| 1. FAQ- Standard Modules |

| 1.1. FAQ for Sales Mgmt Modules |

| 1.1.1. FAQ- Sales Order Management (SO) |

| 1.1.1.1. How do I determine if an order can be shipped sooner than the scheduled due date? |

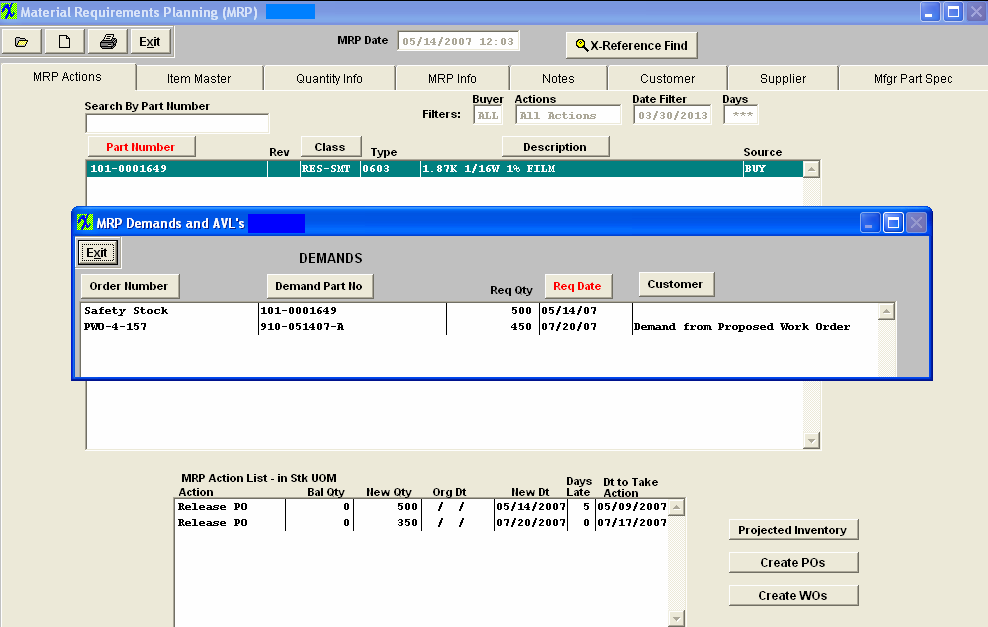

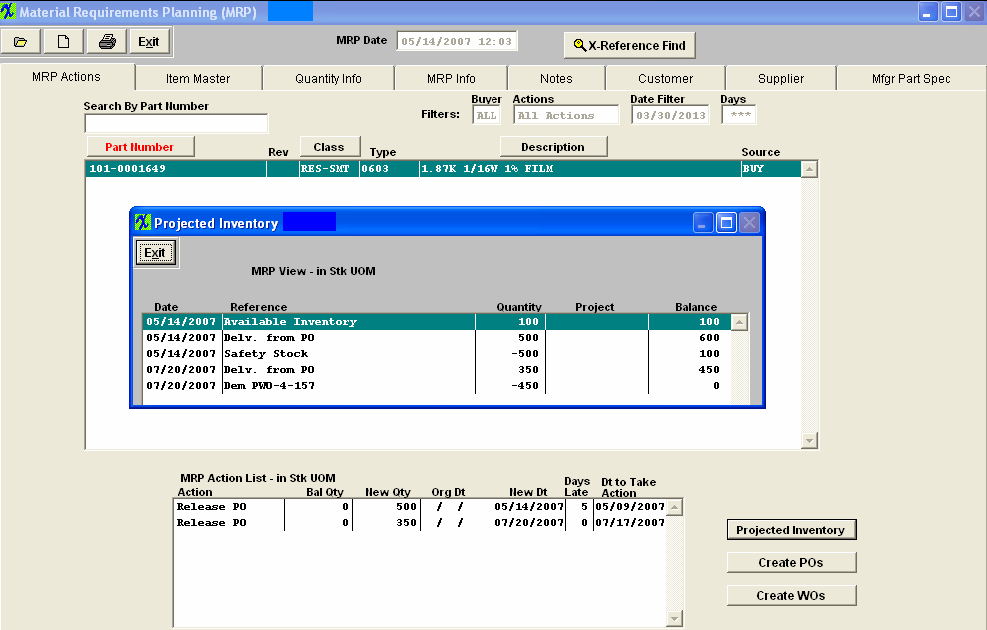

Question: What reports or screens can we view to see the material status, so we can determine whether or not we can change the Sales Order Schedule Due Date in order to ship it earlier? Answer: First check the Customer Order Status screen by customer PO and/or Sales Order number. From this screen you will be able to determine the status of any work order(s) in progress and if there are any shortages. Second you may run a Kit Material Availability W/AVL Detail (Simulation) report, by product number and revision. This report will display the Quantity on Hand and the Quantity Available for each part used on that product. Third you can check the MRP status of the product for proposed work orders and purchase orders. This will inform you if the scheduled delivery date (s) will be met. |

| 1.1.1.2. How is the SO Lead Time Calculated? |

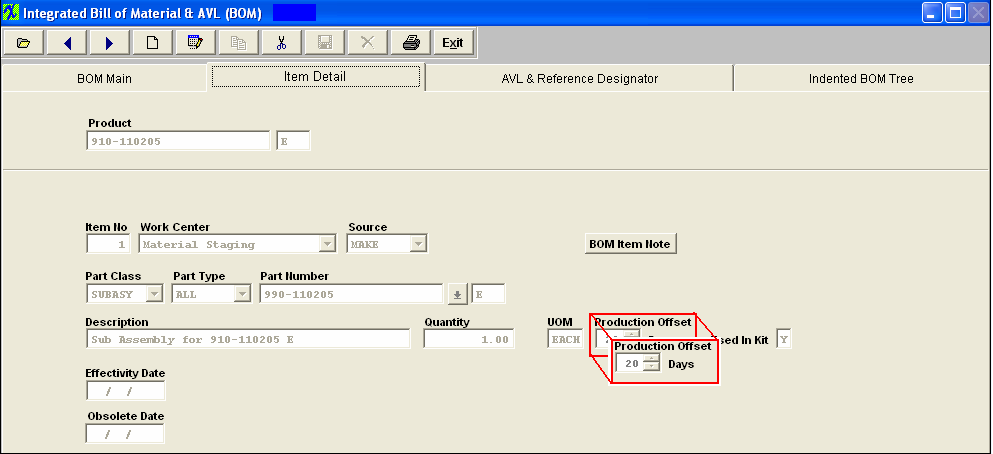

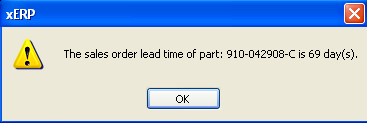

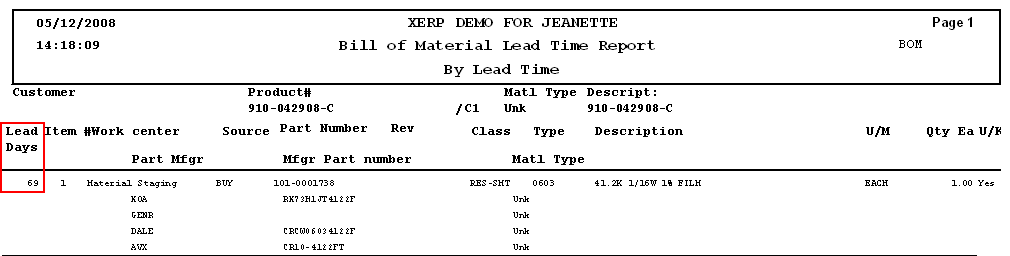

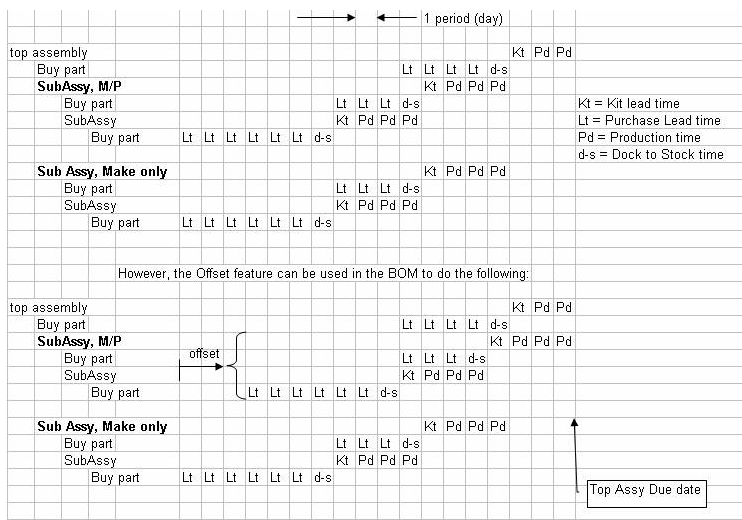

Within the Sales Order module there is a button called “SO Lead Time.”This button will display the Longest Lead Time based on the following: Component Purchase Lead Time 12 weeks (60 days) Product Kitting Lead Time 2 days Product Production Lead Time 7 days Total Sales Order Lead Time 69 days  This should match the Lead Times from the Bill of Material Lead Time report.

Note: The SO lead-time does NOT calculate the purchase lead-times of buy parts associated to sub assemblies. It will consider the kitting and production lead-times of the make part itself along with any buy components on the top level assembly in calculating the longest lead-time. The system assumes that the sub-assembly is complete at the time your kitting it for the top assembly.

|

| 1.1.1.3. Where Are The Seven Price List Cost Catagories And Sales Types Setup? |

The seven Cost Categories are setup in the Sales Type & Price Itemization module and are typically: Material Cost, Assembly Labor, Documentation, Overhead Burden, Rush Premium, NRE Amortization, and NRE One Time Chg. Price List information is is displayed in the Sales Price List Information screen. |

| 1.1.1.4. Reports |

Can a Crystal Report be used to show Cost Category information not available in MANEX reports?

In the RMA module, there are no reports for RMA back logs. The RMAs should be showing up on the back log report with a negative number for the returns due back and a positive number for the shipments due out. |

| 1.1.2. FAQ - RMA Mgmt Module |

| 1.1.2.1. How do I Create an RMA to Refund the Customer their Money rather than Fixing and Returning the Product? |

|

| 1.1.2.2. How Do I Handle the Shipping Cost on a Returned Item? |

How do I handle the Shipping Cost that the Customer Paid to Return the Board??? We sold 100 boards @ 62.00 each. (No Shipping Cost on Invoice) Problem: Customer returned one of the boards and took credit for the cost of the board which was $62.00 + $7.49 for the shipping cost that the customer paid to return the board (which was not part of the original Invoice) = $69.49 Resolution: Create a Standard RMA for the Cost of the board $62.00 and since the shipping was not part of the invoice you will NOT be able to included that cost on the RMA, so you will then need to Create a General Credit Memo for the shipping cost of $7.49 and then use that CM in the AR Offset module to apply against the Invoice.

|

| 1.1.2.3. How Does Processing an RMA with $$ Amount affect the GL? |

Q. - How does Processing an RMA with $$ amounts affect the GL?

A. - The user may enter full price for both the return and re-work. The Prints Screens attached below <<RMA_With_$$$.docx>> displays the basic procedure followed for processing an RMA through the system where both of the items have a $$ associated with them and how it affects the GL accounts.

|

| 1.1.2.4. How Does Processing an RMA with no $$ amount affect the GL? |

Q. - How does Processing an RMA with $$ amounts affect the GL? A. -A. - The user may enter zero for both the return and re-work. The Prints Screens attached below <<RMA_Without_$$$.docx>> displays the basic procedure followed for processing an RMA through the system where both of the items DO NOT have $$ associated with them and how it affects the GL accounts. |

| 1.1.2.5. Why is FGI credited and WIP debited when an RMA is received? |

Q - Why is FGI credited and WIP debited when an RMA is received?

