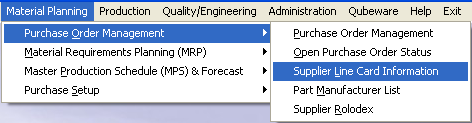

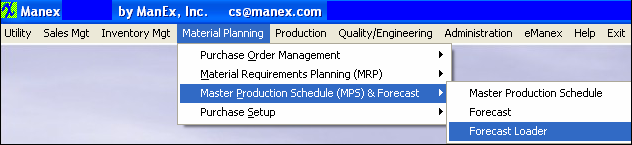

| 1. Material Planning |

| 1.1. Purchase Order Management |

| 1.1.1. Purchase Order Management |

| 1.1.1.1. Prerequisties - PO Mgmt | ||||||||||||||||||||||

After activation, "Purchase Order Management" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

Optional Prerequisites for Entering a New PURCHASING

|

| 1.1.1.2. Introduction for PO Mgmt |

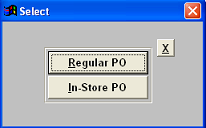

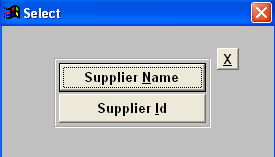

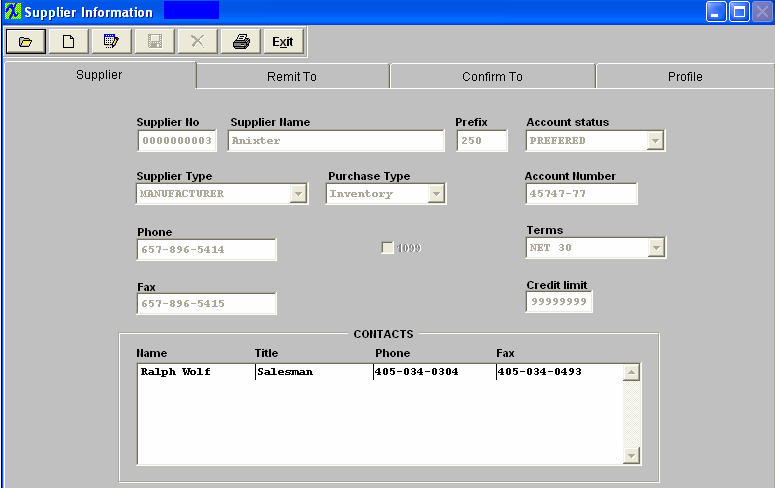

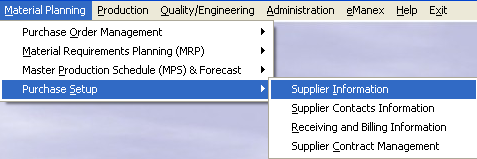

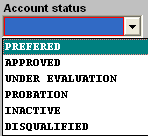

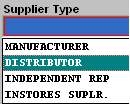

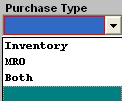

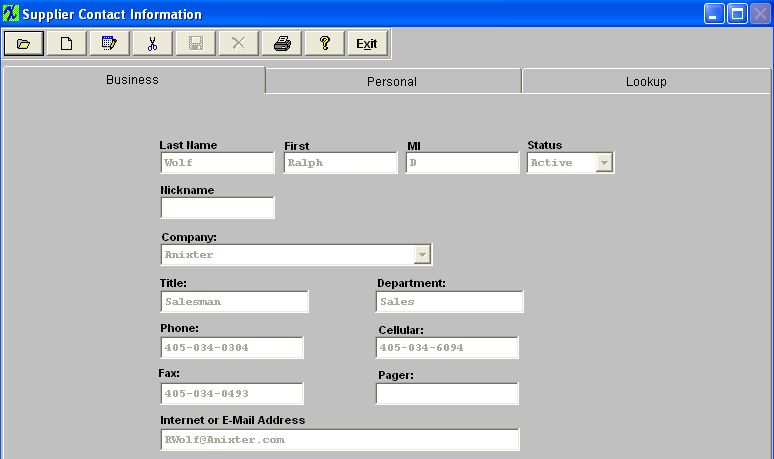

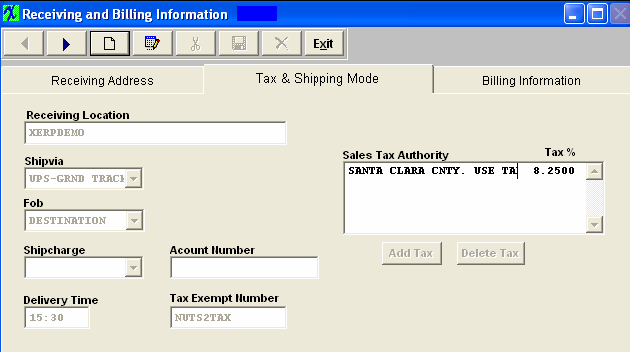

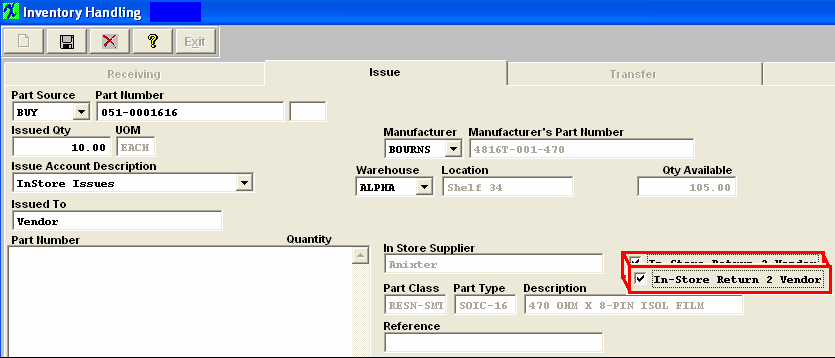

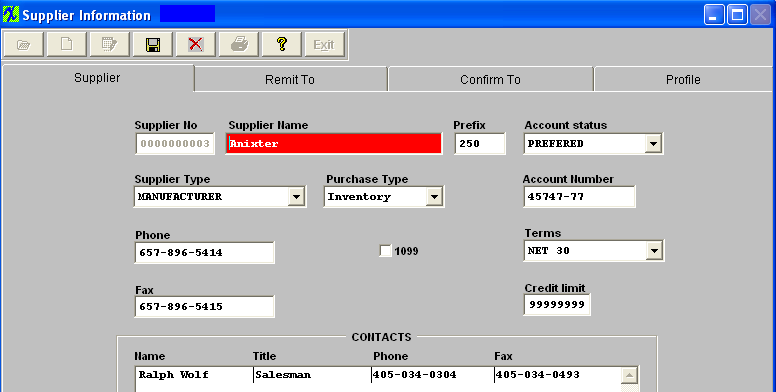

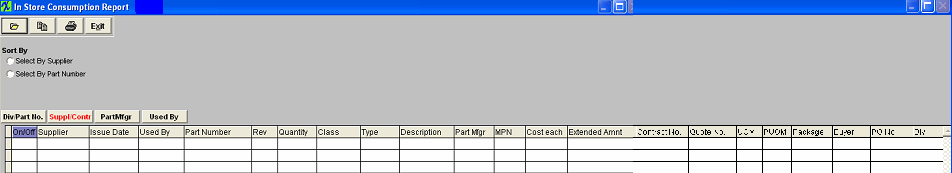

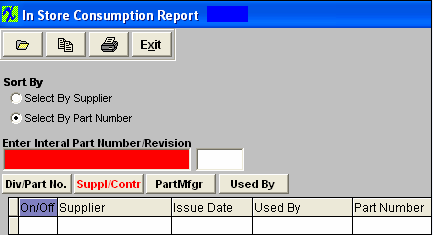

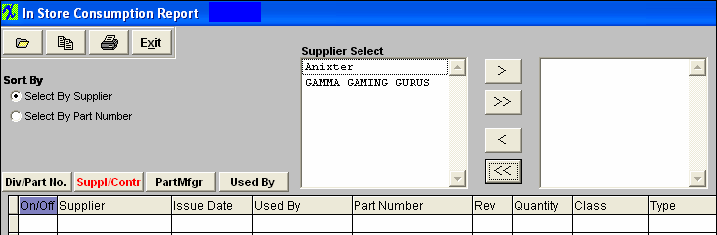

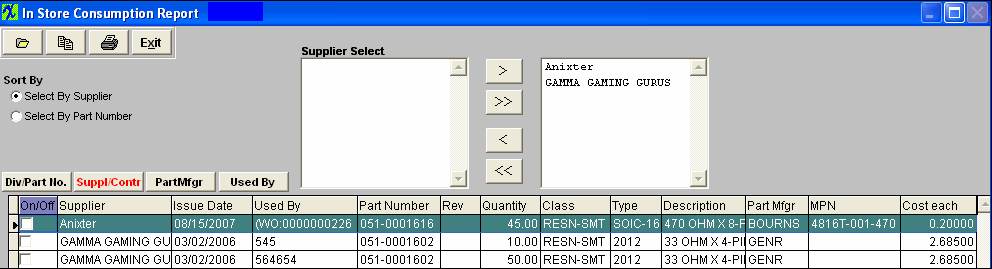

The PURCHASING Module is the place where all procurement is done. This module allows the user to add purchase orders to the system, and to add items to each purchase order. Edit functions are available both at the purchase order level and at the item level. The process begins by selecting a Regular PO or an In-Store PO, then selecting a supplier for the order. The supplier is selected from a list of suppliers established in the Supplier Information module. After selecting a supplier, the user may enter orders for various types of material. Inventory material is ordered to be placed in on hand inventory and used in the making of product. The user may also select MRO parts, parts which are not kept in inventory, but are expensed as they are purchased and distributed to the requester when they are received. (MRO parts may be defined in the item master and kept in inventory, if desired.) There is also a selection for Services. The user may add a new part by selecting the part class and type, then choosing from a part matching that criteria, or go directly to the part number edit box and enter the part number without visiting the class and type box. The buyer may have entered a specific manufacturer of the item, providing that the manufacturer and the part number have been entered in the inventory item master. If there is only one manufacturer, that manufacturer will be the default manufacturer entered in the purchase order. If the user is adding an inventory item to the order, the system will add in the details from the item master once the part number is established. Purchased items may have the delivery schedule established for one or more deliveries. The delivery date entered in the purchase order is meant to be the date the material lands on the user’s dock. The user may enter either the stocking quantities based on the stocking unit of measure or the purchasing quantities, based on the purchase unit of measure. If the units of measure are different, the user must have defined the relationship between the different units in the Unit of Measure Conversion. Entering one quantity will automatically calculate and enter the other quantity. The user enters the unit price and whether or not the item is taxable. If it is taxable, the tax percentage will be supplied based on the data entered in the Tax &Shipping Mode tab. The system will display the extended amount of the item on the order based on the quantity and price. Note: If the Tax Information has not been filled in, the Purchase Order will NOT calculate any sales tax. Therefore, it is important that the user set this up properly. The user may define the quantity that may be received over the amount of the order by entering an overage percentage. This will allow incoming receiving to accept quantities up to the amount of overage specified for the order. The user may enter specific notes about the item on the purchase order, to be printed on the order. They may also view and edit any item master notes that may exist for the part, and may also view the procurement history for the part. Once entered, all orders require an approval. The approval authority established in the Purchase Order Authorization tab is used to determine whether or not an individual may approve an order. It is possible to allow two approvals to orders, and to set different approval limits for each of them. Orders will be identified as temporary orders until approved, after which they will have a permanent number assigned. Change orders to purchase orders must also be approved in the same manner. Once an order is changed, it cannot be printed or acted upon until it is approved again. Details about the remittance, delivery point, billing etc. will be completed with Supplier default information, and may be reviewed for the order if necessary. In-Store purchasing overview: In-Store is the situation where the Supplier has placed raw materials in the user’s warehouse. The Supplier still owns the raw materials. When the user is ready to use the Supplier’s raw materials, he/she issues an In-Store Purchase Order. For In-Store POs, the user may select by Supplier or by Part Number. Then the user may find records according to the selection. Once found, the user may create a PO for the In-Store Consumption. In-Store Purchasing also includes receiving. |

| 1.1.1.3. Fields & Definitions - PO Mgmt | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Purchase Order Items

This will allow user to cancel an individual item on a PO. Since the system does not allow you to delete a line item that has had any kind of transaction, we needed a way for users to cancel individual line items without having to cancel the entire order within the system. If any parts have been accepted, it cannot be cancelled. Once a part has any receipts the user cannot delete the line, so if they reject the total received qty they can cancel the line to prevent it from affecting the PO, or PO history for the other line items. If they do not want to reject the entire qty then their only option is to reduce the balance qty to the accepted qty.

Detail Definitions

T Directive Buttons

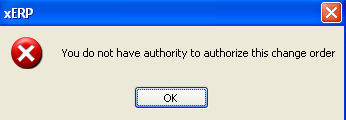

The following buttons are displayed on the Purchase Order screen. After a purchase order is created or edited, it must be approved before it can be printed and issued to a supplier. Certain employees may be granted authority to approve purchases up to a certain total dollar value. Those authorized personnel may approve purchase orders under that amount. If only one signature is required, the order will be finalized and released. If it is a new order, and automatic PO numbering is enabled, Manex will assign the next available number to the order. The action is taken by clicking on the Approval button and responding with an authorized password. If two signatures are required in order to release a purchase order, then a second person with approval authority for the amount of the order must approve the order, by clicking on the Final Approval button and responding with an authorized password.

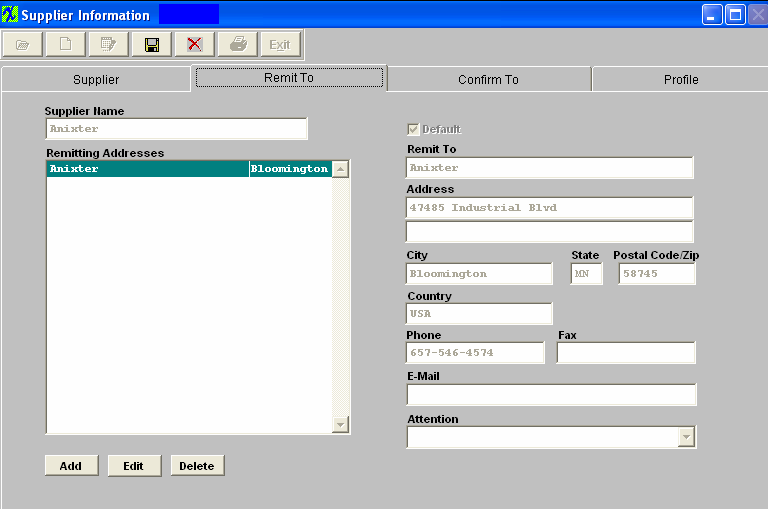

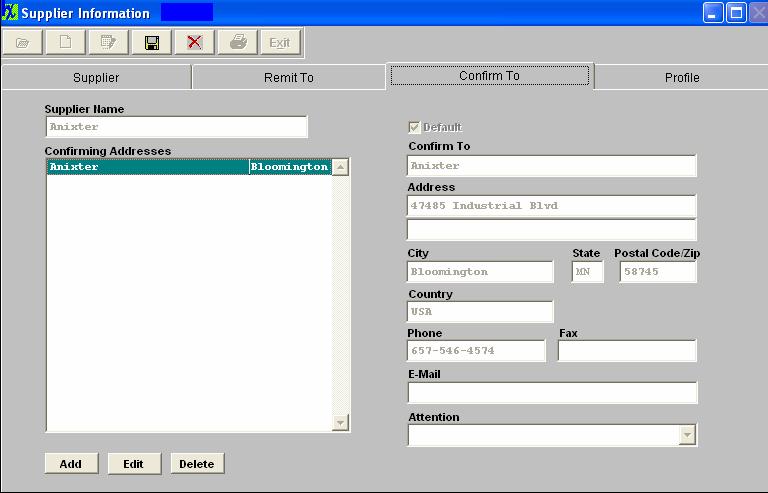

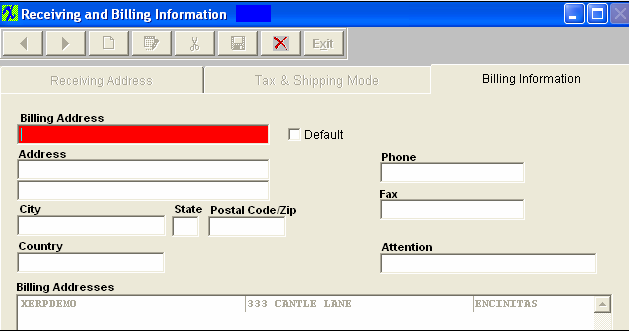

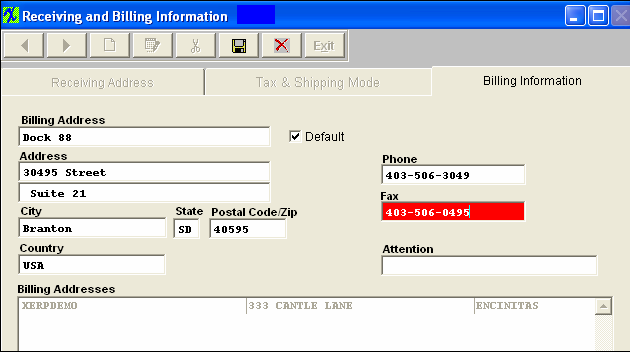

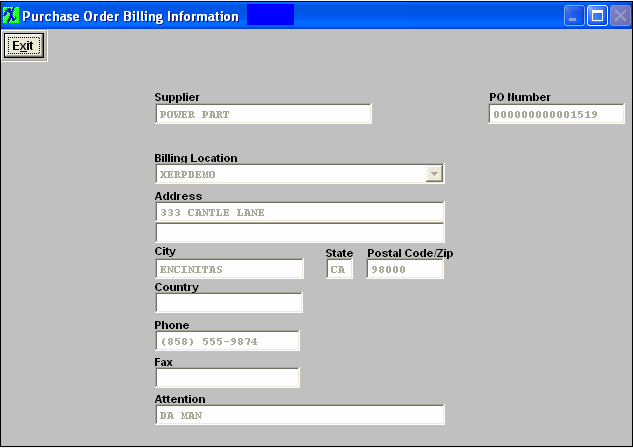

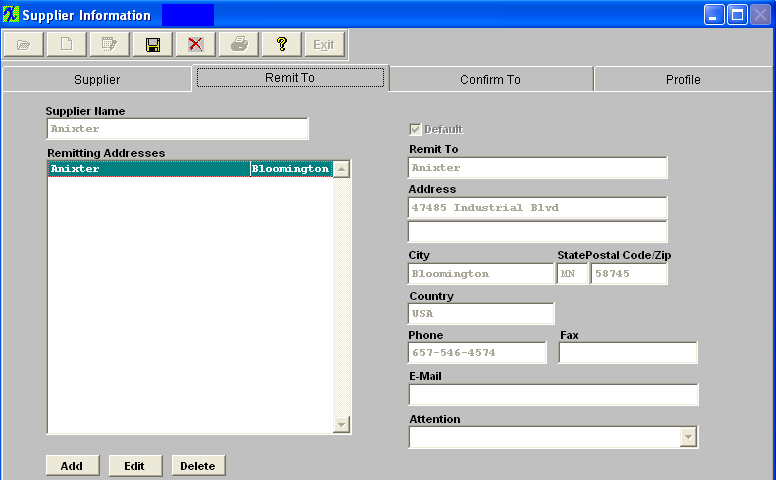

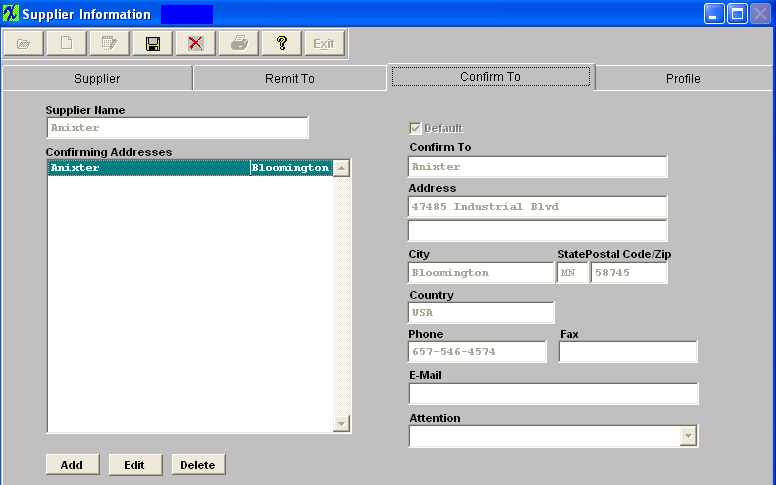

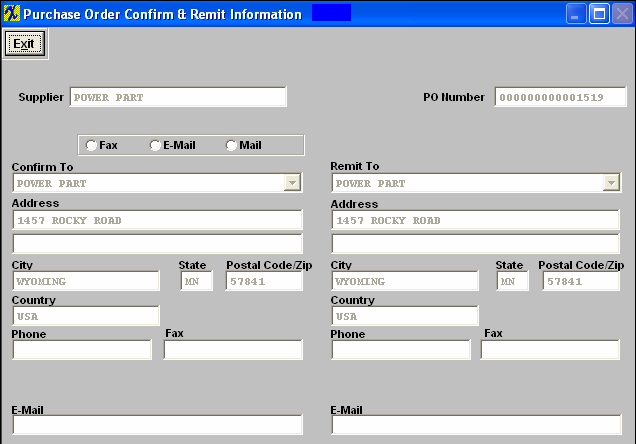

Confirm/Remit Screen Field Definitions

CONFIRM TO

REMIT TO

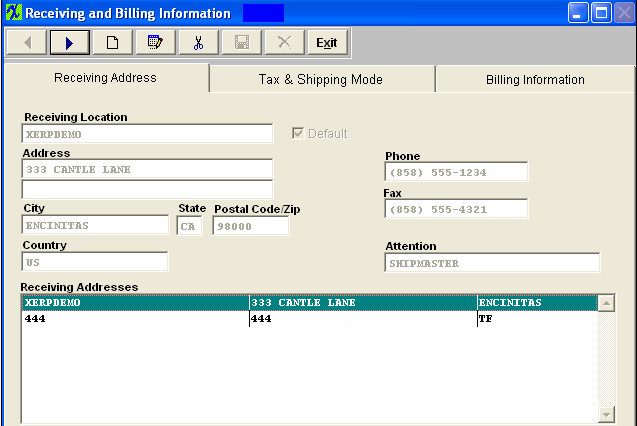

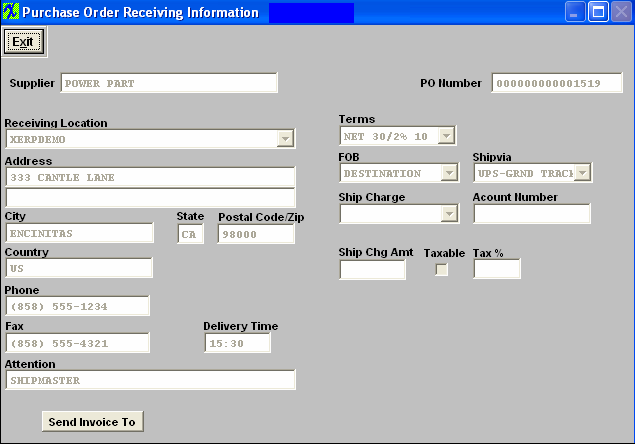

Receiving Screen Field Definitions

Supplier |

The supplier or vendor with whom the order was placed. |

PO Number |

The Purchase Order number of the order. New purchase orders that have not been approved will display a temporary number until approved. |

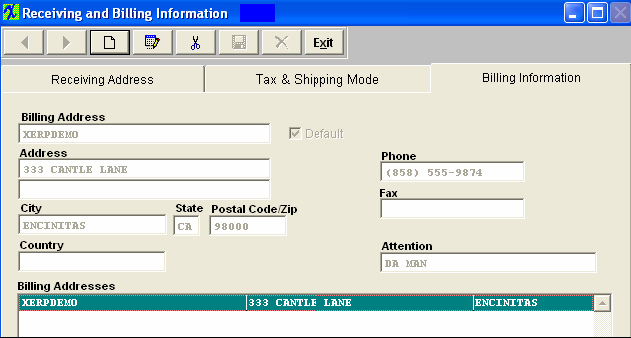

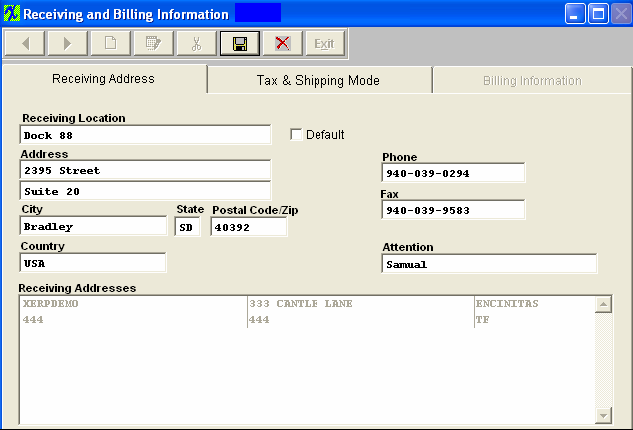

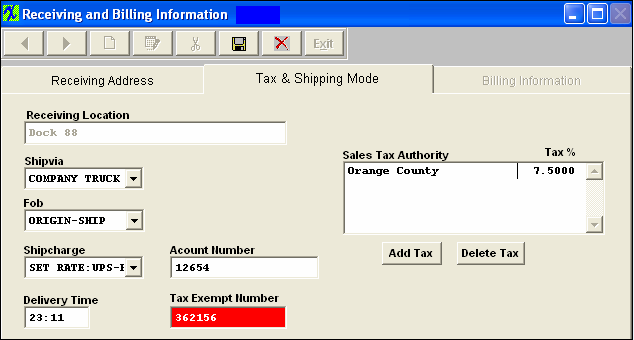

Receiving Location |

The company and address to which the order is to be shipped. |

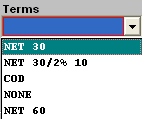

Terms |

The terms of the purchase order. |

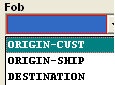

FOB |

The FOB point for the order. |

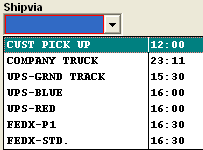

Ship via |

The preferred shipping carrier for the order. |

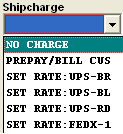

Ship Charge |

How the freight costs are to be paid. |

Account Number |

If needed, the freight company account number for the carrier to charge. |

Ship Chg Amt |

The shipping charge cost for the order. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

Taxable |

Indicates if the freight charges are taxable. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

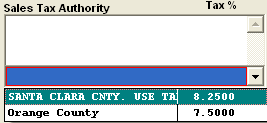

Tax % |

The tax rate for the shipping charges. This is referenced on Purchase Order Forms Only. These amounts wIll not be carried over to the PO Reconcilliation. |

Delivery Time |

The preferred delivery time for receipts. |

Attention |

The name of the person to whom the shipment is directed. |

DIRECTIVE BUTTONS

Send Invoice To Screen Field Definitions

Schedule Field Definitions

|

| 1.1.1.4. How To ..... for PO Mgmt |

| 1.1.1.4.1. Find a Purchase Order | ||||||||||||||||

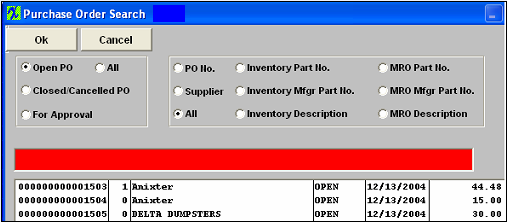

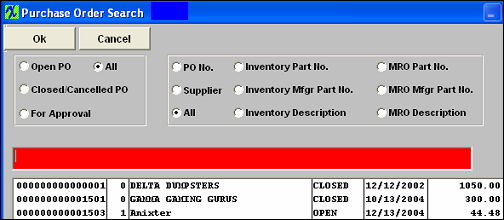

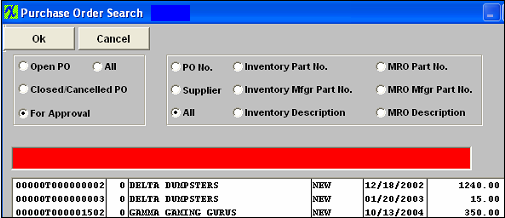

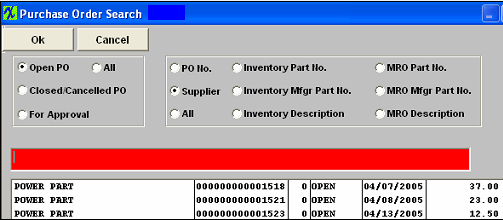

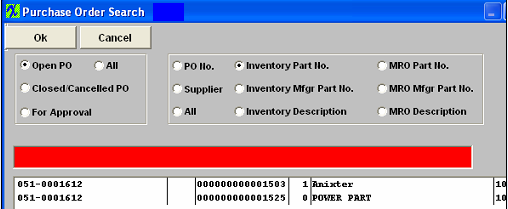

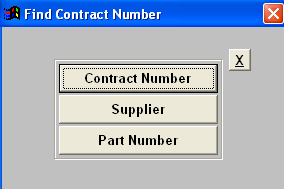

3. Once you’ve made your “search for” choice, determine the search method by choosing between PO Number, Inventory Part Number, MRO Part Number, Supplier, Inventory Manufacturer Part Number, MRO Manufacturer Part Number, All, Inventory Description, or MRO Description.

