Find the Purchase Order that you would like to edit.

Pressing the Edit record action button in the Purchase Order screen will allow the user to modify all the following information:

- The Confirmation Name, Buyer, PO Priority, Supplier Ack., check or uncheck Freight Included box.

- The Status field will only be enabled in the edit mode for users with approval rights. User MUST have approval rights to Modify the PO Status.

- Order quantity and unit price, min/multi qty, purchase lead time, overage amount, Firm Plan or First Article.

- Add or Deletion of a Line Item

- By depressing the Add button allows the user to add additional items to the PO.

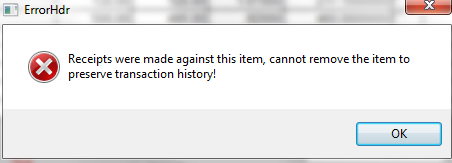

- By depressing the Delete button you can delete an existing line Item from the PO, only if there have been no receipts against the line item. If there have been receipts against the line item user will receive the following warning and will not be able to delete the line item.

- If there have been no receipts agains the line item, highlight the line item that you wish to delete, then depress the Delete button.

- The user will be asked to validate the deletion before proceeding.

- If you select OK the item will be deleted from the order. Once a line item has been deleted from the Purchase Order user will loose all links and will NOT be able to restore the item.

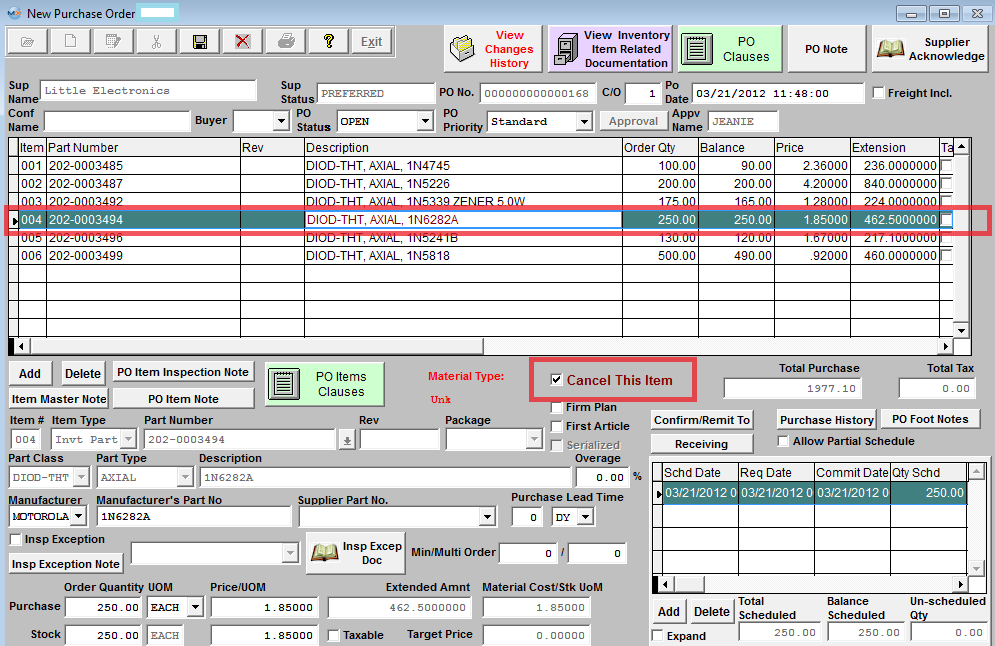

A user can Cancel a line item rather than deleting the line item from the PO by checking the "Cancel this Item" box.

-

This will allow user to cancel an individual item on a PO. Since the system does not allow you to delete a line item that has had any kind of transaction, we needed a way for users to cancel individual line items without having to cancel the entire order within the system. If any parts have been accepted, it cannot be cancelled. Once a part has any receipts the user cannot delete the line, so if they reject the total received qty they can cancel the line to prevent it from affecting the PO, or PO history for the other line items. If they do not want to reject the entire qty then their only option is to reduce the balance qty to the accepted qty. Cancelled line items will be excluded from the Purchase Order reports within the module. A line item that has been cancelled will be displayed in Red. A cancelled line item will be able to be restored by unchecking the "Cancel this Item" box.

- Information about the terms, FOB, Ship Via, Ship Charge, and Account number, Ship Charge Amount, whether taxable, the tax %

- Schd Date, Requested Date, Commit Date, Quantity Scheduled, Warehouse, Location, Distribute To and Schd Notes.