A - When an RMA is received, it is first received to inventory, then issued to the RMA as some kind of credit is issued to the customer, depending on the amount entered in the RMA module. The Credit Memo is automatically created, accounting may be notified automatically that it was created, and they approve the transaction. Additionally, WIP is debited, because the material is NOT consigned, but valued inventory.

|

| 1.1.2.6. How does an RMA impact MRP? |

How does an RMA impact MRP?

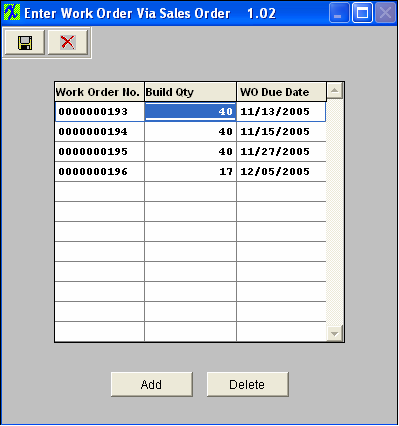

If the user enters a scheduled delivery for both the returning item(s) (a minus quantity, those coming back to the user) and the reship items (a positive quantity, returning the items to the customer) on the RMA. MRP will display a demand for a Rework Firm Order for their replacements, to satisfy the return to customer requirements based off the scheduled delivery date entered in the RMA. Note: When the RMA Receiver is created the Work Order due dates are generated automatically based on the date the RMA was created. This date may need to be reviewed and adjusted to match the RMA reshipment date. MRP will NOT instruct you to reschedule a rework firm work order, so it is important to make sure these two dates match.

RMA's will NOT drive MRP:

If the RMA only has the return to User, (a minus quantity), but not a return to the customer(a positive quantity), then the product will become available for other orders, if it makes it to FGI. If the user scraps it in this case, there is NO impact to MRP, as there is no requirement to replace the items. If there are other requirements for the same item, however, then MRP will use the rework order as a source for additional demands.

There would be no reason to create an RMA to ship only, without the return to our user. We would call that a Sales Order. Which would be visible anywhere. The Word attachment <<RMA Orders Affect MRP.docx>> will display how MRP works if the RMA's are properly processed through the system.

|

| 1.1.3. FAQ - Customer Information |

| 1.1.3.1. What is the Credit Limit Restrictions based on? |

Question: What is the Credit Limit Restrictions based on? Answer: The Credit Limit check takes place within the Packing List. The program gets the total Accounts Receivable (AR Aging) + Not Posted Invoice (invoice not printed out of the Admin/Invoice module) + Open SO Amounts. Compares it to the Credit Limit setup in the Customer Information module. This is based on having the "Include Open Orders for Credit Approvals for Shipping" option checked, (within the Print PL/Invoice setup module) (if you do not want to include open Sales Orders you would want to uncheck this option) and the "Enforce Credit Limit at Shipment" option checked, (within the Sales-A/R setup module)(uncheck this option if you do not want to Enforce the Credit Limit at Shipment). You also have the ability, to authorize a user to approve the credit limit exceed message or not (within the Security module, Packing List option screen). Make sure that these options are marked properly to get the results you are expecting. |

| 1.1.4. FAQ- Quote Management (QOT) |

| 1.1.4.1. QOT Total Part Demands Question | |||||||

|

| 1.2. FAQ for Inventory Mgmt Modules |

| 1.2.1. FAQ- Inventory Control Management (ICM) |

| 1.2.1.1. Can ManEx Value Raw Material based off of the Purchase Price versus Std Cost? |

Q. Can ManEx Value Raw Material based off of the Purchase Price versus Std Cost? A. Our system operates on a “Standard Cost Basis” (SCB). This means that the value of inventory does not fluctuate based on the purchase price, and that users do not have to use FIFO (First In, First Out) inventory management for financial reasons. (They may wish to because of other considerations, such as shelf life.) Because of SCB, we necessarily utilize Purchase Price Variance (PPV) to account for the difference between the SCB value and the actual purchase cost. This measure also helps companies set their standard cost, based on a review of the PPV for given components. Once a reasonable standard cost is established, then the Purchasing department has metrics through the PPV reports to determine whether or not they are improving on price negotiations, or are unable to attain the standard cost. Purchasing departments with a positive PPV are contributing to the bottom line of the company. Because of this, Purchasing will tend to navigate standard costs to the higher side of average. With correct Standard Costs, Marketing Department can better control their margins. And Marketing will tend to drive standard costs to the lower side of average, thus improving their margins. ManEx does not have a direct provision for assessing current inventory based on purchase price. An approximation could be offered by combining the PPV of the last month with the on-hand inventory value. This is an approximation, because there may be old and/or obsolete inventory which was received at a significant PPV, and would not be accurately valued considering only the standard cost. But there is provision within ManEx to account for inventory based on purchase price. It involves the utilization of the Project module. All inventory in which the company may wish to evaluate based on the purchase price would have to be allocated to a project at the time of purchase. When this is done, the purchasing information for the components bought against a project is retained. It can be recovered through the use of reports in the Project Module. The job costing module will also identify the purchase price information for components allocated to a job or work order. Another method of tracking original costs is by using Lot Tracking. When Lot Tracking is used, the purchase information is retained with the Lot Information. A report may then be generated to report the original pricing of lot tracked material in inventory. While these two methods are currently available, a third is in development. When we complete the IPKey development, and of the company elects to use the IPKey tracking, we will be able to create reports that will identify the purchase price of all inventory, although it will not be the book value of inventory. |

| 1.2.1.2. Can a "Netable" part be excluded from MRP? |

The term "Netable" applies to parts that may be considered as supply to meet MRP demands. You cannot have a "Netable" part that is excluded by MRP. In order to differentiate between inventory with an AVL with the same MPN, but one is RoHS compliant and the other not, we recommend that the user establishes a warehouse with a "noncompliant" location. Making that location non-nettable will prevent MRP from considering the part as available, but still allow usage of the part in kitting. In order to do that, we have added the "Allow use of Non-netable Warehouse Locations" feature to the Kit Default Setup screen, this allows the user to choose whether or not non-nettable material may be used in the kit lists (except for MRB warehouses, which can never be used without disposition). Any parts in the MRB warehouse are deemed questionable until the parts are validated and returned to a normal warehouse. So they will NOT be considered by MRP. Also keep in mind you cannot ship form a non-netable location.

|

| 1.2.1.3. Can the Part Souce be changed from MAKE to Make/Buy on a Product? |

Q. Can the Part Souce be changed from MAKE to Make/Buy on a Product?

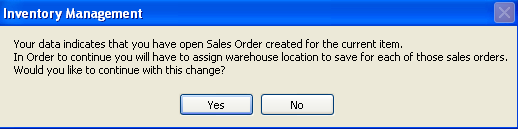

A. Yes, the Part Source can be changed from MAKE to Make/Buy on a Product. If the product is set as a MAKE part in the system and user edits the record and checks the Make/Buy, the program will search for any open Sales Order line items for that MAKE part.

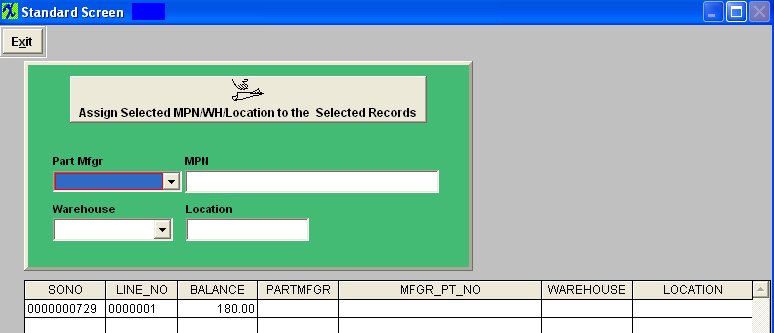

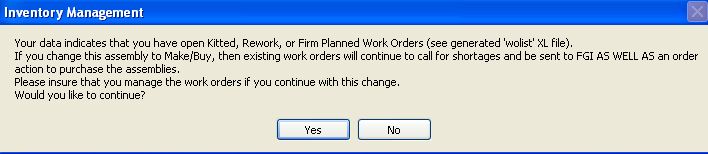

If found, the system will check if more than one MPN and location is assigned to the part. If only one MPN/Location is assigned the system will just modify data within the tables, if more than one location exists, the system will open a screen where user can select multiple Sales Orders in the grid and select which MPN/Location they want to assign to those SO's.  The system will also check that the MAKE part has no Work Orders that are Firm Planned or Kitted. If there are such Work Orders the system will prompt a warning message and let the user decide if they want to continue with the changes.  |

| 1.2.1.4. Can I return Transferred Stock back to the Instore Location? |

Question - What if a user accidentally transferred inventory from an instore location to the main warehouse. The user was supposed to issue 1 pc rather than all 250, however they transferred all 250 to the main warehouse. How can I transfer the extra 249 pcs back to the instore location.

Answer - As soon as you transfer the stock out of the In-Store location into the MAIN1 warehouse – the system automatically has the records ready to go for creating the In-Store Purchase Order. As soon as the user takes them out of the In-Store location the system assumes that they have been consumed and that you need to pay the Supplier for those items. You can NOT simply return them back to In-Store location because of a human error. There is two options:

Option 1 - if you choose to pay the supplier ahead of schedule - generate the IPS PO. Option 2 - If you do NOT choose to pay the supplier ahead of schedule and want to wash out the transfer, here is what we would suggest to do:

|

| 1.2.1.5. Can I clear 0.00 qty MRB locations? Utility available. |

These type of records are supposed to be cleared automatically after the PO DMR has been processed out of the system, but on ocassion that they do not clear, you can use this utility. It will go through and find any MRB location that is open on screen with 0.00 qty on hand and clear them from the screen.

Please be sure to follow the procedure below to install this program. It is highly recommended that you follow this procedure on your TEST system first before applying it against your Live ManEx System. 1.) Create a Backup of your Live ManEx System

2.) Extract { clear0mrb.ixe } into the ManEx Root Directory 3.) Change the file name extension from ixe to exe

4.) Run the Executable

5.) Verify the Results

6.) Remove { clear0mrb.exe } from the ManEx Root Directory

Once satisfied with the results in your test system, you may proceed with your Live ManEx System. |

| 1.2.1.6. Can I clear 0.00 qty WO-WIP locations? Utility available. |

These type of records are supposed to be cleared automatically after the WO-WIP has been processed out of the kits but on ocassion that they do not clear, you can use this utility. It will go through and find any WO-WIP location that is open on screen with 0.00 qty on hand and clear them from the screen.