The rest of the right hand selections are essentially the same as for those illustrated above. 5. After finding the Purchase Order, the Purchase Order screen appears, populated with any parts on order.

|

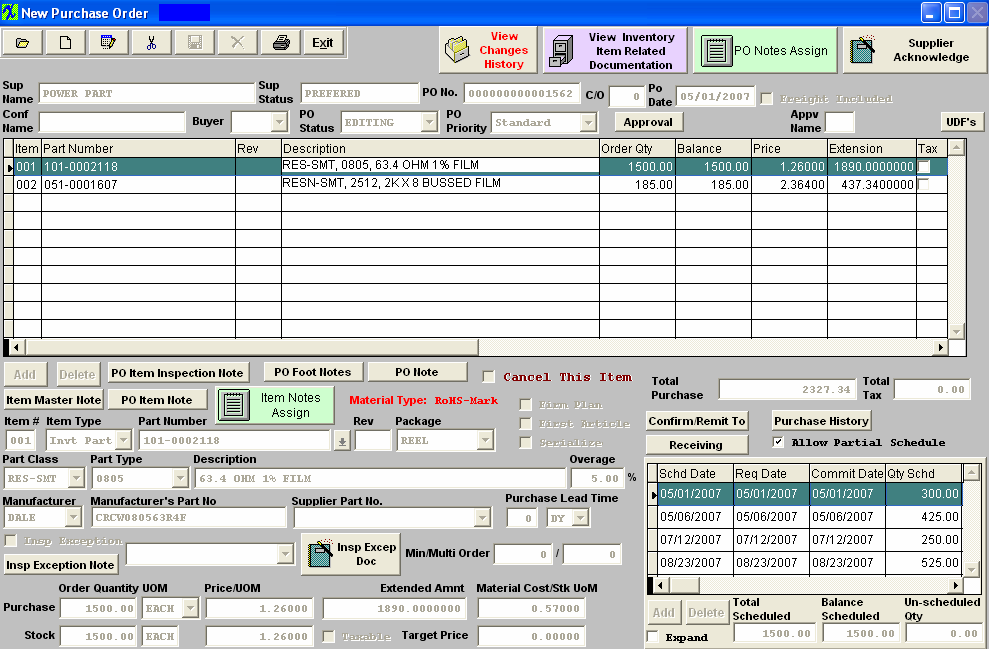

| 1.1.1.4.2. Add A Purchase Order | ||||||||||||

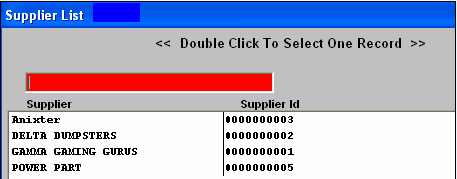

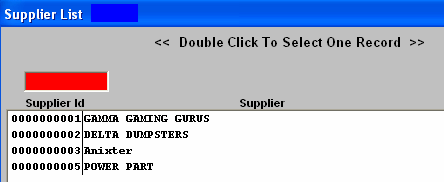

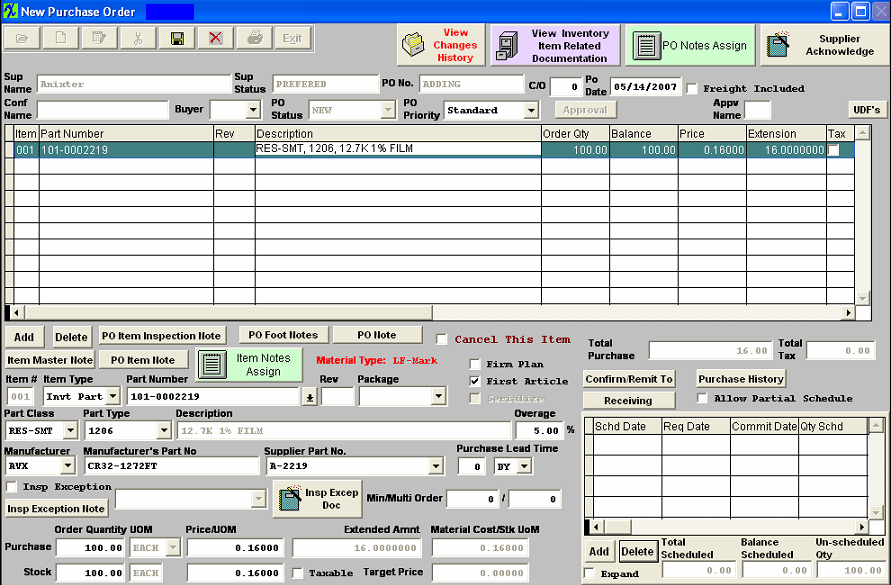

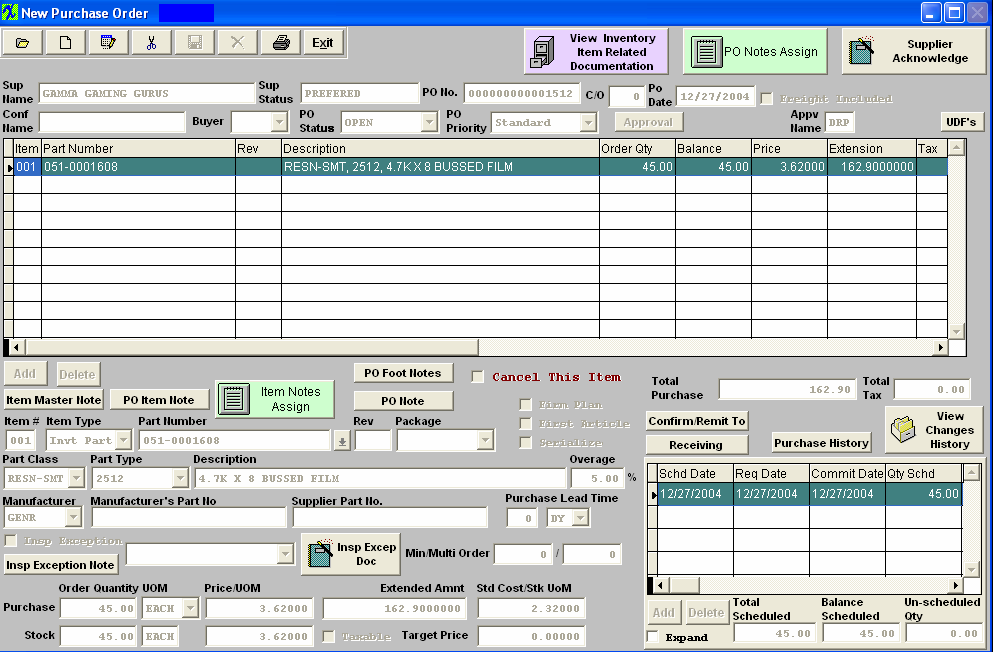

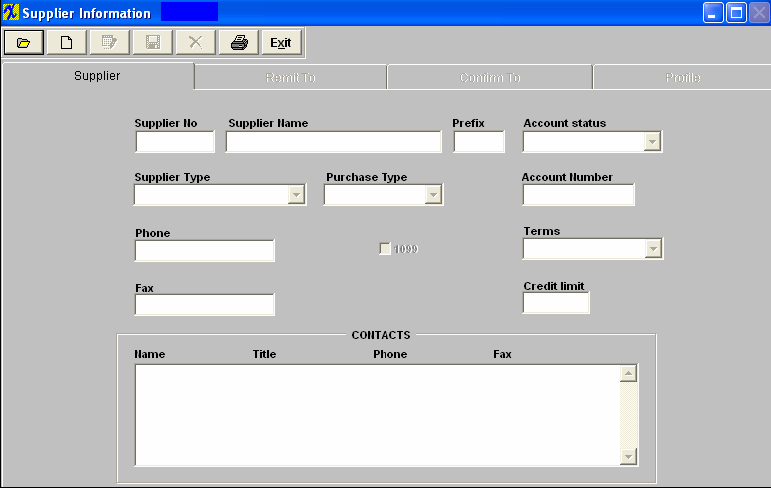

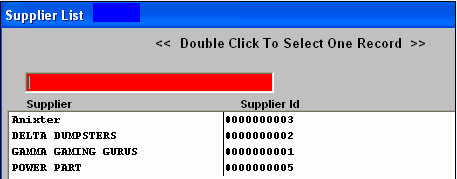

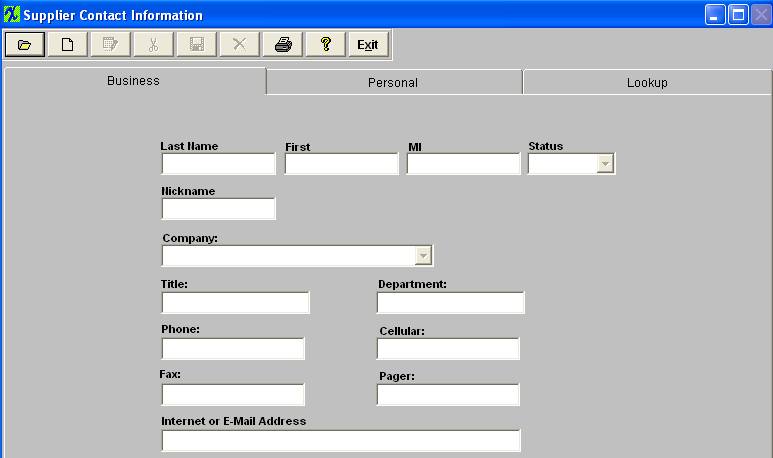

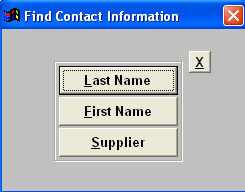

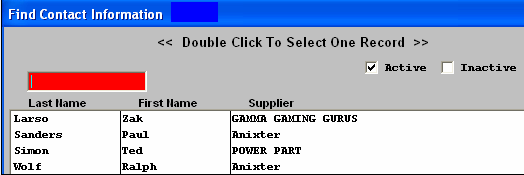

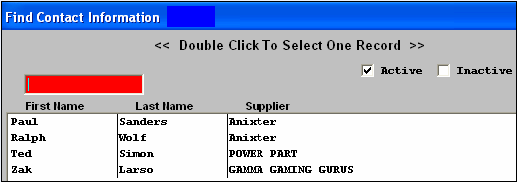

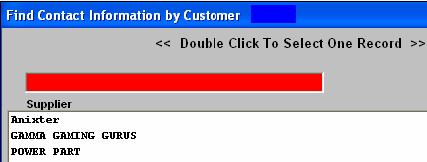

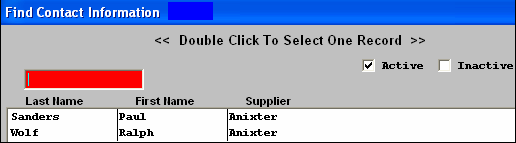

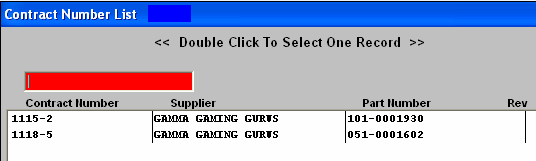

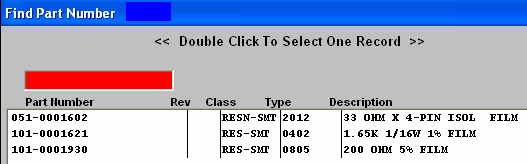

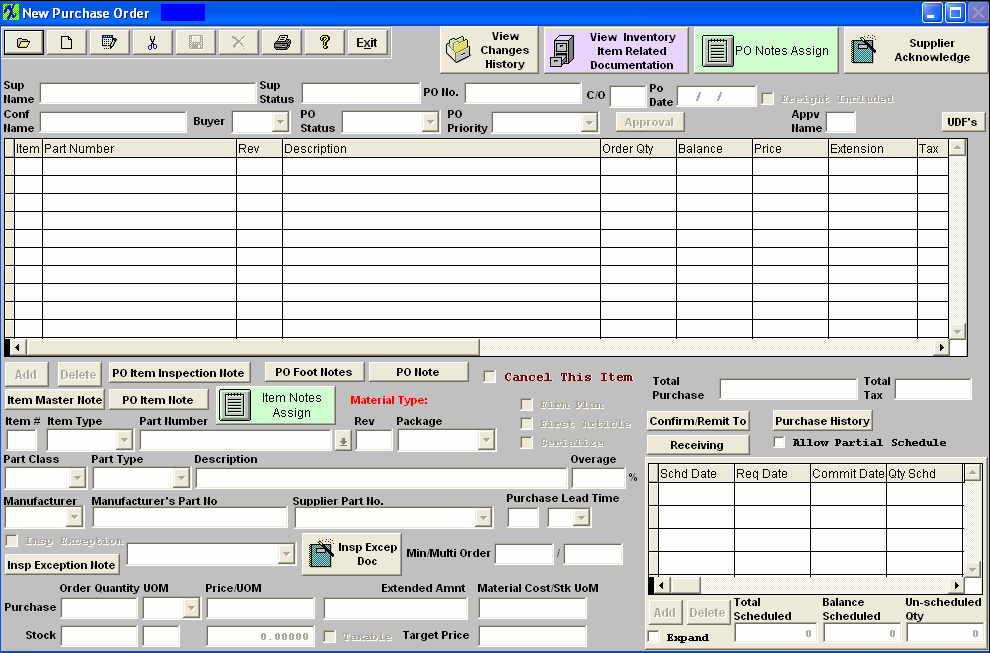

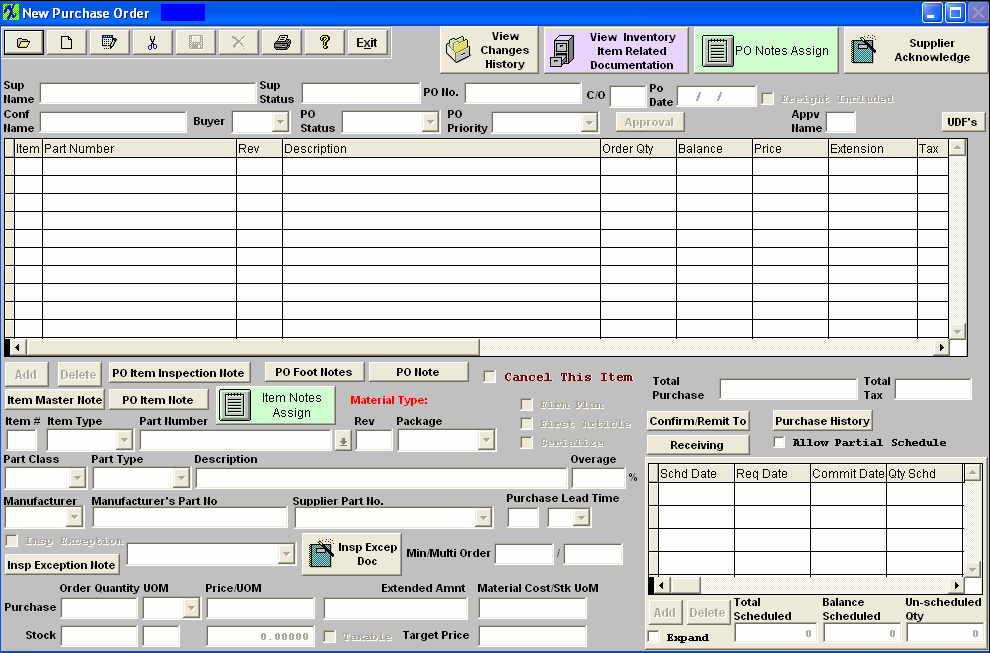

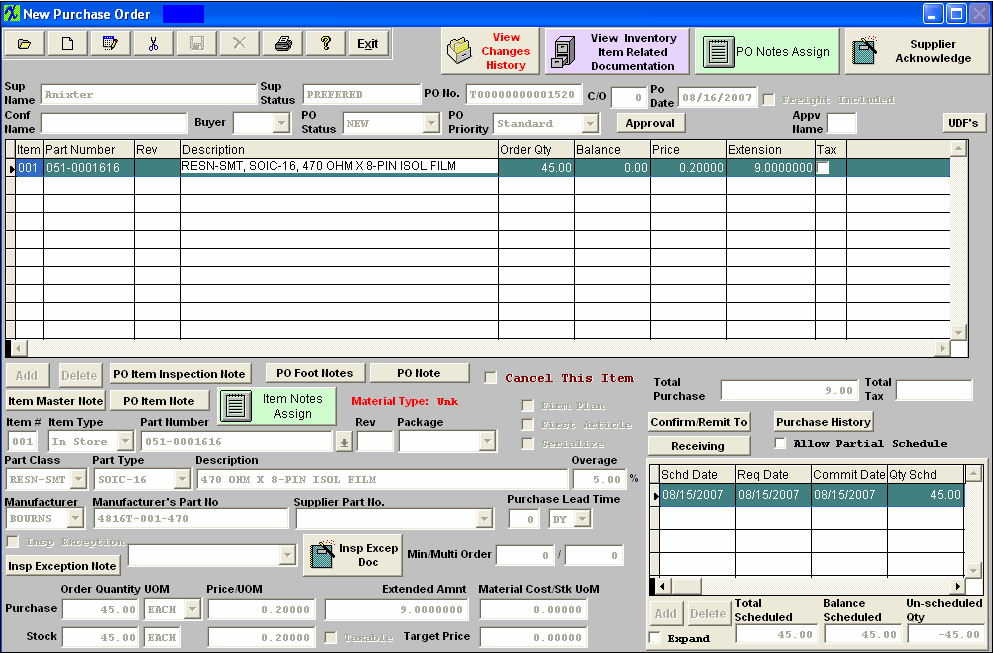

The following screen will appear:

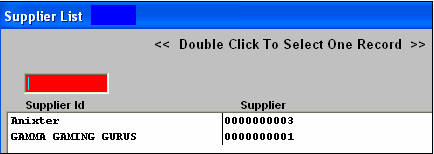

The user may enter the number or name in the red edit box above the Supplier or Supplier ID label, or scroll down to select a supplier. Double clicking on a supplier or pressing the ENTER key on a highlighted supplier selects the supplier and displays the Purchase Order screen with the supplier included. Once a supplier is identified, the remaining information fields become active. The user can CANCEL the action if needed. The user then may fill in the Confirm Name, Buyer and add items to the purchase order.

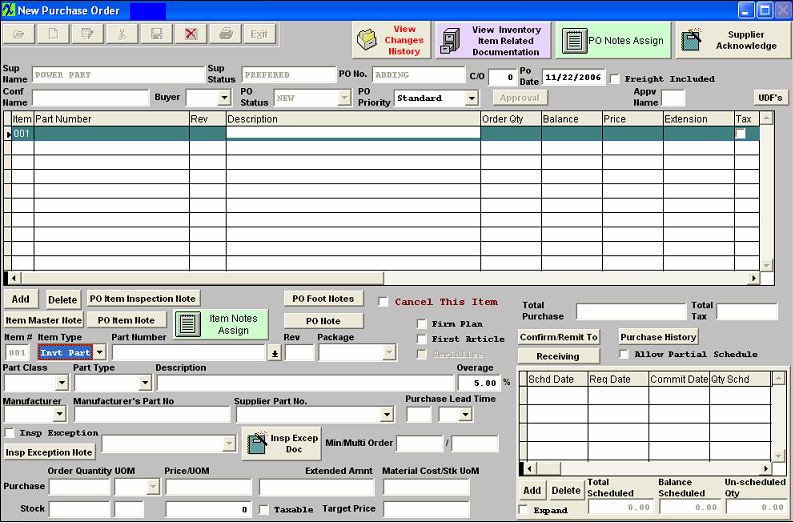

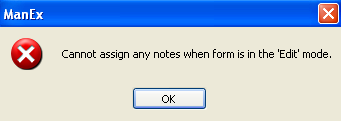

Entering Item Detail Information

|

| 1.1.1.4.2.1. Inventory Part | ||||||||||||||||||||||||||||||

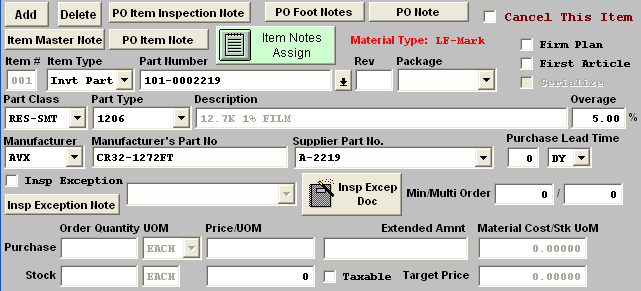

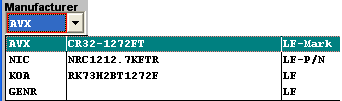

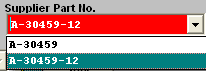

Selecting Inventory Parts as the item type, the user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. Once a part number from Inventory has been entered, ManEx completes the boxes associated with the item master.

The user may edit or add a percentage amount of extra material that will be allowed to be shipped against the order. By entering a percentage in the OVERAGE field, receiving will be allowed to receive extra parts up to the limit imposed in this field. The user may also edit or add in purchasing lead time and min/mult order quantities through the Purchase Order Management module.Once the record has been saved this information will then be updated within the Inventory Control Management under the MRP Info screen. The user may check the box for Inspection Exception and select from the Inspection Exception Pulldown (which is established in the Inspection Exception Setup module). The user will then also be allowed to enter any Inspection Exception Notes and/or Load Insp Excep doc that pertain to that PO line item. This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system. The user is then prompted for the purchase order quantity of parts to be ordered. The user may enter either the Purchase Quantity or the Stocking Quantity, and ManEx will complete the other field based on the purchase/stocking unit of measure and conversion field.

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter qty of 24 into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

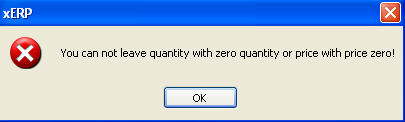

Then the unit price is entered (Price Each). The extended amount is shown, calculated by extending the quantity by price. (If the inventory part that you are creating a line item for currently has a standard cost of 0.00 within inventory control the system will prompt the user if you wish to take that Purchase Order Price entered and use it as the standard cost for that item within inventory control). This can not be controlled by the Security level due to the fact that it is better practice to have a $$ assigned to the ICM record before the Purchase Order Receipt is accepted into the system. Otherwise you will have stock that is not valued properly, accounting records that will not be correct, etc. . . . So this is why ManEx allows any Purchase Order user to populate the STD cost field for that record with the purchase $ that you are loading. BUT . . Once a Std Cost is associated with the ICM record - the users within Purchase Order Management should no longer be able to change that value through the PO module. The user may then indicate that the items are taxable by clicking on the Taxable check box. The Stock/BOM field will update automatically based upon the conversion table defined in setup. The completed screen should appear as follows: Before saving the order you will need to check the expand box and enter the Schedule detail information.

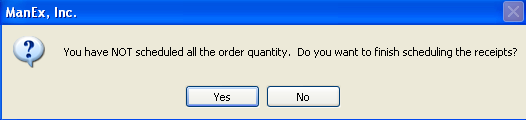

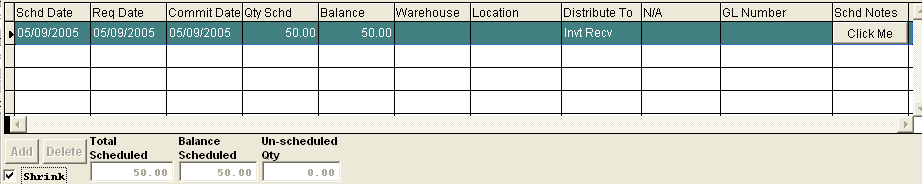

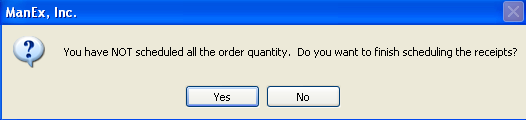

There are situations when the users will either not enter a schedule or enter a partial schedule at time of creating PO. If the scheduled qty does not match the order qty or the "Allow Partial Schedule" box is unchecked, upon depressing the Save button the following message will be displayed. This gives the user the option to stop the save process and return to the item and schedule or continue on and save without scheduling. Some users may not know an exact date for scheduling at the time of the PO creation and just create the PO to get the part on order. Then upon the supplier response add the scheduled dates to the PO at a later time. This is why we do not enforce the scheduling at the time of the PO creation.

If the "Allow Partial Schedule" box is checked upon saving the PO without a schedule or a partial schedule this message will not be displayed.

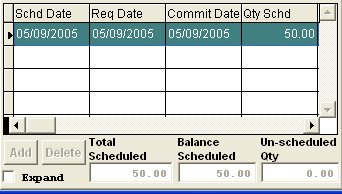

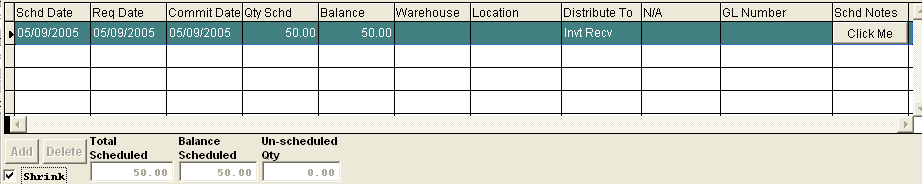

Entering Schedule Detail Information

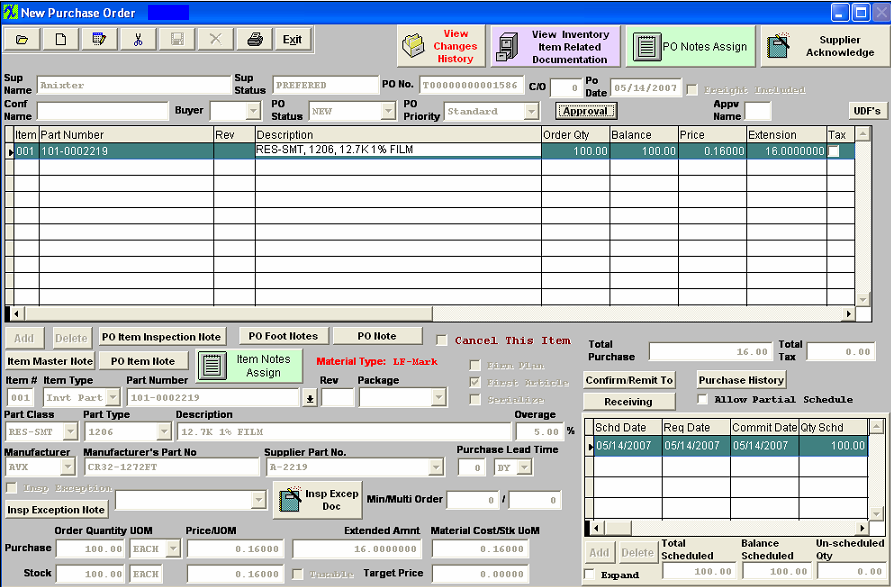

The item will schedule automatically by adding the lead time to todays date and schedule the entire order amount. (Note: MRP will NOT acknowledge qty's that are not scheduled).

