This procedure is used after accounting has Reconciled the Purchase Order. If accounting has NOT yet reconciled the purchase order, see Rejecting Items if Accounting hasn't Processed the Invoice.

Note that the discrepant material must be transfer into the MRB (materials review board) warehouse via Inventory Handling before you can proceed.

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

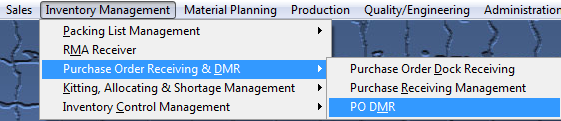

The following screen will be displayed, enter Inventory Management / Purchase Order Receiving & DMR (discrepant material return) / PO DMR (discrepant material return).

|

|

The following screen will be displayed:

Depress the Add button and user will be prompt for a password.

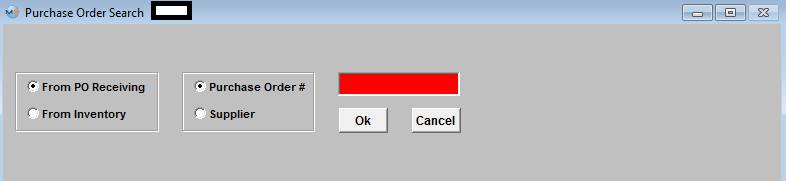

The following screen will be displayed:

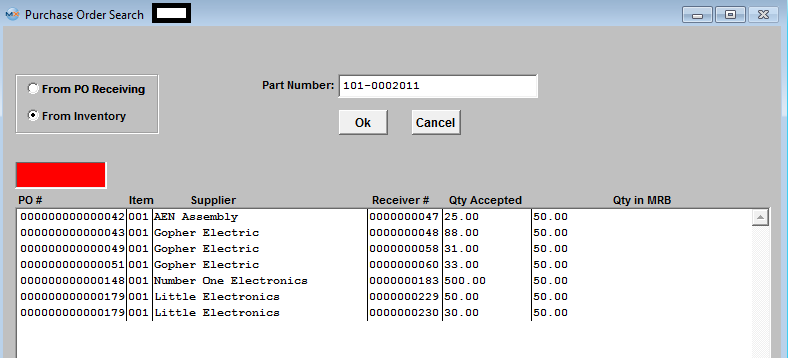

Select the "From Inventory" radio and the following screen will be displayed.

Enter in the Part Number and depress the OK button. The following screen will appear (If there is more than one Purchase Order involved it will list them all)

Highlight the Purchase Order of Choice, Depress the OK button. Information regarding that part number for the Purchase Order selected will display:

Enter in the returned qty in the "Return Qty" field, enter in the RMA number in the "RMA # field" and enter in your name, initials, etc in the "Confirm By" field.

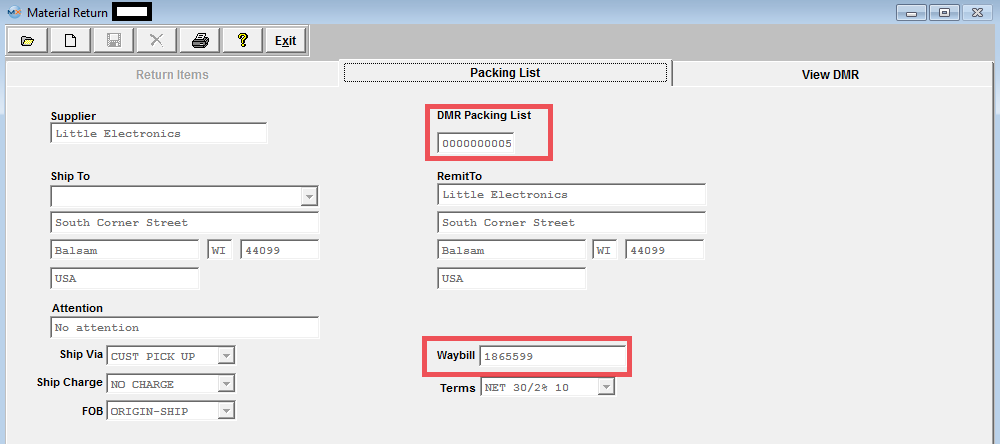

Depress the Packing List tab, and enter in a DMR Packing List number (if set to manual) for the return, and a Waybill number if applicable.

Depress the Save button. The following screen will be displayed:

Once the DMR (discrepant material return) has been added and saved, a Debit Memo will be created, if an AP invoice exists (in order for a AP Invoice to exist you have to have reconciled the PO and transferred it to AP). If Debit memo numbering is manual, the user will be prompted for the number. Additionally, the corresponding entry will be created and the balance in the Accounts Payable Aging will adjust as soon as the Debit Memo is printed. If a PO DMR is created for parts "From Inventory" and the PO has NOT been reconciled and Transferred to AP the qty rejected will be put back on the PO.

The following message will be displayed and the system will NOT be able to create a DMR from Inventory for a part that has been changed from being a Lot-Coded part to a Non-Lot Coded part or visa-versa after PO Receipt has been created.

User should change lot code tracking status with caution. If a part has lot code history and the lot code tracking is de-activated the entire lot code history is wiped out.

1.

If accounting HAS reconciled the PO but HAS NOT transferred the reconciled invoice into AP Aging, the following message will appear:

If the invoice happens to be in a Saved Check batch the following warning will be displayed:

|