Please be sure to follow the procedure below to install this program. It is highly recommended that you follow this procedure on your TEST system first before applying it against your Live ManEx System. 1.) Create a Backup of your Live ManEx System

2.) Extract { clearwowip9.ixe } into the ManEx Root Directory 3.) Change the file name extension from ixe to exe

4.) Run the Executable

5.) Verify the Results

6.) Remove { clearwowip9.exe } from the ManEx Root Directory

Once satisfied with the results in your test system, you may proceed with your Live ManEx System. |

| 1.2.1.7. Can Users Print Component Labels to help Shop Floor Locate and Identify Parts? |

Can Users Print Component Labels to help Shop Floor Locate and Identify Parts?

Yes, Manex has the ability to print bag labels and box labels for parts and work orders. |

| 1.2.1.8. Do Users Create Separate Part Masters for Components not Interchangeable in Both Directions? |

Do Users Create Separate Part Masters for Components not Interchangeable in Both Directions? Some users create different part numbers for the same part, but used by different customers. Others take advantage the ability in Manex to identify AVL requirements by specific customers without creating multiple sets of part numbers for the same part. This has the advantage of having all requirements under one part number, and avoiding excess inventory because of the likelihood that some of the part numbers will be forgotten when they could be used for a new requirement. There is also provision for a customer to eliminate a specific AVL for a part associated with a specific assembly. |

| 1.2.1.9. Do Users put the Revision Level in the Description or do they use the Revision Field? |

Do Users put the Revision Level in the Description or do they use the Revision Field?

ManEx encourages users to take full advantage of the nomenclature provided. The CLASS field, of 8 characters, is used for the top level of a part class, e.g. resistor, capacitor, etc. The TYPE field, also 8 characters, is used for a subset of the class. The PART NUMBER field, of 25 characters, is specific to a specific set of parameters for a part class and type. And the REVISION, of 4 characters allows for distinctions between revisions of the same part numbers. So fully utilized, there are a total of 45 characters to precisely descript an inventory part. There are a variety of additional fields to identify specific characteristics of a given part, such as the source, the material type, and several different cost structures. |

| 1.2.1.10. Does the ABC Calculation Consider Leadtime? |

Q. Does the ABC Calculation consider Leadtime?

A. Yes, the ABC calculation does consider leadtime, but it is only the leadtime entered in the ABC code setup that is considered. The Dock to Stock is also used in the MRP calculations as part of the leadtime to get parts to the stockroom. There are three approaches to establishing ABC codes. The FIRST is Manual where there is no calculation involved. Whatever the user selects at the time an item is added to inventory (or anytime thereafter) will be the ABC code, and it won't be changed. The SECOND approach is to calculate the ABC codes based on inventory value AND usage. The Usage is also calculated in the ABC code setup and works like this: The usage is based on how much material is issued to the kits, or out of the stockroom, and it checks the data for the last 30 days. So the first time the calculation is done, the total amount of issues are gathered, and become the usage for the last 30 days, and become the estimated usage. This number is multiplied by 12 and assigned as the EAU (Estimated Annual Usage). The NEXT month, the calculation is repeated. Only this time, if the user wishes, the data can be averaged with the previous months calculation to give a two month picture of usage. This is done by giving the second calculation a weight of 50% (2 months). The two months are averaged, and extended by 12 to establish a new EAU. In the third month, the process is repeated, except that the weighted would not be 33%, to average three months. The user can decide if they want to stop at a three-month rolling average, and use 30% each month thereafter, or go for a four-month rolling average and keep it at 25%. Or, if the user has an unusual month, they can change the weighted for that month up or down, depending on whether it was a good or bad month. The THIRD approach is to calculate the ABC codes based on inventory value at the time of the calculation. This is done by extending the cost of all inventory items into a list, with the highest value at the top of the list. The part at the top of the list might be Large PCB, with only one in stock valued at $1,000,000. Or it could be a Small PCB, with 100,000 in stock valued at $10 each. It is the extension of the value that is sorted by the highest number first. The total value of all of the stock is then calculated. In the setup, if the "$ On Hand" is selected, each ABC code must be assigned a percentage, and the total of the percentages assigned to each code must total 100%. Typically, A codes are assigned around 80%, B codes are 15% , and C codes are 5%, but each User can make their own choices. Then the inventory list ordered by the highest value is examined and the first 80% (cumulative) are assigned A codes, the next 15% assigned B codes, and the last 5% assigned C Codes. The codes are then reviewed again, to see if there are any long leadtime conditions attached to the ABC codes. If there are, the code may be increased (towards A) depending on the leadtime entered in the setup for the code. The reason for this is that some users may wish to count very long leadtime items more frequently than the ABC code would suggest. You may have a $0.25 part that would normally be a C code, but has a 26 week leadtime. So you would want to keep a closer eye on that part, because it would not be good to have everything but a $0.25 part to build an assembly. So the ABC code would be increased to B or A (depending on the ABC setup) so the part is counted more frequently than it would if it stayed a C code part. In ManEx, we allow more than the standard ABC codes, so it the user wanted a finer cut at the distribution, they could have up to 26 ABC codes if they had a need, and all of this would still apply. Once the EAU is calculated, the EAU is used to extend the inventory value of each item, and the stacked values are assigned ABC codes as described in the THIRD approach. The leatime consideratiion also is applied after that. |

| 1.2.1.11. How Inventory, BOM's and AVL's are Connected |

| 1.2.1.12. How do Users Handle Passive Components as far as Inventory Control, Issuing Full Reels, Floor Stock, Order Point vs MRP Actions? |

|

How do Users Handle Passive Components as far as Inventory Control, Issuing Full Reels, Floor Stock, Order Point vs MRP Actions? ManEx allows the issuance of partial or full reels to work orders. The amount actually needed for the work order is calculated, and the remainder of the reel is available for MRP and subsequent work orders, even though the reel is in WIP. We call it Work Order WIP, or WOWIP. Additional work order may have the same parts kitted directly from WOWIP to a new work order. Additionally, some companies simply issue a full reel to an inventory warehouse called floor stock, for the inexpensive items. In turn, the same items are marked "do not kit" so that the stockroom doesn't have to create a transaction. The operators simply grab a reel, and return the remainder to the floor stock after the kit is completed. This necessitates updating or reordering floor stock as the supplies are depleted.

|

| 1.2.1.13. How do Users Handle Issues by Manfacturing Part Number when they are Under the Same Internal PN? |

How do Users Handle Issues by Manufacturing Part Number when they are Under the Same Internal PN?

ManEx provides for multiple identifications of manufacturer part numbers for a given part. The user has the option to manage in any way they see fit. |

| 1.2.1.14. How do Users Cope with Substitutions of Passives with Tighter Tolerance and/or Higher Voltages? |

How do Users Cope with Substitutions of Passives with Tighter Tolerance and/or Higher Voltages?

Generally, a different ManEx part number is assigned for specific tolerances, as they are for different values and parameters. Sometimes users will use the ANTI-AVL to exclude some manufacturer from a BOM which is engineered with marginal tolerances. |

| 1.2.1.15. How does Pull-in Push-out days affect MRP? |

Question - How does Pull-in Push-out days affect MRP? Answer - Pull-in/Push-out uses the order policy, demand due date, demand quantity, minimum order qty, and safety stock to determine if an existing order needs to be rescheduled and/or have the qty adjusted when the demand date changes. It does not allow for grouping orders outside the order policy setting, or produce more than is needed for a specific demand (over the min order quantities or safety stock).

For example: If the order policy is set to daily, and the existing work order is setup to meet a monthly demand, the user will get an action message to adjust the work order according to a daily grouping of the demand (reduce the existing wo qty and create new wo(s) as needed). In the same scenario, if the order policy was changed to monthly, then the single work order should not be affected. If the user wants to maintain an order policy that is NOT consistent with their desired grouping, they must either firm plan the order, or create a separate Work Order for each demand grouping. The latter would result in multiple Work Order’s due on the same day with a qty set for each demand’s required qty rather than one Work Order on that day for the total demand. |

| 1.2.1.16. How does the Cycle Counting affect ICM Records? |

The approach to cycle counting is based on the ABC codes setup with the System setup. No matter how the ABC codes are assigned, they are used for the cycle count the same way. When the cycle count button is activated, these events take place:

For example, lets say that A parts have a 30 day cycle, B parts a 90 day cycle and C parts a 180 day cycle. Let's say there are 500 A parts, 2,000 B parts, and 15,000 C parts.