At this time the user has the option to change the Schd date/Req date/commit date information and also the Qty Schd.

Note: If user is not following MRP suggestions when creating POs they need to keep in mind inspection time when entering a schedule for a PO.

If the user wants to modify the automatic scheduled date, they can either manually adjust the Date information by highlighting the field and typing in the new date, or place the cursor in the Due Date field.Type in a ?. A calendar will appear. Depress the desired delivery date.To advance into the next month, depress the > button. Schedule Field Definitions

Pressing the Save button at the top of the screen saves the order and item(s) entered, and assigns a temporary number to the order. After adding items to the purchase order and saving them, the Purchase Order will display all items added to the order.

The user may use the scroll bars at the right and bottom of the items listed to scroll over additional information. The user may modify the column widths in the current view by placing the cursor on the right border of the column in the column header, and pressing the left mouse button. Moving the border while holding the mouse button then releasing at the new location resizes the columns.

|

| 1.1.1.4.2.1.1. Allocate to Special Work Order or Project |

Introduction Inventory Allocation is used to allocate (reserve) quantities of existing items in stock or future Purchase Order deliveries to a Work Order or Project Number.This allocation prevents issuing the quantity reserved to any other use except the Work Order or Project Number specified. Purchase Order Line Item allocations may be removed prior to receipt of the parts by editing the Purchase Order.After receipt of parts allocated by Purchase Order, the allocation may only be removed after the parts are in stock, by using the Inventory Allocation module. ALLOCATION OF PURCHASE ORDER DELIVERIES Allocating a PO Line Item is used to make sure that the item will be reserved for a particular Work Order or Project Number when it is received.PO line item allocation is generally used when allocating to a Work Order or Project Number for which the items are not available in stock.Line Shortages of items not on the BOM, which are not in stock, are an example of typical PO Line Item Allocations.To allocate Purchase Order Line Item Deliveries to a Work Order or Project Number:

PROCEDURES To Allocate a PO Line Item to a Work Order or Project Number:

To Un-allocate a PO Line Item that has not yet been Dock Received:

To Un-allocate a PO Line Item that has already been Dock Received:

|

| 1.1.1.4.2.2. MRO Items |

MRO stands for Maintenance, Repair and Operations. Generally this is used for supplies, etc. purchases. After selecting the Item Type to be "MRO" If the MRO item is included in inventory

a. The user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. b. Fill in the quantity and unit price. If the MRO item is NOT included in inventory a. The user may enter in the Suppliers part number manually (or leave blank) and then jump to the description field and enter the description.

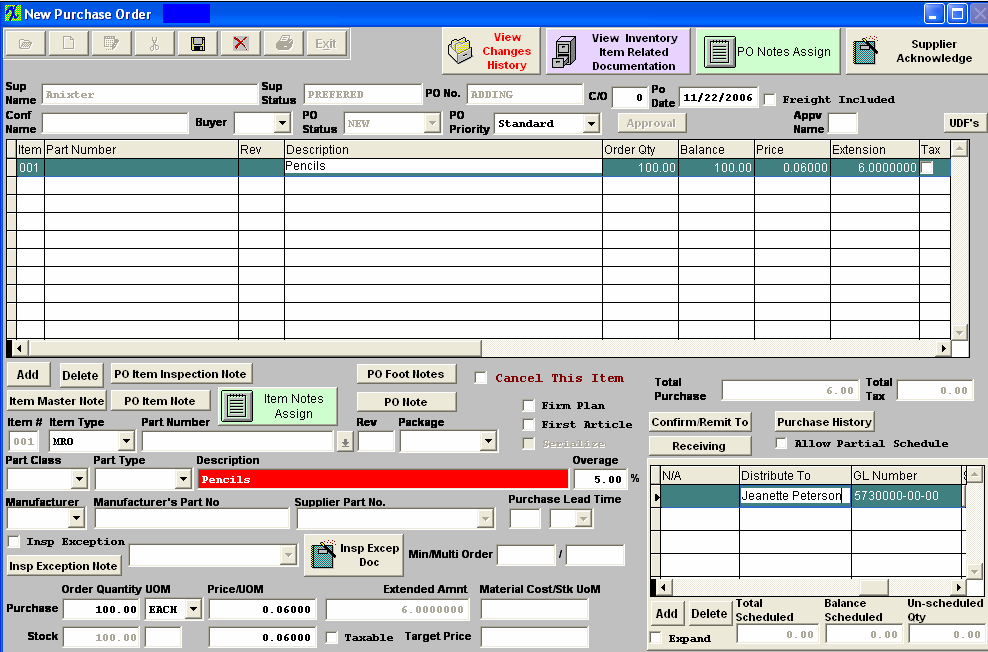

The finished screen should look like the screen displayed:

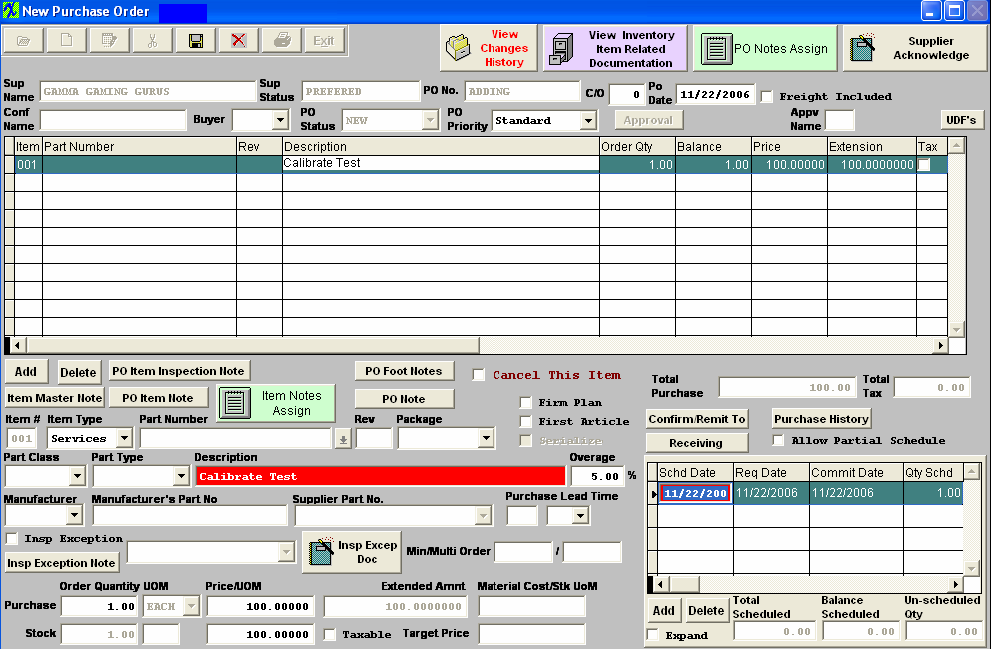

The completed Schedule screen will appear as follows:

|

| 1.1.1.4.2.3. Service Items |

Service items are for those instances where the assembly is outsourced. After selecting the Item Type to be "Service"

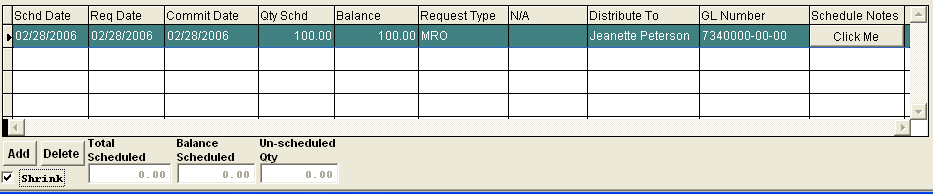

The finished screen should look like the screen displayed:

The completed Schedule screen will appear as follows:

|

| 1.1.1.4.3. Edit, Cancel, or Close a Purchase Order |

Find the Purchase Order that you would like to edit. Pressing the Edit record action button in the Purchase Order screen will allow the user to modify all the following information:

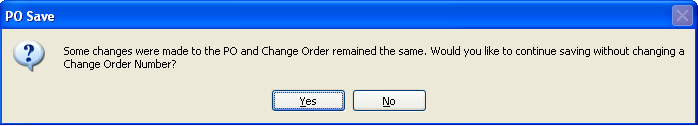

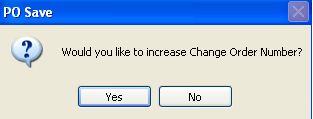

Depress the Save record action button after you have finished with editing the record. The user will then need to approve the order. If user has the "Auto Assign new Change Order # Upon Approval" box checked within the Purchase Setup module, the reminder will NOT be issued and CO# field becomes NOT editable. When the user approves the change the Change Order number will be automatically increased. If user has the "Auto Assign New Change Order # Upon Approval" box unchecked within the Purchase Setup module when user makes changes the CO# will stay the same, the system will prompt the reminder, and user may manually assign a change order number if applicable. There are situations when an item may not have a schedule or may have a partial schedule. If the "Allow Partial Schedule" box is checked within the Purchase Setup module, the system will NOT ask any questions when saving a po with only partial schedule. (Note: MRP will NOT acknowledge qty's that are not scheduled). If the "Allow Partial Schedule" box is unchecked within the Purchase Setup module, user will receive the following popup warning when editing and saving that line item or any other line item on that same purchase order:

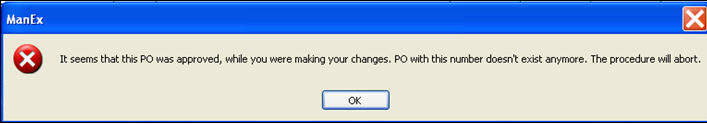

NOTE: If the "Auto Assign new Change Order # Upon Approval" box is checked, and PO is new and the user goes into the "Edit" mode prior to approval, no changes will be made to the CO# on screen or in the "View Changes History" screen. If PO has been approved and the user goes into the "Edit" mode the next CO# will be referenced in the "View Changes History" screen but will NOT increase on screen until PO has been approved. If the user goes to the "Edit" mode more than once before approving the change the CO# will only increase once in the "View Changes History" screen. NOTE: If users enter a PO number manually using a "T", then changes the numbering to Auto, and later edits and approves this PO the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change. If multiple users are editing the same PO and the PO has not been approved yet, so it still has a temp # and the 1st users approves the PO, while the 2nd user is still making their changes, when the 2nd user goes to exit and save their changes they will receive the following message:  Manex tracks all revisions of a Purchase Order and each receipt against each revision of the order. The system will NOT allow any changes to a Purchase Order which has parts in Dock Receiving that have not yet been processed in the Purchase Order Receiving & Inspection module. Cancel a Purchase Order Find the Purchase Order you want to cancel. Press the Edit record action button in the Purchase Order screen this will allow the user to change the PO status from Open to Cancel. Note: User MUST have approval rights to Modify the PO Status.

Closing out a Purchase Order At times, the user may wish to close out a In the above set of circumstances, the user will be allowed to change the ORIGINAL order quantity by removing the rejected quantity via the DMR procedure. When the Received quantity PLUS the DMR quantity is LESS than the order quantity, the user will be allowed to decrease the order quantity by that many. Original Order 100; Received quantity 100; Rejected quantity 5. Returned to supplier via DMR 5. At this point, the user may reduce the quantity ordered, AND the accompanying amount scheduled to 95. This action will close out the Purchase Order. The user must depress the Edit button. Change the Purchase Order Quantity, then change the Quantity Scheduled so that the total of the schedule dates exactly equals the new quantity. Depress the Save button. Approve the PO and the

|

| 1.1.1.4.4. E-mail Purchase Order(s) | ||

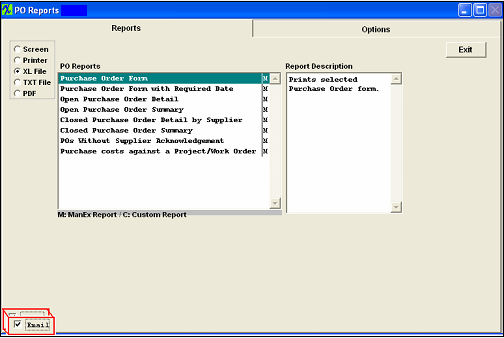

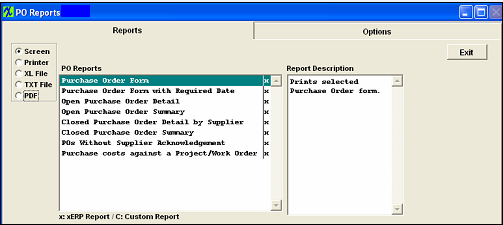

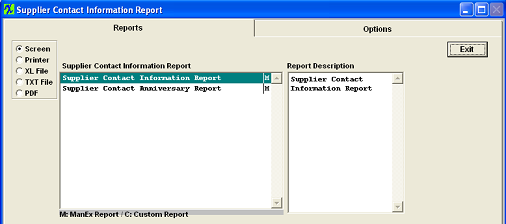

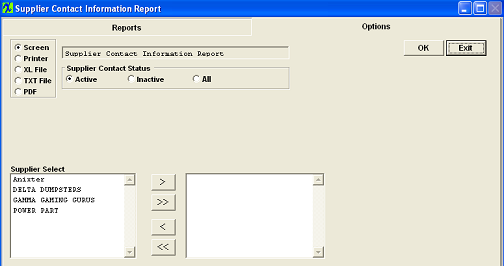

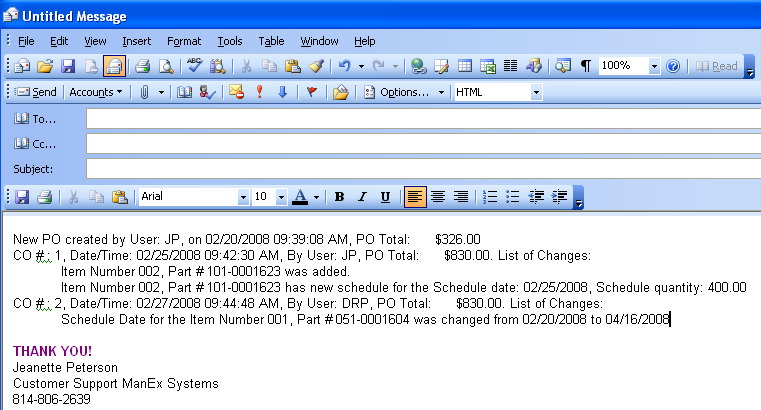

To e-mail a Purchase Order report(s), depress the Reports button.

Note: You MUST have the e-mail setup within the Trigger.exe setup and working before the PO e-mail will work.

The reports screen will appear:

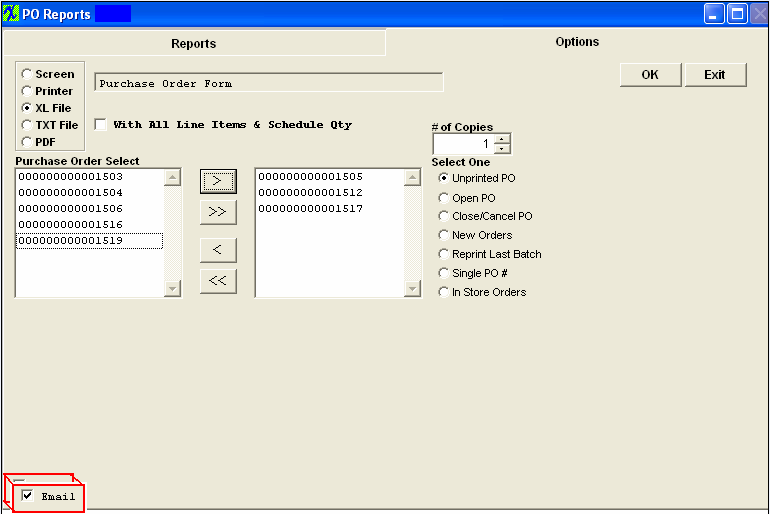

Complete the Option tab with the information required: Note: User has the option to check the Email box on the Options screen also.

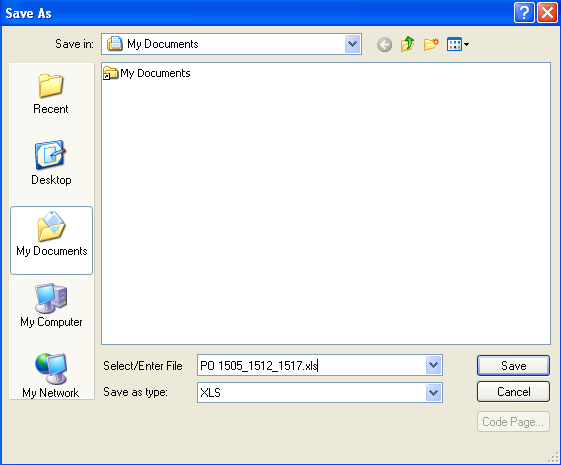

Depress OK. The following screen will appear. Select or Enter File Name.

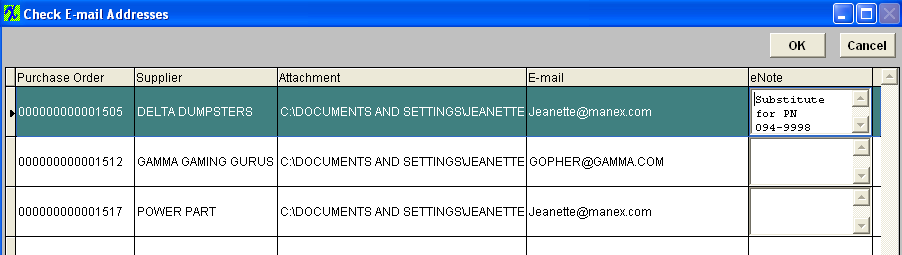

Depress Save, the following Check Email Addresses screen will appear. Within this screen you can enter an e-mail address or add any special notes needed:

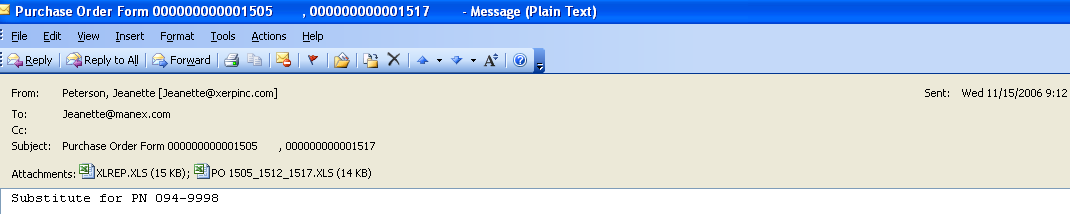

Depress OK and documents will be sent to e-mail addresses assigned. The following is what the receiver will receive:

|

| 1.1.1.4.5. Approve a Purchase Order | ||||

The following screen will appear:  Approve PO Pressing the Approval button in the Purchase Order module will ask for the user’s password. The user must enter a password that has been authorized (within the Purchase Setup module) to approve the dollar amount of the order.

Entry of an authorized password and approval will inactivate the 1st approval button and place the initials of the person approving the order next to the approval button , (If in the Purchase Setup , the company has selected to allow one approval of purchase orders). Then upon approval the temporary Purchase Order number will be replaced with a permanent PO number (replacing the "T" with a "0").

If in the Purchase Setup , the company has selected requiring two approvals, then the process must be repeated for the second approval, and the temporary Purchase Order number will be replaced with a permanent PO number (replacing the "T" with a "0") once both approval are granted. Note: That if the Purchase Order is an Service or In-store order, once the

If the user has elected to use manual purchase order number,the screen will prompt the user for an order number to be applied to the purchase order. Note: If users enter a PO number manually using a "T", then changes the numbering to Auto, and later edits and approves this PO the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change.

|

| 1.1.1.4.5.1. Inventory Part | ||||||||||||||||||||||||||||||

Selecting Inventory Parts as the item type, the user may jump directly to the part number box (click on it) and enter a part number. Or, the user may step through the Part Classes and Part Types to narrow the focus and then select a part from the desired part type. Once a part number from Inventory has been entered, Manex completes the boxes associated with the item master.

The user may edit or add a percentage amount of extra material that will be allowed to be shipped against the order. By entering a percentage in the OVERAGE field, receiving will be allowed to receive extra parts up to the limit imposed in this field. The user may also edit or add in purchasing lead time and min/mult order quantities through the Purchase Order Management module.Once the record has been saved this information will then be updated within the Inventory Control Management under the MRP Info screen. The user may check the box for Inspection Exception and select from the Inspection Exception Pulldown (which is established in the Inspection Exception Setup module).The user will then also be allowed to enter any Inspection Exception Notes and/or Load Insp Excep doc that pertain to that PO line item.This information will then be displayed within the PO Receiving as reference information to the users that are processing the Receipts through the system. The user is then prompted for the purchase order quantity of parts to be ordered. The user may enter either the Purchase Quantity or the Stocking quantity, and Manex will complete the other field based on the purchase/stocking unit of measure and conversion field. Then the unit price is entered (Price Each). The extended amount is shown, calculated by extending the quantity by price. (If the inventory part that you are creating a line item for currently has a standard cost of 0.00 within inventory control the system will prompt the user if you wish to take that Purchase Order Price entered and use it as the standard cost for that item within inventory control). This can not be controlled by the Security level due to the fact that it is better practice to have a $$ assigned to the ICM record before the Purchase Order Receipt is accepted into the system. Otherwise you will have stock that is not valued properly, accounting records that will not be correct, etc. . . . So this is why ManEx allows any Purchase Order user to populate the STD cost field for that record with the purchase $ that you are loading. BUT . . Once a Std Cost is associated with the ICM record - the users within Purchase Order Management should no longer be able to change that value through the PO module. The user may then indicate that the items are taxable by clicking on the Taxable check box. The Stock/BOM field will update automatically based upon the conversion table defined in setup. The completed screen should appear as follows: Before saving the order you will need to check the expand box and enter the Schedule detail information. Entering Schedule Detail Information

At this time the user has the option to change the Schd date/Req date/commit date information and also the Qty Schd. Note: If user is not following MRP suggestions when creating POs they need to keep in mind inspection time when entering a schedule for a PO.

If the user wants to modify the automatic scheduled date, they can either manually adjust the Date information by highlighting the field and typing in the new date, or place the cursor in the Due Date field.Type in a ?. A calendar will appear. Depress the desired delivery date.To advance into the next month, depress the > button. Schedule Field Definitions

Pressing the Save button at the top of the screen saves the order and item(s) entered, and assigns a temporary number to the order. After adding items to the purchase order and saving them, the Purchase Order will display all items added to the order.

The user may use the scroll bars at the right and bottom of the items listed to scroll over additional information. The user may modify the column widths in the current view by placing the cursor on the right border of the column in the column header, and pressing the left mouse button. Moving the border while holding the mouse button then releasing at the new location resizes the columns. |

| 1.1.1.4.5.1.1. Allocate to Special Work Order or Project |

Introduction Inventory Allocation is used to allocate (reserve) quantities of existing items in stock or future Purchase Order deliveries to a Work Order or Project Number.This allocation prevents issuing the quantity reserved to any other use except the Work Order or Project Number specified. Purchase Order Line Item allocations may be removed prior to receipt of the parts by editing the Purchase Order.After receipt of parts allocated by Purchase Order, the allocation may only be removed after the parts are in stock, by using the Inventory Allocation module. ALLOCATION OF PURCHASE ORDER DELIVERIES Allocating a PO Line Item is used to make sure that the item will be reserved for a particular Work Order or Project Number when it is received.PO line item allocation is generally used when allocating to a Work Order or Project Number for which the items are not available in stock.Line Shortages of items not on the BOM, which are not in stock, are an example of typical PO Line Item Allocations.To allocate Purchase Order Line Item Deliveries to a Work Order or Project Number:

PROCEDURES To Allocate a PO Line Item to a Work Order or Project Number:

To Un-allocate a PO Line Item that has not yet been Dock Received:

To Un-allocate a PO Line Item that has already been Dock Received:

|

| 1.1.1.4.5.2. MRO Items |

MRO stands for Management Required Options. Generally this is used for supplies, etc. purchases. After selecting the Item Type to be "MRO"

The finished screen should look like the screen displayed:

The completed Schedule screen will appear as follows:

|

| 1.1.1.4.5.3. Service Items |

Services items are for those instances where the assembly is outsourced. After selecting the Item Type to be "Service"

The finished screen should look like the screen displayed:

The completed Schedule screen will appear as follows:

|

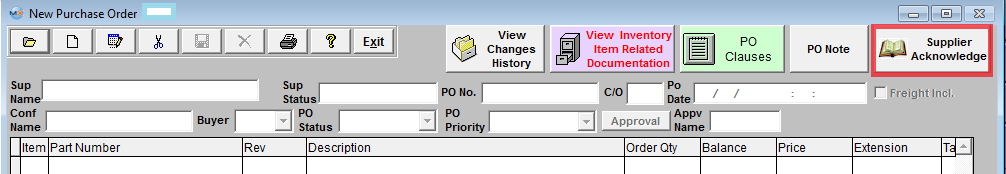

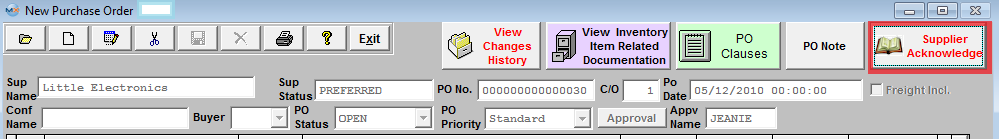

| 1.1.1.4.6. Load Supplier Acknowledgement |

How to attach or load a Supplier Acknowledge document to a PO. Note: User is only allowed to load one document per Purchase order.

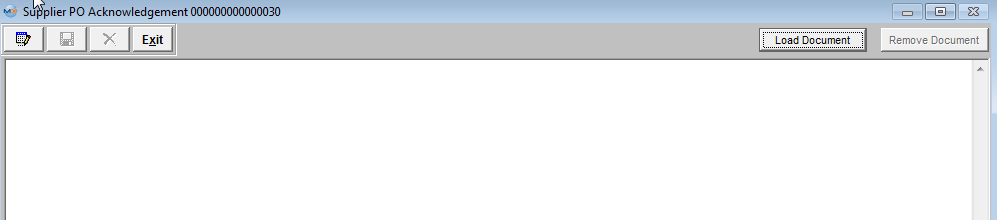

Depress the "Supplier Acknowledge" button and the following screen will appear:

To load images or documents, depress the "Load Document" button, up in the right hand corner of the screen. A browser screen will appear similar to the one below:  Find and highlight the desired Image file, as illustrated.

Once the file name appears, depress the Ok button. Note: that the user can also load other document types by changing the File of Type to ALL

The file will appear in the screen as displayed:  Depress the Save action button to save the changes or depress the Abandon changes action button to abandon changes. Exit will bring the user back to the Purchase Order Management module. If user selected to Save the Supplier Acknowledge button will be displayed in Red as shown below.

|

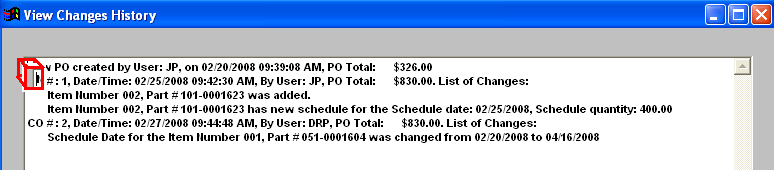

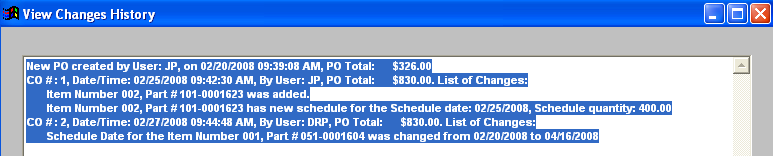

| 1.1.1.4.7. Copy "View Change History" Notes |

Find the Purchase Order you want to Copy the "View Changes History" notes on.

Depress the "View Changes History" button, When in the “Change PO history” screen, click on the vertical scroll (on your keyboard), you will see the cursor appeared on the top inside the window with the text.

