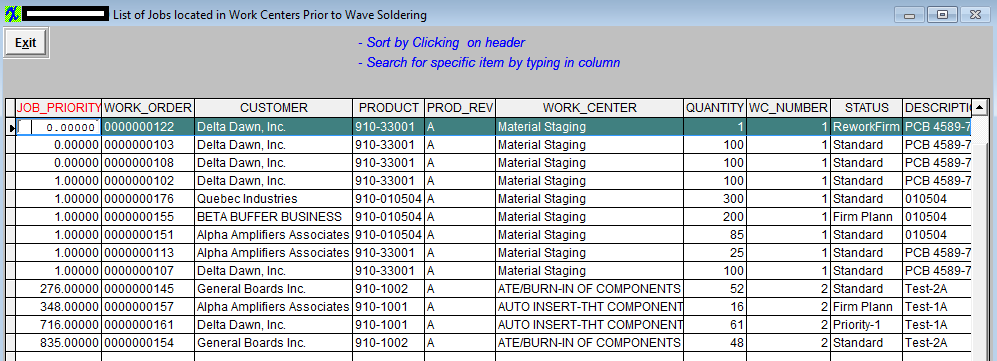

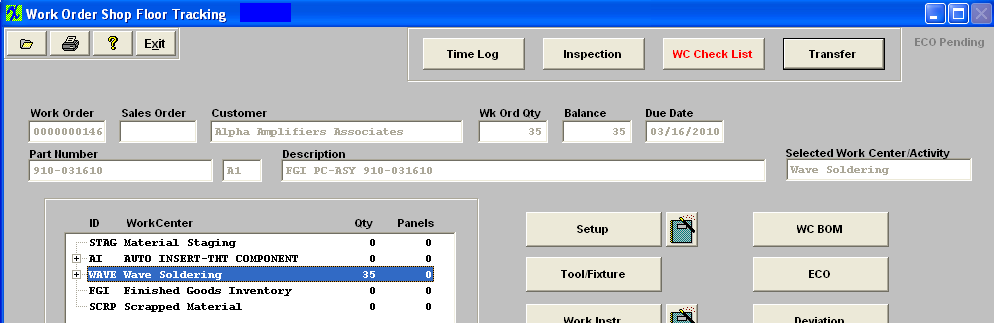

Highlight the current Work Center where quantity is displayed, as illustrated:

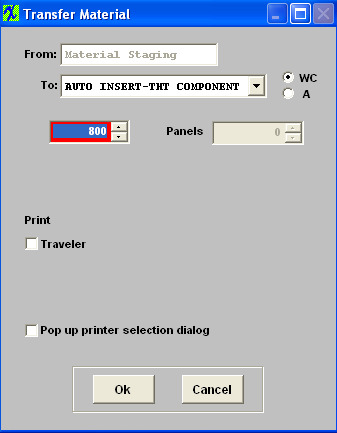

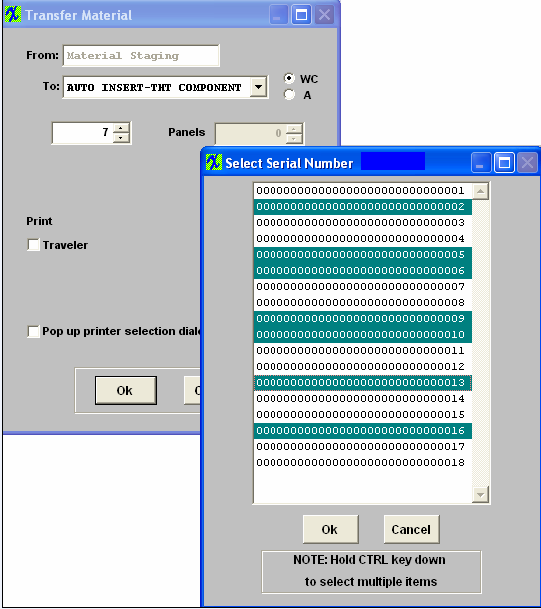

Depress the “Transfer” button. The system will prompt for a password. The following dialogue box will be displayed. The user may elect to transfer material within work centers (WC) or within activities (A) by pressing the appropriate radial button on the screen. Manex will determine the next area to transfer product based on the product routing, and enter the location in the “To:” field.

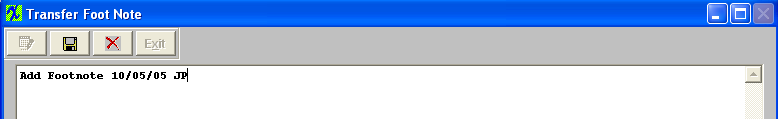

Next, Manex lists the number of products at the current location. The user may move all items, or select the quantity to be moved. This may be done by simply over-writing the quantity or by using the “arrows” to raise or lower the quantity shown. Depressing the Footnote button will bring up a note screen.

Depress the Edit button, Type in the footnote. Depress the Save button. Depress the Exit button. Depress the OK button. The material will transfer and the Traveler will go directly to the default printer. (This report requires that the user have the bar code font available).

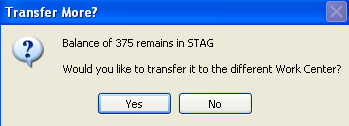

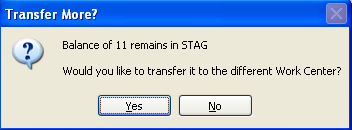

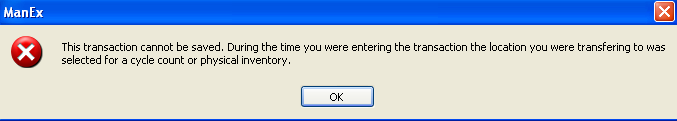

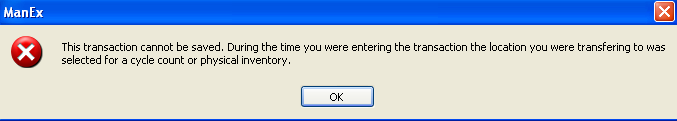

If a balance still remains in the selected work center then the system will prompt the user if they would like to transfer to a different Work Center. Yes – will bring up the Transfer Material screen again. No – will bring you back to the regular Shop Floor Tracking module. If the product is included in an active Cycle count, or Physical Inventory count, the following message will appear after depressing the OK button on the transfer screen anud user will not be allowed to transfer product until the count has been completed and posted.

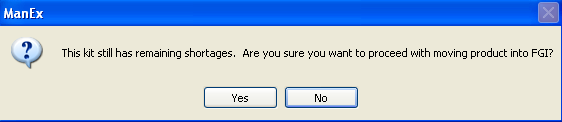

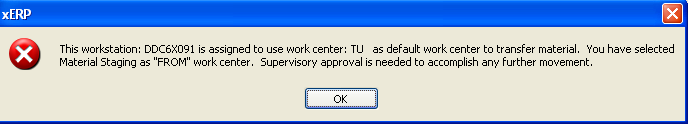

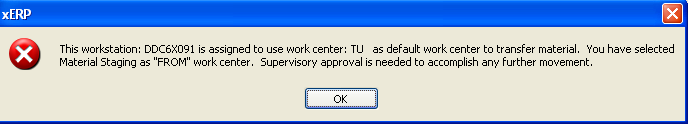

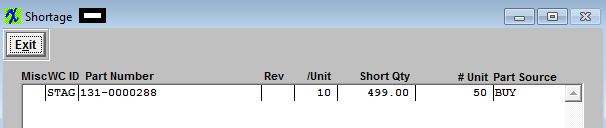

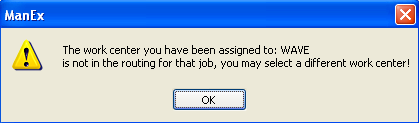

If user is transfering product into FGI and the Work Order has any item(s) that has short qty > 0 and the "Ignore Kit" box is NOT checked the following message will popup giving the user the option to continue moving the product or not.  Transferring Serialized product If the work station being used to transfered serialized material is assigned to use a default work center in Production Work Center/Activity Setup module, when the user first opens the module, the module will use the default work center assigned for this workstation, if the transfer is "FROM" a different work center other than the default and user is NOT a supervisor or has the option "Allow Changing Default Work Center for Serial Number Transfer" box checked within the Security module, they will receive the following message:

When user depresses "OK" a supervisor approval is required to continue. After supervisor’s password is entered, the default work center will be changed to the one that the supervisor entered password for. For example: the workstation is assigned to use “TU” as default work center, now if user chooses to use “AI” to transfer, the system will ask for supervisor’s password, if user cancels the password, the default work center will still be “TU”, but if the supervisor enters his/her password on this machine, the default work center will be changed to “AI”. If now the user tried to transfer from “TU” again, the system will ask for supervisor’s password again. If user exits the module and come back, the default work center will be “TU” again.

If the user is tracking by serial numbers, and if the user is transferring a lesser quantity than displayed, Manex will display a screen from which to select the serial number(s) to be moved in the transaction.

The user may select one or more serial numbers to match the quantity being transferred, and then press the OK button. The user must select the proper number of serial numbers or the transaction will be cancelled.

Since less is being transferred, the following message will appear: Yes – will bring up the Transfer Material screen again. No – will bring you back to the regular Shop Floor Tracking module.

Discussion on the Accounting Entries If the user also has accounting installed, then the appropriate journal entries will forward to the Accounting “Release to General Ledger” screen. Briefly, assuming that the user has the material cost set up in the Inventory Control Item master, then when the product reaches the Work Center “Finished Goods Inventory”, the entry will be to debit Finished Goods Inventory (or the warehouse home general ledger number of the product) and to credit WIP .If the product ended up in the Work Station “Scrap”, then the debit would be to the default scrap general ledger account, as set up in the Accounting Set Up. Configuration Variance If the Material Cost per the product was not equal to the sum of the standard costs per the BOM components, then a configuration variance will be created. Please refer to the “Wip Value" Article #913 for further explanation. |

| 1.1.4.3. Use Work Center CheckList within SFT Module |

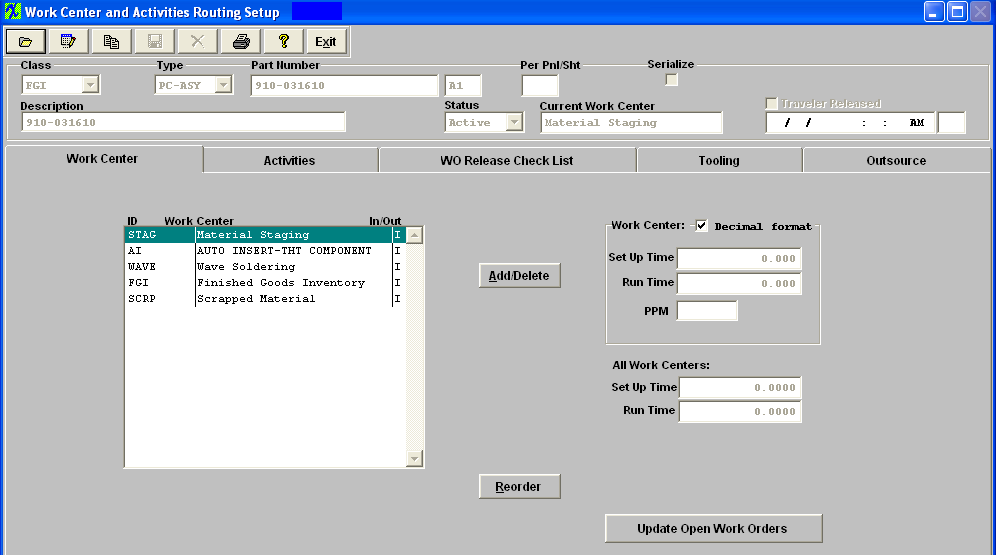

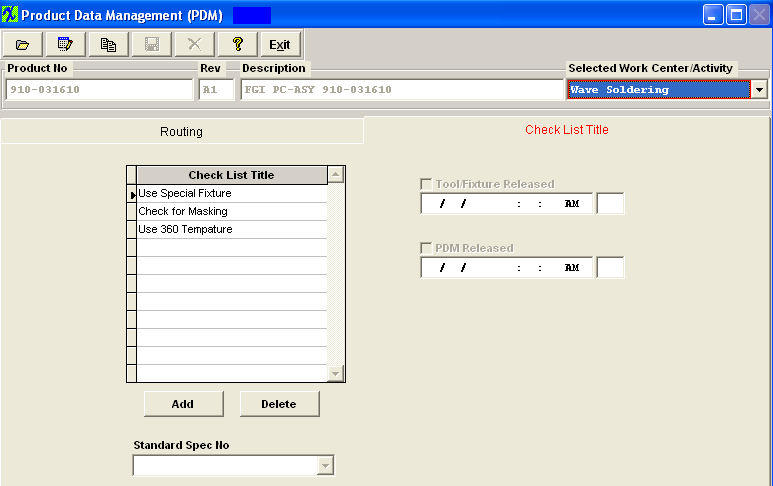

Create a Routing within the WO Traveler Setup module for Product. For further detail see Article #850  Create a Checklist for a Specific WC within the PDM module. For further detail see Article #2824 .

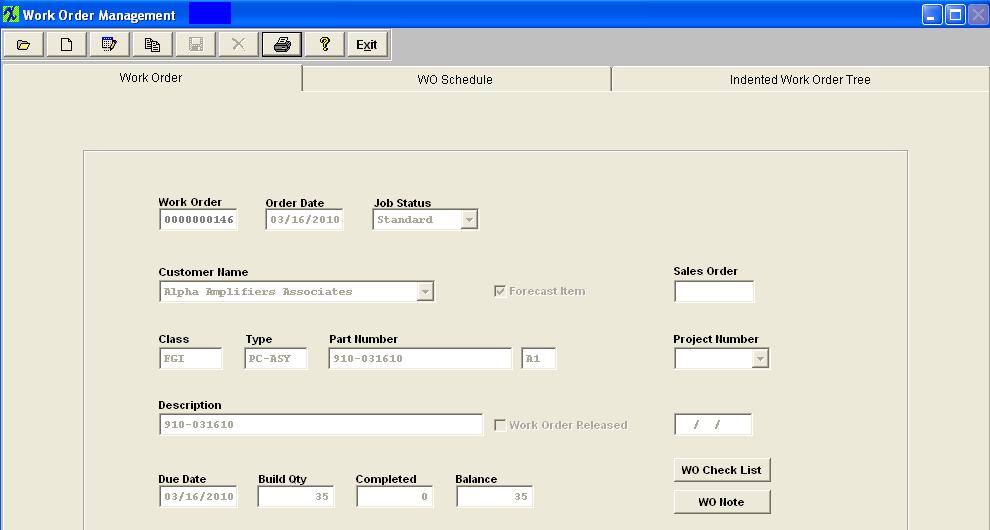

Create a Work Order for the product within the Work Order module. For further detail see Article #1815.

The Traveler Released box within the WO Traveler Setup MUST be checked.

The Tool/Fixture Released box and the PDM Released box within the PDM module MUST be checked.

The kit must be Released and the Kit Complete box within the Kitting module MUST be checked.

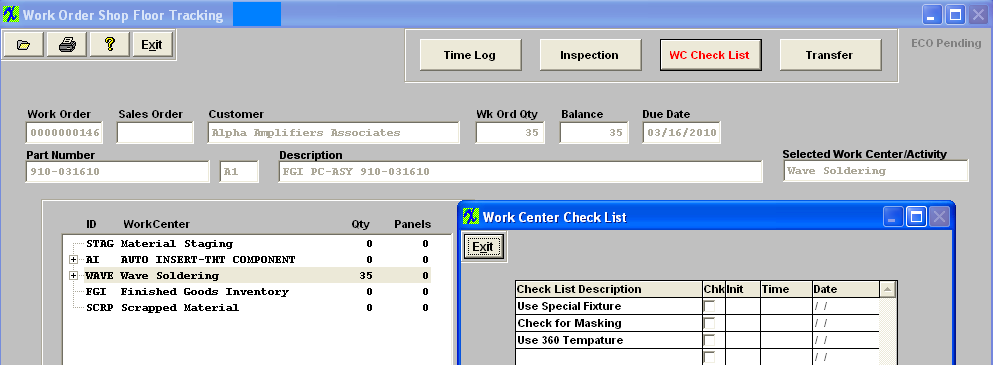

Transfer product through SFT when product reachs the Work Center with the checklist the "WC Check List" butoon will be displayed in Red (as displayed below).

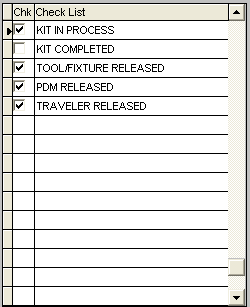

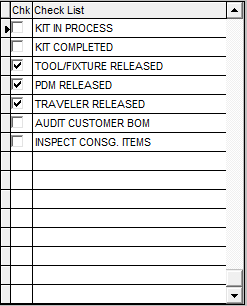

Click on the "WC Check List" button and the check list will appear (as displayed below):

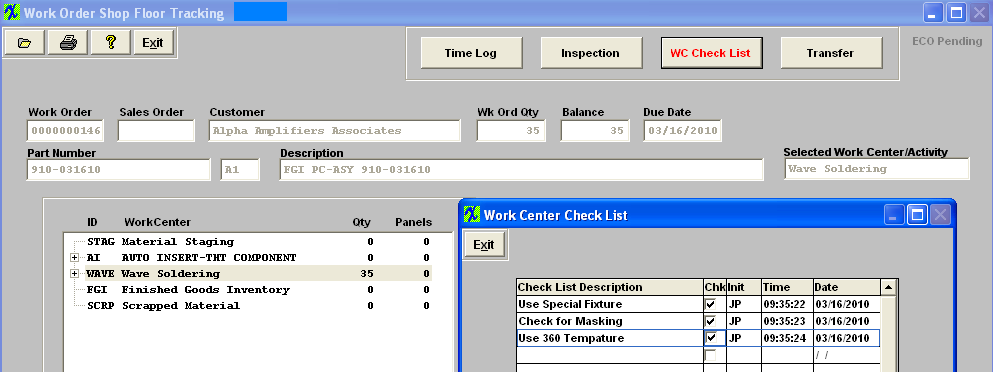

User must then review the list and check the box when task has been completed and their initials, time and date will default in (as displayed below): Note: This check List is for reference only and WILL allow the users to transfer product to the next Work Center if not all items have been checked off.

Once all the boxes have been checked within the Work Center CheckList user may complete the transfers. Note: This checklist is for users to check if they do all the necessary task, but it does NOT enforce the user to check all items before the user can transfter to next WC.

|

| 1.1.4.4. Enter Defect Data Entry |

| Follow the Steps in Article #1769 to move product by using the Defect Entry Module. |

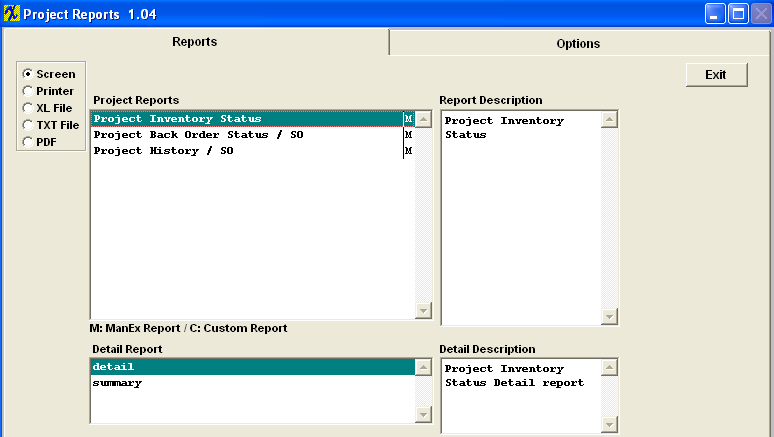

| 1.1.5. Reports - SFT by WO |

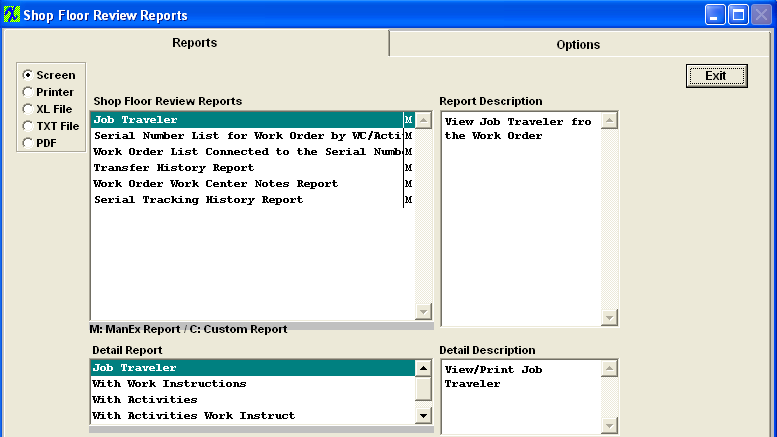

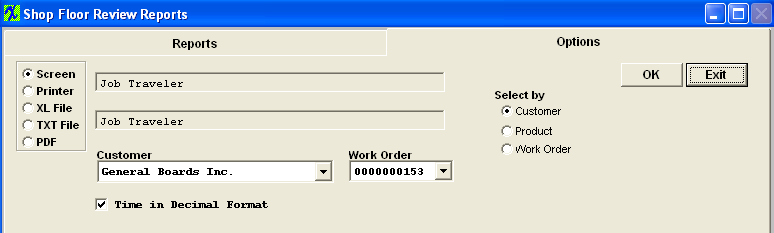

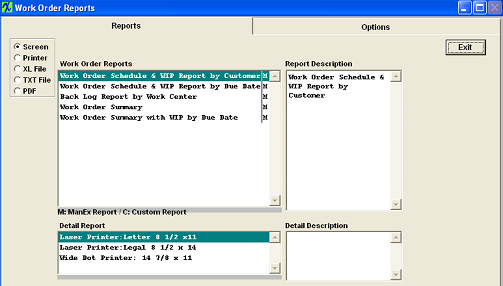

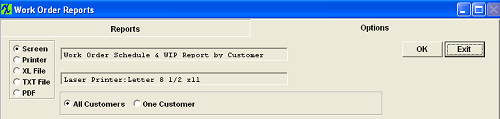

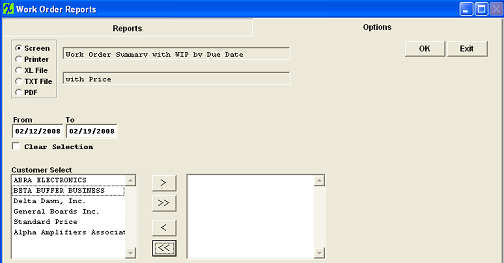

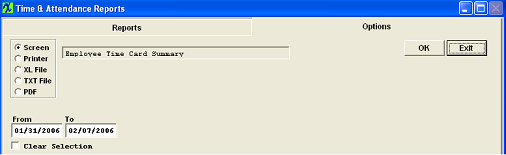

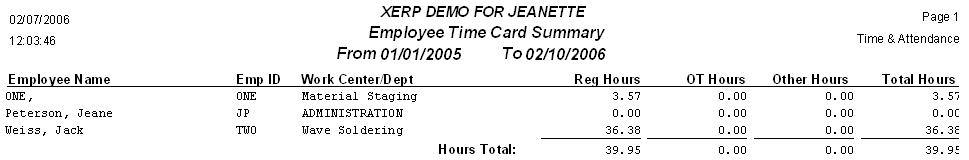

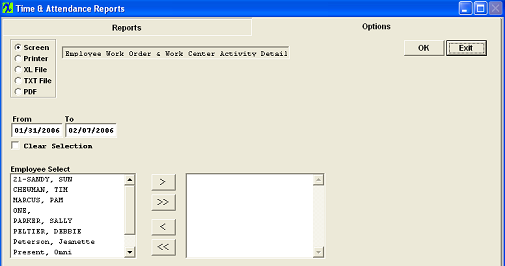

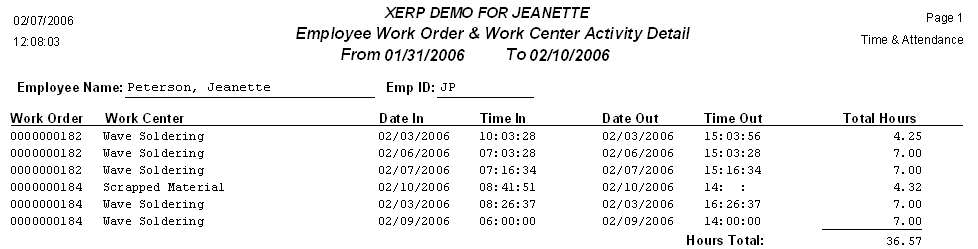

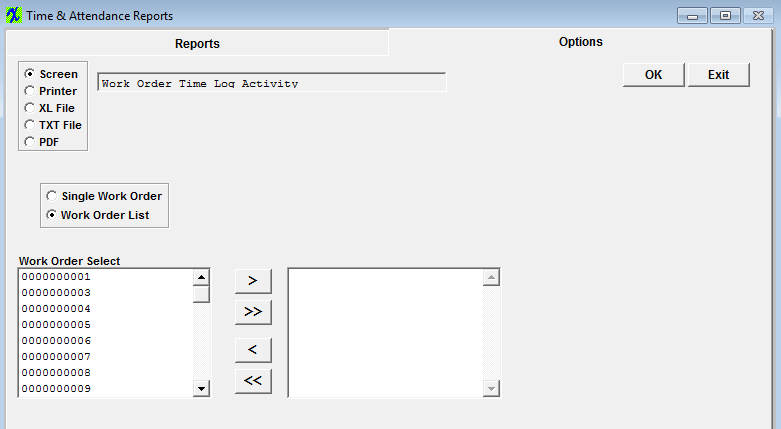

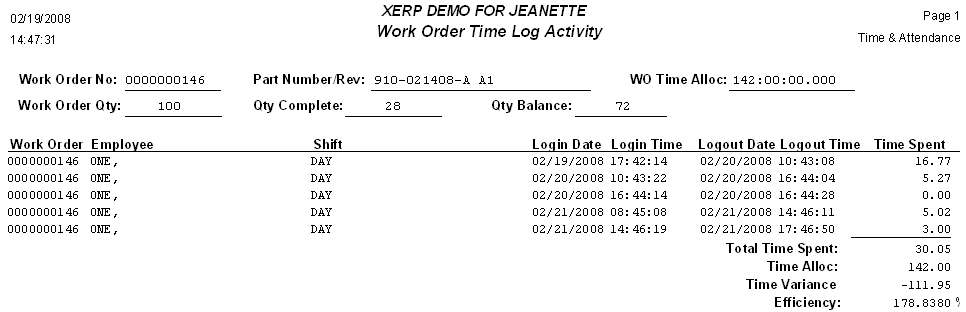

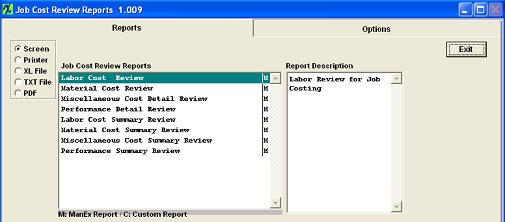

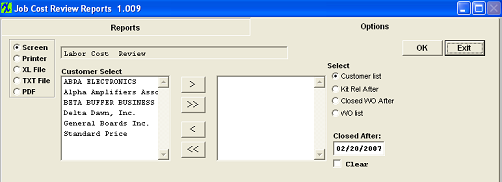

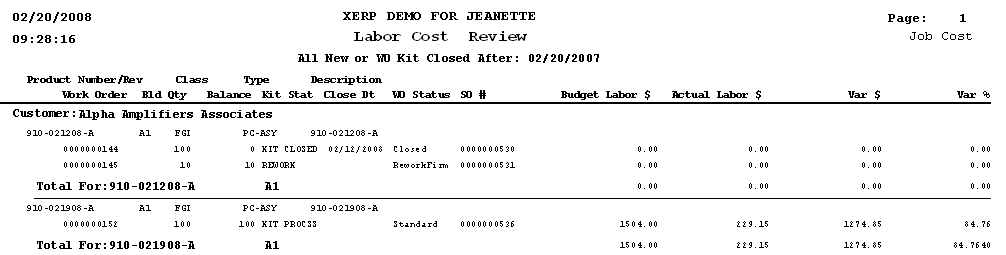

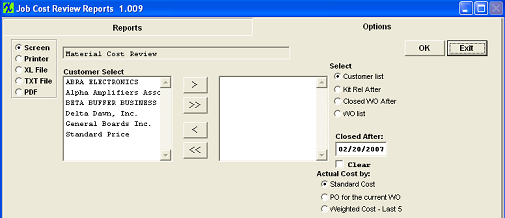

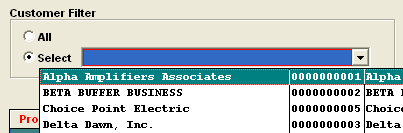

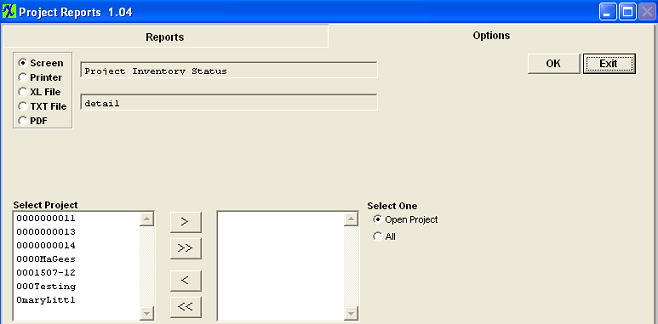

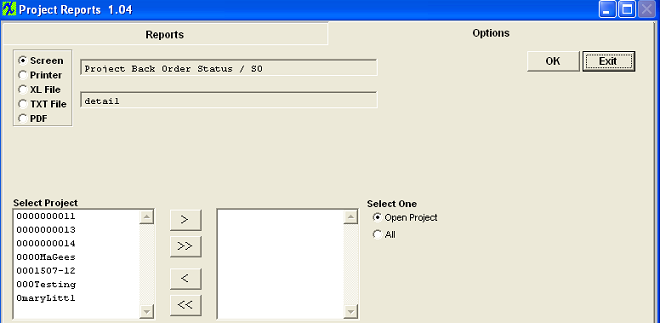

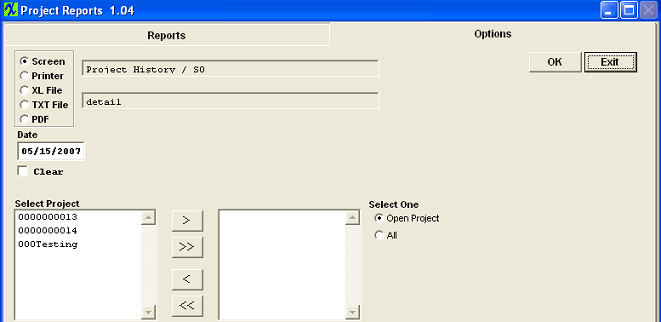

To obtain reports, depress the Report button. The following screen will appear:

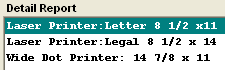

JOB TRAVELER REPORT Highlight the “Job Traveler” report. Make the desired selections in the Detail Report Section. Note: The Work Instruction may not appear in the Traveler if the user prints it to an Excel Worksheet file. Some of the reports are quite complex, with multiple relationships and filters. In this instance, the Work Instructions are in a different data base than the routing and therefore will not be available. Then depress the Options tab. The following screen will appear:

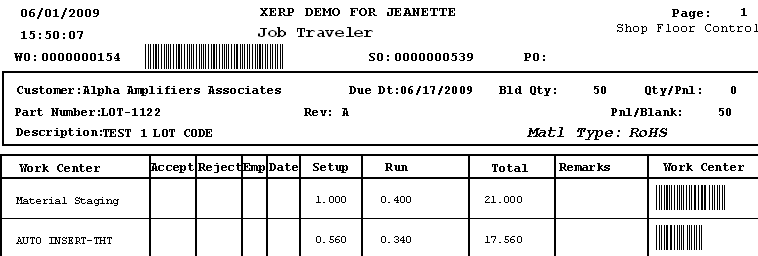

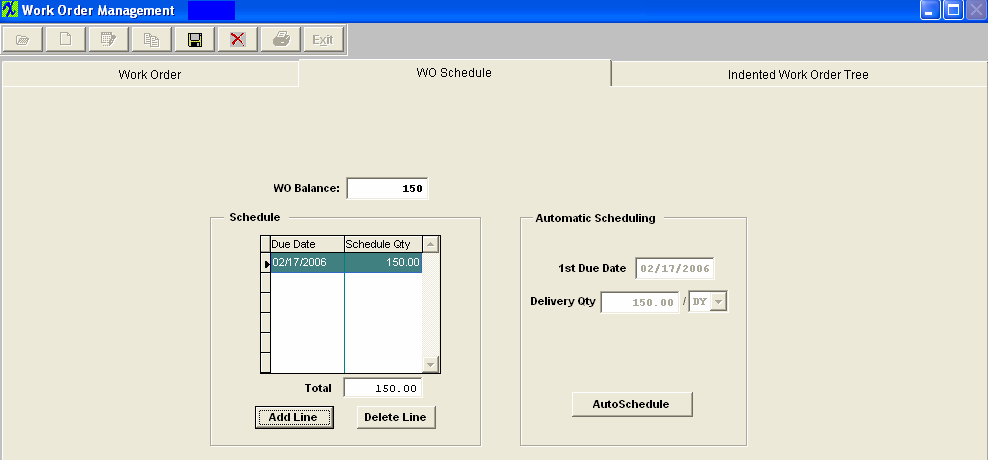

Select the desired radial selection:Customer, Product or Work Order. Select the desired Customer and Work Order by using the Down Arrows next to the fields. If you do not want time in decimal format, uncheck the box. The following reports will be displayed:

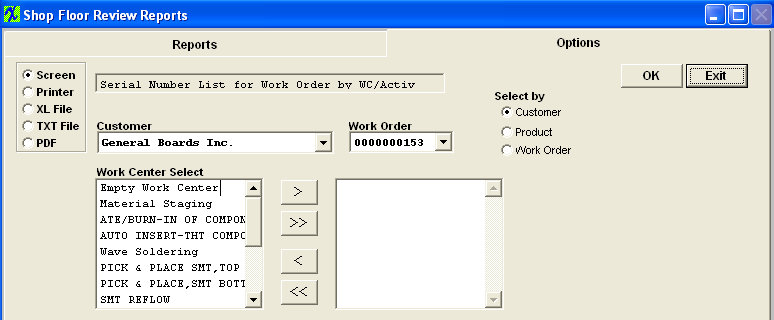

SERIAL NUMBER LIST FOR WORK ORDER BY WC/ACTIVITY REPORT Highlight the “Serial Number List for Work Order by WC/Activity” report. Depress the Options tab. The following screen will appear:

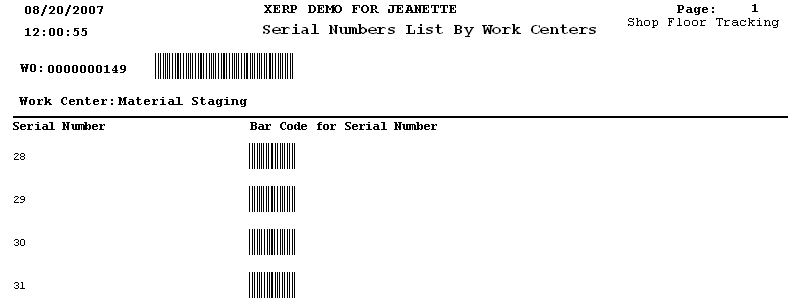

Select the desired radial selection:Customer, Product or Work Order. Select the desired Customer and Work Order by using the Down Arrows next to the fields. Highlight the Work Center and depress the > button. If you want all work centers, depress the >> button. The leading zero's for SN will be removed from Report.

The following report is available:

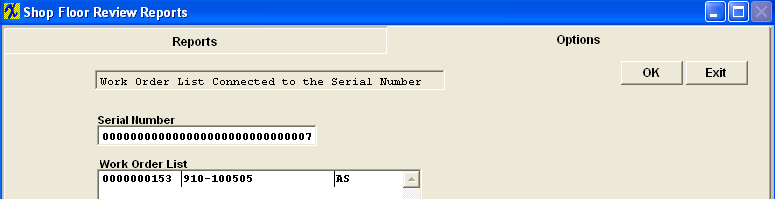

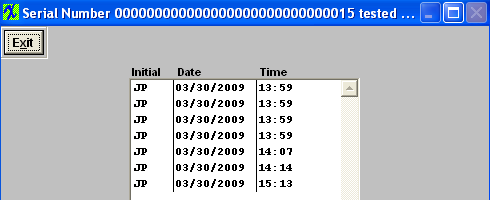

WORK ORDER LIST CONNECTED TO THE SERIAL NUMBER REPORT Highlight the “Work Order List Connected to the Serial Number” Report. Note:that this report is a View screen only – no report will be generated as an output. Depress the Options tab. Type in the Serial Number and the following will display.

Hitting the OK button will bring you back to the Shop Floor Tracking module. TRANSFER HISTORY REPORT

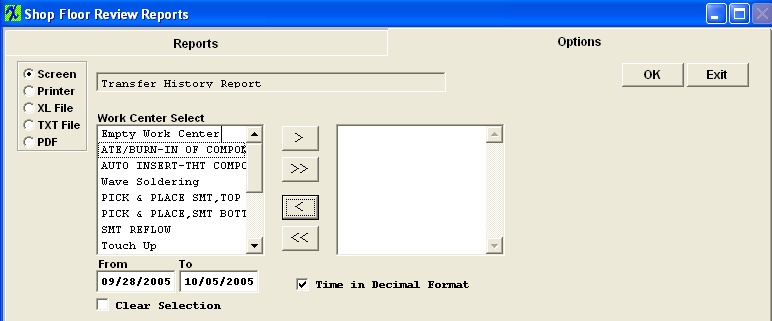

Highlight the “Transfer History” report. Depress the Options tab. The following screen will appear:

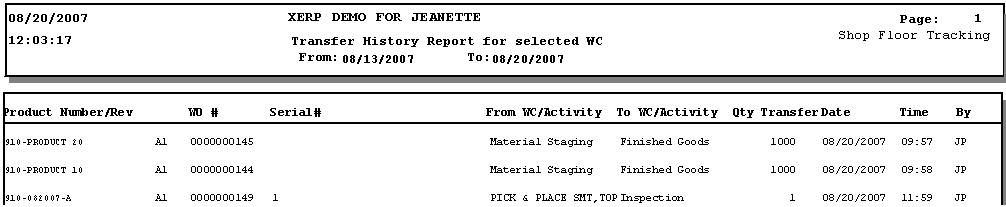

Select the Work Center by highlighting and depressing the > button. If all Work Centers are desired, depress the >> button. If you do not want time in decimal format, uncheck the box. Enter in the desired Date Range. Leading zero's for SN will be removed from report. The following Report will be displayed.

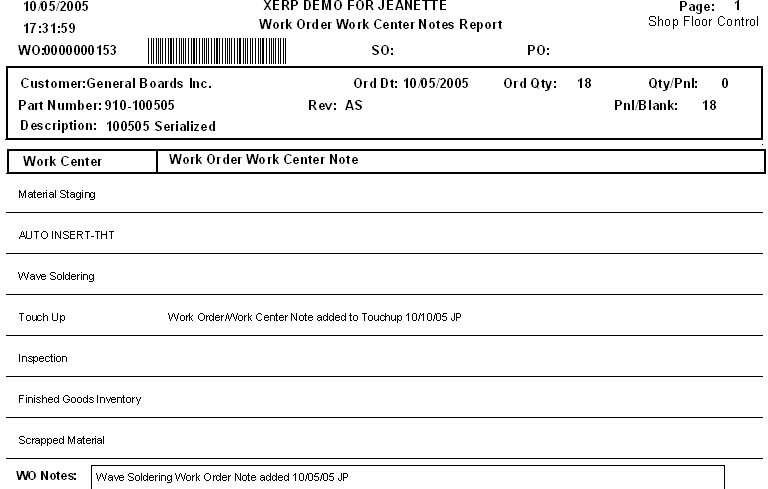

WORK ORDER WORK CENTER NOTES REPORT

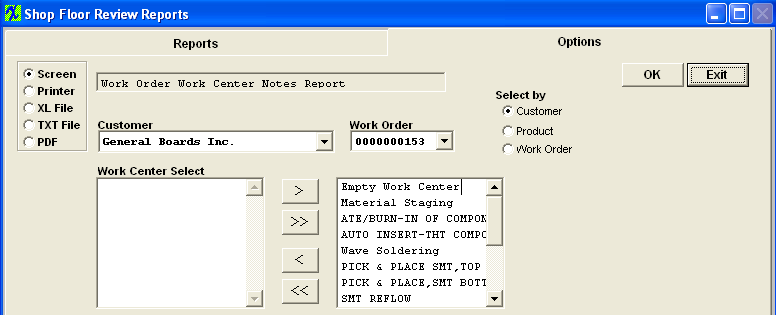

Highlight the “Work Order Work Center Notes” report. Depress the Options tab. The following screen will appear:

All Work Centers are selected by default. If you wish to deselect any Work Centers use the < Button. The following report will be displayed:

SERIAL NUMBER TRACKING HISTORY REPORT Highlight the “Serial Number Tracking History” report. Depress the Options tab.The following screen will appear:

Select the desired radial button: Single Entry or Range. Enter Serial Number. Leading zero's for SN will be removed from report. The following report will be displayed: This report will gather transfer history and defect history for those serial numbers that have been linked to more than one work order and display the transfer history and defect history for all those work orders.

|

| 1.1.6. FAQ's - SFT |

| Facts and Questions for the Shop Floor Tracking Modules |

| 1.1.7. Test & Repair (T & R) (OPTIONAL Module) |

| 1.1.7.1. Prerequisites for the T & R Module |

|

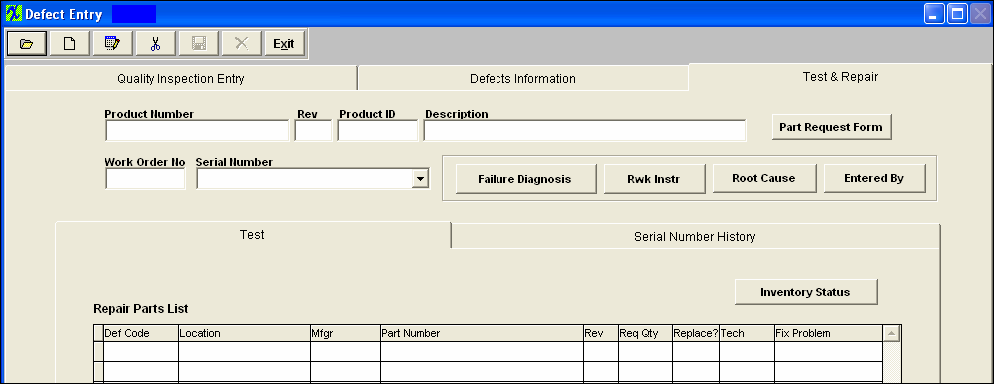

The Test & Repair is actually a separate OPTIONAL module, but has been included into the Defect Entry screen for ease of use for the operators. After activation, Work Order Shop Tracking, Defect Code Entry, and Test & Repai access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access. To use Test & Repair Management module, Serial Numbering is REQUIRED. This information is entered using the Work Order Management Serial Number Control module. |

| 1.1.7.2. Introduction for the T & R Module |

Test & Repair Management (T&R) has been designed to capture testing results and failure information such as: In-circuit Testing, Sub-Assembly Functional Testing and System Final Assembly Testing. Once this information has been entered this will allow the users the ability to see the Serial Number History and view all of the testing and repair results as well as when it had been shipped to customers. It will also keep track of any associated returns or warranty work that had been done against this particular Serial Number, continuing history as long as the unit is in service.

|

| 1.1.7.3. Fields & Definitions for the T & R Module |

| 1.1.7.3.1. Test & Repair Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Test & Repair Screen Field Definitions

The Test & Repair is actually a separate OPTIONAL module, but has been included into the Defect Entry screen for ease of use for the operators.

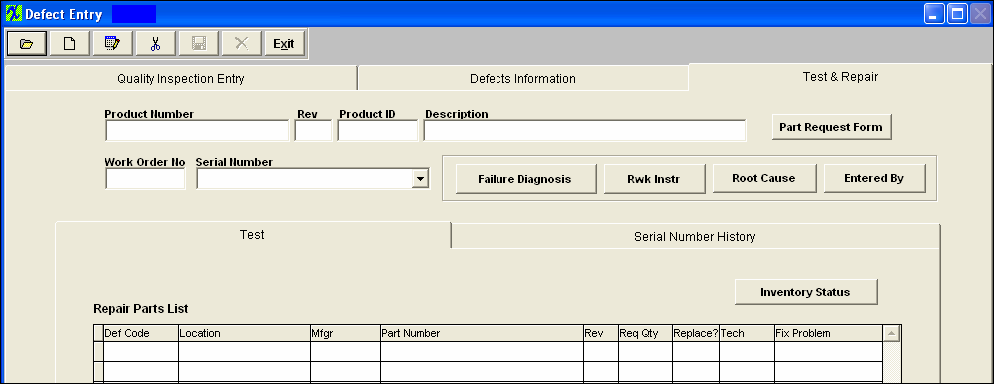

The internal number assigned to the assembly. The revision number associated with the Product Number. This field is no longer used and will be left blank. The description of the Product Number. The number of the work order which was inspected. The serial number of the assembly which failed inspection. Test Tab Field Defintions Repair Parts List

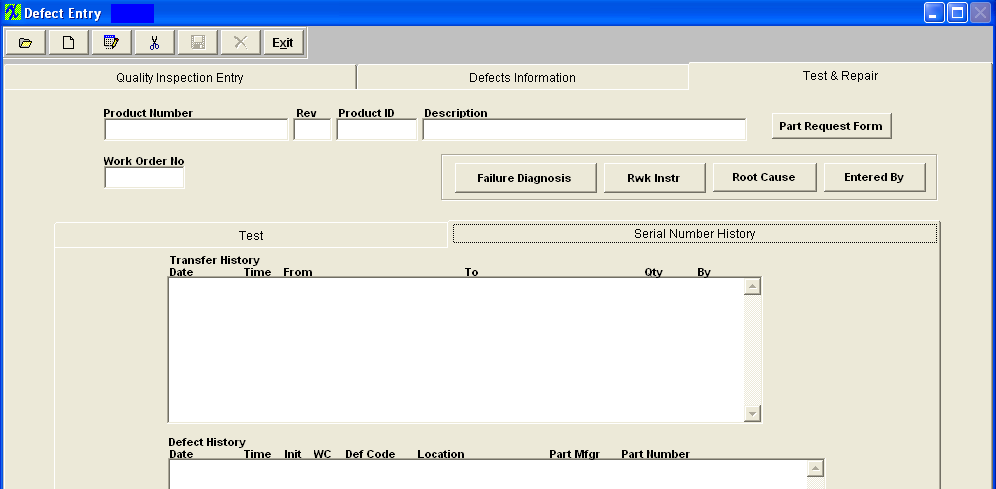

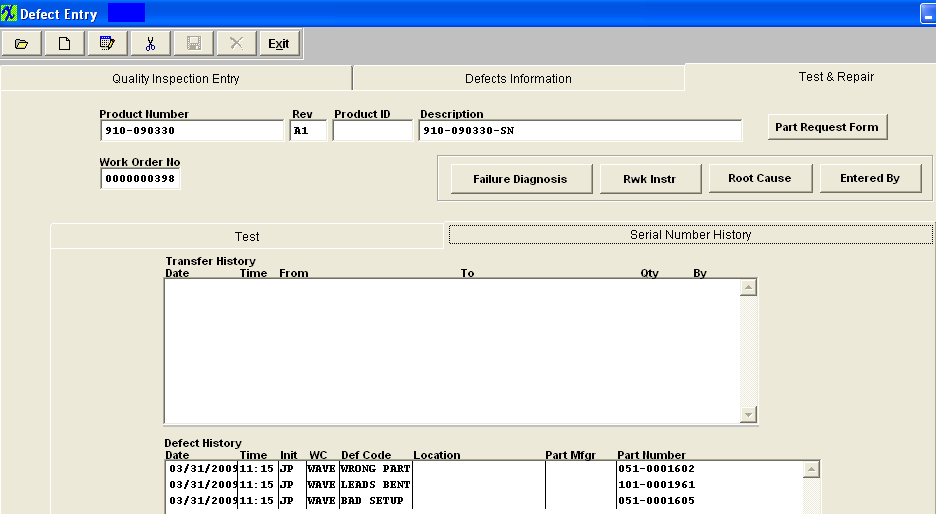

Serial Number History tab  Transfer History Section

Defect History Section

|

| 1.1.7.4. How To ...... for the T & R Module |

| 1.1.7.4.1. Add Test and Repair Information | ||||||||||

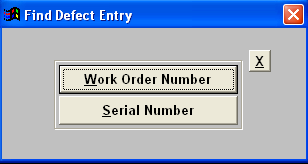

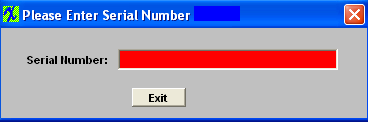

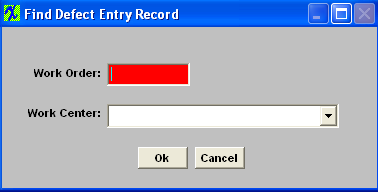

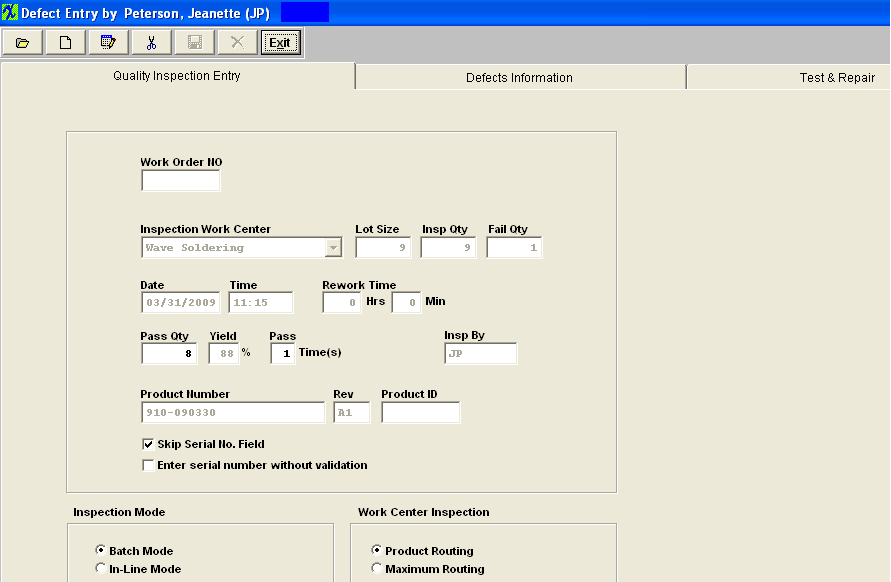

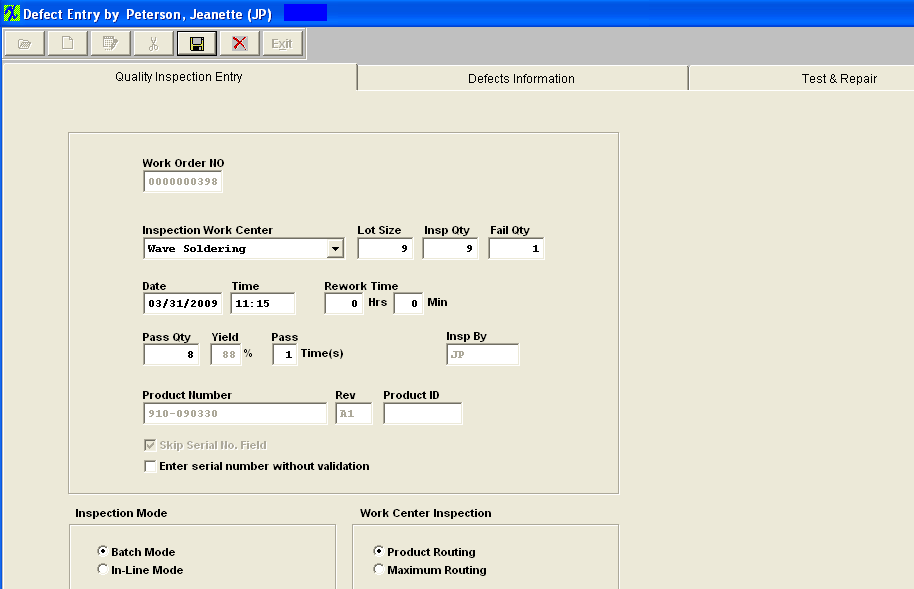

When the user has completed the Defect information, they may enter the Test & Repair tab to enter more information about the part, or may depress the Open/Find record button to find this information at a later time.

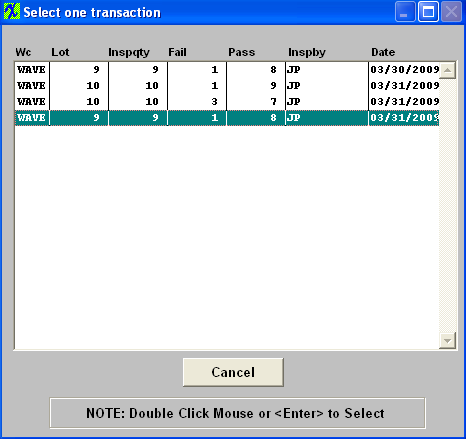

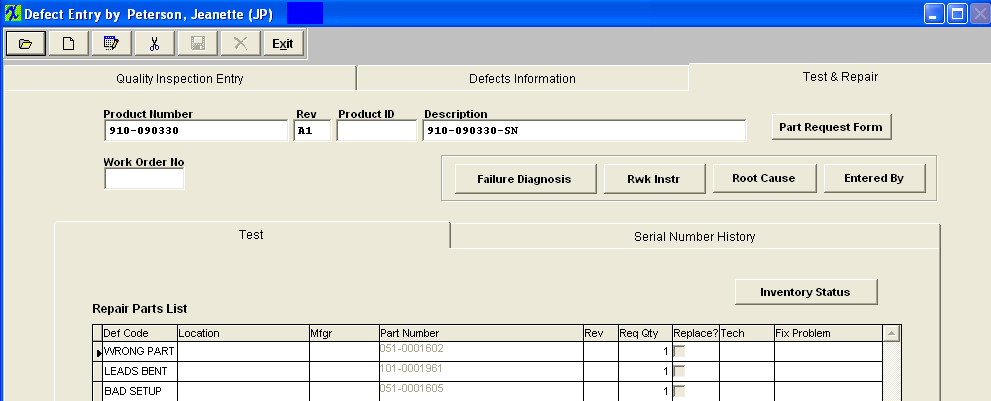

Once user has selected a transaction the following screen appears displaying the record you selected:

Depress the Edit button and enter your password, user may at this time edit the Quality Inspection Entry info, the Defects Information, or the Test & Repair info:

Depress the Test & Repair Tab: (System will only display information for one serial number at a time).

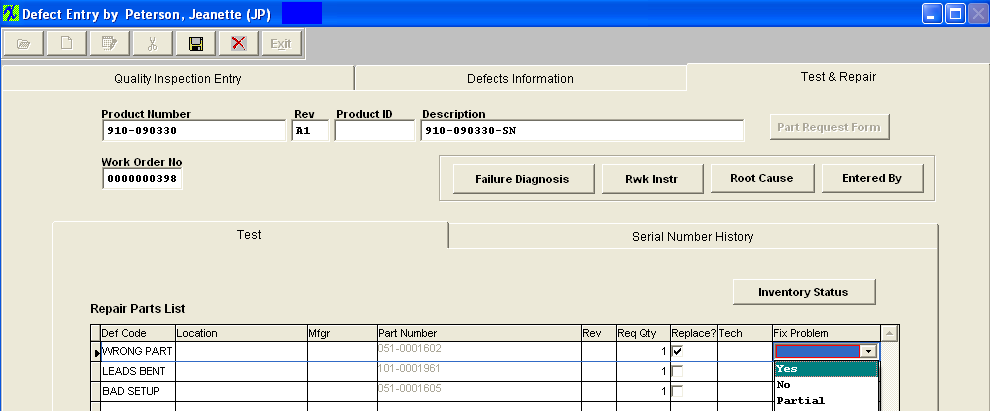

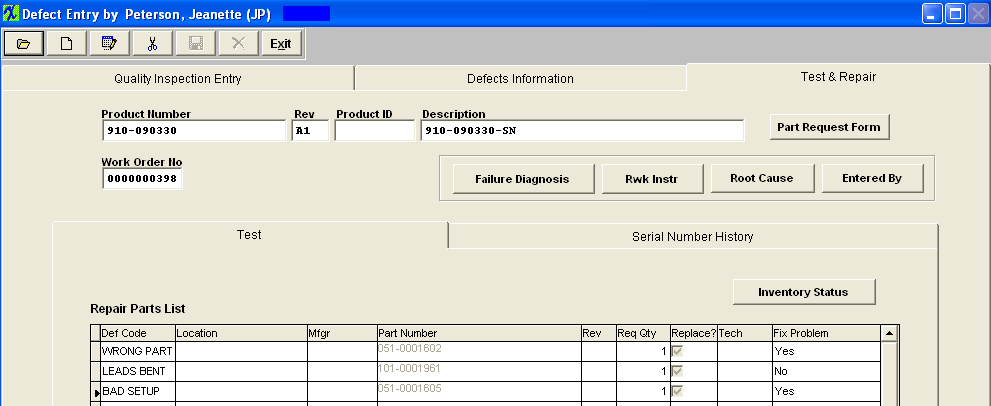

In the edit mode user can edit the required qty, check the Replace? box, or select to Fix Problem from the pull down:

NOTE: To have the initials of the technician who fixed the defect displayed, user must double click in the field.

Depress the Save button to save changes or Depress the Abandon changes button to abandon changes.

