| 1. FAQ- Inventory Handling |

| 1.1. How to Transfer Parts back into Invt. if they have been Rejected Via PO Receiving |

Q. How to transfer parts back into Inventory if they were rejected via Po Receiving.

A. If the PO Receipt has NOT been reconciled via PO Reconciliation, then user should be able to go back to the Original PO Receiver and and Edit the Accepted and Rejected qty's. The Inventory and receiving records should update upon saving the changes. A. If the PO Receipt has been reconciled via the PO Reconciliation, then user will be required to process a PO DMR to return the product to the Supplier. If for some reason you may not be returning the product to the Supplier you may want to make a note on the PO DMR. (For example: Scrapping the part instead of returning it per supplier). This will take the item out of MRB location. If the supplier is NOT going to be shipping the replacement part you will want to reduce the PO Order qty to close out the PO.

|

| 1.2. How to Ship Product without FGI or barcode Serial Numbers |

Only existing material or product may be shipped. Therefore, any inventory to be shipped must have quantities in stores or finished goods. There is no other way to ship. Material may be placed in finished goods (or stores) by using the Inventory Material Handling (receiving) procedure. If a product has been defined as requiring serial numbers, then they must be entered in order to ship the product. The serial numbers may or may not be barcoded. If not, the numbers will have to be entered by hand. Please refer to the Work Order Management and Packing List Management procedures. |

| 1.3. How to Delete FGI that is Incorrect |

| By doing an Inventory Material Handling Issue procedure. |

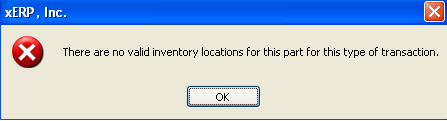

| 1.4. What the Message "There are no Valid Inventory Locations for this part for this Type of Transaction" means. |

This message is a general message user gets when the program can not find any warehouse/location for this part number. The program checks much more than just the part is locked in cycle count or physical inventory. It also filters out "MRB" warehouse(for receiving), can not be "WIP" or "WO-WIP", can not be marked as "deleted", apply instore criteria.... It all checks in one or few SQL commands, it filters out all records that don't meet the criteria. If all records are filtered out, then user will get this message. |