Depress the "CTRL" button + the vertical scroll buttons to highlight the information you wish to copy;

Depress the "CTRL + C" to copy, then paste to a document, e-mail, etc....

|

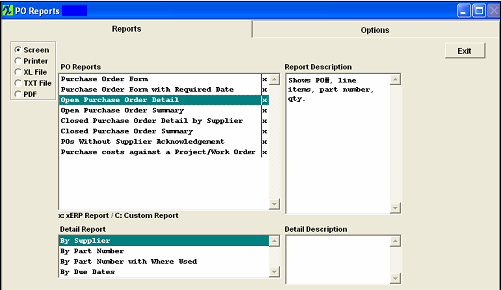

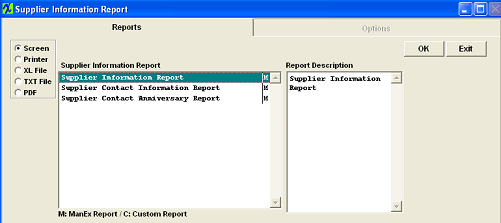

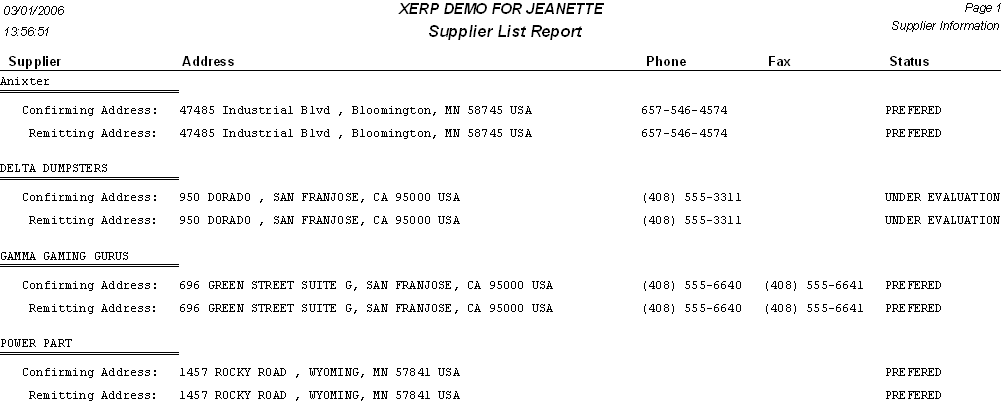

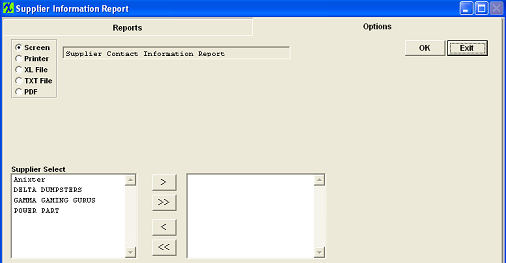

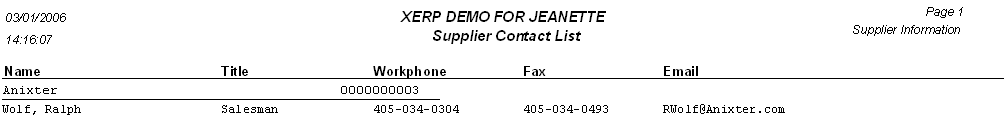

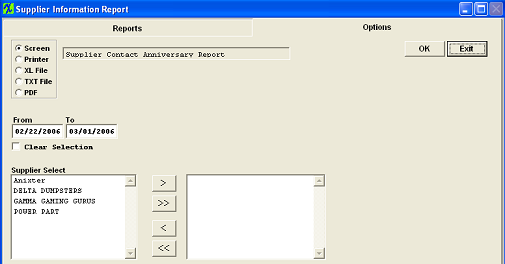

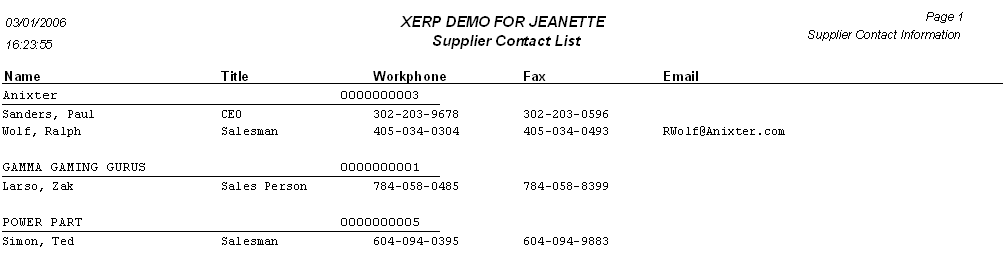

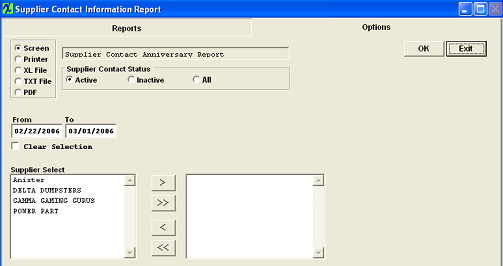

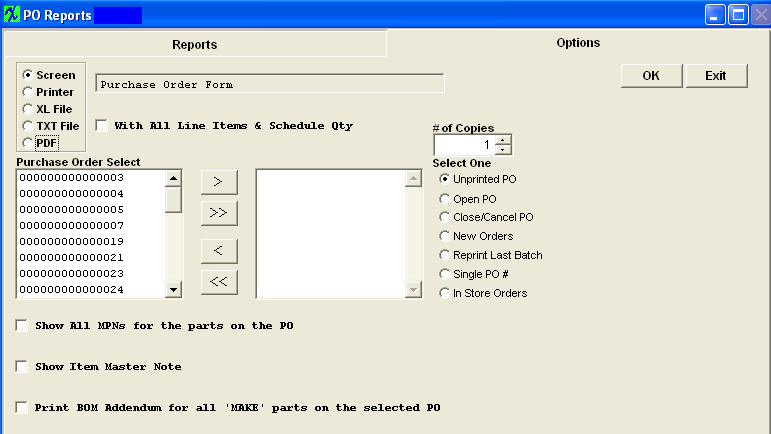

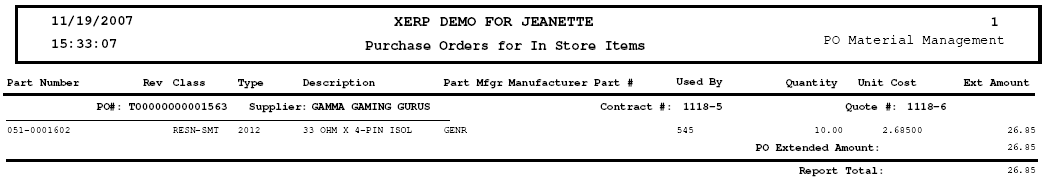

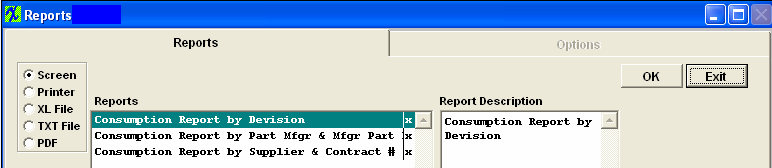

| 1.1.1.5. Reports - PO Mgmt | ||||||||||||||||||

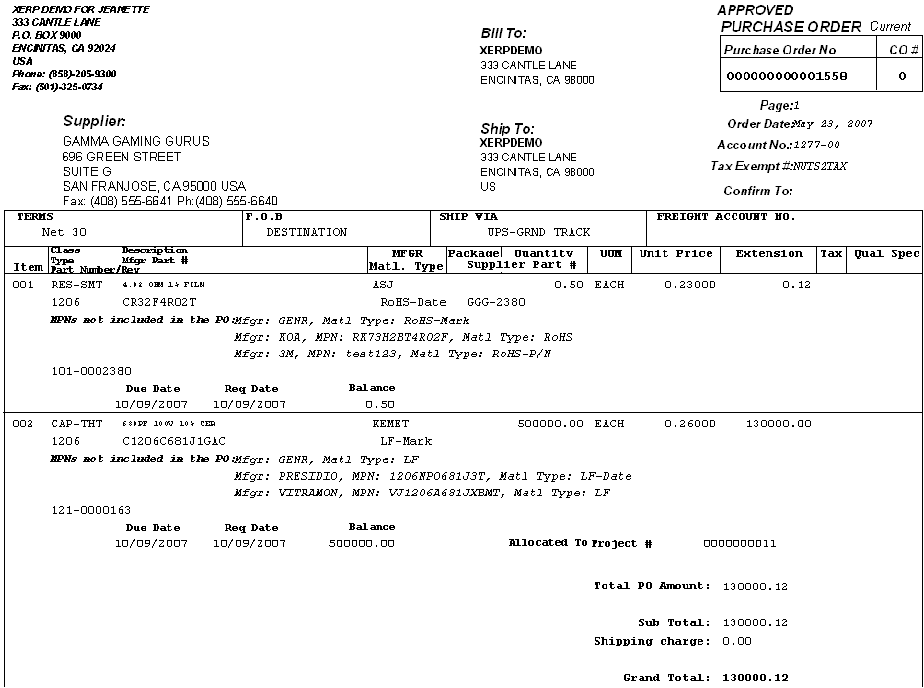

PURCHASE ORDER FORM report

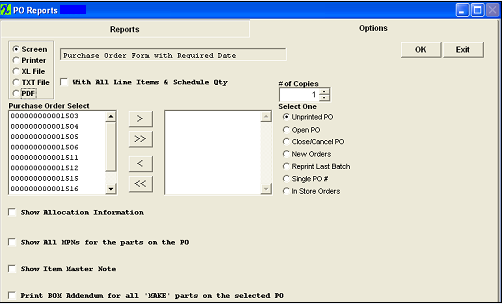

If you want all line items & scheduled quantities to print, check that box.

Select the number of copies you want by toggling the up and down arrows. Select one of the following options: Unprinted PO, Open PO, Close/Cancel PO, New Orders, Reprint Last Batch, Single PO #, In Store Orders by clicking on the radial. NOTE: Depending on which one of these options you select will depend on what will be displayed on the report. For Example: If User selects Open/Active the report will have "APPROVED" at the top of the report (as displayed below) and prints out the Purchase Order form AFTER some receiving has occurred against that PO, then ONLY the un-received still open amounts will print on this form. Any line items COMPLETELY RECEIVED or CANCELED will NOT display on the PO form. If User selects Close/Cancel PO the report will have "CLOSED" at the top of the report and will display the original scheduled balance. Highlight the PO of interest and depress the > button. To select all POs, depress the >> button. Check the "Show All MPNs for the Parts on the PO" box if you want all MPNs listed on the report. Check the "Show Item Master Note" box if you would like the Item master notes to be displayed on the report.

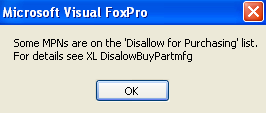

Check the "Print BOM Addendum for all "MAKE" parts on the Selected PO" When the users add a Make/Buy part to a Suppliers PO, and checks this option the system will then print a "BOM Indented with AVL" report as an addendum to the PO form. Each BOM will be printed as a separate report and will reference PO and item on the PO. If the AVL on the approve vendor list for any of the items on the BOM happens to be checked as "disallow to buy" this AVL will not be included within the addendum to the PO.

Depress the OK button

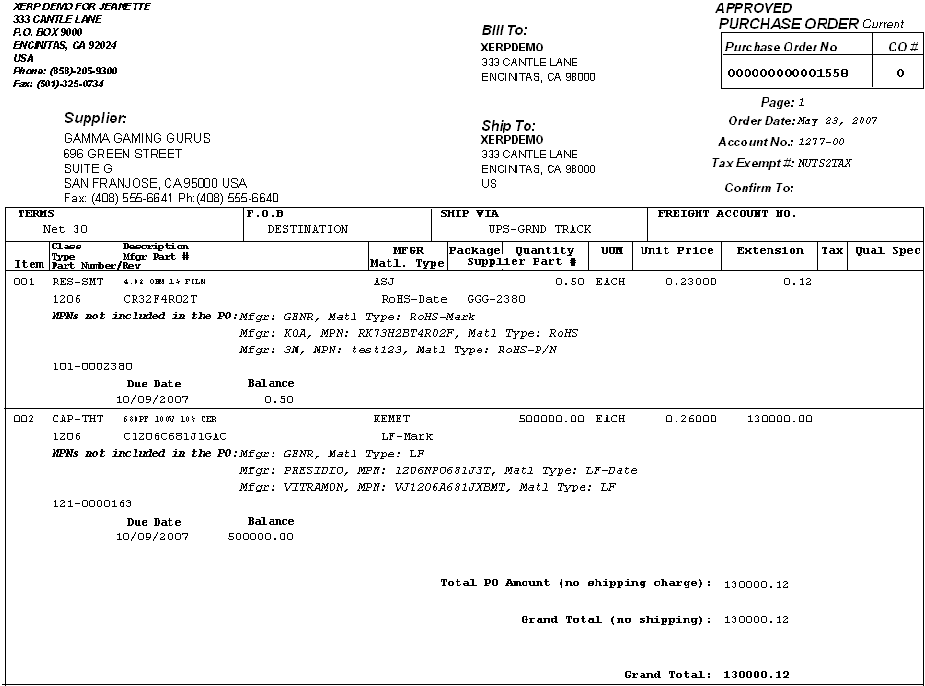

When this report is printed is will display the Approval status of the order, it will also display the Supplier Part Number if entered in the ICM module.

The following report will be displayed:

PURCHASE ORDER FORM with REQUIRED DATE report

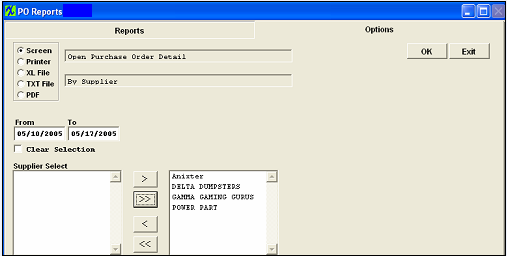

This report is exactly the same as the Purchase Order Form report above, except that this report will also show the Required Date information. If you want all line items & scheduled quantities to print, check that box. Select the number of copies you want by toggling the up and down arrows. Select one of the following options:Unprinted PO, Open PO, Close/Cancel PO, New Orders, Reprint Last Batch, In Store Orders by clicking on the radial. The following report will be displayed: OPEN PURCHASE ORDER DETAIL report

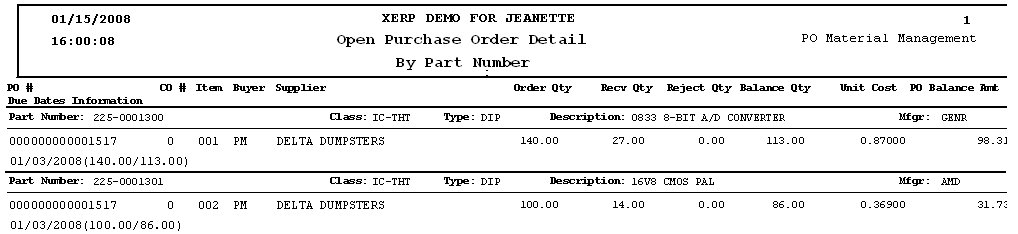

The following report will be displayed:

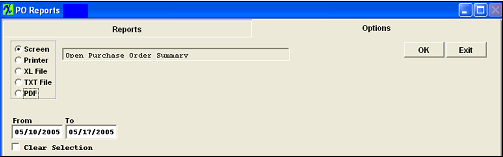

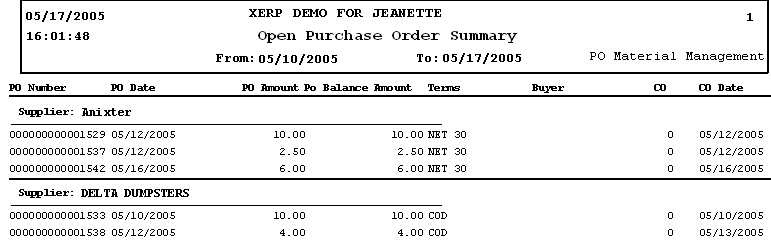

OPEN PURCHASE ORDER SUMMARY report

The following report will be displayed

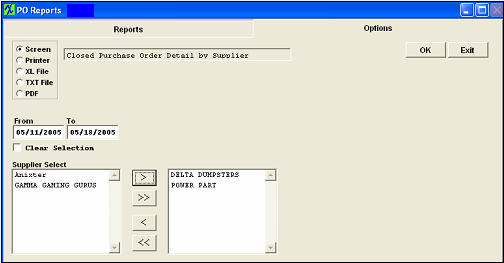

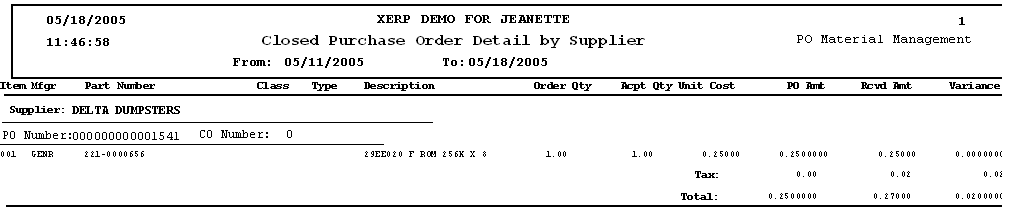

CLOSED PURCHASE ORDER DETAIL BY SUPPLIER report

The following report will be displayed

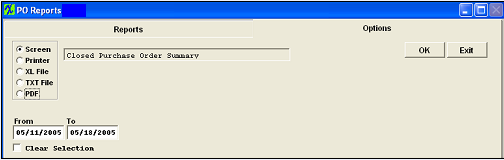

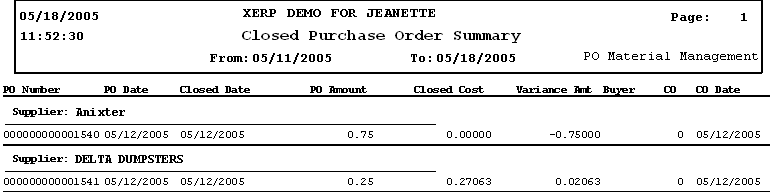

CLOSED PURCHASE ORDER SUMMARY report

Enter in the desired Date Range. Depress the OK button. The following report will be displayed

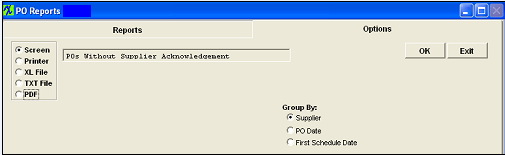

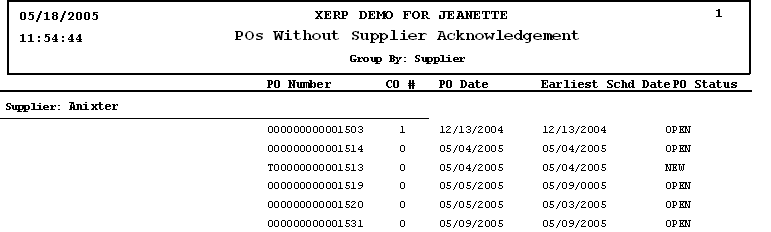

POs WITHOUT SUPPLIER ACKNOWLEDGEMENT report

Select one of the Group By options: Supplier, PO Date, First Schedule Date by clicking on the radial. Depress the OK button. The following report will be displayed

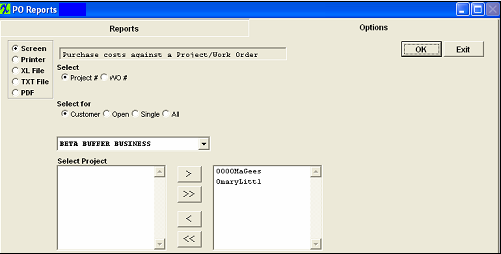

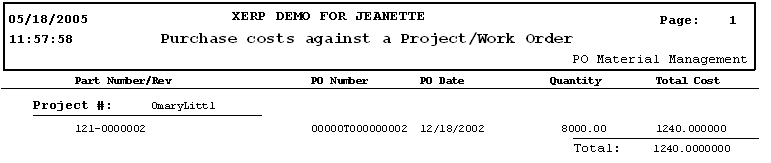

PURCHASE COSTS against a PROJECT/WORK ORDER report

Select Project # or Work Order # by clicking on the radial. Select for: Customer, Open, Single, or All by clicking on the radial If select by customer, then choose the customer from the pull down menu. Highlight the Project and select by using the > button. For All Suppliers, depress the >> button. Depress the OK button. The following report will be displayed

|

| 1.1.1.6. FAQs - PO Mgmt |

| Facts and Questions for the Purchase Order Module |

| 1.1.1.7. ManEx Minutes (PO) |

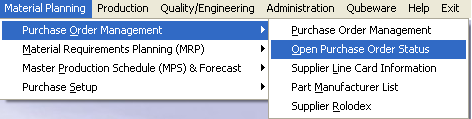

| 1.1.2. Open Purchase Order Status |

| 1.1.2.1. Open Purchase Order Status | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

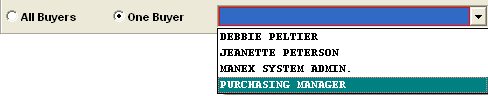

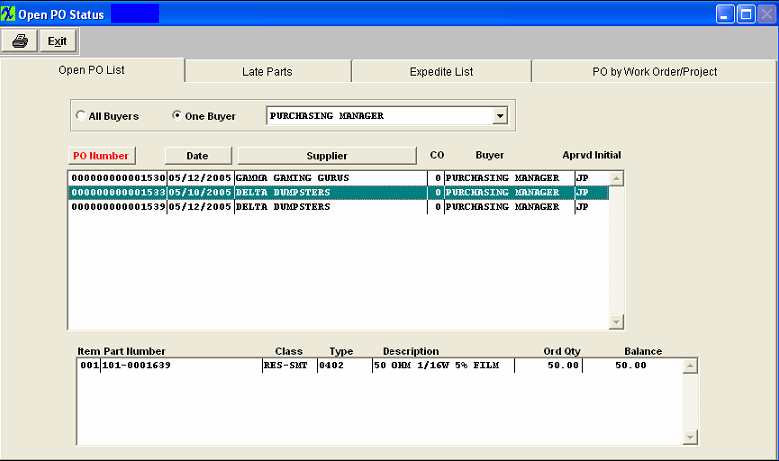

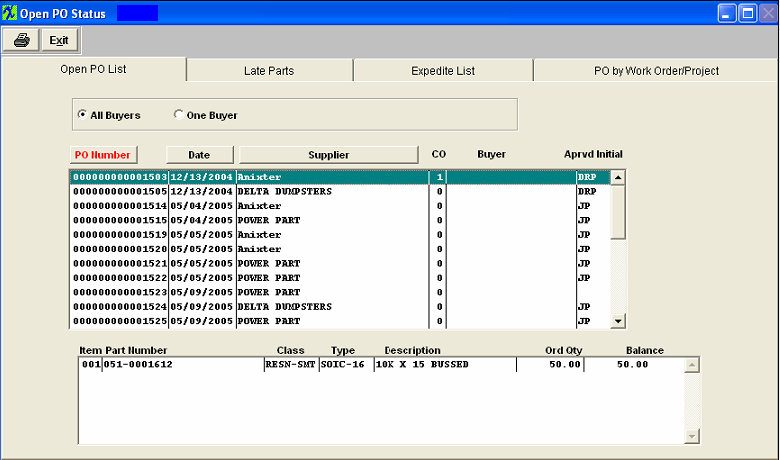

OPEN PURCHASE ORDER LIST tab The Open Purchase Order List screen will show all Open Purchase Orders

The Open Purchase Order List will display that buyer only. Highlight the Purchase Order to be viewed.The detail will appear at the bottom of the screen, as illustrated:

Open P O List Field Definitions

Purchase Order Number |

The number of the Purchase Order |

Date |

The date of the purchase Order |

Supplier |

The name of the Supplier |

ChgOrd |

The number of the Change Order |

Buyer |

The name of the Buyer |

Aprvd Initial |

The initials of the approver |

Item |

The line item number |

Part Number |

The user’s number for the part purchased |

Class |

The classification pertaining to the Part Number |

Type |

The type within the classification |

Description |

The description of the part |

Ord Qty |

The quantity ordered. |

Balance |

The un-received balance |

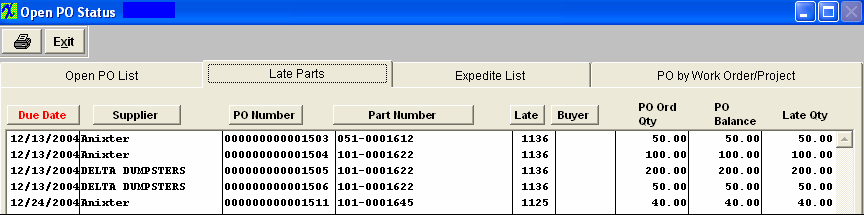

The user may sort by Purchase Order Number, Date or Supplier by depressing on the applicable button. To obtain a report for this screen, depress the Print button. LATE PARTS Tab The Late Parts Quick View screen will show all Purchase Order that are late compared to the schedule dates.

Late Parts tab Field Definitions

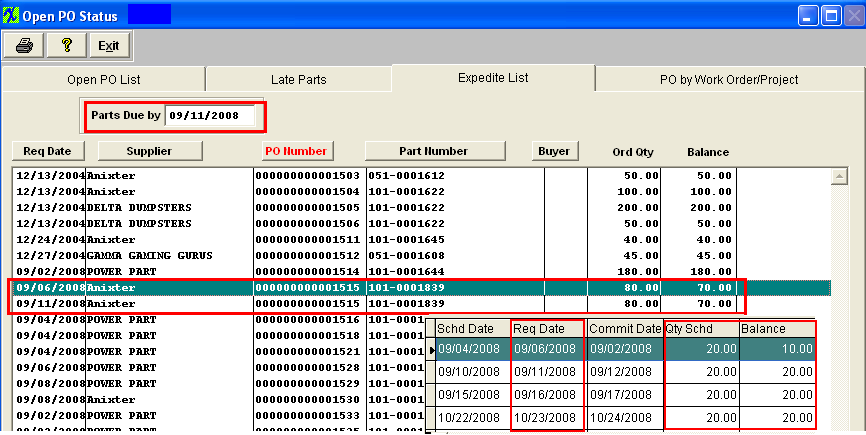

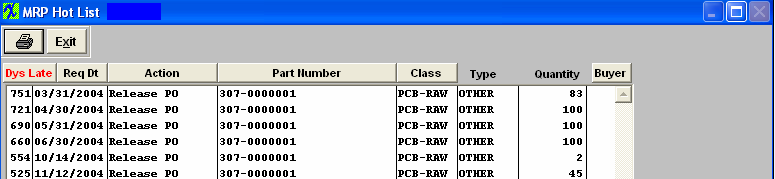

EXPEDITE LIST Tab The screen will show you the Purchase Orders which will be coming due by the Date entered Within the "Part Due By" field. The balance displayed will be the un-received quantity, NOT the quantity per schedule. To view the scheduled qty double click on the line item of interest and a popup will appear displaying the PO screen.