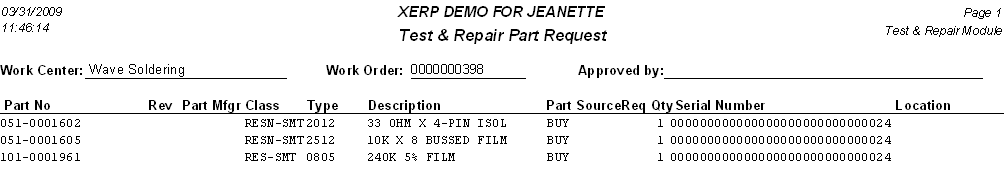

User may at this time print the "Part Request Form" which will need to be approved and hand delivered to the stockroom, so they may fill the shortage(s) and issue part(s) to the kit.

To View the Serial Number History depress the "Serial Number History" tab

|

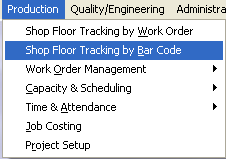

| 1.2. Shop Floor Tracking by Bar Code (OPTIONAL Module) |

| 1.2.1. Prerequisties - SFT by Bar Code | ||||||||

|

ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. This module is designed primarily for transfer of products in shop floor tracking and input of inspection data by serial number and defect code. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com"contactus.aspx

After activation, "Shop Floor Bar Code" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.2.2. Introduction - SFT by Bar Code |

Overview: Manex Manufacturing System Software has bar code scan and print capability which is designed primarily for transfer of products in shop floor tracking and input of inspection data by serial number and defect code. Installation: Bar Code Shop Floor Tracking is an extra cost option; it is not a part of the Core Manex MES modules. Upon purchase of the module, Manex will send a soft key to activate the module.

Specification:

|

| 1.2.3. Fields & Definitions for SFT by Bar Code |

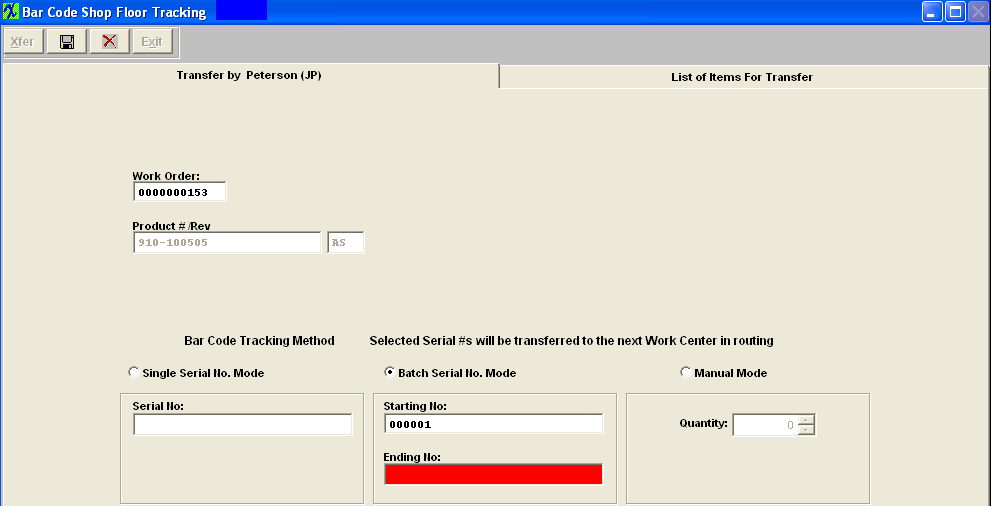

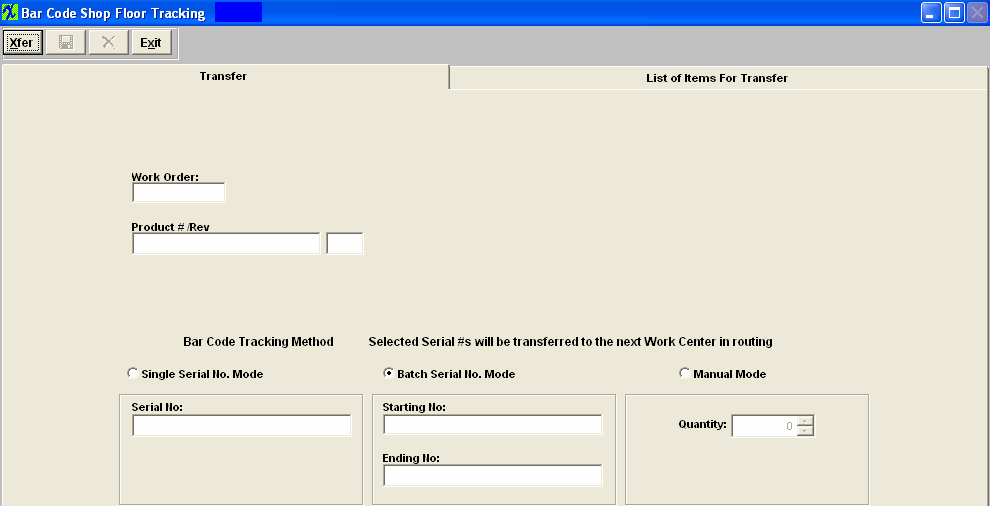

| 1.2.3.1. Transfer Tab | ||||||||||||

Single Serial No. Mode

Batch Serial No. Mode

Manual Mode

|

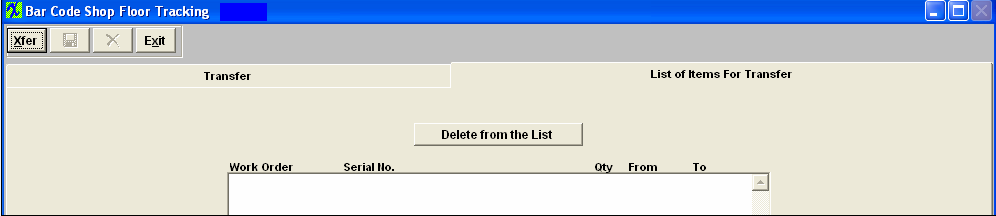

| 1.2.3.2. List of Item for Transfer Tab | ||||||||||

|

| 1.2.4. How To ..... for SFT by Bar Code |

| 1.2.4.1. Install Bar Code Font |

|

The following procedures must be followed for each workstation from which the user expects to print barcodes. If the following font is not installed, the barcodes will print very large and will not be usable.

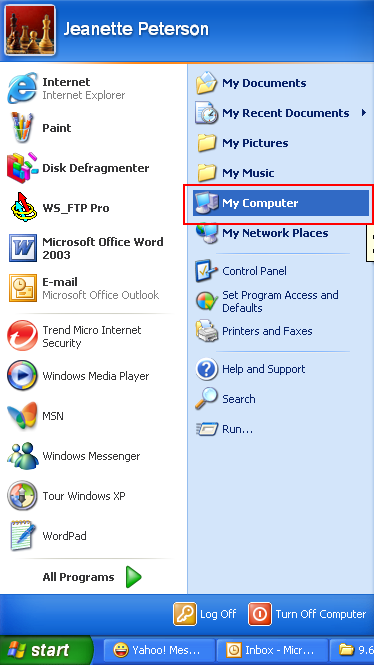

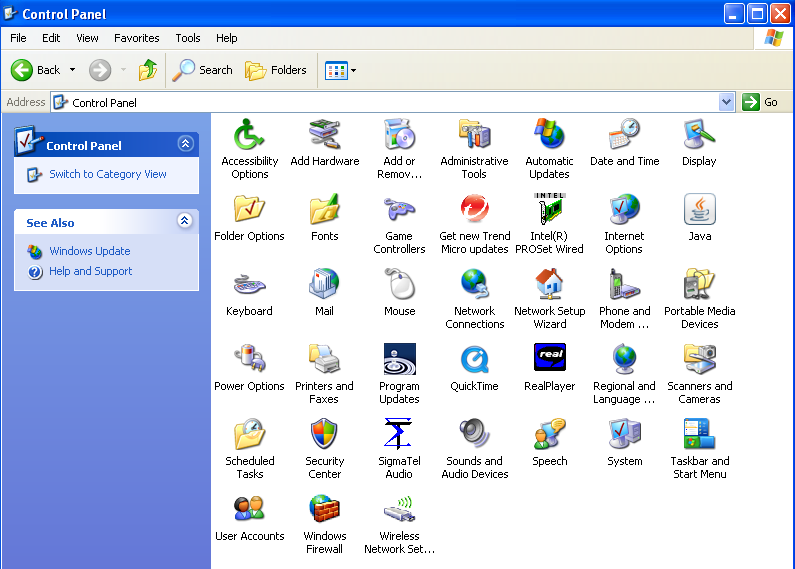

1.Go to Start

2.Select My Computer

3.Select Control Panel  4.Select Fonts

5.Select File

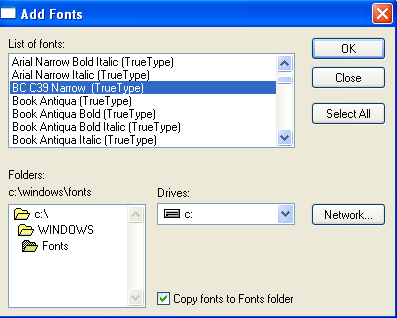

6.Select Install New Font. In the Add Fonts dialog box, go to the system location for fonts in your system.In most cases, it will be in C:"Windows"Fonts.

7.The font BC C39 should show up in the List of fonts window. Highlight it. Be sure there is a check mark in the Copy fonts to Fonts folder box and click OK. If this font is NOT listed then you can Download the attached [BarCodeFont_C39N.zip] file and extract it into your C:"WINDOWS"fonts directory.

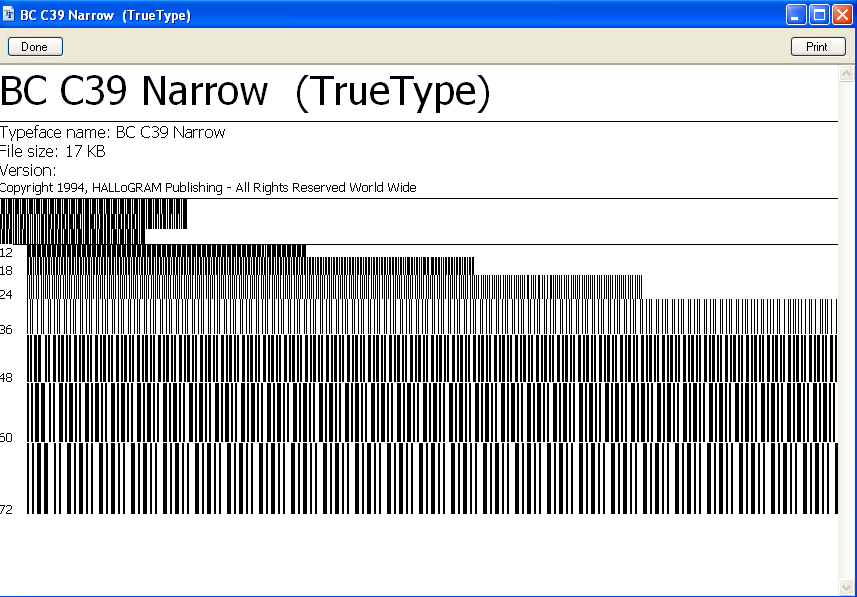

8.The new font will appear in the Fonts window. Double clicking on the font will produce the following:

|

| 1.2.4.2. Transfer Product | ||

The following screen will be displayed:

Depress the Xfer button. Type in your password or scan employee id . The user can either enter in the Work Order number (which will then display the Product and Rev) or go to the Bar Code Tracking Method section and enter in the Serial Numbers desired. The system will then default the Work Order #, Product and Rev onto the screen.

The Bar Code Tracking method is dependant on how it is setup within the Shop Floor Tracking Defaults . Note: When in "Single Serial no. mode" if the serial number entered has more than one work order associated instead of asking user to select the WO number everytime, if the serial number is linked to previously entered WO, the system will just take the WO and save to 2nd page. If the serial no scanned does not match the previous entered WO, then a WO selection box will be presented to the user.

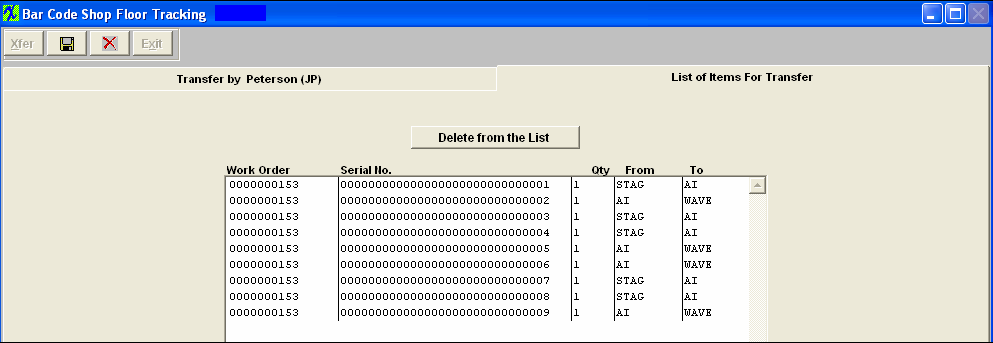

Once the Serial Numbers have been selected, go to the List of Items for Transfer screen. The Work Order number, Serial No., Quantity, From Work Center and To Work Center or from Work Center to Activity will display, depending on the selection within SFT Defaults to Transfer by WC or Activity.

Depress the Save button. The items will then be properly transferred within the system.

If the product is included in an active Cycle count, or Physical Inventory count, the following message will appear after depressing the OK button on the transfer screen and user will not be allowed to transfer product until the count has been completed and posted.

If the work station being used to transfer serialized material is assigned to use a default work center in Production Work Center/Activity Setup module, when the user first opens the module, the module will use the default work center assigned for this workstation, if the transfer is "FROM" a different work center other than the default and user is NOT a supervisor or has the option "Allow Changing Default Work Center for Serial Number Transfer" box checked within the Security module, they will receive the following message:

When user depresses "OK" a supervisor approval is required to continue. After supervisor’s password is entered, the default work center will be changed to the one that the supervisor entered password for. For example: the workstation is assigned to use “TU” as default work center, now if user chooses to use “AI” to transfer, the system will ask for supervisor’s password, if user cancels the password, the default work center will still be “TU”, but if the supervisor enters his/her password on this machine, the default work center will be changed to “AI”. If now the user tried to transfer from “TU” again, the system will ask for supervisor’s password again. If user exits the module and come back, the default work center will be “TU” again. |

| 1.2.5. FAQ's - SFT |

| Facts and Questions for the Shop Floor Tracking Modules |

| 1.3. Work Order Management |

| 1.3.1. Work Order Management |

| 1.3.1.1. Prerequisties for WO Mgmt | ||||||||

Prerequisites for Entering a New Work Order

After activation, "Work Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

A Customer database must be established in the Customer Information module. The Bill of Material must be entered (AVL optional)

|

| 1.3.1.2. Introduction for WO Mgmt |

The Work Order Module is used to record the details required for initiating assembly of products. The whole purpose of the WO Release is for various departments to fulfill their part of the task of releasing the WO on-line to avoid doing it manually. This is a very valuable feature and should not be by passed. This is why we do not allow the Work Order to be released within the Sales Order module.

The user initiates the internal flow of work actions by completing the Work Order. This order includes Kitting the material for the order, issuing the material to the production line, tracking the assembly of the order, and completing and evaluation of production performance.

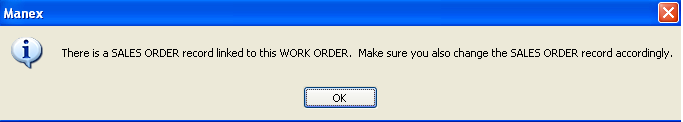

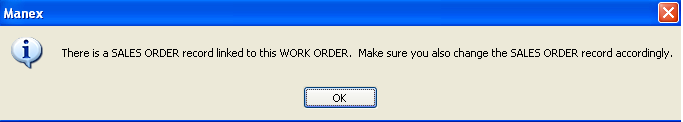

A Sales Order number will be displayed if the Work Order was created within the Sales Order Mgmt module. If you are entering a Work Order through the Work Order module, you can manually link an existing Sales Order to the Work Order. Only if the Sales Order and Work Order is for the same customer and same product number. Keep in mind though that even if you have the SO linked to a WO does not mean that the quantities will always be the same. The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. A message is displayed to the users that they will have to make the same changes to the WO.

NOTE: ManEx does not allow a Work Order to be created for a Make/Buy Product, (due to MRP calculating incorrect demand and showing incorrect message with safety stock).

|

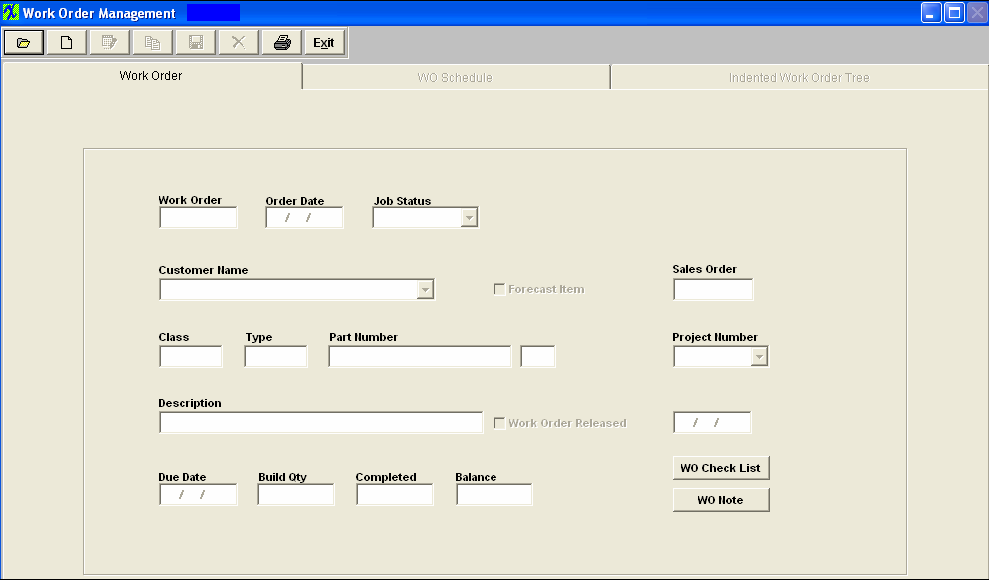

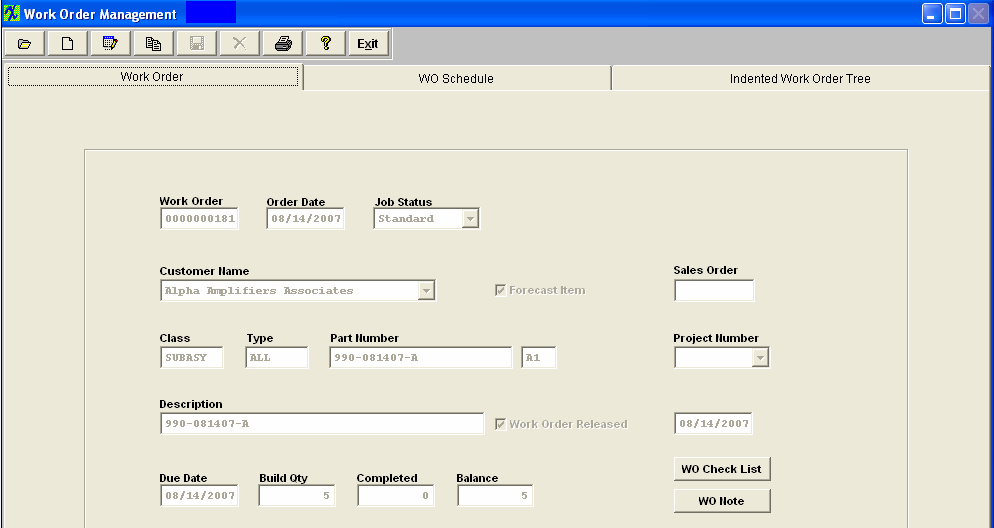

| 1.3.1.3. Fields & Definitions for WO Mgmt |

| 1.3.1.3.1. Work Order Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||

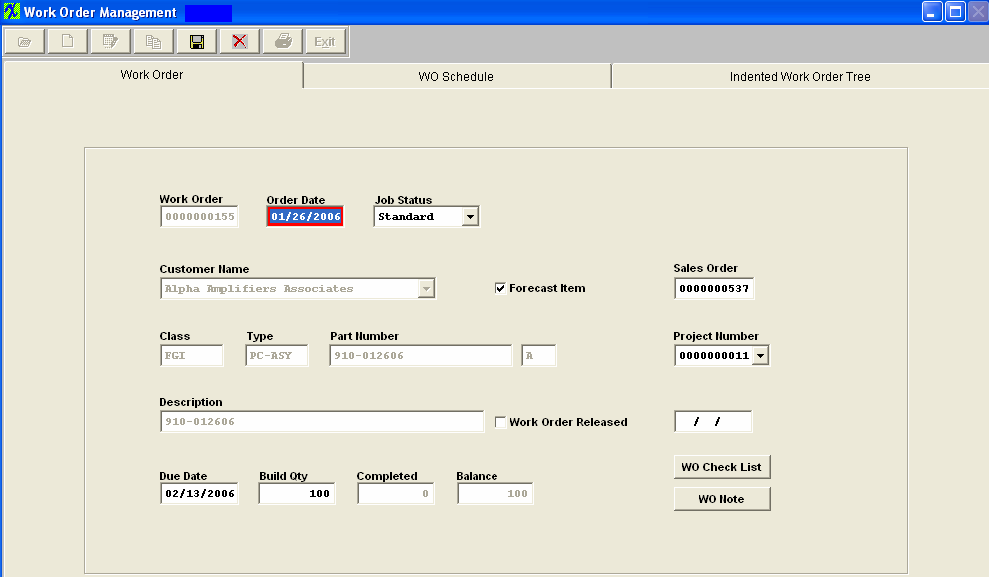

|

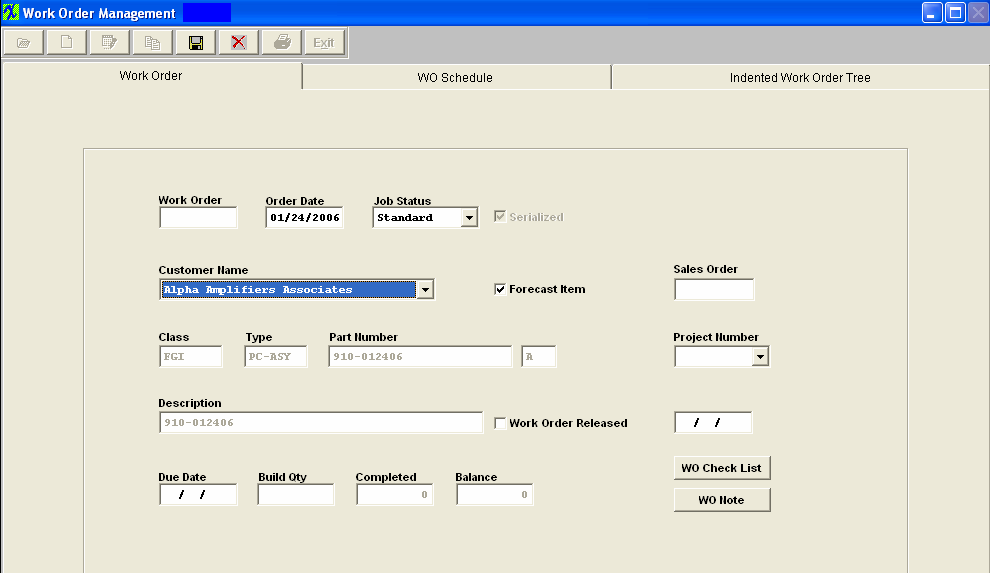

Work Order Tab field definitions

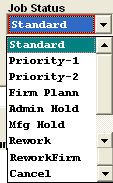

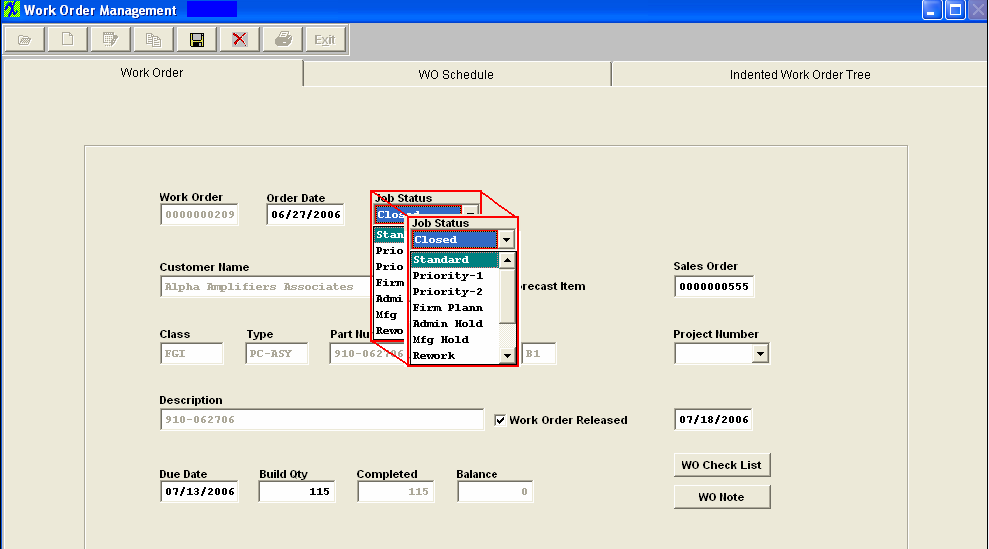

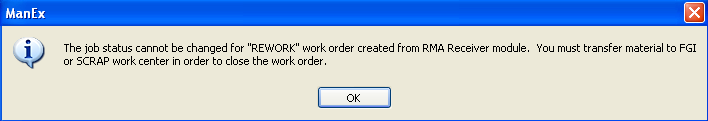

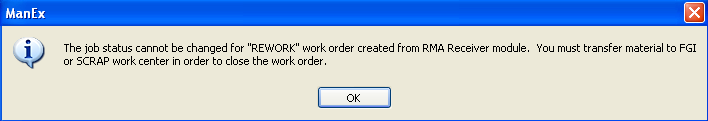

The number assigned to the Work Order. The date the Work Order was created. The status of the Work Order: Standard; Priority-1; Priority-2; Firm Plann; Admin Hold; Mfg Hold; Rework; ReworkFirm; or Cancel. Rework = users will use this status if they do not want to have it included as available to meet demands. NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status. Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled. Also, users will NOT be allowed to edit or change the Bld qty because when product is brought into the system with an RMA Receiver it is then automatically issued as itself to the kit at that time. If BOM is assigned to specific customer, and if there is CONSG part in the BOM -- Only that customer will be available in the WO customer list If BOM is assigned to specific customer, and no CONSG parts in the BOM -- Default to that customer, but all other customers are available to be selected. If BOM is not assigned to specific customer, all customer should be available. A Sales Order number will be displayed if the Work Order was created within the Sales Order Mgmt module. If you are entering a Work Order through the Work Order module, you can manually link an existing Sales Order to the Work Order. Only if the Sales Order and Work Order is for the same customer and same product number. Keep in mind though that even if you have the SO linked to a WO does not mean that the quantities will always be the same. The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. A message is displayed to the users that they will have to make the same changes to the WO. The type with the classification of the product to be assembled. The number of the make part to be assembled The revision number pertaining to the part number. The description of the part to be assembled. If this box is unchecked, you are able to kit the work order but you will not be allowed to process the material through SFT. Once this box has been checked, you will be able to move the material through SFT. If user is using the WO checklist feature this box will not be checked until all checkpoints including the "Kit Complete" have been marked off. Once the "Kit Complete" checkpoint has been checked the WO Released checkbox will be checked automatically. The date the Work Order was released. The number of units which must be completed. The number of units already completed. The number of units which still must be completed. Depressing this button will display the applicable Work Order Check List (shown below). WO Check List Screen field definitions:

A check mark in this box means that the check list item has been completed. The description of the check list item. The initials of the person who performed the check. The date of the check list performance. The time of the check list performance. |

| 1.3.1.3.1.1. Changing Work Order Status, how it affects Kit Status and MRP? |

Once a Kit has been flagged as "In Process" the Work Order management module will not allow the users to change the WO status between Standard and Rework.

WO form Modifications: When a user is trying to change the status for the work order from the "REWORK" to any other status we check the KIT data and if the KIT has only line shortages present the KIT status will become empty (instead of "KIT PROCSS"). The reason is that MRP is checking for the KIT status in order to determine whether it needs to explode the BOM to get the demands for this work order or BOM is already exploded. When changing status from anything to "REWORK" check CURVAL () because if someone else pulled the kit for that work order while the user was editing the status the kit status might already be updated to the "KIT PROCSS".

