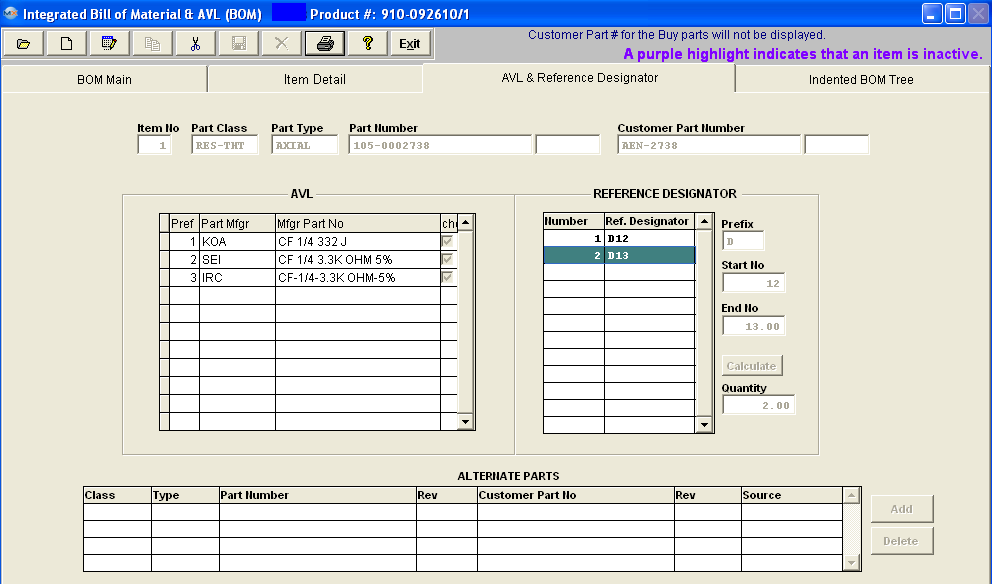

When the user has displayed component parts on the summary screen, and has highlighted one of the parts, pressing on the AVL & REF Tab will display Part Manufacturer and Reference Designation information about the component part.

The first row of Information displays the selected detail part information.The Customer Part Number will be displayed if entered in the Item Master.

The Left Center portion of the screen displays the Approved Vendors List (AVL). These manufacturers and their part numbers have been selected and designated as approved sources for this particular BOM assembly. When the BOM for the assembly has a customer assigned to it, then Manex will pull the approved AVL's from the customer side NOT the Internal side. If no customer is assigned to the BOM then the AVL’s will be pulled from the internal side. For further detail see Article #2560 . NOTE: If "GENR" is approved on the BOM MRP will consider any inventory for that part even if the AVL is not approved on the BOM.

The left hand column displays the preference order, as assigned in Inventory Control Management.

The right hand column box must be checked for the Kit to issue the part to the Work Order. (At least one AVL must be selected as approved within the BOM module before save will be allowed).

The Right Center portion of the screen displays the reference designators assigned to the component. These fields are optional, but must be completed if reference designator information is to be used in the quality defect collection information. (The ref designators are case sensitive).

The bottom portion of the screen is available to list alternate parts that may be used in the absence of the primary part. However, these alternate parts are not listed on kit lists, and are only displayed on this screen. On the BOM, Manex provides a place for users to identify “Alternate Part” for each part called out in the BOM. However, this is for information and cross reference ONLY and there is no connection with the MRP, Purchasing or Kitting, etc. modules. The concept here is that if the engineers want to include alternate (not preferred, and not on AVL) parts for the possibility that in case purchasing can’t get the original parts called for by MRP, they could look up the alternate part on the BOM, and then order that part. However, to get the part into the kit, they will have to add the alternate part as a line shortage to the Work Order, and also check the “ignore shortage” for the part(s) originally required and short on the Work Order. Then MRP will work as needed, and the kit will show the alternate part as a (line) shortage until filled. Incidentally, creating the line shortage and checking the ignore shortage for the original part will result in an MRP directive (the next time it is run) to buy the alternate (line shortage) part. Please refer to the Material Requirements Planning and the Kitting, Allocating & Shortage Management modules.

AVL & Ref Designator Field Definitions

COMPONENT INFORMATION

| Item No |

The item number assigned to the components in the BOM. |

| Part Class |

The Part Class of the component part.

|

| Part Type |

The Part Type of the component part.

|

| Part Number |

The component part number.

|

| Rev |

The Revision number of the component. |

|

Customer Part Number

|

The customer part number as entered in the Item Master.

|

| Rev |

The Revision number of the customer’s part number.

|

AVL INFORMATION

| Pref |

The order of preference number.

|

| Part Mfgr |

An approved manufacturer for the component on the current BOM. NOTE: When the BOM for the assembly has a customer assigned to it, then Manex will pull the approved AVL's from the customer side NOT the Internal side. If no customer is assigned to the BOM then the AVL’s will be pulled from the internal side. For further detail see Article #2560 .

|

| Mfgr Part No |

The commercial part number.

|

| Checkuse |

This box must be checked for kitting to pull the component. NOTE: If "GENR" is approved on the BOM MRP will consider any inventory for that part even if the AVL is not approved on the BOM. (At least one AVL must be selected as approved within the BOM module before save will be allowed).

|

REFERENCE DESIGNATOR INFORMATION

| Number |

The sequential number assigned to each occurrence of the component on the assembly.

|

| Ref Designator |

The assigned location for each occurrence of the part. (The ref designators are case sensitive).

|

| Prefix |

A prefix assigned to reference designators for the current component. Is usually a “C” for capacitors, “R” for resistors, etc |

| Start No |

If the user wishes to fill in the reference designators automatically, then the start number will be the beginning number in the sequence of reference designators assigned.

|

| End No |

If the user wishes to fill in the reference designators automatically, then the end number will be the last number in the sequence of reference designators assigned.

|

|

Pressing the Calculate button will fill in all reference designators with the prefix plus incremental numbers beginning with the start number entered. |

| Quantity |

The quantity of components used in the assembly.

|

ALTERNATE PART INFORMATION

These items are the same as previously described.

DIRECTIVE BUTTONS

|

Pressing the Add button in the ALTERNATE area will allow the user to add additional item master part numbers as approved alternates.

|

|

Pressing the Delete button in the ALTERNATE area will allow the user to remove item master part numbers as approved alternates.

|

|