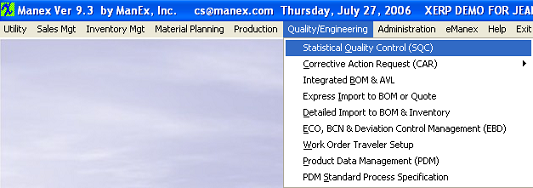

| Enter Quality/Engineering/Statistical Quality Control (SQC) Module |

|

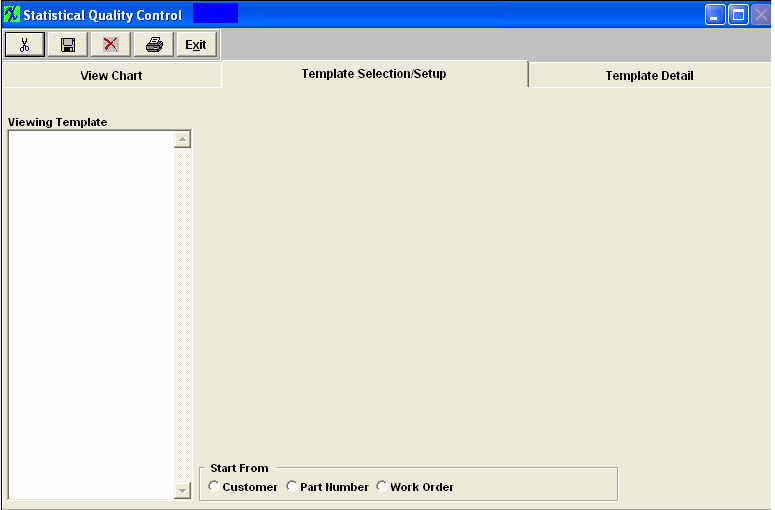

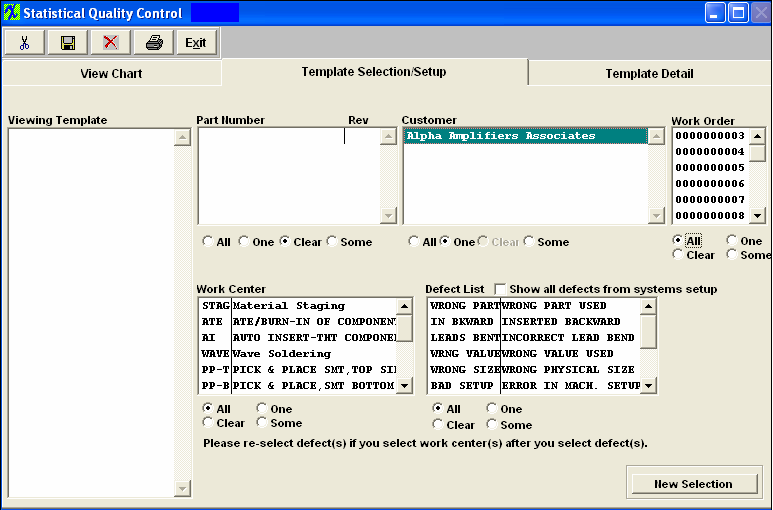

The following screen will be displayed:

Template Selection Setup

This is the first screen to be used in the module. In this screen, STATISTICAL QUALITY CONTROL graphics are created by selecting parameters to be considered in the graph.

This screen operates differently than all other ManEx screens. When bringing up the SQC module, the user is first presented with a template screen from which to choose parameters to be included in the information displayed.