Expedite List Field Definitions

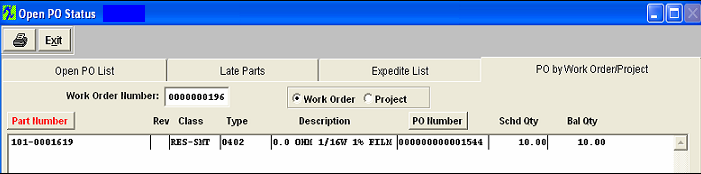

The user may sort by Req Date, Supplier, P O Number, Part Number, or Buyer by depressing the appropriate button. To obtain a printout of this screen, depress the Print button. PO By WORK ORDER/PROJECT Tab This screen will list Purchase Order details if the Work Order or Project allocation field contains a Work Order or Project Reference. Select either Work Order or Project by clicking on the radial.Type the Work Order or Project number in the red box and hit enter. P O By Work Order/Project Tab definitions

The classification within which the part number belongs The type within the classification within which the part number belongs The purchase order number which was used to order the part The amount originally scheduled to purchase The user may sort by purchase order by depressing that button. To obtain a report for this screen, depress the Reports button. |

| 1.1.2.2. ManEx Minutes (Open PO Status) |

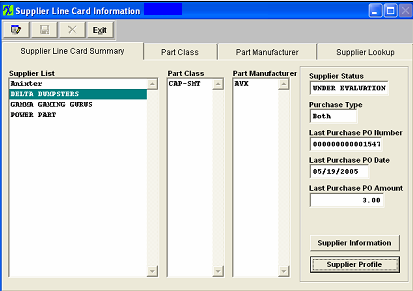

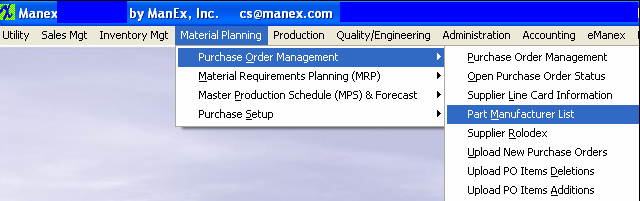

| 1.1.3. Supplier Line Card Information | ||||||||||||||

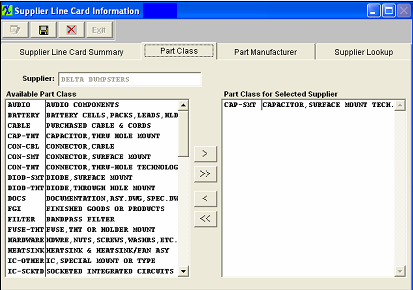

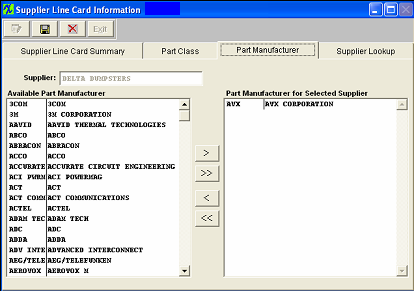

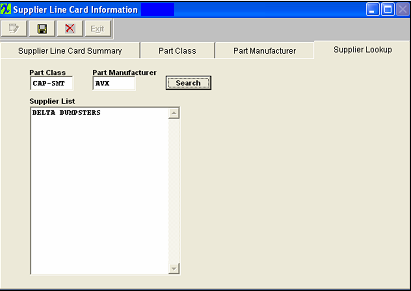

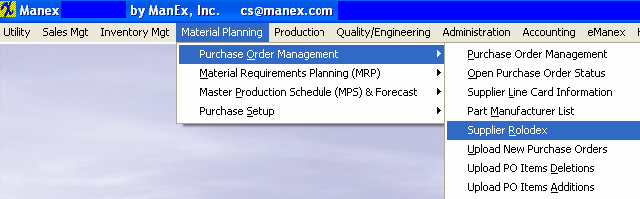

Supplier Line Card Information

|

| 1.1.4. Part Manufacturer List | ||||

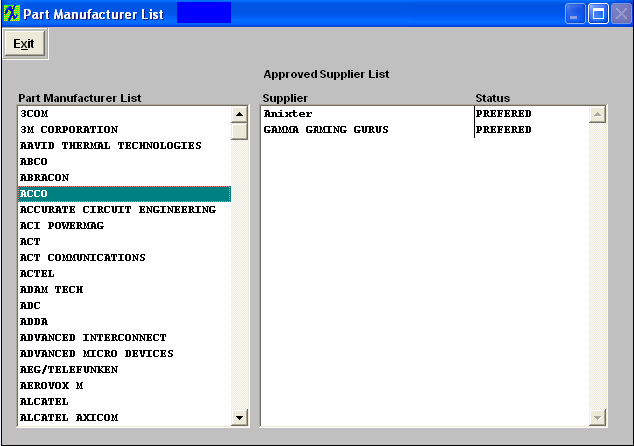

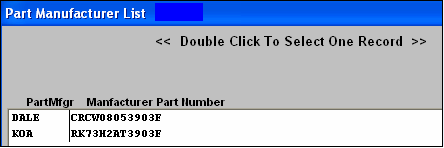

Part Manufacturer List The part manufacturer cross references the manufacturer to the supplier who distributes that manufacturer’s goods

|

| 1.1.5. Supplier Rolodex | ||||

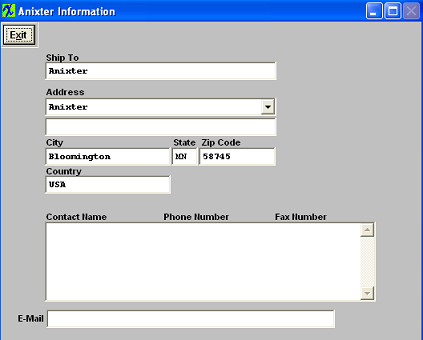

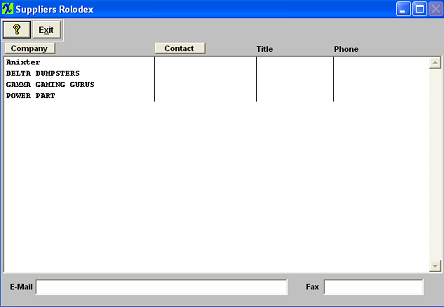

Supplier Rolodex The Supplier Rolodex is a list of all suppliers, plus their respective contacts.

|

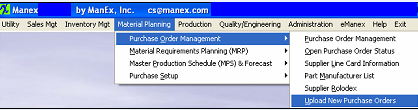

| 1.1.6. Upload New Purchase Orders |

| 1.1.6.1. Prerequisites for New PO Upload |

|

User must have the Express Import to BOM or Quote Module After activation, "PO Import" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

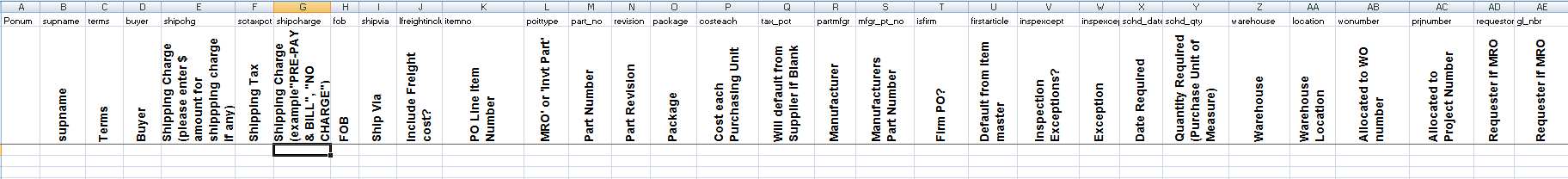

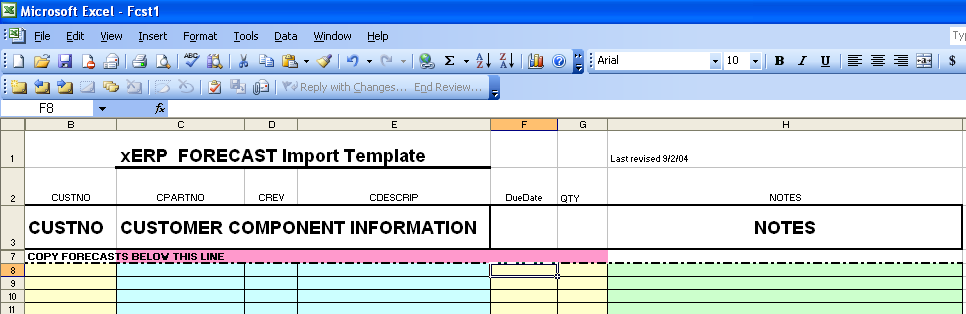

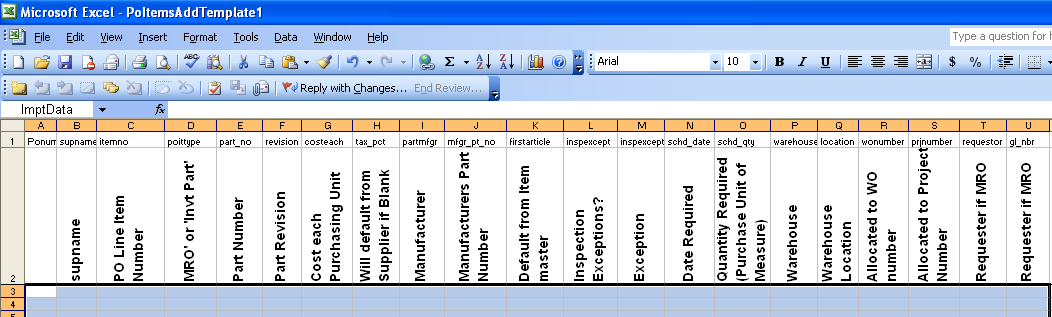

User has to complete the required fields in the PoUploadTemplate.xlt in the xlfiles directory to create

If user wants the system to automatically approve all the POs uploaded the "Auto Approve PO when importing from XL" box must be checked in the Purchase Setup module. If this is NOT checked in the Purchase Setup module then all the POs will be uploaded as "NEW" and users will be required to approve within the Purchase Order Management module.

|

| 1.1.6.2. Introduction for New PO Upload |

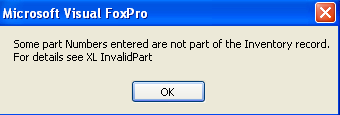

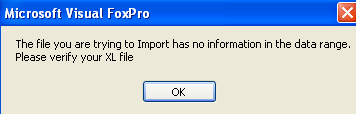

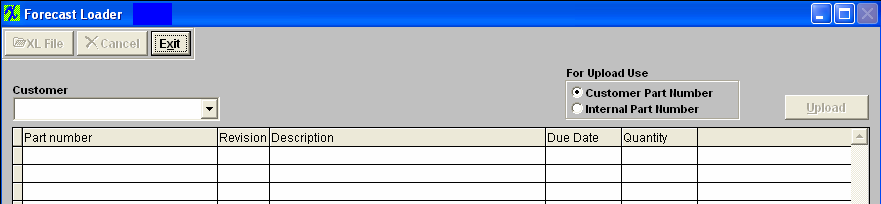

This module gives our users the capability to take electronic files provided by the suppliers from quote and availability of items, copy and paste that information into the ManEx PO Upload template format. Users will have the flexibility to load a large PO into the system all at once, or upload multiple purchase orders for different suppliers at once, etc. During the upload process the system will find any problems with the template, the user will be prompted and exception XL files will be created within the POExceptionXL directory for the users to review and disposition. |

| 1.1.6.3. Fields and Definitions for New PO Upload |

| 1.1.6.3.1. PO Upload Template | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

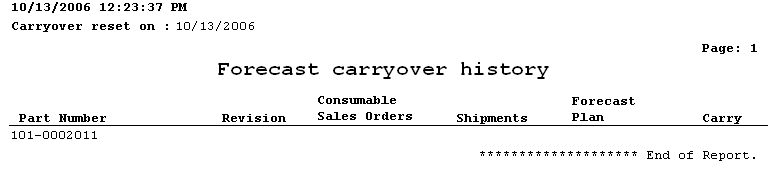

|

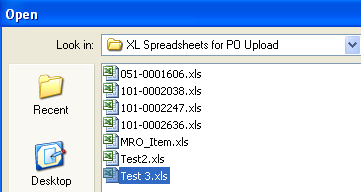

| 1.1.6.4. How To ....... for New PO Upload |

| 1.1.6.4.1. Add - Upload a New PO | ||||||||||||||||

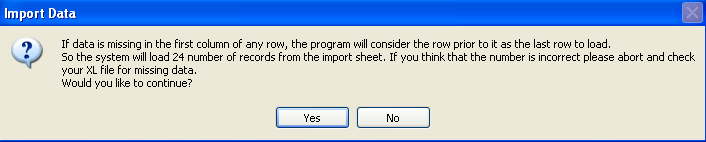

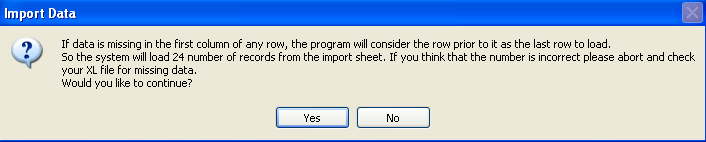

If system does not find any problems with the template the following message will appear: This message is for user to verify the number of recorrds being loaded from the import sheet. User may depress "YES" to continue the upload or "NO" to abort the upload.

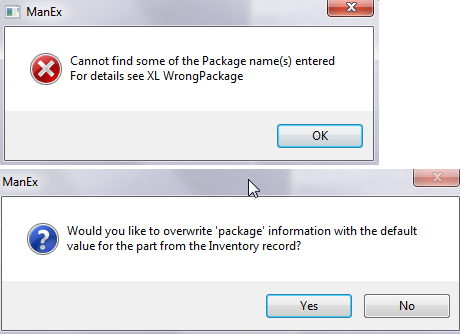

If a package type was entered that does NOT exist in System Setup, the following prompts we be displayed, an XL file will be created for review, and you will have a choice to overwrite the Package" information with the defaults value for the part from Inventory records and continue or cancel and fix the XL file.

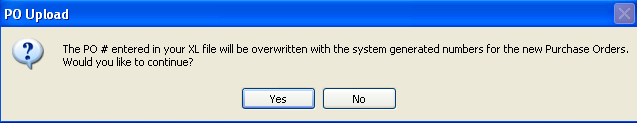

If user selects Yes to continue the following message will appear if system is setup to Auto create PO Numbers, or Manual create PO Numbers without Auto Approve selected (if Auto Approve is selected along with Manual create PO Numbers this message will NOT be displayed. Depress Yes to Continue and No to Abort Upload.

|

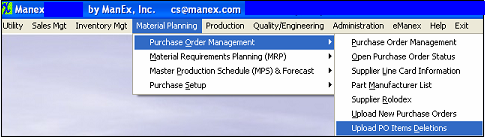

| 1.1.7. Upload PO Items Deletions |

| 1.1.7.1. Prerequisites for PO Upload Deletions |

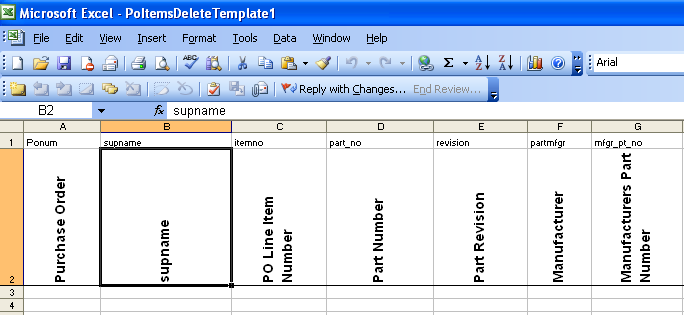

User must have the Express Import to BOM or Quote Module. After activation, "PO Import" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access. User has to complete the PoItemsDeleteTemplate.xlt in the xlfiles directory to create If user wants the system to automatically approve all the POs after the "Upload PO Items Deletions" the "Auto Approve PO when importing from XL" box must be checked in the Purchase Setup module. If this is not checked in the Purchase Setup module then all the POs will be updated with the PO Items Deletions and the PO status will be changed to "EDITING" and users will be required to approve the PO within the Purchase Order Management module.

If user wants the system to automatically assign a new change order number upon upload after approval the "Auto Assign New Change Order # Upon Approval" box must be checked in the Purchase Setup module. If this is not checked in the Purchase Setup module then upon upload user will receive a popup window giving them the option of updating the change order # after the upload or not.

|

| 1.1.7.2. Introduction for PO Upload Deletions |

|

This module gives our users the capability to remove one or multiple items from one or multiple POs. As long as the PO is not closed or cancelled and items have no receipts against them.

|

| 1.1.7.3. Fields and Defintions for PO Upload Deletions |

| 1.1.7.3.1. Upload PO Items Deletions Template | ||||||||||||||

|

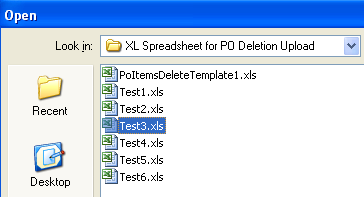

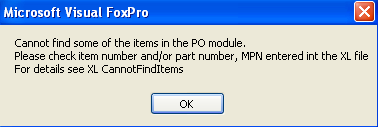

| 1.1.7.4. How To ........ for PO Upload Deletions |

| 1.1.7.4.1. Add - Upload PO Items Deletions | ||||||||||

If system does not find any problems with the template and the "Auto Assign New Change Order # Upon Approval is not checked in Purchase Setup the following message will appear:

|

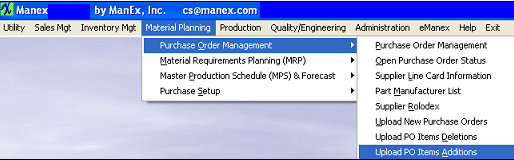

| 1.1.8. Upload PO Items Additions |

| 1.1.8.1. Prerequisites for PO Upload Addtions |

User must have the Express Import to BOM or Quote Module. After activation, "PO Import" access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rghts” will automatically have access.

User has to complete the PoItemsAddTemplate.xlt in the xlfiles directory to create If user wants the system to automatically approve all the POs after the "Upload PO Items Additions" the "Auto Approve PO when importing from XL" box must be checked in the Purchase Setup module. If this is not checked in the Purchase Setup module then all the POs will be updated with the PO Items Additions and the PO status will be changed to "EDITING" and users will be required to approve the PO within the Purchase Order Management module.

If user wants the system to automatically assign a new change order number upon upload after approval the "Auto Assign New Change Order # Upon Approval" box must be checked in the Purchase Setup module. If this is not checked in the Purchase Setup module then upon upload user will receive a popup window giving them the option of updating the change order # after the upload or not.

|

| 1.1.8.2. Introduction for PO Upload Additions |

This module will allow users to upload additional items to an existing PO.

|

| 1.1.8.3. Fields and Definitions for PO Upload Addtions |

| 1.1.8.3.1. Upload PO Items Additons | ||||||||||||||||||||||||||||||||||||||||||

|

| 1.1.8.4. How To ............. for PO Upload Additions |

| 1.1.8.4.1. Add - Upload PO Items Additions | ||||||||||||||||

If system does not find any problems with the template and system is setup to Auto create PO Numbers the following message will appear: This message is for user to verify the number of recorrds being loaded from the import sheet. User may depress "YES" to continue the upload or "NO" to abort the upload.

|

| 1.2. Material Requirement Planning (MRP) |

| 1.2.1. Prerequisties for MRP | ||||||||

|

Prerequisites Required for Entering a New MATERIAL REQUIREMENTS PLANNING:

After activation, "Material Requirements Planning" (MRP) access for each user must be setup in the ManEx System Security module. Users with “Supervisor Rights” will automatically have access.

|

| 1.2.2. Introduction to MRP |

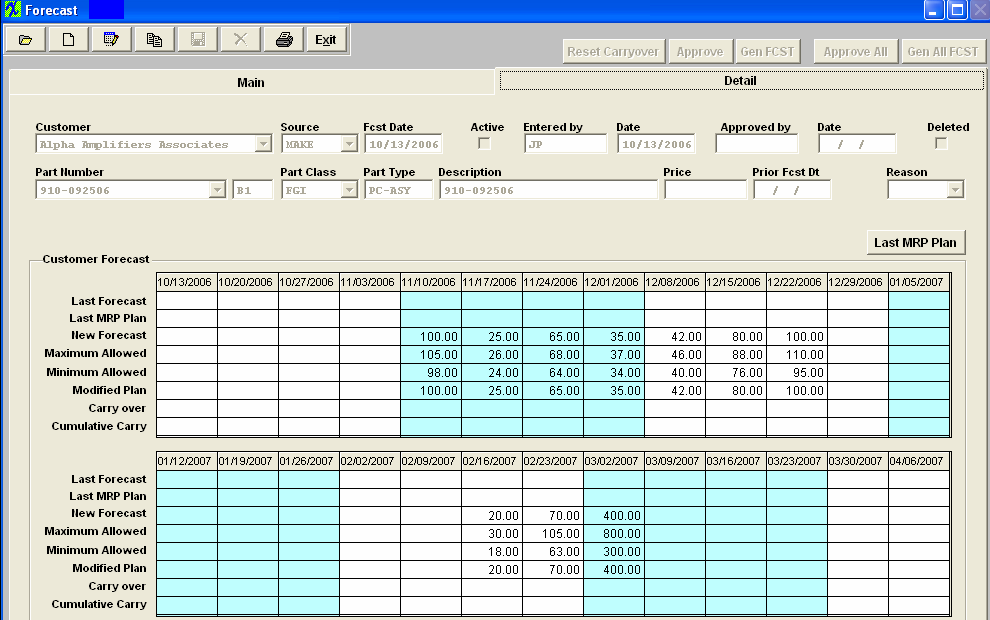

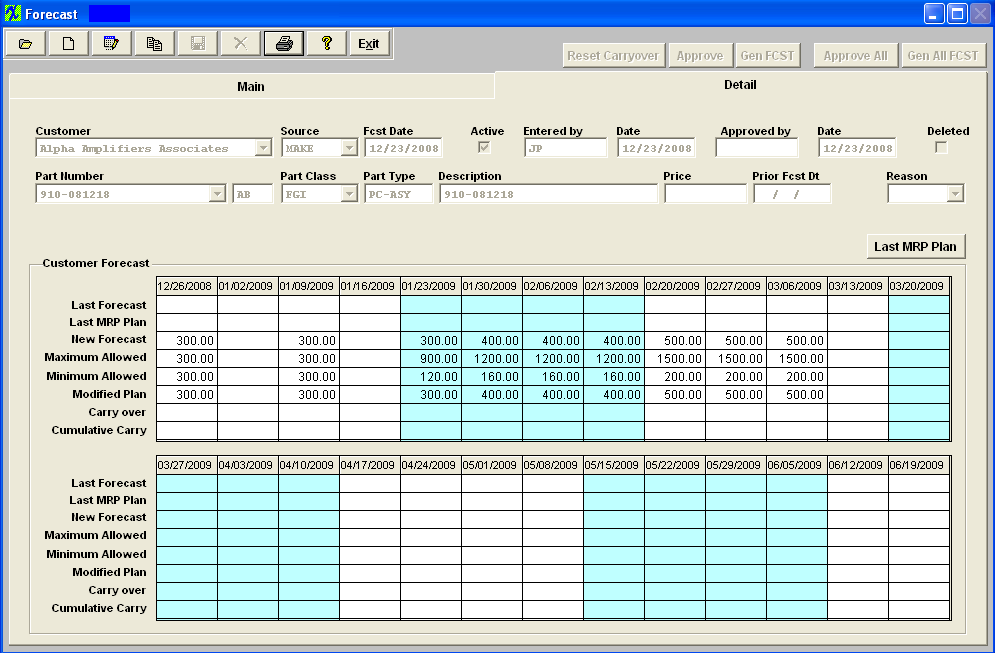

The Material Requirements Planning (MRP) Module is the heart of Inventory Control. In ManEx, the Material Requirements Planning actions drive the user towards zero inventory on hand through the scheduling and rescheduling of open orders for products and parts. When the Material Requirements Planning module runs, it accumulates all of the demands for products and parts, determines the available supply and recommends actions to be taken to meet the demand in the time required. (The attached Print Screens below <<BOM_Setup_MRP_Actions.docx>> displays an example of a BOM setup and how MRP gives the actions). The MRP module will also modify those recommendations by MRP policies established in the MRP Default Setup and in the Inventory Control Mgmt MRP Info for each part. MRP runs through a large number of tables and records to compile its calculations, and provides a snapshot of suggested actions at the same time it is ran. If users are changing things during this process it could definitely cause some strange outcome. To prevent this situation we strongly suggest that you use the Nightly MRP trigger. (Refer to Article #416 for more detail on trigger setup). Note: If you find the need to re-run MRP during the production work day then we suggest that you notify all departments that MRP is going to be ran and ask them to remain out of the system until the MRP run is complete. This will help assure that the most accurate MRP run is possible.

All lead times are calculated with the Production Calendar. Policies may be used to determine whether the part is ordered on a Lot for

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter qty of 24 into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

Article #3597 explains the process MRP goes through to optimize the On-Hand Inventory to Demands.

Buffer times for placing purchase orders and for placing work orders may be defined and included.

The Dock to Stock value (setup in the ABC types ) is taken into consideration for MRP leadtime calculations in the projected requirement of the receipt of purchased parts. (For more detail refer to Article #1469). If a part has a Production Off-set time setup in the Bill of Materials , this is also taken into consideration for MRP leadtime calculations. (For more detail refer to Article #572).

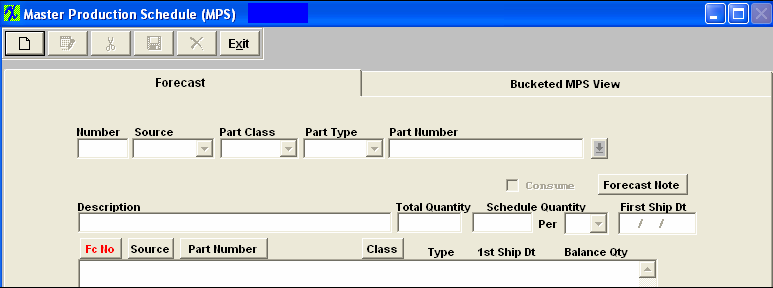

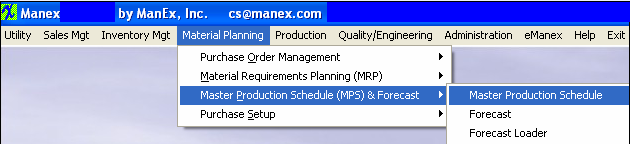

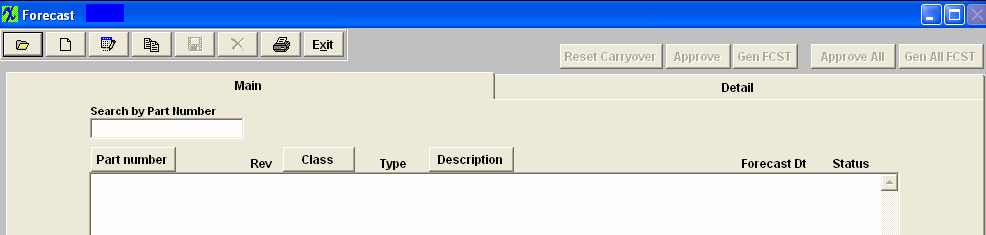

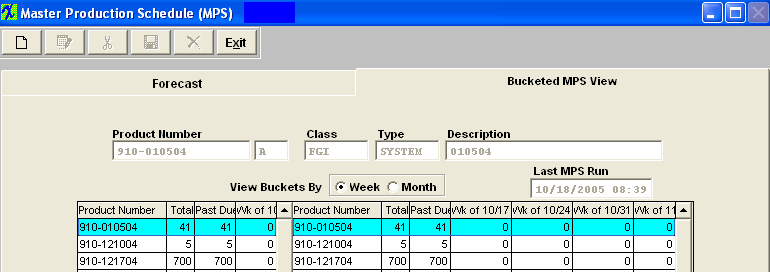

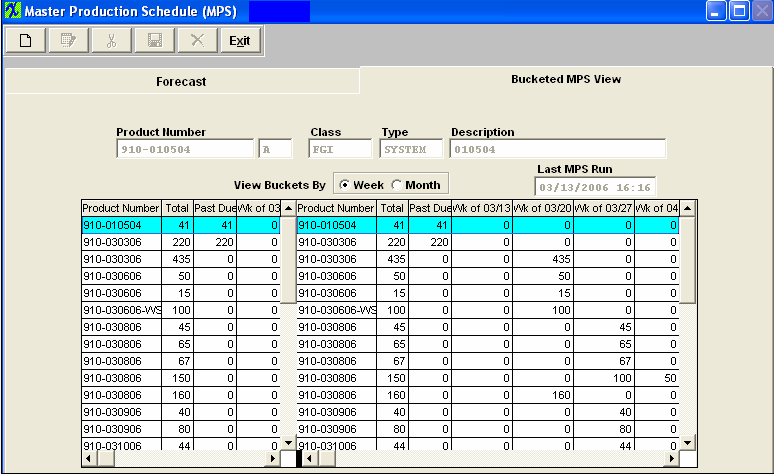

The Material Requirements Planning module will run the Master Production Schedule generation automatically before running the Material Requirements Planning module.