KIT form Modifications:

In the save method when line shortages are added and rework work order is selected replace start date and initials only when they are empty. When re-opening the KIT, check if work order status is rework kit status has to be "REWORK" as well. When saving, after issuing items from the inventory, do not update Kit Status if WO status is not "REWORK". For the regular WO if BOM is already exploded and shortages are created the kit status would be already updated, but if BOM was not exploded and only line shortage are present we do not want to change the kit status because MRP will only use line shortages and miss all the demands from the BOM.

|

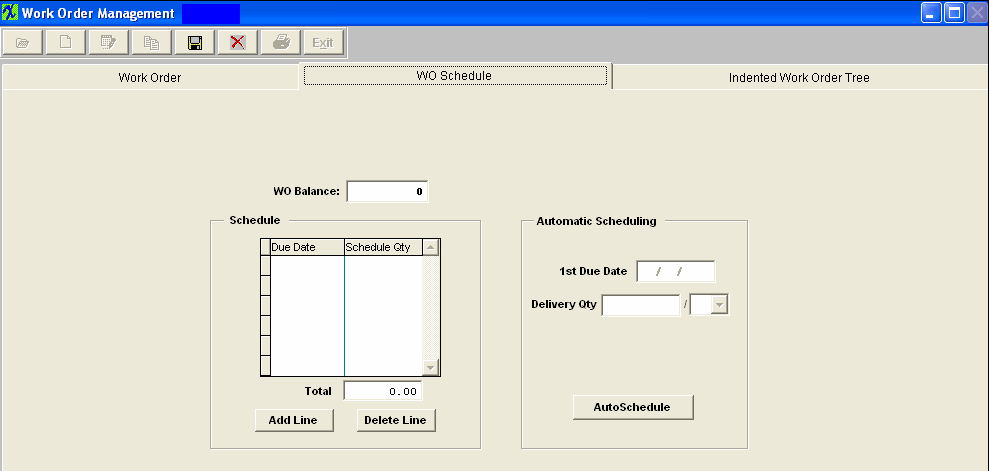

| 1.3.1.3.2. Work Order Schedule Tab | ||||||||||||||||||||

Work Order Schedule Field definitions

Schedule

Automatic Scheduling

Note: Keep in mind that this is for your reference only - this screen does not affect any other portion of the ManEx system. |

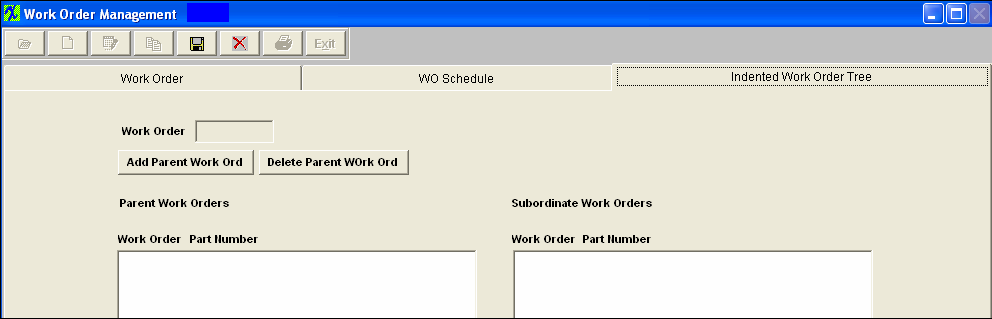

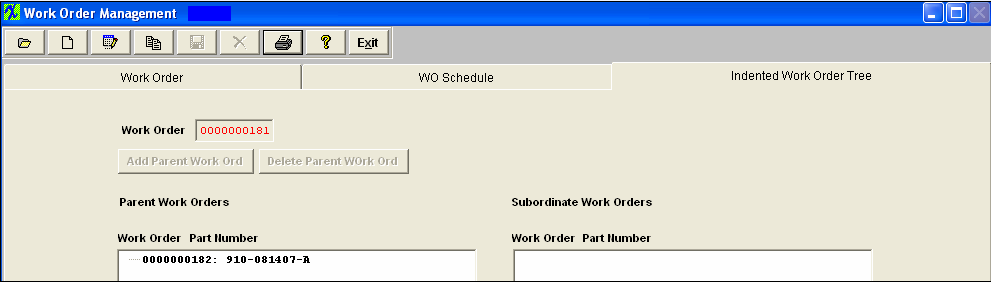

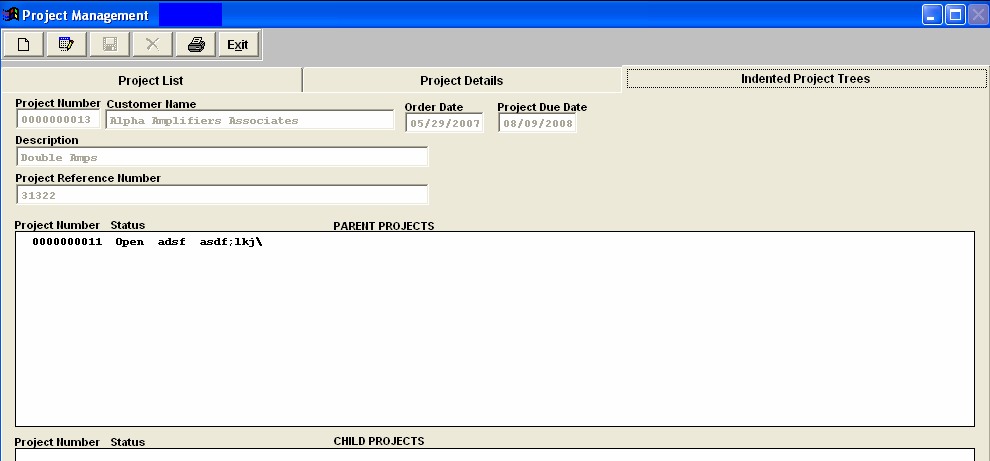

| 1.3.1.3.3. Indented Work Order Tree | ||||||||||||||

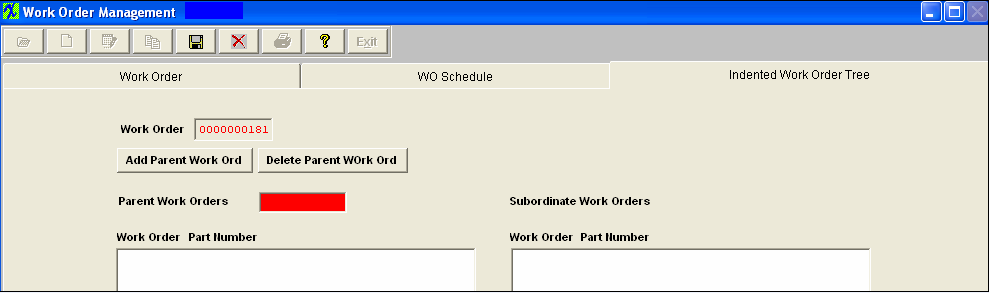

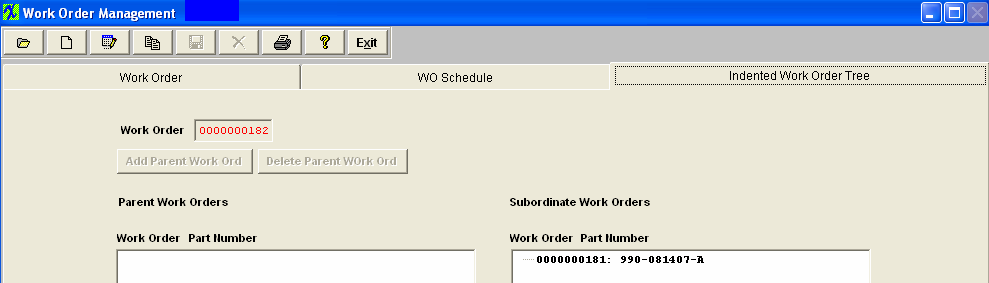

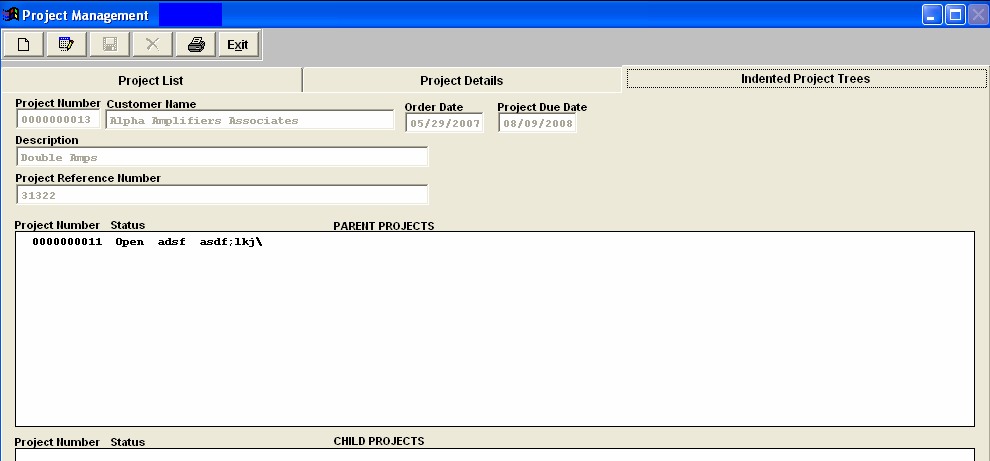

Indented Work Order Tree field definitions

Parent Work Orders

The Work Order number of the parent work order. The number of the part to which the parent work order pertains. (Subordinate) Work Orders

|

| 1.3.1.4. How To ..... for WO Mgmt |

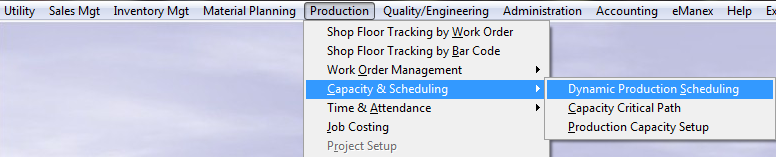

| 1.3.1.4.1. Find a Work Order | ||||||||||||||||||

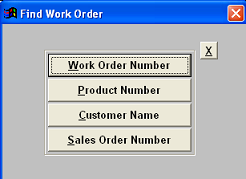

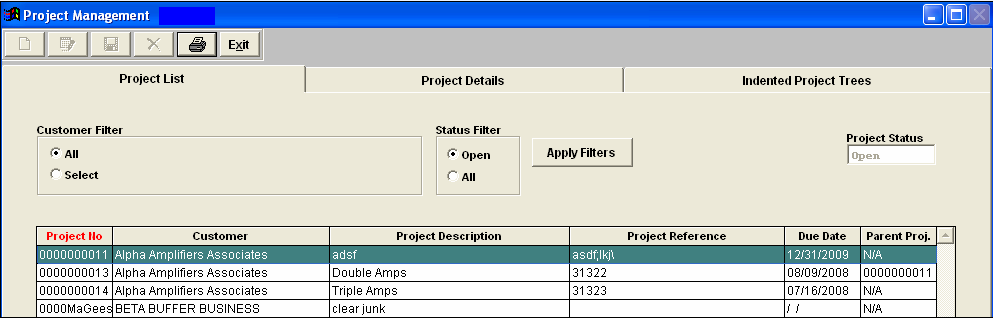

|

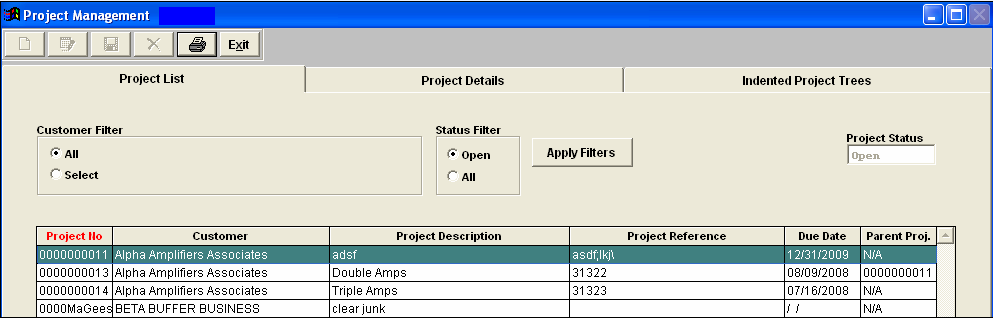

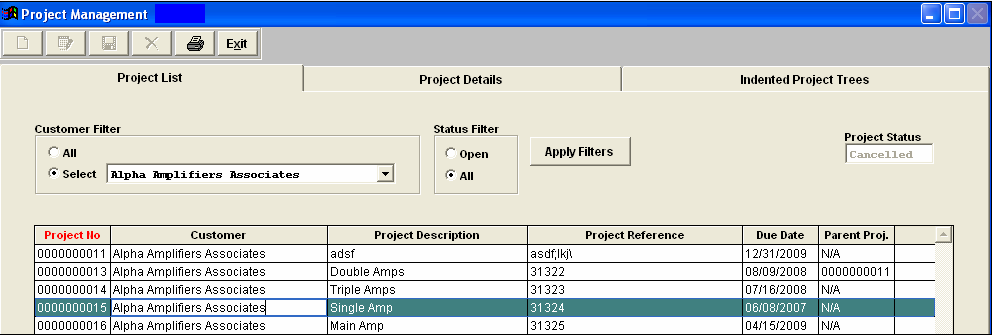

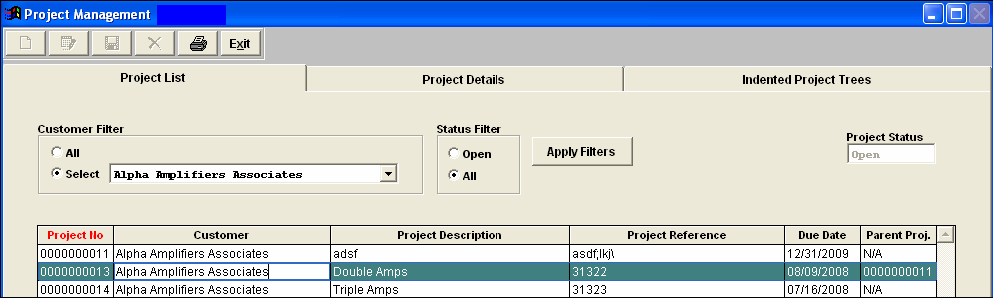

The following screen will apear:

When the screen first opens, the user is limited to only four of the eight action buttons shown: Find an existing Work Order, Add a new Work Order, Print a report, or Exit.

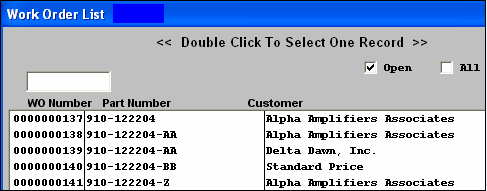

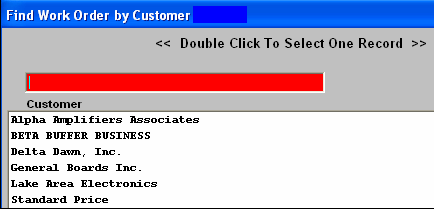

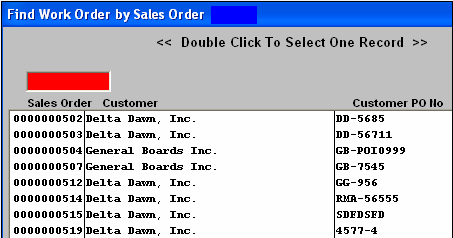

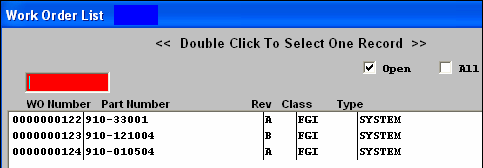

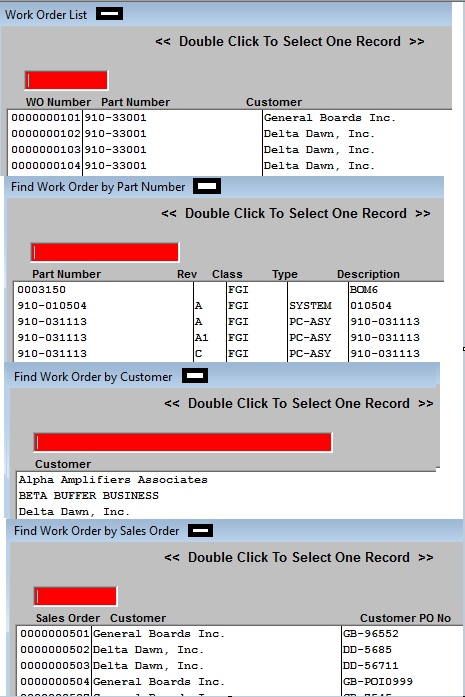

Pressing the Find Action Button displays the following sequences: User may choose to find or search for an existing order: by entering the Work Order Number, by entering a Product Number, by entering a Customer Name, or by entering a Sales Order Number.

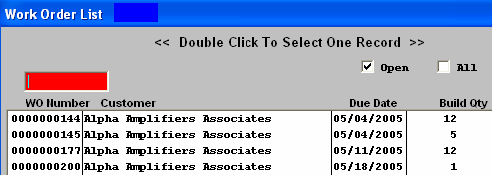

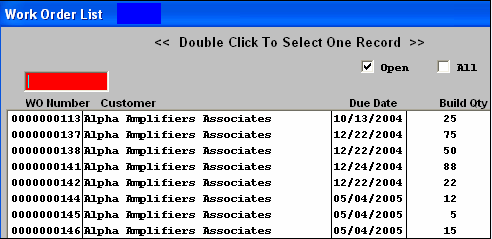

If the user elects to find an order by the Work Order Number, a screen appears listing work orders in numerical order, along with the Part Number and Customer name. User has the option to view Open orders only or All orders. The user selects the work order by either entering it into the red box, or scrolling down the list and clicking on the selected order.

|

| 1.3.1.4.2. Add a Work Order | ||||||||||||||

|

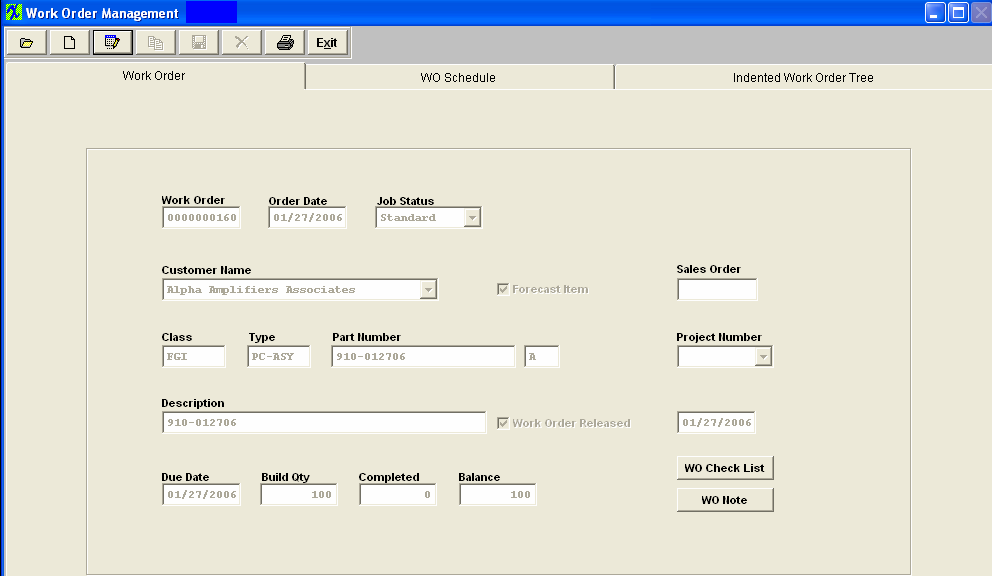

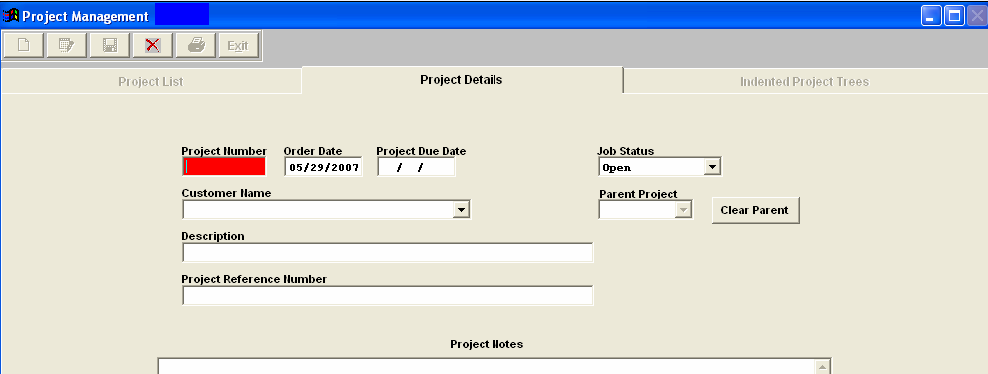

The following screen will appear:

To ADD a new work order, depress the Add Action button. The user is first prompted for the appropriate password:

Note: If the Product Number you are looking for does not appear in the Find screens listed above you may want to check the Part Source of the Product number you are looking for. ManEx does not allow a Work Order to be created for a Make/Buy Product, (due to MRP calculating incorrect demand and showing incorrect message with safety stock). And the screen is populated with information about the part number.

If the work order numbering is set to manual, the first prompt is for the Work Order Number. MANEX will enter the current system date as the Order Date, and the user may revise the date if desired

Serial Number box. If this box is checked, the units must have a unique serial number assigned. (Note: Serial numbers are assigned in the Work Order Serial Number Control Module). Sales Order Number. A Sales Order number will be displayed if the Work Order was created within the Sales Order Mgmt module. If you are entering a Work Order through the Work Order module, you can manually link an existing Sales Order to the Work Order. Only if the Sales Order and Work Order is for the same customer and same product number. Keep in mind though that even if you have the SO linked to a WO does not mean that the quantities will always be the same. The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. A message is displayed to the users that they will have to make the same changes to the WO.

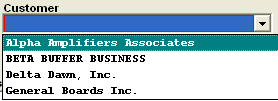

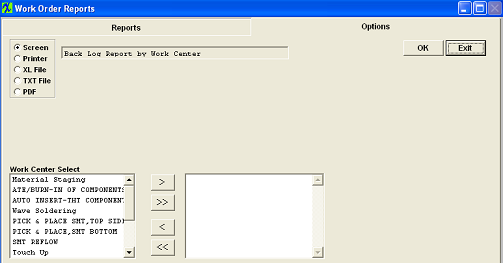

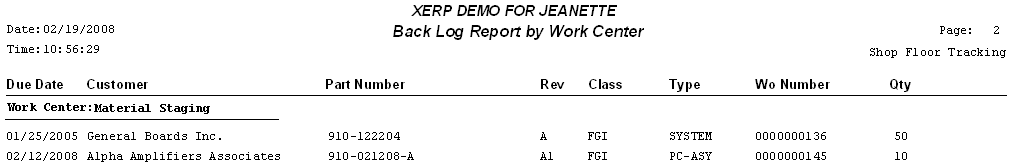

If BOM is assigned to specific customer, and if there is CONSG part in the BOM -- Only that customer will be available in the WO customer list If BOM is assigned to specific customer, and no CONSG parts in the BOM -- Default to that customer, but all other customers are available to be selected. If BOM is not assigned to specific customer, all customer should be available. If the work order is ready to start being moved through SFT (material obtained and shortages at a minimum), then the user may check the Work Order Released box, which will allow the material to be moved through Shop Floor Tracking. If MRP is used, the demand for the material will be generated, but the work order cannot begin production. To see a list of unreleased work orders, request Back Log Report by Work Center as discussed in the Reports section. After that, the user enters a Due Date for the order (the date due of finished goods), and the Build Quantity. The shipped quantity will be set to zero, and the balance due to the same as the work order build quantity. Work Order Schedule Tab After all the information has been entered in the Work Order screen, depress the WO Schedule tab. The following screen will appear: Note: Keep in mind that this is for your reference only - this screen does not affect any other portion of the ManEx system.

There are two modes available for completing a scheduled delivery for a product: Automatic and Manual. In the Automatic mode, MANEX will take a beginning date and a quantity to be delivered each period (Days, Weeks or Months) and schedule out the delivery. The following activities are available: Automatic Scheduling. Pressing this button enables the scheduling box and places the default lead time date in the 1st Due Date box. (The user may establish a default number of days in the System Setup.) The user can then use that date, or enter the first (beginning delivery) date the customer expects to receive the order. The WO Schedule tab allows the user to divide the shipment into multiple deliveries of equal parts. For example, if the order is for a total of 100 pieces, and the customer wishes delivery to be at the rate of 10 units each day, then the delivery quantity should be entered as 10. The next box allows the user to select the delivery intervals. The options are by day (DY), week (WK) or month (MO). After selecting the delivery interval, pressing the SAVE button creates a line for each delivery date in the sequence requested. In this WO Schedule tab, the user may further edit, delete or add lines. Manual Scheduling. Pressing the Add Line button enables the delivery schedule box and places the cursor in the Due Date box. The user can then enter the first (beginning delivery) date the customer expects to receive the order. Next, the Ship Date (the date the order is to leave the user’s dock) will be entered by MANEX based on the transit days entered. This date can then be modified by the user if a different date is desired. Then the scheduled quantity is entered. The Shipped quantity will be completed by MANEX when the line has material shipped against it. Additional lines may be added or deleted by pressing the appropriate button. The total number of units scheduled will be displayed at the bottom of the box, so the user can verify all units have been scheduled.

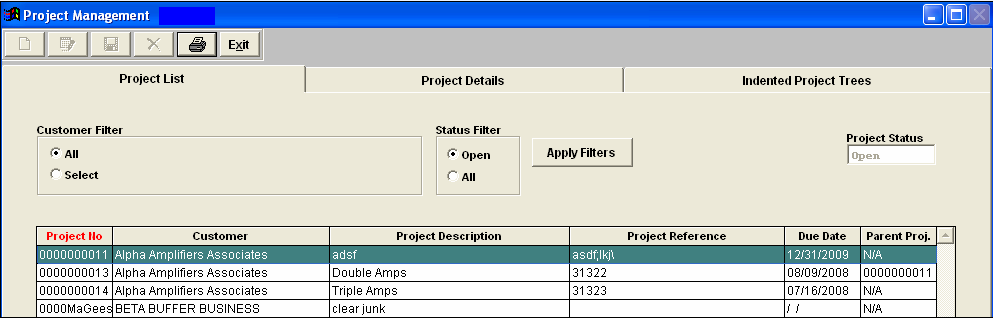

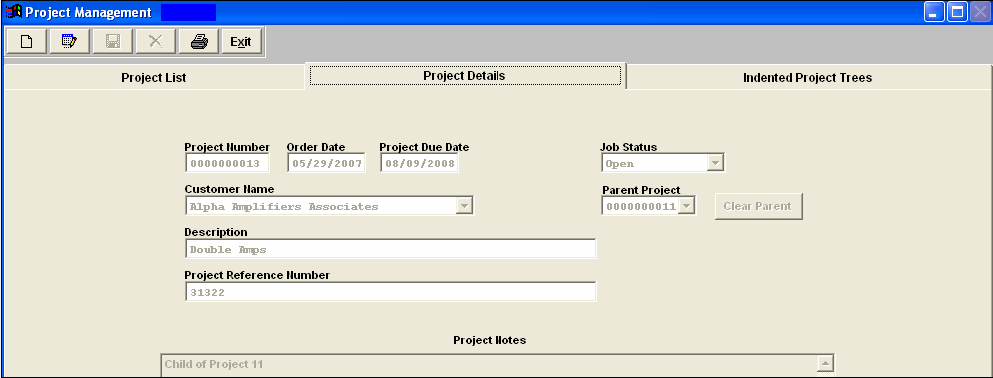

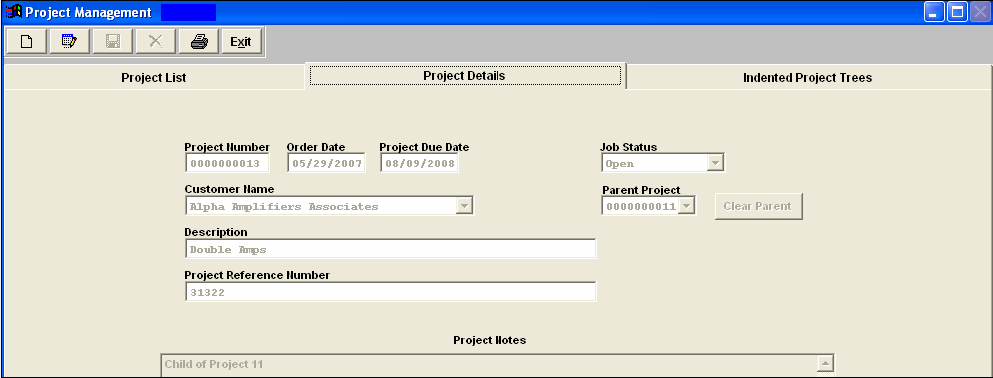

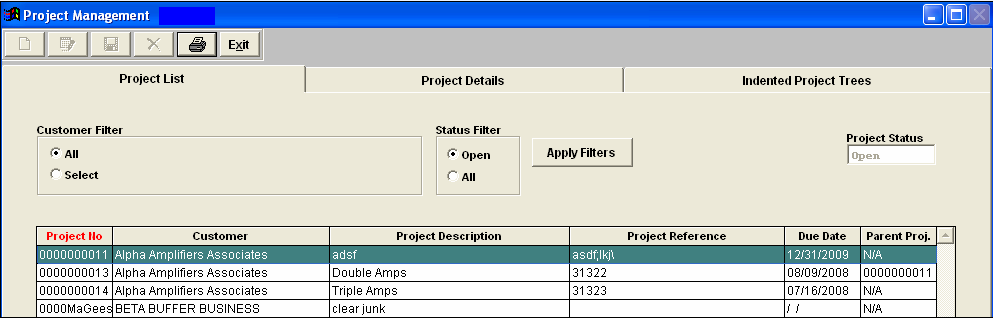

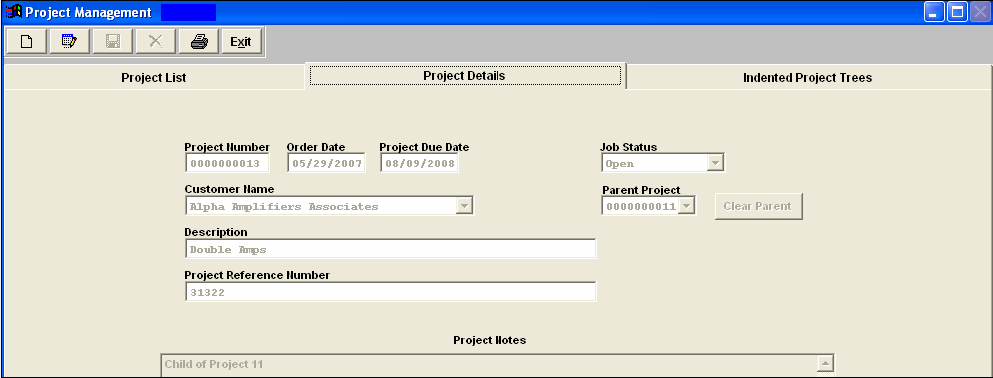

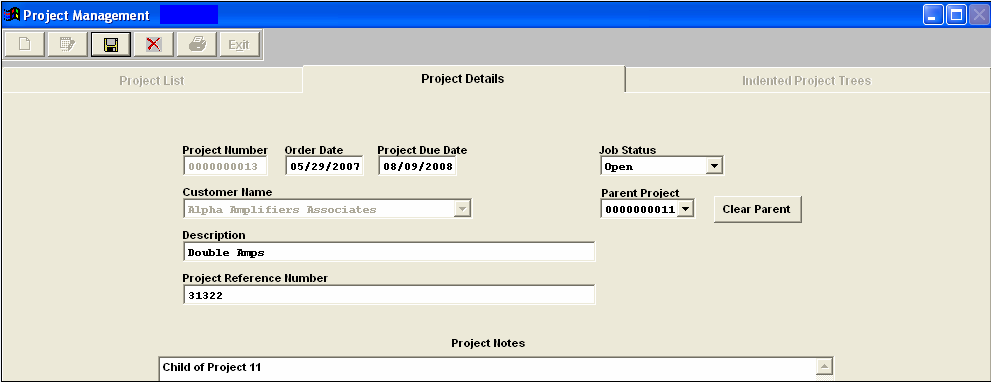

Indented Work Order Tab If the user has multi-level products, and there are other work orders upon which the current work order depends having material, then the Indented Work Order tab will allow the user to establish relationships between those work orders and the current one.

