| 1. Production |

| 1.1. Prerequisties for Production Setup |

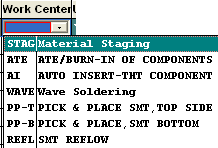

In general, the production work is divided up among several departments. Some products may require that some work that is done in each of these departments. Other products may require that work be done in only a few of all the departments in operation. In order to identify the work processes for each product, ManEx allows the user to define Work Centers. These Work Centers describe a physical aspect (usually) of production operations that applies a specific type of labor to the product. Examples of work centers may be: SMT - where the product is assembled on a surface mount line; AI - where parts are Auto-Inserted into the product; Wave - where the parts are wave soldered; Cleaning; Inspection; Test; etc. Each of these work centers contains within it, a common aspect of production. For example, in SMT, the surface mount operator’s pay scale is probably higher than other parts of production, the parts are all contained within one area, the setup time is appropriate to one lot of a given product, and the parts are contained within the work area. If inventory counting is necessary, the user can identify that the parts are in the work center.

The user may create as many work centers as necessary to define the production activities that occur within the operation. Within a work center, the user may establish additional definitions, called Activities. These activities may be set up separately from the work centers, and then used as needed within individual work centers. The activities may be assigned their own hourly charge rate. And within an Activity, there is yet another classification called sub-activities, which have activity costs associated with them. These activity costs are established in the Activity Cost & Volume Type setup. Also, in this section the setups for Quality items are accomplished, and will be discussed in each setup. Outside Program Calls Setup is also available.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.1.1. Manex Notes Matrix |

See the word attachement <Notes Matrix.doc>> for a table which shows the cross-reference for all ManEx Notes.

|

| 1.2. Introduction for Production Setup |

This section covers the production setup to be used in all production related modules. Please take time to think about how you want to use these tables for best production management. Some sample data is provided with this setup as a guideline. These tables are used in various modules throughout the system. The production application module setup section allows you to prepare tables for specific production related modules your company has purchased. Once setup in the system, you will be able to use these tables and/or perform certain functions automatically. These tables are completed by preparing worksheet tables and/or setting certain switches.

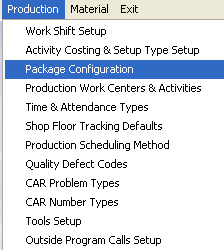

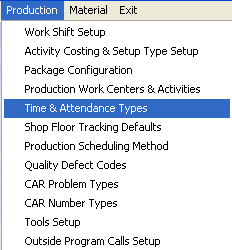

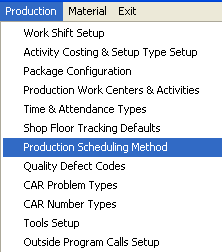

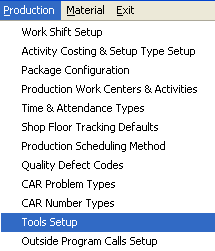

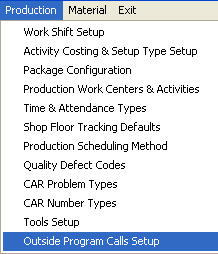

Production System worksheet covers the following modules: Work Shift Set Up, Activity Costing & Volume Type Set Up, Package Configuration, Production Work Centers & Activities, Time & Attendance Types, Shop Floor Tracking Defaults, Production Scheduling Method, Quality Defect Codes, CAR Problem Types, CAR Number Types, Tools Setup and Outside Program Calls Setup.

|

| 1.3. Work Shift Setup |

| 1.3.1. Prerequisites for Work Shift Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-a" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.3.2. Introduction for Work Shift Setup |

| 1.3.3. Fields & Definitions for Work Shift Setup | ||||||||||||||||

|

| 1.3.4. How To ..... for Work Shift Setup |

| 1.3.4.1. Setup the Work Shift Module | ||

|

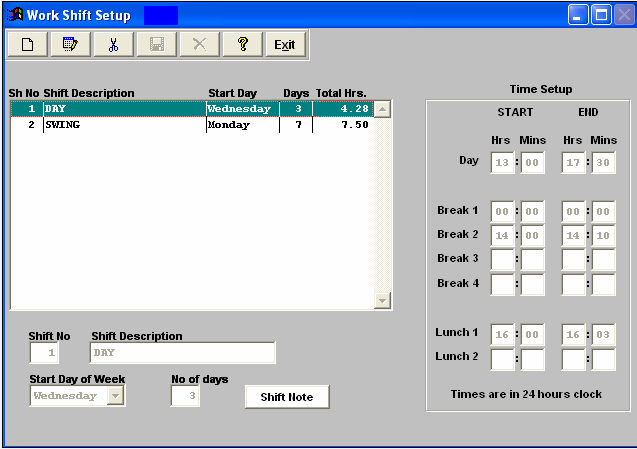

The following screen will appear:

The user may Add new or Edit and Delete existing shifts. The user must either Save or Abaondon to close the screen. Where Used: In the job routing functions for a product. «Mark as Completed in RoadMap in Section B Item 3-a» |

| 1.4. Activity Costing and Setup Type Setup |

| 1.4.1. Prerequisites for Activity Costing & Setup Type Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-b" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.4.2. Introduction for Activity Costing & Setup Type Setup |

This module is essential if you are using Activity Based Cost (ABC) methodology for managing the production floor. The information entered here forwards to Production Work Center/Activity Setup. Then both setups are used in the MANEX Capacity Planning module.

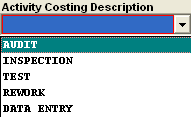

Activity Costing and Activity Volume Type Description setup is a requirement only if your company is employing Activity Based Cost (ABC) methodology for managing the production floor. The Activity Costing and Activity Volume Type Descriptions are used in Production Work Center/Activity setup to assign Activity Costs and Activity Volume Types to a production Work Center/Activity. The Activity Volume Type Description is a pre-requisite for Production Work Centers & Activities / Activity Setup & Run tab. Your company should become knowledgeable about the principles of ABC prior to using Activity Costing and Activity Volume Type Descriptions.Activity Cost and Volume types allow the users to define the costs and capacity for individual activities within a work center. It is used in the capacity planning module to determine available and required capacities. It is also used to assign costs of operation. For example, there may be several machines that can do the same job in a work center. However, one may have a higher operating cost, but also greater capacity. Both machines can be displayed as a resource. The selection of the machine is performed in the routing and capacity modules. |

| 1.4.3. How To ..... for Activity Costing & Setup Type |

| 1.4.3.1. Setup the Activity Costing & Setup Type Setup Module | ||

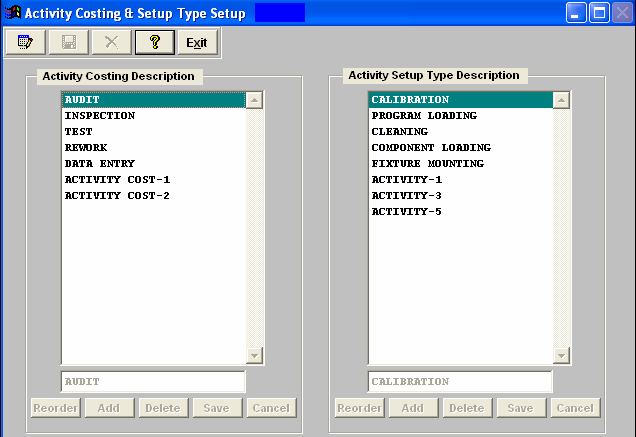

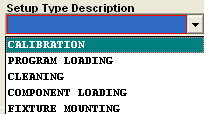

The following screen will appear:

To ADD new descriptions to these tables, click on the Edit button. The Reorder, Add, Delete buttons will become available under each column. Depress the Add button, enter the description. When complete depress the Save or Cancel button under the table. To DELETE existing descriptions to these tables, click on the Edit button. The Reorder, Add, Delete buttons will become available uder each column. Highlight the description you want to delete, depress the Delete button. When complete depress the Save or Cancel button under the table. to REORDER descriptions to these tables, click ont he Edit button. The Reorder, Add, Delete buttons will become available under each column. Depress the REORDER button, then click and drag the activities to the desired order. When completed depress the Save or Cancel button uder the table. Where Used: In the Production Work Center/Activity Setup.