|

| 1.2.1.17. How does the "Disallow this Part from Purchase" affect MRP? |

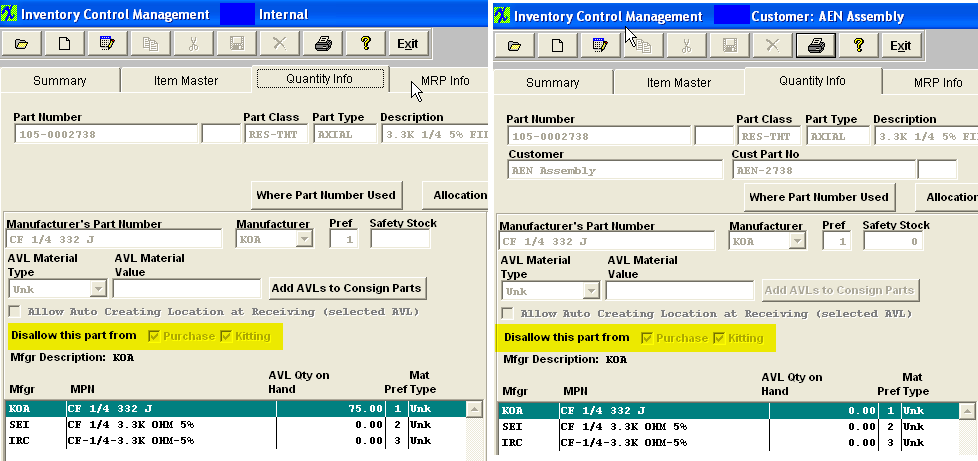

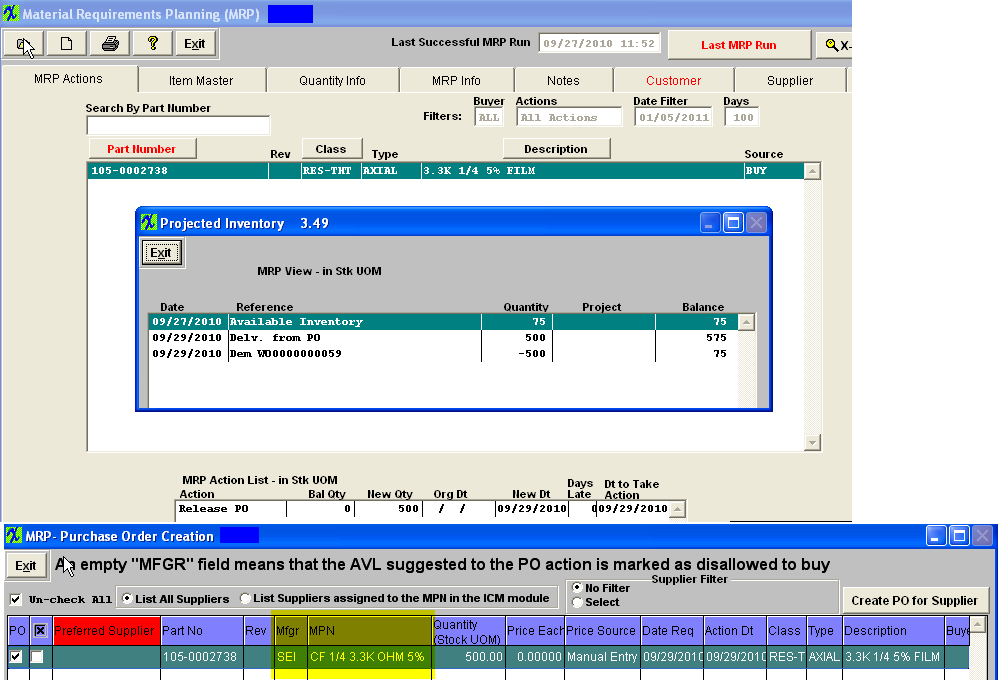

Q. How does the "Disallow this Part from Purchase and Kitting" affect MRP?

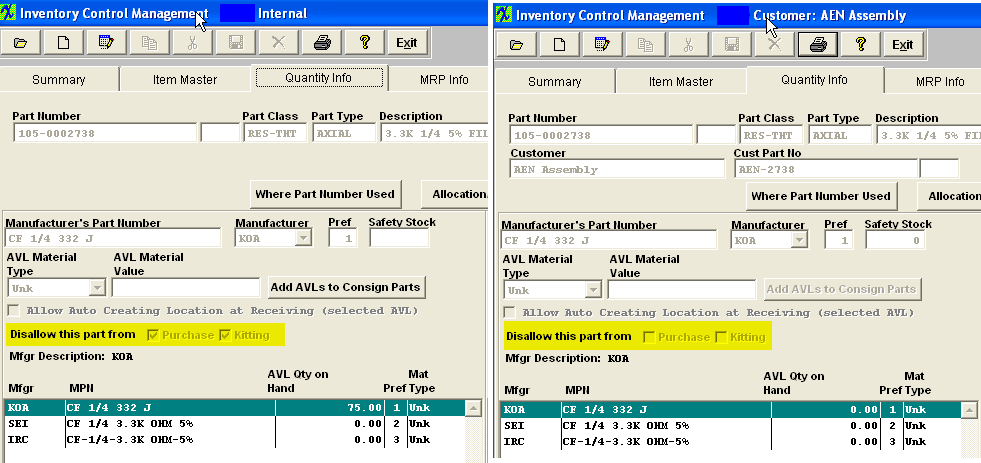

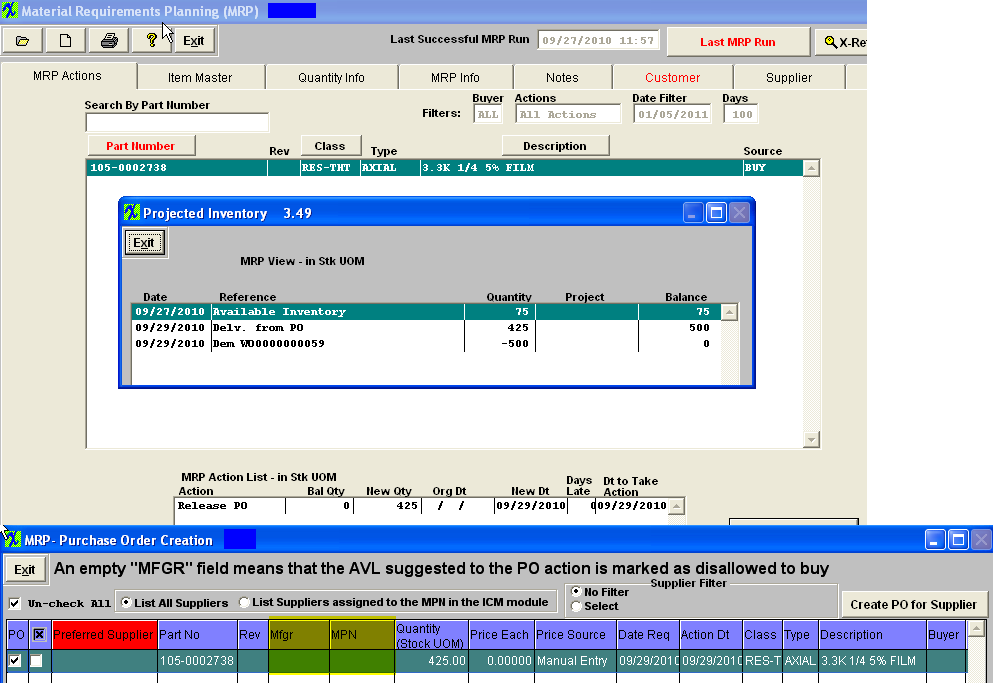

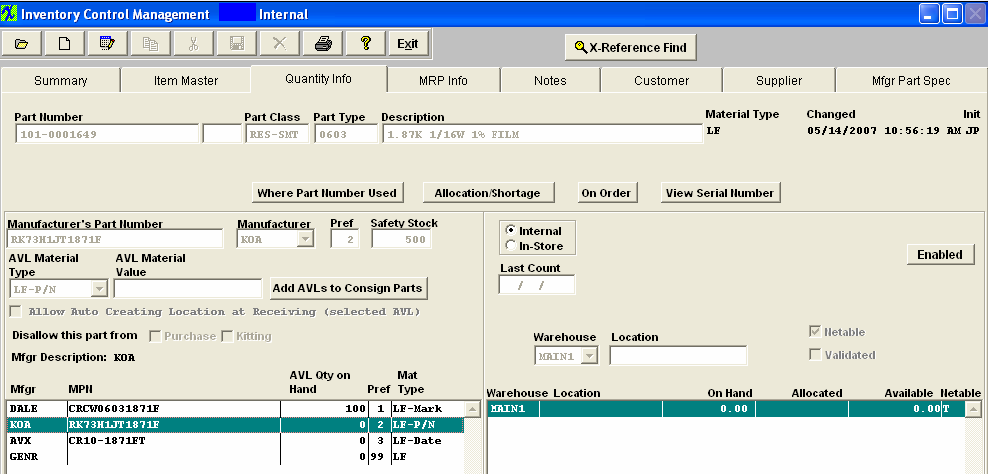

A. If the AVL suggested to the PO action is flagged as "Disallow this Part from Purchase and Kitting" on the Internal Side and either does NOT exist on the customer side or is NOT flagged on the Customer side.

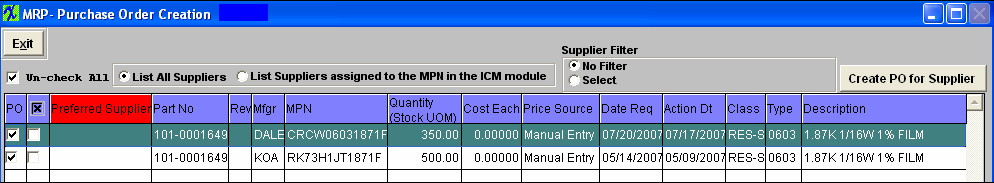

The system WILL use the qty on hand and MRP WILL give Release PO actions if there is a need for the part and the part WILL be displayed on the Create PO screen with the Mfgr and MPN fields blank. (as displayed in the print screens below) This should flag the user to further investigate and see that it is flagged as "Disallow this Part from Purchase" and that they will need to either remove the flag from the approved AVL or add additional AVL's to ful-fill the demands. Notice at the top of the "Create PO" screen there is a note that explains what the empty "MFGR" field means.  If the BOM is assigned to a customer and the AVL exists on the consigned side then the user MUST also check the "Disallow this Part from Purchase and/or Kitting" checkboxes on the consigned side.

The system WILL NOT use the qty on hand and MRP WILL give Release PO actions if there is a need for the part for the next approved AVL on the Create PO screen. (as displayed in the print screens below)

|

| 1.2.1.18. How the Manex Automatic Part Numbering System is Setup to Operate. |

The part numbers are not intelligent(outside of ManEx they have no meaning). Without the software to provide complete information, it is just a number. The main concern when creating a part number is not to ensure a sequential part numbering by class, but rather the ability to track additional information (AVL, on hand qty, where used, standard cost, etc) by one internal part number. Because of this, the actual number doesn't really matter as long as the system knows which additional information to attach to the internal part number. This is why ManEx works as well with a manually created number as with an auto-generated number. If you use auto-numbering, the numbers can be arranged on the shelf in ascending order (even if there are gaps between the numbers). The auto-numbering in ManEx simplifies the part number creation process and provides a count of the total parts in your system (141-0001000 to the 1000th part loaded). Additionally, it is common in this industry to add new parts and obsolete old parts as the customer base changes and grows over time. Even if the parts were setup sequentially by class and type, as you suggetsed, they would eventually have gaps in the numbers as old parts are made obsolete. There is a no way to prevent this and it is not worth your time to fix it after it has occurred. Not having all parts numbered sequentially by class and type does not affect the quality of the information provided. Users are able to purchase, track inventory, and kit all parts by part number. ManEx will still accurately maintain all important information by part, by customer, and by BoM. If is absolutely critical to have all parts by class and type sequentially numbered. Users do have the option of manually creating the part numbers. This will allow you to use any part numbering method. Go to the Number System module to Setup "Auto" or "Manual" numbering. Note: With the auto-numbering setup the way it is you can have 10 million parts in your system. |

| 1.2.1.19. How the Inventory Control AVL Pref Code Works |

| In response to some of the questions/misunderstandings from our customers we had determined that the Preference Order assigned through the Inventory Control Module to the AVL's might be confusing. Some of the users were considering "0" as the lowest and "1" as the highest. Preference order is a numeric field and the system considers "0" as the highest Preference then 1, 2, 3, . . . . . The Pref that is assigned to the AVL's will dictate how other modules within the system (MRP, Purchasing, Kitting, Allocation) determine what is suggested or defaulted into the screens. The system used to default in all AVLs with the Pref "0" now as a result of some customers considering "0" as the lowest we have made changes to the code so now the system will default all new AVL's to Pref of "99". If all locations are equal to "99" then the system will consider them in alpha order. But as soon as a user assigns 1, 2, 3 then they will be properly considered in that order throughout the system. Note: If the part is on a Customer BOM and assigned to that Customer then the Preference's from the Customer part number will dictate how other modules within the system (MRP, Purchasing, Kitting, Allocations) determine what is suggested or defaulted into the screens. The 8.1 Update will automatically go through the system upon running the program and look for any "Blank" or "0" Pref and default them to "99". |

| 1.2.1.20. How is the EAU(Estimated Annual Usage) Calculated? |

The Estimated Annual Usage (EAU) is calculated by taking the most recent 30 days of issues to kits, and multiplying that by 12 (months). WHen the user first begins using the EAU, the factor shoudl be 100%, meaning that the full 30 days is used to extend to an annual quantity. If the month following (after another 30 days of experience), running the EAU again will weight the second run against the first run. So the factor for the second run should be 50% (or the equivalent of a 60 day average). In the third month, (after a total of 90 days of data), the factor would be 33%, thus averaging out all three months and extending that average for a year's period. If the user wished to maintain a rolling 3 month average, then the following months would also be 33%. A 4 month rolling average would be obtained if the user entered 25% on each subsequent month. Another consideration is that if the user just finished a really big month, with record consumption (an presumably sales), and doesn't want the blip to cause excessive forecasted EAU, they might enter a 20% factor instead of 25% or 33%. On the other hand, if the user has a very slow month, and doesn't expect it to continue, they might want to give a higher rating to that month, say 35% instead of 25% or 33%. This would have the effect of not understating the expected EAU.

