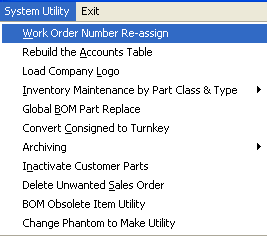

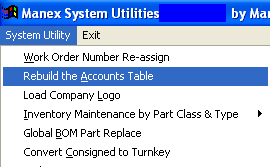

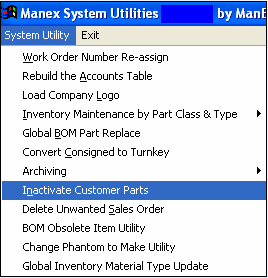

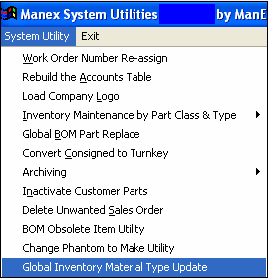

| 1. System Utilities |

| 1.1. Work Order Number Re-assign |

| 1.1.1. Prerequisites for Work Order Number Re-assign |

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.  |

| 1.1.2. How To ..... for Work Order Number Re-assign |

| 1.1.2.1. Change a Work Order Number | ||

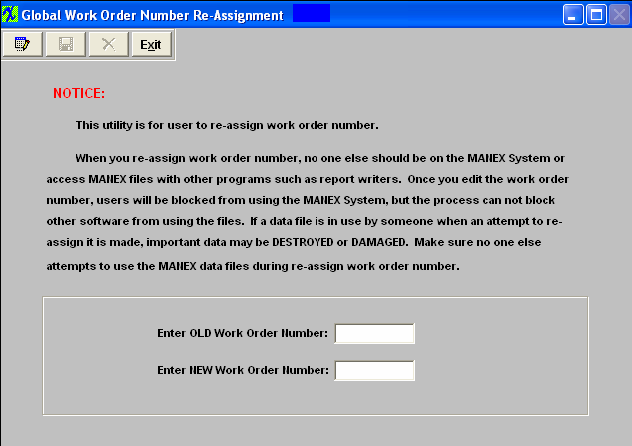

The following screen will appear:

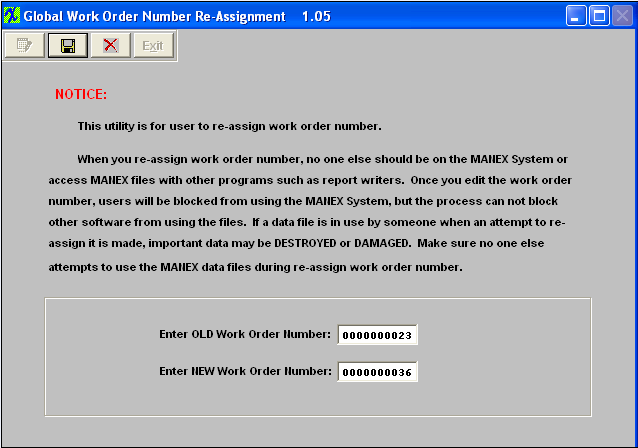

Depress the Edit button. Enter the old Work Order Number and the New Work Order Number:

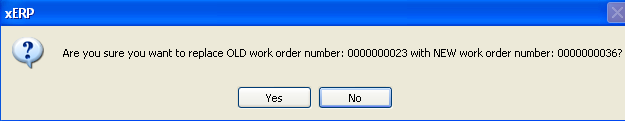

Depress the Save record button to save changes. Depress the Abandon changes button to abandon changes. If you depress the Save record button the following message will appear:

Depress "Yes" and the Work Order will be updated with change. Depress "No" and the Work Order will not be updated with change.

|

| 1.2. Rebuild Accounts Table |

| 1.2.1. Prerequisites for the Rebuild Accounts Table |

| After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access. |

| 1.2.2. Introduction for the Rebuild Accounts Table |

| This module will Rebuild the entire chart of accounts. The entire chart of accounts will be recreated and balances recalculated. |

| 1.2.3. How To Rebuild Accounts Table |

| 1.2.3.1. Rebuild Accounts Table | ||

The following message will appear.

Depress the Yes button, and the system will begin the process of updating the accounts. The entire chart of accounts will be recreated and balances recalculated When the system has finished with this process the following message will be displayed.

|

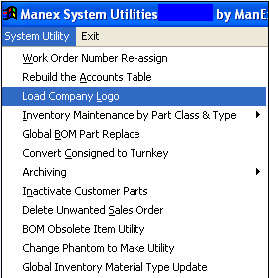

| 1.3. Load Company Logo |

| 1.3.1. Prerequisites for Load Company Logo |

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access. |

| 1.3.2. Introduction to Load Company Logo |

| 1.3.3. How To ...... Load Company Logo | ||

Image files may be retained on any server available to users. The most important concept is to understand that the folder(s) used must be shared and available to all users of ManEx. The complete path to the image is stored in the ManEx program. So when loading an image within the program, the source must be as mapped through the network neighborhood. Loading in this manner will allow each client to properly find the images, regardless of how ManEx itself is mapped.

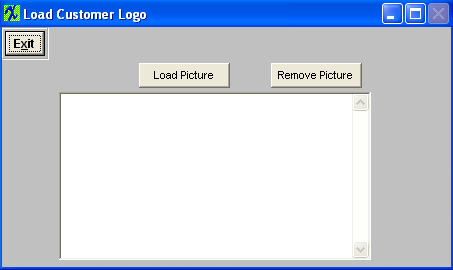

The following screen will appear.

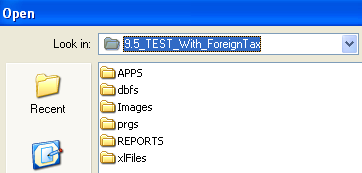

Depress the Load Picture button. Then the browser will appear.

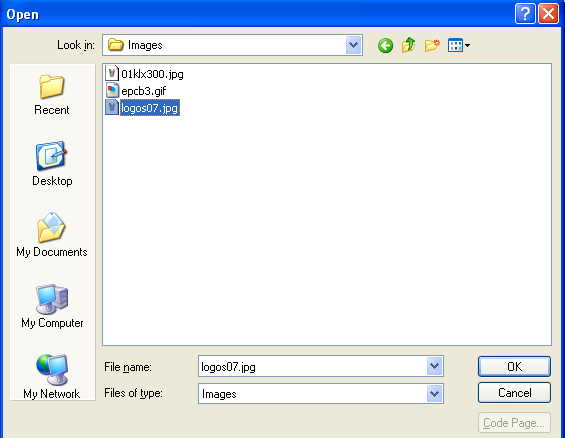

Locate your ManEx server (or wherever your images are stored), and select the appropriate folder until you arrive where your desired image resides. Once your find your desired image, click on the file name.

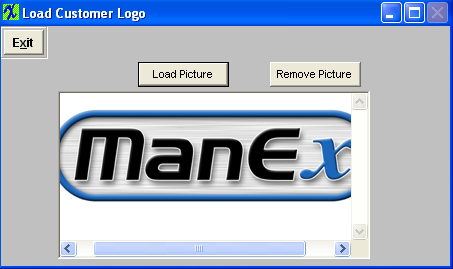

Depress the OK button, and the image should then display in the Load Customer Logo screen.

If you wish to remove the loaded image, then simply depress the “Remove Picture” button and the file will be removed.

Then the logo will print on all associated documents.

|

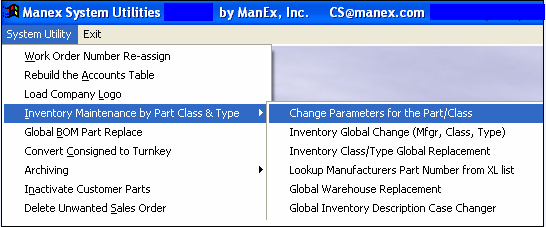

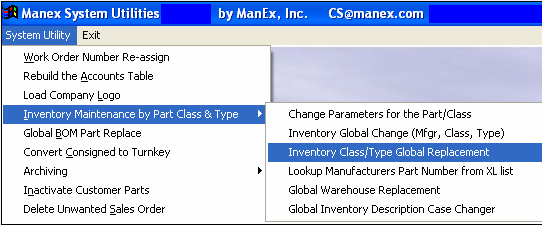

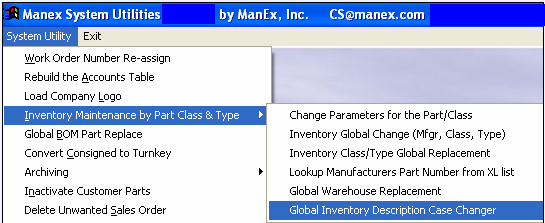

| 1.4. Inventory Maintenance by Part Class & Type |

| 1.4.1. Change Parameters for the Part/Class | ||

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

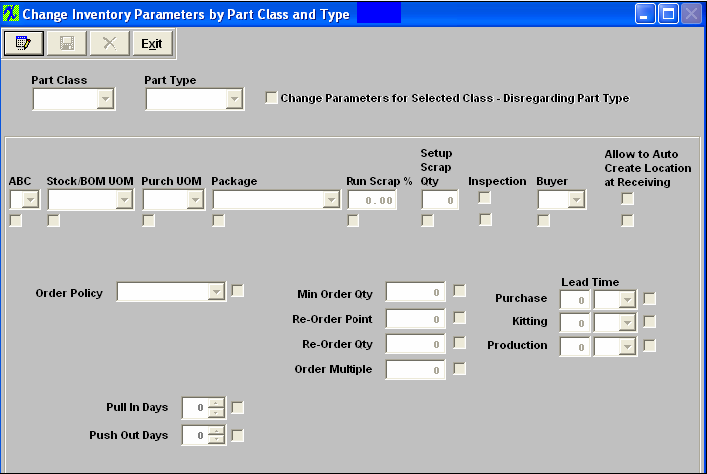

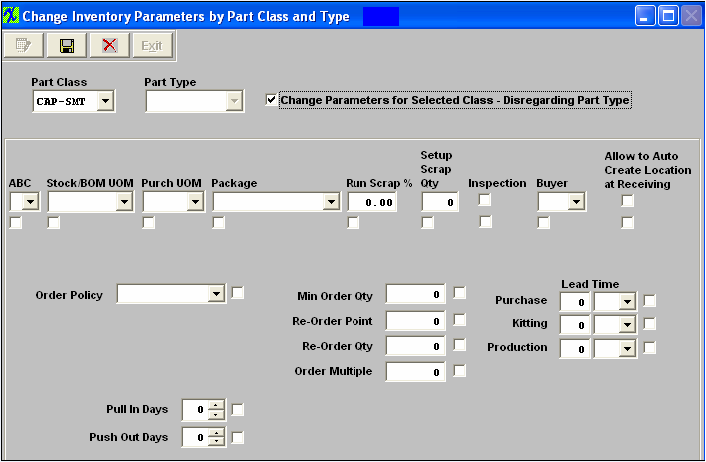

The following screen will appear:

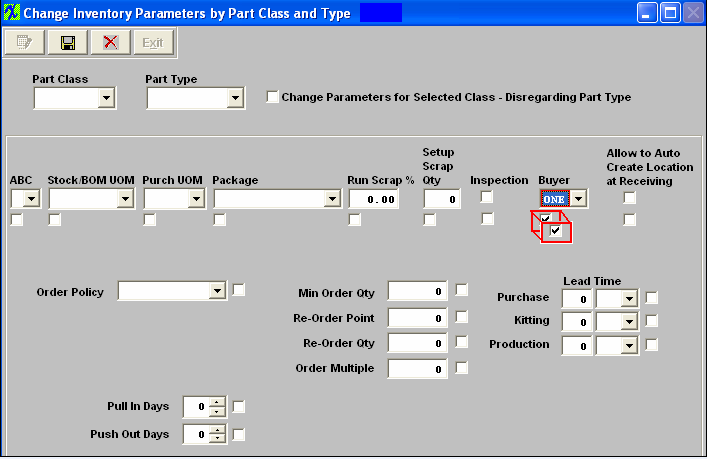

Depress the Edit action button, Select the Part Class and Type you want changes to affect. (Note: If you want the changes to affect all part types within the Part Class Check the "Change Parameters for Selected Class - Disregarding Part Type" box)

Enter the changes, the boxes next to the fields being changed must be checked also for the changes to be implemented. If this box is NOT checked the change will NOT be implemented.

Depress the Save changes action button to incorporate changes to part class and type, or depress the Abandon changes action button to abandon changes.

|

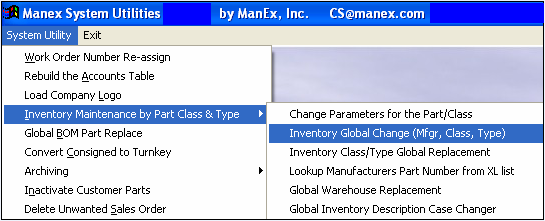

| 1.4.2. Inventory Global Change (Mfgr,Class,Type) | ||

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

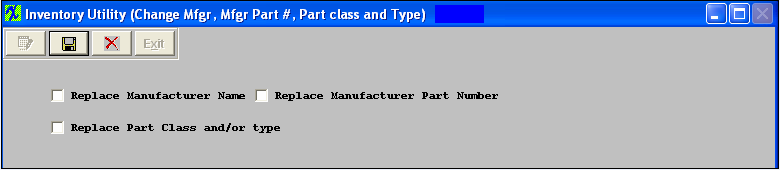

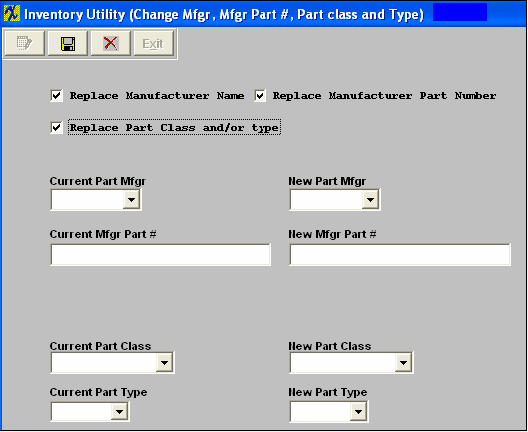

The following screen will appear:

Check the box for which changes you want to make, additional fields will appear on screen for more information as shown below:

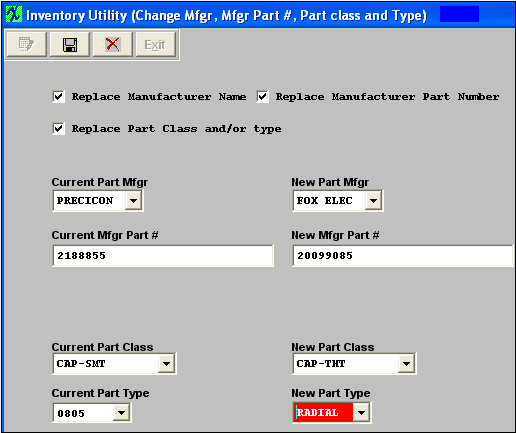

Enter the Current information and the New information as shown below:

Depress the Save changes action button to proceed with the changes, or depress the Abandon changes action button to abandon changes.