Depress the Add Parent Work Ord button. A red box will appear, as illustrated below:

Type the Parent Work Order number into the box. After entering a valid work order, the user is presented with a screen completed with the work order information, but with a blank work order number (if numbering is manual). After entering the work order, the schedule and quantity, the new work order may be saved. Once all information is entered, the user may either Save by depressing the Save Record action button, or Abandon Changes by depressing the Abandon Changes Action buttons. |

| 1.3.1.4.3. Edit a Work Order |

Find an existing Work Order After a Work Order has been found, it may be edited by selecting the Edit Action button.

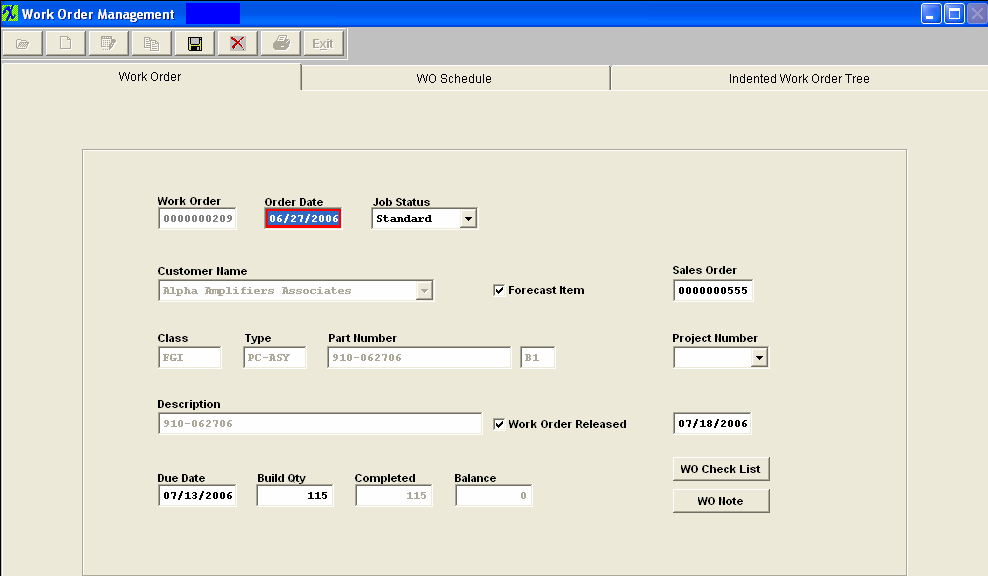

All fields available for editing will be enabled for modification. The fields which may be edited are: Order Date, Job Status, Work Order Release, Due Date, Build Qty. The user may also add a note, or add or delete a parent work order. Note: Once a Kit has been flagged as "In Process" the Work Order Management module will NOT allow the users to change the Work Order status between Standard and Rework. For further detail see Article #2691 .

If the user wishes to change the Build Qty on a Work Order in process on the Floor the system will provide the users with what work center location they would like to reduce the qty from to match the new Work Order Qty. At this point the Kitting module will still show the original WO qty and what was picked. But if they depress the Update Kit button it will refresh the kit based off of the new WO Qty and now the qty that was adjusted will become WO-WIP. Which means it is available to fulfill any other demand that might be out there. Then upon Closing the kit the user has the option to cost that wo-wip to the kit or return it to stock. If they return it to stock it will have no affect on their Mfgr Variance for that work order.

If the user is going to reduce the Build Qty on a Work Order that will change the WO status to "CLOSED", upon Closing the kit the system will take the original quantity pulled to the kit and automatically cost the different to the kit without giving any option to the user. So, if the user does NOT wish to have the extra parts automatically costed to the kit upon closing they will need to change the WO status from "CLOSED" to "STANDARD", return to the Kitting module and "UPDATE" the kit, then return to the WO and edit/save the record without making any changes – the Status will automatically update to Closed. See attached word document <<PS_961_090427.docx>> for an example.

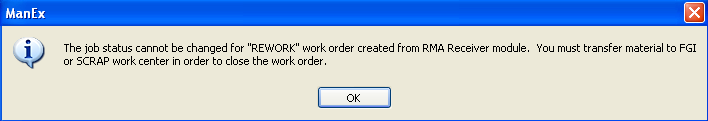

NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status, due to the fact that when the Work Order is created from RMA module all kitting, serial number, .... records are created and if user changes the WO status the system may loose track of these records. User will receive the following message if they try to change the job status on a Work Order that was originated from an RMA Receiver.

Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled. Also, users will NOT be allowed to edit or change the Bld qty because when product is brought into the system with an RMA Receiver it is then automatically issued as itself to the kit at that time. At the conclusion of the modification process, the user may either Save the changes by depressing the Save changes action button or Abandon the changes by depressing the Abandon changes action buttons. The following message will be displayed to the user if a SO is linked to a WO:

NOTE: The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. |

| 1.3.1.4.4. Cancel A Work Order |

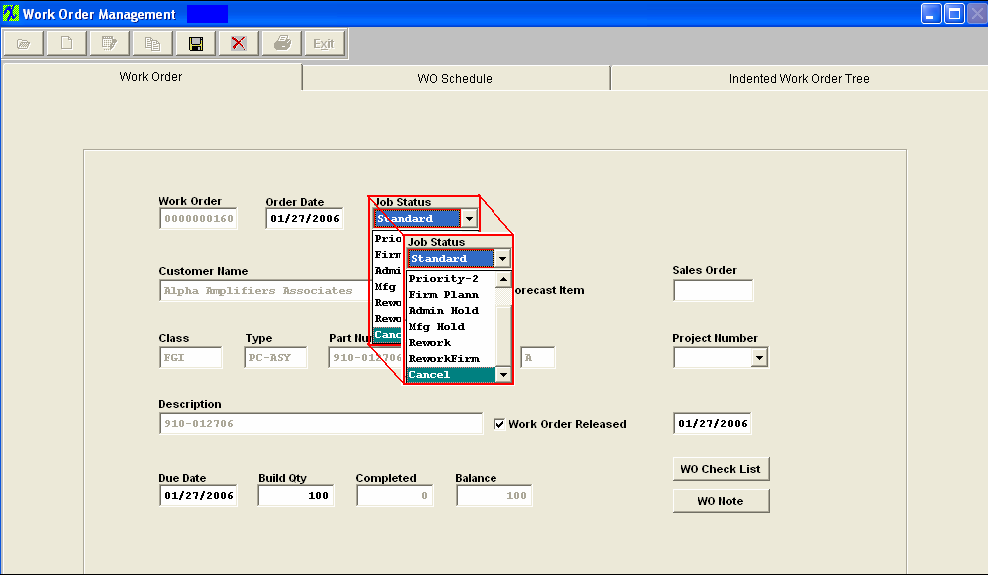

Find the Work Order you want to cancel.

Depress the Edit button and enter your password. Depress the arrow next to the Job Status and change the Job Status to Cancel as displayed below.

Depress the Save action button. Note: You can’t Cancel a Work Order that has been kitted. If you must cancel a kitted Work Order, go into the Kitting & Shortage Mgmt module and de-kit the order.

NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status, due to the fact that when the Work Order is created from RMA module all kitting, serial number, .... records are created and if user changes the WO status the system may loose track of these records. User will receive the following message if they try to change the job status on a Work Order that was originated from an RMA Receiver.

Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled or re-opened. |

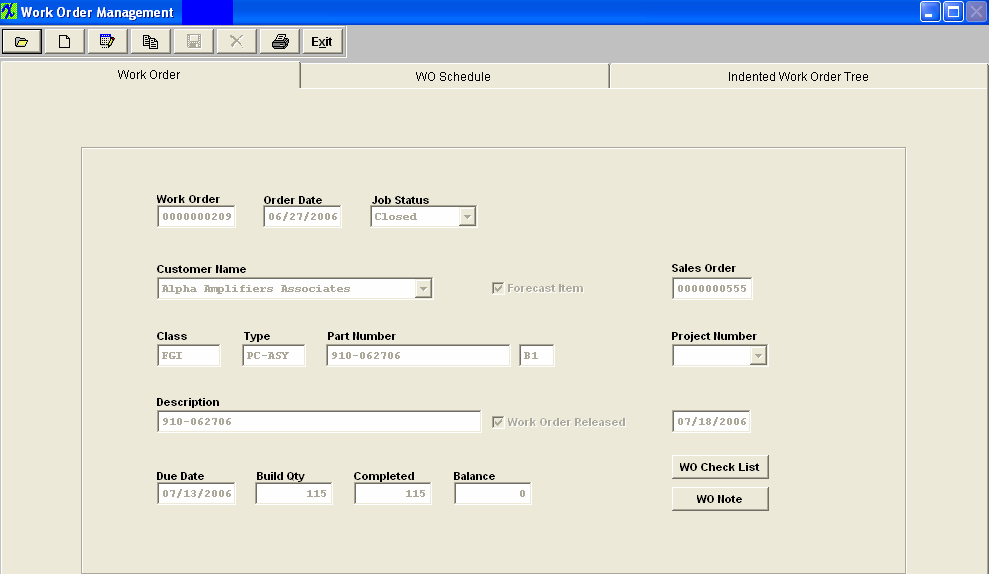

| 1.3.1.4.5. Manually Re-Open or Close a Work Order |

Find a Closed Work Order

Depress the Edit action button and change the Job Status from Closed to Standard

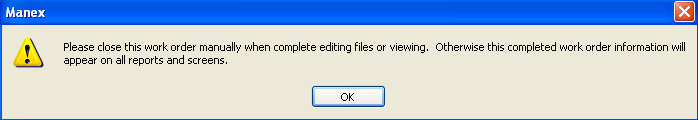

User will receive the following warning

Depress OK then Depress the Save record action button, The following message will be displayed to the user if a SO is linked to a WO:  NOTE: The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other. Depress OK WO status is changed from closed to Open/Standard

To Manually Close Work Order Find Work Order with Job Status anything other than "Closed" Dperss the Edit action button (do not edit anything)

Depress the Save record Action button. The following message will be displayed to the user if a SO is linked to a WO:

NOTE: The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other.

Depress Ok and Job Status will automatically change to Closed

NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status, due to the fact that when the Work Order is created from RMA module all kitting, serial number, .... records are created and if user changes the WO status the system may loose track of these records. User will receive the following message if they try to change the job status on a Work Order that was originated from an RMA Receiver.  Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled or re-opened.

|

| 1.3.1.4.6. Add a Parent Work Order |

Indented Work Order Tab If the user has multi-level products, and there are other work orders upon which the current work order depends having material, then the Indented Work Order tab will allow the user to establish relationships between those work orders and the current one. Find an existing Child Work Order

Go to the Indented Work Order Tree tab. Depress the Edit button. Depress the Add Parent Work Ord button. A red box will appear, as illustrated below:

Type the Parent Work Order number into the box. The Parent Work Order number will disappear and will not appear in the Work Order box until the Save record action button is depressed as displayed below. Depress the Abandon changes Action buttons to abandon changes.

Find the Parent Work Order, go to the Indented Work Order Tree tab and the Child Work Order linked will be displayed:

|

| 1.3.1.5. Reports for WO Mgmt | ||||||||||||||||||

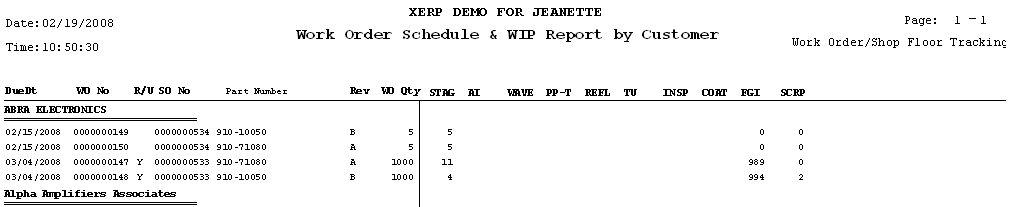

Work Order Schedule & WIP Report by Customer

The following report will print: This report provides a listing of the status of each job on the production floor. With this report, users can see where each board is in production.

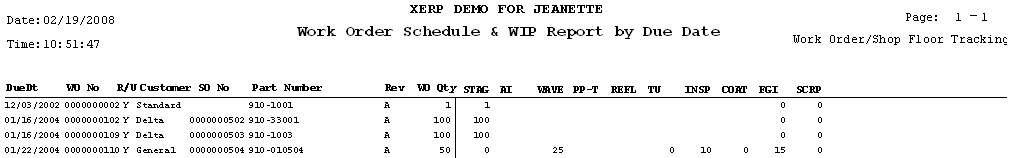

Work Order Schedule & WIP Report by Due Date

The following Report will print: This report provides a listing of the status of each job on the production floor. With this report, users can see where each board is in production by Due Date.

Back Log Report by Work Center

The following report will print:

Work Order Summary

The following report will print:

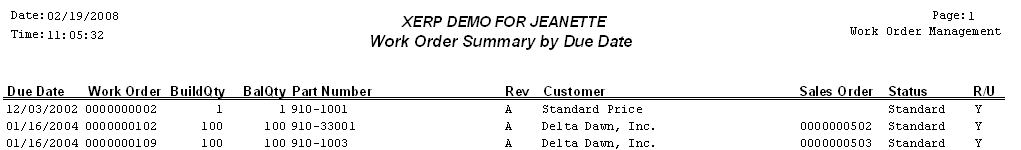

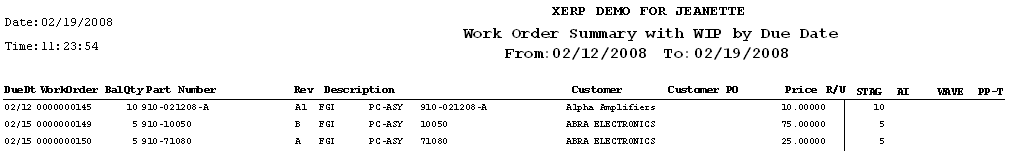

Work Order Summary with WIP by Due Date

The following Report will print: The report can show up to 11 work center information at one time, if user has more than 11 work centers, the program will generate another set of report with same header information (due date, wono, build qty, part number...), with the rest of work center information (at right side). If you run by Screen, Printer...., it should appear twice too.

|

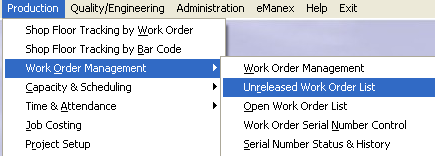

| 1.3.2. Unreleased Work Order List |

| 1.3.2.1. Prerequisites for Unreleased WO List | ||||||||||||||

Prerequisites for Viewing the Work Order Release Check list:

After activation, "Work Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access. Note: This screen is only to view the checklist.

|

| 1.3.2.2. Introduction for Unreleased WO List |

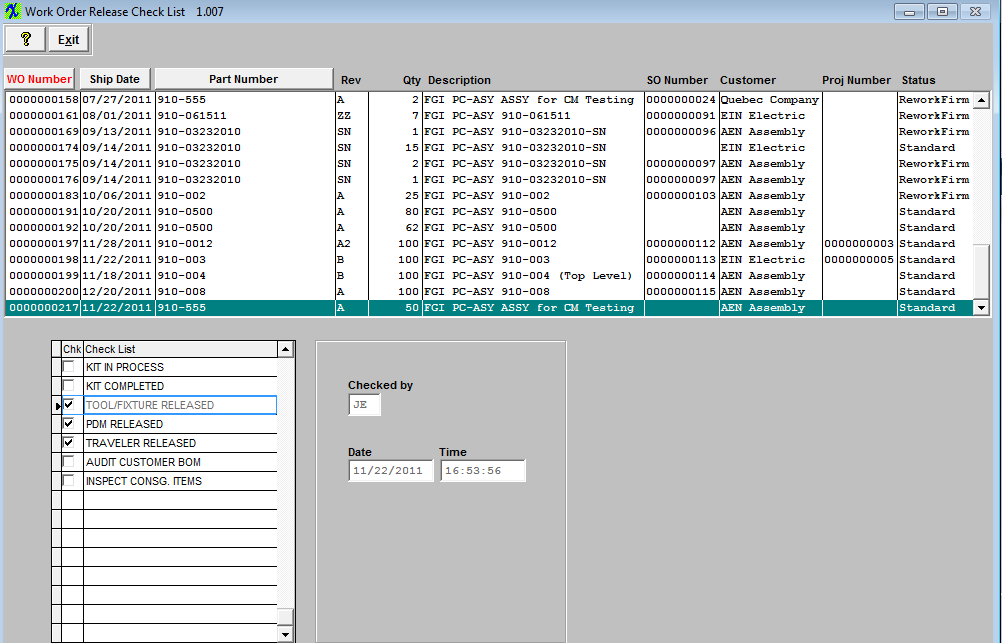

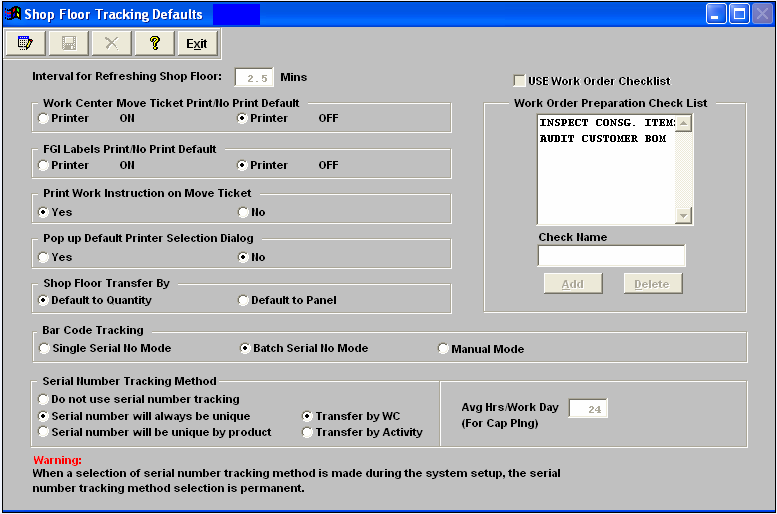

The Work Order Release Check List is originally developed in System Setup in the Shop Floor Tracking Defaults set up screen. The Work Order Release Check List displays the following: Work Order Number, Scheduled Ship Date, Part Number of the assembly, Revision Number pertaining to the assembly, Quantity in the Work Order and the Check List Items with information regarding items checked, by whom, the date and time.

The Work Center Check List Module is used to record that a process detailed in a check list established for the work center has been completed. The users must view and acknowledge that a procedure has been performed, and enter their concurrence and time of event. This information is created in the PDM (Product Data Management) module.

The overall purpose of the Work Order Release Check List is to provide better kitting status control and at the same time make the job a little easier for Production Control/Schedulers by automatically checking to see if various affected departments have checked off their part of the list. Then once everything has been checked, the work order can be released so scheduling can be started and material can start moving through SFT.

|

| 1.3.2.3. Fields and Definitions for Unreleased WO List | ||||||||||||||||||||||||||||||

Highlight the line you are interested in viewing. The information at the bottom of the screen will display the check list items associated with the assembly. If the item listed has been performed, there will be a check mark at the left of the item and the user may view the name of the person who performed the checking plus the date and time checked.

|

| 1.3.2.3.1. Check List Items | ||||||||||||||||

|

|

| 1.3.2.4. How To ...... for Unreleased WO List |

| 1.3.2.4.1. View and Approve Work Order Checklist Items | ||||||||||||||||

The following screen will appear:

Highlight the line you are interested in viewing. The information at the bottom of the screen will display the check list items associated with the assembly.

If the item listed has been performed, there will be a check mark at the left of the item and the user may view the name of the person who performed the checking plus the date and time checked. User will NOT be allowed to process material through SFT until the Work Order Release box within the Work Order module has been checked off (Note: this box will NOT be checked until ALL checkpoints including the "Kit Complete" have been checked). This is to prevent moving material in SFT until everything has been approved. NOTE: If a user has the Work Order Checklist feature active and tries to use the PO Receiving shortage and issues feature within the PO Receiving, it will not recognize the shortages until the kit has been flagged as "Kit Complete". It is designed this way because the user will not know if the parts are short until the kit is completed.

You may have parts in the inventory and have not pulled them to the kit yet. If you allow seeing the shortage (which may not be a shortage because parts are not pulled yet) from the PO receiving, the receiver may be trained to automatically issue to the shortages first, but it may not be a shortage because parts have not been pulled from inventory, so how would they know if it is a real shortage or just not pulled from inventory yet.

|

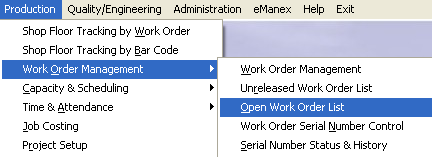

| 1.3.3. Open Work Order List | ||||||||||||||||||

The list of Open Work Orders displays the following: Work Order Number, Customer Name, Sales Order Number, scheduled Due Date, Job Status (Standard, Priority, Administrative Hold, Rework, etc.), Build Quantity, Completed Quantity and Balance.

Selecting Open Work Order List will bring up the following screen:

Field Defintions

|

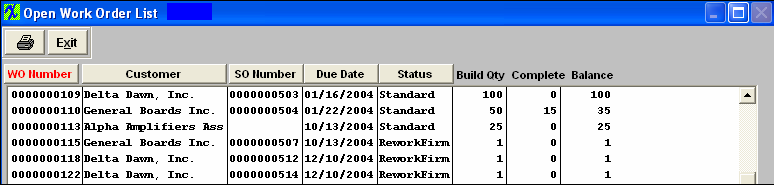

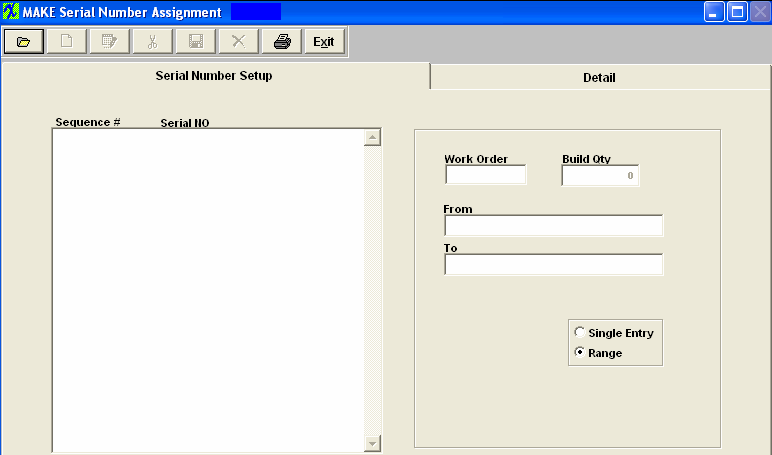

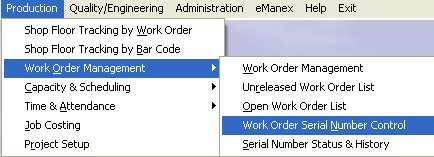

| 1.3.4. Work Order Serial Number Control |

| 1.3.4.1. Prerequisites for WO SN Control | ||||||||||

There must be a Work Order. The part number must exist for a product or part. The Bill of Materials must be entered (AVL optional). The method must have been set up in Shop Floor Tracking Defaults. The option must have been selected in the Inventory Control Management Module |

| 1.3.4.2. Introduction for WO SN Control |

The Work Order Serial Number Control Module is used to set up serial numbering for a particular Work Order. |

| 1.3.4.3. Fields & Definitions for WO SN Control |

| 1.3.4.3.1. Serial Number Setup Tab | ||||||||||||||||

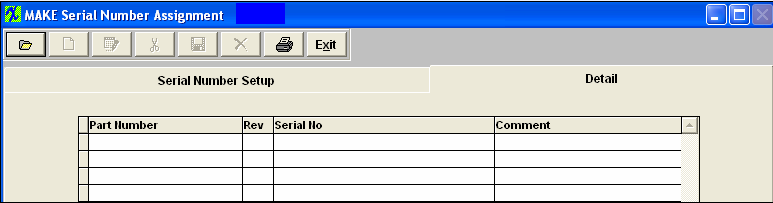

Serial Number Setup Fields & Definitions

|

| 1.3.4.3.2. Detail Tab | ||||||||

|

| 1.3.4.4. How To ..... for WO SN Control |

| 1.3.4.4.1. Find a Work Order for Serial Number Setup | ||||||||||||||||||

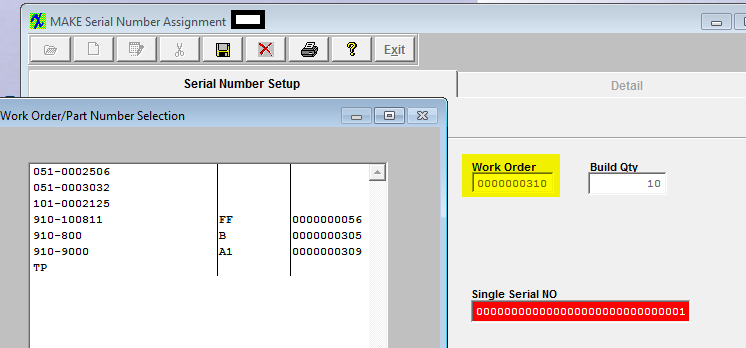

|

The following screen will apear:

Pressing the Find Action Button displays the following sequences: User may choose to find or search for an existing order: by entering the Work Order Number, by entering a Product Number, by entering a Customer Name, or by entering a Sales Order Number.

If the user elects to find an order by the Work Order Number, a screen appears listing work orders in numerical order, along with the Part Number and Customer name. User has the option to view Open orders only or All orders. The user selects the work order by either entering it into the red box, or scrolling down the list and clicking on the selected order.