|

| 1.2.1.21. How to "Disallow this Part from Purchasing/Kitting" if there is more than one customer that uses the same MPN. |

Question: If I have more than one customer that uses the same MPN, how do I "Disallow Part from Purchasing/Kitting" for only one of the customers? Answer: If the part is listed on the BOM as a customer/consigned item then it is controlled by the "Disallow Part from Purchase/Kitting" option within the Customer Level of Inventory Control Management. If the part is a BUY part on BOM(s) for different customers the Kitting module is controlled by the "Disallow Part from Purchase/Kitting" option within the Inventory Control Management module Since it is BUY on the BOM the system is looking at the BUY settings. For further detail see Article #3211 . For Buy parts that are used for multiple customers we recommend that you un-check that AVL so it is no longer approved at the BOM's level for that product. |

| 1.2.1.22. How can I Identify all Duplicate MPNs in my System? |

Q: How can I Identify all Duplicate MPNs in my System?

A: There are many utilities to identify all internal parts that use a selected MPN. However, if you want a master list of all parts so that you can review and delete any that are not needed, below is a simple set of instructions you can follow: 1. exported the Parts List by Manufacturer & Mfgr Part Number report to excel (accessible from Inventory Control)

2. delete all non-BUY parts 3. move the MPN column before the part number column

4. sort by MPN, then by internal part number

5. delete uniq_key column data and replace with formula (use the attached spreadsheet to see our example of the formula used)

6. add conditional formatting to highlight each part number change

7. filter out blanks in column with formula

This creates an easy to read list of all MPNs used more than once under different internal part numbers.

Once the data is in SQL, they can use this view to show all buy MPNs that are used on more than one internal part number.

SELECT TOP (100) PERCENT LIST.MFGR_PT_NO, INV.PART_NO, INV.REVISION, INV.PART_CLASS, INV.PART_TYPE, INV.DESCRIPT

FROM (SELECT MFGR_PT_NO

FROM (SELECT TOP (100) PERCENT MPN1.UNIQ_KEY, MPN1.MFGR_PT_NO

FROM dbo.INVTMFHD AS MPN1 INNER JOIN dbo.INVENTOR AS INV1 ON MPN1.UNIQ_KEY = INV1.UNIQ_KEY

WHERE (INV1.PART_SOURC = 'BUY')

GROUP BY MPN1.MFGR_PT_NO, MPN1.UNIQ_KEY

HAVING (MPN1.MFGR_PT_NO <> '')) AS L1

GROUP BY MFGR_PT_NO

HAVING (COUNT(MFGR_PT_NO) > 1)) AS LIST INNER JOIN dbo.INVTMFHD AS MFG ON LIST.MFGR_PT_NO = MFG.MFGR_PT_NO INNER JOIN dbo.INVENTOR AS INV ON MFG.UNIQ_KEY = INV.UNIQ_KEY

GROUP BY LIST.MFGR_PT_NO, INV.PART_NO, INV.REVISION, INV.PART_CLASS, INV.PART_TYPE, INV.DESCRIPT

ORDER BY LIST.MFGR_PT_NO, INV.PART_NO

|

| 1.2.1.23. How can ManEx help me in Eliminating Attrition and Scrap? |

Q. How can ManEx help me in Eliminating Attrition and Scrap?

ManEx has several standard and optional features designed to simplify the process of identifying, tracking, and eliminating attrition and scrap. .

In Process Upgrades

|

| 1.2.1.24. How can ManEx help me Streamline Inventory Tracking & Control? |

Q. How can ManEx help me Streamline Inventory Tracking & Control?

ManEx was designed from the ground up for electronic contract manufacturing. As a result, no other system fulfills the needs better. ManEx has many standard and optional modules designed to streamline inventory tracking and control.

|

| 1.2.1.25. Inventory PN/Consigned PN/Supplier PN Relationship |

The main information for an item master (Internal part) is contained in the INVENTOR table. For every AVL that is added to the part, a record is created in the INVTMFHD table. The AVL is linked to the item master by the field Uniq_key in each table. When an inventory warehouse/location is added to an AVL, another record is added to the INVTMFGR table. The Warehouse information is linked to the AVL information by the Uniqmfgrhd field. When a User adds a customer part number to an item master (internal part), an additional record is added to the INVENTOR table. This record contains the same information as the internal part, but with a DIFFERENT Uniq_key, and is identified with a Part_sourc field as CONSG, and includes the customer part number and revision. This additional record is used both for consigned information and to identify the customer part number by customer. It is linked to the internal part through the Int_uniq field, which contains the internal uniq_key associated with the customer part. When the customer part number is added, the AVLs and Locations are also duplicated in the INVTMFHD and INVTMFGR tables, in the same linking as described for the internal parts. When a supplier part number is added to the table INVTMFSP. There the supplier information is contained as well as the supplier part number. Because it is linked specific to an AVL, it is linked by the Uniqmfgrhd field to the INVTMFHD table, in similar fashion as the INVTMFGR table. Diagrammatically, it could be described as: INVENTOR . . . . . . . . . . . . . . . . . Item Master So there will be one set of these for every internal part number, and may be multiple sets of the same information for different customer part numbers. |

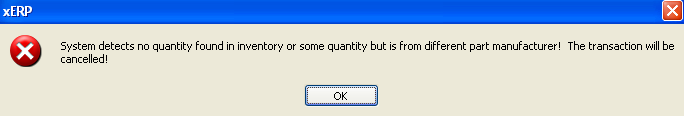

| 1.2.1.26. System Detects no Quantity found in inventory or some quantity but is from a different part manufacture! Transaction will be cancelled. | |||||||

|

| 1.2.1.27. What would cause records to be pulled into the Update kit screen? |

Question: User had made a few changes to the BOM through the Bill of Material Module and then went into the Kit module and depressed the update kit button. A large number of items appear to be dispositioned and issued to the kit for items that had no qty changes, etc. . . Answer: One of the possible reasons could be the fact that the user went through and changed the assigned workcenter on the BOM. So when the update kit checks the existing kit to the new BOM changes it sees all of the Workcenter changes and bring them in for disposition. If the kit was pulled while the BOM Workcenter was STAG then the user edits the WC on the BOM to Final Inspection, when the update kit button is depressed that item will be pulled into the screen for disposition. |

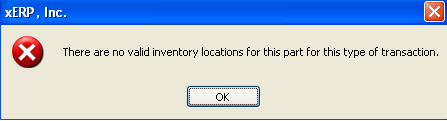

| 1.2.1.28. What the Message "There are no Valid Inventory Locations for this part for this Type of Transaction" means. |

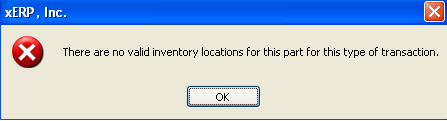

This message is a general message user gets when the program can not find any warehouse/location for this part number. The program checks much more than just the part is locked in cycle count or physical inventory. It also filters out "MRB" warehouse(for receiving), can not be "WIP" or "WO-WIP", can not be marked as "deleted", apply instore criteria.... It all checks in one or few SQL commands, it filters out all records that don't meet the criteria. If all records are filtered out, then user will get this message. |

| 1.2.1.29. Why are the Inventory Transaction Detail Log Reports not displaying the correct WHSE for the original receipt? |

Inventory Transaction Detail Log Report & Log Report with Balance does not display the original whse on the first receipt. This is due to the fact that the DMR module will require a Receivier record to be selected, and the original accept information on that receipt is then changed to reflect the most recent Reject records saved. The Trans Log numbers will be correct, but the original receipt whse info will be changed to reflect current.

Please see attachments PO Ex 1 & PO Ex 2.

|

| 1.2.1.30. Why is Purchase History Indicating no History Available if Parts on PO were Received? |

Q. Why is Purchase History Indicating no History Available if Parts on PO were Received?

A. If the PO has a status of "Cancel" this subsequently deletes all the purchase history related to this PO for all parts on this PO. If you would like this PO displayed in the purchase history for the parts that had receipts you would need to edit and re-open the PO, apporve the PO, cancel the individual line items if there has NOT been any receipts against them, and re-approve the PO. The PO status will then change to closed but the PO history for the received items will now appear in the Purchase History screen. The information in the PO History button comes from the last 10 PO's including their CO (status 'closed', 'open', or cancelled' if received qty >0) and from the Original PO date. NOTE: The system will alow the user to Cancel the Entire PO even if the items within have had receipts, but will not let you cancel the individual line item if there has been any receipts against it. |

| 1.2.1.31. Why is the Weighted Cost different from the PO History Info? |

Q. Why is the Weighted Cost different from the PO History Information?

A. The reason the weighted cost is different from the PO history information is because it derives from a complete different source.

The information in the weighted cost button comes from current PO table, latest CO numbers (status 'open' or 'closed'). The date is NOT a PO original date, but the Version date the PO was last changed, no matter what was changed on the PO. So the system will select PO with the latest version date for the given part and then calculate the average. For further detail see Article 924 .

The information in the PO History button comes from the last 10 PO's including their CO (status 'closed', 'open', or cancelled' if received qty >0). So the system will select PO's from the PO original date. For further detail see Article 924 .

|

| 1.2.1.32. Why isn't the Beginning Balance 0 on the Part Transaction Log with Balance 0? |

Q. Why isn't the Beginning Balance "0" on the Part Transaction Log with Balance Report?

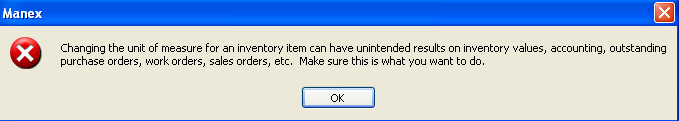

A. If user changes the Unit of Measure on a part with qty on hand within the system it WILL affect the beginning balance. See the attached Print Screens <<Changing_UOM_Conversion_092309_a.docx>> for an example.