Note: All Purchase orders with Status of Open and Closed will be updated when changing the MFGR info. Users will NOT loose history when replacing a mfgr, part class and/or type. The history reports will still retain the transactions but the reports will show the new manufacturer, Class and/or type. They will NO longer display the old mfgr, class and/or type.

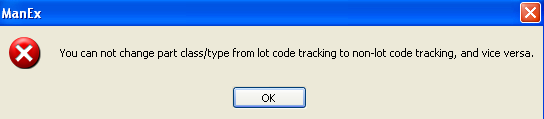

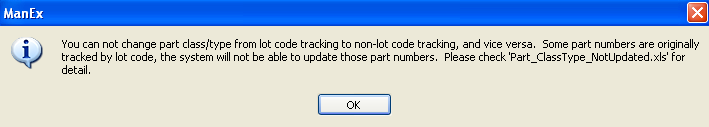

User will receive the following message upon save if they are attempting to change parameters from Lot Coded parts to Non Lot Coded parts or visa versa. This change can only be done within the Inventory Control module.

|

| 1.4.2.1. Manex Minutes for Mfgr Change |

| 1.4.3. Inventory Class/Type Global Replacement | ||

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

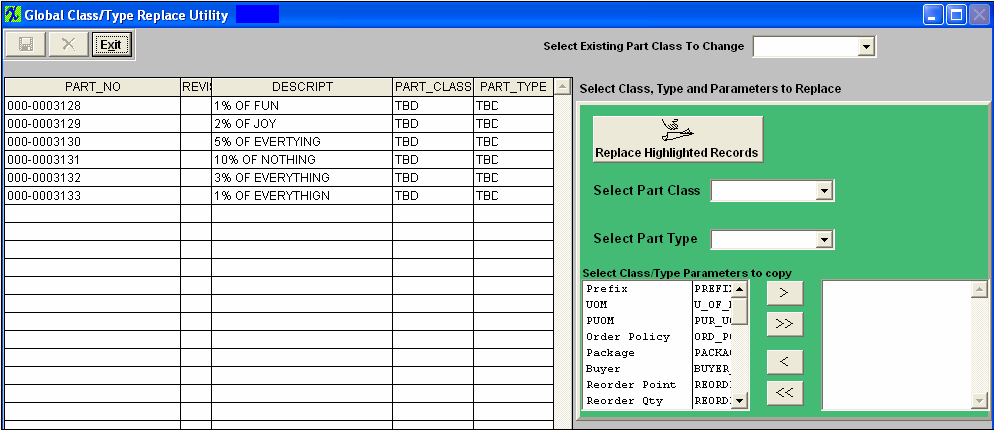

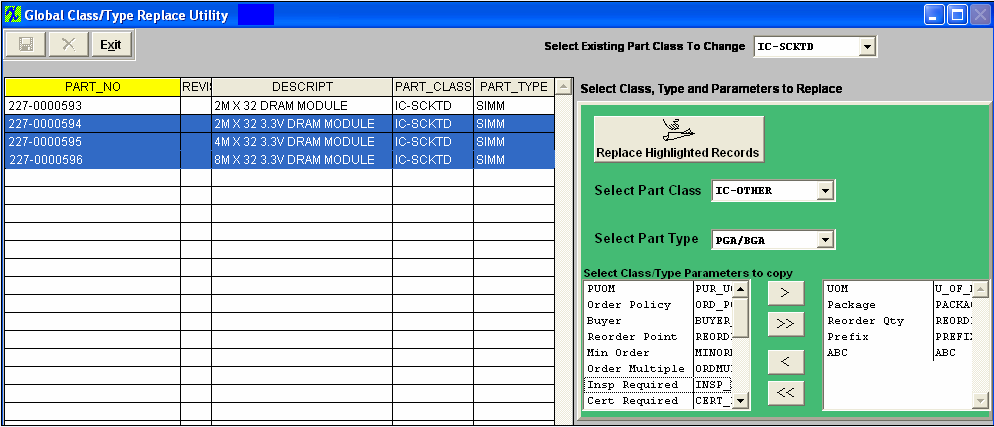

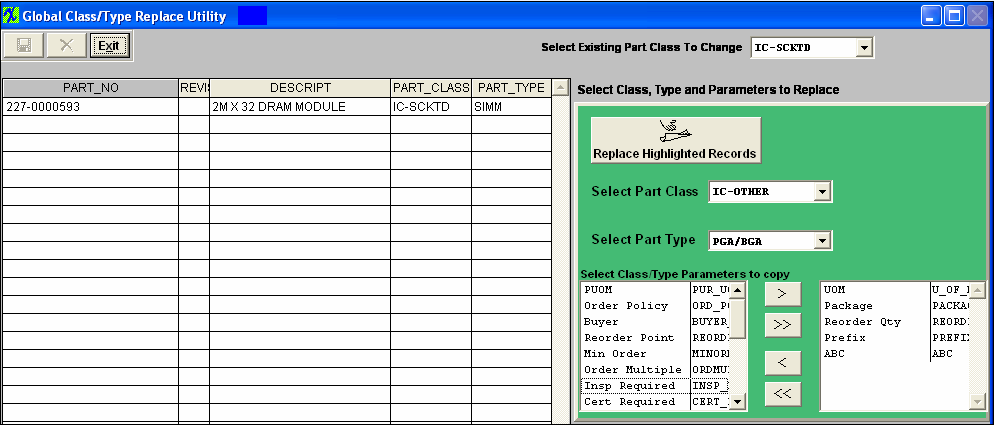

The following screen will appear:

Select the Existing Part Class from the Pull Down, and the part numbers that exist in this Part Class will be listed in the left as shown in the screen below.

Select the Part Class and Type you are replacing the highlighted records with from the Pull downs. Select the Class/Type Parameters you want copied.

Highlight the part numbers you want replaced. Once you have completed all of the required fields, depress the "Replace Highlighted Records" button, the Save action button, and the Abandon Changes button will become available. Depress the Save action button to make the changes, depress the Abandon changes action button to abandon changes.

After the parts have been updated the parts replaced will disappear from the screen, and user may select another part class to change or depress the Exit button to exit this screen.

User will receive the following message if they try and change a part from Lot Coded to Non- Lot Coded or visa versa using this utility. This change can only be done within the Inventory Control module.

|

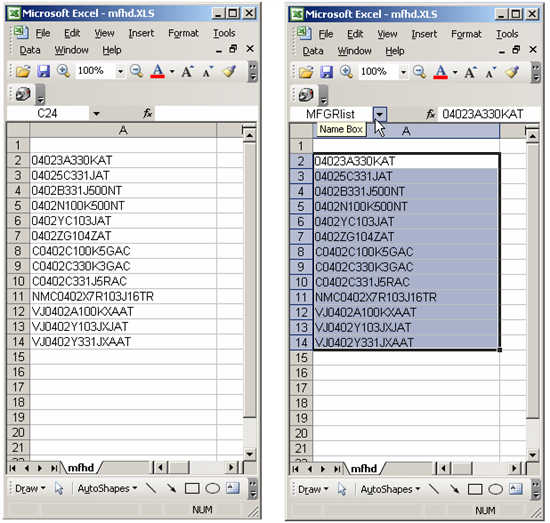

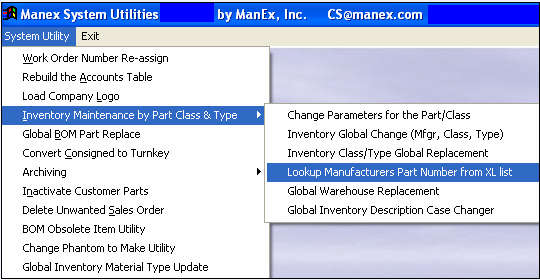

| 1.4.4. Lookup Mfgr Part Number from XL List | ||||

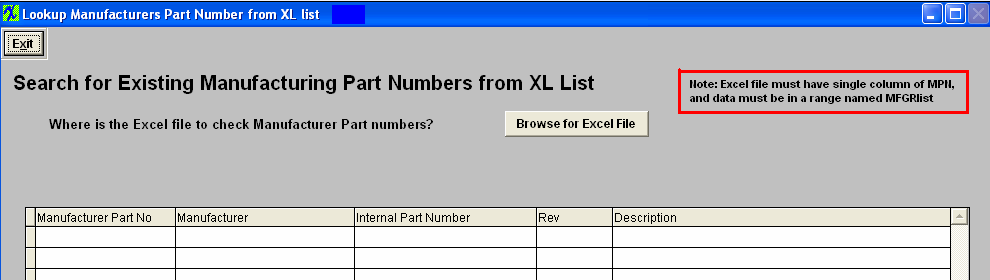

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

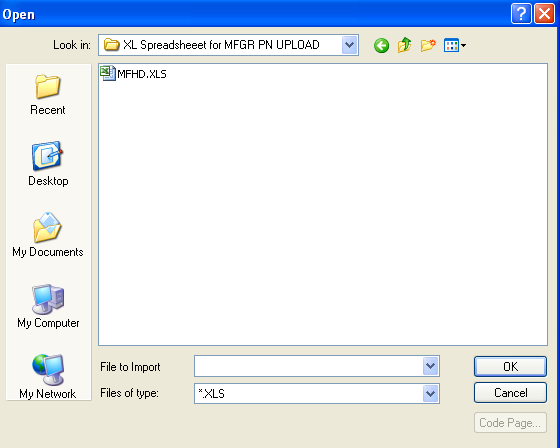

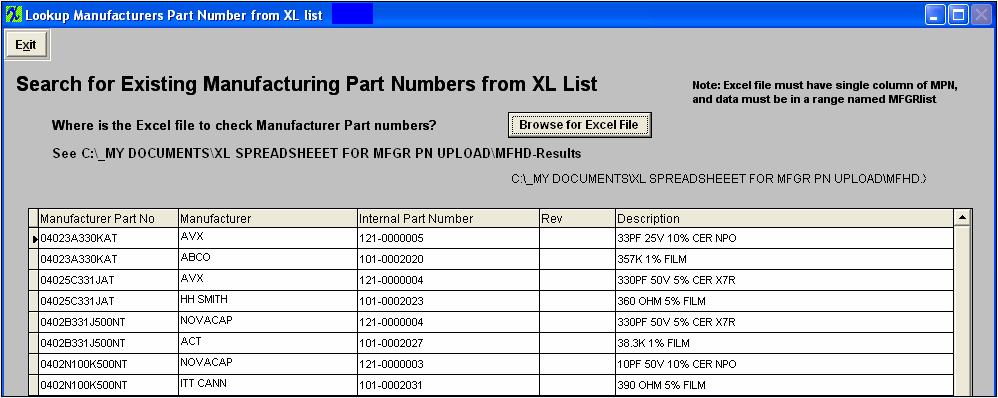

The following screen will appear: (Be sure to read the Note)

Browse and find the spreadsheet.  View the results:

|

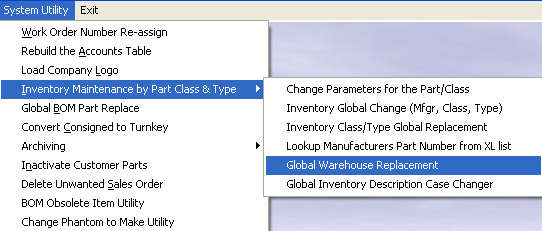

| 1.4.5. Global Warehouse Replacement | ||

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

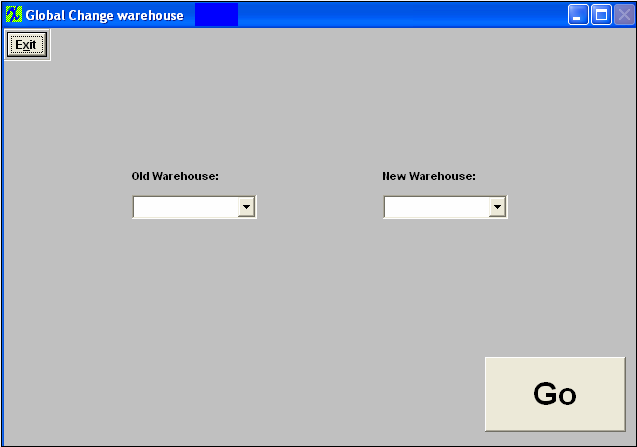

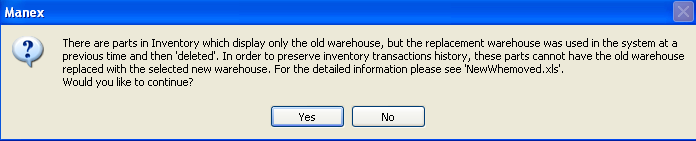

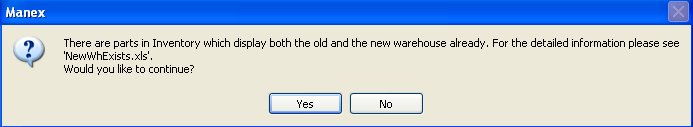

The following screen will appear:  Enter the Old Warehouse and the New Warehouse, depress the "Go" button and the old warehouse will be replaced with the new warehouse. System will NOT allow you to replace the existing warehouse with a warehouse that previously existed and then deleted. If system locates these types of records the following message will be displayed and a 'NewWhemoved.xls' spreadsheet will be created with detailed information.  If the system finds parts in inventory which display both the old and the new warehouses, the following message will be displayed and a 'NewWhExists.xls' with detalied information will be created.

|

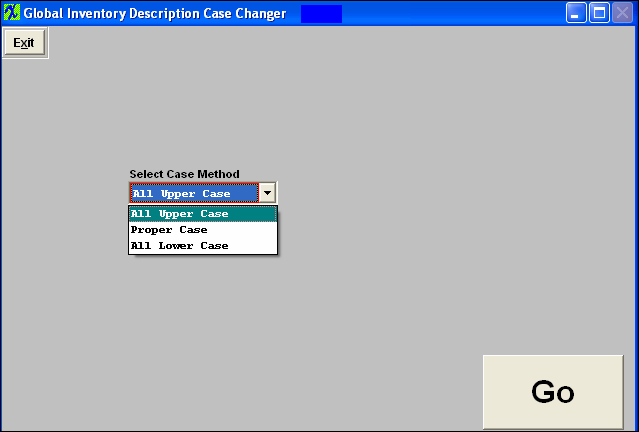

| 1.4.6. Global Inventory Description Case Changer | ||

The following screen will appear:

Select the Case Method from the Pull down, and depress the "Go" button. NOTE: This will change ALL the existing Inventory Description Case.