«Mark as Completed in RoadMap in Section B Item 3-b» |

| 1.5. Package Configuration |

| 1.5.1. Prerequisites for Package Configuration |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-c" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.5.2. Introduction for Package Configuration |

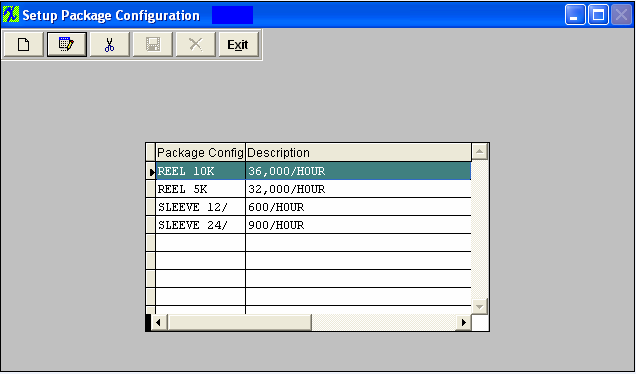

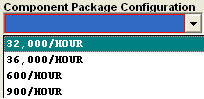

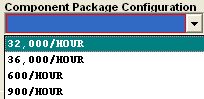

Package configuration setup is provided so that the user may define a machine’s Units Per Hour. This definition can then be accessed in the Production Work Centers & Activities setup/Activities Setup & Run tab. |

| 1.5.3. Fields & Definitions for Package Configuration | ||||

|

| 1.5.4. How To ..... for Package Configuration |

| 1.5.4.1. Setup the Package Configuration Module | ||

The following screen will appear:

To ADD a record, depress the Add button, type in the Package Configuration and description. To EDIT a record, depress the Edit button, edit the Package Configuration and/or description. To DELETE a record, highlight the Package Configuration and description you wish to delete, depress the Delete button. "Mark as Completed RoadMap Section B Item 3-c"

Where Used: In the Production Work Center/Activity Setup. |

| 1.6. Production Work Center & Activity Setup |

| 1.6.1. Prerequisites for Production Work Centers & Activities |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-d" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.6.2. Introduction for Production Work Centers & Activities |

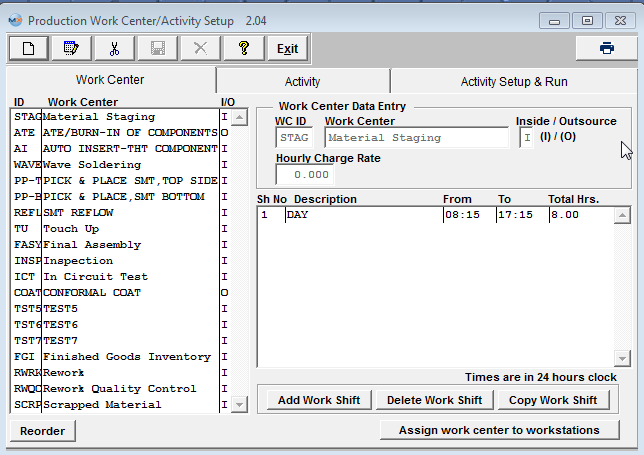

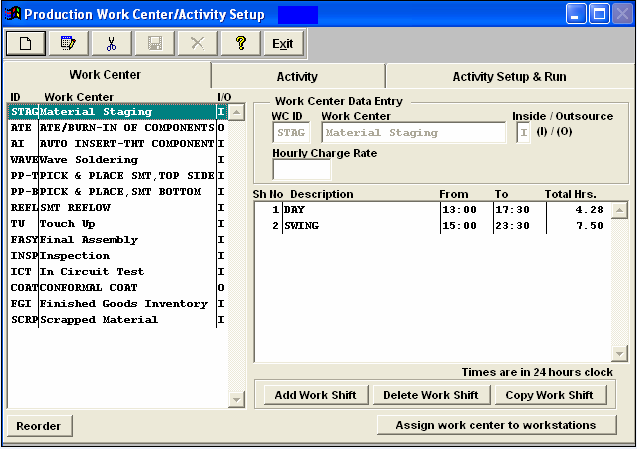

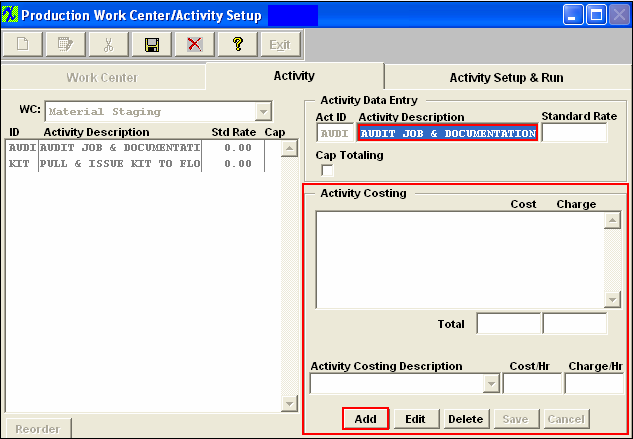

| Production Work center activities are optional sub-sets of work center departments. Activities may be defined prior to establishing work centers, and then used as more detailed actions within a work center. Each of these activities may be assigned a separate hourly charge rate. |

| 1.6.3. Fields & Definitions for Production Work Centers & Activities |

| 1.6.3.1. Work Center Tab | ||||||||||||||||||

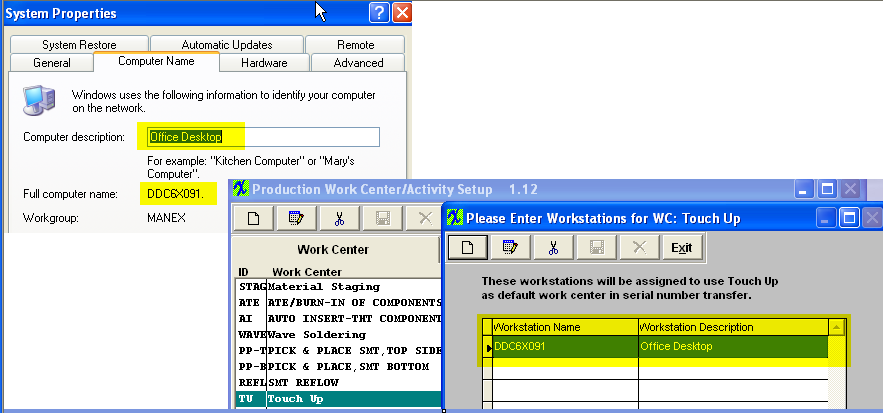

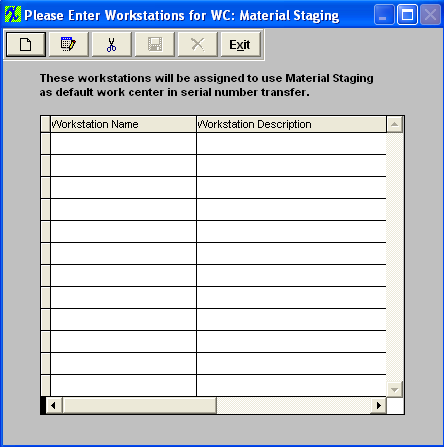

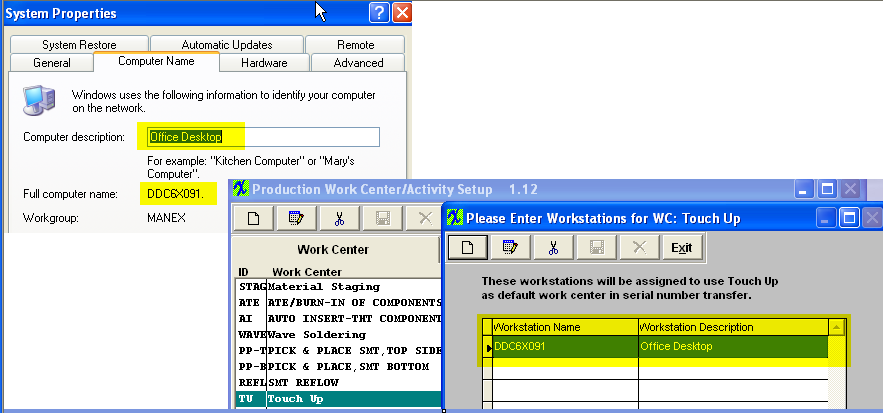

Assign work center to workstations (button)

If a customer wants to install workstations along the production line, with scanners to read serial numbers as they passed down the line, this button provides the ability to limit a work station (specific computer) to be able to only transfer material “FROM” a certain Work Center on serialized Work Orders only. So, when a user first opens the "SFT by WO" or "Shop Floor Tracking by Bar Code" module, the module will use the default work center assigned for this workstation, but if user chooses to use a different work center, supervisor approval or a user that has the option "Allow Changing Default Work Center for Serial Number Transfer" box checked within the Security module is required to continue. After a supervisor's or user with this option’s password is entered, the default work center will be changed to the one that the supervisor entered password for. For Example: the workstation is assigned to use “TU” as default work center, now if user chooses to use “AI” to transfer, the system will ask for supervisor’s password, if user cancels the password, the default work center will still be “TU”, but if the supervisor enters his/her password on this machine, the default work center will be changed to “AI”. If now the user tried to transfer from “TU” again, the system will ask for supervisor’s password again. If user exits the module and come back, the default work center will be “TU” again.

