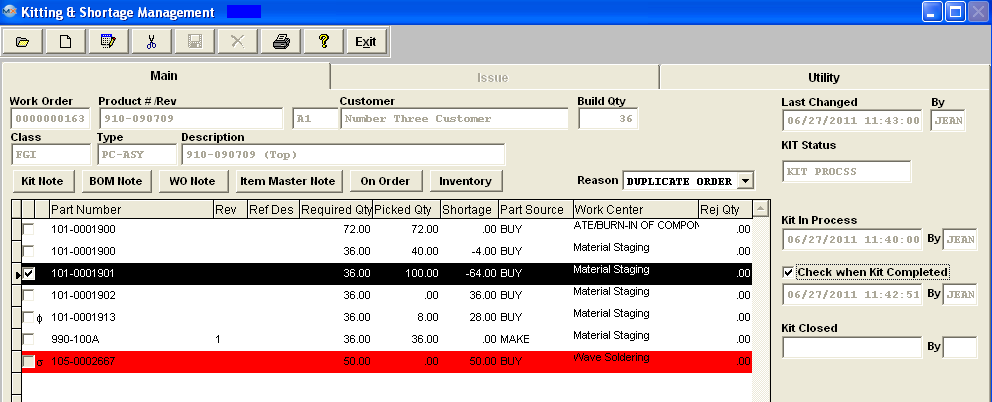

Main Screen Field Definitions

| Work Order |

The work order selected for kitting activities |

| Product # |

The Part number assigned to the assembly in the work order |

| (Rev) |

The Part Number Revision for the assembly |

| Customer |

The customer for the work order |

| Build Qty |

The quantity of assemblies to be made for the work order |

| Class |

The classification of the assembly |

| Type |

The type of assembly |

| Description |

Consists of the Inventory Control Item Master Description |

| Last Changed |

Date and Time of Last Change to this Work Order/Kit |

| By |

User ID of person who made last change to this Work Order/Kit |

| Kit Status |

KITSTATUS ( character field) may be empty, or one of the following: Kit Closed, Kit Process, Rework. If the KIT MANAGEMENT screen has been opened, and any material issued to the kit, the condition of this field will be changed from empty to Kit Process. This field is NOT dependant on the KIT field, but by the logic described in Article #2679 , and cannot be changed unless the kit is released.

|

| Reason |

When user pulls kit, edit, update..... all these details are saved in a table called "Kadetail". All these records will have a "short reason" which is hard-coded in the program. Here are some examples:

Procedures Reasons

Edit kit(edit qty or delete): KIT MODULE/REV

New Kit Pull KIT MODULE/Issu

Auto Kit KIT MODULE

Kit Update KIT UPDATE or KIT MODULE/Upd(if user has overissue)

Delete part DEL

Add misc shortage ADD

Edit misc shortage EDT

If it's a line shortage, then user can select the reasons that's set up in System Setup . So, when user highlights an item, the user will be able to view all different reasons for this item.

|

| Kit in Process |

Date and Time status of Kit was changed to "Kit in Process" |

| By |

User ID of person who changed kit status to "Kit in Process" |

| Check when Kit Completed |

Date and Time when Kit Complete box was checked |

| By |

User ID of person who checked the Kit Complete box |

Component Section

|

This is the “Ignore Shortage” box: If you want to remove the component from the shortage reports and MRP, check the box at the left of the part number. Note: the box for checking KITTED shortages only works with those items that are kitted based on the BOM for the assembly. Checking the boxes means that the part on the BOM will NOT be considered for MRP purposes, and not show up on shortage lists. This is the only way you can get a part on the BOM off of the shortage list. Line shortages, however, can be edited to make them larger or completed. The user will not be able to create a line shortage, then try to check the “ignore shortage” box, this box is disabled for added line shortages. |

|

This symbol before a part number is to inform the user that this part is originating from a Phantom BOM.

|

|

When shortages have been saved for the work order, they will be added to the Kit Status section of the main information tab. The item will be preceded with the rho (? ) symbol to differentiate it from a kit shortage. |

| Part Number |

The part number of a component belonging to the Bill of Materials for the assembly |

| Rev |

The part number revision of the component |

| Ref Designator |

The Reference Designator as assigned in the BOM Module |

| Required Qty |

The number of parts required of the component in the work center shown. (A component may be used in more than one work center.) This qty may include Setup Scrap if the "Setup Stcrp" box is check on the BOM Header Information and/or Run Scrap if selected to include scrap in the Kit Default Setup . |

| Picked Qty |

The number of parts already picked from stores for the work order |

| Shortage |

The quantity of parts short for the work order will be displayed as a positive number, the quantity of parts issued as an overage will be displayed with a negative number. |

| Part Source |

The source code for the part, BUY, MAKE, Phantom or Consigned |

| Work Center |

The work center in which the part is needed and to which it is to be kitted |

| Rej Qty |

If parts have been rejected during the kitting process, the quantity of parts rejected |

DIRECTIVE BUTTONS

The following buttons are displayed on the Kitting Main screen

|

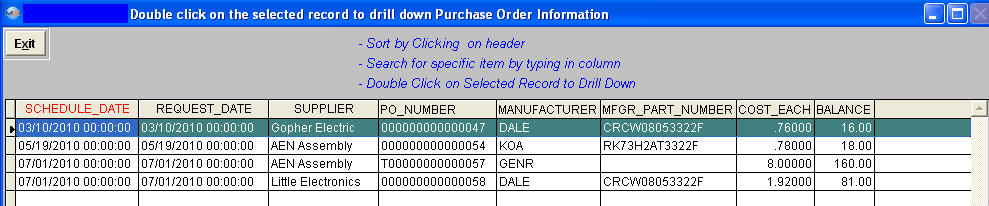

The Inventory button will display on hand and location information for the part highlighted, as shown below:

User may:

- Sort by Clicking on header

- Search for specific item by typing in column

|

|