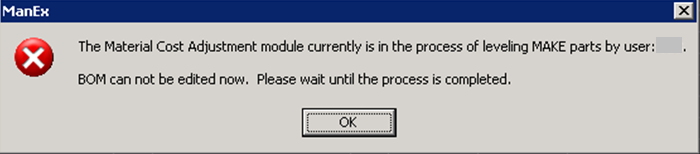

ManEx DOES NOT recommend users to change the Unit of Measure while there is qty on hand within the system. If users change the Unit of Measure while there is still qty on hand within the system, the system will display the following warning message within the Inventory Control Management.  Make sure that this is what you want to do. If users choose to continue with the change despite the warning, this is going to affect your Beginning Balance and probably affect your Accounting records.

Your best option is to adjust the inventory either through Inventory Cycle Count, Physical Inventory, or Inventory Handling to the correct current on hand inventory. Then you may need to make a journal entry to nullify the transaction created by adjusting the inventory.

ManEx CANNOT change the beginning balance because it is a computed value derived from the current balance and modified by all the preceding transactions to arrive at a beginning balance. Neither can we simply change the current balance to zero, or anything else , because of the implications that will ripple through accounting.

|

| 1.2.1.33. When does the System use Stock UOM versus Purch UOM? |

Question - When does the System use Stock UOM versus Purch UOM?

Answer - The system tracks the stocking UOM within inventory, kitting, MRP, etc. The Purchase UOM is only used when creating the PO and accepting it into inventory. Once the item is accepted into inventory it is converted over to stock UOM and from that point forward everything within the system is using the Stock UOM.

NOTE: When creating a PO for an item with different purchasing and stocking UoMs, be sure to enter the MRP suggestion into the Stocking qty field rather than the purchasing qty field. The system will automatically convert the stocking unit into the purchasing unit for the purchase order qty.

For example if the buyer is creating a PO for an item that is used by inches but sold by the foot, the user would enter the 24 inches into the stocking qty field and the PO would automatically convert it to 2 feet in the purchasing qty field. So the supplier deals in feet, but ManEx deals in inches. The conversion between the two are established in the Unit of Measure & Conversion module.

Some examples may be:

Stocking Unit Purchasing Unit Conversion

1 Soda 1 Six Pack 1 to 6

Inches Feet 1 to 12

Inches Centimeters 1 to 2.54

And in some cases, some odd equivalents Feet pounds based on how many pounds a foot of cable weighs. Cable would be used in the factory in feet, but is purchased by weight.

Ounce small bottle distributor may sell by the bottle, small or large, and have specific ounces in a bottle.

So even though we might have 10 employees, and each want a soda, we have to buy two six packs.

|

| 1.2.1.34. Why doesn't the Inventory Valuation Report Match the GL Balance for the Inventory GL Account Number? |

Possible reasons why the Inventory Valuation report would not match the GL balance for the Inventory GL Account # Section A Before comparing the Inventory Valuation to the GL Balance the following items needs to have been done.

NOTE: Concerning the "Inventory and WIP Valuation Report" the WIP Value on this inventory report should not be used as a validation to the GL Account balance for WIP. This report was created in order to give the end users an idea of what was actually in WIP for components at this time. The GL balance for the WIP account will more than likely never match this value due to the fact that so many variables come into play when generating the GL Transactions for WIP. (shortages, over issues, partial job moved into FGI, kit not closed yet,Configuration Variance, Manufacture Variance, etc. . .) And one component can be used through out many jobs at any given time, and these jobs could be in various stages within production, it is not possible for the person attempting to compare these values to go through and validate all kit shortages, over issues, what has been partially moved into FGI, etc. . .

Section B If you find that the Inventory Valuation report value and the GL Account value do not match even after following the above suggestions below might be a number of other items that contributed to the discrepancy:

If you have followed the above suggestion and confirmed that the Setup is correct and that no Journal Entries have been created against these accounts and you find that you still have a discrepancy between the Inventory Valuation reports and the GL Account Balances, please proceed with the following:

|

| 1.2.1.35. Why doesn't the Material Type Change update the Customer Part Number? |

Q. When I Change the Material Type on an AVL for an Internal Number why doesn't it change the AVL for the customer part number?

A. The AVL Material Type is carried forward for the consign part when the consign part is first added to the system or when new AVL was added to the internal part and the user elects to add this AVL to the existing consign parts. If the user later changes the Material Type on the internal part, the change is NOT carried over to the consigned part, because there is some cases when there is more than one customer part number linked to an internal part number and each customer may use the parts differently. So user will need to manually change the AVL material type for each consigned part number.

|

| 1.2.1.36. Why doesn't ManEx allow users to Auto Approve POs generated from MRP? |

Q. Why doesn't ManEx allow users to Auto Approve POs generated from MRP?

A. ManEx does not allow users to Auto Approve POs generated from MRP due to the fact that these POs are only "suggested" by MRP from data entered into the system. We feel it is good practice for an individual in purchasing to review the POs created upon approval due to the fact that: 1. POs could get generated from incorrect data entry caused by human error (and gets) attention from a human in dealing with the output. 2. To prevent un-necessary inventory purchased at the customers expense. 3. The PO generated may require a $$ amount Approval level check also. “ . |

| 1.2.1.37. Why doesn't the Supplier Tab display in Red to indicate a Supplier is Available? |

| We are aware that the supplier tab is not displayed in Red on the Inventory Screen when there are supplier's available. We have investigated this and found that this would slow the system down alot. Since the suppliers are AVL specific once a part number was found the system would then have to search and find all the AVL's and Suppliers asigned to that part number before displaying part on screen. This could take a large amount of time depending on how many AVL's and supplier files the system would have to search. |

| 1.2.1.38. Why doesn't the system allow you to assign multiple part numbers for the same customer to one internal part number? |

Question: Why doesn't the system allow us to assign multiple part numbers for the same customer to one internal part number? Answer: While a seemingly simple request, it would take a massive overhaul of the inventory module to accomplish. Additionally, we would have to add provisions wherever a customer part number is used, for the user to elect which one to use in every instance. For example, when printing an invoice, we offer the option to include a customer part number. If we made this change, we would be forced to have the user define which one every time a part shipped out. Often our users customers want their own part numbers on the packing list and invoice, not our users internal part numbers. We offer that capability, should the user elect to print customer part numbers on the forms (even though shipping turnkey internal part numbers), and if there were multiple customer part numbers, the user would have to pick one each time a product is shipped. How would the shipping clerk know which one to pick if there were multiple customer numbers? We create a consigned version each time a user adds a customer part number. This item then serves to provide links for AVL processing by customer. While technically, this record is for the details of the permissible AVL’s for the customer, it is also used when consigned items are involved. When MRP runs, it checks each product for a customer connection. Then it checks to see if there is a customer part number for the product, and if there is, uses the “consigned” part number to determine the AVL’s that can be used in the part. This is true regardless of the part source (Buy, Make, etc.). If we have multiple customer part numbers (which would be multiple consigned records for a given internal part), we would have to come up with some way for MRP to know which “consigned” part to use for AVL. And, we have to be aware that the user may have different AVL approvals for different customer numbers, either intentionally or by oversight.

|

| 1.2.1.39. WIP - FAQs |

| 1.2.1.39.1. What will happen if the Std Cost is changed during the time the kit is in WIP? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

First, it means that the WIP account is proplery address AFTER all kits are closed, and GL records are released and posted. When there is a cost adjustment while there are components in WIP, the value of the WIP account is not updated until the kits are closed. Then, the WIP value is updated, but erroneously attributed to manufacturing variance instead of cost adjustment. So, making major cost adjustments when there is a large amount of affected inventory in wip will result in major discrepancies in the reported WIP VALUE from the Production reports and the WIP account value in accounting. When all kits so affected are closed, the discrepancy will be corrected. Put another way, the Production WIP VALUE is calculated on the current inventory in kits (by calculating the remaining assemblies in the kit, extending the QPA for each component based on the current BOM, subtracting any shortages and extending by the CURRENT Standard cost per component) and the GL reports are based on the value at the time of issue to the kit. At the time this happens, (when the kit is closed) the value of all items issued to the kit is totaled and compared to the value of the totaled BOM component cost for the assemblies completed at the time of the kit closing.. The difference is currently logged as a manufacturing variance. To validate the standard cost of the items issued in the INVT_ISU records with the current standard costs, system will total that value, and subtract it from the total manufacturing variance for each work order. Then the true manufacturing variance should be realized, and the difference due to standard cost changes posted at the same time to the inventory adjustment account. Then, the total of the manufacturing variance and the total of the cost adjustment change should add up to the total difference between what was actually issued to WIP and what should have been issued to WIP (via the BOM). bld qty = 100

|

| 1.2.1.39.2. The kit amount calls for fractions. Will this cause problems? |

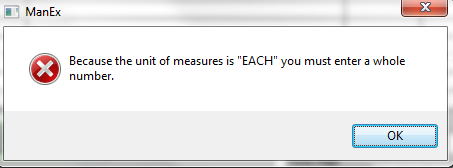

| Note that in MANEX, the Unit of Measure “Each” is treated as being an integer unit. That is, you can only have one or multiples of an “Each”, but not a fraction of an “each”. You can have fractions of inches, feet, pounds, ounces and any other Unit of Measure. Although you can use fractions in the Bill of Material, the user can’t kit fractions of “each” parts. MANEX will round up to the nearest whole number. The proper way to approach the situation where the kit amount is expressed in fractions, is to use any Unit of Measure other than “Each”. |

| 1.2.1.39.3. What can cause a difference between the WIP Evaluation Report and the Balance Sheet? |

| Miscellaneous kit shortages issued to the kit (items without Item Master Inventory information nor standard cost), will not show on the WIP Evaluation report. Any Journal Entries to the General Ledger WIP account associated with movement, adjustments and corrections will not be included in this report. If a user happened to kit materials to a work order that did not have a standard cost associated with the parts, the Balance sheet will reflect no wip value, but subsequent assignment of standards to the parts will affect the WIP Evaluation report, but not the General Ledger.