|

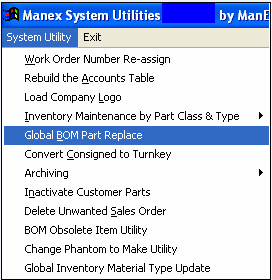

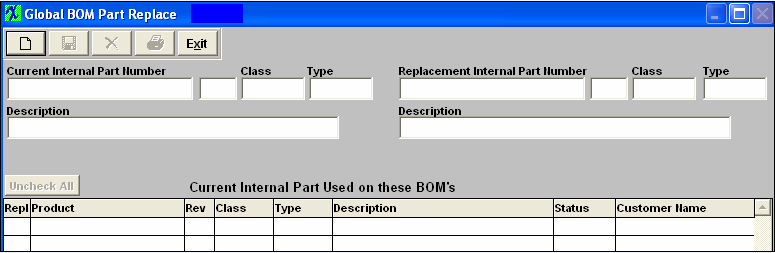

| 1.5. Global BOM Part Replacement | ||

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

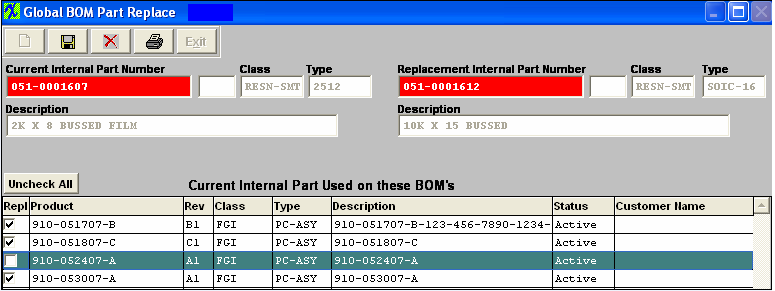

The following screen will be displayed:

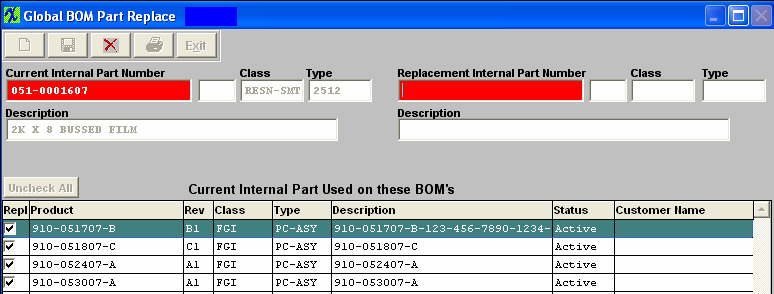

Depress the Add Record icon. Then enter in the Current Internal Part Number. The Part number Class, Type and Description will default in, along with the related BOM’s.

Enter in the Replacement Internal Part Number, the part number Class, Type, and Description will default in.

Select which BOM's to be updated by checking the Repl Column. Depress the Save record action button to proceed, or depress the Abandon changes action button to abandon changes.

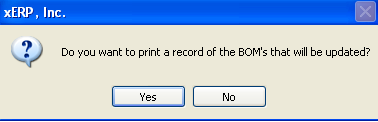

If the Save record action button is depressed the following message will appear:

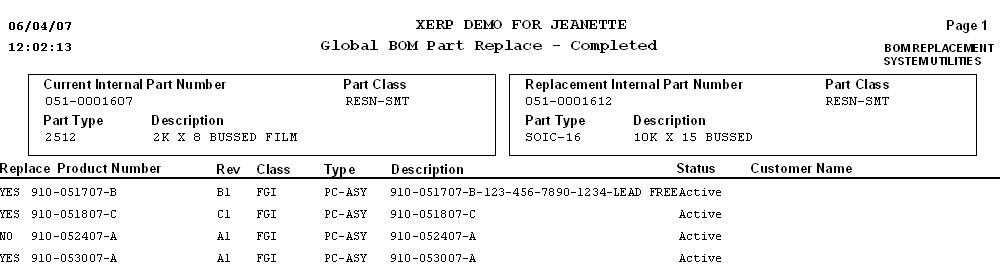

Select Yes, and the following report will be displayed.

|

| 1.5.1. ManEx Minutes for Global Replacement |

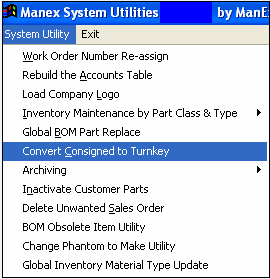

| 1.6. Convert Consigned To Turnkey | ||

|

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

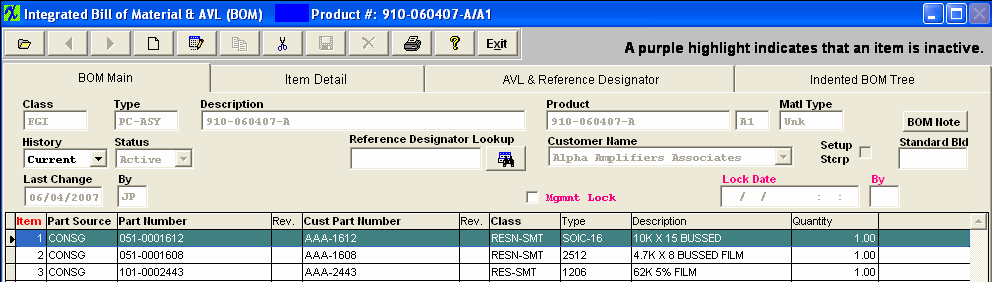

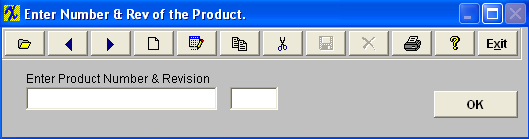

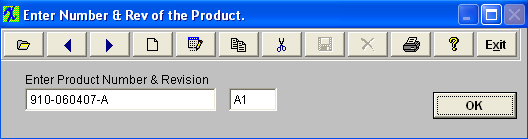

The following screen will appear:

In the system you have a BOM already setup with Consigned part numbers.

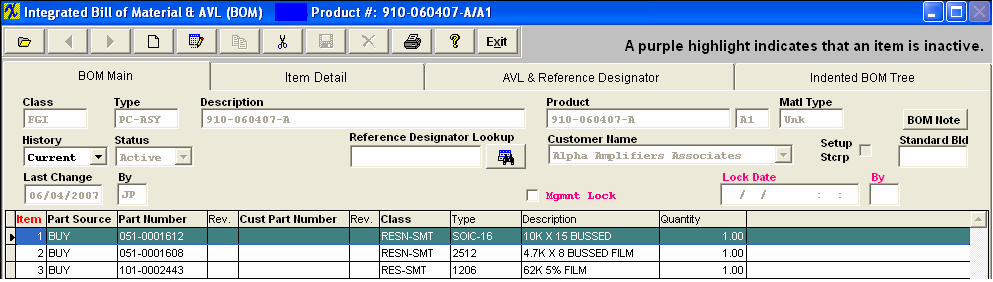

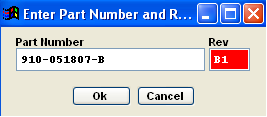

Type teh Product Part Number (Assembly) and applicable revision number into the fields:  Depress the OK button. You will receive a message that the conversion has been completed.

Return to the ManEx system and verify that the BOM has been properly converted over to Turnkey.

|

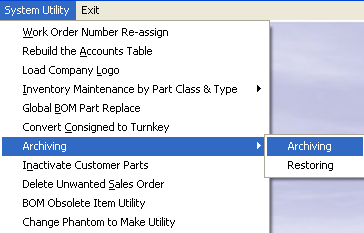

| 1.7. Archiving/Restoring |

| 1.7.1. Prerequisites for Archiving/Restoring |

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

|

| 1.7.2. Introduction for Archiving/Restoring |

The Archiving and Restoring Utility will allow users to Archive their unused files, which should help speed up the response time for users with large databases. These files will be removed from your Live Manex System and placed in the archive directory setup by the user performing the archiving. (We strongly recommend that you do not remove this directory once it is setup or you will loose all files for restoring). Only supervisor or user with "EDIT" rights in System Utility can run archiving/restoring programs. When the archiving or restoring is loaded, it will open database exclusively. Therefore, no user can run any other programs at the same time. This program will have "Back" and "Next" buttons to lead you to what you should do next, you also can go back to change whatever you selected before you click the "Archive" button. The program will create a spreadsheet of what's going to be archived, if you click "OK" then it will continue to archive those records. The Archiving features will not affect accounting in any way, because once the transactions are created within the system from regular ManEx that information is retained in different accounting tables. "ResetArcLock.exe" is in your ManEx Root Directory. This is in case user interrupts the program or reboots the machine during archiving, the system will still think the user is doing the archiving. This program will clear out the flag, and at the end, this program will also ask user to re-run datamaintenance.exe to keep data integrity. NOTE: For those users who have archived data, when user finds a record, let's say a PO. The program will go to check current ManEx database to see if the part numbers of all PO items exist. If not, the program will tell user that one or more items are "removed". It might be deleted or archived, and the program will ask user if he/she wants to check the archived part number list. If user selects "Yes", the message also tells user it will take a while to find the archived information. If user selects "No", then the program will not go to archived database to check, and user can find another PO to continue. When processing a new inventory part and depressing the "Save" record icon, the system will only check the "Live" database for duplicate part number. When user restore part numbers from archived database, for now, those duplicate old part numbers will be filtered out and won't be restored to current database.

|

| 1.7.3. How To ..... for Archiving/Restoring |

| 1.7.3.1. Setup the Directory | ||

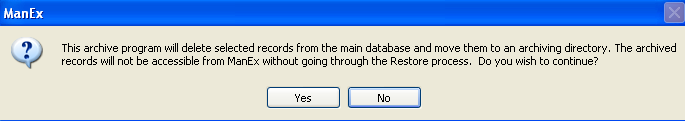

The following warning will appear:

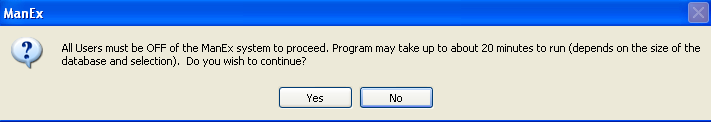

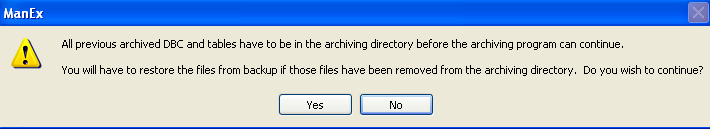

Depress "Yes", to continue the archiving process, the following warning will appear:

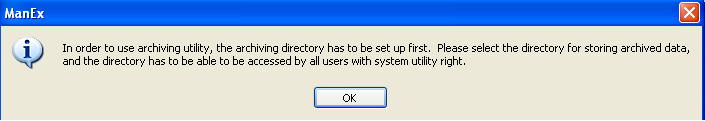

Depress "Yes", to continue the archiving process, the following warning will appear, to select the directory;

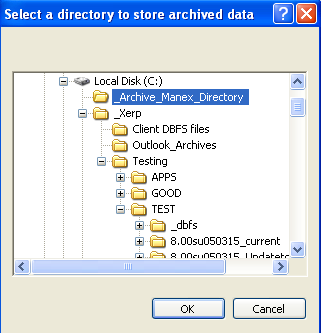

Depress "OK", and a list of directory files will appear. ManEx strongly suggests that the directory selected for storing archived data is placed on the Server, so the directory is accessable to all users with system utility rights. After user selects the archiving directory, the system will create archiving DBC tables in the archiving directory and will move data from existing database to the archived database. Once these files have been created they CANNOT be removed from the archiving directory. The user can re-set the path to a new location and move all files to new location, but the new directory does have to have all files in order to work. The user can copy the DBC files to a CD or backup, but those files CANNOT be removed from the archiving directory, once they have been created.

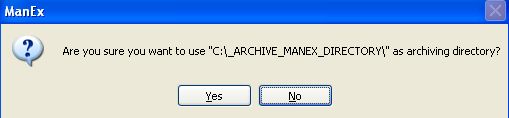

Depress "OK", a warning screen appears to verify the path created.

Depress "Yes", and the user may proceed with the Archiving process.

|

| 1.7.4. Work Order/Kit/SQC |

| 1.7.4.1. Prerequisites for WO/Kit/SQC |

The prerequisites required to archive Work Order/Kit/SQC items:

|

| 1.7.4.2. How To ..... for WO/Kit/SQC |

| 1.7.4.2.1. Archiving | ||

The following warning will appear:

Depress "Yes", to continue the archiving process, and the following warning will appear:

Depress "Yes", to continue the archiving process, and the following warning will appear:

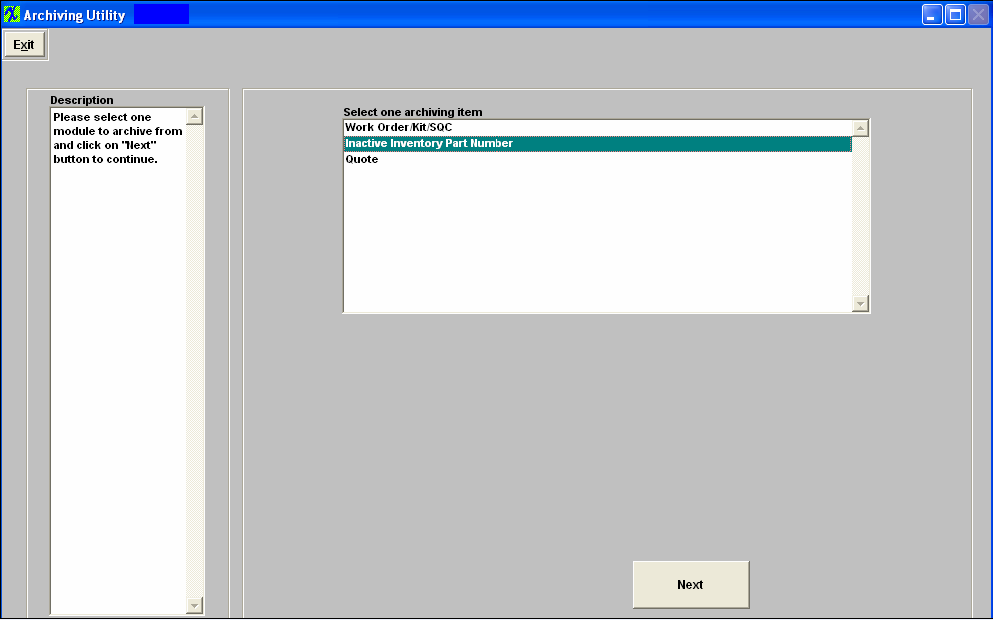

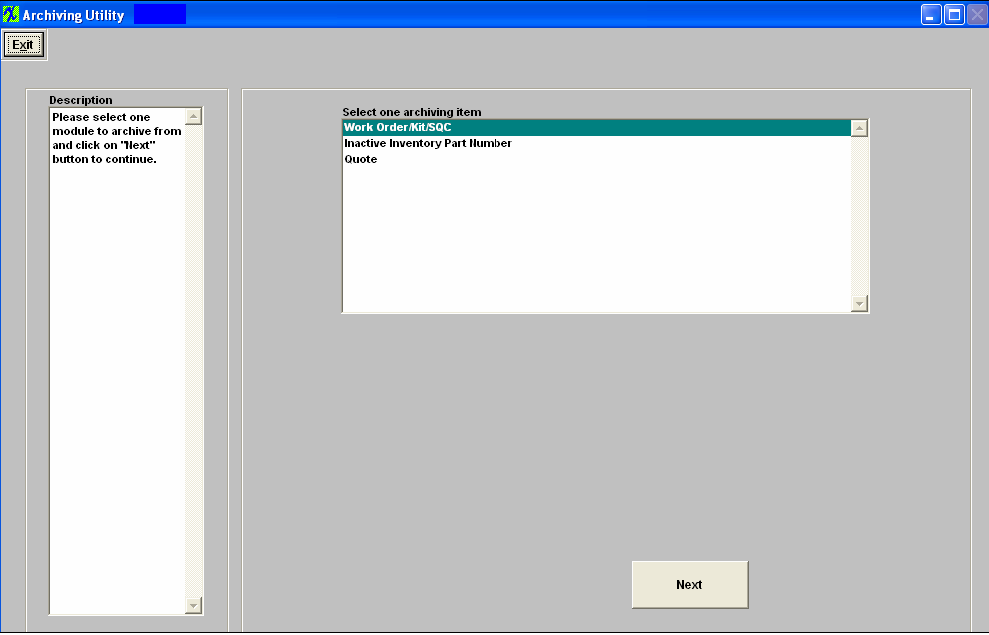

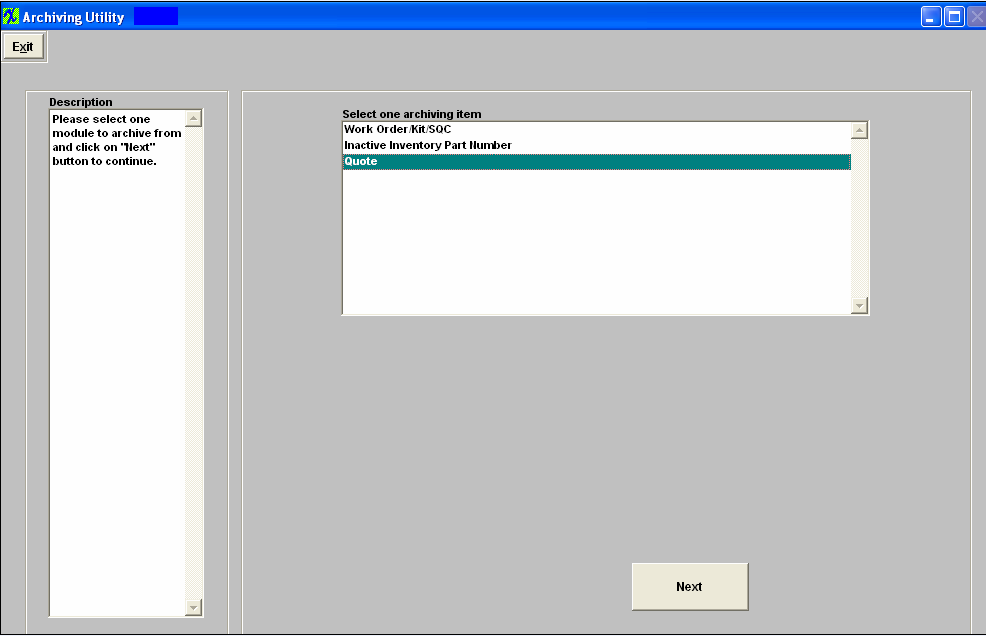

Depress "Yes", to continue the archiving process, and the following screen will appear:

Highlight Work Order/Kit/SQC and depress Next;

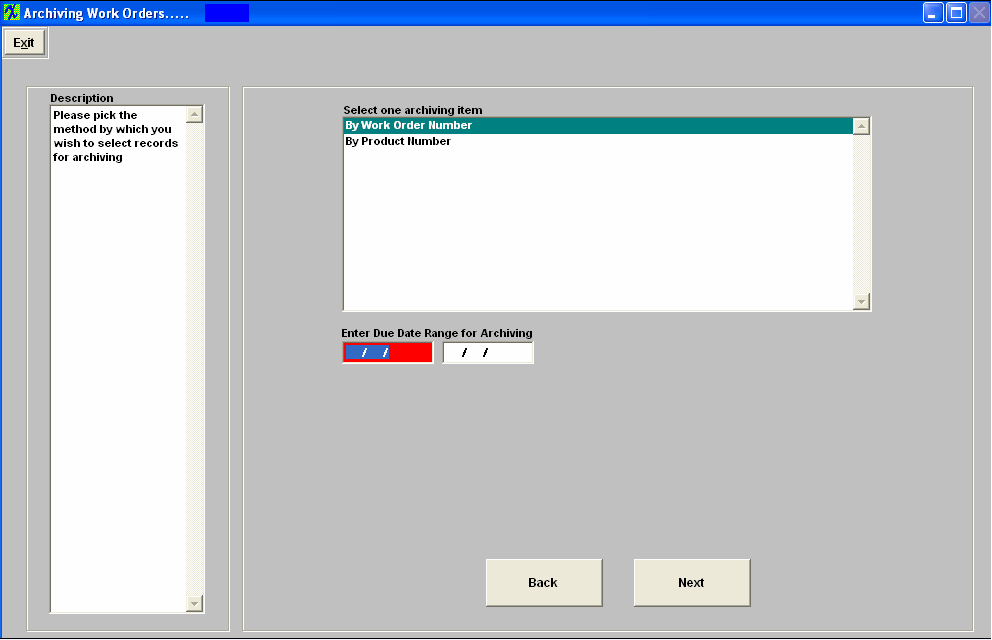

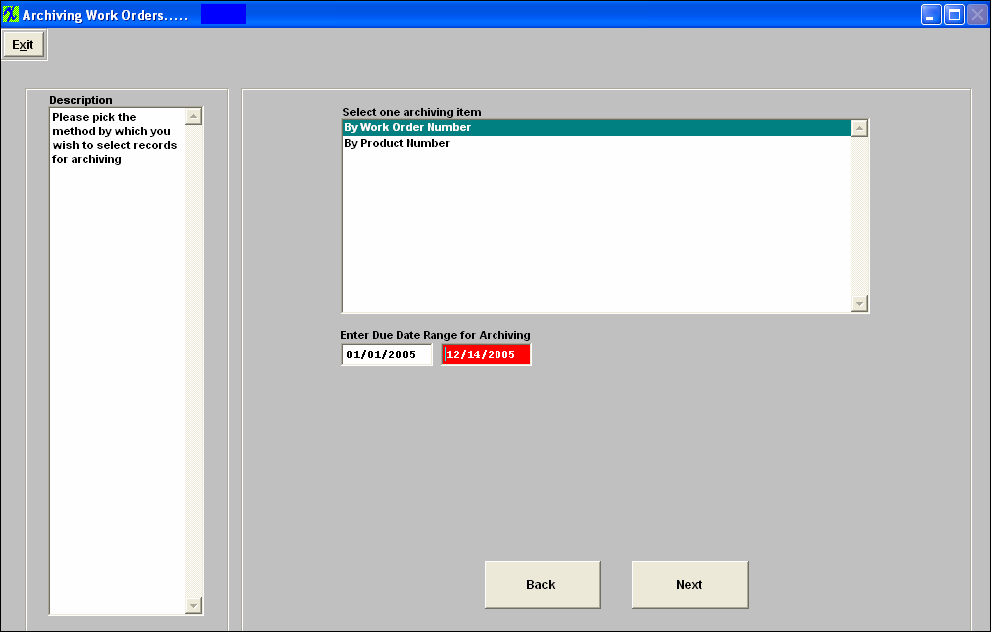

Highlight selection: By Work Order or By Product Number. Complete the Due Date Range

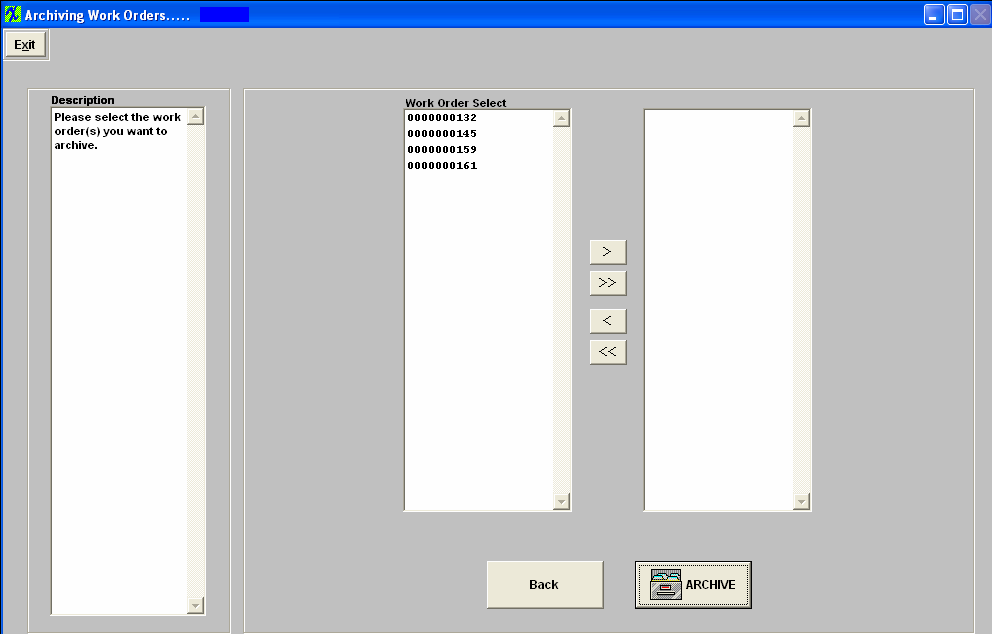

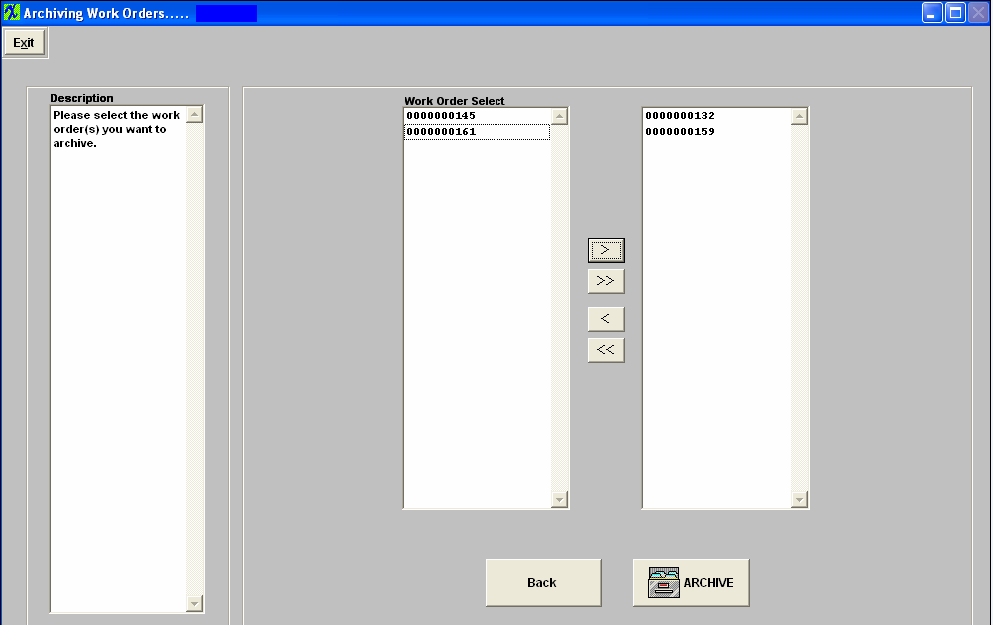

Depress Next, and a list of Work Orders with a status of either Closed, Cancelled, and/or Kit Closed will appear;

To select the Work Orders to be archived, highlight the Work Order and depress the > button. If you would like to archive all work orders listed depress the >> button.

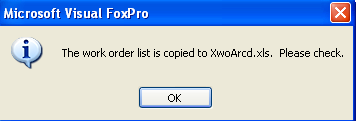

Depress the ARCHIVE button, the following message will appear:

Depress OK, a verification screen will appear asking if you want to continue the archive.

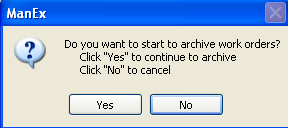

Depress "Yes", the following warning will appear.

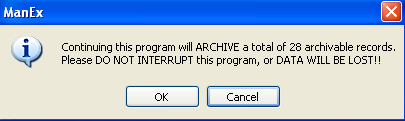

Depress "OK", the following message will appear.