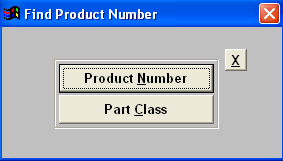

When the user elects to find an order by the Product Number, a screen appears listing part numbers in numerical order. The user selects the part number by either entering it into the red box, or scrolling down the list and clicking on the selected part.

|

| 1.3.4.4.2. Assigning Serial Numbers to Work Order | ||||||||||

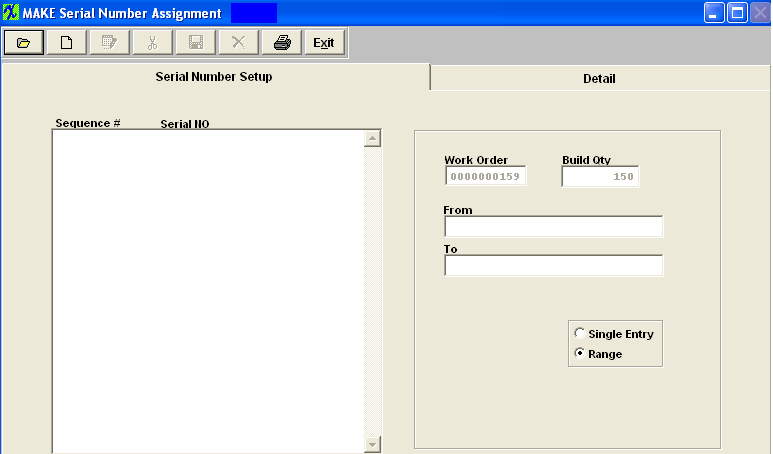

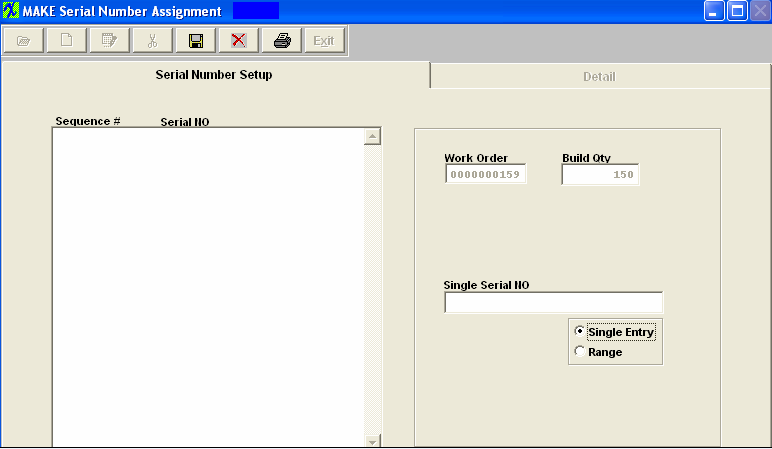

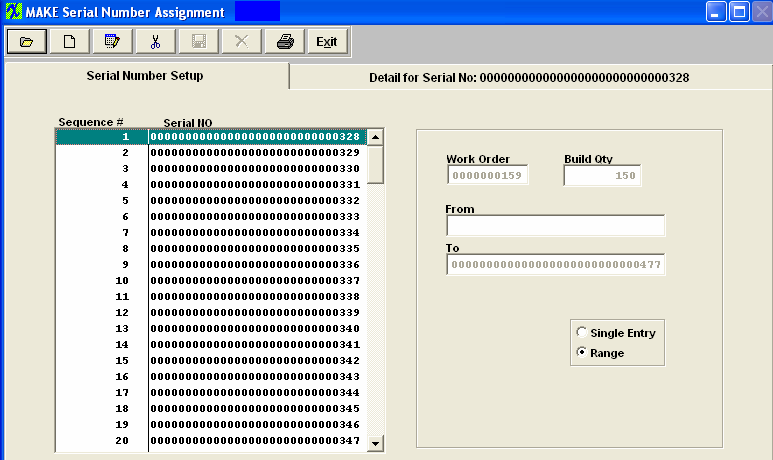

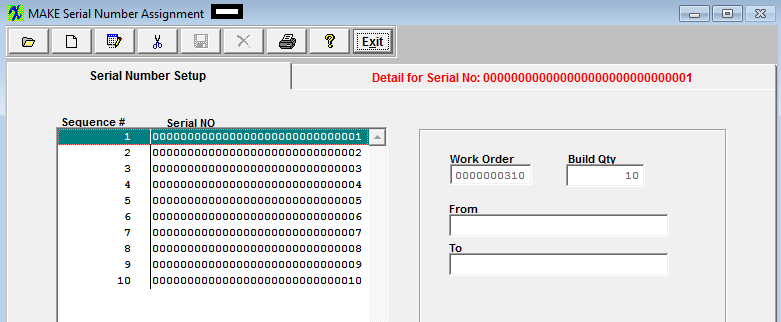

After Finding the Work Order. The following screen will appear, listing the Work Order and Build Qty. The Add record action button also becomes available.

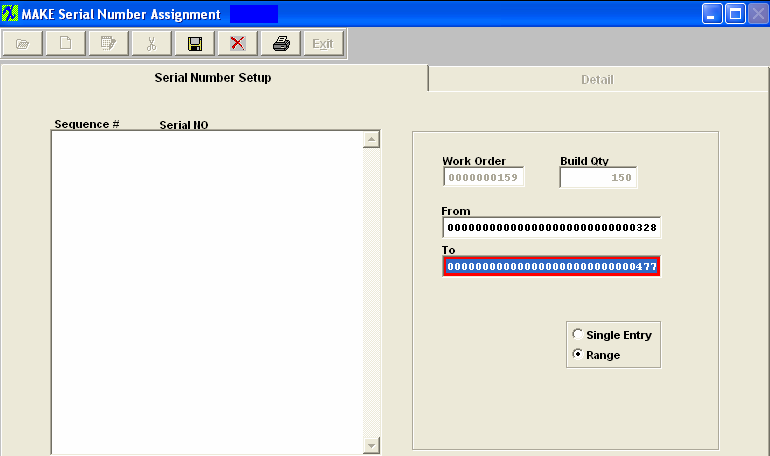

Depress the Add record action button. Type in the password. Select Single Entry or Range method of assigning serial numbers by choosing the appropriate radial. If you select Single Entry, the following screen will display, only allowing you to type in one Serial number at a time.

If you select Range, the following screen will display, allowing you to type in From and To Serial numbers.

Note: The system will force individual entry for serial numbers with prefixes or characters. If user enters both character and number in one field, then it is hard to know which part (character or number) needs to be increased first. So the system cannot predict how the range is intended to increment: For Example if user enters a SN range of A101 to Z110. The system does not know how the user wants the range setup A101, B101, C101 or A101, B102, C103, etc.

Depress the Save record action button and the range of numbers will populate on the left side of the screen. As displayed below: If you depress the Abandon changes action button the screen will abort and the serial numbers will not be saved.

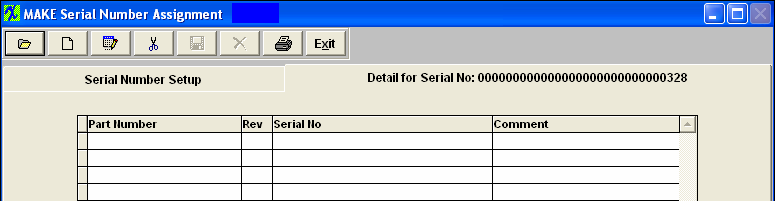

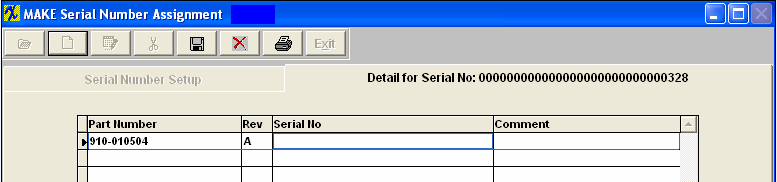

Whether or not the system will allow you to enter duplicate serial numbers will depend on the method for tracking serial numbers chosen in System Setup. At the beginning of a ManEx implementation the company must decide a method for tracking serial numbers. Once this decision has been made and set up in Shop Floor Tracking Defaults it cannot be changed. Detail for Serial Numbers To enter detail for serial numbers, highlight the pertinent serial number and then depress the Detail Tab. The following screen will appear:

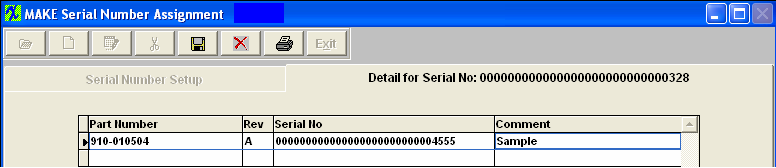

Enter in Serial No and Comments if applicable.

Depress the Save record action button to save, or depress the Abandon changes action button to abandon changes.

|

| 1.3.4.4.3. Editing Serial Numbers |

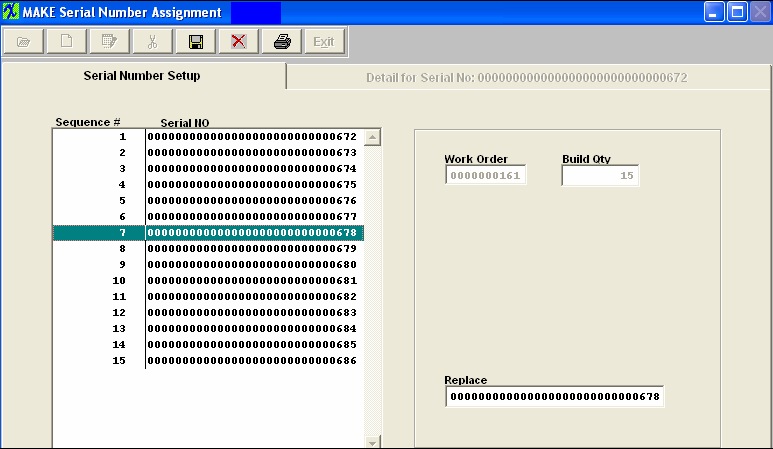

Find an Existing Work Order.

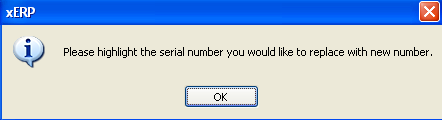

Depress the Edit action button. Enter your password. Receive the following message:

Depress OK and highlight the Serial number you would like to replace.

Type the correction into the Replace box. The Serial NO for that Sequence # will change. Depress the Save changes action button to save changes, or depress the Abandon changes action button to abandon changes. If you want to delete ALL of the Serial Numbers, depress the Delete action button. Then depress the Save changes action button. |

| 1.3.4.4.4. Invoking Serialization after the Work Order is Started |

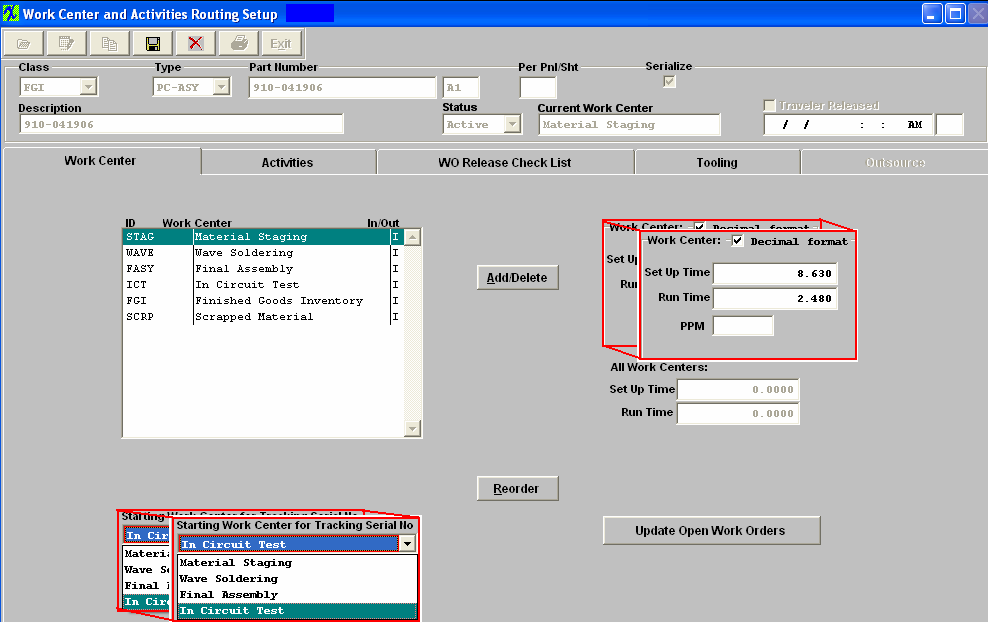

Invoking Serialization after the Work Order is Started If you already have a Work Order started and then decide to invoke serialization, in order to assign serialization to a product with an open work order, in the Shop Floor Tracking Module, the parts must all be in a Work Center which is PRIOR to the Work Center in which serialization is to be applied.

Then the Work Center can be updated and the product moved BACK to the appropriate Work Centers after the product is serialized. If the Work Order has been completed and the product is in the Finished Goods Work Center, the user may move the product back to a “non-serial Work Center” and then serialize and update the Work Order. Then the user should move the parts back into the Finished Goods Work Center. If the parts in Finished Goods were already shipped, the user can use the Inventory Handling module to temporarily increase the finished goods to the needed quantity. Then they can be backed into the Work Order. After running these parts back down the chain, the user would use Inventory Handling to take the parts back out of inventory. |

| 1.3.4.4.5. Serial Number Turn-On Process |

There is no easy way to have some work orders without serialization and some with for the SAME product. Turning on Serial Numbers on a product with OPEN Work Orders must be done carefully. Here are some processes: 1. Using the same product and the SAME Revision – ship all of the non-serial numbered product PRIOR to turning on serialization OR don’t turn on serialization until you are ready to serialize everything not shipped. To serialize everything not shipped, you will have to move product back to the Work Center where serialization is started, then turn on serialization in Work Order Traveler Setup (for further information see Article #1134) and click on the “Update Open Work Orders”. Be sure to update all of the open work orders. If you don’t, you won’t be able to ship anything that was not updated. (The items will be in a black hole and will need a programmer to get them out.) 2. Using the SAME Revision, but using the special character trick: a. Copy the product number to the new product in the Inventory Control item Master but put "00" in front of the Rev. See Article #1058 for further instructions on copying a product number. b. Then copy the existing product BOM to the new 00 revision product. See Article #1104 for further instructions on copying a BOM. c. Turn on serialization for the new 00 rev product and copy the routing from the old product. Be sure to select which Work Center you want serialization to start. See Article #1106 for further instructions on how to turn on the serialization. d. Enter all new Sales orders using the 00 revision product number. e. When you have shipped all of the old non-serialized product, inactivate the product number in the Inventory Control module. See Article #1058 for further instructions on how to inactivate a product number. 3. Using a different revision number: a. Copy the product number to the new product revision in the Inventory Control Item Master. See Article #1058 for further instructions on copying a product number. b. Then copy the existing product BOM to the new revision product. See Article #1104 for further instructions on copying a BOM. c. Turn on serialization for the new revision product and copy the routing from the old product. Be sure to select which Work Center where you want serialization to start. See Article #1106 for further instructions on how to turn on the serialization. d. Enter all new Sales Orders using the revision product number. 4. You may prefer to create new revisions using the ECO module. It can change the revision of product in Work orders in WIP, but DO NOT turn on the serialization in the ECO module. See Article #1133 for further instructions on the ECO module. a. First change the revision of the product using the ECO module b. Then move the product back to the Work Center where you want serialization to begin in the Shop Floor Tracking module. See Article #1106 for further instructions on how to turn on the serialization. c. Then turn on serialization and select “Update Open Work Orders” in the Work Order Traveler Setup and click on the “Update Open Work Orders”. Be sure to update all of the open work orders. If you don’t, you won’t be able to ship anything that was not updated.(The items will be in a black hole and will need a programmer to get them out.) |

| 1.3.4.4.6. Re-work Work Order Serial Numbers |

If the rework Work Order is created from RMA, then the user doesn’t need to assign the serial number for the Work Order. The system will automatically transfer all serial numbers to the new re-work Work Order when the user creates the RMA Receiver. For a complete discussion of the RMA process, please refer to Article #1610. If the user MANUALLY creates a re-work Work Order, the following conditions for assigning existing serial number to a re-work Work Order will be:

When a Re-work Work Order is established for a serialized product, the user may select existing serial numbers that are in inventory (finished goods) that are to be reworked. Rework Work orders will not accept NEW serial numbers. When a serial number is placed in the rework Work Order, the serial number must exist in finished goods, and the number of serial numbers transferred to the Work order must equal the quantity of assemblies for the Work order. The part number for the serial number that is moved into the rework Work Order does not need to be the SAME part number and revision as the rework Work Order. Thus, if a user wants to upgrade part number 123 rev A to part number 123 rev B, they can transfer the parts to the Work Order and identify the serial numbers transferred. Parts may also be changed to a new part number: Part Number 123 rev A can be placed into a re-work Work Order for part number 234 rev C. The only condition is that the quantity and number of serial numbers must match. Once the record is saved a line shortage for the rework work order will be created and serialized parts will be issued to the "Rework" work order and the old part number will be removed from FGI at the time the new part number is moved into WIP. See example below:

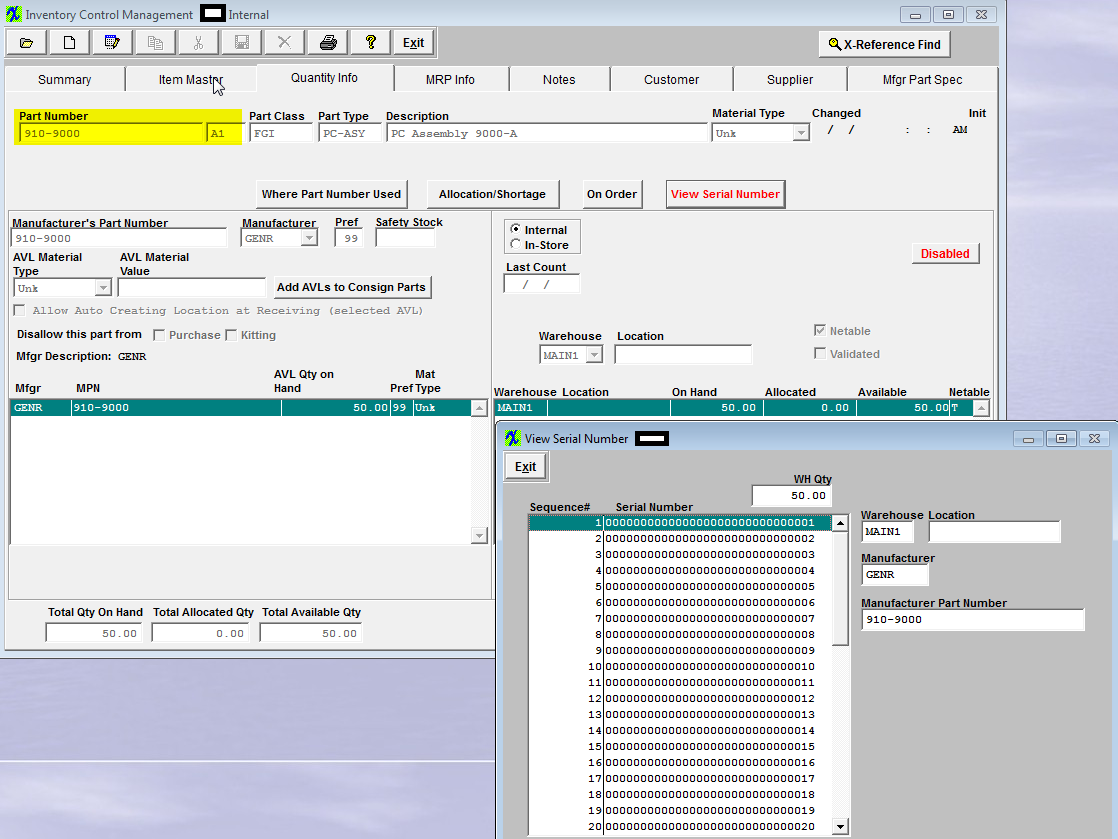

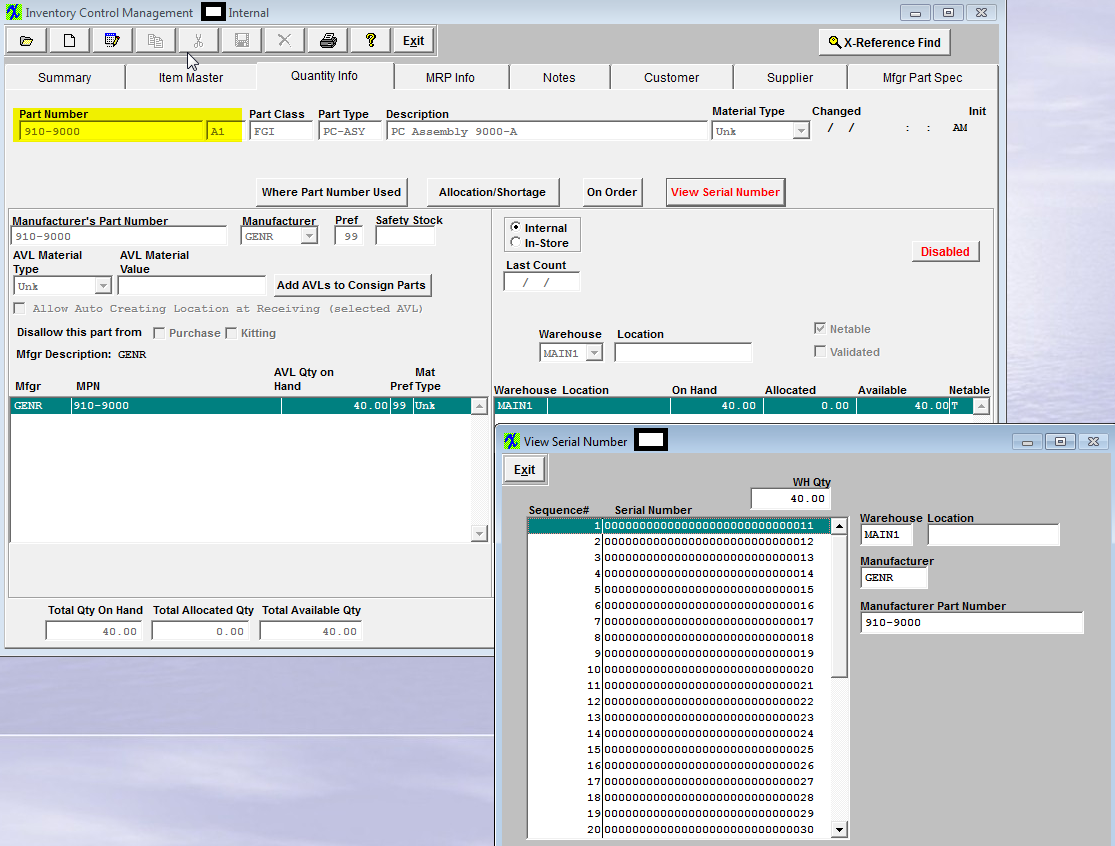

Serialized Inventory Parts (910-9000 Rev. A1) in FGI

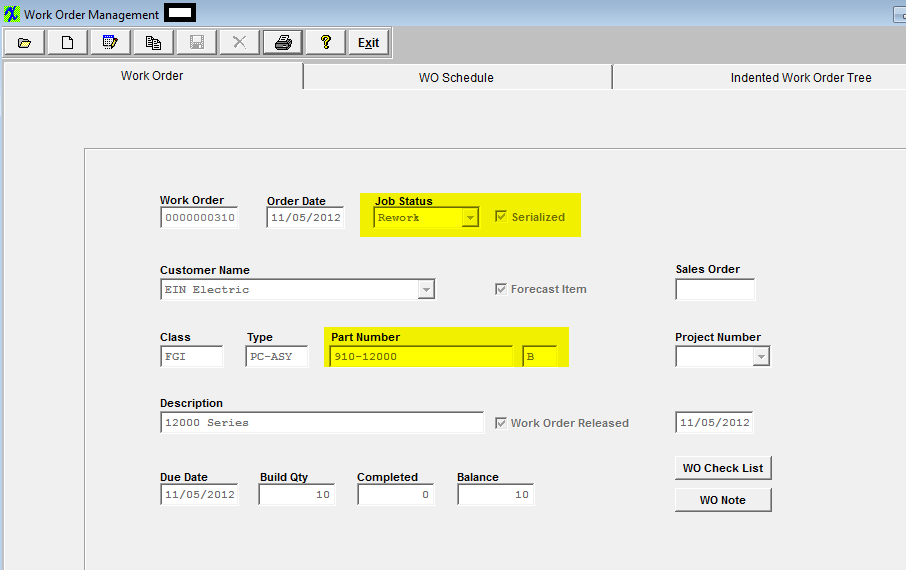

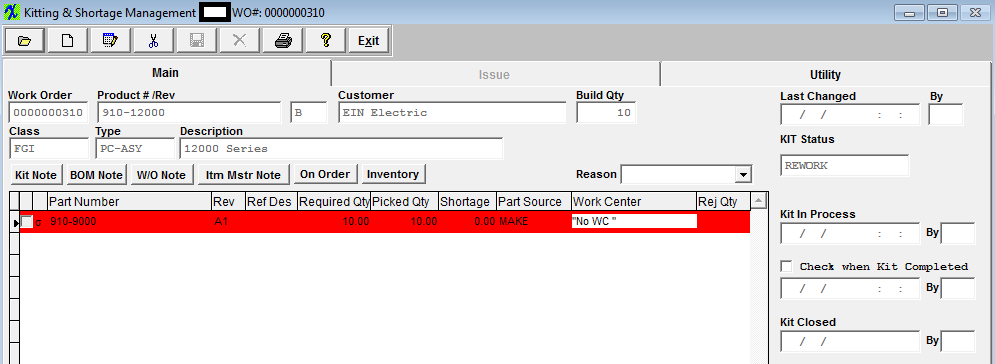

Create a Rework Work Order using a different Part Number (910-12000 Rev. B)

Enter the Work Order Serial Number Control Module and enter in the SN's you want to rework, if the SN you entered is found in other locations a screen will appear displaying all the PN's that have this SN in FGI and user can select which PN they want to pull this SN from

Once user has assigned all the SN's to this WO, they should depress the Save button

Now user can go to the Kitting Module and release the kit. The Make Parts #910-9000 Rev. A1) have already been issued to the Kit.