When setting up a workstation user must enter the Full computer name in the Workstation Name field and the Computer description in the Workstation Description field. See Example below.

Defect Code Entry In-Line Mode, the system will check to see if the serial number is currently in the Work Center which was set up here. If not, a special supervisor’s password is required to transfer the serial number FROM a different Work Center. After the supervisor password is entered, the system will use the new Work Center to be the default FROM Work Center until the user closes the screen. The next time the user opens the screen, the default FROM Work Center will be changed back to the one defined in Systems Setup. |

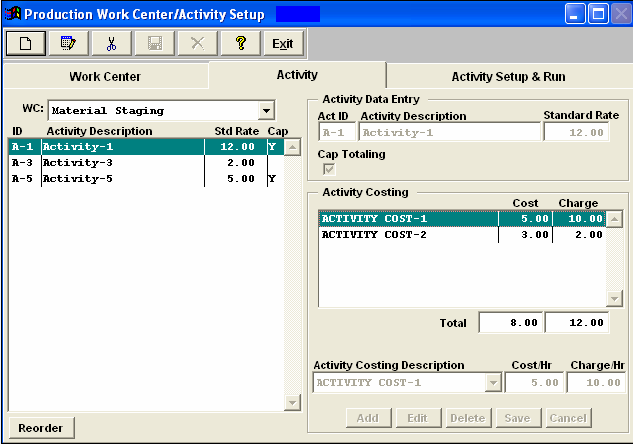

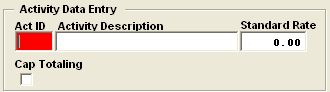

| 1.6.3.2. Activity Tab | ||||||||||||||

This is the description of the work center highlighted in the Work Center tab. Activity ID This is the abbreviated (4 character) code for the name of the activity. Activity Description This is the description of the activity being performed.It may take 25 characters in length. Standard Rate This is the standard hourly rate for the activity performed within the Work Center. Cap Click here for capacity totaling election.Capacity totaling means that if multiple activities are used in a work center, and if there are multiple resources in the activities, the capacity will be the sum of the resources rather than limited by just one resource. Activity Costing Description This field is selected from the available activity costing descriptions created in the Activity Costing & Setup module within system setup. This is the field used to enter hourly charge rates, for each activity. The formatting is three digits to the left of the decimal, and two to the right (999.99). If this optional field is entered, it will be used to determine the hourly charge rate of the activity to which it is assigned.

|

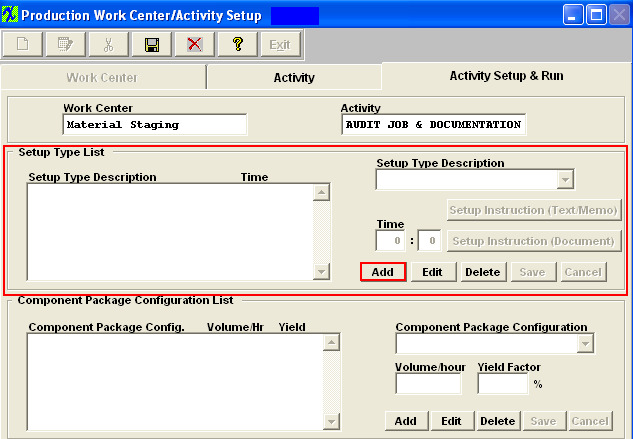

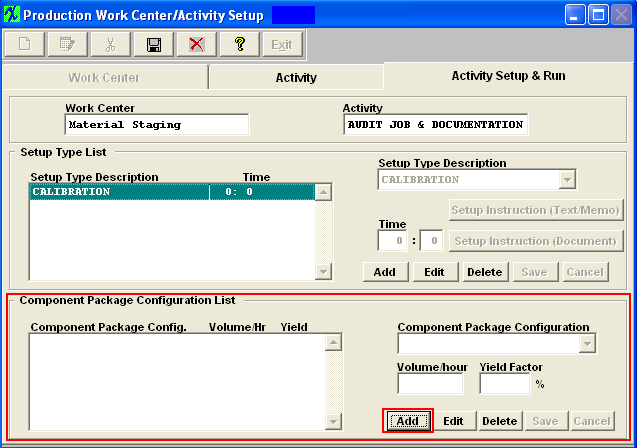

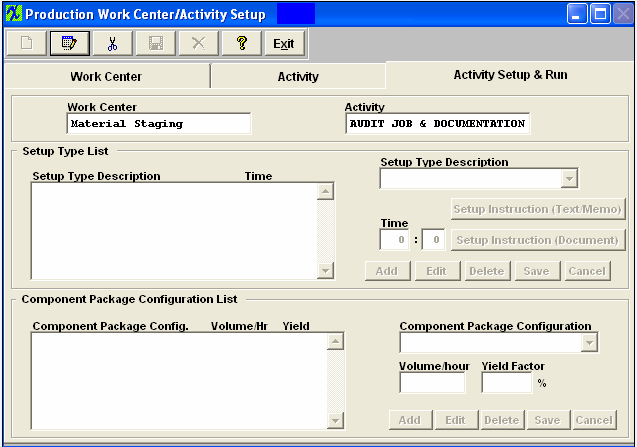

| 1.6.3.3. Activity Setup & Run Tab | ||||||||||||

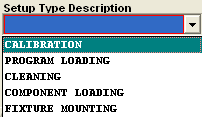

The information set up in this screen will be used in Capacity Planning & Dynamic Scheduling modules. Setup Type List The Setup Type description is input into a previous screen “Activity Costing & Setup Type Setup/Activity Setup Type Description”.

Component Package Configuration List The Component Package Configuration is set up in a prior screen. See Setup Package Configuration.

Note: In order to add Times in Routing, the Run and Setup Time MUST be selected in the Production Schedule Setup module.

Using Run and Setup Times in the Production Schedule Setup module is preferred when there is great variability in the products produced and the setup and run rates in each Work Center.

Using the Run and Setup Times in System Setup under this module, Work Center Setup, is preferred when the product flow is uniform, the machine rates are well established and the setup times very uniform regardless of product. Use of Run and Setup Times in the Production Schedule Setup module is optional unless either Job Costing or Capacity Planning Modules are in use. |

| 1.6.4. How To ..... for Production Work Centers & Activities |

| 1.6.4.1. Setup the Production Work Centers & Activities | ||||||||||||||||||||||||||||||

|

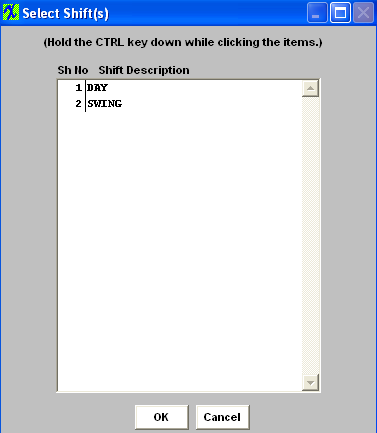

To Assign Work Center to Workstations In this screen, highlight the name of the Work Center. Depress the button at the bottom of the screen "Assign work center to workstations", the following assignment screen appears:  To enter a new assignment, depress the Add button. When setting up a workstation user must enter the Full computer name in the Workstation Name field and the Computer description in the Workstation Description field. See Example below.

Once all changes are complete depress Save or Abandon changes.