In summary, the WIP Evaluation report will provide users with a picture of parts issued to work orders that should be in WIP, and is a guide to the approximate value of WIP Inventory. But it is the General Ledger that keeps accurate track of the real WIP value. |

| 1.2.1.39.4. If there is no actual inventory count for WIP inventory, only a dollar amount, then what is the WIP Evaluation report as found in the Inventory Control reports listing? |

| The WIP Evaluation Report is a calculated value of inventory that was kitted. It may or may not equal the accounting value of WIP, as the accounting value can be adjusted by transactions outside inventory, such as journal entries. But the WIP report will be a very close approximation of the WIP value. It is determined by the following sequence:

First, only open work orders are considered. Closed or Cancelled work orders are not included. Then the balance of assemblies due for each work order is determined. For each work order included, the original quantity of each part kitted for the work order is determined based on the kit pull, and extended by the balance of the work order, and by the standard cost of those parts. Then kit shortages are checked. All shortages for the work order are then subtracted from the total value of the work order. This information is then displayed within this report. This information continues to be reported until the balance of a work order is zero and the kit is closed. At that point, all WIP value associated with the work order is returned to zero. |

| 1.2.2. FAQ- Inventory Handling |

| 1.2.2.1. How to Transfer Parts back into Invt. if they have been Rejected Via PO Receiving |

Q. How to transfer parts back into Inventory if they were rejected via Po Receiving.

A. If the PO Receipt has NOT been reconciled via PO Reconciliation, then user should be able to go back to the Original PO Receiver and and Edit the Accepted and Rejected qty's. The Inventory and receiving records should update upon saving the changes. A. If the PO Receipt has been reconciled via the PO Reconciliation, then user will be required to process a PO DMR to return the product to the Supplier. If for some reason you may not be returning the product to the Supplier you may want to make a note on the PO DMR. (For example: Scrapping the part instead of returning it per supplier). This will take the item out of MRB location. If the supplier is NOT going to be shipping the replacement part you will want to reduce the PO Order qty to close out the PO.

|

| 1.2.2.2. How to Ship Product without FGI or barcode Serial Numbers |

Only existing material or product may be shipped. Therefore, any inventory to be shipped must have quantities in stores or finished goods. There is no other way to ship. Material may be placed in finished goods (or stores) by using the Inventory Material Handling (receiving) procedure. If a product has been defined as requiring serial numbers, then they must be entered in order to ship the product. The serial numbers may or may not be barcoded. If not, the numbers will have to be entered by hand. Please refer to the Work Order Management and Packing List Management procedures. |

| 1.2.2.3. How to Delete FGI that is Incorrect |

| By doing an Inventory Material Handling Issue procedure. |

| 1.2.2.4. What the Message "There are no Valid Inventory Locations for this part for this Type of Transaction" means. |

This message is a general message user gets when the program can not find any warehouse/location for this part number. The program checks much more than just the part is locked in cycle count or physical inventory. It also filters out "MRB" warehouse(for receiving), can not be "WIP" or "WO-WIP", can not be marked as "deleted", apply instore criteria.... It all checks in one or few SQL commands, it filters out all records that don't meet the criteria. If all records are filtered out, then user will get this message. |

| 1.2.3. FAQ - Kitting & Shortage Management |

| 1.2.3.1. Do Users have the Ability to Modify the Work Order BOM to Reflect Actual Components Issued? |

Do Users have the ability to Modify the Work Order BOM to Reflect Actual Components Issued?

Users have the ability to add additional parts to a work order whether or not they are in the BOM. Likewise, if they complete an order without issuing a full complement of parts, the work order may be completed, but a manufacturing variance will be created.

|

| 1.2.3.2. How can ManEx help me Streamline my Kitting Process? |

Q. How can ManEx help me Streamline my Kitting Process?

ManEx has several standard and optional features designed to streamline the kitting process. This provides unmatched visibility and control. Additionally, planned upgrades to increase visibility, documentation, and ease-of-use are close to completion.

In Process Upgrades

|

| 1.2.3.3. How are the GL Accounts are Affected when Processsing a Kit through the System? |

The Print Screens attached below <<Kit_Process_Resulting_Trans.docx>> displays the procedure that is basically followed for processing a kit through the system and the resulting transactions that hit the GL at each stage.

o Issue Parts to the Kit

o Create the Packing List and Invoice the customer o Create the AP Check to pay the Supplier for the components o Create AR Deposit for when the customer paid the original invoice |

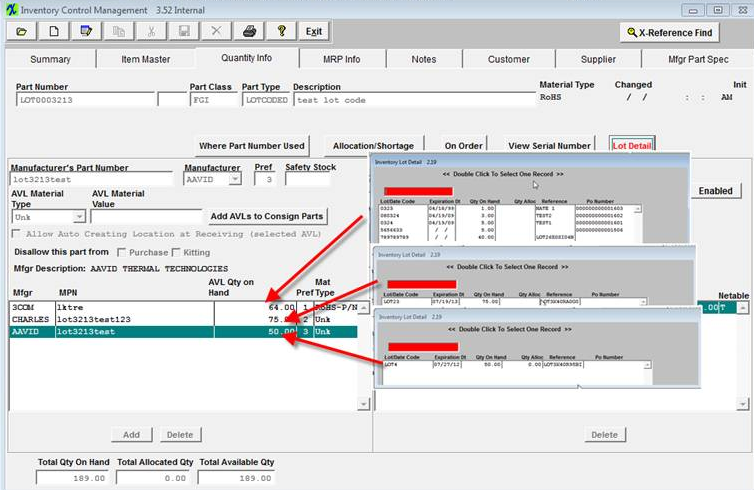

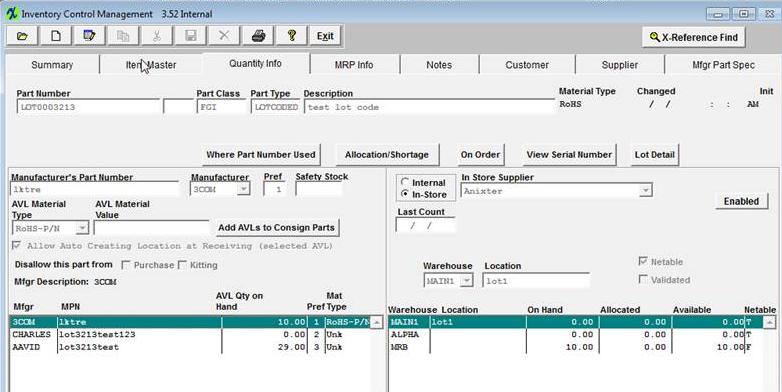

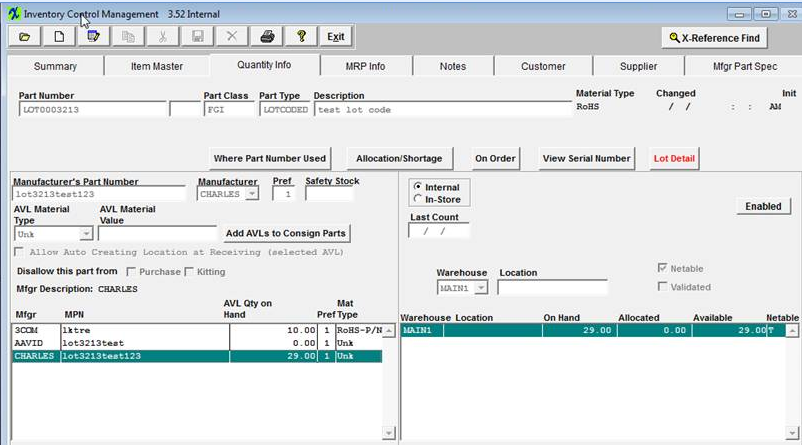

| 1.2.3.4. How are Lot Coded Parts Picked when Auto Kitting? |

If Auto Kitting is selected for Lot Coded parts it first pulls by Allocation, then preference code, then Alpha numeric order.

If preferences are setup Lot Coded parts will be picked by preference code first, if all preference codes are the same then the Lot Coded parts will be picked by Alpha numeric order. (See examples below)

If preferences are setup it will go by preference code first.

After auto kit. Only AAVID AVL is left with qty 29 even though it did have earlier expiration date then AVL CHARLES. AAVID is preference # 3.

If all the preferences are the same, it will go by Alpha numeric order. This time Charles is left as it would be last for Alpha numeric.

|

| 1.2.3.5. Is it Possible to Record Attrition before Closing a Kit? |

Question: Is it Possible to Record Attrition before Closing a Kit?

Answer: We have been reviewing with the programmers and no matter what we do, the users will have to take some kind of action to let the system know that the overissues are no longer available. Proposed System Modification: We are thinking the best approach is that the user must create a line shortage for the parts lost in production. And then, propose that we modify the kitting program, so that if there are overissues of the part, we automatically reduce the overissue by the amount of the shortage (or to zero if there are less overissued parts than the shortage), and increase the quantity issued to the kit accordingly. This will cut out the extra steps described in our temp work around, and remove the overissues from available supply for MRP. If there are no overissues, or not enough overissues to cover the line shortage, then the remainder will be left as shortages, available to kit from the stockroom in the normal kitting routine. Suggested Work Around: o The users have items with over-issue/wo-wip on a kit (Pick qty = 10 require qty = 8, overissue = 2) o Qty 2 becomes damaged or un-useable o The user can add the line item shortage to the kit for that part number and desired qty 2 o Go to the original item on the kit and change the pick qty from 10 to 8 – which will remove the qty of 2 from wo-wip and placing it back into main stock o Go to your line items shortage and now pick the qty 2 from main stock to the shortage. This takes it out of circulation and upon closing the kit will be accounted for within the MFgr Variance. |

| 1.2.3.6. Is it Possible to return more than was expected when closing kits? |

Question: When parts with a Run Scrap percentage are issued to a kit they will show up as WIP in inventory. When inventory goes to return the actual excess parts they cannot because it is not considered extra. Is it possible to return more than was expected when closing kits? Answer: No. It is not possible for ManEx to program the system to predict when the user will actually use all of the Run Scrap and when you don’t within production. Solution: User will need to edit the line item on the kit, by reducing the pick qty to account for the Run Scrap that was not used. This will then reflect what was expected to be used and what was actually used in production. The MFGR variance will account for the difference upon closing the kit. |

| 1.2.3.7. Is there any way to track the serial numbers on a serial-numbered sub-assembly kitted to a higher level assembly? |

A. There is no serial number kitting capability – so to kit sub-assemblies to a higher assembly by serial number, use the serial number assignment detail tab to enter subassemby serial numbers connected to a higher serialized assembly. (Please see the Work Order Management manual). If the higher assembly is not serialized, there is no place to connect or track serial numbers for lower assemblies except back to the Work Order. |

| 1.2.3.8. Is there a report that will give you the Detail of a Kit Closure Variance? |

Q. Is there a report that will give you the Detail of a Kit Closure Variance?

A. It would be difficult to recreate the variances for the following reasons:

For the Configuration variance, we would have to list the complete costed BOM for the assembly, as well as show the standard MATERIAL cost for the assembly. But both would be dependant on the values AT THE TIME of the transaction to FGI. And for that reason, looking at the current costs may not yield the same answer. So the costed BOM would have to be based on the same date as each transaction was processes. And the standard Material cost of the assembly has to be the same as it was at the time of transaction. And that is the essence of the report as it shows now. I don’t think we could determine the specifics of any one component involved in the generation of the configuration variance. And if they do cost rollups, they can make sure that there are no configuration variances (until they change the standard cost of the components or assembly or change the quantity of the components, or add or delete components).

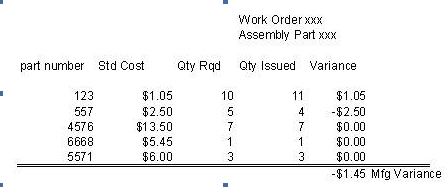

For the Manufacturing Variance, we take the sum of the components actual issued to the work order at their standard cost at the time of the kit close and bounce if off of the costed BOM at the time of the kit closing. (Configuration variance already addresses the difference between the standard cost and the bom cost.) So in this case, it may be possible to create a report that lists the components and their costs based on the BOM, and compare it to a list of the components and their costs actually kitted. It might look something like:  |

| 1.2.3.9. Why doesn’t the Kitting screen and WO Shortage Reports include Setup Scrap? |

Q. Why doesn’t the Kitting screen and WO Shortage Reports include Setup Scrap?

A. The Setup Stscp box MUST be checked on the BOM Header Information if you want the setup scrap qty’s to be included in the Kitting, WO Shortage Reports and MRP calculations.