And Removed from FGI for the Old PN (#910-9000 Rev. A1)

|

| 1.3.4.5. Reports - WO SN Control | ||

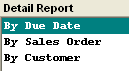

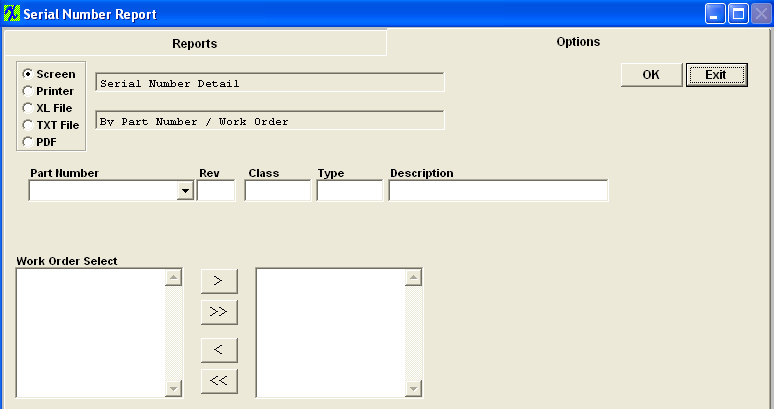

The Serial Number Setup Screen will appear. Depress the Report action button and the following report menu will appear: Decide upon the Output.Select Screen, Printer, XL File, TXT File, or PDF. Select the Detail Report you want by highlighting either By Part Number / Work Order or By Serial Number. Depress the Options Tab. The following screen will appear:

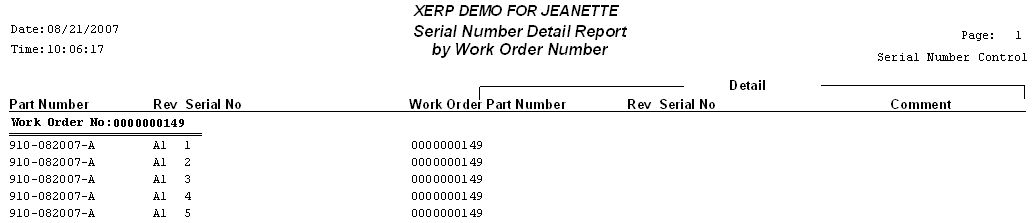

Depress the down arrow at the left of the Part Number field. A list of Part Numbers will appear. Select the appropriate Part Number. A list of all Work Orders pertaining to that Part number will display. Highlight the Work Order of interest and depress the > button. Depress the OK button. If you want all of the Work orders, depress the >> button. The leading zero's for SN's will be removed from Report. The following report will print:

|

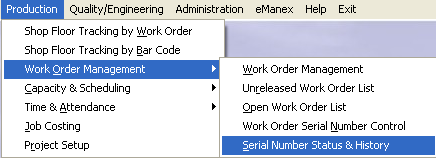

| 1.3.5. Serial Number Status & History | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

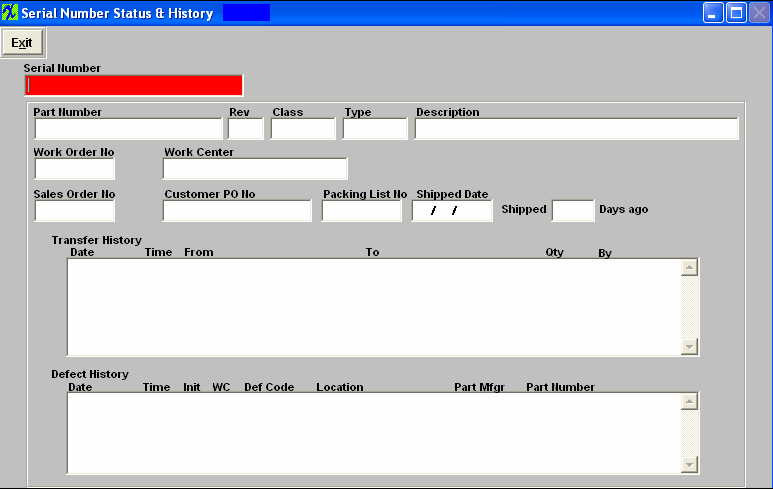

The following screen will appear:

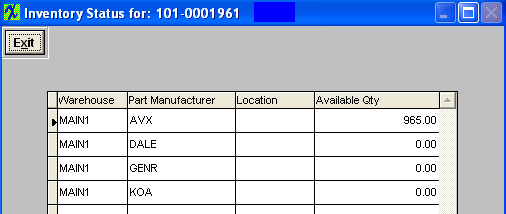

Enter a serial number in the Serial number box (red box) and all the following information will appear;

Serial Number Status & History Fields and Definitions

Transfer History Fields & Definitions

Defect History Fields & Definitions

|

| 1.3.6. FAQs - Work Order Mgmt |

| Facts & Questions for the Work Order Module |

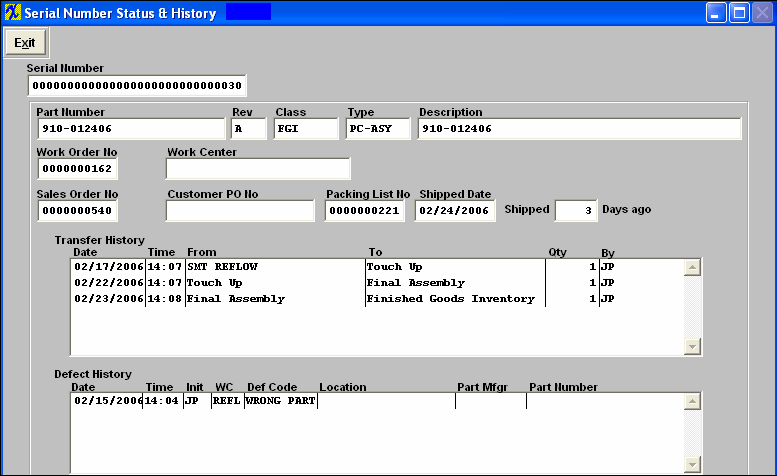

| 1.4. Capacity & Scheduling (OPTIONAL Module) |

| 1.4.1. Dynamic Production Scheduling |

| 1.4.1.1. Prerequisites for Dynamic Production Scheduling |

Setup Required:

ManEx’s standard module configuration allows most users to accomplish their daily tasks. For those users wanting to get more from ManEx by leveraging the total solutions, this is one of the optional modules available for purchase. This screen provides visibility of all open and scheduled orders. To place an order or to learn more about this specific module or any of the other optional modules please contact us at http://manex.com\contactus.aspx After activation, "Dynamic Production Scheduling" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access. User MUST activate the Re-Schedule trigger and setup e-mail for the notification. This trigger will re-schedule all of the jobs that were scheduled and still open. The purpose is to recalculate “In” and “Out” date/time for the Work Centers to make capacity view more accurate, otherwise in/out of the WC will not recalculate (only priorities of the job are) and capacity view will be always off. The Dynamic Production Schedule module is based on the following setup:

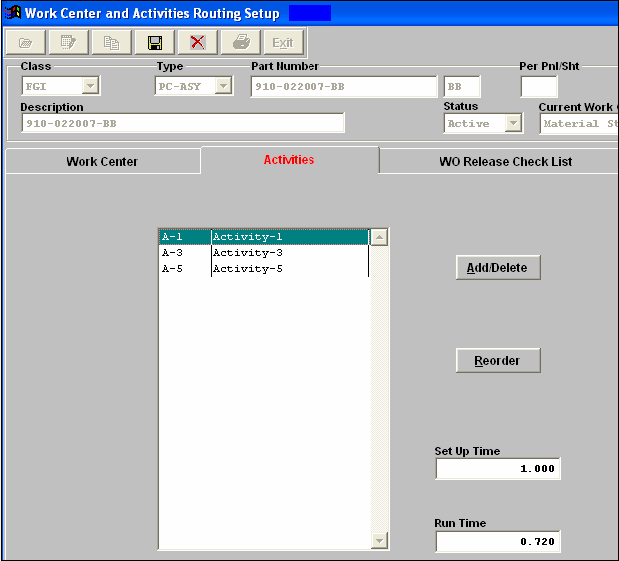

The prcoess time within the Dynamic Production Schedule module is calculated from the Setup and Run time entered in the Work Center and Activities Routing Setup.

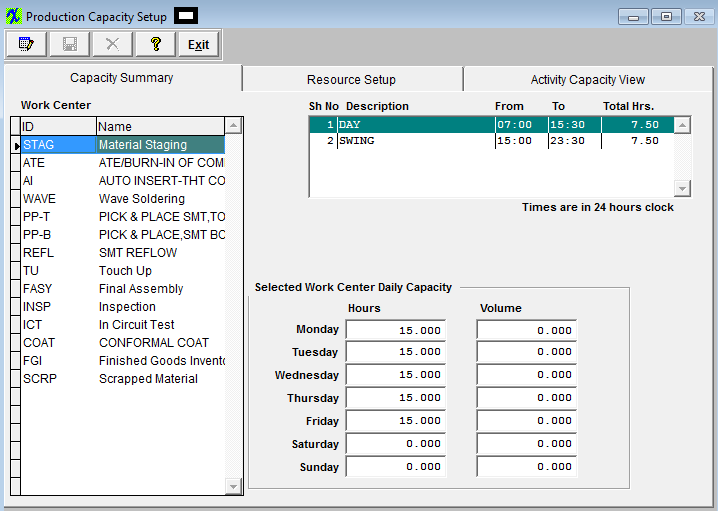

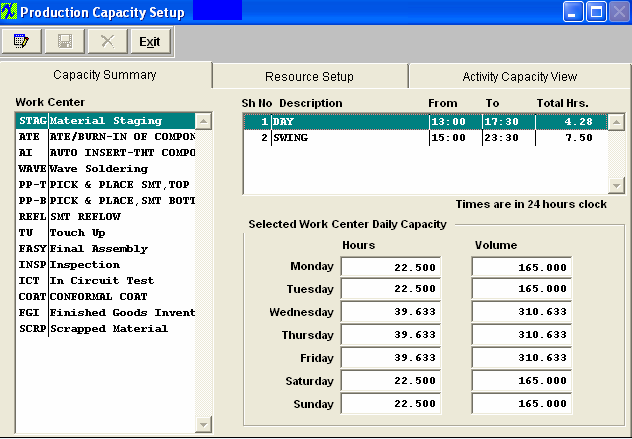

The Production Capacity Setup module.  Also check the status of the Work Order of interest – it can not be on Administrative Hold (for example), to complete the scheduling.

|

| 1.4.1.2. Introduction for Dynamic Production Scheduling |

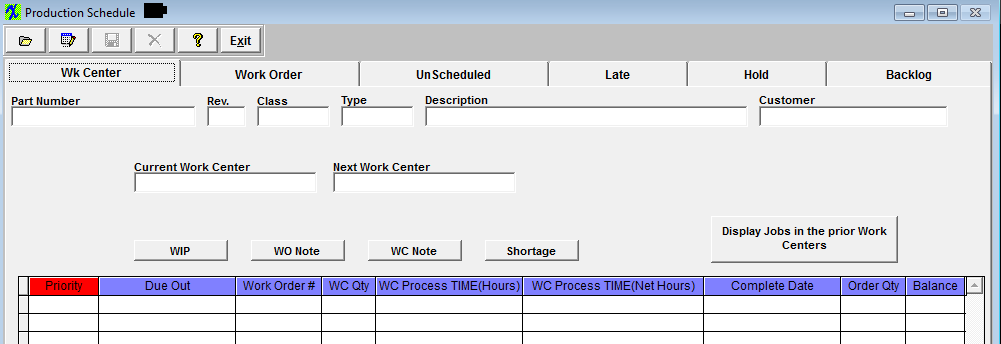

This screen provides visibility of all open and scheduled orders. Users are able to see when capacity constraints may hinder production and any time in the future. This module can provide sufficient notice to adjust the production schedule or adjust capacity to maximize production and meet promised delivery dates. It will also indicate when a job will not be completed on time based on processing time remaining and the current due date.

This module will aide in managing jobs by the work orders and/or work centers based on customer requirements (due date or complete date). The work orders can be managed by work center with the ability to prioritize within each work center. This module will allow you to view and schedule the workload to ensure deadlines are met. The system will assume that you have a 24 hour capacity shop. The idea behind the work order schedule module is not to predict when the job will move through the shop, but to accurately prioritize the job so the user knows which job has to be processed first. To get a better understanding on how this module calculates the priority for a job see the attached word document <Production Schedule Module>.

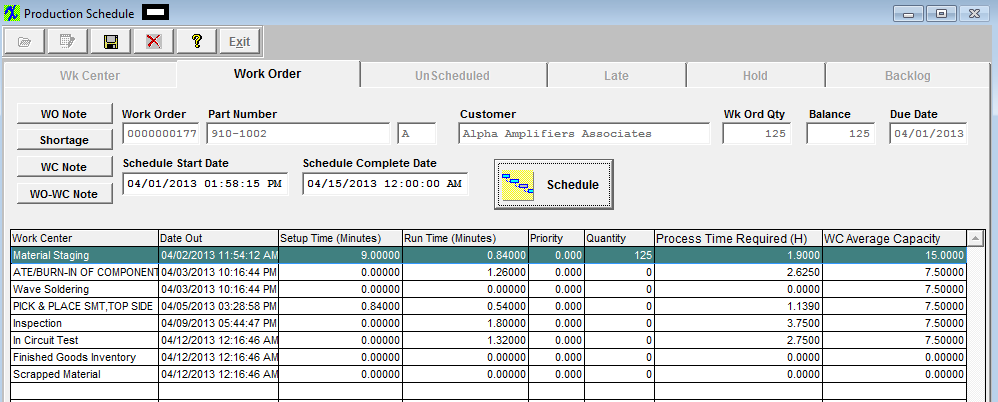

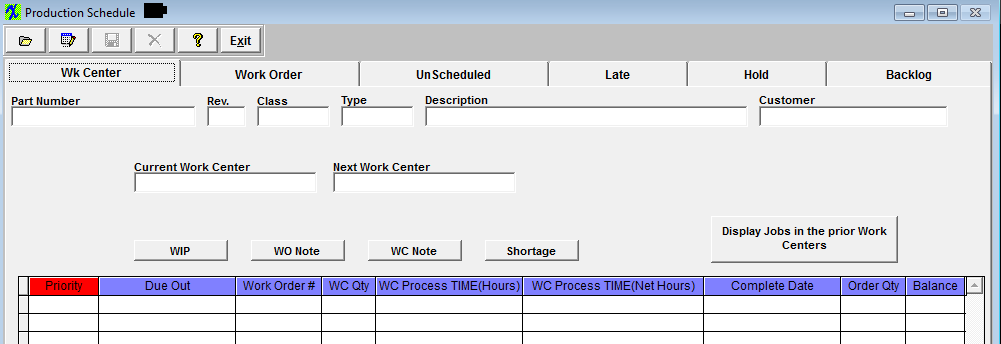

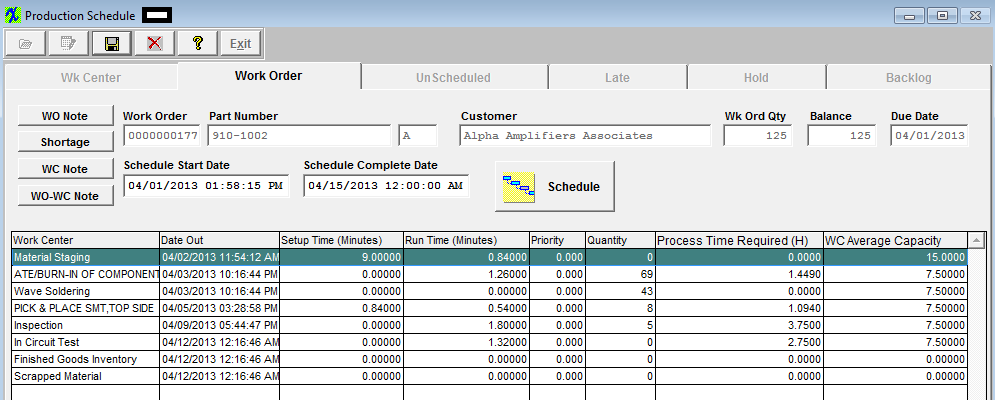

The Work Center Tab - allows user to view all the work orders scheduled for a specific work center

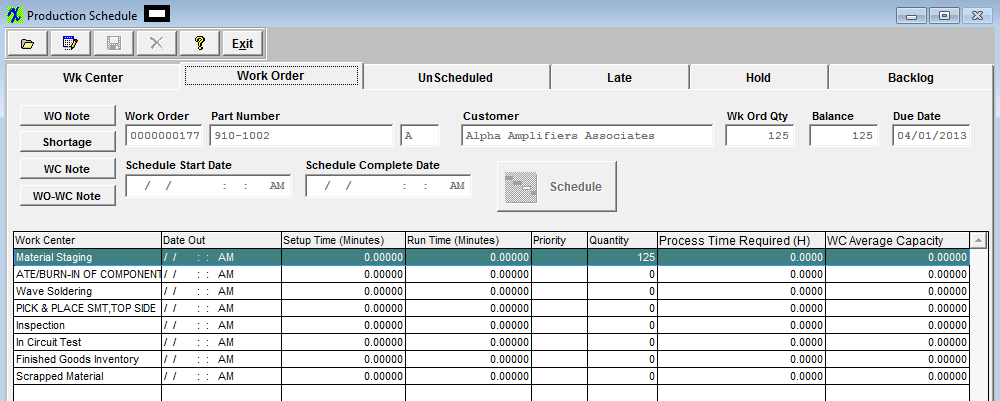

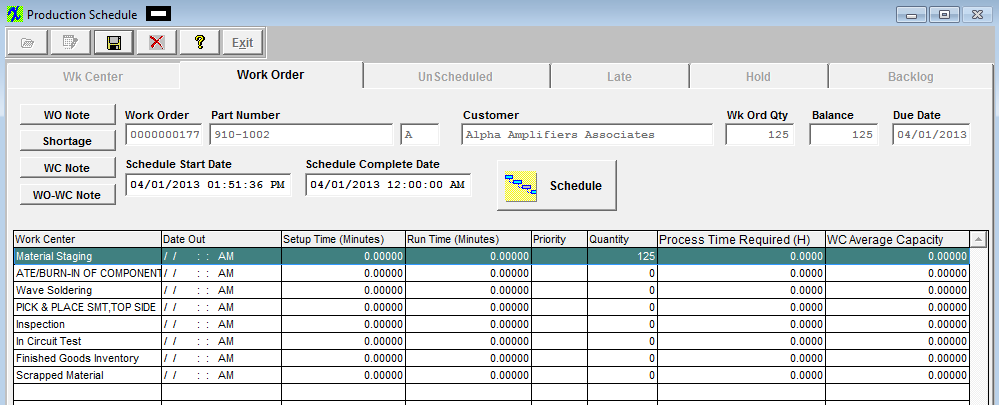

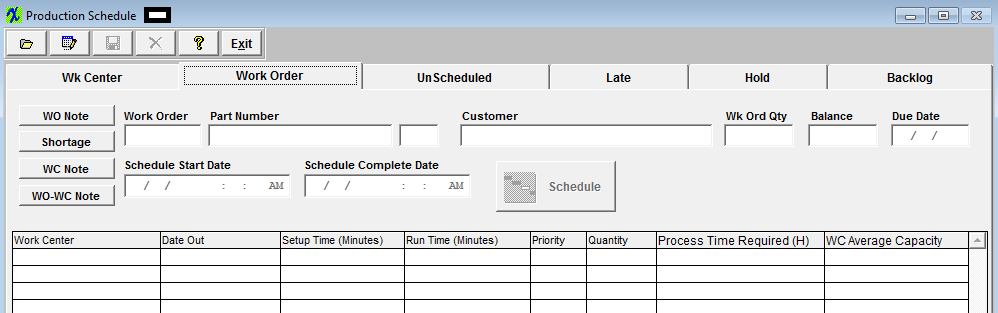

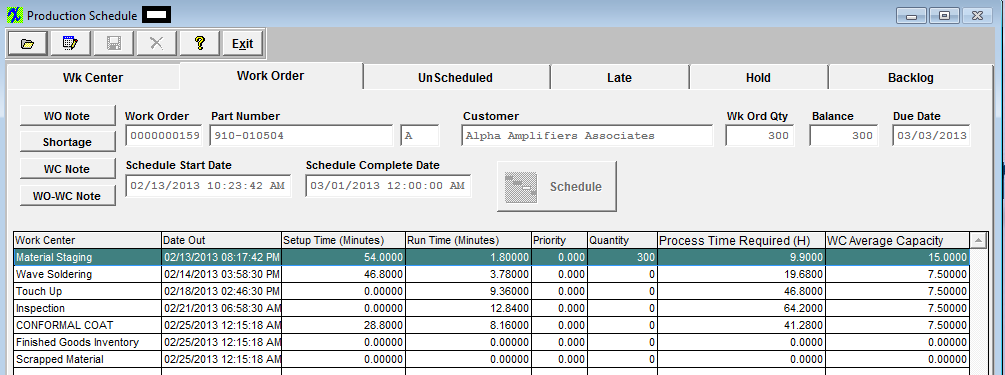

The Work Order Tab - allows the user to schedule the work order

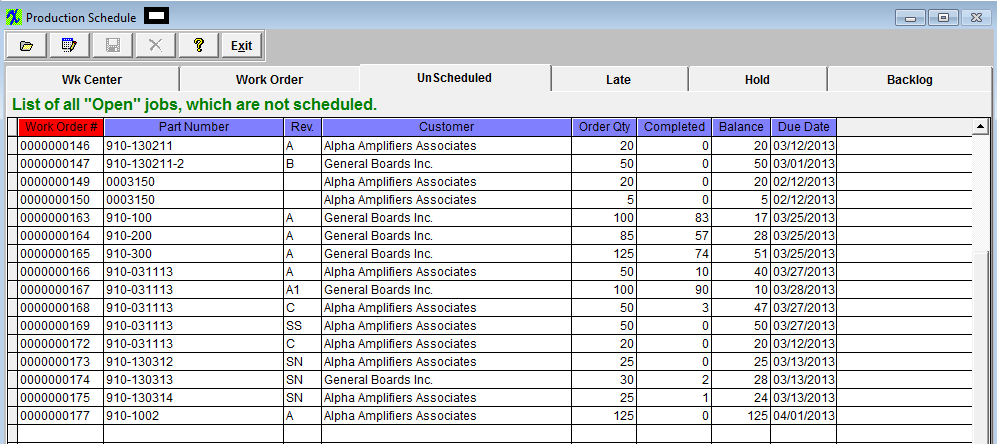

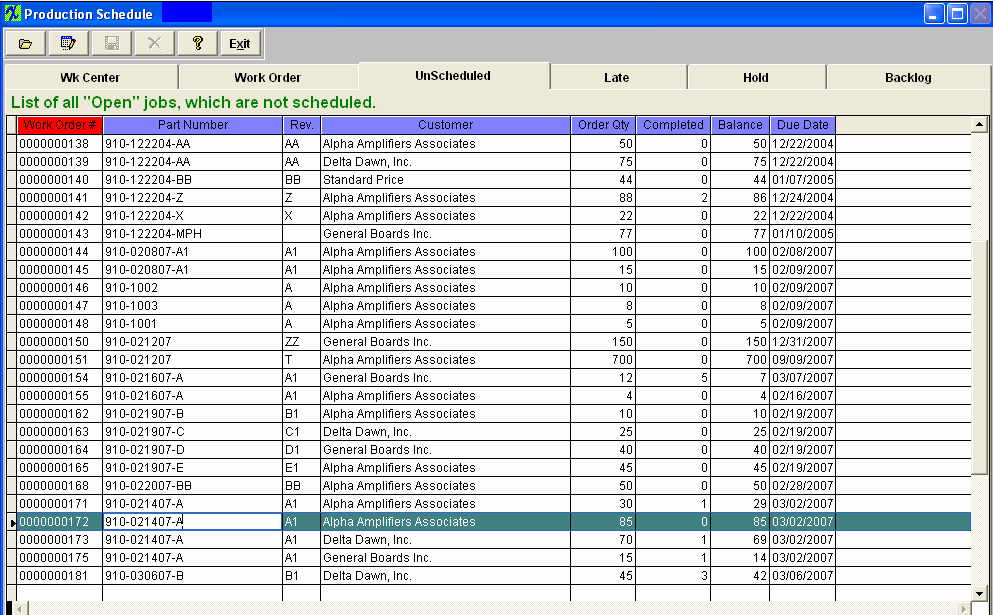

The Unscheduled Tab - displays all Work Orders with a status of "Open" that are not scheduled

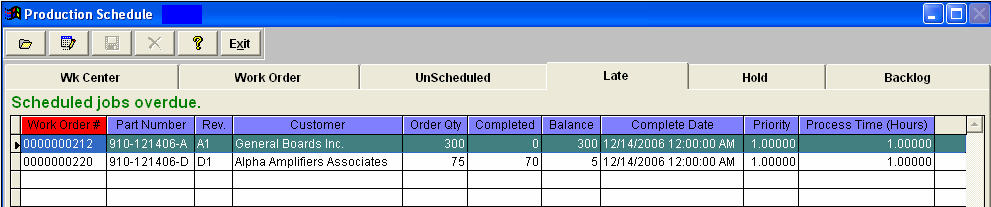

The Late Tab - displays a list of Work Orders that have exceded the WO due date, unless they have opt to use the Trigger then it will display a list of Work Orders that have exceded the Complete Date

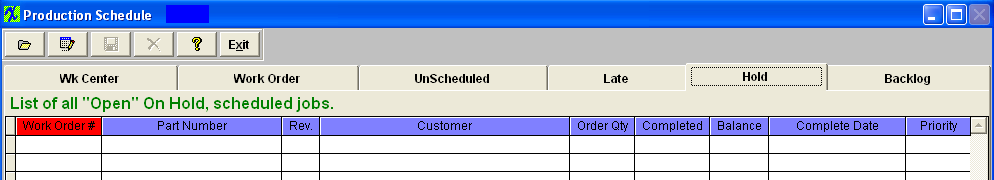

The Hold Tab - displays a list of Work Orders that have a status of "Hold"

The Back Log Tab - displays a list of Work Orders with a status of "Open" that have been scheduled and still have a balance remaining

|

| 1.4.1.3. Fields and Definitions for Dynamic Production Scheduling |

| 1.4.1.3.1. Work Center | ||||||||||||||||||||||||||||||||||||||||||||

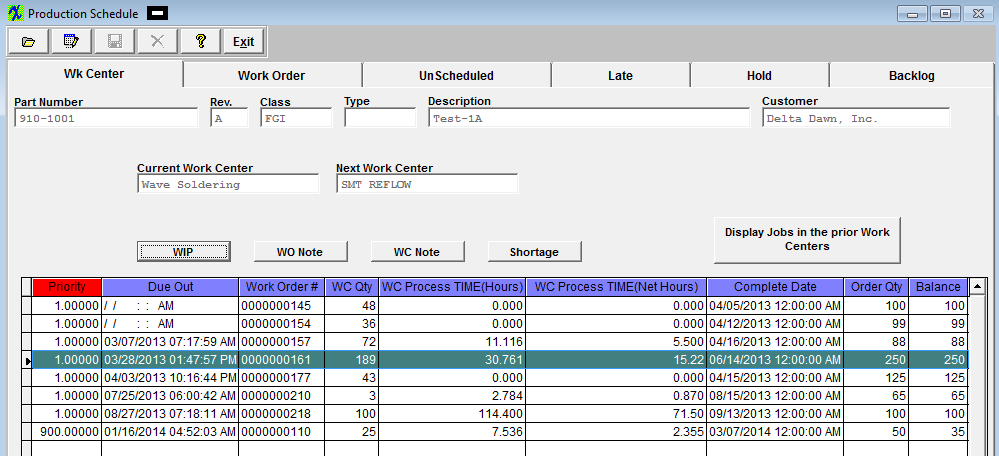

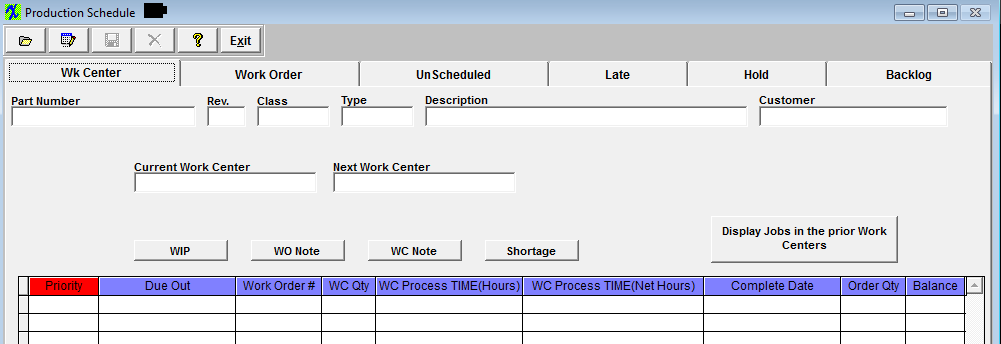

The Work Center Tab - allows user to view all the work orders scheduled for a specific work center

Work Center Tab Fields and Definitions

|

| 1.4.1.3.2. Work Order Tab | ||||||||||||||||||||||||||||||||||||||||||

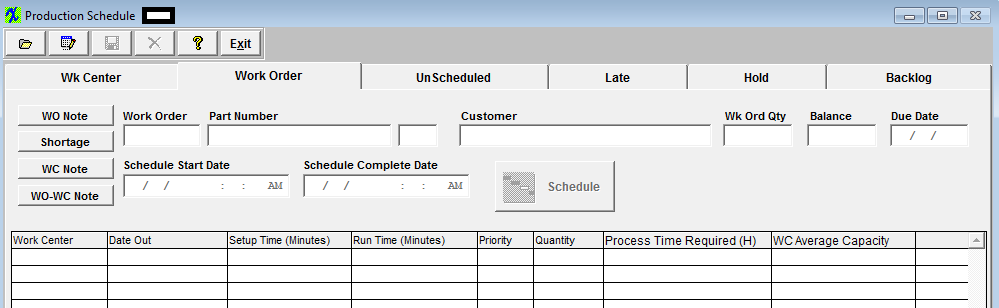

The Work Order Tab - allows the user to schedule the work order  Work Order Tab Fields and Definitions

|

| 1.4.1.3.3. Unscheduled Tab | ||||||||||||||||

The Unscheduled Tab - displays all Work Orders with a status of "Open" that are not scheduled  Unscheduled Tab Field and Definitions

|

| 1.4.1.3.4. Late Tab | ||||||||||||||||||||

The Late Tab - displays a list of Work Orders that have exceded the WO due date, unless they have opt to use the Trigger then it will display a list of Work Orders that have exceded the Complete Date

|

| 1.4.1.3.5. Hold Tab | ||||||||||||||||||||

The Hold Tab - displays a list of the Work Orders that have a status of either “Administrative Hold” or “Manufacturing Hold” on them:  Hold Tab fields and Definitions

The user may sort the display by clicking on the Work Order, Product Number, Build Quantity, Complete, Balance or Complete Date header buttons.

|

| 1.4.1.3.6. Backlog Tab | ||||||||||||||||||||||

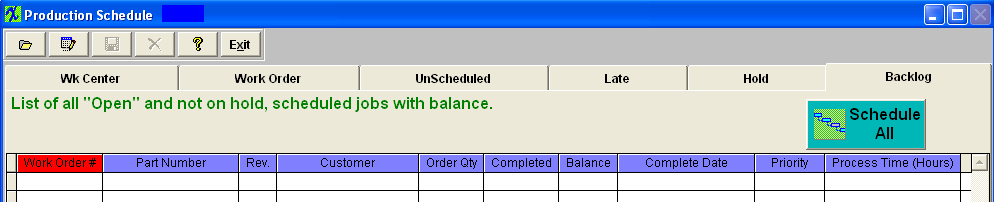

|

The Backlog Tab - displays a list of Work Orders with a status of "Open" that have been scheduled and still have a balance remaining

Backlog Tab fields and definitions

The user may sort by Work Order, product Number, Build Quantity, Complete, Back Order or Completion Date by clicking on the header buttons. |

| 1.4.1.4. How To ...... for Dynamic Production Scheduling |

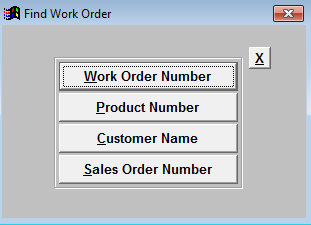

| 1.4.1.4.1. Find Work Order | ||||||

The following screen will appear:  Depress the Work Order tab. The following screen will appear:

Depress the Find button.