Where Used: In all Shop Floor related Activities. «Mark as Completed in RoadMap in Section B Item 3-d» |

| 1.7. Time and Attendance Types |

| 1.7.1. Prerequisites for Time & Attendance Types |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-e" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.7.2. Introduction for Time & Attendance Types |

These types are established to be available during time and attendance tracking in production. Please refer to the Time & Attendance Management module. If the user chooses to track an employee’s time, the time may be associated with attendance or a specific job (Work Order). Attendance is in for the day and out at the end of the day, like a time clock. Job (Work Order) logging is when an employee begins work on a work order (product) or finishes working on a work order. When the employee visits the screen for job (Work Order) logging, they are prompted to define whether they are logging in for attendance, defined as “Time Clock” or job defined as “Job (Work Order) In Or Out”. |

| 1.7.3. Fields & Definitions for Time & Attendance Types | ||||||||||||||||||||||

|

| 1.7.4. How To ..... Time & Attendance Types |

| 1.7.4.1. Setup the Time and Attendance Module | ||

|

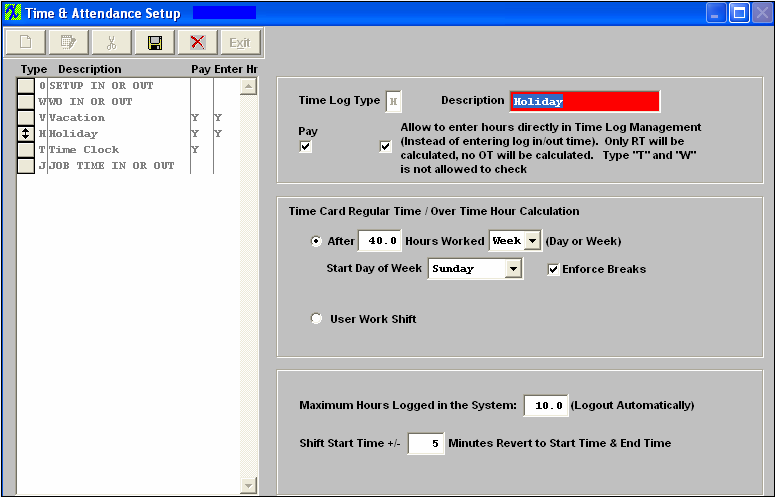

The following screen will appear:

The ADD, EDIT, and DELETE buttons are available. The user adds a type by clicking on the ADD button and entering the type in the entry field box. Time and Attendance Types indicate how the hours are to be collected. (In the future, General Ledger Numbers will be associated with each type listed.) Therefore, each type of job (Work Order) logging will collect charges accordingly. If you check the Pay box, that means the company will pay for that type. For example, an unexcused absence would NOT be checked, but Jury Duty might be checked if it is the company policy to pay for jury duty. "Allow to enter hours directly in Time Log Management" checkbox in T&A setup, if it's checked, the user will be able to enter hours directly in Time used field for that type in the Time Log Management module. Once user adds a new record for a time log type which is allowed to enter hours directly, the time in and time out fields will be blank out and disabled, and user can enter how many hours for that record directly. Otherwise, the user has to enter time in/out.

The system only allows user to enter "RT" no "OT" can be entered. Therefore, user can not check type "W" or "T" to enter hours directly. The system will have to calculate the total log in time and determine what's the RT and OT for type "W" and "T".

The time in and out will also be blank if the type is "H" -- holiday, and the system will use shift to calculate the RT, no OT will be calculated.

Overtime hours are established for determining overtime pay if the timeclock function is used without shift data per person. Hours entered in excess of X hours per day or week would be counted as overtime.

User Work Shift - user will check this radial if they want this as a work shift. Maximum hours logged on in the system is the number of hours which, if a user has remained logged on, the system would automatically log them off, assuming that they left without logging off. Note: ManEx suggests that you populate this field with a number of 1-24. If left empty or with a -0-, the automatic loggout process will NOT run and will NOT logout the user automatically.

This field is restricted to only allow a minimum entry of "0" and a maximum entry of "24". Shift Tolerance allows users to consider a line at the timeclock .If an employee logs in a few minutes early, or late, the system will log them in at the beginning of their shift. Once you have completed all modifications to screen depress the Save or Abandon changes button.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In all job logging functions for a product’s work orders. «Mark as Completed in RoadMap in Section B Item 3-e» |

| 1.8. Shop Floor Tracking Defaults |

| 1.8.1. Prerequisites for SFT Defaults |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-f" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.8.2. Introduction for SFT Defaults |

There are a number of functions within MANEX that the user may establish as default conditions during operations. Each function relating to this setup screen is described in the Fields & Definitions article. |

| 1.8.3. Fields & Definitions for SFT Defaults |

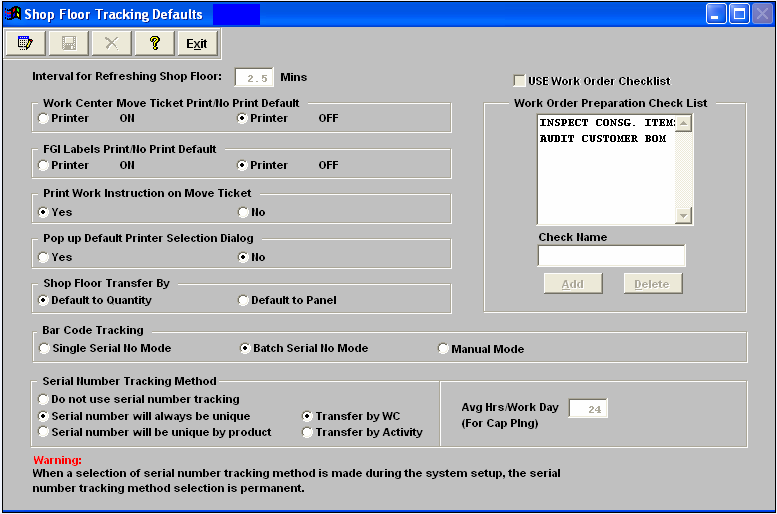

Interval for Refreshing Shop Floor When the user is in the Shop Floor module, and has information displayed on the screen (for example, the wip status of a work order). The user then leaves the screen up and alone to do another task (say breaks for lunch). Then the data represented by the screen may actually undergo changes by other employees. If the user does not use the screen in the meantime, when they return from their alternate task, the information on the screen would be incorrect (because someone else moved material). ManEx performs a periodic update (refresh) to Shop Floor screens when the user has information displayed on the screen, but has not performed any functions in the meantime. The period of the refresh rate is initially set to every two and a half minutes by ManEx. So, if the user has a work order tracking screen displayed with a work order showing wip, and does not perform any transaction for 2-1/2 minutes, ManEx will automatically update the information on the screen. This timing is initially set at 2-1/2 minutes, but the user may change this period in this setup. However, the trade-off for shorter periods is increased network traffic, and setting too many workstations to be refreshed every few seconds will seriously impact the server’s ability to deliver data. Use Work Order Check List User MUST check this box to activate the Unreleased Work Order List module. Work Order Preparation Check List If user has selected to use the "Work Order Check List" they must create a Work Order Preparation Check List. These items will be defaulted into the Work Order Release Check List (within the Work Order Traveler Setup module). Then they will be able to create a checklist for a product (within the Work Order Traveler Setup module), selecting one or more from this table, and it/they will be used to record that an action was taken for the work order, by whom and when it occurred within the Unreleased Work Order List module. Examples of check lists might be: Verify product revision, perform tooling setup, complete first article, deburring, or any other critical function for which the user wishes to have a verifiable record of being accomplished. The description of the checklist item may be up to 20 characters in length. Note: In order to complete the Unreleased Work Order List user MUST also have the Product Data Management (PDM) optional module. Work Whenever a product is moved from one work center to another, the user has the option to print a move ticket (like a traveler) for each transaction. This move ticket may be printed and accompany the material to the next work center, identifying the work order, product date, work center, etc. The user may choose to turn this feature off by selecting the “Printer OFF” button in the setup. If the printer is turned on (“Printer ON”), then a sheet with the details will be printed for every product movement. FGI Label Printing Defaults Whenever a product is moved from one work center to the Print Work Instructions on Move Tickets If the user chooses to print move tickets, then they may also choose whether or not work instructions and work order notes are included in the printing.

