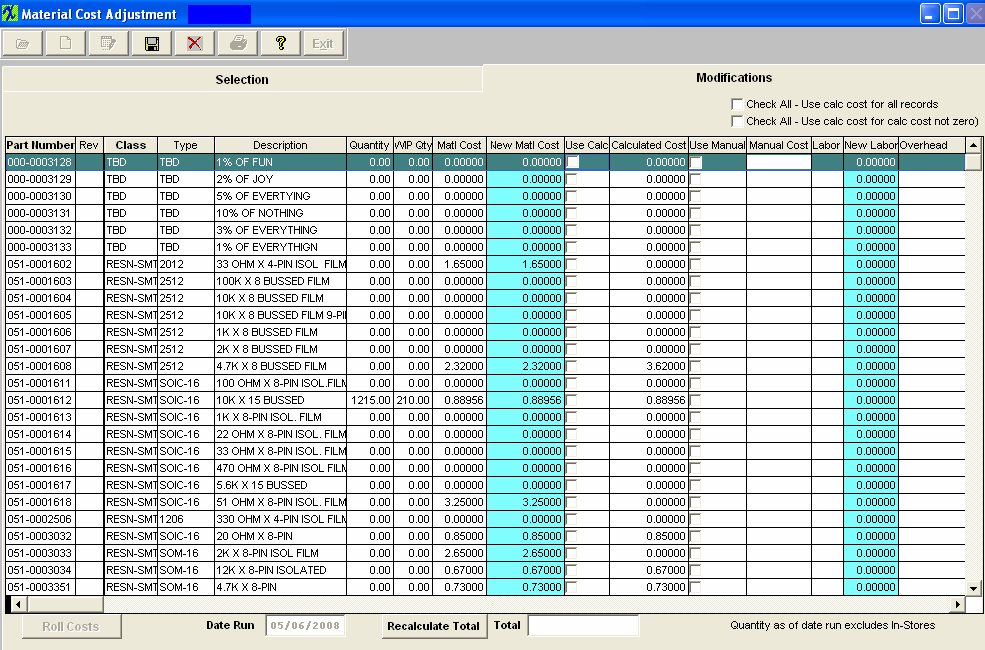

Modifications tab field definitions

| Check All - Use calc cost for all records |

If this box is checked - the system only checks the record if the calcualted cost > 0. If this box is checked at one level, this option will carry forward as checked when users move to the next levels. |

| Check All - Use calc cost for calc cost not zero |

if this box is checked - the system will check all records to use calculated cost no matter it's zero or not. If this box is checked at one level, this option will carry forward as checked when users move to the next levels. |

|

| Part Number |

The number the user has assigned to the part within the ICM module.

|

| Rev |

The revision number assigned to the Part Number within the ICM module.

|

| Class |

The classification to which the part belongs.

|

| Type |

The type within the classification to which the part number belongs.

|

| Description |

The description assigned to the Part Number within the ICM module.

|

| Quantity |

The quantity is the number of units currently owned. This excludes all un-purchased In-Stores Inventory. ( for explanation on In-Store Inventory See Purchasing Manual) See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative.

|

| Material Cost |

This cost is defaulted in from the cost currently assigned to the part number through ICM or PO .

|

·Important Note - If accounting is installed: For all buy parts, the standard cost field must have data entered. If this data is missing (or wrong), the Raw Materials Inventory and the Work In Process (WIP) will be incorrect for the accounting records. All make parts which are not labor only (the customer brings you the kit and all you do is apply the labor), must have data entered in the standard cost field. Additionally, the data entered in the standard cost field for the make part must equal the sum of the Bill of Materials components.(Please refer to Bill of Materials Reports – Bill of Material With Standard Cost.) If the data is missing or wrong on a Make Part, the Work In Process, Cost of Goods Sold and Finished Goods Inventory will be wrong for the accounting records. If the sum of the Bill of Materials components does not equal the standard cost per the Item Master, a configuration variance will generate.

| New Material Cost |

This represents the revised or up-dated Standard Cost. This column is colored so users can easily differentiate between the old cost and new cost.

