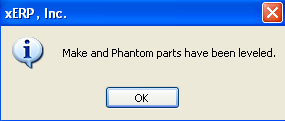

The Level Make Parts button causes the system to find all Indented Bills of Materials. Then the system “tags” the lowest indenture. Users will NOT be able to add or edit any BOM during this process. If a user is already in the process of modifying a BOM and this process is started the user will NOT be allowed to save the changes until the leveling process is complete.

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

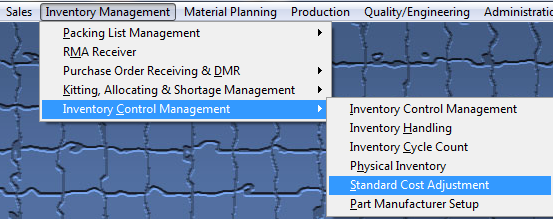

The following screen will be displayed, select Inventory Management/Inventory Control Management/Standard Cost Adjustment

|

|

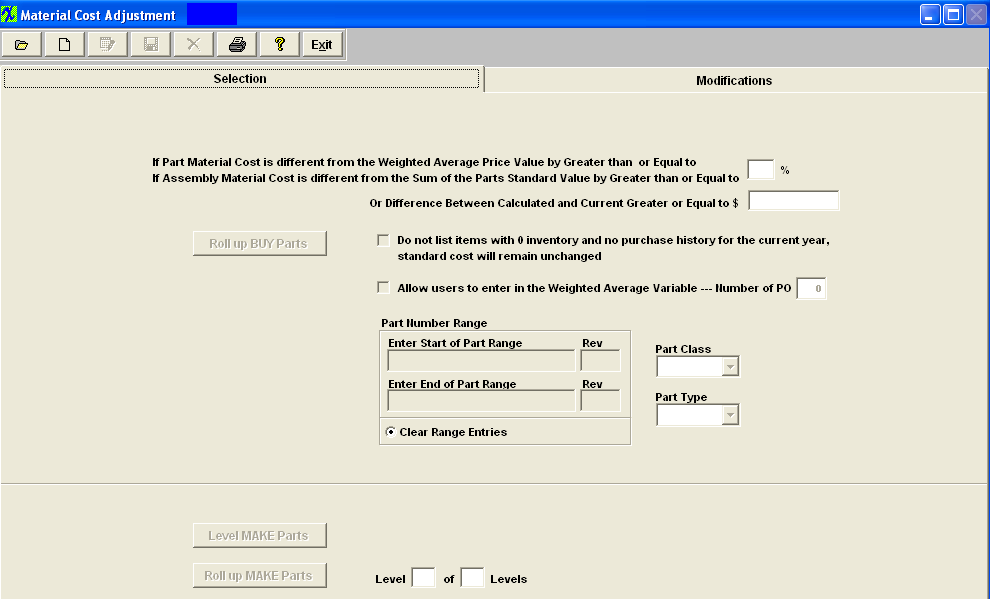

The following screen will be displayed:

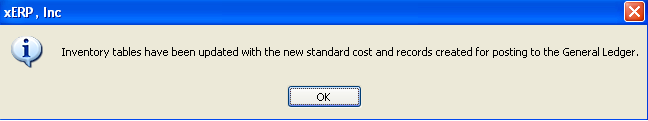

Depress the Add Record (Start New Cost Roll) action button, enter password, then depress the Level MAKE Parts button. The following message will appear once the update has been completed.

Depress the OK Button. The following screen will be displayed:

The Level of Levels information automatically updated to the next level that needs to be Rolled up.

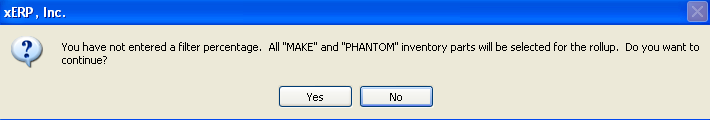

Then depress the Roll up Make Part button. The following message will be displayed:

Depress "Yes" to continue. If a rollup already exists the following option screen will be displayed:

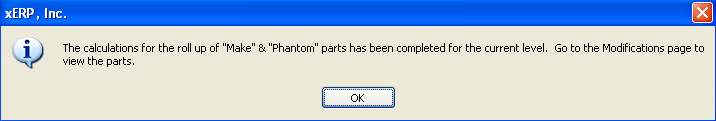

Depress "Yes" to continue. The following message will be displayed:

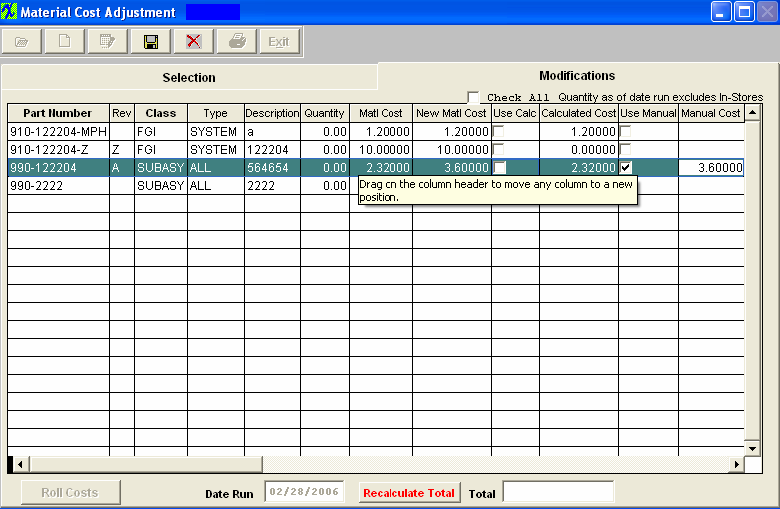

Enter into the Modification screen, only the Level 1 of 2 Levels assemblies will be displayed (sub-assemblies, etc). Depress the Edit Record action button and select the Use Calculated or Use manual to make any changes. If Use Manual is selected then you have to enter in the Manual Cost.

Save the changes and depress the “Roll Costs” button. The following message will be displayed:

Depress the OK Button, then return to the Selection screen.

The Level of Levels information automatically updated to the next level that needs to be Rolled up.

Depress the Add Record (Start New Cost Roll) action button, enter password, then depress the Roll up MAKE Parts button to roll up Level 2 of 2 Levels. Continue this process to level all indents starting with the lowest to the highest.

Once the highest level has been reached the Modufications screen will be poplulated with all the Finished Goods Inevntory parts.

a) For the PHANTOM parts the standard cost calculated is based on their components (SUM of component's qty * component standard cost). Once the standard cost is calculated for the PHANTOM part, the cost roll up will treat the PHANTOM part as a single entity on the top assembly BOM and proceed as it was a BUY part with the std cost already entered.

b) If one of the component parts on the top level is a MAKE (not MAKE_BUY) and HAVE components assigned to it, the cost roll up will NOT include the std cost of the parts itself, it will only include the std cost of its subcomponents.

c) If one of the component parts on the top level is a MAKE (not MAKE_BUY) and does NOT HAVE parts assigned to it the cost roll up will include the std cost of the part itself.

d) If one of the component parts on the top level is a MAKE and MAKE_BUY the cost roll up will included the std price for the part itself and will NOT include the std costs for the subcomponents. For an example see the Word attachment <<The Std Cost of the MAKE_BUY_081211.docx>>).

e) If one of the component parts on the top level is a MAKE and a Phantom/Make the cost roll up will NOT include the std price for this part because the cost roll up will include the cost of this parts components.

Note: The calculated cost will only include the costs for ACTIVE parts and subassemblies as of the date of the roll up and will NOT include any parts that may have been identified as inactive either in the item master or in the obsolete date of the part on the BOM.

The values displayed should be in sync with the BOM with Std Cost Report values. The following may be why the Standard Cost Roll is different from the Cost BOM Reports.

a) On the costed BOM Report for a Make/Buy assembly we display the value of the BOM in the costed report, but that total is NOT used in subsequent rollups to higher levels only the standard cost is.

b) In Kit Default Setup , user can exclude scrap and setup scrap in Kitting, MRP, and Cost Rollup, this will overwrite what user check in the BOM. Therefore, if user checks "Setup Scrap" checkbox in BOM, but checks to exclude in cost roll, the costroll will not calculate setup scrap cost, but BOM will always calculate setup scrap cost if the Setup Scrap checkbox in check in BOM. |