Pop up Default Printer Selection Dialog

If the user wishes to move material by the panel, sheet or roll, they may select “Default to PANEL” as the method of tracking quantities. This requires the user to define in the product definition the number of products contained in a panel/sheet/roll. Then, if this method is chosen, the user moves panels and ManEx keeps track of the number of units. If the user chooses to identify material movement by quantity of product, then the “Default to Quantity” button should be selected. If the user is tracking serial numbers through the production process, and is using the ManEx bar code tracking module, then they have the option of defining a default method for picking up the bar-coded serial numbers. One option is to scan one serial number at a time, and collect those serial numbers for processing a transaction. Another option is to enter the beginning and ending serial number of a series of serial numbers and allow ManEx to fill in all of the serial numbers in between for processing a transaction. The third option is for the user to manually enter the quantity of boards to be moved. If the boards are serialized, then a list of serial numbers is presented to the user from which to select the serial numbers being moved with the quantity of parts. The user has the option to change any of these defaults at the time of entry. Please refer to the Shop Floor Tracking Management manual. The ManEx Manufacturing System Software has bar code scan and print capability which is designed primarily for transfer of products in Shop Floor Tracking and input of inspection data by serial number and defect code. Installation: Bar Code Shop Floor Tracking is an OPTIONAL module; it is NOT a part of the Core ManEx MES modules. · Upon purchase of this module, ManEx will send a soft-key to activate the module · After activation, Bar Coding access for each user must be setup in the ManEx Security module. Users with “Supervisor’s Rights” will automatically have access.

· Each client workstation (individual PC) which will be printing Reports, Travelers, Labels, Serial Tags, Physical Inventory Tags and Defect Lists with Bar Coding must have the font installed as an active Windows font.

· If Bar Coding of Serial Numbers is desired, the Serial Number tracking must be setup in Shop Floor Tracking Defaults . Specification: · ManEx uses the Microsoft Truetype BC C39 Narrow Font. See Article #1225 for the installation procedure. · Use of a Y-Type keyboard-emulation scanner is supported by ManEx. The scanner output goes into ManEx via the keyboard-input cable. Bar code fields may be scanned or manually entered with the scanner installed. · Most scanners require ¼” of white space surrounding the bar code. Laser and inkjet printed labels must have adequate resolution, contrast and clarity to print barcodes that are readable. · ManEx recognizes a bar code by an asterisk (*) at the beginning and end of the bar coded field. Serial Number Tracking Method At the beginning of a ManEx implementation, the user must decide a method for tracking Serial Numbers. THIS DECISION, ONCE STARTED, IS IRREVOCABLE. The decision to be made is:

1, Do NOT use Serial Number tracking. If this box is checked users will NOT be allowed to check the serialized box within the ICM module, and they will receive a warning message. 2, Serial Number will always be unique. This will insure that a serial number is unique throughout the company; (meaning once used, can NEVER be used again, no matter what product). 3, Serial Number will be unique by Product. This will allow duplicate serial numbers to be used throughout the company, but they must be unique for a given product, (can be used for other products, but never again for the same product). If Serial Numbers are NOT to be used, then the option will NOT appear when creating new part numbers within the ICM module. If Serial Numbers ARE used, then the user will have the option when creating parts within the ICM module to either serialize the part or leave it unserialized. If Serial Numbers are used on a part, then the user MUST enter Serial Numbers in order to move product through the SFT for shipment. The user will also need to define whether Serial Numbers are to be transferred by Work Center or by Activity within a Work Center. For further detail on why the system enforces the uniqueness per Product rule and will not base the uniqueness on SN that exist in the Qty at that time see Article #2495.

Avg Hrs/Work Day (For Cap Plng)

The system assigns the Average Hrs/Work Day as 24 hours. This field is for reference only.

|

| 1.8.4. How To ..... SFT Defaults |

| 1.8.4.1. Setup the Shop Floor Tracking Defaults | ||

The following screen will appear:

The user may edit any of the defaults by clicking on the Edit button and selecting the default to be changed. Check List items may be added by clicking on the Add button and entering the description of the item to be listed.

Use Work Order Check List User MUST check this box to activate the Unreleased Work Order List module. Work Order Preparation Check List If user has selected to use the "Work Order Check List" they must create a Work Order Preparation Check List. These items will be defaulted into the Work Order Release Check List (within the Work Order Traveler Setup module). Then they will be able to create a checklist for a product (within the Work Order Traveler Setup module), selecting one or more from this table, and it/they will be used to record that an action was taken for the work order, by whom and when it occurred within the Unreleased Work Order List module. Examples of check lists might be: Verify product revision, perform tooling setup, complete first article, deburring, or any other critical function for which the user wishes to have a verifiable record of being accomplished. The description of the checklist item may be up to 20 characters in length. Note: In order to complete the Unreleased Work Order List user MUST also have the Product Data Management (PDM) optional module. Serial Number Tracking Method can NOT be changed once a selection has been made at the beginning of a ManEx implementation. THIS DECISION, ONCE STARTED, IS IRREVOCABLE. The decision to be made is:

1, Do NOT use Serial Number tracking. If this box is checked users will NOT be allowed to check the serialized box within the ICM module, and they will receive a warning message. 2, Serial Number will always be unique. This will insure that a serial number is unique throughout the company; (meaning once used, can NEVER be used again, no matter what product). 3, Serial Number will be unique by Product. This will allow duplicate serial numbers to be used throughout the company, but they must be unique for a given product, (can be used for other products, but never again for the same product). If Serial Numbers are NOT to be used, then the option will NOT appear when creating new part numbers within the ICM module. If Serial Numbers ARE used, then the user will have the option when creating parts within the ICM module to either serialize the part or leave it unserialized. If Serial Numbers are used on a part, then the user MUST enter Serial Numbers in order to move product through the SFT for shipment. The user will also need to define whether Serial Numbers are to be transferred by Work Center or by Activity within a Work Center. For further detail on why the system enforces the uniqueness per Product rule and will not base the uniqueness on SN that exist in the Qty at that time see Article #2495.

When the user has completed the changes they must press the Save or Abandon button, before exiting. Where Used: In all shop floor functions for a product’s work orders.

Mark as Completed in RoadMap Section B Item 3 |

| 1.9. Production Scheduling Method |

| 1.9.1. Prerequisites for Production Scheduling Method |

|

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.9.2. Introduction for Production Scheduling Method |

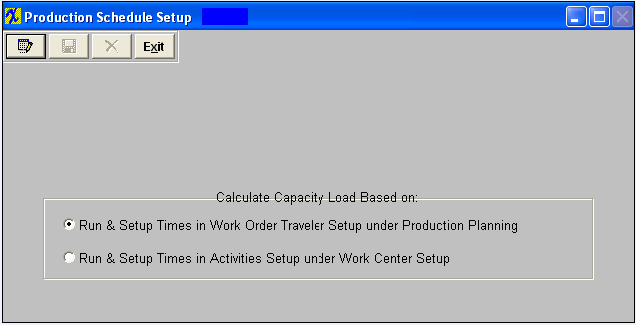

In this setup, the user defines the method to be used by ManEx to determine the capacities and scheduling in the Capacity Planning module. |

| 1.9.3. Fields & Definitions for Production Scheduling Method |

The default, “Run & Setup Time” will calculate the resources and costs associated with those entered in the work center setups and activities for the product. The costs will be based on the work center rates, and the capacity on the product routing information. The Activities Drivers option may be used in conjunction with the Job Planning module, and will calculate the costs and durations based on parameters entered by the users in the planning module.Normally, the Run & Setup time option is used.However, once the system has an active capacity planning module in place, the user may use Activities Drivers to schedule priorities in the Dynamic Scheduling Module. No change is required in this setup unless the user is going to make extensive use of the job planning module. Note: In order to add Times in Routing, the Run and Setup Time MUST be selected in this module. |

| 1.9.4. How To ..... for Production Scheduling Method |

| 1.9.4.1. Setup Production Scheduling Method | ||

|

The following screen will appear:

The user may click on the Edit button to change the defaults. The user must Save or Abandon changes after entering the Edit Mode. Where Used: In all shop floor functions defining labor costs, and for Capacity Planning Modules. «Mark as Completed in RoadMap in Section B Item 3-g» |

| 1.10. Quality Defect Codes |

| 1.10.1. Prerequisites for Quality Defect Codes |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-h" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.10.2. Introduction for Quality Defect Codes |