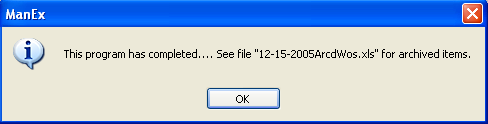

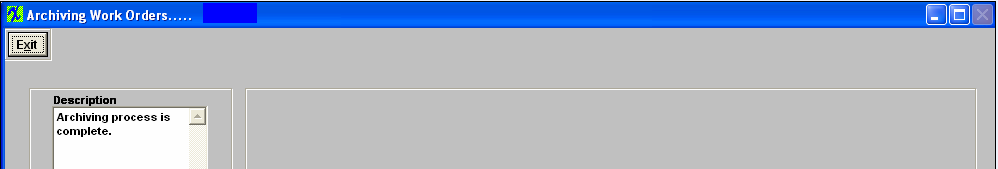

Depress "OK", and the screen will display the the archiving process is complete.

|

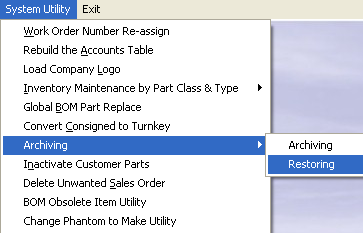

| 1.7.4.2.2. Restoring | ||

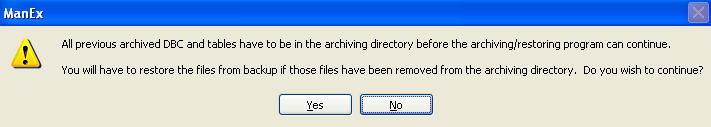

The following warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

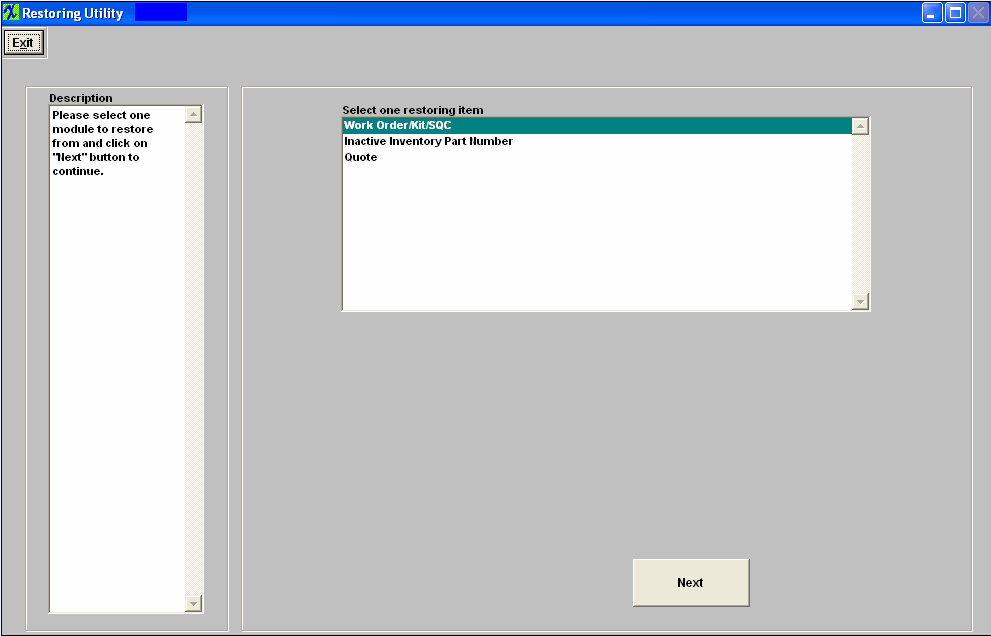

Depress Yes, to continue and the following screen will appear: Select item to restore: Work Order/Kit/SQC, Inactive Inventory Part Number, Quote.

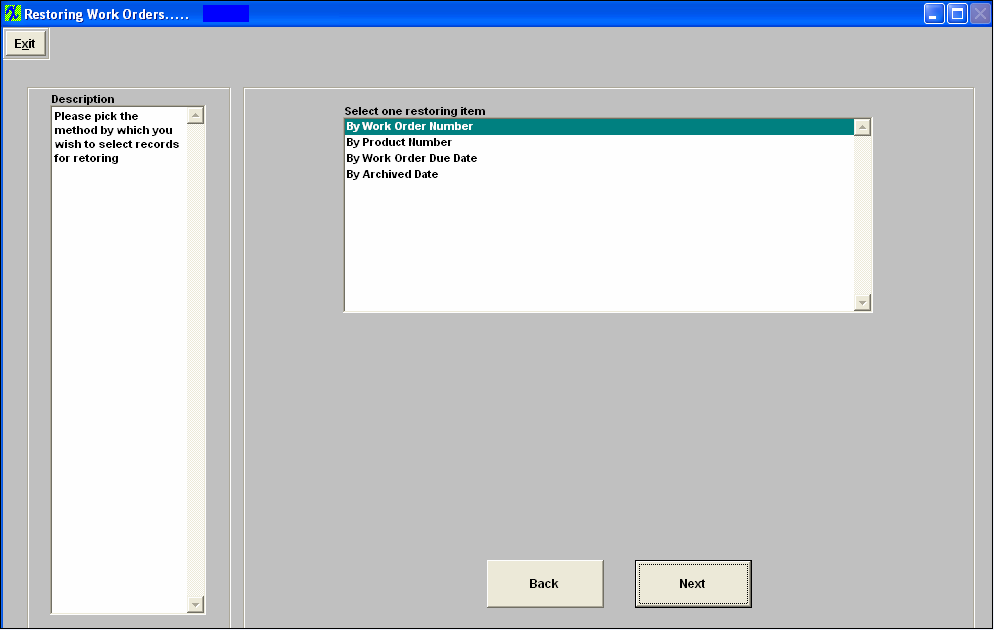

Depress Next, another option screen will appear: Select to view Work Order list by: Work Order Number, Product Number, Work Order Due Date, or Archived Date.

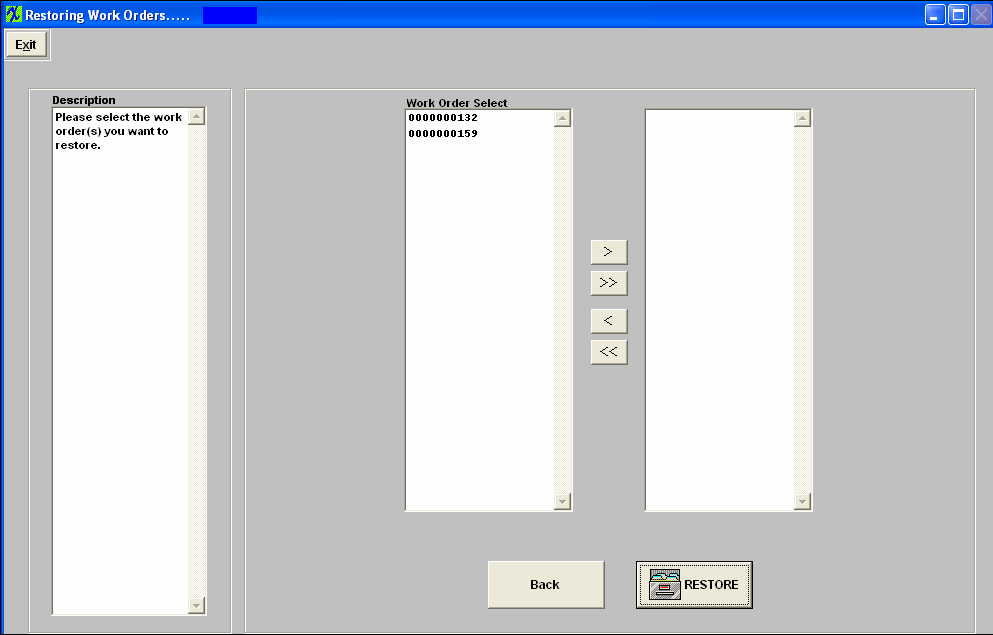

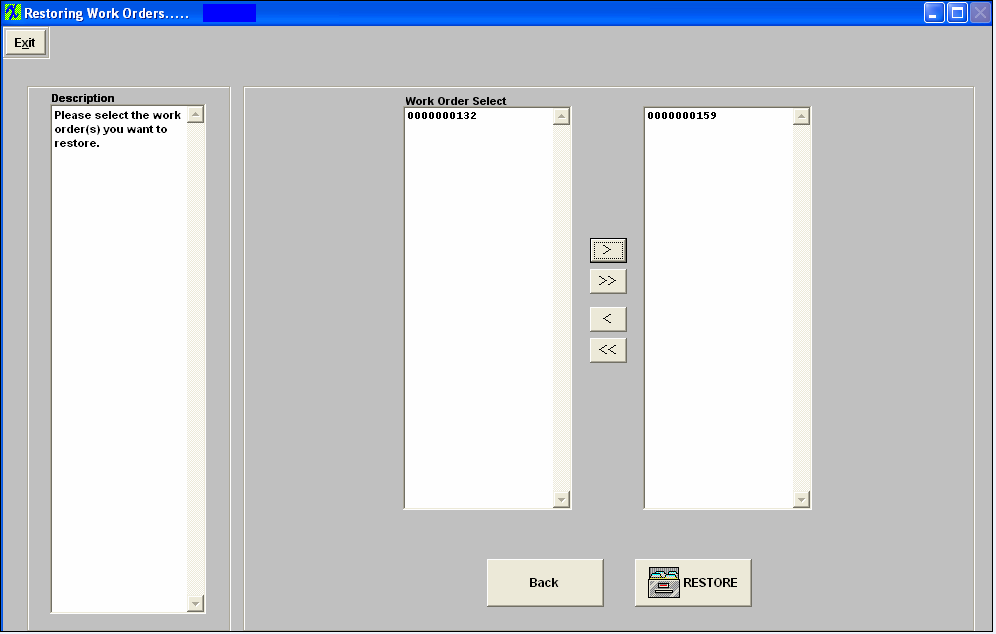

Depress Back to return to previous screen or depress Next to continue. A list of Work Order that have a status of Closed, Cancelled, and/or Kit Closed will appear:

Select the Work Order(s) to restore by highlighting them and depressing the > button. If you would like to restore all the Work Orders listed depress the >> button.

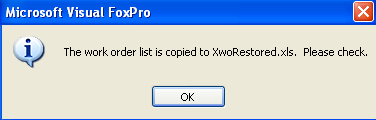

Depress the Back button to return to the previous screen. Depress the RESTORE button to continue, the following message will appear:

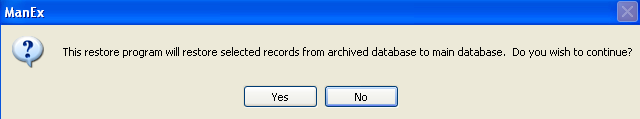

Depress OK, the following screen will appear:

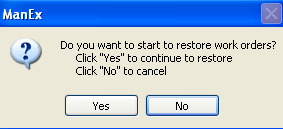

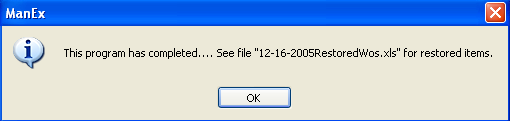

Depress Yes to continue, and receive the following message:

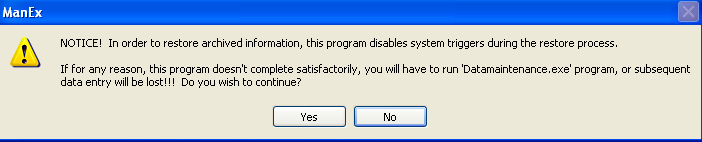

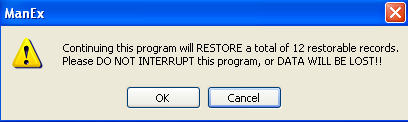

Depress OK, and receive the following message:

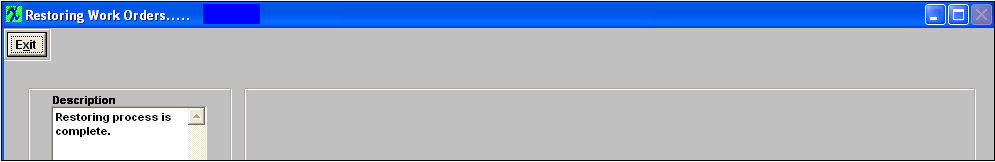

Depress OK, and the following screen will appear:

|

| 1.7.5. Inactive Part Number(s) |

| 1.7.5.1. Prerequisites for Inactive PNs |

After activation, System Utility access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

The following criterias must be meant before an Inactive part can be archived:

|

| 1.7.5.2. Introduction for Inactive PNs |

When an internal part number is changed to "Inactive", it will change all customer part numbers to "Inactive" as well, if those customer part numbers do not have qty OH, open SO, use in BOM, open Kit..... If the system finds any of these conditions to be true it will not allow the status to be changed on the customer part or the internal part. Even if a customer part number is "Inactive", it doesn't mean it's ok to be archived. If a customer part number meets the archive criteria, it will be listed in the archive list. Let's say, I have an internal part number with 2 customer part numbers associated, if all three part numbers meet the archive criteria, then all three will be listed on the archive list for user to select. If user selects one customer part number to archive without selecting internal part number, only the customer part number will be archived. If user selects internal part number to archive without selecting customer part numbers to archive, the program will archive those two customer part numbers also. When a new part is created, the program will check to see if the same part number already exists in archived database, if yes, then user can not add the same part number again.

The "restore" part list will display the internal part numbers and the customer part numbers that have been archived. If the user only selects customer part number to restore and doesn't select internal part number to restore, the program will restore internal part number as well.

After parts have been restored, if the material types are no longer in current system setup, the program will change those deleted material types to "UNK" |

| 1.7.5.3. How To ..... for Inactive PNs |

| 1.7.5.3.1. Archiving | ||

The following warning will appear:

Depress "Yes" to continue, the following warning will appear:

Depress "Yes" to continue, the following warning will appear:

Depress "Yes" to continue. The following screen will appear: Highlight what you wnat to archive; Work Order/Kit/SQC, Inactive Part Number, or Quote.

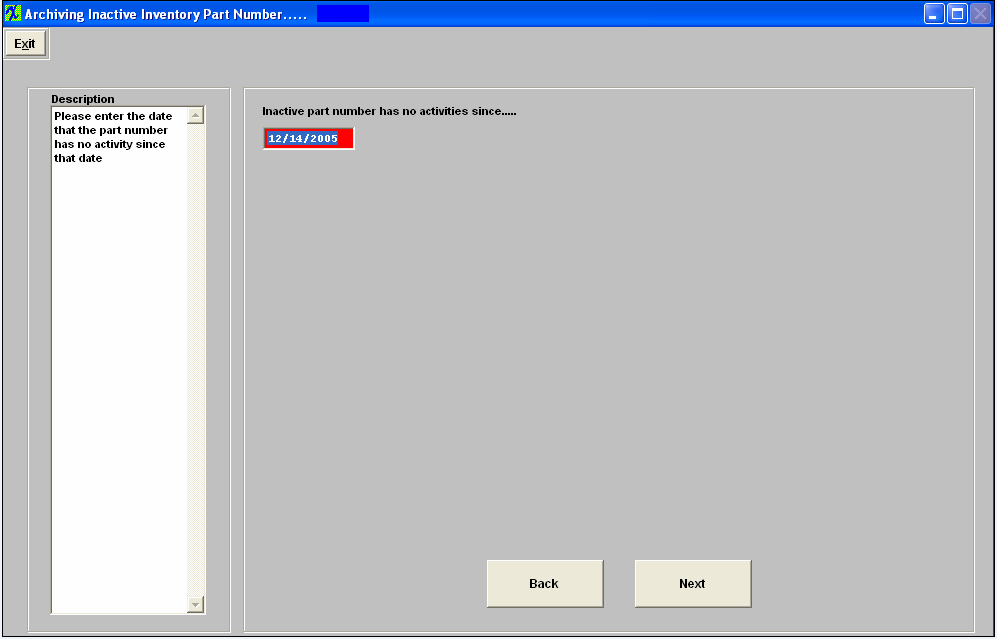

Depress Back (to go back to previous screen) or, Next, the following screen will appear: Inactive part number has no activities since ..... (This is intended to be the last changed date of the Part Number not the Transaction date)