When the user enters the system, he/she may select how they want to start the process of selection. Click on the Customer, Part Number or Work Order radial.

|

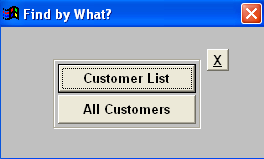

Clicking on the Customer radial will bring up the following selection screen:

Select either Customer List or All Customers. |

|

|

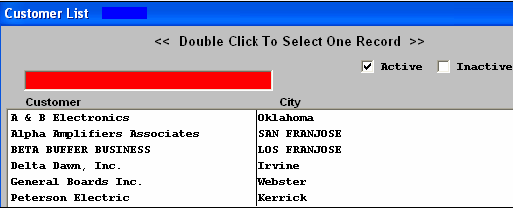

Selecting by Customer List will bring up the following selection screen:

(If the user selects by All Customers, the same screen will appear except All available Customers will be listed within the Customer section)

Type the desired customer into the red box or highlight and double click.

|

|

The following screen will appear:

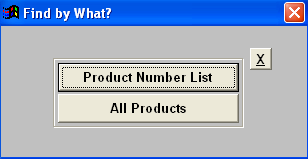

| If the start is from Part Number, the following selection will appear: |

|

|

If the user selects Product Number List, the following list will appear:

(If the user selects All Products, the same screen will be displayed except all products will be listed in the part number section)

Type the Part Number into the red box or highlight and double click.

|

|

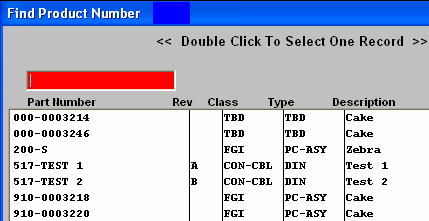

The following screen will appear:

|

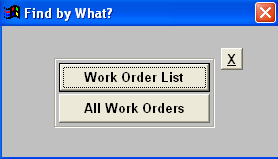

If the user starts with the Work Order start, the following selection will appear:

|

|

|

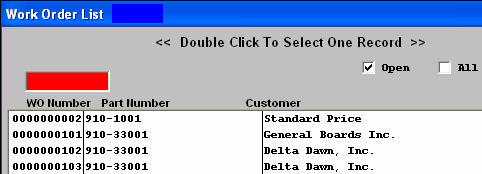

If the user selects the Work Order List option, the following list of Work Orders will appear:

(If the user selects All Work Orders the same screen will be displayed except all work orders will be listed in the Work Order section)

Select between Open or All. Type the Work Order Number into the red box or highlight and double click.

|

|

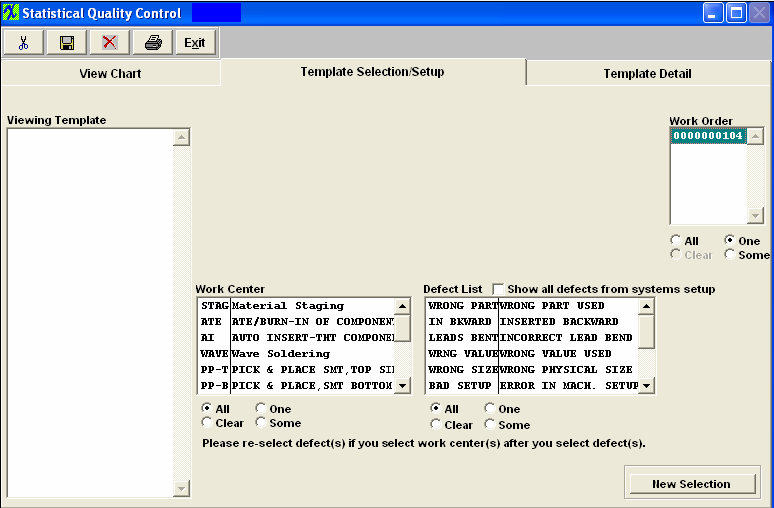

The following screen will appear:

|

In the Work Order section, choose from All, One or Some. If you’ve selected one, highlight the desired work order. If you want more than one, depress the Ctrl key and click on the ones desired.

|

|

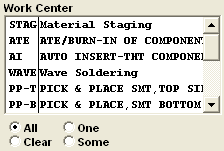

In the Work Center section, choose from All, One or Some. If you’ve selected one, highlight the desired work center. If you want more than one, depress the Ctrl key and click on the ones desired.

|

|

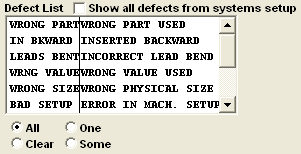

Make the same selection in the Defect List section. If you want all defects displaying as per the System Setup, check the Defect List box.