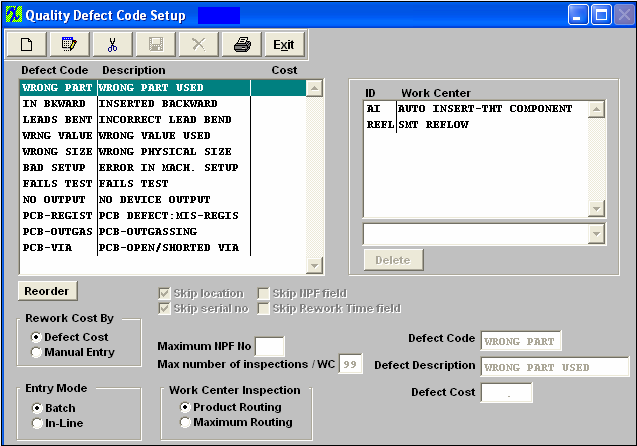

In Shop Floor Tracking, the ability to record the results of quality inspections is available to the user. These records usually contain information about the lot or work order being inspected, the quantity of parts viewed, the quantity of parts rejected and the number and types of defects observed in the process. In the ManEx Quality Defect Setup, the user has the opportunity to define these defects, and to shape the manner in which they are used. |

| 1.10.3. Fields & Definitions for Quality Defect Codes |

Entry Mode: The results of inspection may be entered in ManEx in two basic ways: 1, in Batch Mode; and 2, using In-Line processing. Batch mode allows the user to perform the inspection on a batch or lot of materials, and enter the observations at a later time. In this mode, the user does not automatically forward the product to the next workstation, but merely inspects it and allows production personnel to move the material. Using the In-Line mode is like inserting an inspection step at the end of a work center, viewing the parts one at a time, and passing or failing the part. If the part passes, it is moved by ManEx to the next work center, and the user has only to physically move the parts to the next workstation. The ManEx WIP tracking automatically moves the part to the next work center. Parts which fail the inspection may stay in their current work center, be moved to another (rework) work center, or passed on to the following work center, at the option and discretion of the operator. Most users prefer to use the batch processing, which accommodates sampling procedures, instead of In-Line processing, which always requires 100% inspection. In this setup area, the user selects the default condition for defining the method of data entry.

Rework Cost By: The Cost of Quality may be determined in one of two possible ways: 1, by defining a specific cost to each defect code; and 2, by manual entry of the actual rework time as determined by the inspector during inspection. In this setup area, the user selects whether to track the costs by Defect Cost (assigned to each defect code), or Manually (by entering the rework time as defects are determined). Defect Code: During the defect logging and entry process, the user will be presented with a list of defects from which to choose the defect observed. These defects codes and descriptions are entered and defined in this setup. The code is a ten-digit character field that will be used to identify the defects on charts, graphs and data collected and printed. The user may enter as many defect codes as needed.

While the user may enter the defect codes in any order they wish, the defect codes may be rearranged so that the most used codes are at the top of the list. This becomes a time-saver when actually entering defects on a lot, as the defect codes are presented in the same order as ordered in the setup. This is done after defect code entry by clicking on the REORDER button just below the defect codes. After pressing this button, the screen will place a small button in front of each defect code. The user may then use the windows drag & drop method to click on a button, hold the mouse button down and drag the code to the order desired. When satisfied that the most used defect codes are at the top of the list, click on the DONE button to secure the order. Alternatively, the user may wish to enter in alphabetical order to ease searches if there are no predominant defects.

Also, to aid the inspector in selecting a defect code, the user may associate a given defect code with one or more work centers. The user selects from the established work centers to include as many work centers for a specific defect as desired. Work centers may also be deleted from a defect code, if the user wishes.

In this manner, the inspector will have a smaller list of defects to select from, but which would include all of the defects for the work center in which the inspection is being performed. The ability to see just defects associated with a specific work order is determined in this setup. Defect Description: The description is a 20-character field that helps the user further define the code. Defect Cost: The cost is defined by numeric field formatted as 999.99, and represents the cost of each occurrence of a defect. Work Center Inspection: The user has the option of viewing defects based on the product routing (Product Routing), or to view all defects (Maximum Routing). The Maximum Routing will show ALL defect codes in inspection, the Product Routing will only display those that have been related to a work center in which the inspection is taking place. However, the user can still opt to see the max (ALL) defects within the Defect Entry screen. Skip Location: Associated with the Defect Entry screens are subsets of information relating to the defects observed. Some of these subsets may be very useful to analyze defects causes and origination. If the user completes the Reference Designators in the Bills of Materials, then entering the reference designation for each defect may provide directions for investigation of repeated failures on an assembly. ManEx provides the capability to track the defects to locations, but if the user opts not to enter location information, then they may set the default condition of the screen to exclude location information. Checking the “Skip Location” box on the setup screen does this.

Skip serial no: If the user is not using serial number tracking for defect data collection, this too may be omitted by checking the “Skip Serial No” box on the setup screen. Skip NPF field: The Skip NPF field “no problems found” will cause the Defect Entry screen to by-pass this information. The Maximum NPF No box, no problems found, is provided for the user to record when observing the product. If, in the Defect Entry screen, the serial number had previously been rejected, and analysis of the product yield no further problem, either with cosmetics or function, then the user may change this number to 1, meaning the first time it was inspected or tested, no problem was found. If the product serial number is subsequently rejected again, and a second inspection finds a problem, the number may be incremented to a “2”. This will alert users to repeated rejections of a product serial number, one or more times with no discernable defects. If the number of times that a part has experienced an NPF (no problems found) exceeds that established here in the system setup, the user will not be allowed to go further. “Maximum number of inspections/WC” Box: This field is for serial number use only. The user may define how many times a given serial number can pass through a given |

| 1.10.4. How To ..... for Quality Defect Codes |

| 1.10.4.1. Setup Quality Defect Codes Module | ||||

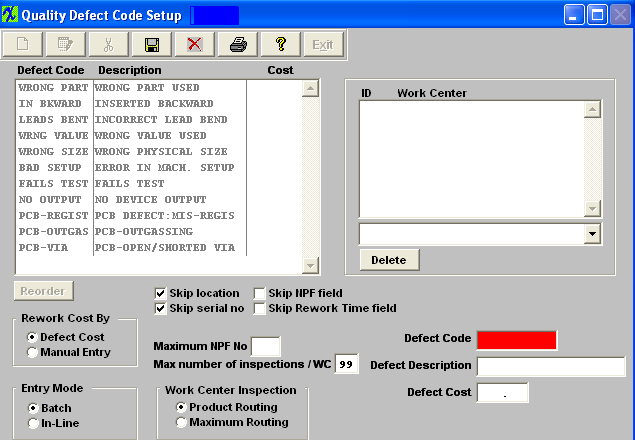

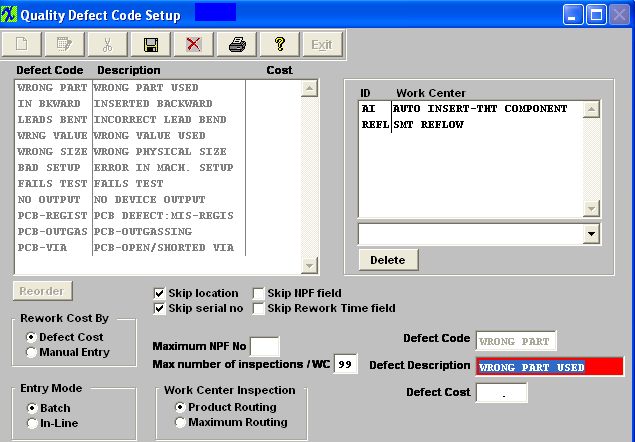

The following screen will appear:

The user initiates a new defect code by clicking on the Add button. Note: When creating a new Defect Code you will want the Defect Code descriptive as possible because this is what appears in the Pareto Chart in the SQC module information. NOTE: The "Defect Code" field is NOT editable once it has been saved.

Enter in the maximum NPF number. Type in the desired number of times for Maximum number of inspections /WC.T his field is for serial number use only. If the user selects the “Skip Serial Number” field, this max number will be come invisible. In the Shop Floor Tracking module, Inspections section, once the pass number of a serial number exceeds the max number as set up here, a supervisor or special rights password is needed to continue.