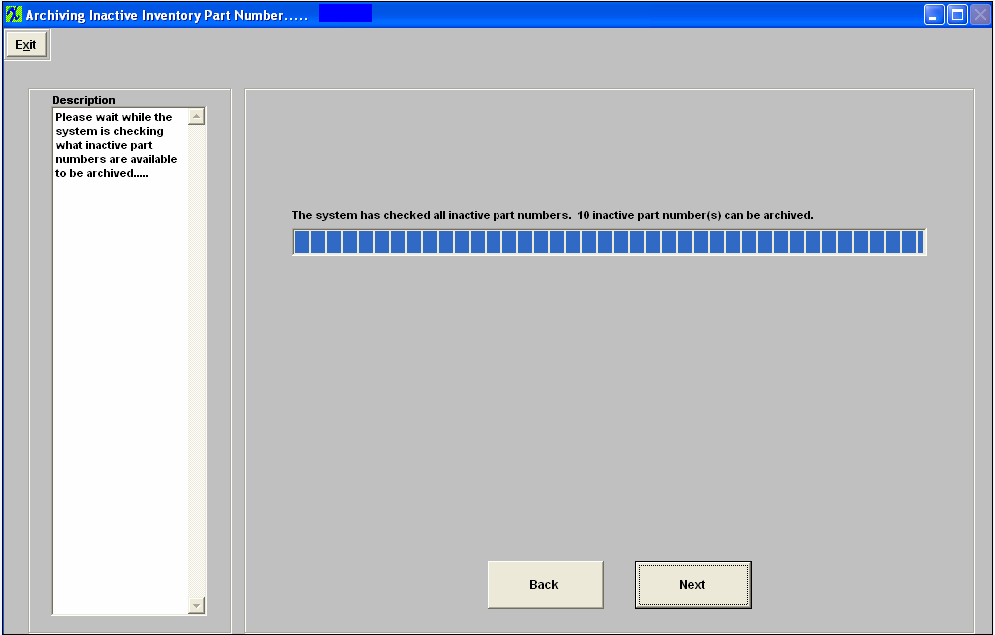

Complete date, and depress Back (to go back to previous screen) or, Next and the following screen will appear, displaying the number of inactive part number(s) that can be archived

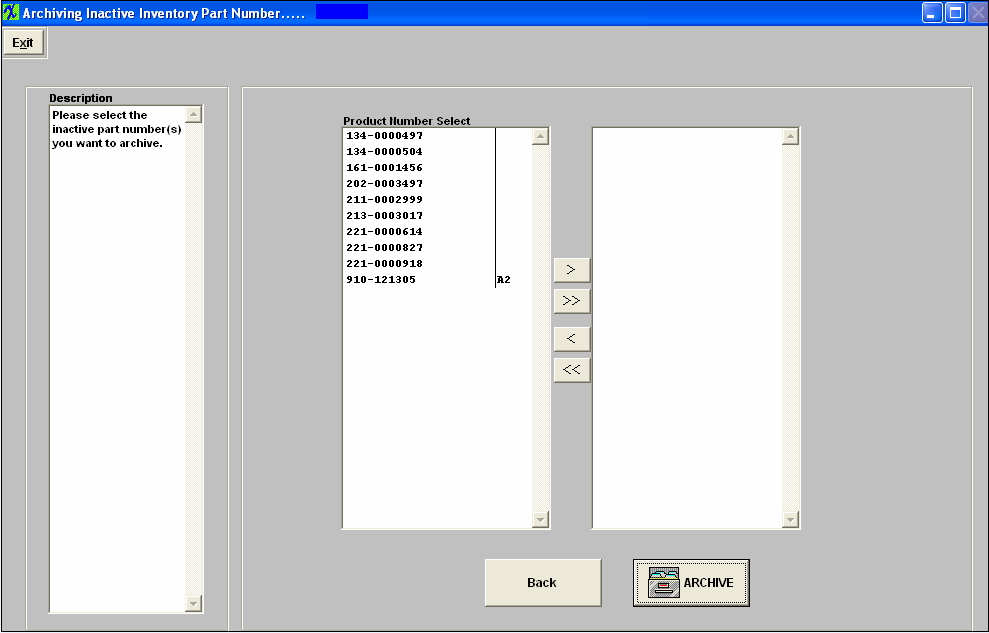

Depress Back (to go back to previous screen), or Next, and the following screen will appear listing the Inactive part numbers to select from:

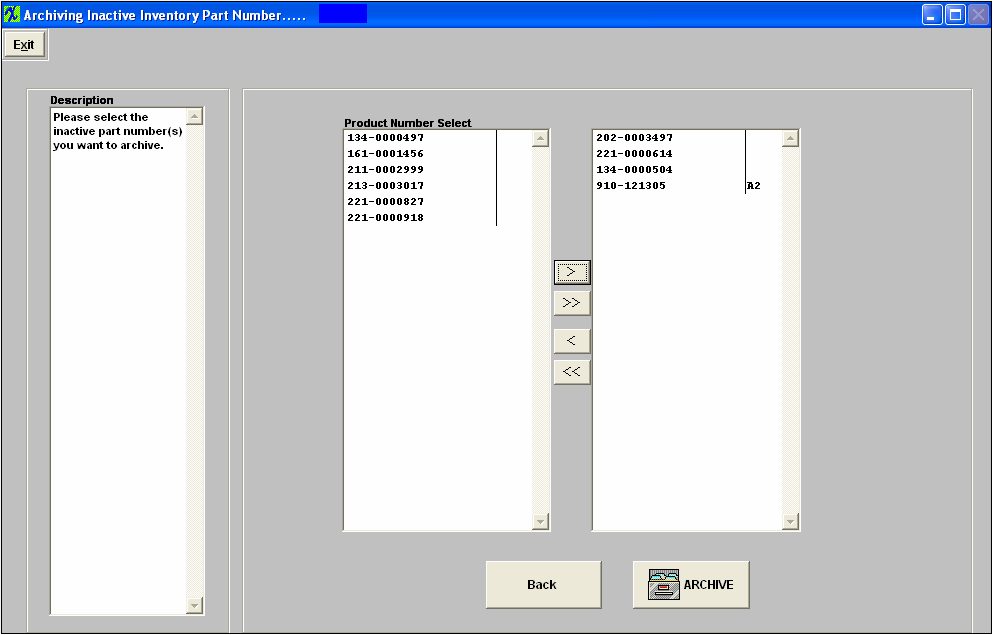

Highlight the part number(s) you would like to archive then depress the > button. If you want to archive all the part numbers listed depress the >> button.

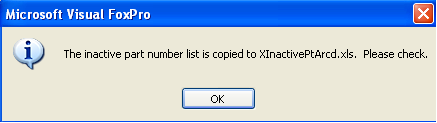

Depress the Back button (to go back to the previous screen), or deperss the ARCHIVE button, a message will appear informing you that the xl spreadsheet has been created;

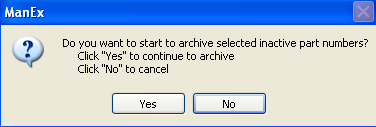

Depress OK, and the following message will appear to continue or cancel the archive.

Depress "Yes" to continue to archive, the following message will appear to continue or cancel the archive.

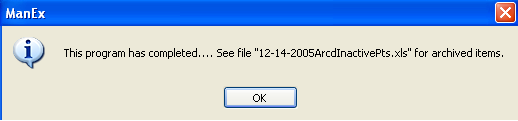

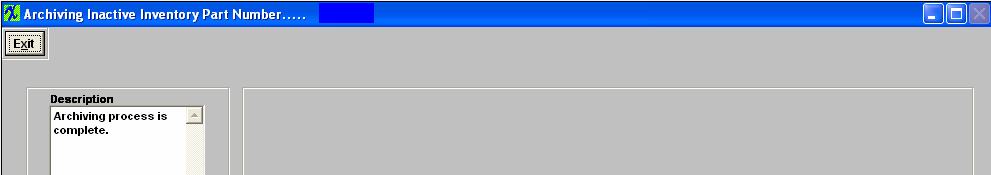

Depress OK, the following message will appear, informing the user that the archiving has been completed and referencing the xls file to view the archived items.

Depress OK, the archive screen will clear.

|

| 1.7.5.3.2. Restoring | ||

The following warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

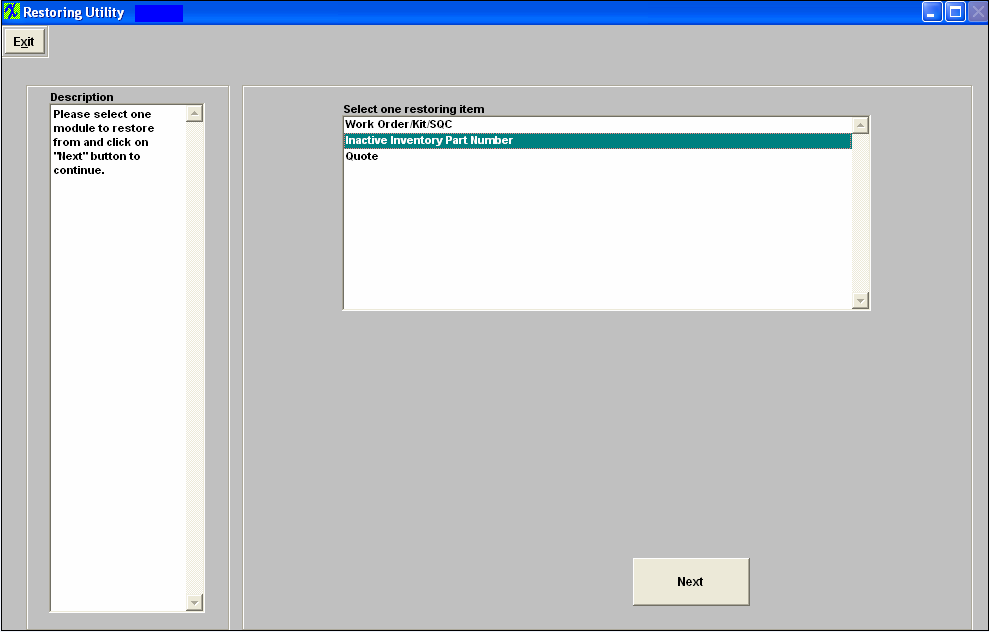

Depress Yes, to continue and the following screen will appear: Select item to restore: Work Order/Kit/SQC, Inactive Inventory Part Number, Quote.

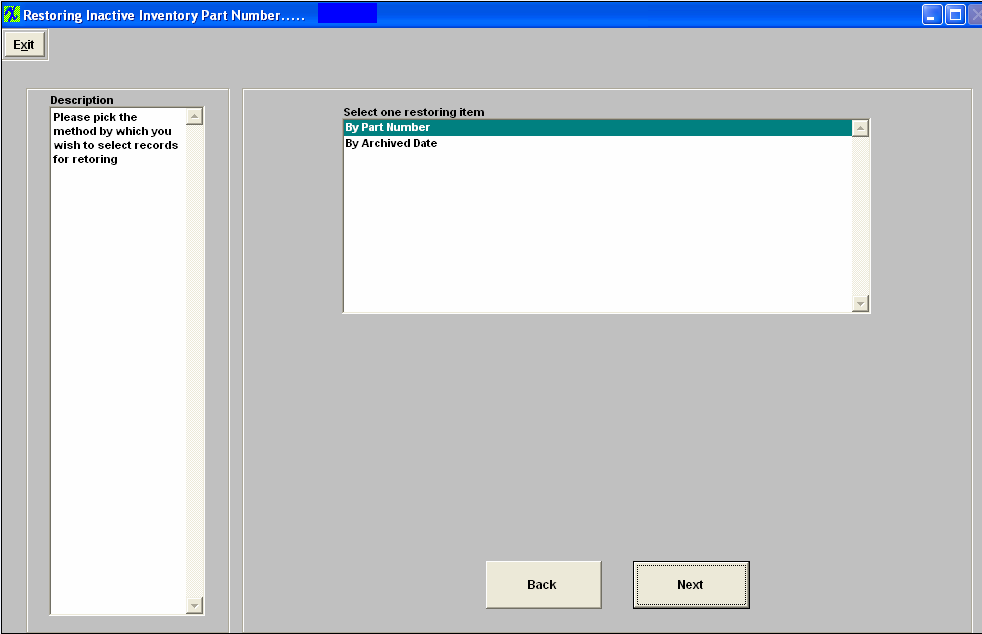

Depress Next, another option screen will appear: Select to view Inventory Part Number list by: Part Number, or Archived Date.

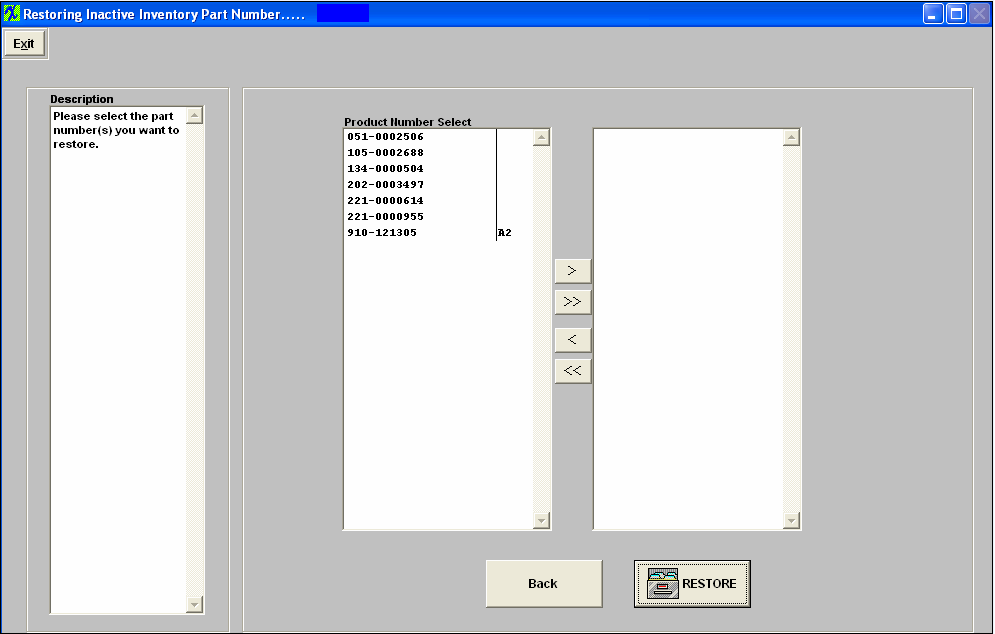

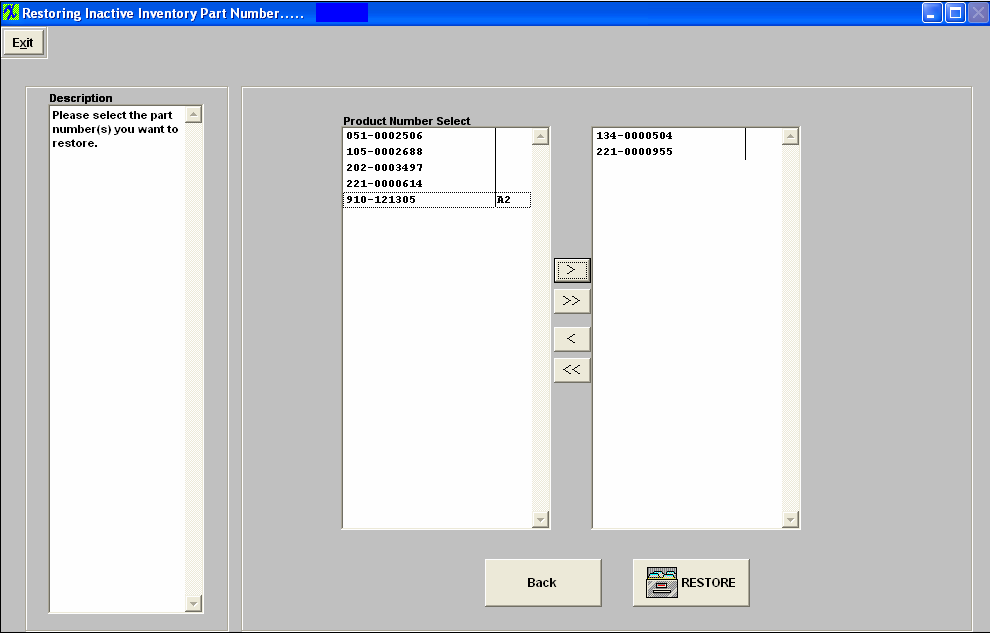

Depress Back to return to previous screen or depress Next to continue. A list of Inventory Part Numbers, that have a status of Inactive will appear:

Select the Part Number(s) to restore by highlighting them and depressing the > button. If you would like to restore all the Part Numbers listed depress the >> button.