- Modify or add any information in the Item Master Notes, PO Item Notes, PO Notes, and PO Foot Notes. (Depending on how the user has System Setup/Material/Purchase Setup module marked depends on whether user can edit the notes without going into edit mode on the PO record. If the "Require approvals for Date changes and Notes" is marked as "Yes" then it will force the users to first put the PO in edit mode before they will be allowed to edit any notes and the note changes will be recorded in the "View Changes History" screen. But if it is marked "No" then the notes become editable without the actual record in Edit mode and the note changes will NOT be recorded in the "View Changes History" screen).

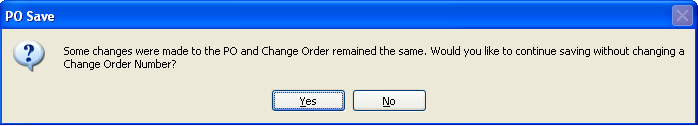

Depress the Save record action button after you have finished with editing the record. The user will then need to approve the order. If user has the "Auto Assign new Change Order # Upon Approval" box checked within the System Setup/Material/Purchase Setup module, the reminder will NOT be issued and CO# field becomes NOT editable. When the user approves the change the Change Order number will be automatically increased. If user has the "Auto Assign New Change Order # Upon Approval" box unchecked within the System Setup/Material/Purchase Setup module when user makes changes the CO# will stay the same, the system will prompt the reminder, and user may manually assign a change order number if applicable.

There are situations when an item may not have a schedule or may have a partial schedule. If the "Allow Partial Schedule" box is unchecked within the System Setup/Material/Purchase Setup module, user will receive the following popup warning when editing and saving that line item or any other line item on that same purchase order. If the box is checked the system will not ask any questions when saving a po with only partial schedule. (Note: MRP will NOT acknowledge qty's that are not scheduled).

NOTE: If the "Auto Assign new Change Order # Upon Approval" box is checked, and PO is new and the user goes into the "Edit" mode prior to approval, no changes will be made to the CO# on screen or in the "View Changes History" screen. If PO has been approved and the user goes into the "Edit" mode the next CO# will be referenced in the "View Changes History" screen but will NOT increase on screen until PO has been approved. If the user goes to the "Edit" mode more than once before approving the change the CO# will only increase once in the "View Changes History" screen.

NOTE: If users enter a PO number manually using a "T", then changes the numbering to Auto, and later edits and approves this PO the "T" will be changed to "0". The system has no way of knowing that the PO was manual numbered before the change.

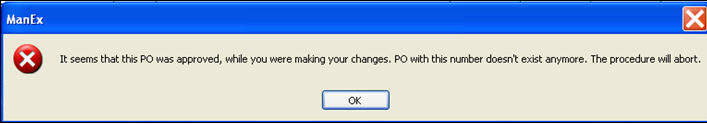

If multiple users are editing the same PO and the PO has not been approved yet, so it still has a temp # and the 1st users approves the PO, while the 2nd user is still making their changes, when the 2nd user goes to exit and save their changes they will receive the following message:

Manex tracks all revisions of a Purchase Order and each receipt against each revision of the order. The system will NOT allow any changes to a Purchase Order which has parts in Dock Receiving that have not yet been processed in the Purchase Order Receiving & Inspection module. Cancel a Purchase Order

Find the Purchase Order you want to cancel. Press the Edit record action button in the Purchase Order screen this will allow the user to change the PO status from Open to Cancel. Note: User MUST have approval rights to Modify the PO Status.

Closing out a Purchase Order

At times, the user may wish to close out a PO to suppliers who have either shipped short or overages of ordered components. For example, say a user has a Purchase Order for 100 components. 100 units are received with 5 rejections. (See the DMR procedures). This would show the Purchase Order showing a quantity of 5 for a balance. What if the user informs the supplier that they do not want the last 5 pieces.

In the above set of circumstances, the user will be allowed to change the ORIGINAL order quantity by removing the rejected quantity via the DMR procedure. When the Received quantity PLUS the DMR quantity is LESS than the order quantity, the user will be allowed to decrease the order quantity by that many. Original Order 100; Received quantity 100; Rejected quantity 5. Returned to supplier via DMR 5. At this point, the user may reduce the quantity ordered, AND the accompanying amount scheduled to 95. This action will close out the Purchase Order.

The user must depress the Edit button. Change the Purchase Order Quantity, then change the Quantity Scheduled so that the total of the schedule dates exactly equals the new quantity. Depress the Save button. Approve the PO and the PO status will change to close.

|