ManEx Material Requirements Planning module may be run without logging users off the system. The work station used to run Material Requirements Planning should have at least 120MB available on the hard drive, and works best with 96MB memory or more. A Material Requirements Planning regeneration creates time-phased material requirements at the part (component) level by netting demand from the Master Production Schedule (MPS), open Sales Orders, Internal orders, Shortages and open Work Orders (released but not picked) against supply from inventory, open purchase orders and Finished Goods. The regeneration must also occur with demand synchronized: Master Production Schedule forecasted demand that has been consumed by Sales Orders should be relieved and Work Orders that are released but not picked should be picked or cancelled.

MRP Actions for Make/Phantom parts - If the actions originates from a higher level assembly for the Make/Phantom, then the MRP will display "Phantom" in the action section. This indicates to the user that there are no actions required and is listed so users can investigate where component actions are originating from. If the Make/Phantom is required directly for an Order itself, it will follow the same WO action rules as a regular Make product.

Planned Purchase Orders from previous demand that have been placed must be entered and/or firmed.

A Firm Planned Purchase Order tells MRP that the purchasing decision was intentional and MRP will NOT try to override. Discrepant material should either be moved into Material Review Board or Inspection Hold for disposition. If Material Review Board or Held material is not to be looked at as available material for Material Requirements Planning purposes, it should be in a Non-nettable warehouse or inventory location. For example: (If parts are rejected in PO receiving the parts are dispositioned into the MRB warehouse (which is Non-nettable) so MRP is not seeing the qty in MRB but is seeing the open PO). Transactions must be current with the location of materials. WIP (Work In Process) shrinkages must be expressed as Work Order shortages in the system.

MRP is designed to calculate from the Kit Shortage and not from the Lead times once the parts have been pulled to the kit and the kit status is changed to "Kit in Process". Once the parts have been pulled to the kit, the systems is assuming that the shortages are needed by the WO due date, rather than the Prooduction lead time, so MRP then calculates using the due date of the WO as the date the materials must be on hand, MRP no longer takes the production lead time into consideration.

NOTE: The Re-Order Point/Qty fields have NO AFFECT on MRP at all. MRP will NOT consider these fields for any calculations (these fields have no connection with MRP). These fields are intended to control stock on overhead items. Print the "Inventory Material Reorder List" report (located in the Inventory Control module) to show items which have dropped below re-order point minimums.

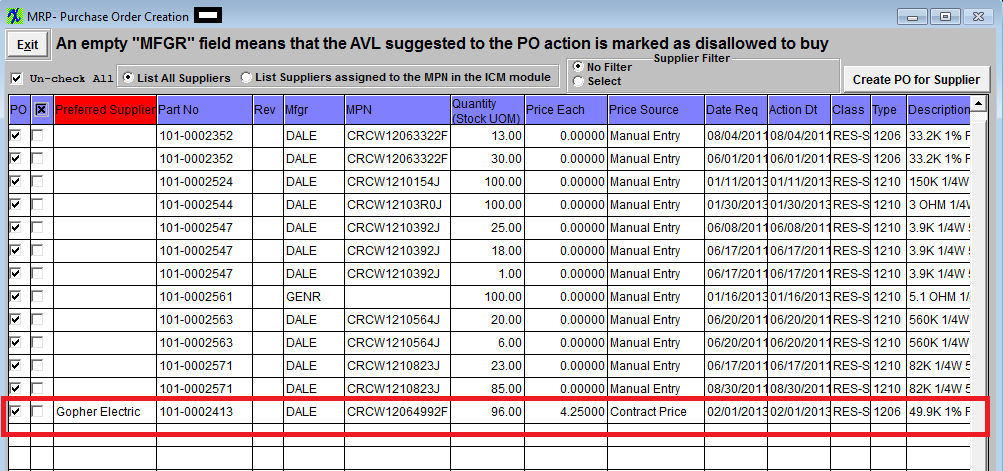

MATERIAL REQUIREMENTS PLANNING PROCESS Confirm status of system data for Material Requirements Planning validity Updated Forecast and Master Schedule Updated Item Master file data Lead Times entered and up to date Shrinkage factors current Order policies set Orders firmed as required Independent Demand items identified Inventories current Receivings current Safety Stocks appropriate Bills of Material current and complete Confirm system availability to run Material Requirements Planning Timing good for snapshot of data Transactions current Set the parameters for running the Material Requirements Planning Netable Inventory Locations flagged Discrepant material dispositioned Horizon set Time fences set for change control Bucket size and number set When executed, the Material Requirements Planning Module takes a snap-shot of the demand for parts and assemblies (created by Sales Orders, Work Order Shortages, Forecasts) and compares it with supply (on-hand inventory, open Purchase Orders with scheduled qty, open Work Orders) in order to generate an Action List of planned new orders and changes to existing ones to meet demand. The comparison is done one day at a time using the make and/or buy parameters from the Item Master/Material Requirements Planning Information screen in Inventory Control Management. The Parameters include: · Order Policy · Minimum Order Quantity · Order Multiples · Purchase Lead Time · Kitting Lead Time · Transit Days · Pull In Days · Push Out Days If the AVL suggested to the PO actions is flagged as "DO NOT PURCHASE" MRP will give Release PO actions if there is a need for the part and the part will be displayed on the Create PO screen with the Mfgr and MPN fields blank. This should flag the user to further investigate and see that it is flagged as "DO NOT PURCHASE" and that they will need to either remove the flag or add additional AVL's to ful-fill the demands. Notice at the top there is a note that explains what the empty "MFGR" field means.

Sales Orders on Hold When the Sales Order is on HOLD it does NOT drive MRP.

User does have the ability to turn off the function of the Sales order driving the demands for the MRP and just use the Work Order for buying components by checking the MRP on Hold box in the Sales Order module per line item or in the System Setup/Sales Order Default module.

If the MRP on Hold is checked in the SO module, MRP will instruct you to cancel all PO(s) you have open for the components needed for this SO.

If the MRP on Hold is checked in the SO module and you create a WO Manually, the MRP will tell you to cancel the WO since there is no SO demand. This can be solved one of two ways. Use the MPS module (Forecast) or Open/Create Firm planned WO’s so the MRP will NOT keep instructing you to cancel the order. This is a perfect solution for customer who wants to build products based on forecast or promised to maintain certain amount of FGI in inventory. The can use the MPS module to accomplish this and use the SO to ship products from FGI inventory. MRP will consider any SO items for the demands unless marked as MRP on Hold. See Article #1244 for further information. Check on Work Orders on either Admin or Production hold. Production Hold on a Work order will disallow movement of the parts. See Article #896 for more detail. MRP is checking work orders to be sure that they aren’t cancelled or closed. Everything else will be considered. MRP checks Sales Orders for OPEN status. Everything else is ignored. If the objective is to stop the shipment from the Sales Order, then in the Sales Order, the user may uncheck the “Sales Ack” box and then shipping won’t be able to initiate a Packing List.

Inventory Items Allocated

MRP does NOT distinguish between inventory items allocated to projects nor Purchase orders allocated to projects in the determination of the available supply (current and future). To do so would enormously complicate the MRP process. MRP WILL determine that the supply will meet the demand, whatever it is.

Should we have locked the requirements by project in MRP, then we could have the situation where we have unallocated inventory on hand, but since it's not for a specific product that requires it, MRP action could create an order action to buy more of the parts specifically for that project. This could result in an enormous amount of excess inventory. Since our objective in MRP is to drive to zero inventory, we do NOT want to ignore any available inventory that might satisfy demands. Conversely, when inventory is allocated to a specific project, and the demands created for another project are analyzed, the inventory on hand will be available to meet the other project demands, but also create the order actions to supply parts for the original project, if there are still demand requirements. In the case of having just enough inventory on hand for a given Project (A), but there are new requirements for Project (B) that precede those for the same parts as project (A), MRP will assume that the inventory on hand will be used for Project (B) first, but get more parts to meet the later date of Project (A). As long as there is inventory available to meet every demand, it will be up to the user to reallocate inventory for the most urgent need. If for some reason user has inventory that belongs to a specific customer and does not want MRP to consider it for any other customer they can change the inventory location to non-nettable.

|

| 1.2.3. Fields & Definitions for MRP |

| 1.2.3.1. MRP Action Tab | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

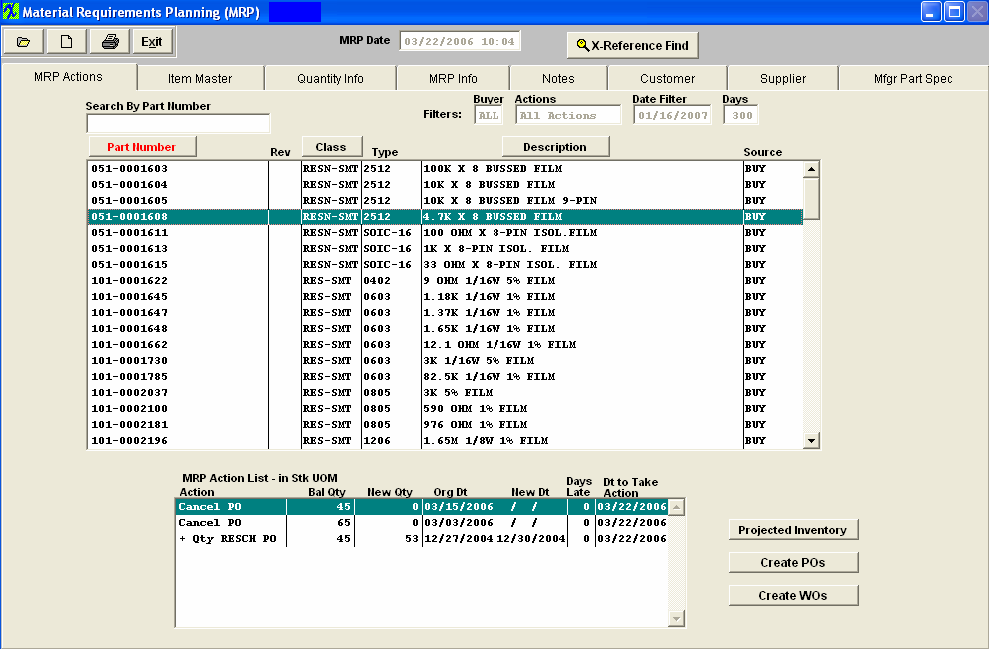

Definition of Material Requirements Planning Action Fields:

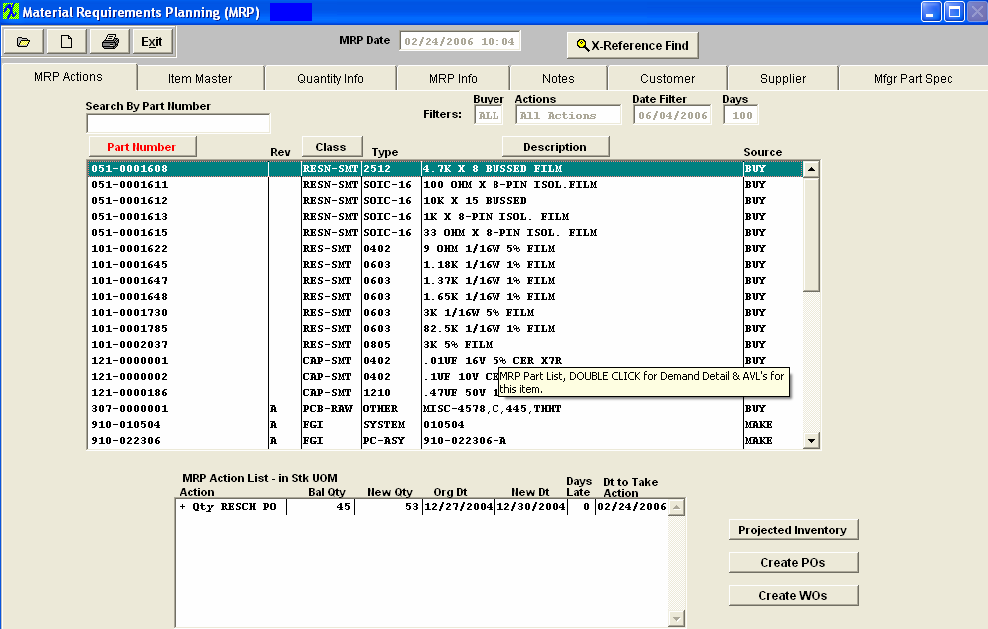

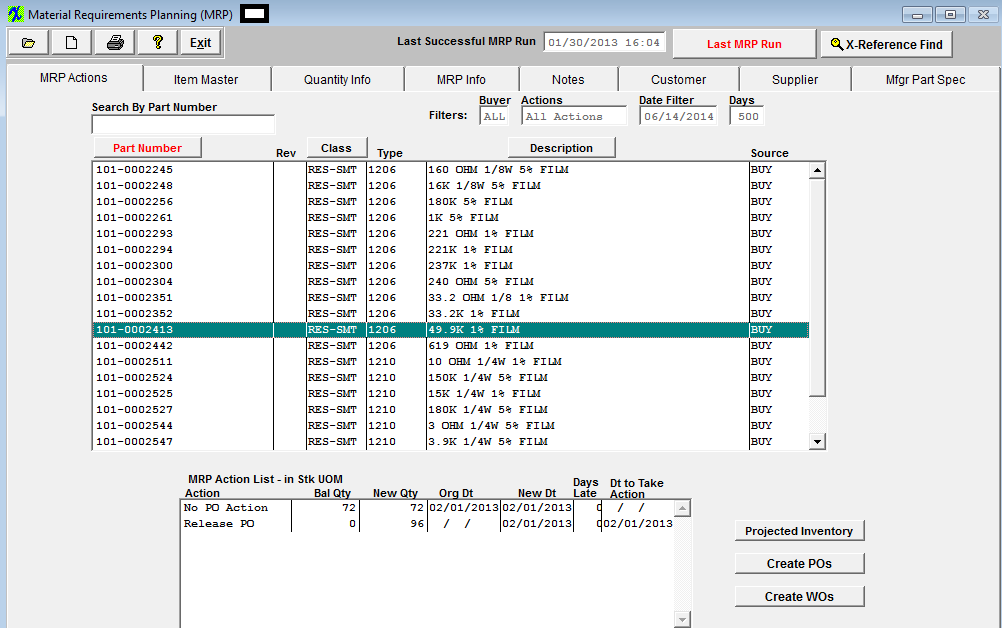

Sorting, Searching and Selecting in the MRP Action Screen The user may sort by the Part Number, Class or Description by depressing the appropriate button. To sort the contents of the Summary screen by Part Number, Part Class or Description, click the button. It will turn red and the list will automatically sort in ascending alphanumeric sequence per the selection. To search for an item by Part Class, click Class and enter the first few characters of the Part Class in the Search by Part Class field. The list will scroll down to the first incidence of each character in the sequence entered.If a character is not found in the position typed, the list will scroll to the bottom. To Search for an item by Description starting with the 1st character on the left, click Description and begin entering the first characters in the field. The list will scroll down to the first incidence of each character in the sequence entered.If a character is not found in the position typed, the list will scroll to the bottom. To Search for an item by a word or character string anywhere in the Description, click on Description, click on the Left button next to the Search by Description window (changes to Random). Enter the search word or characters in the window. Hit return and the first match in the list will be highlighted. Click on the window and hit return to highlight the next match in the summary list. After the last match or if a match is not found, the last item in the summary list will be highlighted. To visually search the summary list, use the scroll bar or arrows to the right of the list.The Source (Buy, Make or Phantom) and total On Hand quantity is displayed in the last two columns. For further Details on any item in the Actions main body list, highlight the item by a search or mouse click and select the appropriate Tab to display the desired detail information. To display changes made in other windows or by other users while this window is open, repeat the Material Requirements Find and refresh the screen data. FILTERS:

Main Body

Material Requirements Planning Action List in Stock Units Of Measure: The information listed in this section pertains to the highlighted part number in the main body above. To see the list for another part number, highlight the part number in the main body.

Note: Dates are calculated with the Production Calendar

Defines the Material Requirements Planning action to be taken for the highlighted part. There are several different actions that will appear depending on the part. For example if the Part is a Make/Phantom part and the action originates from a higher level assembly for the Phantom, MRP will display "PHANTOM" in this section and that will indicate to the user that there are no actions required but is listed so users can investigate where component actions are originating from. If the Make/Phantom is required directly for an order itself, it will now follow the same WO action rules as a regular Make Product would. The projected balance of inventory for the part selected. MRP will display the stock qty UOM. Displays the new quantity that the action requires. MRP will instruct you to Purchase the Stock qty UOM, not the Purchase UOM. The PO Module will display the UOM conversion (if applicable). NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty. For Example: if the item has inches for Stock UoM and Feet for Purchasing UoM, and the MRP demand is 24 , the buyer would enter the qty of 24 into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module. Displays the original (current) date of the existing action. If the action date is earlier than the current date, the number of days late for the action is shown. This is the date by which the action listed must take place. Changing the leadtime of a Buy part will NOT change the due date, only the date to take action. For a Buy part this date is arrived by subtracting the Purchase Lead time from the New Date. For a Make part this date is arrived by subtracting the Kitting and Production Lead times from the New Date which is the Sales Order ship date.

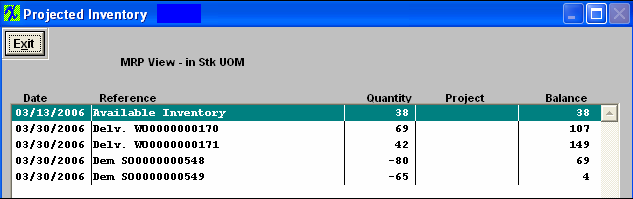

Clicking on the

Definition of fields in the Projected Inventory screen:

The projected date of a Materials Requirements Planning action. The Material Requirements Action. The projected balance of inventory for the part selected.

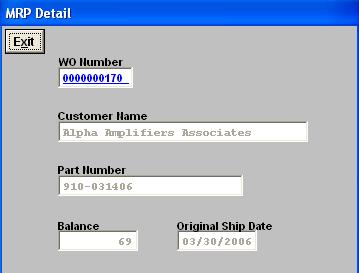

After depressing the Projected inventory button, the reference field was highlighted in the Projected Inventory Material Requirements Planning View in Stock Unit Of Measure and double clicked. The Material Requirements Planning Detail appears.

Material Requirements Planning Field Definitions:

This is the assembly part number where the component part number is highlighted. This is the balance for the Work Order Listed.

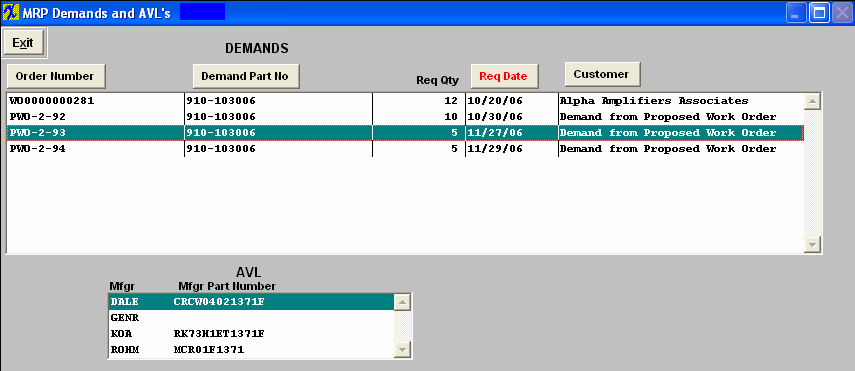

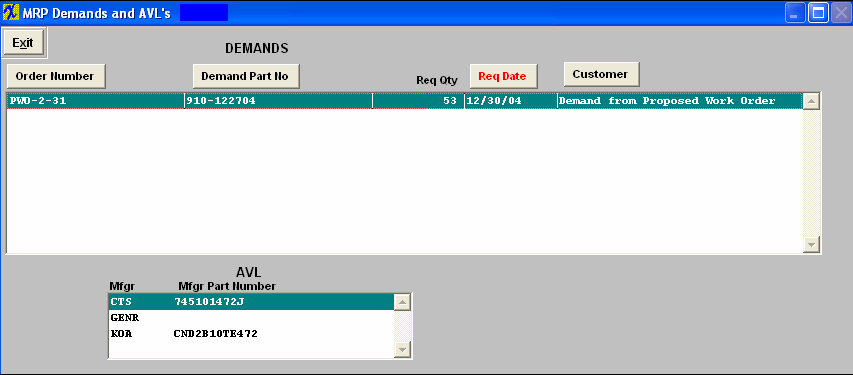

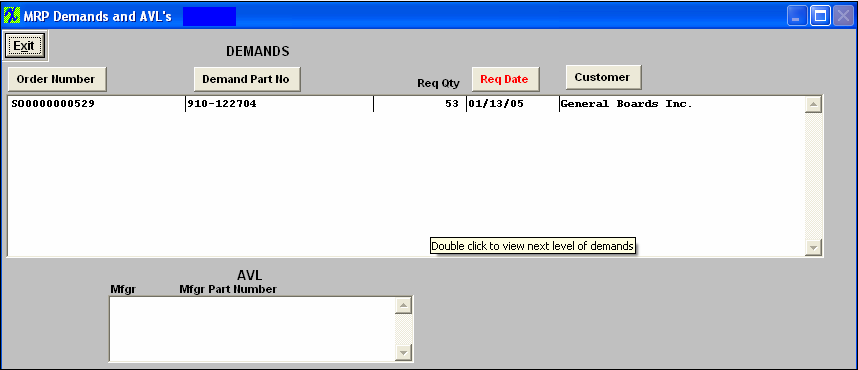

After highlighting a part number in the main body, the Material Requirements Planning Demands and Approved Vendors List appeared, as displayed above:

Material Requirements Planning Demands and Approved Vendor List Field Definitions:

AVL

|

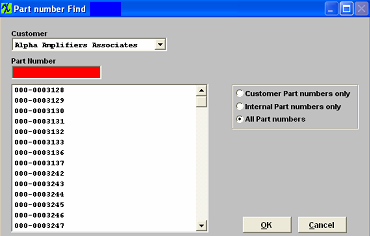

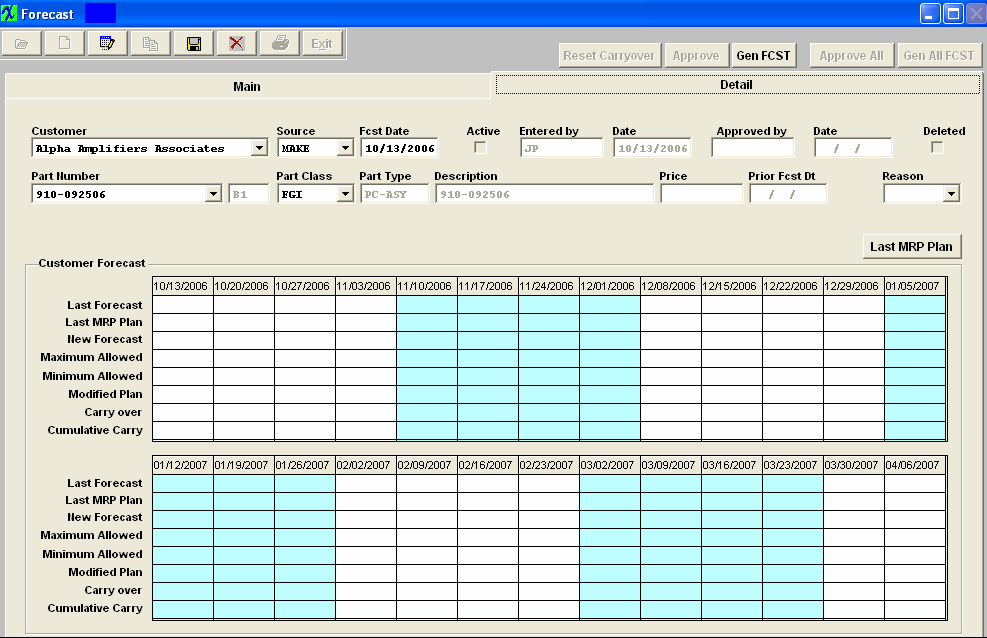

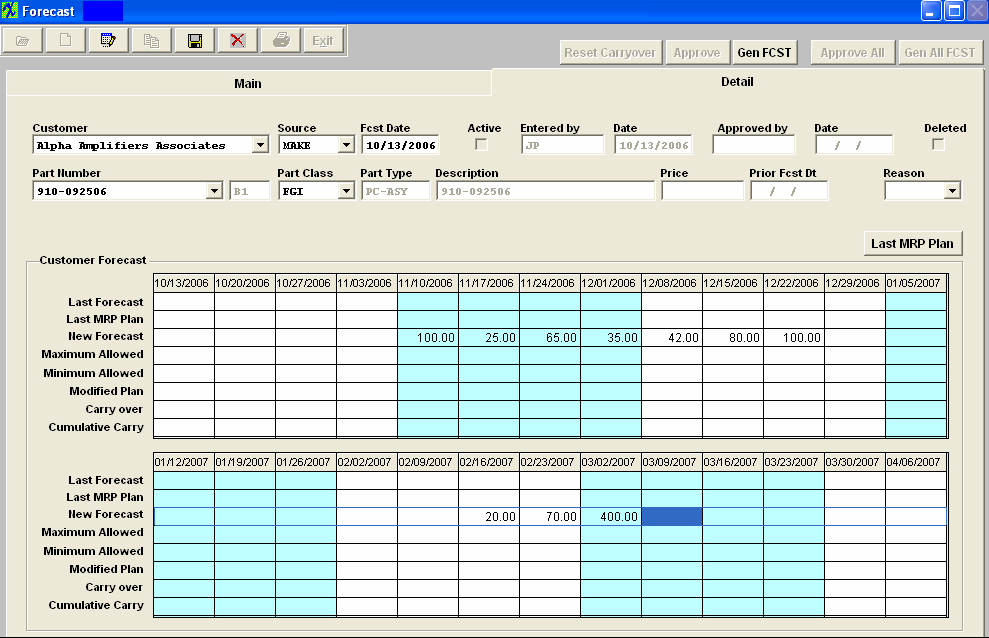

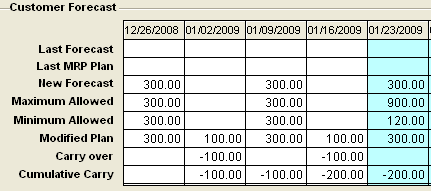

| 1.2.3.1.1. Create POs | ||||||||||||||||||||||||||||||||||||||||

|

| 1.2.3.1.2. Create WO's |

This portion of the MRP module is not fully completed yet in the current version. It is still a work in progress. While it displays the WO’s for quick reference you will still actually have to go into the WO module to create the WO’s as needed. You can also create WO’s directly in the SO module as well at the time you’re creating the Sales orders. |

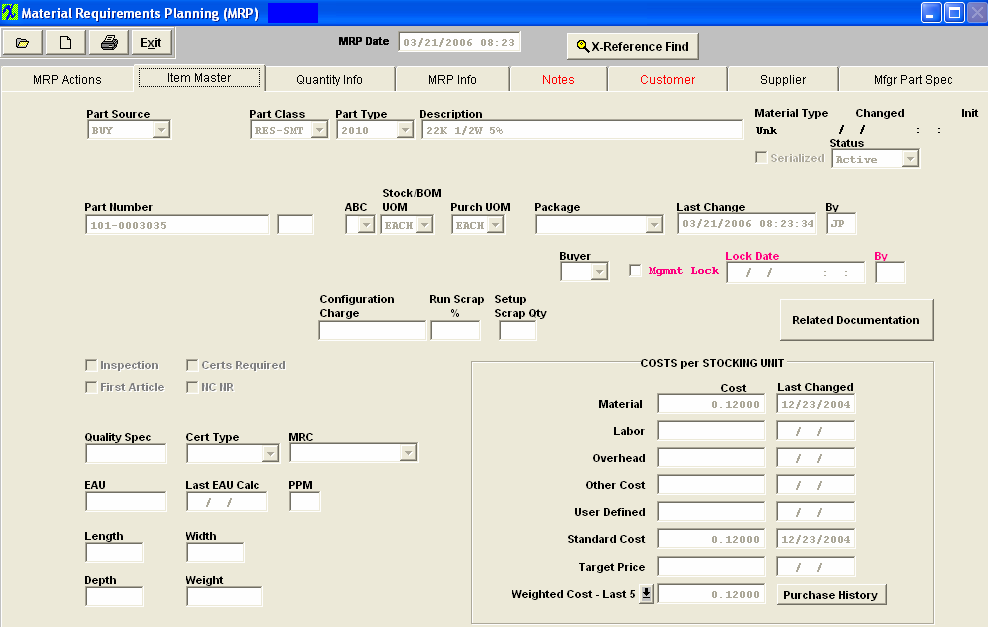

| 1.2.3.2. Item Master Tab |

This screen will display details for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #924 for field definitions. These fields may be edited in Inventory Control Management .