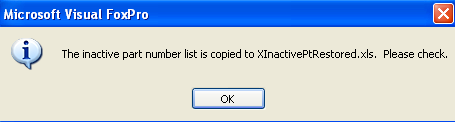

Depress the Back button to return to the previous screen. Depress the RESTORE button to continue, the following message will appear:

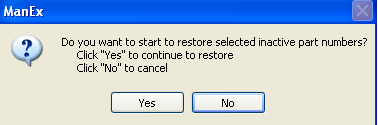

Depress OK, the following screen will appear:

Depress Yes to continue, and receive the following message:

Depress OK, and receive the following message:

Depress OK, and the following screen will appear:

|

| 1.7.6. Quote |

| 1.7.6.1. Prerequisites for Quote |

The prerequisites to archive Quote records are:

|

| 1.7.6.2. How To ..... for Quote |

| 1.7.6.2.1. Archiving | ||

The following warning will appear:

Depress Yes, to continue, and the following warning will appear:

Depress Yes, to continue, and the following warning will appear:

Depress Yes, to continue, and the following screen will appear:

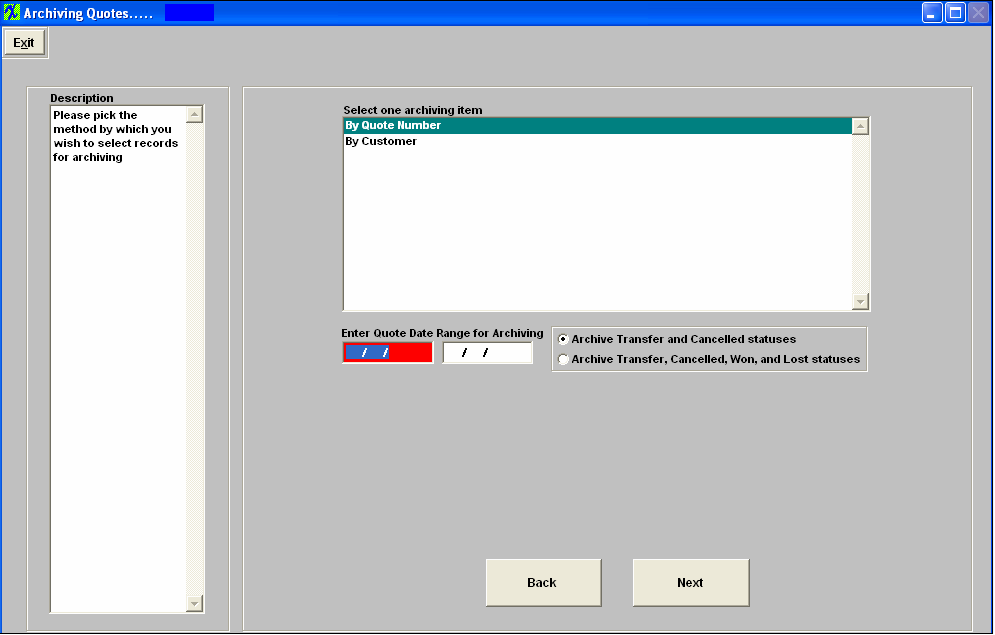

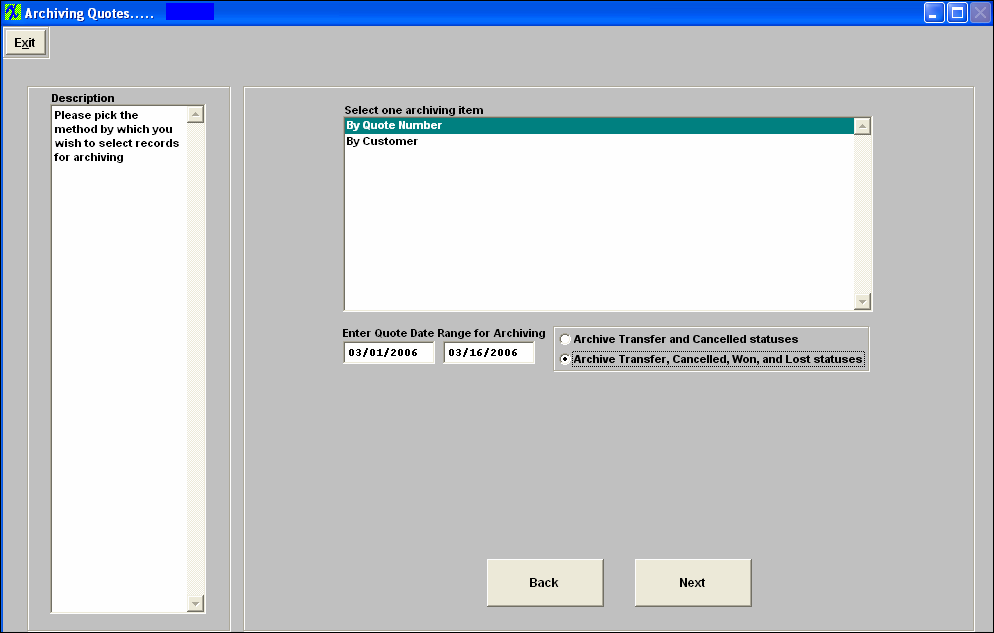

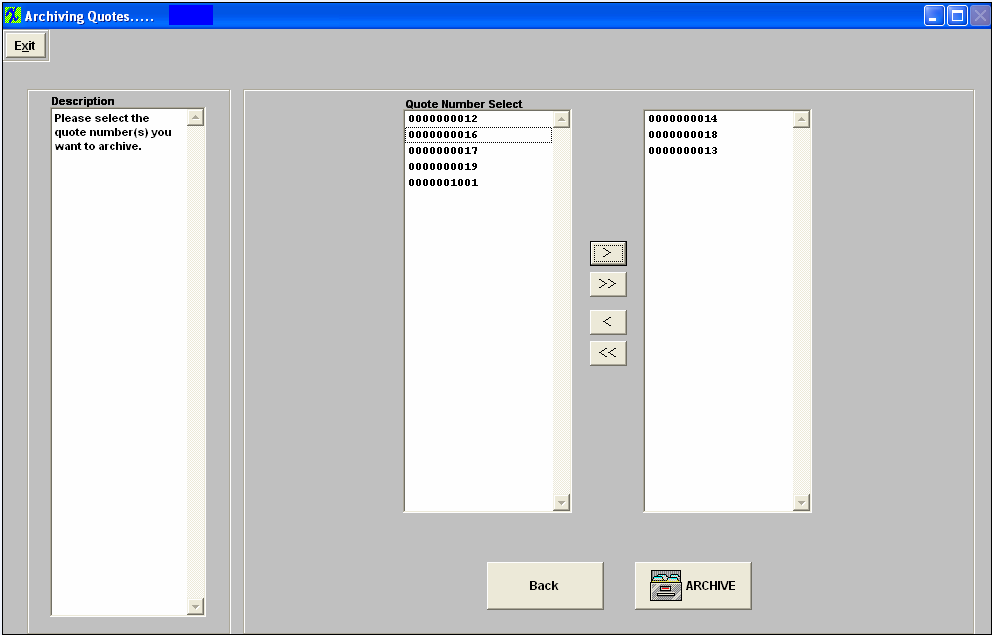

Depress Next, the following screen will appear:

Select to archive Quote by: Quote Number, or Customer. Complete the date range. The default is to only archive "Transfer" and "Cancelled" statuses. For users that would like to archive quotes with "Won" and "Lost" statuses also, they can select the 2nd option.

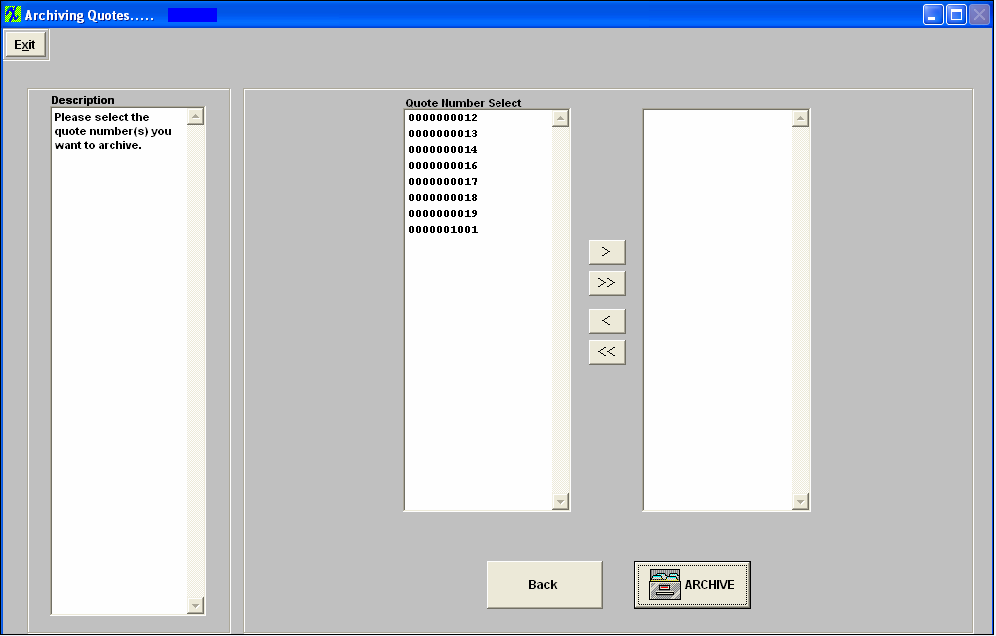

Depress Next, a list of Quote Numbers will appear that have a status of "Transfered" , and "Cancelled", or "Transfered", "Cancelled", "Won", and "Lost", depending on which option was choosen.

Select Quote numbers to archive by highlighting the quote number and depressing the > button. To archive all quote numbers listed depress the >> button.

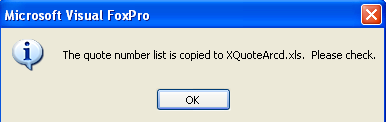

Depress the ARCHIVE button, and the following message will appear listing the xl spreadsheet created.

Depress the OK button, and the following option screen will appear:

Depress Yes, to continue and the following warning will appear:

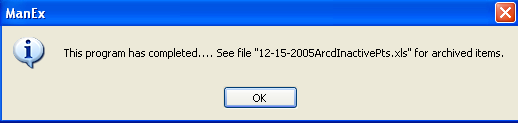

Depress OK, the following message will appear:

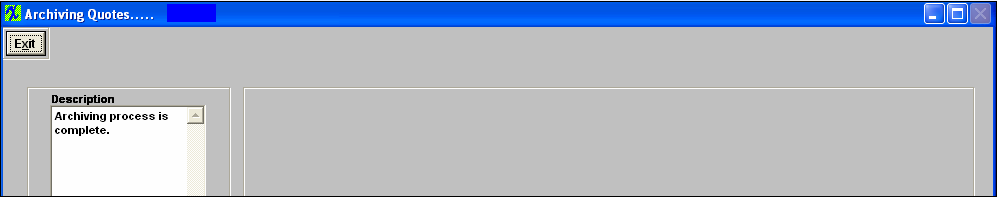

Depress OK, and the following screen will appear.

|

| 1.7.6.2.2. Restoring | ||

The following warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

Depress Yes, to continue and the next warning will appear:

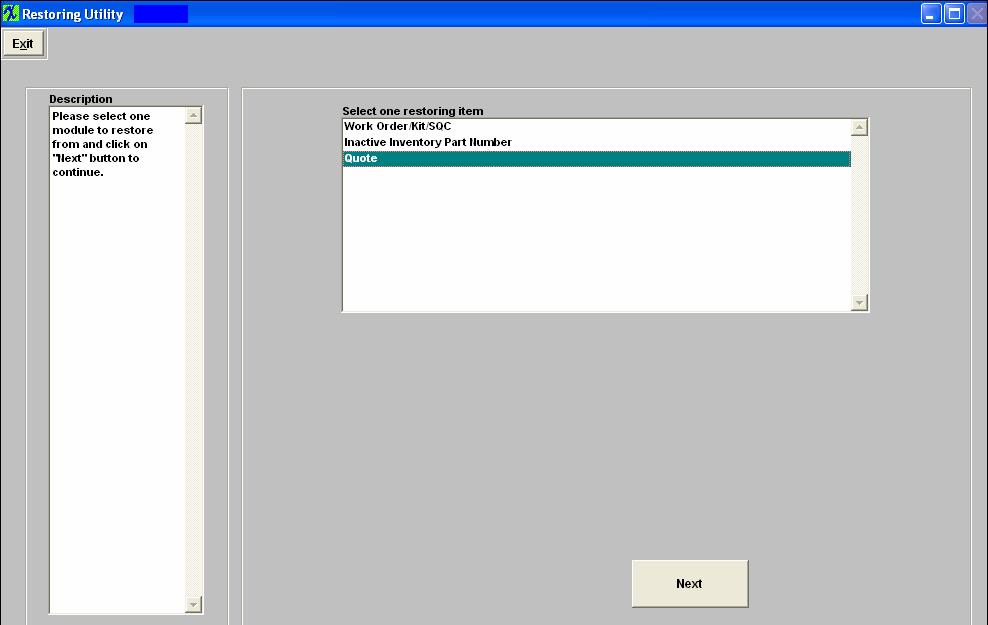

Depress Yes, to continue and the following screen will appear: Select item to restore: Work Order/Kit/SQC, Inactive Inventory Part Number, Quote.