If you want the Run Scrap qty’s to be included in the Kitting, and WO Shortage Reports the Run Scrap MUST be selected in the Kit Default Setup . |

| 1.2.3.10. Why doesn't Kitting use the AVL's in the Order that MRP is Considering them? |

Example Situation: If product #1 has AVL "A" and "B" approved, and product #2 has only AVL "B" approved. And product #1 is kitted before product #2, the system will allow the user to use all of "B" when "A" could have been used and left "B" stock for product #2. Suggested Resolution: If Users wish to avoid the above situation we suggest that you use the Work Order/Project Allocation feature within the Purhcase Order module. Then when the part is received, it is allocated to that Work Order or the Project which will avoid the above situation. MRP is just a program that reviews the supply and demand and creates suggested actions based on the system information. MRP only suggests the actions and the users are the ones that have the sole control of following them or not. It would pose to many restrictions on our users stock if we started having the MRP actually control their stock. |

| 1.2.3.11. Why does it appear as if parts are vanishing from the Kit after Update Kit process is followed? |

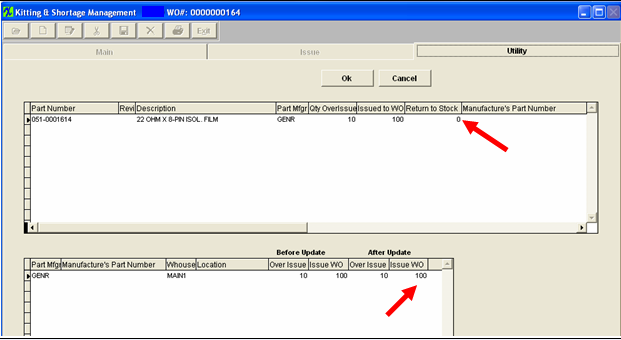

Some of our users were reporting that after they make changes to the BOM and return to the Kit to put the Updates in place that the quantity was not being brought forward into the update kit screen and was NOT returned to stock and seemed to have disappeared from the system. Explanation: If the user is simply just depressing the OK button that stock will be issued to the kit and not returned to stock. When you make changes to the BOM and then update the kit, make SURE that the users are trained to review and disposition every item listed and ensure that they are returning to stock if desired. They can NOT simply just depress the OK button, otherwise they can be issuing parts to the WO, and we can NOT get them back, they will be valued as a Manufacture Variance. The system is operating as intended. The reason why the parts are NOT re-appearing in stock is due to the Same rule would apply if a part was deleted from a BOM and the kit updated. The kitting module would default issue to WO, because it did not have the original Part number information to return directly to stock. This is why it defaults Issue to WO with the option to return to Stock. When you depress the update kit button the item is displayed on screen for disposition. If you take a look at the print screen provided you will see that it is defaulting the qty to be issues to the kit. If the user is simply just depressing the OK button that stock will be issued to the kit and not returned to stock. The value of that stock will be accounted for in the Manufacture Variance upon closing the kit. If you want the inventory to be returned to stock you need to change the qty in the Issue to WO section below to 0.00 and then the Return to Stock qty should update to the amount you wish to have returned to stock.

When you make changes to the BOM and then update the kit, make SURE that the users are trained to review and disposition every item listed and ensure that they are returning to stock if desired. They can NOT simply just depress the OK button, otherwise they can be issuing parts to the WO, and we can not get those back, they will be valued as a Manufacture Variance.

|

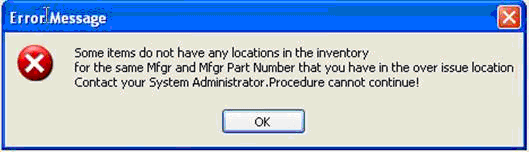

| 1.2.3.12. Why am I unable to Close a kit, due to "Some Items do not have any locations in the inventory” message |

Upon attempting to close a kit, some users may report this type of message that was presented to them.

This more than likely indicates that parts that have been used on the kit are currently in an active Cycle Count or Physical Inventory. Make sure that Cycle Count or Physical Inventory have been posted to Inventory and then attempt to close the kit again.

|

| 1.2.3.13. What Type of Data Actions Occur during Kitting? |

The following data actions occur when Kitting. (In this set of information a limited BOM was created with only two components, one of which was allocated to a project.) When kitting the first part, (which is a part allocated to a project) The “Inv_res” table, will have a record created for this part and a link to the “Fk_Prjunique” project key. Once the user issues it to the kit, the stored procedure (trigger) in INVT_ISU table will be create. Once this record is created, the program will check if the part has any allocation records, and decrease allocation qty (actually insert a negative qty record) if found. It first checks if part is allocated to work order, then checks it it’s allocated to project. The INVTMFGR Qty_oh and Reserved fields are reduced by the amount issued. In the JBSHPCHK table, a recorded is added that the kit is in process. In the KAMAIN table, records of all parts of the kit are added, and the record of the issue is recorded. In the KADETAIL table, all parts in the kit are added as parts shortage, and issue records are added for parts kitted. In the KALOCATE table, a record is added of the issue. In the WOENTRY table, the kit status is changed to true. (on first issue)

In kitting the second part, a non-allocated part: A record is added to the INVT_ISU table, indicating that the parts were issued to WIP, and a specific work order. Various keys are used for tracking purposes. The INVTMFGR Qty_oh field is reduced by the amount issued. In the KAMAIN table records are added of the parts used in the kit, and actual issues thereof. In the KADETAIL table, issue records are added for parts kitted. In the KALOCATE table, a record is added of the issue.

|

| 1.2.3.14. What causes a shortage to not appear on the Shortage Reports? |

A. The shortages will not print or display if the Work Order has been closed, by the shipment of all products to finished goods (in the Shop Floor Tracking module where all of the Work Order units have reached the Work Center Finished Goods). Even if the Work Order was manually re-opened, the balance due would still be zero, and for that reason, the shortages won’t show anywhere. As long as the user has completed the Work Order (zero balances), it won’t drive any requirements nor display as a shortage. The user, may however, still issue material to the work order after the fact, as long as the kit has not been closed. If there are shortages and then the kit is closed, the program will ask if you want to fill the shortages first. (If you’ve closed the kit, you may re-open it, in the Utility tab…and with a high level accounting password).

Another reason the part might not be displayed on the shortage reports is that it is not been scheduled on the PO. The Purchased Part Shortage Summary report is going to display only the actual scheduled qty’s on the PO NOT the ordered qty on the PO.

|

| 1.2.3.15. What causes the double consumption of parts to a kit? |

A. When the kitting records are created via the “Pull Kit” option, they are established from the BOM, by work center and items. If subsequent to a pull item, the user makes a change to the BOM for the product, and then updates the work order, the following events happen: If the change to the BOM involves the deletion of a part from one work center of the BOM and addition of the part to another work center of the BOM, these count as deletions and additions. Of course, normal deletions may also occur, as well as quantity changes. When the update is performed on a work order, the system checks to see if parts have been issued which are no longer needed. If there are parts in this situation, then the user is asked whether the parts are to be returned to inventory, or have been (or are to be) consumed in the work order. If the user responds with a yes – consume the parts, then the parts are deleted from the kit record (not the issue records and transaction records). They will no longer show up as parts required by the work order. They will show up on the kit history list as being issued to the work order. The part that has been moved to a new work order is considered as new part requirement. The program cannot distinguish that the part was already issued albeit for another work center. So the part will show up again as needing to be kitted. If the user has fully kitted a work order, then changes the BOM, then updates the work order from the BOM, but does not return extra parts to stock, the effect will be a requirement to reissue those parts for the new work center, and scrap the ones already issued. The user will probably issue the parts (again) to fill the new shortages. |

| 1.2.3.16. What happened to line shortages entered in kitting and shortage module? |

A. A line shortage entered in the kitting and shortage module will be displayed on the kitting screen until it has been filled. The shortages will be displayed on all shortage reports and screens. After the shortage is filled (issued to the work order) it is no longer a shortage, and will drop off of the kitting screen and all shortage reports. However, records of the issue to the work order may be viewed and printed from the "Work Order Kit and Shortage Issued" report, or the "Work Order Detail Shortage" report, both found in the Kitting and Shortage Reports . |

| 1.2.3.17. When a user uses floor stock selected under U/K (used in kit) on the BOM, how does that affect kitting? |

A. When the kitting reports are issued, they will not contain either the Y or F items marked in the U/K. MRP will be sure that the items are on hand, or ordered in time for the kit, but the items are not directly kitted. Users may pull items out of stock and have it sitting on a barrel on the floor, from which the floor can pull floor stock without further transactions. Or, they can have a warehouse called floor stock, and keep the stuff on the floor, but then they would have to do an issue each time they took parts out of the barrel. |

| 1.2.3.18. We can not issue additional parts to a shortage by dragging the parts down to the kitting window even though the parts are in stock. |

A. Once inventory has been dragged from an inventory location, it can NOT be dragged again to fill shortages left from insufficient inventory on the first kit. The appropriate way to add more inventory to the kit from the same inventory location is to highlight the amount already kitted (in the lower right corner of the issue screen) and change the quantity to the revised quantity. That action will remove the additional quantity from inventory and place it in the work order. |

| 1.2.4. FAQ - PO Receiving & DMR Module |

| 1.2.4.1. How can we attach notes to rejected parts in the PO Receiving Module? |

A. There is a Reject Reason Pull down list available on the PO Receiving Screen. This allows the users to be able to select the Reject Reason code rather then writing notes. This is created within the Return/Shortage Reasons module. |

| 1.2.4.2. Why doesn't the System allow the User to issue Quantities that are Greater than the Shortage Quantity from the "Shortage List & Issue" button in the PO Receiving module? |

Question: Why doesn't the System allow the User to issue Quantities that are Greater than the Shortage Quantity from the "Shortage List & Issue" button in the PO Receiving module? Answer: This would require the receiving code to get into yet another level of complexity to take care of the whole new logic, which KIT module is already designed to deal with. The complexity gets even greater when receiving parts that are lot coded and/or serialized. To deal with this new level of complexity we are facing to issues; 1. Slowing down the PO receiving save routine, which can cause lockups like we experienced before not only in the Problem: User enters the PO Receiving module and receives PO #990026, for part number XXX-OOO, after entering the accept quantity, user goes to "Shortage List & Issue" button to issue part number XXX-OOO to WO #34. The KIT required for part number XXX-OOO is 58.5 inches. The Purchase Order UOM is feet, so the PO Receiving converts the KIT required qty to 58.56 inches. Which is more than KIT required qty, and makes the "Short Qty" negative. So system will not allow user to save the issue. Here is a bit more explanation why the situation (described above) is not allowing to kit from Our tables POITEMS, PORECDTL, and INVTMFGR have qty field with two decimals after the point.