|

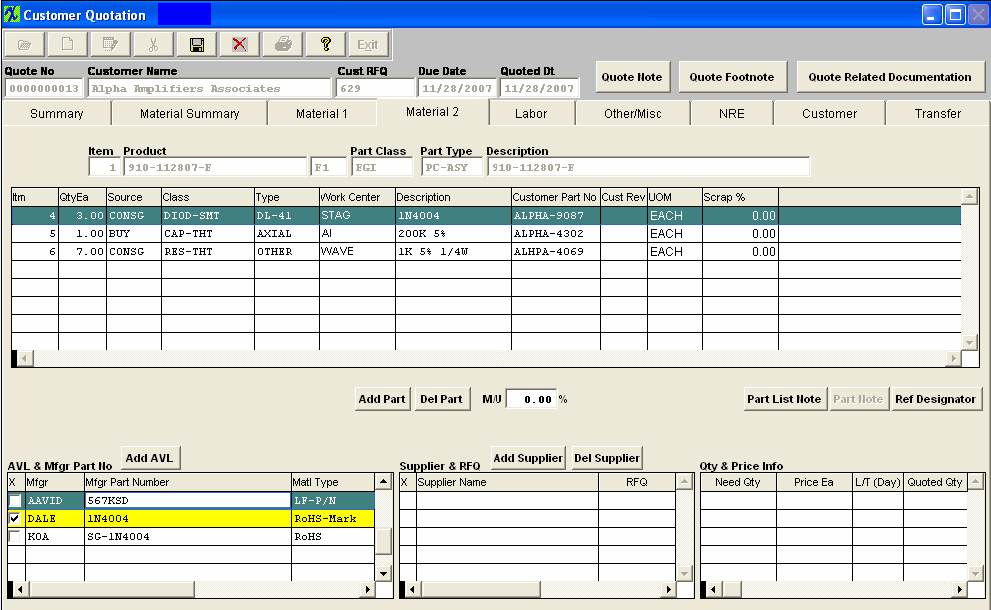

The material 2 tab displays the details of components which are NOT identified in the Inventory Control Item Master. For each line item, the quantity, source, class, type, description, customer part number, customer revision number, unit of measure, and scrap % is displayed. Additionally displayed is the approved manufacturer and the manufacturer’s part number. It also displays the supplier for that component and the request for quote number as assigned in the Component Quote Management module. The need quantity, price each, lead time, quoted quantity, order multiple, minimum order and the price source are also displayed. This information forwards into the Material Summary tab. NOTE: When the parts from Material 2 screen are transferred from quote to BOM, inventory item master part numbers are created for each item. The system does NOT search the inventory item tables for an existing part number and will create new item master part numbers, even if the manufacturers and part numbers are the same.

NOTE: If "AUTO" numbering is selected in the Number System screen for Inventory parts, the system will assign the next part number in sequence (with no revision). If "MANUAL" numbering is selected in the Number System screen for Inventory parts, the Material 2 screen will display three additional fields shown below in Red box: ManEx suggests using the manual numbering if user would like to assign a revision to the internal part numbers.

Material 2 tab field definitions

| Item |

The line number.

|

| Product Number |

The unique number assigned to the product |

| (Rev) |

The revision number assigned to the product.

|

| Class |

The classification of the product.

|

| Type |

The type within the classification pertaining to this product |

| Description |

The description of the product.

|

| Customer Part No |

This is the number which the customer has assigned to the component.

|

| Rev |

This is the revision number which pertains to the Customer Part number.

|

| UOM |

The unit of measure which is used for this component.

|

| Scrap % |

This amount is added to the exact quantity used on an assembly to provide an overage to cover losses during running due to predictable machine and human losses.

|

| Apply Min Order |

This is smallest number of the item that can be ordered from the vendor in one PO.For instance, Surface Mount components on a reel usually have a minimum order of 1000 items or more. This field will only be enabled if the Number System is set to "Manual" for Inventory Parts.

|

| Internal Part Number |

Manually assign an internal part number to the item. This field will only be enabled if the Number System is set to "Manual" for Invventory Parts. |

| Rev |

Manually assign a revision to the item. This field will only be enabled if the Number System is set to "Manual" for Invventory Parts |

|

This button is used to add an item to the list of components needed for the assembly.

|

|

This button is used to delete an item from the list of components needed for the assembly.

|

|

This field displays the mark up percentage which the user will be charging their customer. |

|

This button will be displayed in RED when Part List Notes exist. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when notes exist pertaining to the highlighted part. Depressing this button will allow the user to view these notes.

|

|

This button will be displayed in RED when reference designators exist pertaining to the highlighted part. Depressing this button will allow the user to view the reference designators.

|

|

AVL stands for (Approved Vendor List).This button is used to add an approved manufacturer.

|

|

This button is used to delete an approved manufacturer. |

|

This button is used to add a supplier.

|

|

This button is used to delete a supplier.

|

For the Line Item highlighted:

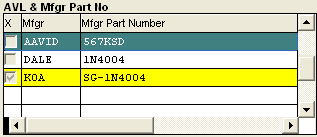

AVL & Mfgr Part No section

X -A check in this box is NOT for the approval of AVL's. When transfering quote there is an option located on the "Transfer Tab" to select to transfer "ALL AVL's" or "Only the selected AVL's". If user chooses to transfer "Only the Selected AVL's", this box MUST be checked, if this is one of the selected AVL's you want transfered to inventory and/or BOM. If user chooses to transfer All AVL's then this box does NOT need to be checked. When a quote is transfered All AVL's transfered will be checked as Approved.

Mfgr - This is the name of the manufacturer assigned to the component.

Mfgr Part Number - This is the number which the manufacturer has assigned to the component.

|

|

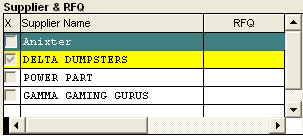

Supplier & RFQ section

|

X – a check in this box denotes that the supplier has been selected.

Supplier Name – The name of the supplier.

RFQ – This is the Request for Quotation number as assigned in the Component Quote Management portion of Customer Quotations.

|

|

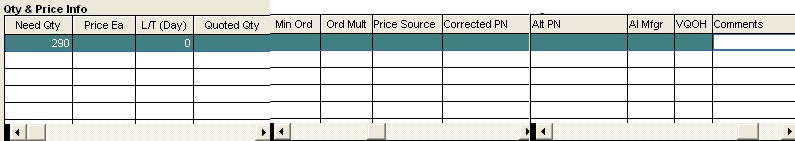

| Need Qty |

The amount required for the quantity represented. |

| Price Ea |

The dollar amount which the Supplier charges the user. |

| L/T |

The lead time will use part class/type setup default leadtime to calculate and is displayed in the number of days between placement of the order and receipt. |

| Quoted Qty |

The number of units quoted by the supplier. |

| Min Ord |

The supplier’s requirement for the minimum quantity per order.

|

| Order Multiple |

This field defines the even multiples of the Unit of Measure in which an item must be purchased.For example, 16AWG Wire might be only available in even hundreds of feet on a spool. |

| Price Source |

The source of the pricing such as Manual, a Request for Quote, etc.

|

| Corrected PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Alt PN |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| AI Mfgr |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| VQOH |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

| Comments |

This field is for reference only. This information is NOT forwarded to any other fields within the system. |

|