|

| Use Calc |

If this box is checked, the calculations determined in the Selection tab were applied to the cost. This box will be automatically checked for phantom (not Make/Phantom) assemblies in the system at each cost roll up.

|

| Calculated Cost |

This column is the result of the calculations determined in the Selection tab as applied to the original Standard Cost.

|

| Use Manual |

If this box is checked, the new Standard Cost was manually typed in and was not determined by any thing in the Selection tab.

|

| Manual Cost |

This column is the result of the new standard cost being entered manually and the Use Manual box being checked.

|

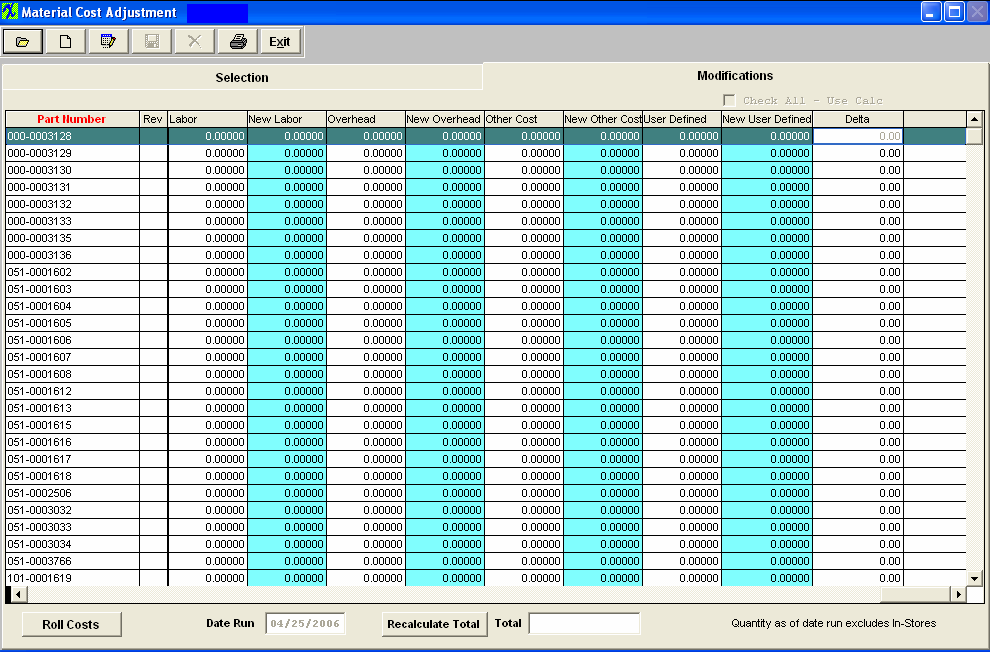

By moving the arrows (at the bottom of the screen) to the right the following fields are also available

| Labor |

The labor cost currently assigned to the part number.

|

| New Labor |

This represents the revised or up-dated Labor cost. This column is colored so users can easily differentiate between the old cost and new cost.

|

| Overhead |

The overhead cost currently assigned to the part number. |

| New Overhead |

This represents the revised or up-dated Overhead cost. This column is colored so users can easily differentiate between the old cost and new cost. |

| Other Costs |

The other costs currently assigned to the part number. |

| New Other Costs |

This represents the revised or up-dated other costs. This column is colored so users can easily differentiate between the old cost and new cost. |

| User Defined |

The user definded costs currently assigned to the part number. |

| New User Defined |

This represents the revised or up-dated user defined costs. This column is colored so users can easily differentiate between the old cost and new cost. |

| Delta |

The column is the net change between the original Standard Cost and the New Standard Cost multiplied by the Quantity.

|

|

If this button is depressed the costs will roll up to all of the Inventory Tables plus the records required for accounting will be created for posting to the General Ledger.

Note: Users have to have special access in order for this button to be enabled. This access is assigned through Security/User Rights. |

| Date Run |

This is the date of the run.

|

|

This button is used to recalculate the total change (Delta) column.

|

| Total |

This is the total of the column “Delta” (change).

|

|