|

|

To make a new selection, depress the New Selection button.

|

Template Detail Screen

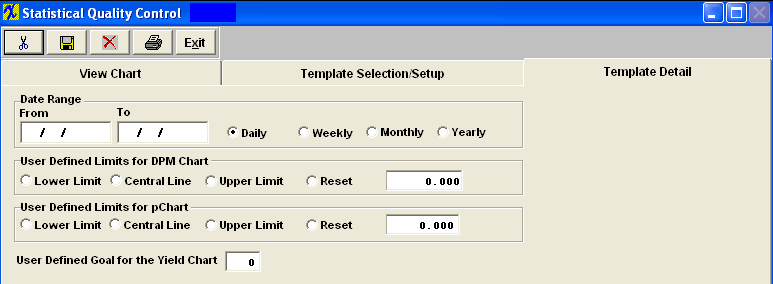

Pressing on the Template Detail tab brings up the following screen:

Enter the Date Range, From and To. Mark the Radial for the view by Daily, Weekly, Monthly, or Yearly.

Mark the radial for the User Defined Limits for DPMO chart: Lower Limit, Central Line, Upper Limit or Reset. Indicate Central Line amount in box.

Mark the radial for the User Defined Limits for pChart: Lower Limit, Central Line, Upper Limit or Reset. Indicate Central Line amount in box.

Indicate the user defined goal for the Yield Chart.

View Chart Screen/Graphs

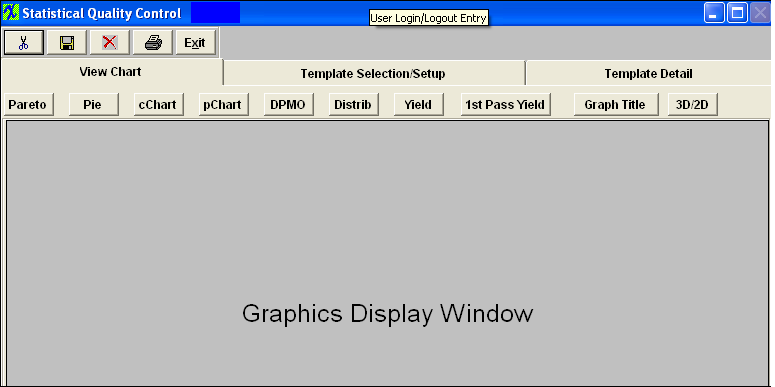

Pressing on the View Chart brings up the Graphics Display Window.

Defect Pareto Chart - The results being displayed in the Pareto Chart are from WO #242 for a build of 500. Qty of 5 with Wrong Part (Displayed in Blue) and Qty of 3 with Leads Bent (Displayed in Green) Total of 8 Failed 500/8 = 62.5% Failed and 37.5% Passed

Note: The black line is a cumulative % of total defects represented by the current defect and all preceding defects. That is why it reaches 100% by the right side of the graph.

Defect Pie Chart - The results being displayed in the Defect Pie Chart are from WO #242 for a build of 500. Qty of 5 with Wrong Part (Displayed in the Blue) 62.5% and Qty of 3 with Leads Bent (Displayed in Green) 37.5%. Total qty failed 8.

