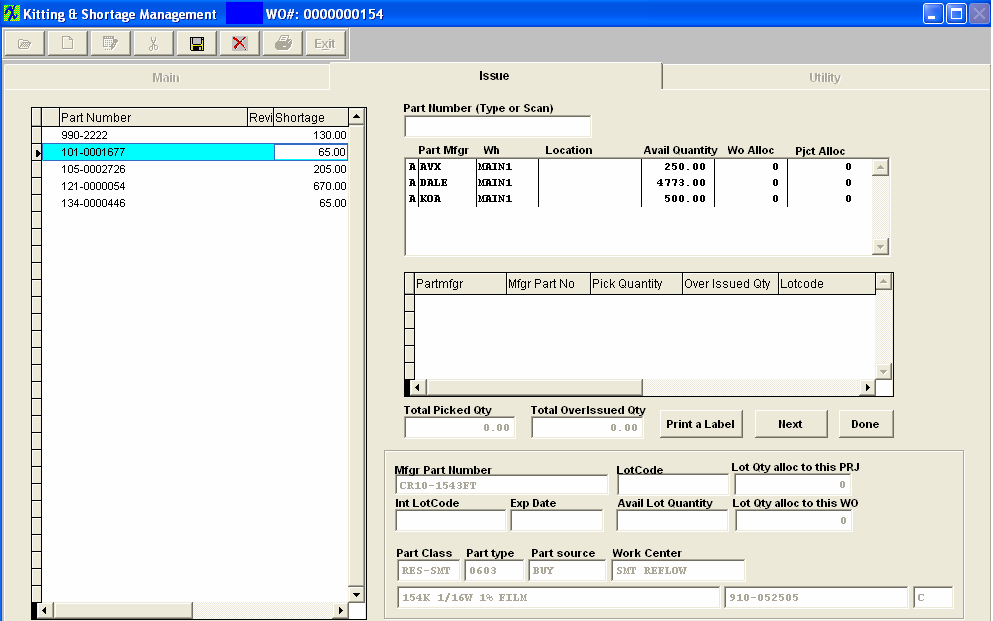

Issue Screen Fields

KIT STATUS SECTION

| Part Number |

The part number of a component belonging to the Bill of Materials for theAssembly.

|

| Rev |

The part number revision of the component |

| Shortage |

The quantity of parts short for the work order.

|

INVENTORY STATUS SECTION

| Part Mfg |

The name of the manufacturer for the highlighted part |

| Warehouse |

The name of the warehouse |

| Location |

The location within the warehouse listed, such as Row 2, Bin 34 |

| Available Qty |

The quantity available for this part for this work order |

| WO Alloc |

The quantity allocated to other Work Orders. |

| Pjct Alloc |

The quantity allocated to other projects.

|

PICKED STATUS SECTION

|

An "A" will be displayed in this column if the Manufacturer is approved |

| Part Mfgr |

The name of the manufacturer for the highlighted part. |

| Mfgr Part Number |

The manufacturer number for the part highlighted |

| Pick Qty |

The qty required for this WO. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. |

| Over issued Qty |

The qty over issued to this WO. See Article #1240 for more detail on why the system will not allow user to enter in a fraction of a number, and an alternative. |

| Lot Code |

The manufacturers lot code for the part highlighted |

| Total Picked Qty |

The quantity of the highlighted part already picked. Below that is the part number of the completed assembly.

|

| Total Overissued Qty |

Any quantity issued over what the Bill of Materials depict. Below that is the revision number of the completed assembly. |

|

When depressing this button a bar code label will be printed |

|

The "Next" button should be used with the top "part number (type or scan)" field. When user types (or scans) the part number the user wants to issue, the cursor on the left list will move to the right part number record, then user can issue it. After the user is done, click the "Next" button, the system will save the issued record, and the cursor will move to top "part number" field again for user to enter whatever part number the user wants to issue next. It doesn't mean the "next one" record in sequence.

|

|

When the user is finished pulling the parts to the kit, they would depress this button and it will bring them back to the Main screen |

LOT CODE INFORMATION

| Mfgr Part Number |

The manufacturer number for the part highlighted |

| Lot Code |

The manufacturers lot code for the part highlighted |

| Lot Qty alloc to this PRJ |

The quantity allocated to this specific project. |

| Int. Lot Code |

The users internal lot code for the part highlighted. |

| Exp Date |

The assigned date of expiration for the lot. |

| Avail Lot Quantity |

The quantity available for that lot which is available to assign to the work order. |

| Lot Qty alloc to this WO |

The quantity allocated to this specific work order. |

ADDITIONAL PART INFORMATION

| Part Class |

The classification of the highlighted part. Below that is the part description |

| Part Type |

The type of part |

| Part Source |

The source for the part: Buy, Phantom, etc. |

| Work Center |

The work center where the part will be needed for the assembly |

|