Items may be re-sorted by clicking on the REORDER button, click on and drag the box of the left side of the defect desired to the (vertical) position desired. When completed with the order, click on the DONE button to return to the edit screen, and Save to record the changes. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Depress the Edit button and work centers assigned to or deleted from the defect code. All fields are editable except for the "Defect Code" field.

When all changes have been completed, the user must Save or Abandon changes.

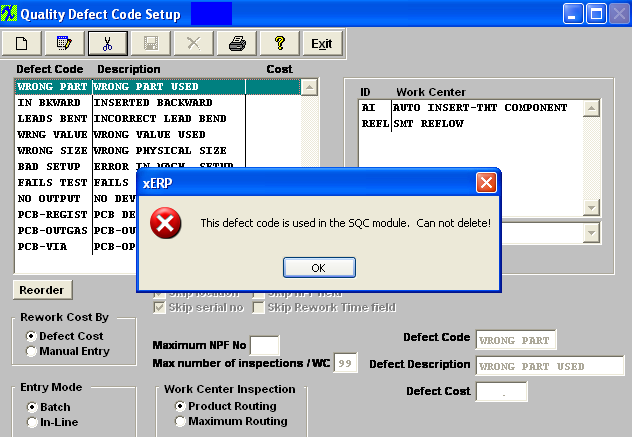

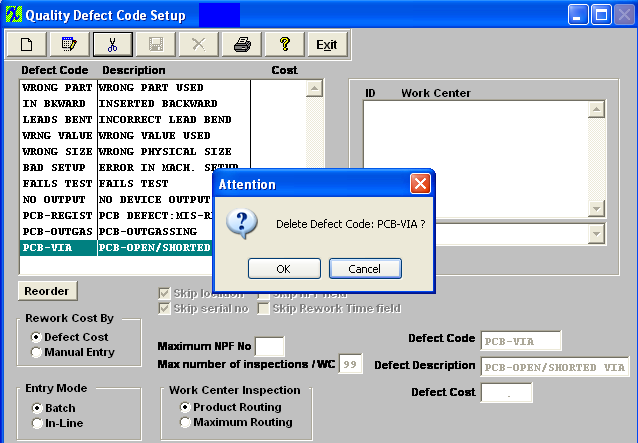

User may ONLY delete a Defect Code if it has not been used in the SQC module. This info needs to be retained for history/reporting purposes. If the defect code has been used in the SQC module user will receive the following warning when trying to delete the defect code.  If defect code has NOT been used in the SQC module the defect code may be deleted. User will receive the following confirmation to be sure they want to delete the Defect Code.

Depress OK to continue or Cancel to abandon the deletion.

Where Used: In all Statistical Quality Control tracking operations and reporting. «Mark as Completed in RoadMap in Section B Item 3-h» |

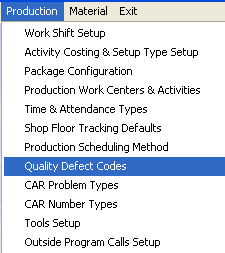

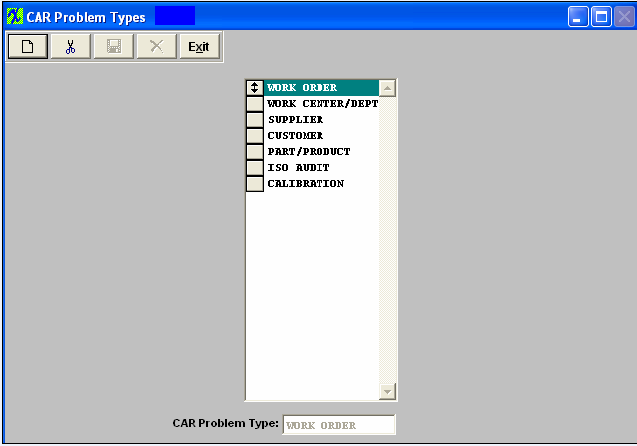

| 1.11. Corrective Action Reporting Problem Types |

| 1.11.1. Prerequisites for CAR Problem Types |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-i" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.11.2. Introduction for CAR Problem Types |

If the user is utilizing the CAR (Corrective Action Reporting) module, then the types of corrective actions may be grouped into specific categories in relation to the nature of the problems. For example, one problem type might be Customer Originated corrective actions. Another might be actions required of a Supplier. Another might be directed toward Engineering or Quality departments, or any company function. Another consideration may be to organize the problem types by the target of the action, like a work order or process.

|

| 1.11.3. Fields & Definitions for CAR Problem Types |

If the user is utilizing the CAR (Corrective Action Reporting) module, then the types of corrective actions may be grouped into specific categories in relation to the nature of the problems. For example, one problem type might be Customer Originated corrective actions. Another might be actions required of a Supplier. Another might be directed toward Engineering or Quality departments, or any company function. Another consideration may be to organize the problem types by the target of the action, like a work order or process.

Once these problem types are defined, they may be placed in order by clicking on and dragging the box to the left of the type to the (vertical) position desired.

|

| 1.11.4. How To ..... for CAR Problem Types |

| 1.11.4.1. Setup the CAR Problem Types Module | ||

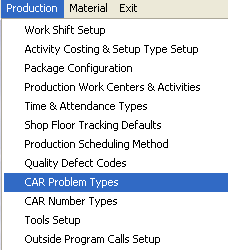

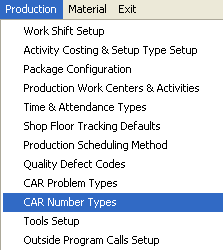

The following screen will appear:

To Add CAR Problem types, depress the Add button, and enter the type in the text box at the bottom of the list. These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In all Corrective Action activities. «Mark as Completed in RoadMap in Section B Item 3-i» |

| 1.12. Corrective Action Reporting Number Types |

| 1.12.1. Prerequisites for CAR Number Types |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-j" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.12.2. Introduction for CAR Number Types |

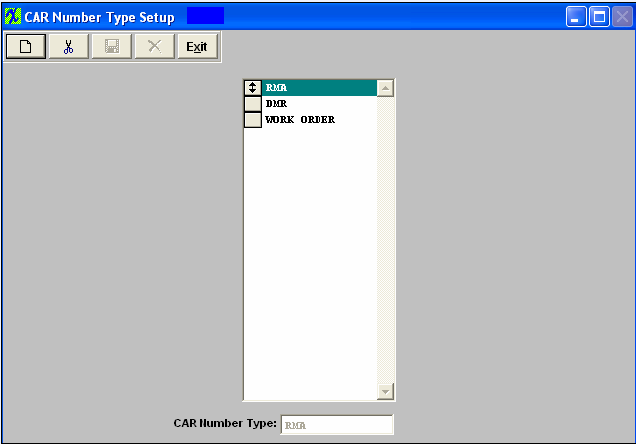

| This Corrective Action Reporting number type refers to the number of the document that resulted in the corrective action. While the Corrective Action Reporting itself has a number assigned to it, there is usually another document that originates the corrective action. This document may be an RMA (Returned Material Authorization) report from the customer (e.g. RMA # 0112), and the Corrective Action Reporting Number type would be “RMA Number”. The source document may be a DMR (Discrepant Material Return) originated by production inspection or incoming inspection. The Corrective Action Reporting number type would be “DMR Number” to describe the number identified in the Corrective Action Reporting report. The number type is used solely to identify the source of the numbered document referred to in the Corrective Action Reporting. |

| 1.12.3. Fields & Definitions for CAR Number Types |

This Corrective Action Reporting number type refers to the number of the document that resulted in the corrective action. While the Corrective Action Reporting itself has a number assigned to it, there is usually another document that originates the corrective action. This document may be an RMA (Returned Material Authorization) report from the customer (e.g. RMA # 0112), and the Corrective Action Reporting Number type would be “RMA Number”. The source document may be a DMR (Discrepant Material Return) originated by production inspection or incoming inspection. The Corrective Action Reporting number type would be “DMR Number” to describe the number identified in the Corrective Action Reporting report. The number type is used solely to identify the source of the numbered document referred to in the Corrective Action Reporting. |

| 1.12.4. How To ..... for CAR Number Types |

| 1.12.4.1. Setup CAR Number Types Module | ||

The following screen will appear:

To add CAR Number types, depress the Add button, and enter the type in the text box at the bottom of the list. The user must Save or Abandon changes.