The Work Order selected will appear on the screen:

|

| 1.4.1.4.2. Find Work Center | ||||||||

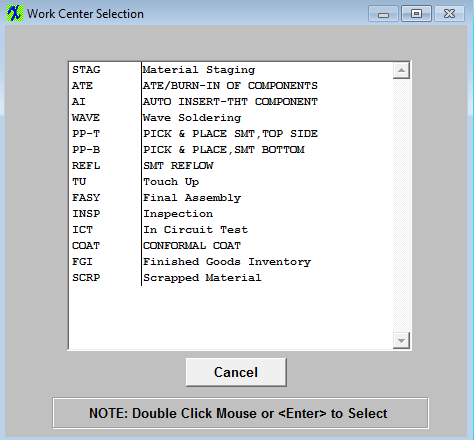

Clicking on the

Depress the Find button and the following

The following will appear for all of the Work Orders listed in the Work Order tab. The user may sort on any of the following buttons: Due Out, Work Order #, Priority, WC Qty, WC Process Time, Complete Date, Order Qty, or Balance.

Depressing the WO Note button will bring up the Notes entered in the Work Order Screen. To add a note, depress the Edit button, type in the note and depress the Save button.

Depress the WC Note button will bring up the notes entered in SFT per work center, for the Work Order highlighted. To add a note, depress the Edit button, type in the note and depress the Save button.

|

| 1.4.1.4.4. Re-Schedule a Work Order |

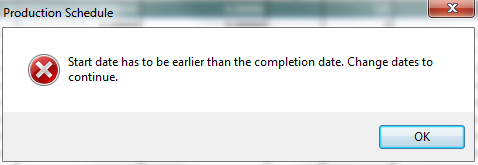

Find a Scheduled Work Order, depress the Edit Button, and enter your password.   Depress the Exit button. Once user has completed the changes they may depress the Save button, to save the changes or the Abandon changes button to abandon the changes.

NOTE: There is also a Capacity Planning Trigger option that my be setup to re-schedule all of the jobs that were scheduled and still open automatically. When the trigger runs, it will recalculate the "In" and "Out" date/time for the Work Centers so the capacity view is current.

|

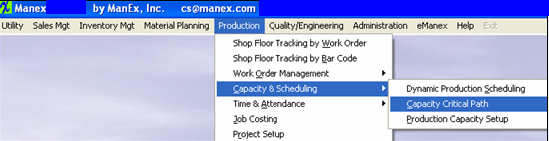

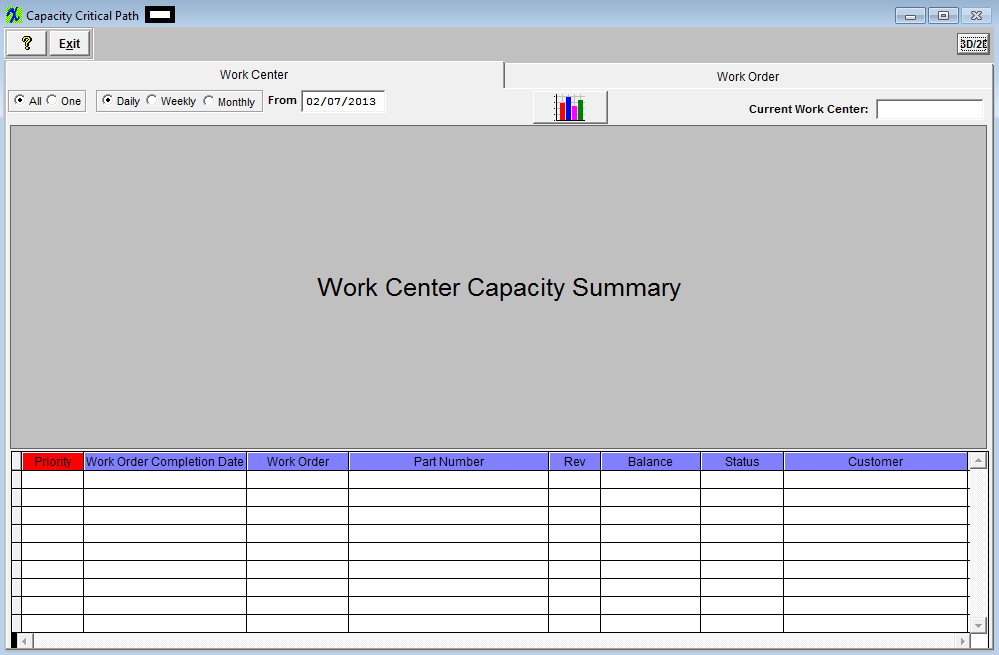

| 1.4.2. Capacity Critical Path |

| 1.4.2.1. Prerequisites for Capacity Critical Path |

After activation, "Dynamic Production Scheduling" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

A Production Schedule must be setup for the Work Order

|

| 1.4.2.2. Introduction for Capacity Critical Path |

| 1.4.2.3. Fields and Definitions for Capacity Critical Path |

| 1.4.2.3.1. Work Center Tab | ||||||||||||||||||||||||||||||

|

| 1.4.2.3.2. Work Order Tab | ||||||

|

| 1.4.2.4. How To ...... for Capacity Critical Path |

| 1.4.2.4.1. Create a Graph | ||

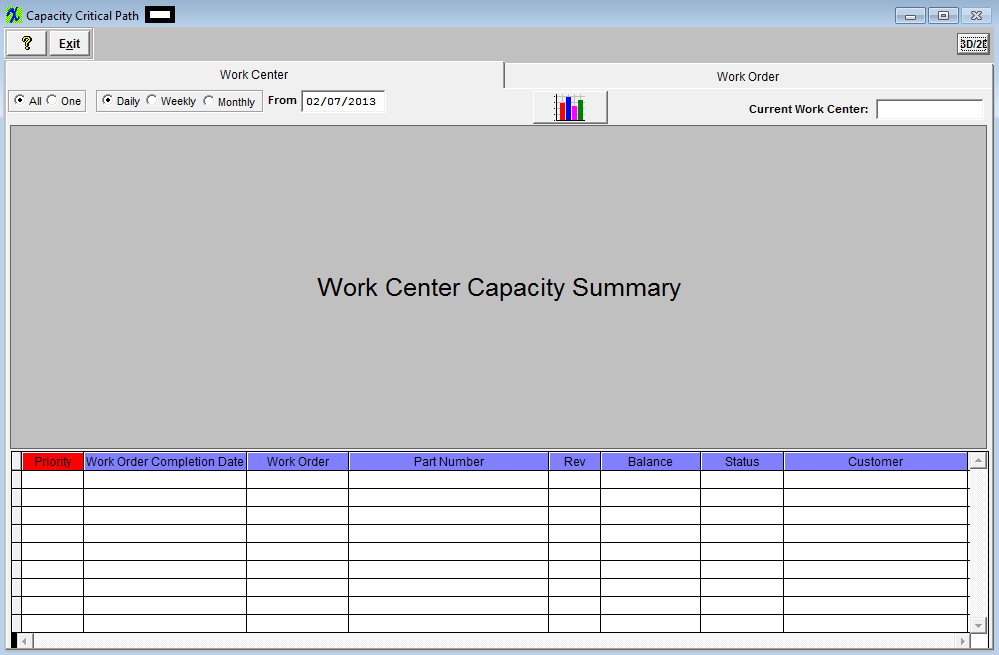

The following screen will appear:

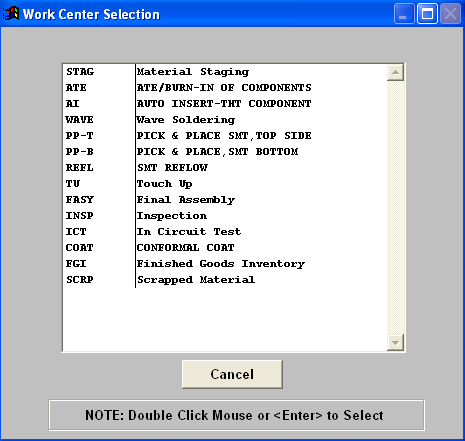

To create a graph, select Work Center(s), by clicking on the appropriate radial

Highlight a Work Center.

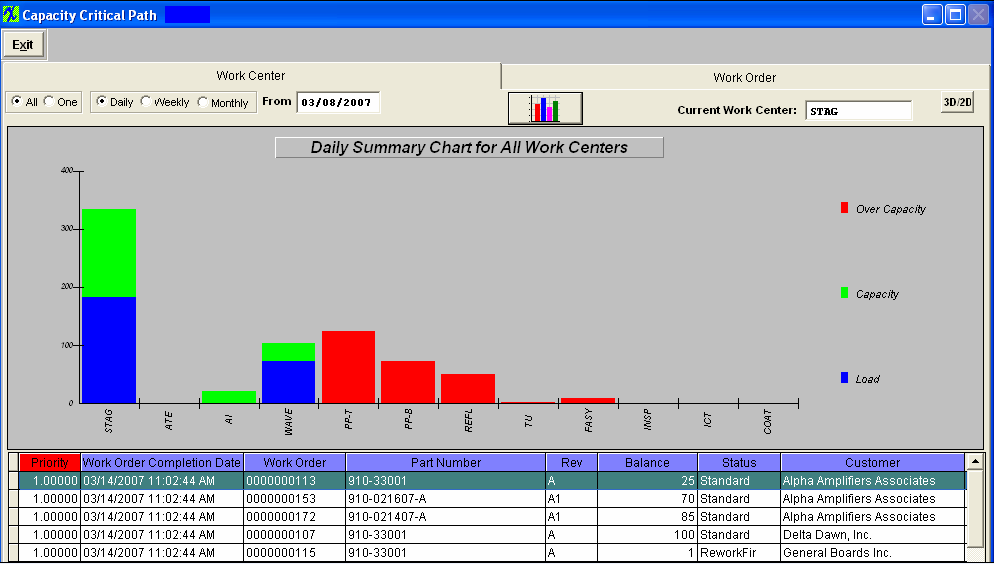

Decide what period you want the graph to cover, Daily, Weekly or Monthly. Type in the From date. Depress the

The bar graph will include all jobs that affect the load (including jobs that are on any type of Hold), so users are not misled about the available capacity. The grid below will display the status of the job and if the user feels that a job should not be included they may re-schedule it to a future date.

To display the detail click on the bar within the BLUE and the detail information for that date will be displayed at the bottom of the screen. The WOs display at the bottom of the screen are sorted by complete date (disregarding the time). User may sort the display at the bottom of the screen, by depressing any of the Header titles. The GREEN on the bar means NO capacity and the RED on the bar means over capacity.

A drill down to the Production Schedule module is available within this screen. If user double clicks on a specific Work Order number in the "Work Order" column the Production Schedule module will open for that work order on the schedule screen, so user may view, edit, etc. When user is finished viewing the Production Schedule module, they may depress the exit button, and it will bring you back to the Capacity Critical Path screen.

Note: The graph and the grid may get out of synchronization. If that happens simply click on the “3D/2D” button. The graph button will work also, but may take longer because it will go through the whole process of collecting the data again.

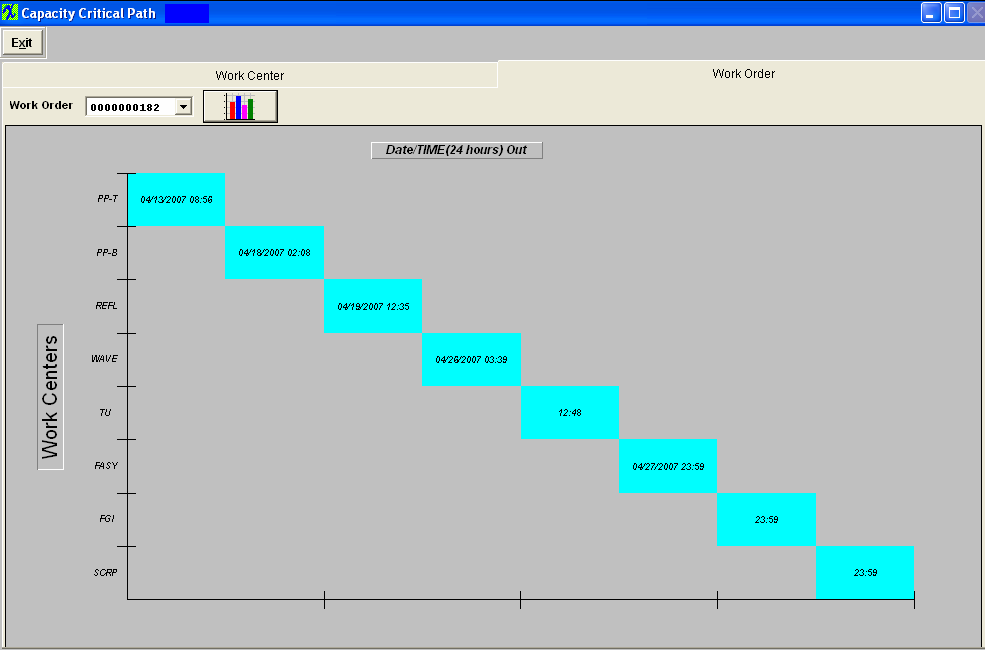

WORK ORDER TAB

Depressing on the Work Order tab will bring up the following:  Select the desired Work Order from the pull down. Depress the

The dates and times displayed in the blue boxes are the dates and times that the product is due to be moved out of the Work Center per the Production Schedule module.

|

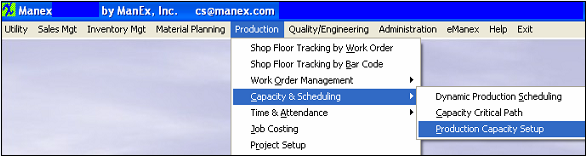

| 1.4.3. Production Capacity Setup |

| 1.4.3.1. Prerequisites for Production Capacity Setup |

The following setup is required before the user will be able to use the Production Capacity Schedule.

After activation, "Production Capacity Setup" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

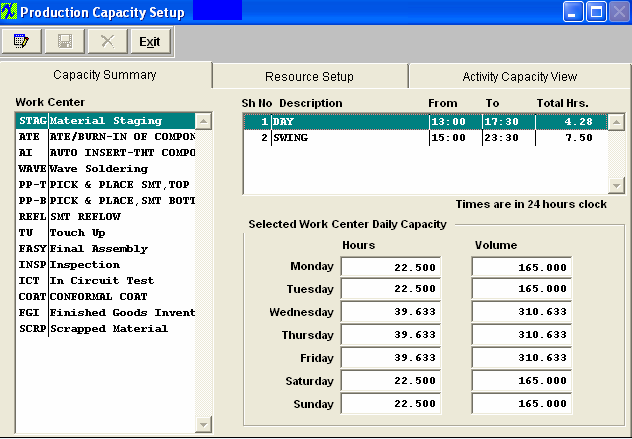

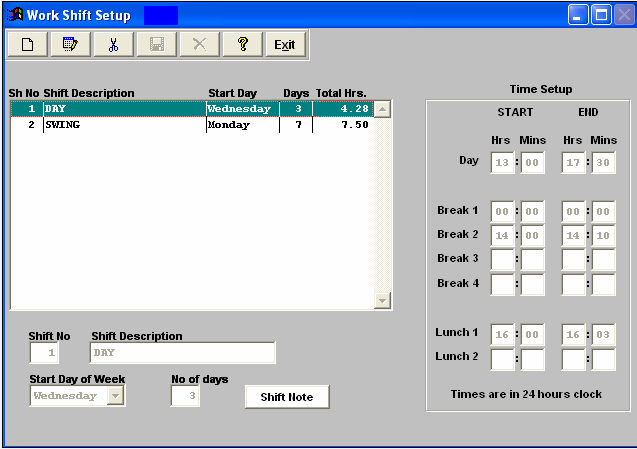

Work Shifts must be setup in the Work Shift setup module. The more work hours you have the higher your capacity.

In System Setup for Shop Floor Tracking Defaults the system assigns the Average Hrs/Work Day as 24 hours.

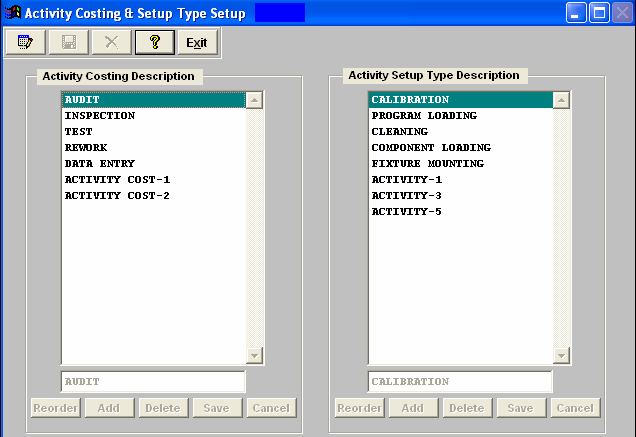

The Activity Costing Description and Activity Setup Type Description must be setup in the Activity Costing & Setup Type Setup module.

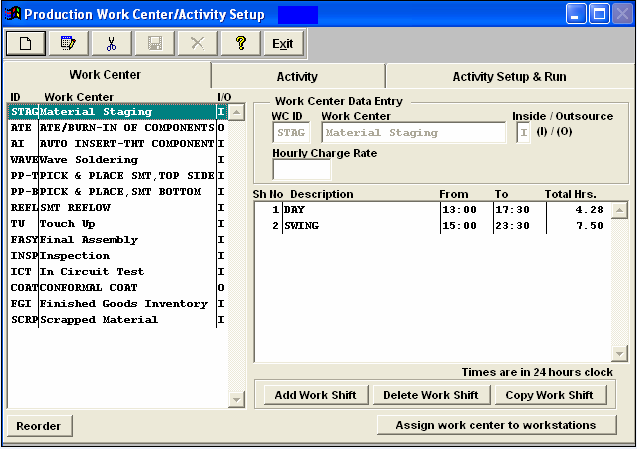

Shifts and activities must be entered to each application Work Center in the Production Work Centers & Activities module.

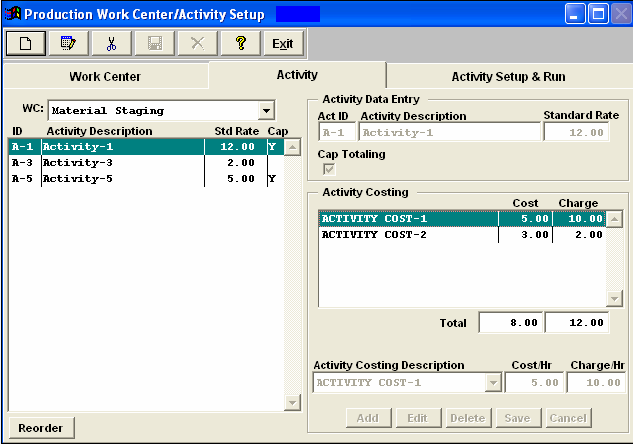

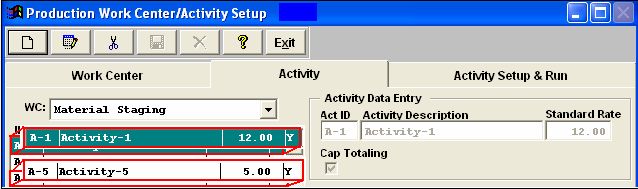

Within the Activity screen, the user checks the Cap Totaling box and enters the applicable Activity Costing information.

The Work Center Activity Setup and Run Times must be entered in the Work Order Traveler Setup module for any applicable product.

Check the status of the Work Order of interest – it can not be on Administrative Hold (for example), to complete the scheduling.

|

| 1.4.3.2. Introduction for Production Capacity Setup |

Capacity is at units/hour/operator-machine. Capacity then depends on the number of resources available, and that includes the number of shifts available. The program determines the duration of the job based on the resources, shifts, and active time during shifts (breaks and meals are excluded). The capacity planning module will stack up the requirements for multiple jobs on the same day and either require the user to add resources, or extend the completion time. Once the extensive setup requirements are met, the user may add a resource assignment. There are two views available in the Production Capacity Setup module. The Capacity Summary screen and the Activity Capacity View screen.From there, the user can enter the Dynamic Production Scheduling module and re-schedule Work Orders. There is also the opportunity to graphically view the Capacity Critical Path. |

| 1.4.3.3. Fields and Definitions for Production Capacity Setup |

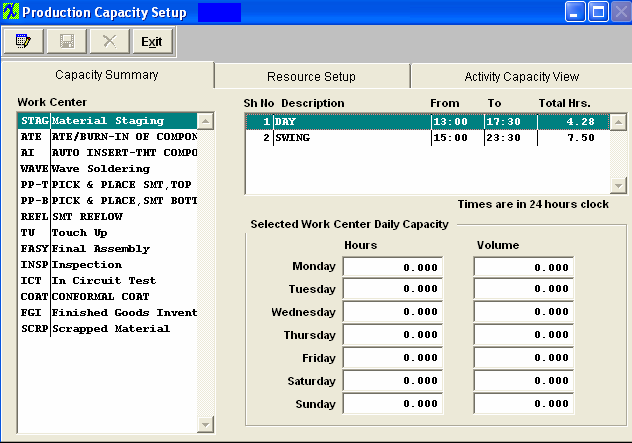

| 1.4.3.3.1. Capacity Summary Screen | ||||||||||||||||

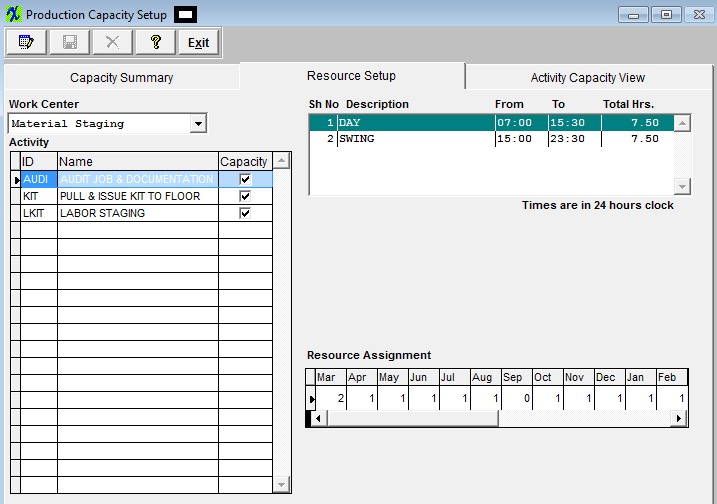

Selected Work Center Daily Capacity

|

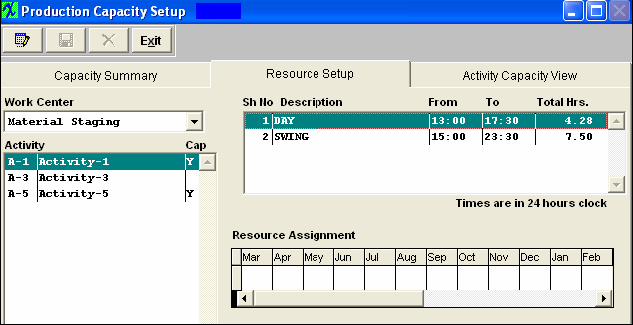

| 1.4.3.3.2. Resource Setup Screen | ||||||||||||||||||

|

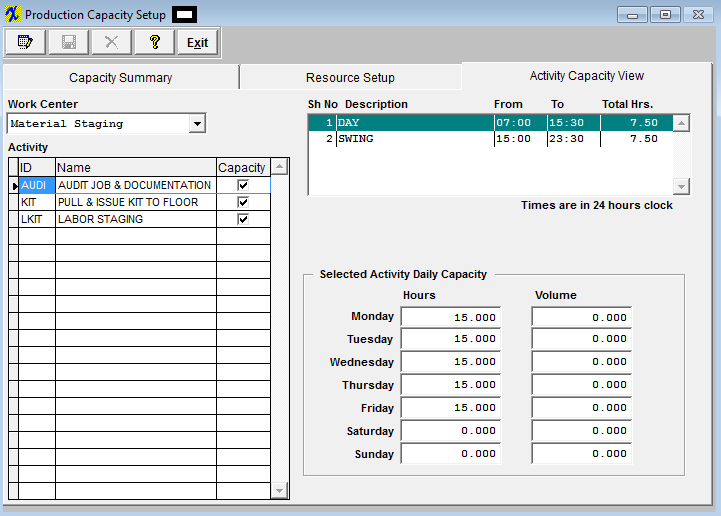

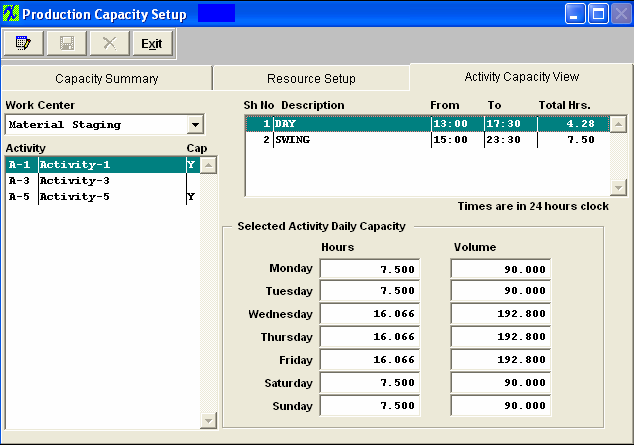

| 1.4.3.3.3. Activity Capacity View Screen | ||||||||||||||||||||

Selected Activity Daily Capacity

|

| 1.4.3.4. How To ....... for Production Capacity Setup |

| 1.4.3.4.1. Production Capacity Setup | ||

The following screen will appear. Each Work Center can have different shifts associated with it, but it must have at least one

To setup the Resources and Capacity pertaining to a

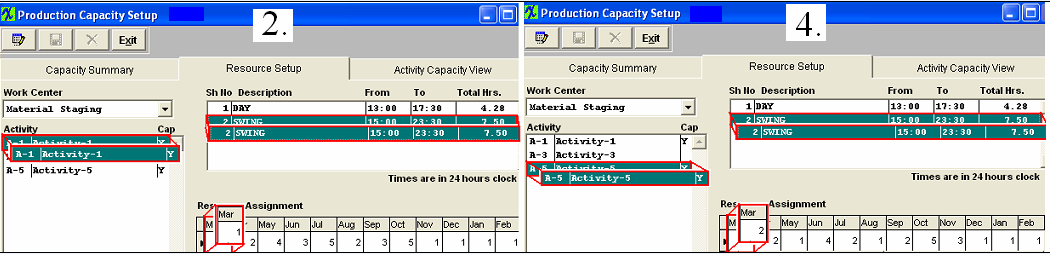

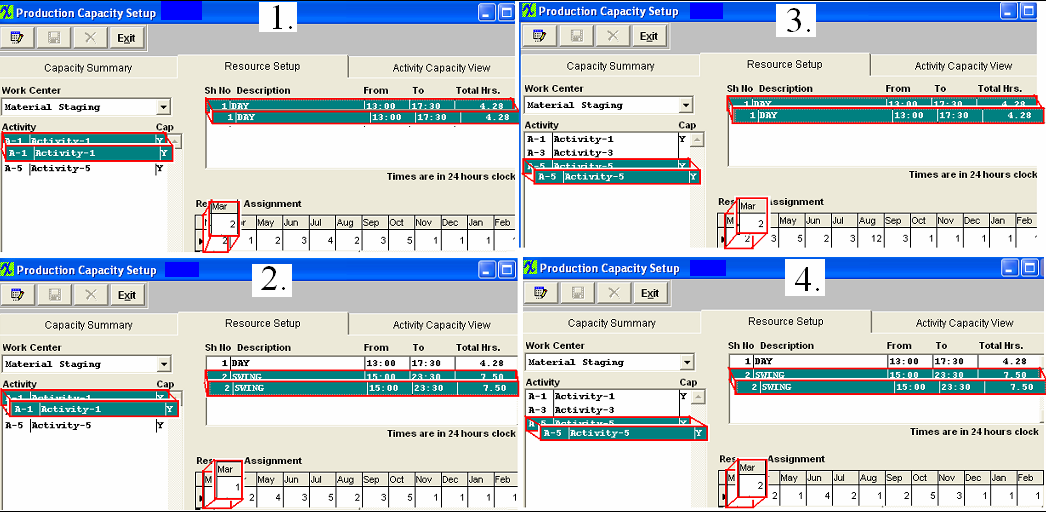

Each time a user enters the Capacity Setup module, the program checks the current date, and updates the month in the "Resource Assigment" grid to show the 12 months from current month. For Example: If the last time a user entered the module was March, so the 12 months are March/2008 to February/2009 (as displayed below). If user re-enters this module in June, the program will change the 12 months to June/2008 to May/2009 and also assign "1" to the 3 new new added months (March, April, and May/2009).

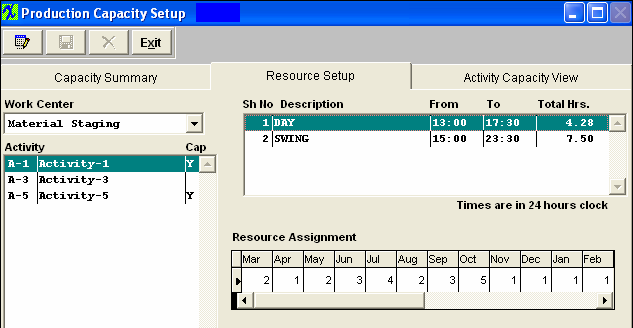

Notice there are three activities listed, but only 2 of them (“Activity-1” and “Activity-5”) will be calculated in the capacity because the “Cap” box has been checked in the Production Work Centers & Activities module.