|

| 1.2.3.3. Quantity Info Tab |

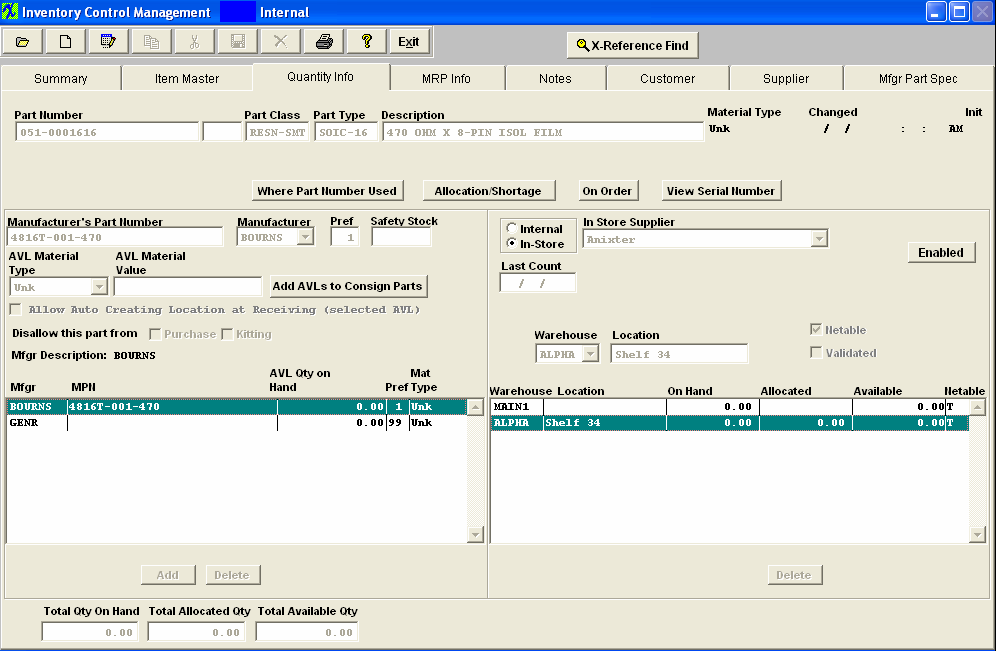

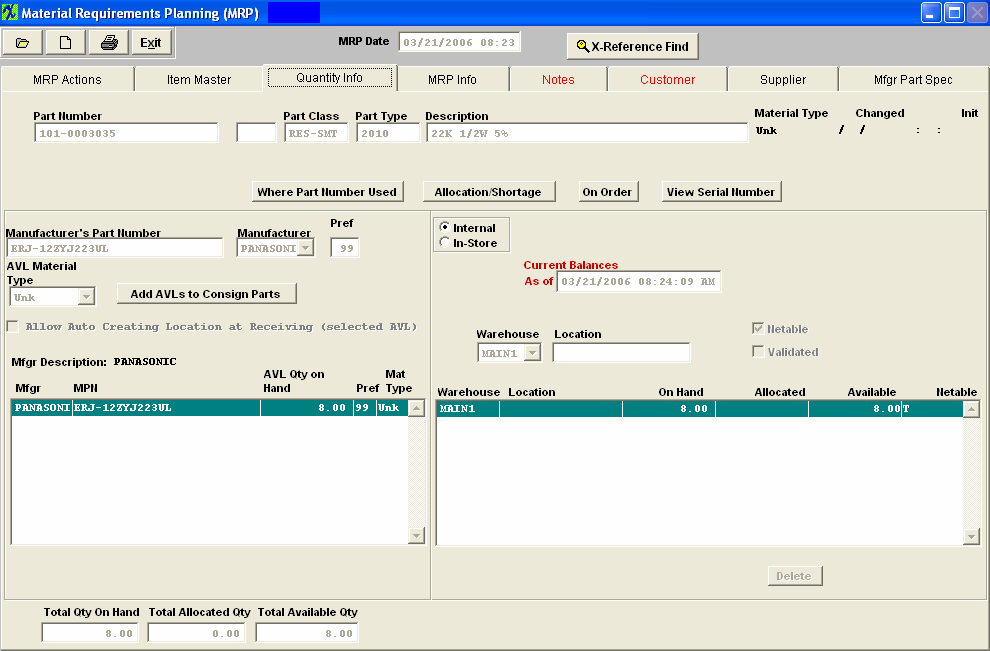

|

This screen will display manufacturer, warehouse and inventory quantities for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #925 for field definitions. These fields may be edited in Inventory Control Management .

Complete inventory stock, allocation and usage information by Manufacturer is displayed or available at the click of a button. All current inventory information about any selected part can be displayed here. |

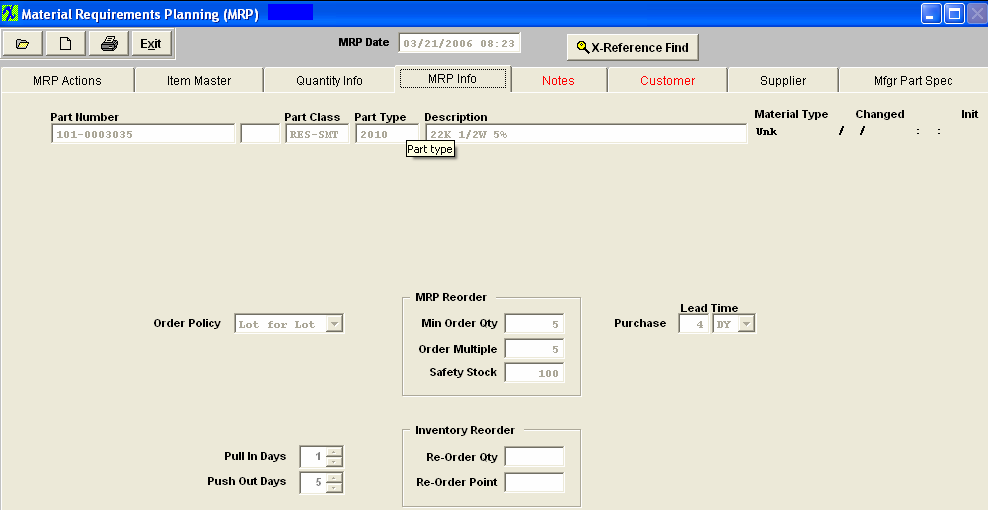

| 1.2.3.4. MRP Info Tab |

|

This screen will display MRP parameters for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #926 for field definitions. These fields may be edited in Inventory Control Management .

|

| 1.2.3.5. Notes Tab |

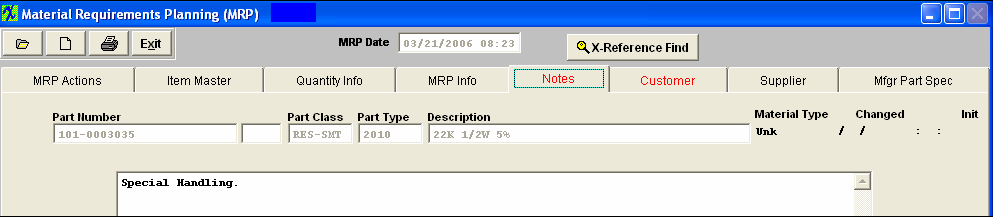

|

This screen will display Inventory Notes for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #927 for field definitions. These fields may be edited in Inventory Control Management .  |

| 1.2.3.6. Customer Tab |

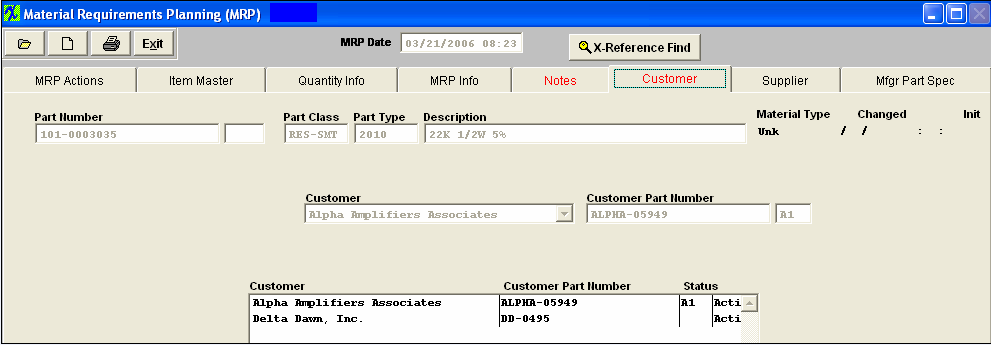

|

This screen will display customer part number(s) assigned to the internal part number for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #928 for field definitions. These fields may be edited in Inventory Control Management .

|

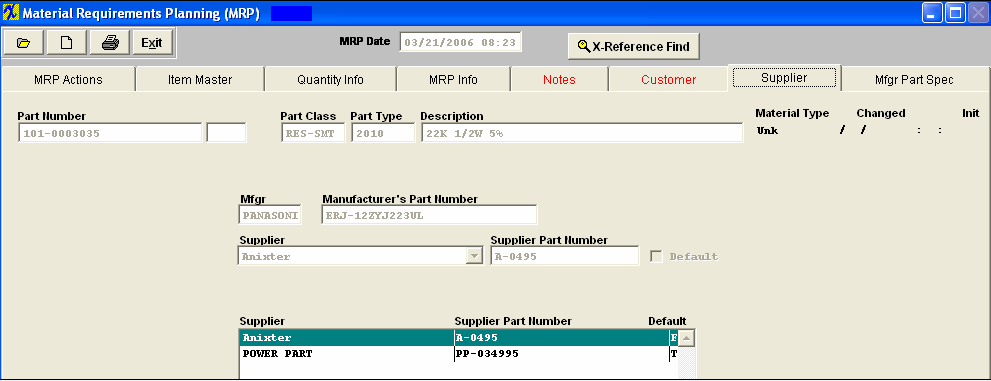

| 1.2.3.7. Supplier Tab |

This screen will display the name of the Supplier and Supplier's Part Number for the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #929 for field definitions. These fields may be edited in Inventory Control Management .

|

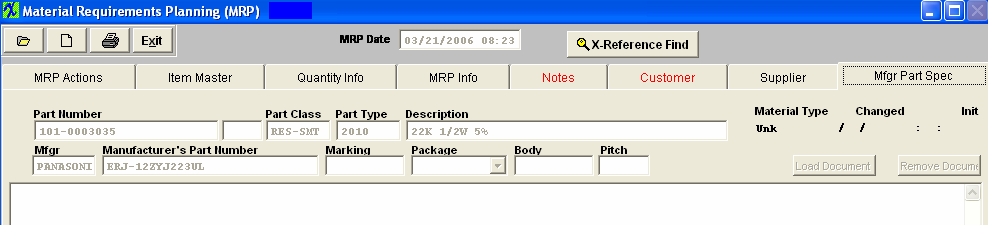

| 1.2.3.8. Manufacturer Part Spec Tab |

|

This screen will display any drawing, photograph, images, or .pdf files linked to the item highlighted in the MRP Action tab, which is being defaulted in from the Inventory Control Management module. See Article #930 for field definitions. These fields may be edited in Inventory Control Management . |

| 1.2.4. How To ..... for MRP |

| 1.2.4.1. Find a Material Requirements Planning (MRP) Record | ||||||||||||||||||||||||

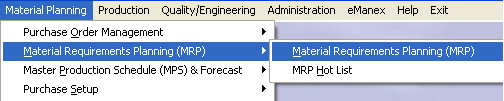

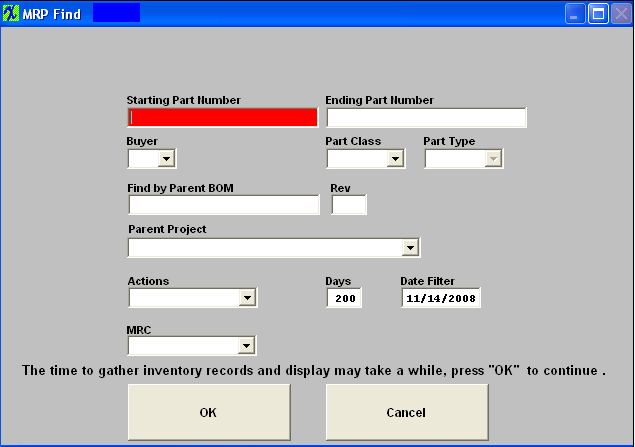

The following screen will appear:

Pressing the Find action Button displays the following sequences: Tips on Using the Material Requirements Planning Find Screen Selection of at least one parameter will reduce the time to retrieve the information. The Find by Parent BOM is specific down to the Revision level. If no information is selected in a Find operation, all part numbers with MRP actions will appear.

Definition of Material Requirements Planning Find Fields:

Starting Part Number and an Ending Part Number Select Buyer from the pull down menu. If you want ALL buyers, leave this area blank. Assigned Buyer will bring up all items assigned to that particular Inventory Buyer. The Buyer assignment is made in Part Class and Type System Setup Defaults or in the Item Master. If you selected a Class, depressing on the down arrow will bring up a list of Types within that Class. Select the Part Type within the Class selected. If you want all of the Types within the Class, leave this field blank. Revision of Parent BOM. If applicable this MUST be entered to located the exact Parent BOM. The "Find by Parent BOM" is specific down to the Revision level. If the exact part number and revison of the Parent BOM is not correct user will receive the following message: Select the action from the pull down. There are the various Material Requirements Planning actions, which the user may filter on such as: All Actions, All Purchase Order Actions, All Work Order Actions, Pull-Ins, Push-Outs, Release Purchase Orders, Release Work Orders, Cancel Purchase Orders, and Cancel Work Orders. Type in the number of days (from the current date), changes the Date Filter accordingly. This is a short-cut to the horizon date. The horizon date for the Material Requirements Planning actions. Parts with actions beyond this date are excluded from the report. The filtered information will populate the Material Requirements Planning Actions screen, as displayed below:

|

| 1.2.4.2. Add (Generate) A Material Requirements Planning (MRP) | ||

Add (Run) a Material Requirements Planning

MRP runs through a large number of tables and records to compile its calculations, and provides a snapshot of suggested actions at the same time it is ran. If users are changing things during this process it could definitely cause some strange outcome. To prevent this situation we strongly suggest that you use the Nightly MRP trigger. (Refer to Article #416 for more detail on trigger setup).

If you find the need to re-run MRP during the production work day then we suggest that you notify all departments that MRP is going to be ran and ask them to remain out of the system until the MRP run is complete. This will help assure that the most accurate MRP run is possible. Then follow the procedure below:

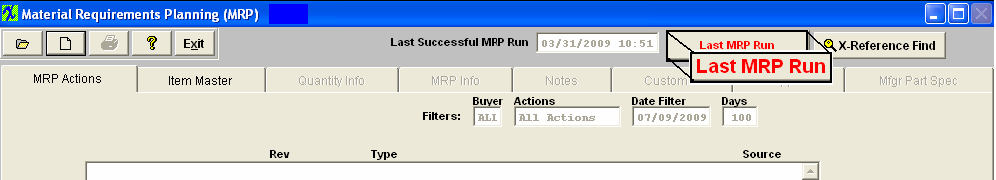

The following Screen will appear:

To run a new Material Requirements Planning (MRP) manually, depress the Add action button (Generate MRP), and enter your password. The following screen will appear:

The time it takes MRP to run is dependent on a number of factors. Here is a list of items that affect the processing time: Once the MRP run is completed and was successful, user will receive the following message:

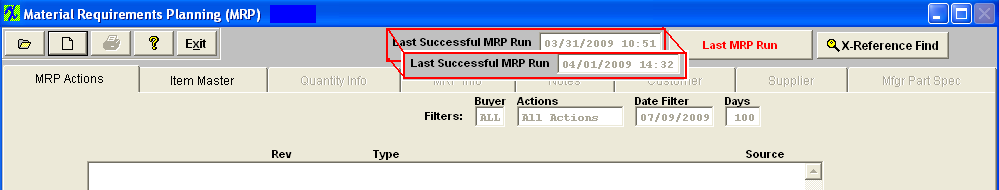

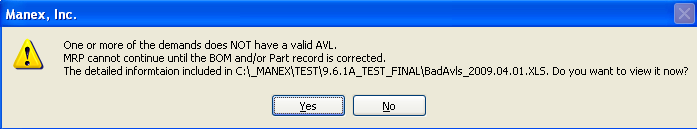

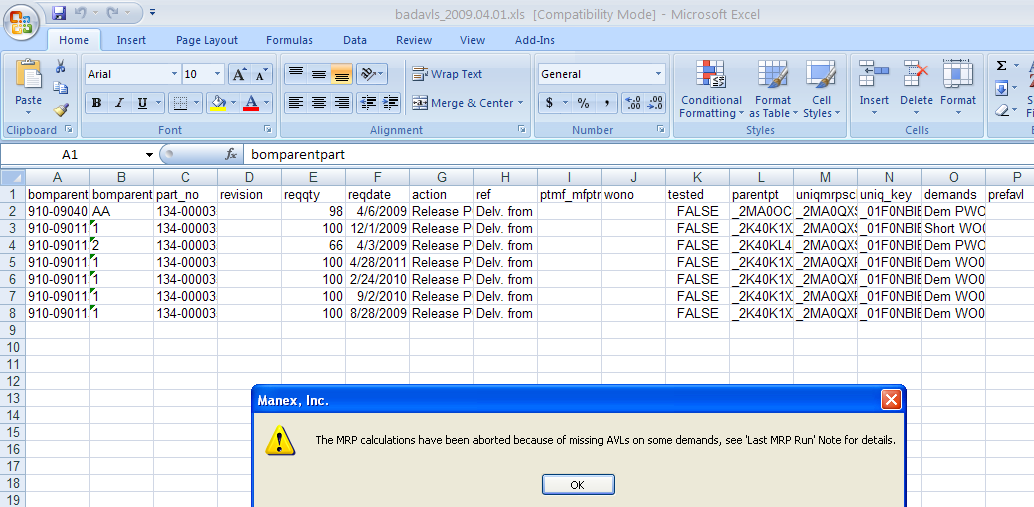

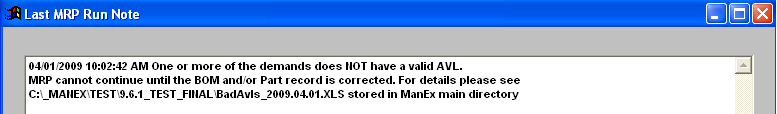

Depress the OK button. The Material Requirements Planning Date at the top right hand side of the screen will change.  If the MRP run was NOT successful due to AVL issues (missing, or exists but is marked as "Do Not Purchase and/or Kit, etc) the following message wil be displayed on screen indicating that MRP will NOT be able to continue until the BOM and/or part records have been correct. Then in addtion to the message an XLS file will be generated and placed in the ManEx Main Directory. This XLS file will contain the records that the user will need to review and address. If an XLS file is generated multiple times a day the system will add "_N" to the name of the XL file, where "N" is the dequence number. For example if MRP is run today three times without fixing a problem or a new problem is generated, the generated files will have names; badavls_2009.03.31_1.xls, badavls_2009.03.31_2.xls, badavls_2009.03.31_3.xls, unless one or all of the files were removed. The user will have the option of viewing the XL file now or later. NOTE: These XL files will need to be manually removed from the ManEx Main Directory.

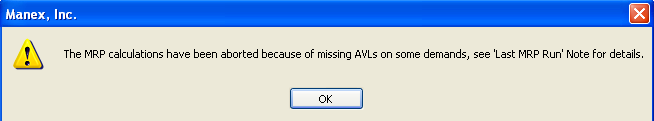

If the user selects "No" the user will receive the following message and they may review the XL file placed in the ManEx Main Directory.

If user selects "Yes" an XL file (similar to the one shown below) will be displayed on screen and also placed in the ManEx Main Directory for later review:

The date displayed in the "Last Successful MRP Run" will NOT change. The "Last MRP Run" button located in RED at the top of the screen will be displayed in a larger font if MRP run failed due to an AVL issue and there will be brief comment expaining what issues the MRP run encountered. This will allow any user that might not have seen the xls spreadsheet to be aware of what had taken place on the last attempt to run MRP.

Double click on the "Last MRP Run" button and similar information will be displayed:

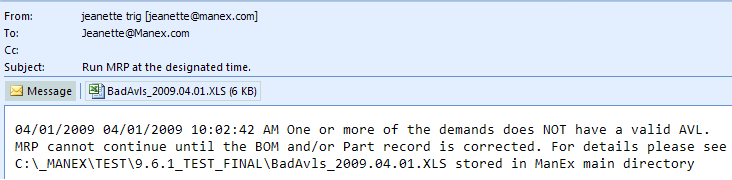

NOTE: If MRP runs from Trigger, and MRP run was NOT successful due to AVL issues an XLS file will be generated and placed in the ManEx Main Directory for review and also be attached to the e-mail sent, informing user that the MRP run was NOT COMPLETED (similar to the one shown below). Upon opening the MRP screen the "Last MRP Run" button will be displayed in a larger font and will have information about the file as displayed above.

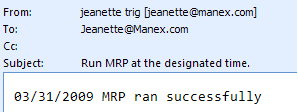

If MRP runs Successfully from Trigger the e-mail sent will be similar to this:

|

| 1.2.4.3. Drilling Down In MRP |

There are several drill downs within the MRP screen. Highlight a Buy Part number of interest on the MRP main screen:

Double click on the highlighted buy part number 051-0001608 and the user can see the assembly of the proposed work order.

Highlight the Proposed Work Order Number and the Approved AVL's will be listed per the BOM.

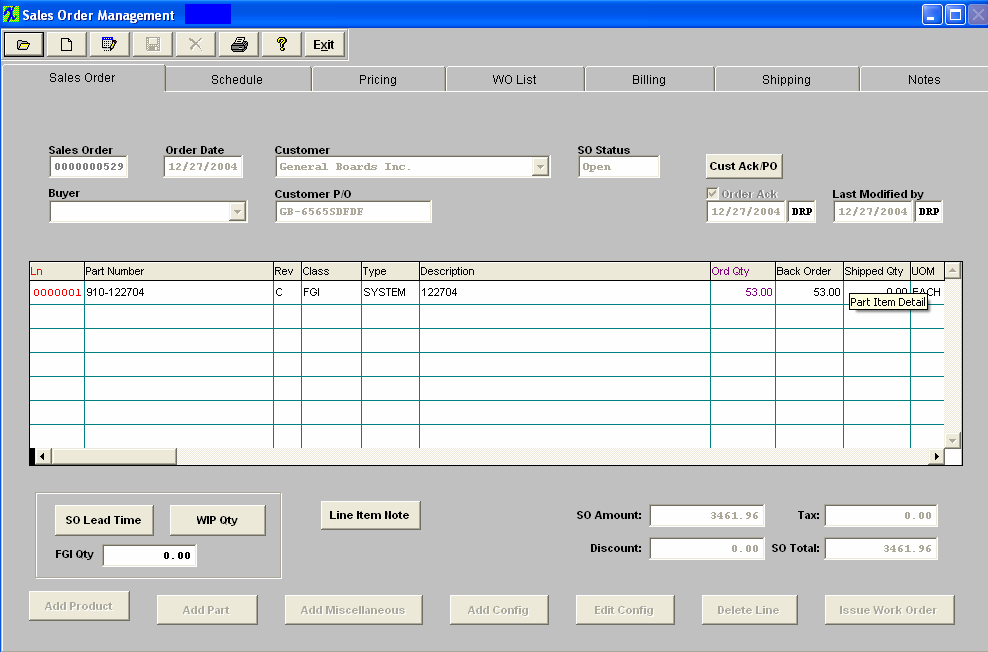

If the User double clicks on the PWO-2-31 (Proposed Work Order) the Sales Order, the assembly, required qty, and Customer will be displayed.:

Highlight and double click on the SO0000000029 and the Original Sales Order will display.

Another Drill down located within the MRP Actions screen is by highlighting one of the actions located in the MRP Action List-in Stk UOM box:

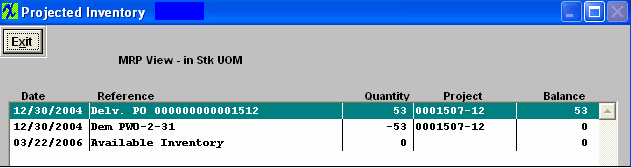

Depress the "Projected Inventory" button. The user will see the same proposed work order number being delivered instead of demand. By this screen, the user can also see what’s driving the requirement for the product and the next level, etc.

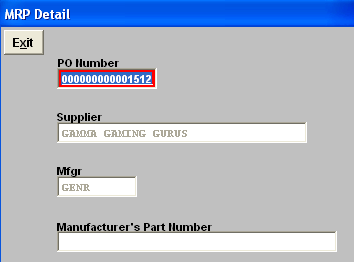

Within this screen you may highlight any of the Reference items and drill down to Sales Order, Inventory Level, Purchase Order, etc. Highlight and double click on the Delv. PO 00000001512 and a PO summary screen will display:

Here you may drill down to display the original PO if you double click on the PO number:

|

| 1.2.4.4. Create POs from MRP Action List | ||

The following screen will appear:

Note: To start creating POs from the MRP action list, make sure you have run MRP creating a fresh MRP action list, and user must have "ADD" rights to the PO module in Security setup.

Find an MRP record.

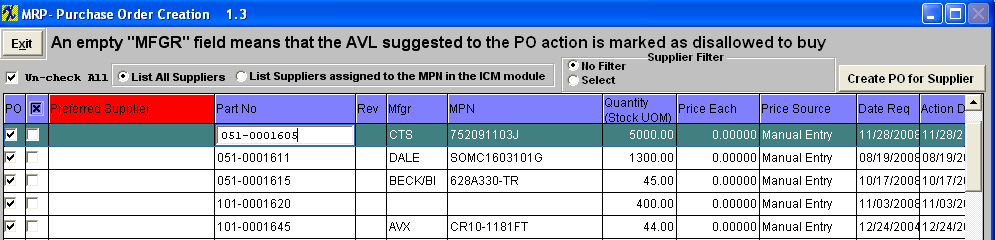

Highlight a part number of interest and depress the Create POs button in the bottom right hand corner, enter user password (user must have "ADD" rights to the PO module), and a list of Release PO suggestions based on the MRP filter that was applied and displayed within the MRP screen will appear. This will allow the buyers to auto created purchase order records based on what MRP is suggesting (mfgr, mfgr pn, etc...)