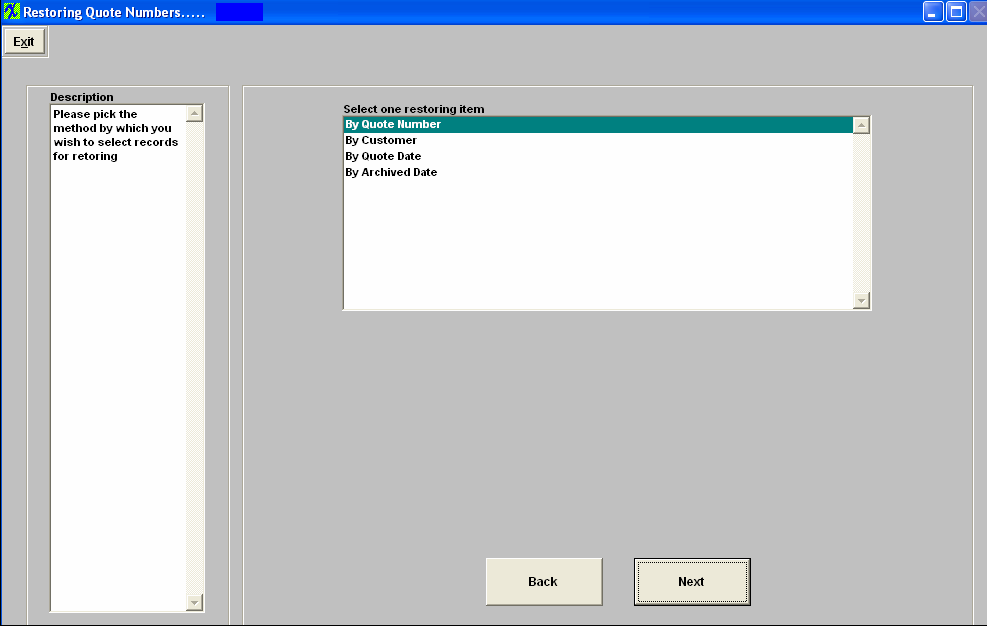

Depress Next, another option screen will appear: Select to view Quote list by: Quote Number, Customer, Quote Date, or Archived Date.

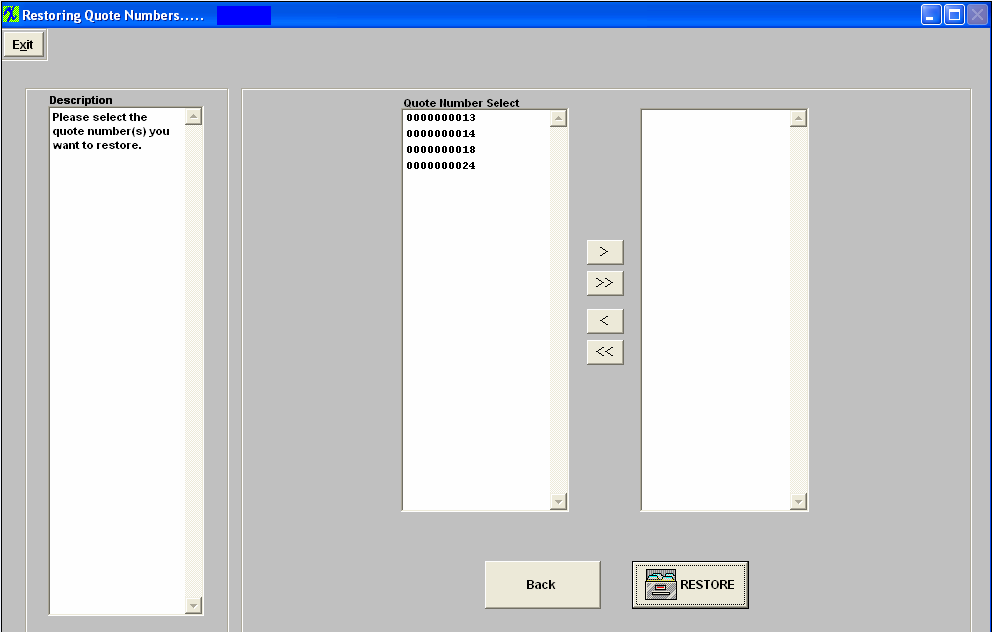

Depress Back to return to previous screen or depress Next to continue. A list of Quotes that have a status of Transfered or Cancelled, will appear:

Select the Work Order(s) to restore by highlighting them and depressing the > button. If you would like to restore all the Work Orders listed depress the >> button.

Depress the Back button to return to the previous screen. Depress the RESTORE button to continue, the following message will appear:

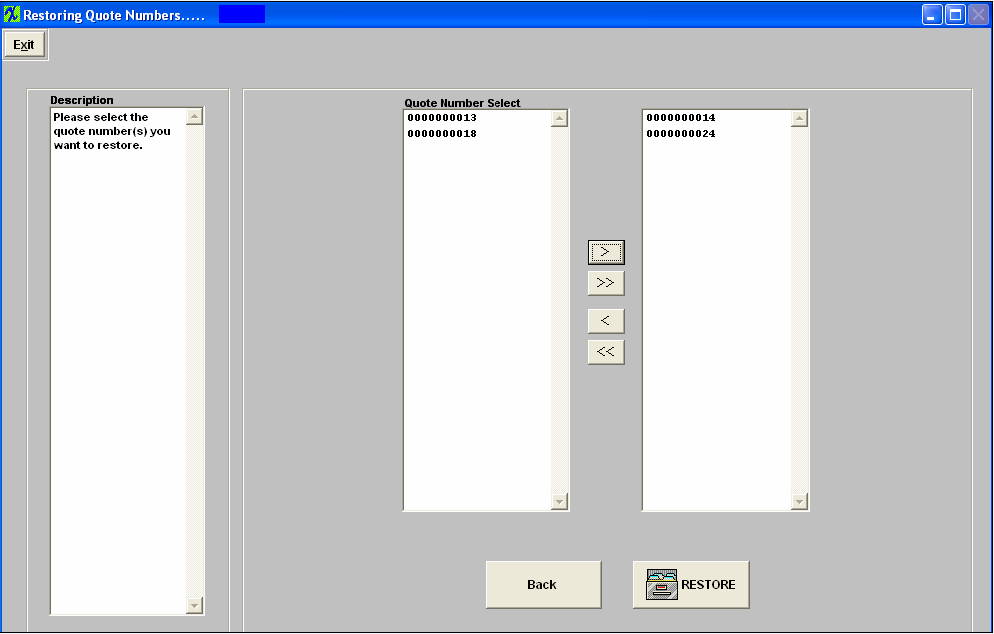

Depress OK, the following screen will appear:

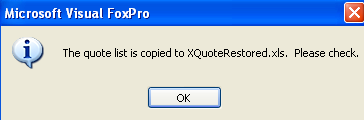

Depress Yes to continue, and receive the following message:

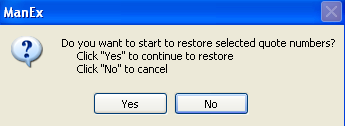

Depress OK, and receive the following message:

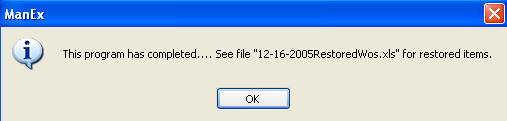

Depress OK, and the following screen will appear:

|

| 1.8. Inactivate Customer Parts | ||

After activation, System Utlity access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

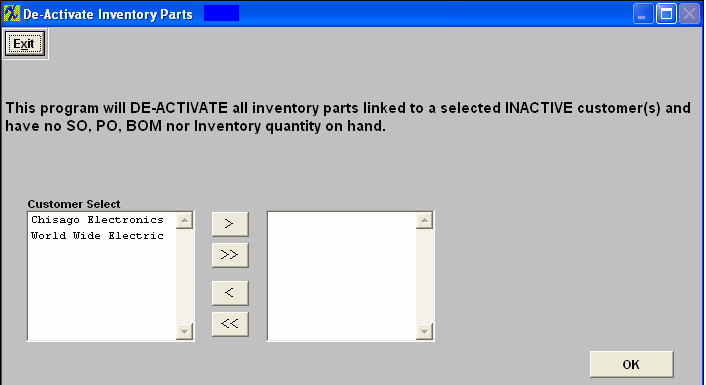

The following screen will appear:

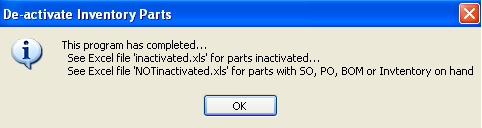

Select the Customer(s), then depress the OK button. The following message will appear:

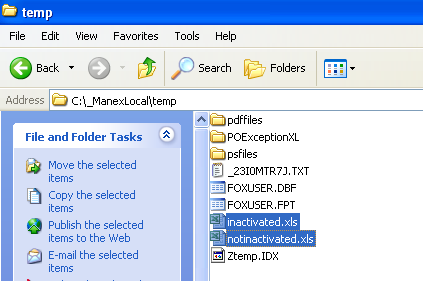

Depress the OK button. The Excel file referenced above will be placed in the ManExLocal\Temp directory on the workstation.

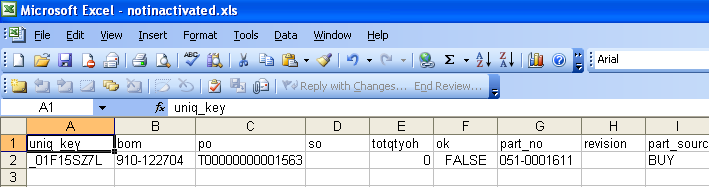

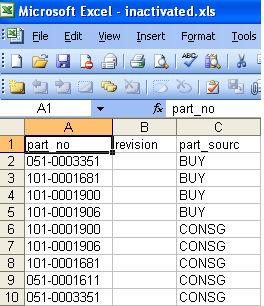

Here is a sample of the XLS files that would be generated. The user can enter the system and the part number records listed in the inactivated.xls file will be marked as “Inactive” within the Inventory control Module.

Part numbers that appeared within the notinactivated.xls file will still remain in the system as “Active”

|

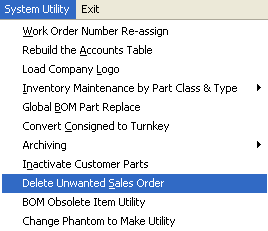

| 1.9. Delete Unwanted Sales Order | ||

After activation, System Utilities access for each user must be setup in the ManEx Security module. Users with “supervisor’s rights” will automatically have access.

The following message appears:

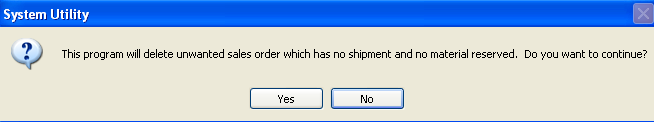

Depress "Yes" to continue

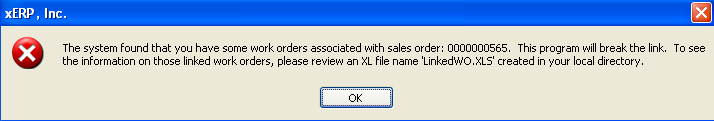

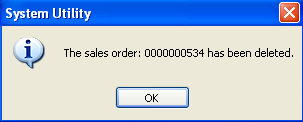

Enter Sales Order Number, depress the enter key, the following message will appear:  Depress OK to continue

|

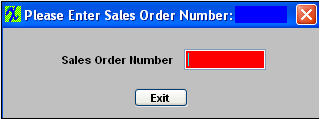

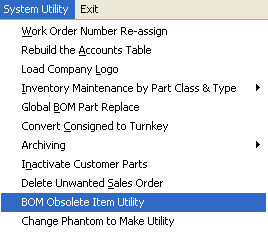

| 1.10. BOM Obsolete Item Utility | ||||||||||

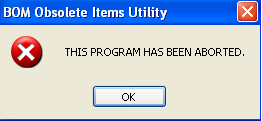

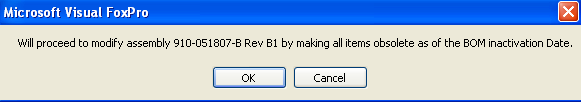

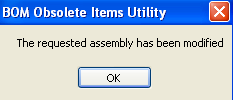

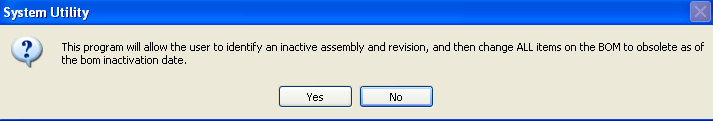

The following warning will appear:

|

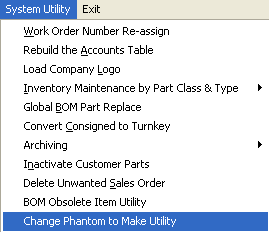

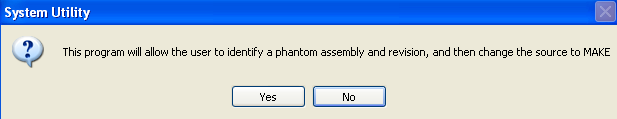

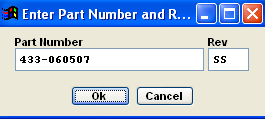

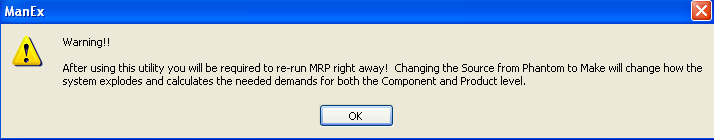

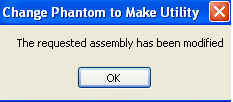

| 1.11. Change Phantom to Make Utility | ||||||||||

|

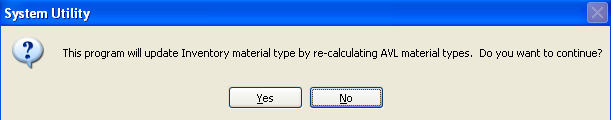

| 1.12. Global Inventory Material Type Update | ||||

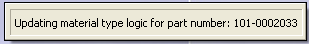

The following warning will appear:

Depress Yes - the following update screen will flash in the upper right hand of the screen When program is complete you will receive the following message: Depress - No - Program will abort with no updates.

|

| 1.13. FAQs - System Utility |

| Facts and Questions for the System Utility Modules |