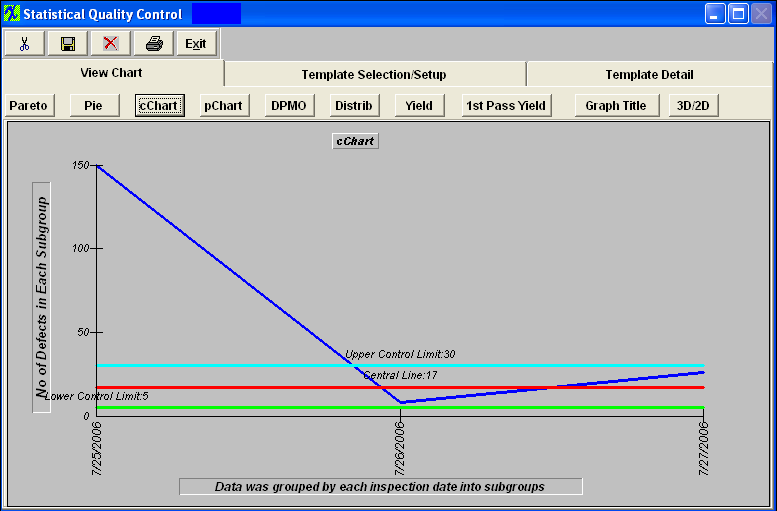

cChart (Not available in 3D) The results being displayed in the cChart are from all Work Orders, Work Centers, and all defects from 062706 thru 072706 (1 month)

The formula for the Central line (Red) is: c = Total Defects (divided by) Number of Subgroups

Upper Control Limit (UCL) = c + 3 (divided by) p

Lower Control Limit (LCL) = c - 3 (divided by) p (or 0, whichever is greater)

pCHART (not available in 3D) The results being displayed in the pChart are from all Work Orders, Work Centers, and all defects from 062706 thru 072706 (1 month)

The formula for the Central line (Red) is: p = Total Number Failed (divided by) Total Number Inspected

Upper Control Limit (UCL) = p + 3 (divided by) p (1-p) divided by n

Lower Control Limit (LCL) = p - 3 (divided by) p(1-p) divided by n (or 0, whichever is greater)

n = number inspected (sample size)

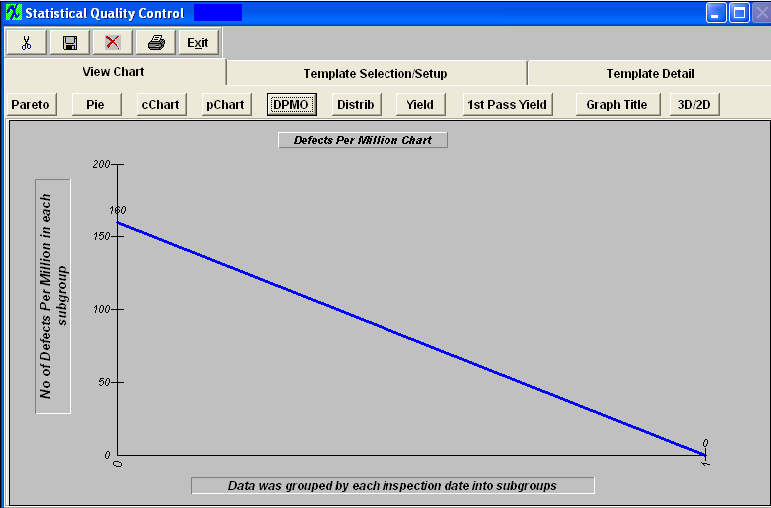

DPMO (Defects Per Million Opportunities) Chart (Which means the number of things wrong observed in the inspection of a part, or board assembly). The results being displayed in the DPMO Chart are from WO #242 for a build of 500. DPMO Example below = 8(Total qty failed)* 1000000/100*500 (Qty Inspected) = 160

Defects Per Million Opportunities. There are several ways to setup the opportunities (which means the number of possible defects that can occur on a product), but it is up to each company to make that decision. For Example: Some may say that a resistor with two leads that are not properly soldered is counted as two defects and some may only count it as one defect, since it is one part that was assembled incorrectly. The opportunity or the standard opportunity is entered in the Work Order Traveler Setup module. The field is called PPM = Parts per million.

The DPMO chart uses the PPM as a reference to measure the actual failures against the total inspected quantity.

See Article #3156 for further detail on DPMO.

The formula for calculating DPMO chart is as follows:

Example (2+3+3) = SUM of defect quantities (8) * opportunities or PPM (1,000,000) (divided by) Qty Inspected (500) (divided by) parts per unit (100) = 160

Daily, Weekly, Monthly, Yearly

On the Y axes the graph shows number of defects per million

One the X axes day or week or month or year

This graph collects defect information for the selected work centers and work orders in the selected date range. The user also has to select if the information will be grouped by day, week, month, or year.