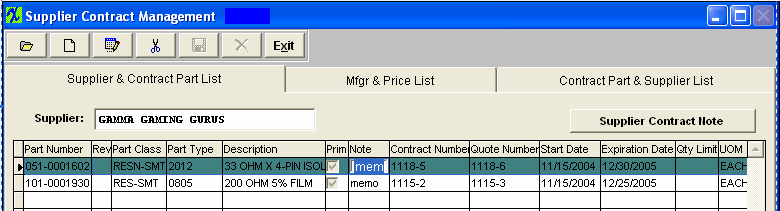

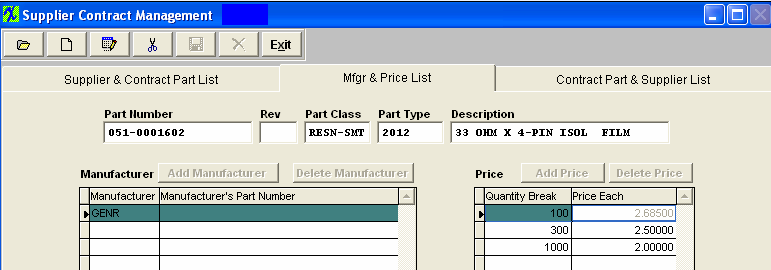

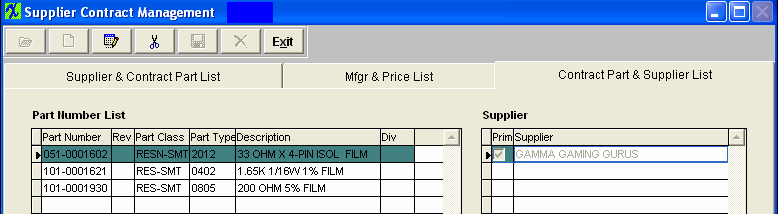

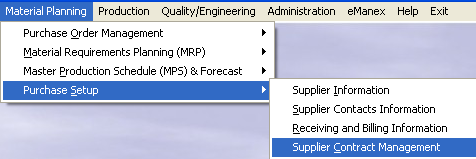

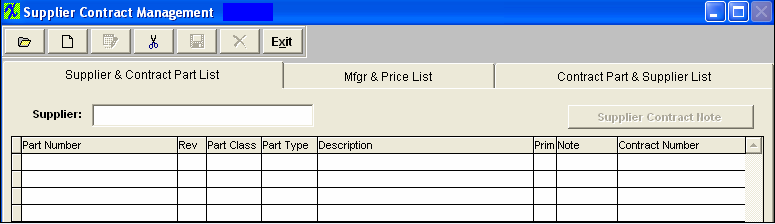

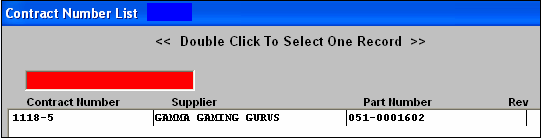

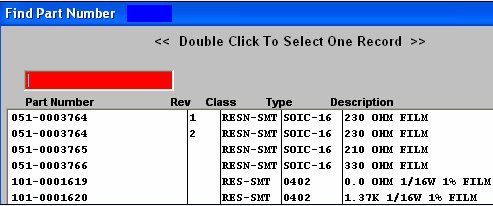

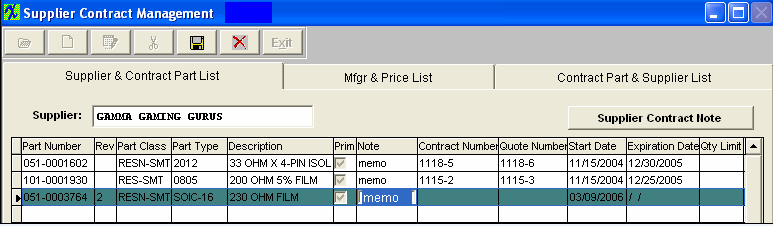

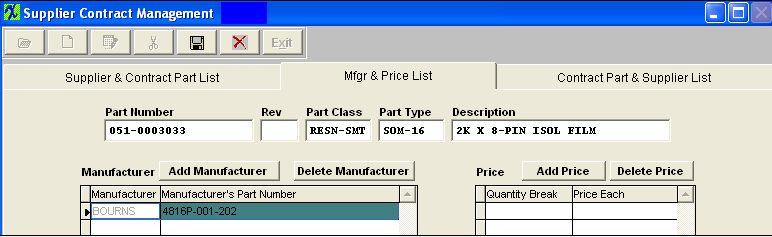

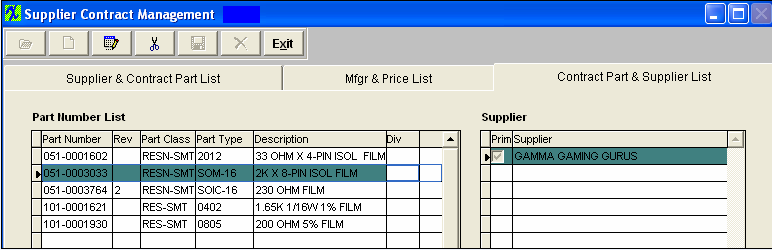

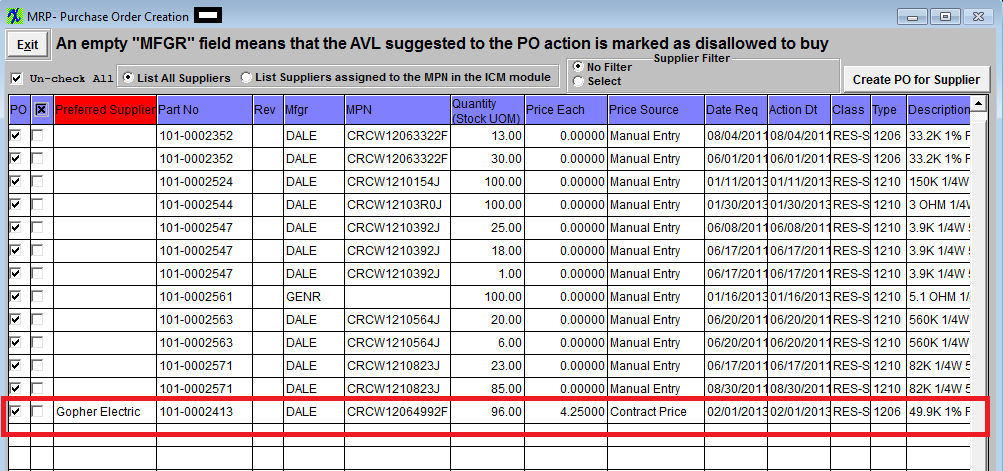

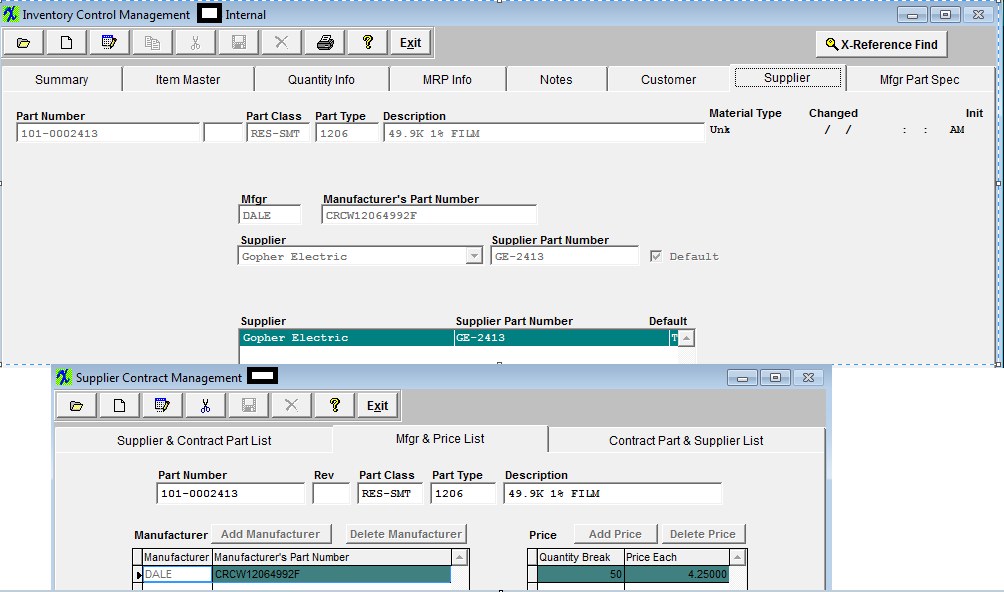

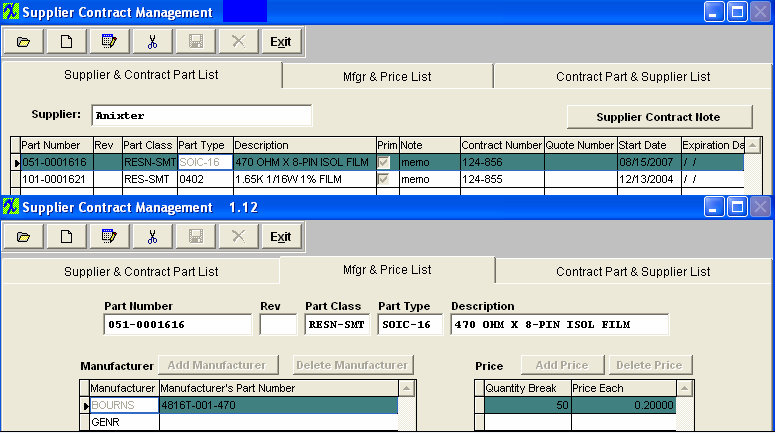

Note: ManEx does NOT offer a pull down next to the Mfgr and/or MPN to select from because within the AVL list there may be AVL's that exist which may satisfy one demand, but not another. Once the user goes to review the PO they can always edit the Mfgr there if they really desire, but while within the MRP the Release PO screen is going to require that you use the AVL that it calculated as the most commonly used AVL for all demands for the aggregation. Note: If the AVL suggested to the PO action is flagged as "DO NOT PURCHASE" MRP will give Release PO actions if there is a need for the part and the part will be displayed on the Create PO screen with the Mfgr and MPN fields blank. This should flag the user to further investigate and see that it is flagged as "DO NOT PURCHASE" and that they will need to either remove the flag or add additional AVL's to ful-fill the demands. Notice at the top there is a note that explains what the empty "MFGR" field means.  If a Supplier is setup within the ICM as a default Supplier and also has contract pricing setup as shown below:

The default supplier will be listed under the Preferred Supplier column and the Contract Price will default in as displayed below within the Red Box.

User may view records by selecting All Suppliers or only Suppliers assigned to the MPN in the ICM module. User may also use the Supplier filter to view records for one supplier at a time.

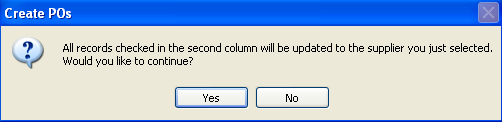

User may manually select the records to have POs created by placing a check in the box in the PO column. If no supplier is defaulted in the Preferred Supplier column from the ICM module, user may check item in the "x" column, select a supplier from the pull-down and receive the following message:

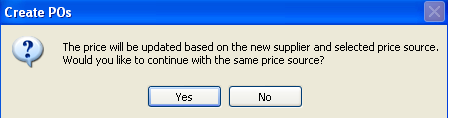

Depress "Yes" to continue and user will receive the following message:

Depress "Yes" and all the records that have the check box to the left of the "Preferred Supplier" column checked will be updated with the selected supplier and all the price source's will stay the same.

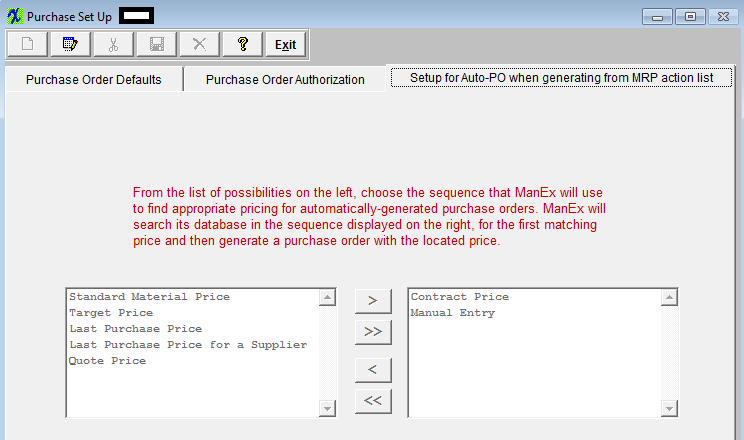

If user selects "No" they may select a different Price Source from the pull down. The only Price sources that will be displayed in the pull down are the ones selected in Purchase Setup. Once a different price source is selected if there is a price associated with that price source that will also default in.

The Cost Each is defaulted in, based on the "Price Source" column (which is setup in the Purchase Setup module). The standard Material Price and the Target Price defaults in from the Inventory Control Mgmt module. The Contract Price is defaulted in from the Supplier Contract Mgmt module. The Quote Price is defaulted in from the Quotation & Estimating module. The quote MUST be approved. If the part is on more than one quote the system will use the price from the most recent quote. The Mfgr and Supplier listed on the Auto PO screen must match the Mfgr and Supplier that was selected on the quote.

NOTE: The Auto PO screen will only find existing parts entered in the "Material 1" screen. There is no way to identify parts from "Material 2" screen. There is no connection between part entered in the quote module "Material 2" screen and the part before it becomes an Inventory part in ManEx until after the "Transfer".

All coulmns in the grid are sortable. To sort on the specific column click the header of the column. By default the items are sorted by "Preferred Supplier" column (red color of the header indicates that the data sorted by the values in the column). Part No and Rev columns are both sorted by Part No and Rev values. If the cursor is in Part No, Mfgr,or MPN columns and the user begins to type the information, the interactive search will be performed and the record pointer will be moved to the appropriate record.

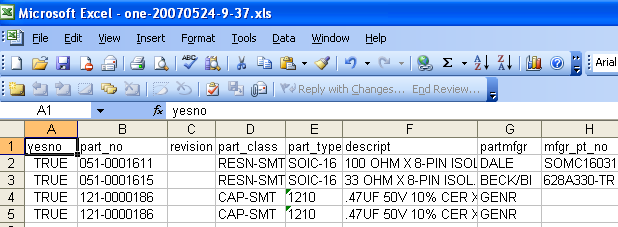

Once user has selected the records, they can depress the "Create PO for Supplier" button and PO's will be created (one for each supplier).

Once the POs have been created an xls report will be generated in the Manex local directory for review. The XL file name is based on the user initials plus the date and time the file is created. For Example if the file created has a name "ONE-20070524-9-37.xls" "ONE" - this is the user's initials; "20070524" - is the date when file was created (YYYYMMDD); "9-37" is the time (Hours-Min) when file was created, so this file was created at 09:37 am.

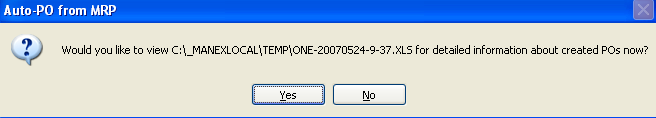

User has the option of opening the created excel file by depressing Yes or No.

|

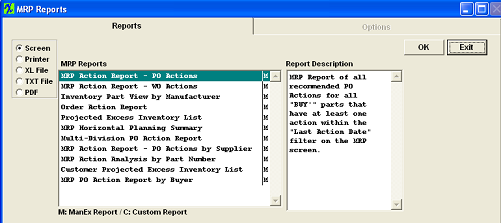

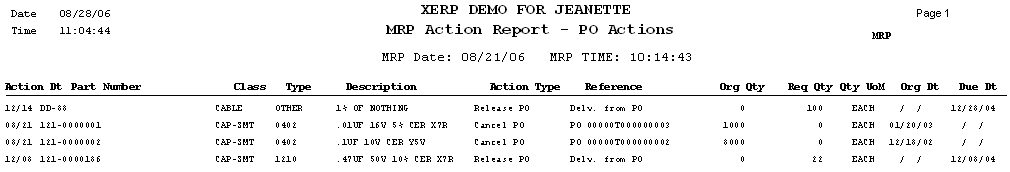

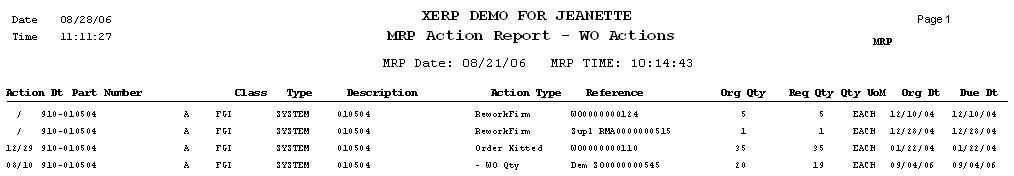

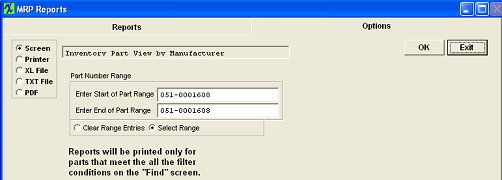

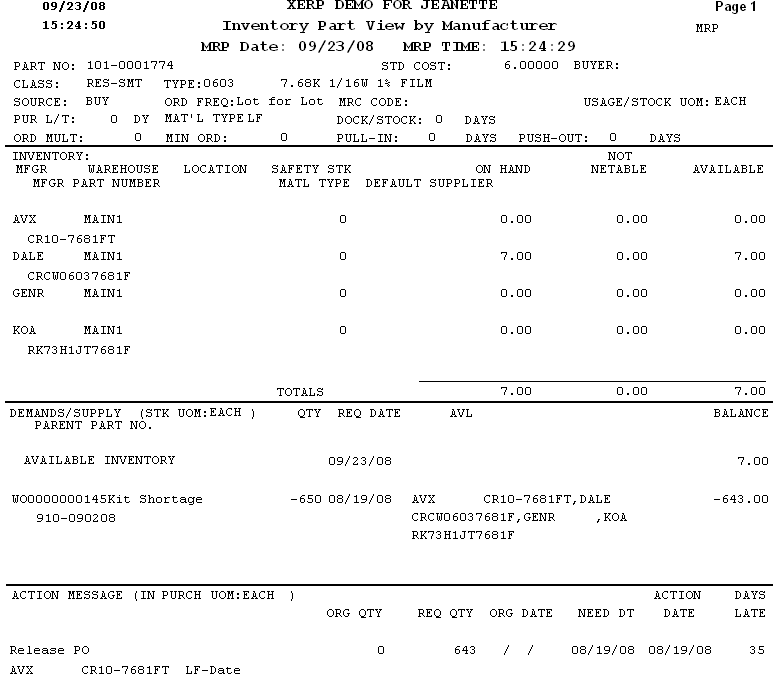

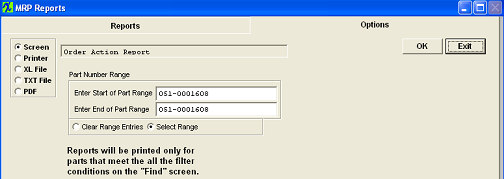

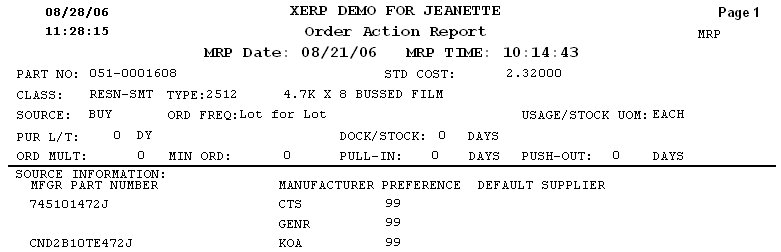

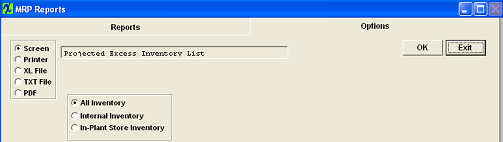

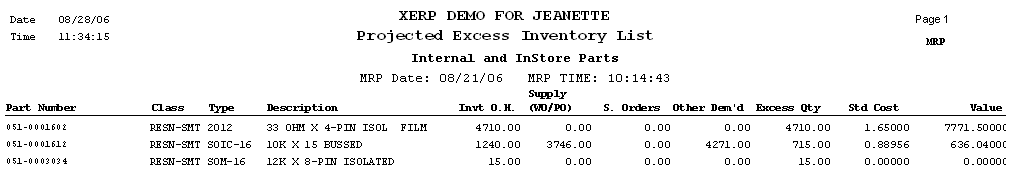

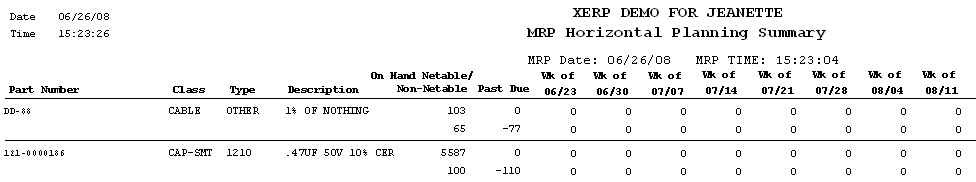

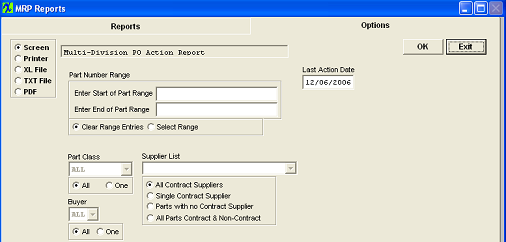

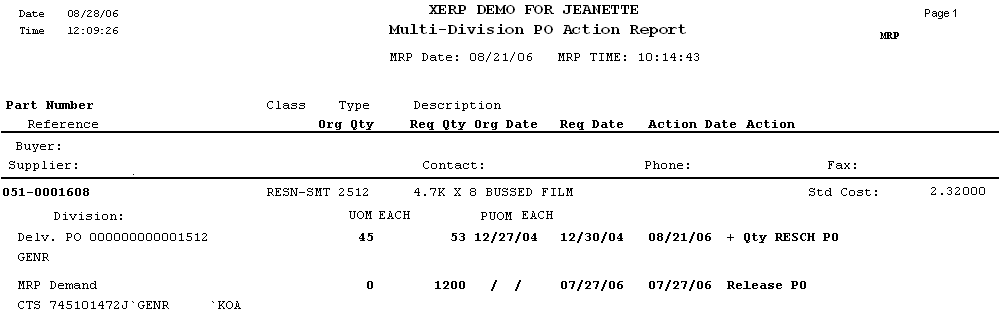

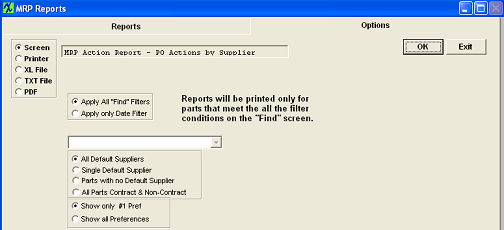

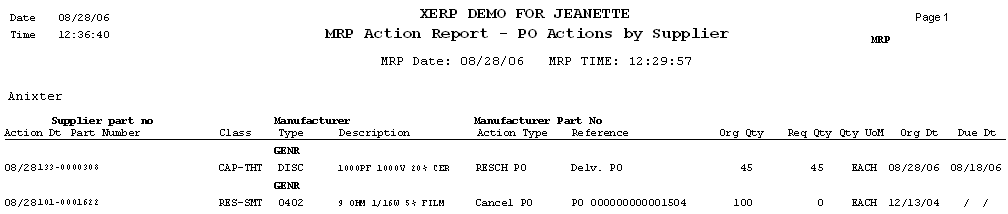

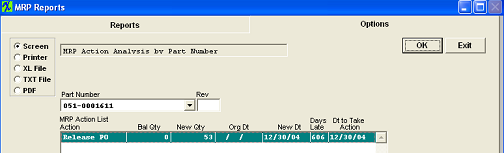

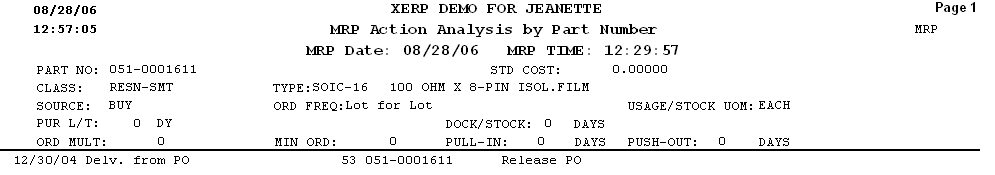

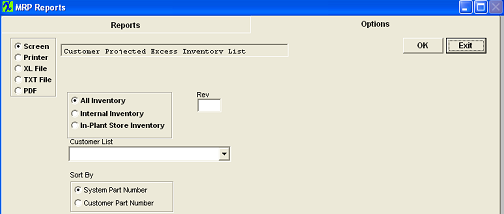

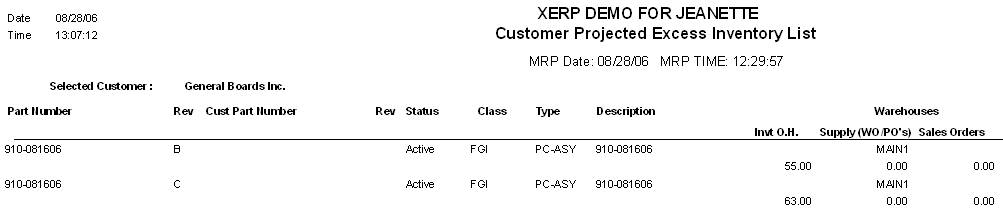

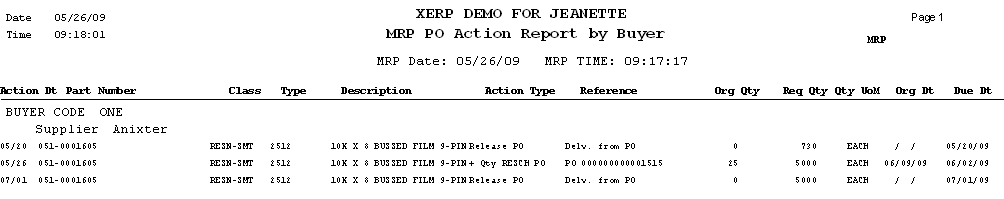

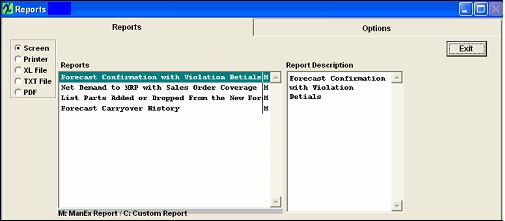

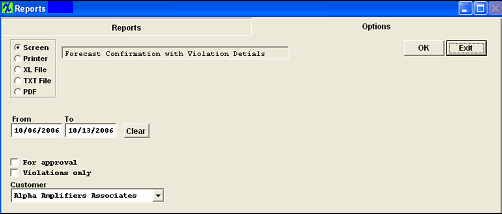

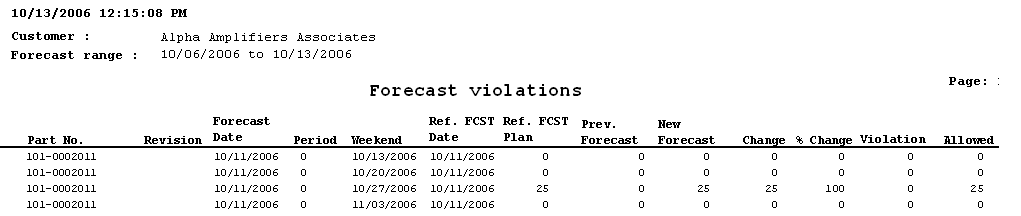

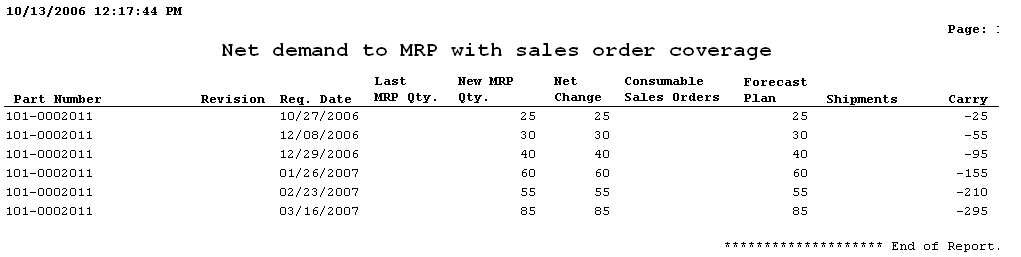

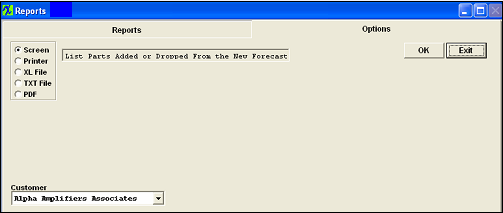

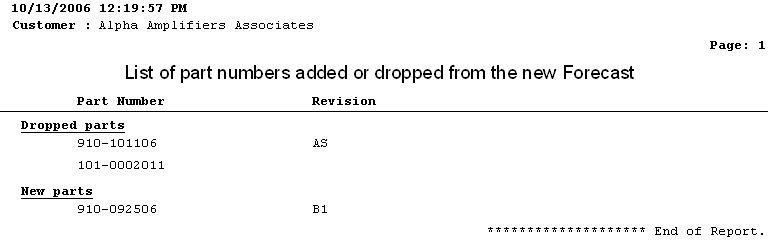

| 1.2.5. Reports - MRP | ||||||||||||||||