These items may be sorted in any order by clicking on and dragging the box on the left side, to the (vertical) position desired. This order will be the order displayed in the pull downs when using this list in other modules within the system. Suggestion: Have the one most used at the top of the list. Where Used: In all Corrective Action activities. «Mark as Completed in RoadMap in Section B Item 3-j» |

| 1.13. Tools Setup |

| 1.13.1. Prerequisites for Tools Setup |

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-k" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.13.2. Introduction for Tools Setup |

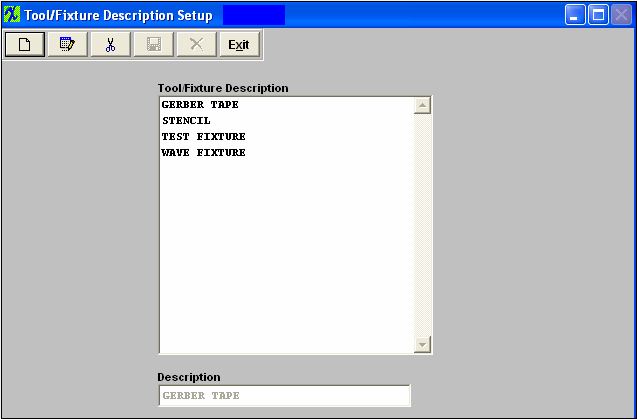

These are the descriptions to be used in the Tools/Fixtures section of the Customer Quote Module.

It’s for non recurring charges relating to tools or fixtures, etc. purchased for a particular make assembly. |

| 1.13.3. Fields & Definitions for Tools Setup |

These are the descriptions to be selected from in the NRE (Non-Recurring Charges relating to Tools and/or Fixtures) section of the Customer Quote module.

|

| 1.13.4. How To ..... for Tools Setup |

| 1.13.4.1. Setup Tools Setup Module | ||

The following screen will appear:

To Add, depress the Add button. Type in the description.

To Edit, depress the Edit button. Highlight the description to be edited. Make any changes. To Delete, depress the Delete button. Highlight the item you want to delete.

Where Used: Customer Quote module.

«Mark as Completed in RoadMap in Section B Item 3-k»

|

| 1.14. Outside Program Calls Setup |

| 1.14.1. Prerequisites for Outside Program Calls Setup |

|

Complete the attached worksheet and "Mark as Completed RoadMap Section B Item 3-l" before continuing the setup.

User MUST have full rights to the "System Setup" in System Security to setup these modules. User with "Supervisor Rights" will automatically have access.

|

| 1.14.2. Introduction for Outside Program Calls Setup |

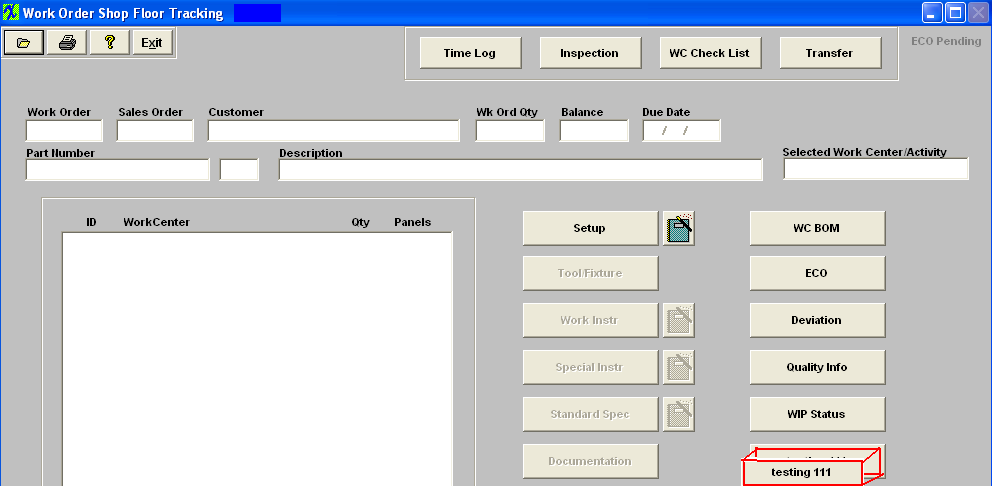

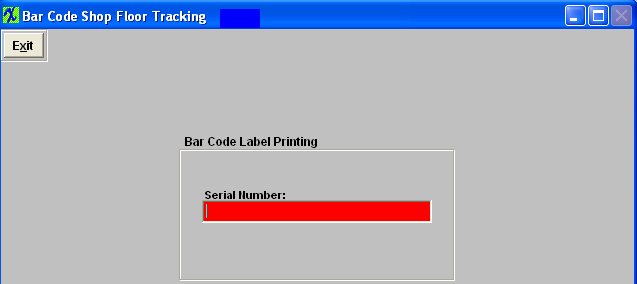

User can enter a program within this screen which is used to create a button that will appear in the Shop Floor Tracking module. In Shop Floor Tracking, when user depresses this button, they will need to enter a serial number, the program will then gather all the part number, work order information into a text file, and the user defined program will use the text file to print the label.

|

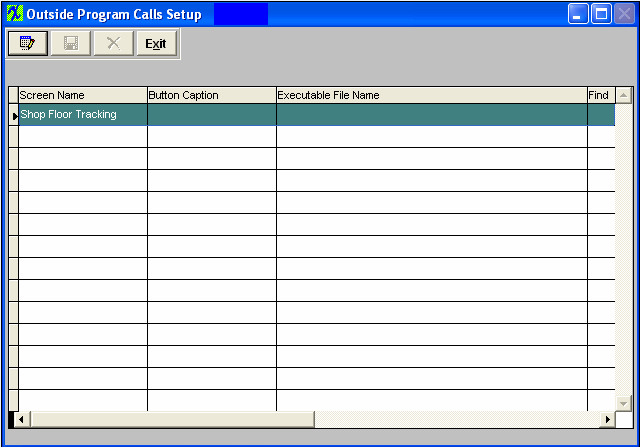

| 1.14.3. Fields & Definitions for Outside Program Calls Setup |

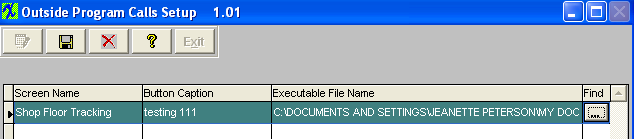

This screen is used to create a button which will appear in the Shop Floor Tracking module. The button will direct the program to a user written program which is used to print labels for serialization.

The system automatically enters the screen name as Shop Floor Tracking. Then the user types in the Button Caption and the name and path of the executable file. |

| 1.14.4. How To ..... for Outside Program Calls Setup |

| 1.14.4.1. Setup the Outside Program Calls Setup Module | ||

The following screen will appear:

The system automatically enters the screen name as Shop Floor Tracking. Depress the Edit button to enter in the caption you want to appear in the Shop Floor Tracking module, then enter in the executable file name.

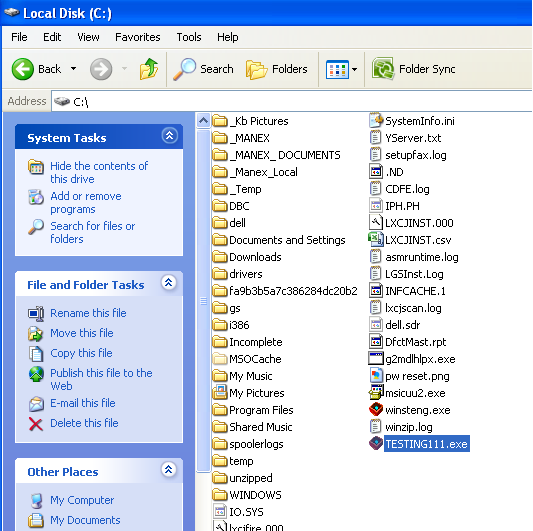

If you don’t know the executable file name, double click on the Find column. The browse window will appear:

If the user Saves the changes. A button will be created in Shop Floor Tracking with the Button Caption name entered in the Setup screen:

When user depresses this button, the following screen will appear and they will need to enter a serial number, the program will then gather all the part number, work order information into a text file, and the user defined program will use the text file to print the label.  Where Used: Shop Floor Tracking module.

«Mark as Completed in RoadMap in Section B Item 3-l»

|