The selected group will be your X coordinates on the graph.

The Y coordinates will be calculated as sum of the defect quantities *opportunities or PPM divided by total Qty inspected (divided by) parts per unit (qty was entered in the routing module) grouped by X coordinate unit (Daily, weekly, monthly, yearly).

This is a data line there is three more control lines displayed on the graph:

Central control line:

Upper control line:

Lower control line

All three lines could be user define lines.

If the lines are not user define lines they calculated as following

Central Line

lnCentralLine=lnTotalDef/lnTotalComp, where lnTotalDef is sum of all defect quantities * 1000000 and lnTotalComp is sum of inspected quantities*Parts Per Unit (entered in the routing module)

At this time system will decide if it can use average group size or not. If the size group varies more tan 15% the system will use variance Upper and Lowercontrol limit. If average group size could be used the average group size gets calculated by taking lnAvrgSubgrSize=lnTotalComp divided by number of groups and rounded to the nearest integer.

Calculation for the Upper Control Line

LnUpperLine=ROUND(((3*(SQRT(lnCentrLine*(1000000-lnCentrLine))))/SQRT(lnAvrgSubgrSize)),3)

Calculation for the Lower Control Line

lnLowerLine = ROUND(lnCentrLine -((3*(SQRT(lnCentrLine*(1000000-lnCentrLine))))/SQRT(lnAvrgSubgrSize)),3)

lnLowerLine = IIF(lnLowerLine<0,0,lnLowerLine)

Defects Distribution Chart - The results being displayed in the pChart are from all Work Orders, Work Centers, and all defects from 062706 thru 072706 (1 month)

Yield Chart - "Yield" = Total number of units handled correctly through the process step(s). This is usually measured in a percentage. The results being displayed in the "Yeild Chart" is the ratio of summed inspected qty and summed passed qty, grouped by date (user can select WO number, defect code to be filtered). The results below are from all Work Orders, Work Centers, and all defects from 062706 thru 072706 (1 month).

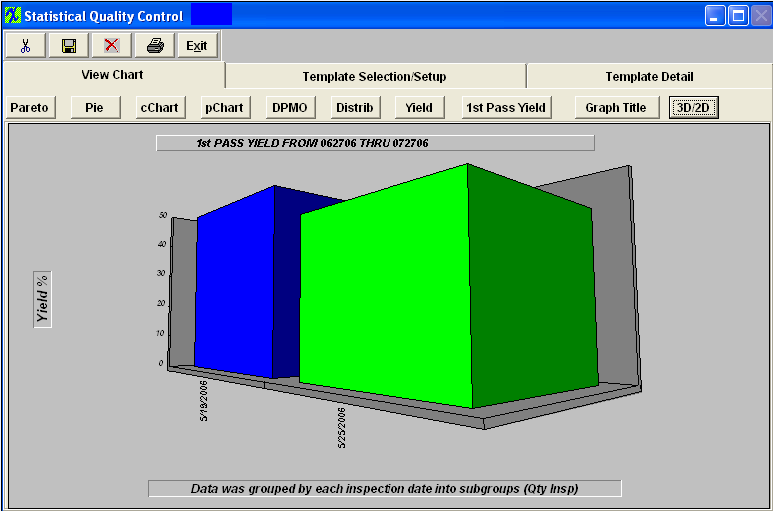

1st Pass Yield Chart The results being displayed are from all Work Orders, Work Centers, and all defects from 062706 thru 072706 (1 month).

1st Pass Yield chart in the SQC module is designed only when the serial number is used for the work order. The system uses the serial number to determine how many serial numbers passed without failure/defects within a work order. 1st Pass Yield chart will be blank if there are no product tracked by serial number within the production floor

To enter a new title, depress the Graph Title button. The following will be displayed:

Enter in the new desired Graph Title. Depress the Exit button, and the graph title will be updated.

3D/2D - This is if you want to view the 1st Yield Chart in 3D

|